A Deep Dive into Oxidizer For Pools Solution

Introduction: Navigating the Global Market for oxidizer for pools

Navigating the complexities of sourcing oxidizers for pools can pose significant challenges for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. As pool maintenance becomes increasingly vital to meet consumer expectations, understanding the various types of oxidizers—ranging from chlorine-based solutions to innovative non-chlorine alternatives—becomes essential. This guide serves as a comprehensive resource, equipping buyers with critical insights into applications, supplier vetting processes, and cost considerations.

With the growing demand for clean and safe swimming environments, the choice of oxidizer can directly impact water clarity, safety, and overall pool health. This guide not only delineates the characteristics and benefits of different oxidizers but also provides a framework for evaluating suppliers based on regulatory compliance and product quality. By addressing key issues such as regional market trends, environmental impacts, and consumer preferences, this guide empowers buyers to make informed purchasing decisions.

As you explore the intricacies of the pool oxidizer market, you will gain the knowledge necessary to navigate supplier relationships effectively, ensuring that your procurement strategy aligns with both operational needs and market demands. Whether you’re looking to enhance your product offerings or streamline your supply chain, understanding the landscape of pool oxidizers is crucial for sustained success in a competitive global market.

Understanding oxidizer for pools Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Calcium Hypochlorite | High chlorine content, effective against bacteria and algae | Commercial pools, resorts, and public facilities | Pros: Fast acting, cost-effective; Cons: Can cause overstabilization if overused. |

| Potassium Peroxymonosulfate | Non-chlorine oxidizer, quick to dissolve, safe for immediate swimming | Residential pools, spas, and wellness centers | Pros: No harsh odors, swim-ready in 15 minutes; Cons: Generally higher cost per treatment. |

| Sodium Dichlor | Stabilized chlorine, effective against a wide range of contaminants | Hotels, gyms, and water parks | Pros: Long shelf life, effective in various conditions; Cons: Can lead to high cyanuric acid levels. |

| Hydrogen Peroxide | Chlorine-free, environmentally friendly, clarifies water | Eco-friendly facilities, natural pools | Pros: Safe for sensitive skin, no chemical odors; Cons: Requires precise dosing to be effective. |

| Non-Chlorine Shock | Variety of active ingredients, quick action for water clarity | Pool maintenance companies, service providers | Pros: Versatile application, reduces chlorine demand; Cons: May not be suitable for all pool types. |

What are the Characteristics of Calcium Hypochlorite in Pool Oxidizers?

Calcium hypochlorite is a widely used oxidizer known for its high chlorine content, making it highly effective against bacteria and algae. It is particularly suitable for commercial pools, resorts, and public facilities where rapid sanitation is essential. When considering B2B purchasing, buyers should evaluate the potential for overstabilization with prolonged use, but its cost-effectiveness and fast-acting nature often outweigh this concern.

How Does Potassium Peroxymonosulfate Stand Out as a Pool Oxidizer?

Potassium peroxymonosulfate is a non-chlorine oxidizer that dissolves quickly and allows for immediate swimming post-treatment. This feature makes it ideal for residential pools, spas, and wellness centers, where user comfort is a priority. B2B buyers should consider its slightly higher cost per treatment compared to chlorine options; however, its lack of harsh odors and rapid effectiveness can justify the investment for facilities prioritizing guest experience.

What Makes Sodium Dichlor a Reliable Choice for Pool Maintenance?

Sodium dichlor is a stabilized form of chlorine that is effective against a broad spectrum of contaminants, making it a popular choice for hotels, gyms, and water parks. It boasts a long shelf life and remains effective in various water conditions. Buyers should be cautious about the potential for increased cyanuric acid levels, which can affect chlorine efficiency. Despite this, its reliability and effectiveness in maintaining water quality make it a staple in pool maintenance.

Why is Hydrogen Peroxide Considered an Eco-Friendly Option?

Hydrogen peroxide is a chlorine-free oxidizer that is gaining popularity for its environmentally friendly profile. It effectively clarifies water and is safe for sensitive skin, making it suitable for eco-friendly facilities and natural pools. B2B buyers need to ensure precise dosing for optimal effectiveness, as improper use can lead to insufficient sanitation. Its appeal lies in its lack of chemical odors and its growing acceptance among environmentally conscious consumers.

How Do Non-Chlorine Shock Treatments Benefit Pool Service Providers?

Non-chlorine shock treatments encompass a variety of active ingredients that quickly restore water clarity while reducing overall chlorine demand. They are particularly advantageous for pool maintenance companies and service providers looking to offer versatile solutions. While not suitable for all pool types, their ease of application and ability to enhance water quality make them a compelling option for businesses aiming to improve service offerings and customer satisfaction.

Key Industrial Applications of oxidizer for pools

| Industry/Sector | Specific Application of oxidizer for pools | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Regular pool maintenance in hotels and resorts | Ensures guest safety and satisfaction through clean water | Compliance with local regulations, bulk purchasing options |

| Municipal Recreation | Public pool sanitation and water quality management | Reduces health risks, enhances community trust | Cost-effectiveness, availability of large quantities |

| Fitness Centers | Maintenance of swimming pools in gyms and health clubs | Promotes a hygienic environment, attracting more members | Compatibility with existing systems, rapid delivery times |

| Aquatic Facilities | Treatment of competition and leisure pools | Maintains optimal water conditions for events and training | Reliable supply chain, adherence to international standards |

| Spa and Wellness Centers | Oxidation of spa water to ensure cleanliness | Enhances customer experience and safety | Product efficacy, eco-friendly options |

How is Oxidizer for Pools Used in the Hospitality Industry?

In the hospitality sector, particularly in hotels and resorts, oxidizers are critical for maintaining pool water quality. Regular use of oxidizers helps eliminate contaminants introduced by guests, such as sweat, oils, and debris, ensuring a safe swimming environment. This is vital for guest satisfaction and compliance with health regulations. For international buyers, sourcing products that meet local environmental standards and offer bulk purchasing options can significantly reduce costs and ensure consistent water quality.

What Role Does Oxidizer Play in Municipal Recreation?

Municipal recreation facilities rely heavily on oxidizers for the sanitation of public pools. These chemicals help control algae growth and eliminate harmful bacteria, thus reducing health risks associated with swimming. For municipalities, the value lies in fostering community trust and ensuring public safety. When sourcing oxidizers, decision-makers must consider cost-effectiveness and the ability to procure large quantities to meet seasonal demands, especially in warmer climates.

Why are Oxidizers Important for Fitness Centers?

In fitness centers, the maintenance of swimming pools is essential for providing a hygienic environment for members. Regular oxidation treatments help keep the water clear and free from harmful microorganisms. This not only enhances the user experience but also attracts more members who prioritize cleanliness. Buyers in this sector should focus on the compatibility of oxidizers with existing pool systems and ensure rapid delivery times to avoid service interruptions.

How Do Aquatic Facilities Benefit from Using Oxidizers?

Aquatic facilities, including competition and leisure pools, utilize oxidizers to maintain optimal water conditions for both recreational and competitive use. These chemicals are essential for ensuring that water remains clear and free from contaminants, which is crucial for hosting events and training sessions. For international buyers, establishing a reliable supply chain is important, along with ensuring that products adhere to international safety and quality standards.

What is the Impact of Oxidizers on Spa and Wellness Centers?

In spa and wellness centers, oxidizers are used to treat spa water, ensuring cleanliness and enhancing the overall customer experience. By effectively removing organic contaminants, these products help prevent unpleasant odors and skin irritations, which can deter customers. When sourcing oxidizers, businesses should look for products that offer high efficacy and eco-friendly options to align with the wellness trend and meet consumer expectations.

3 Common User Pain Points for ‘oxidizer for pools’ & Their Solutions

Scenario 1: Managing Algae Growth in Commercial Pools

The Problem:

B2B buyers, particularly those managing large commercial pools such as resorts or community centers, often face the persistent challenge of algae growth. Algae can flourish due to heavy bather loads, environmental factors, and inadequate chemical balance. This not only affects the aesthetic appeal of the pool but also poses health risks and may lead to costly downtime for cleaning and treatment. The frustration escalates when traditional sanitizers fail to fully eliminate algae, requiring a more robust solution.

The Solution:

To effectively combat algae growth, it’s essential to incorporate a multi-faceted approach with oxidizers specifically designed for pool maintenance. Utilizing a powerful shock oxidizer, such as potassium peroxymonosulfate, can provide immediate and effective results. This non-chlorine oxidizer breaks down organic contaminants and restores clarity to the water. For optimal results, establish a regular shock treatment schedule—ideally, performing shock treatments weekly during peak usage times and after heavy rain or events. Additionally, regularly monitor water chemistry to maintain balanced pH levels, as this enhances the efficacy of oxidizers. Sourcing high-quality, reliable oxidizers from established suppliers ensures consistency and reliability in treatment, enabling pool managers to maintain a pristine swimming environment.

Scenario 2: High Stabilization Levels Compromising Water Quality

The Problem:

Buyers dealing with long-term pool maintenance often encounter the issue of overstabilization when using chlorine-based oxidizers. Over time, the buildup of cyanuric acid can reduce the effectiveness of chlorine, leading to poor sanitization and potential health hazards. This issue is particularly prevalent in regions with high sunlight exposure, where stabilizers are commonly used to protect chlorine from degradation. The challenge lies in finding a solution that effectively lowers stabilization levels while ensuring water quality.

The Solution:

A strategic approach is to integrate non-chlorine oxidizers into the treatment regimen. These products, such as those based on potassium peroxymonosulfate, do not contribute to stabilizer buildup and work effectively even in high-stabilization environments. Implementing a routine of non-chlorine shock treatments can help restore water quality without the risks associated with chlorine overload. To maximize effectiveness, conduct regular water tests to monitor cyanuric acid levels and adjust treatment frequencies accordingly. Additionally, educate pool staff on the importance of balancing oxidizer use with regular maintenance practices, ensuring a sustainable and healthy swimming environment.

Scenario 3: Difficulty in Sourcing Reliable Oxidizers in Emerging Markets

The Problem:

For B2B buyers in emerging markets, such as those in parts of Africa and South America, the challenge of sourcing reliable oxidizers for pools can be significant. Factors such as limited availability, inconsistent quality, and high costs can impede effective pool maintenance. Many buyers find themselves overwhelmed by the myriad of products available and unsure which options will deliver the best results for their specific needs.

The Solution:

To navigate these challenges, buyers should focus on building relationships with reputable suppliers who specialize in pool chemicals. Conduct thorough research to identify manufacturers with a strong track record in the industry. Establishing partnerships with local distributors can also facilitate easier access to quality products. When selecting oxidizers, prioritize those that have been tested and proven effective in similar environmental conditions to ensure compatibility. Additionally, consider bulk purchasing agreements to reduce costs and ensure a consistent supply of oxidizers. Engaging in training sessions for staff on the proper application and dosage of oxidizers will further enhance maintenance efforts, leading to improved pool conditions and customer satisfaction.

Strategic Material Selection Guide for oxidizer for pools

What are the Key Materials Used in Pool Oxidizers and Their Properties?

When selecting oxidizers for pools, several materials are commonly utilized, each with distinct properties, advantages, and limitations. Understanding these materials is crucial for B2B buyers looking to make informed purchasing decisions that align with regional standards and customer preferences.

How Does Calcium Hypochlorite Perform as a Pool Oxidizer?

Calcium hypochlorite is one of the most popular oxidizers used in pool maintenance. It is known for its strong oxidizing properties and ability to effectively eliminate bacteria and algae. This compound typically operates well at ambient temperatures and has a high stability in dry form, making it suitable for long-term storage.

Pros: It is relatively cost-effective and widely available, making it a preferred choice for pool maintenance. Its high chlorine content ensures effective sanitation.

Cons: However, calcium hypochlorite can lead to overstabilization in pools if used excessively, which may complicate water chemistry management. Additionally, it requires careful handling due to its corrosive nature.

Impact on Application: Calcium hypochlorite is compatible with various pool types, including vinyl and gunite, but should not be mixed with other chemicals without proper knowledge.

Considerations for International Buyers: Buyers from regions such as Europe and the Middle East must ensure compliance with local regulations regarding chlorine use and storage, such as REACH in the EU.

What Role Does Potassium Peroxymonosulfate Play in Pool Oxidization?

Potassium peroxymonosulfate (MPS) is a non-chlorine oxidizer that is gaining popularity for its effectiveness in removing organic contaminants without the harsh effects of chlorine. It operates effectively at a wide range of temperatures and is less corrosive compared to chlorine-based oxidizers.

Pros: MPS allows for swimming shortly after application, making it convenient for pool operators. It also does not produce harmful chloramines, which can irritate swimmers.

Cons: The primary limitation is its higher cost compared to traditional chlorine-based oxidizers. Additionally, it may require more frequent applications to maintain water clarity.

Impact on Application: MPS is suitable for all pool surfaces and is particularly favored in commercial settings where rapid water turnover is essential.

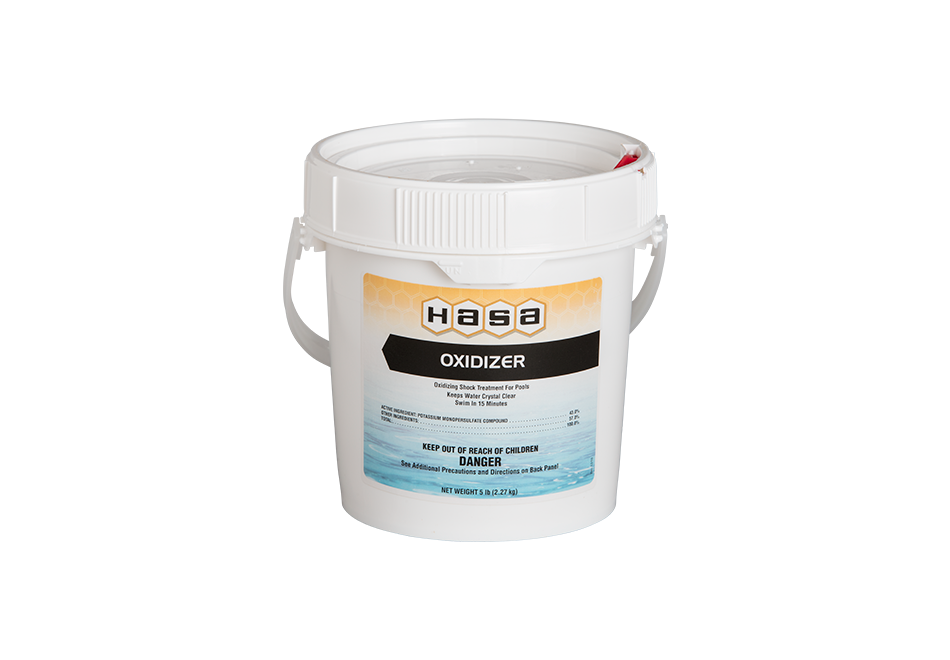

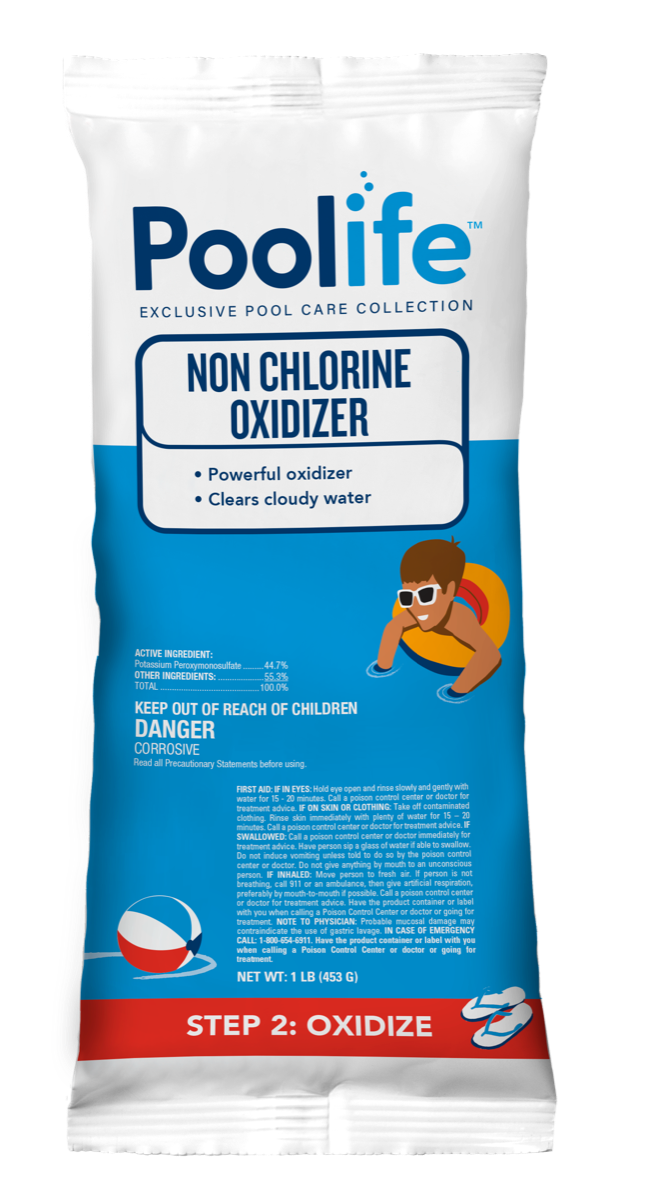

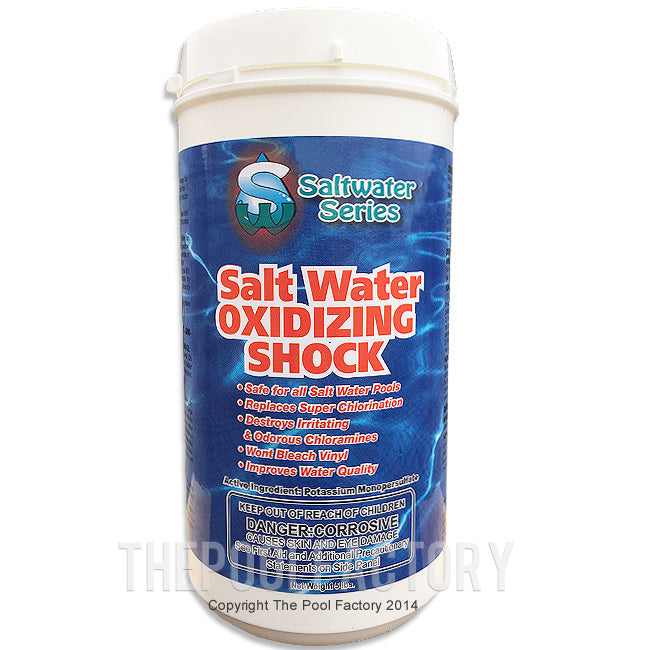

Illustrative image related to oxidizer for pools

Considerations for International Buyers: In regions like South America and Africa, buyers should consider the availability and cost-effectiveness of MPS, as well as local regulations regarding chemical use in public pools.

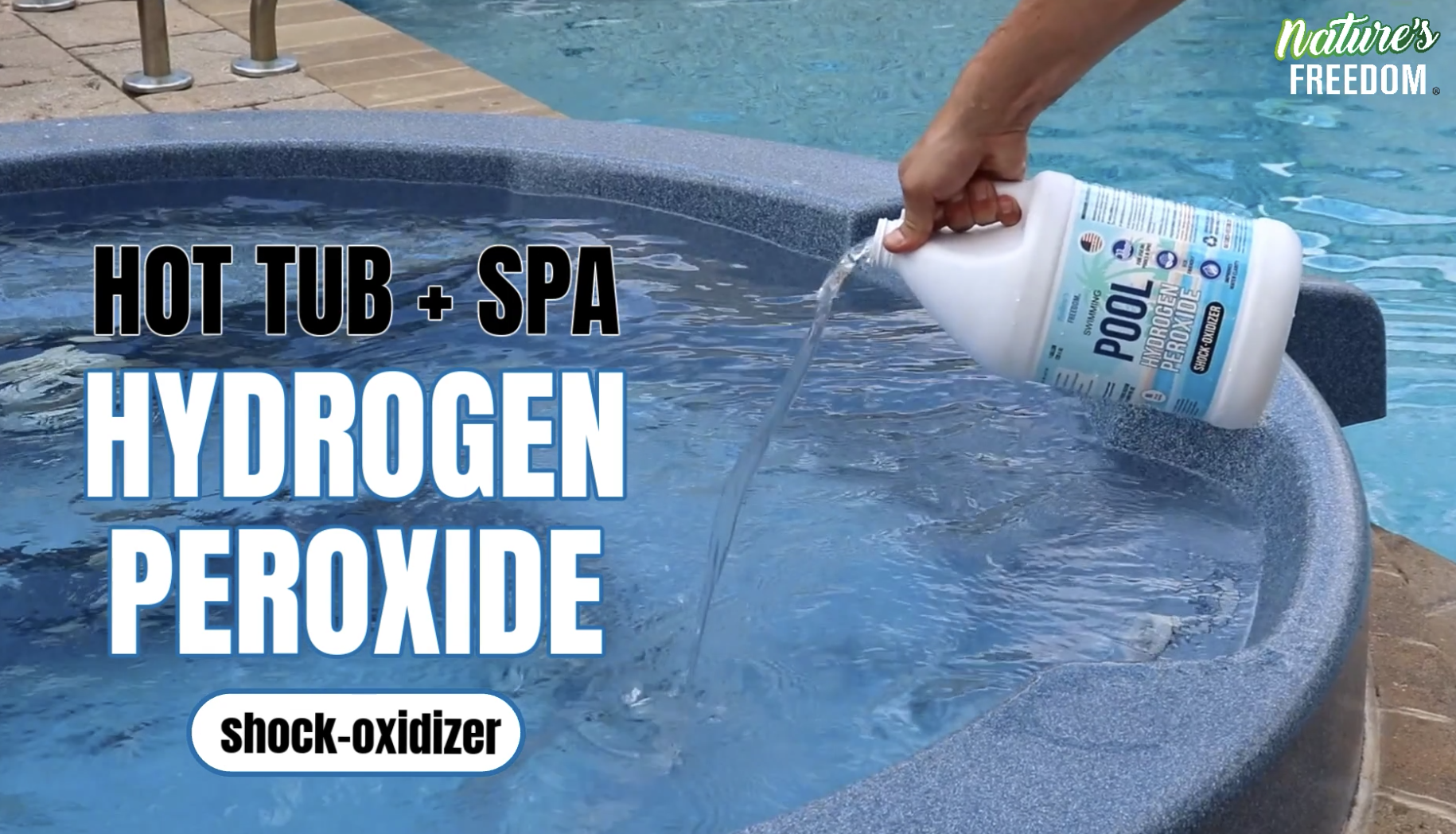

How Effective is Hydrogen Peroxide as an Oxidizer for Pools?

Hydrogen peroxide is another alternative oxidizer that is gaining traction in pool maintenance. It is known for its ability to break down organic contaminants and improve water clarity.

Pros: Hydrogen peroxide is environmentally friendly and leaves no harmful residues, making it a safe choice for pool sanitation. It is also effective at a wide range of pH levels.

Cons: However, it can be more expensive than traditional oxidizers and has a shorter shelf life, requiring careful inventory management.

Impact on Application: This oxidizer is compatible with various pool types but may require specialized handling and storage conditions due to its reactive nature.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should ensure compliance with local chemical regulations and standards, such as DIN, when sourcing hydrogen peroxide.

What Are the Benefits of Using Sodium Dichloroisocyanurate?

Sodium dichloroisocyanurate (DCCNa) is a stabilized chlorine compound that serves as an effective pool oxidizer. It is often available in both granular and tablet forms, making it versatile for different applications.

Pros: DCCNa is highly effective at killing bacteria and controlling algae, with a long shelf life and stability in various conditions.

Cons: Its cost can be higher than that of calcium hypochlorite, and it may contribute to the buildup of cyanuric acid in the pool, necessitating careful monitoring.

Impact on Application: DCCNa is suitable for all pool types and is particularly favored in warmer climates due to its stability under sunlight.

Considerations for International Buyers: Buyers from the Middle East and Africa should be aware of the potential for cyanuric acid buildup and ensure that they have the means to manage water chemistry effectively.

Summary Table of Oxidizer Materials for Pools

| Material | Typical Use Case for oxidizer for pools | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Calcium Hypochlorite | Regular shock treatment for residential and commercial pools | Cost-effective and widely available | Risk of overstabilization | Medium |

| Potassium Peroxymonosulfate | Quick shock treatment for commercial pools | Allows swimming shortly after use | Higher cost and frequent applications | High |

| Hydrogen Peroxide | Eco-friendly treatment for residential pools | Leaves no harmful residues | Shorter shelf life | High |

| Sodium Dichloroisocyanurate | Stabilized shock treatment for all pool types | Long shelf life and stability | Potential cyanuric acid buildup | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for oxidizer for pools

What Are the Key Manufacturing Processes for Pool Oxidizers?

The manufacturing of pool oxidizers involves several critical stages, each designed to ensure that the final product meets safety, efficacy, and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing oxidizers for pools.

1. Material Preparation: What Raw Materials Are Used?

The manufacturing process begins with the selection and preparation of raw materials. Common oxidizers for pools include calcium hypochlorite, potassium peroxymonosulfate, and hydrogen peroxide. Each material has specific handling and storage requirements to maintain its stability and effectiveness.

Illustrative image related to oxidizer for pools

During this stage, suppliers must ensure that the materials meet international quality standards. This involves sourcing from reputable suppliers and conducting initial quality checks. For example, calcium hypochlorite should have a minimum active chlorine content to ensure its efficacy as a pool shock treatment.

2. How Is the Forming Process Conducted?

Once the materials are prepared, the next step is the forming process. This typically involves the mixing of raw materials in controlled environments to create a homogeneous blend. Key techniques include:

- Dry Mixing: For solid oxidizers, powders are blended to achieve uniform distribution of active ingredients.

- Liquid Formulation: In the case of liquid oxidizers, precise measurements are crucial. Automated systems are often used to ensure consistency in the formulation.

At this stage, manufacturers must adhere to strict protocols to avoid contamination, which could compromise the product’s quality.

3. What Assembly Techniques Are Utilized?

The assembly stage involves packaging the oxidizers into their final form, whether in bags, bottles, or bulk containers. This stage often includes:

- Automated Filling: For liquid products, automated machines fill containers to precise volumes, minimizing human error.

- Sealing and Labeling: Proper sealing is essential to prevent leakage and ensure product integrity. Labels must include crucial information, such as active ingredients, usage instructions, and safety warnings.

Quality assurance checks are performed at this stage to verify that all products are accurately labeled and sealed according to regulatory requirements.

Illustrative image related to oxidizer for pools

4. What Finishing Processes Are Applied?

Finishing processes enhance the product’s shelf life and usability. This may include:

- Drying: For solid oxidizers, drying ensures that moisture levels are controlled to prevent degradation.

- Quality Control Testing: Before the final product is released, it undergoes rigorous testing to ensure it meets specified performance standards. This includes checking for potency, solubility, and pH levels.

How Is Quality Assurance Implemented in Pool Oxidizer Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, particularly for products intended for pool sanitation. B2B buyers should be aware of the QA protocols that reputable manufacturers implement.

1. What International Standards Govern Pool Oxidizer Production?

Manufacturers of pool oxidizers are often required to comply with international quality standards, such as ISO 9001, which focuses on effective quality management systems. Adherence to these standards helps ensure that products are produced consistently and meet customer expectations.

In addition to ISO standards, specific industry regulations may apply, such as CE marking in Europe, which indicates that products comply with health, safety, and environmental protection standards. For manufacturers targeting markets in the Middle East or Africa, regional certifications may also be necessary.

Illustrative image related to oxidizer for pools

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to maintaining product quality throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves the inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, samples are taken at various stages to verify that the manufacturing process is under control.

- Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted to ensure compliance with specifications.

Each checkpoint serves as a safeguard, allowing manufacturers to identify and rectify issues before they escalate.

3. What Common Testing Methods Are Used?

Testing methods for pool oxidizers can vary based on the type of product. Common methods include:

- Chemical Analysis: This verifies the concentration of active ingredients, ensuring that the product performs as intended.

- Stability Testing: Products are subjected to various environmental conditions to assess their shelf life and stability over time.

- Microbial Testing: Ensures that the product is free from harmful contaminants, particularly important for products used in water sanitation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing pool oxidizers, B2B buyers should take proactive steps to verify the quality control practices of potential suppliers.

Illustrative image related to oxidizer for pools

1. What Should Buyers Look for in Supplier Audits?

Requesting audits from suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should look for:

- Documentation of Compliance: Ensure that suppliers can provide documentation demonstrating adherence to international standards such as ISO 9001.

- Audit Reports: Recent third-party audit reports can reveal the effectiveness of a supplier’s quality management system.

2. How Important Are Quality Control Reports?

Quality control reports should be available upon request. These reports should detail the results of testing conducted at each quality checkpoint, providing transparency into the product’s quality.

3. What Role Do Third-Party Inspections Play?

Engaging third-party inspectors can offer an unbiased evaluation of a supplier’s manufacturing and quality control processes. This is particularly beneficial for B2B buyers in regions like Africa and South America, where local regulations may vary significantly from international standards.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from various regions face unique challenges when sourcing pool oxidizers.

- Regulatory Differences: Understanding the local regulations in different regions, such as the Middle East or Europe, is crucial. Some countries may have stringent import regulations that require additional documentation or certifications.

- Cultural Considerations: Building relationships with suppliers can vary significantly across cultures. In some regions, trust and rapport are essential, while in others, formal agreements and documentation take precedence.

By being aware of these nuances, B2B buyers can navigate the complexities of international sourcing more effectively.

Conclusion

In summary, understanding the manufacturing processes and quality assurance practices for pool oxidizers is essential for B2B buyers. By paying attention to the key stages of manufacturing, relevant international standards, and effective quality control measures, buyers can make informed sourcing decisions that ensure they receive high-quality products suitable for their markets.

Illustrative image related to oxidizer for pools

Practical Sourcing Guide: A Step-by-Step Checklist for ‘oxidizer for pools’

Introduction

Sourcing oxidizers for pools is a critical task for B2B buyers in the swimming pool maintenance sector. This guide provides a structured checklist to ensure you make informed purchasing decisions, optimize your supply chain, and maintain high water quality standards for your customers. By following these steps, you can streamline the procurement process and enhance your operational efficiency.

1. Identify Your Pool Type and Needs

Understanding the specific requirements of the pools you service is essential. Different pool types (e.g., vinyl, gunite) may have varying oxidizer needs based on factors like size, usage, and local environmental conditions. Consider:

– The frequency of use and the number of bathers.

– Local climate impacts on pool maintenance.

2. Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications for the oxidizers you need. This includes the type (chlorine vs. non-chlorine), formulation (e.g., calcium hypochlorite, potassium peroxymonosulfate), and dosage requirements.

– Why this matters: Specifications ensure compatibility with existing pool systems and help avoid over-stabilization or other chemical imbalances.

3. Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in pool oxidizers. Look for companies with a solid reputation in your target markets, such as Africa, South America, the Middle East, and Europe.

– What to consider: Supplier experience, product range, and customer reviews can provide insights into reliability and service quality.

4. Request Product Samples

Before making a bulk purchase, request samples of the oxidizers you are considering. Testing these products in actual pool environments will help you evaluate their effectiveness and suitability.

– Key points: Assess performance, ease of application, and any side effects on water clarity and balance.

5. Verify Supplier Certifications

Ensure that your chosen suppliers adhere to relevant industry standards and regulations. Certifications from recognized bodies can indicate product quality and safety.

– Important checks: Look for compliance with EPA guidelines and local regulations in your region to avoid legal issues and ensure product efficacy.

6. Evaluate Pricing and Terms

Compare pricing structures and contract terms from various suppliers. Understand the total cost of ownership, including shipping, taxes, and potential discounts for bulk purchases.

– Considerations: Evaluate payment terms and return policies to protect your investment and maintain flexibility.

7. Establish a Communication Plan

Once you’ve selected a supplier, set up a clear communication plan to streamline orders, deliveries, and support. Regular communication ensures that any issues are addressed promptly and helps build a strong partnership.

– Action items: Schedule regular check-ins and establish points of contact for both parties to enhance collaboration and service delivery.

Illustrative image related to oxidizer for pools

By following this checklist, B2B buyers can effectively source oxidizers for pools, ensuring they meet the highest standards of quality and efficiency in their operations.

Comprehensive Cost and Pricing Analysis for oxidizer for pools Sourcing

What Are the Key Cost Components in Sourcing Pool Oxidizers?

When analyzing the cost structure for pool oxidizers, several components come into play. Materials form the backbone of the cost, with the type of oxidizing agent significantly affecting pricing. For instance, calcium hypochlorite and potassium peroxymonosulfate are commonly used, each with distinct cost implications based on their availability and sourcing logistics.

Labor costs are another essential factor, encompassing the workforce involved in production, packaging, and quality control (QC). Automated manufacturing processes may reduce labor costs but could increase initial capital expenditure. Manufacturing overhead accounts for utilities, rent, and equipment maintenance, which can vary widely based on geographical location and operational efficiency.

Illustrative image related to oxidizer for pools

Tooling costs are also significant, especially for custom formulations or packaging. These costs can add to the initial investment but may lead to savings through economies of scale for large orders. Logistics play a critical role as well, including transportation, warehousing, and customs fees, which can escalate depending on the distance and regulatory requirements.

Lastly, the margin represents the profit markup applied by manufacturers or distributors, influenced by market demand and competitive landscape.

How Do Price Influencers Affect the Cost of Pool Oxidizers?

Several price influencers can impact the final cost of pool oxidizers. Volume or Minimum Order Quantity (MOQ) is crucial; larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to avoid excess inventory while benefiting from bulk pricing.

Specifications and customization can also drive up costs. Custom formulations that meet specific quality standards or regulatory requirements may incur additional charges. Buyers should balance the need for specialized products against the potential for higher expenses.

Material quality and certifications are vital, especially for international buyers who must comply with various safety and environmental standards. Products that meet high-quality certifications often come at a premium, but they can reduce long-term operational costs through improved performance and reduced chemical usage.

Illustrative image related to oxidizer for pools

Supplier factors, including their reputation, reliability, and service levels, also influence pricing. Established suppliers may charge more but offer better support, quality assurance, and faster delivery times.

Incoterms can significantly affect overall pricing. Understanding terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for international buyers to calculate total landed costs accurately.

What Tips Should Buyers Consider for Cost Efficiency in Pool Oxidizer Sourcing?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings. Establishing long-term relationships with suppliers can provide leverage for better pricing and terms. Buyers should prepare to negotiate based on their purchasing volume, payment terms, and delivery schedules.

Understanding the Total Cost of Ownership (TCO) is crucial. This encompasses not just the purchase price but also logistics, storage, and disposal costs associated with pool oxidizers. By evaluating the TCO, buyers can make more informed decisions that lead to long-term savings.

Pricing nuances vary by region. For instance, tariffs, taxes, and local market conditions can affect the cost structure. Buyers should stay informed about regional pricing trends and potential fluctuations based on currency exchange rates or geopolitical factors.

Illustrative image related to oxidizer for pools

While indicative pricing can be found through online platforms and supplier catalogs, it is essential to recognize that these are often subject to change. Buyers should request quotes and conduct market comparisons to ensure they are receiving competitive pricing tailored to their specific needs.

In conclusion, a thorough understanding of the cost components, price influencers, and strategic buying practices can empower B2B buyers to navigate the complexities of sourcing pool oxidizers effectively.

Alternatives Analysis: Comparing oxidizer for pools With Other Solutions

Exploring Alternatives to Pool Oxidizers

In the realm of pool maintenance, oxidizers play a critical role in maintaining water quality by eliminating contaminants. However, there are various alternative methods and solutions available that can also help achieve clean and clear pool water. This analysis will compare traditional pool oxidizers with two viable alternatives: UV water treatment systems and mineral sanitizers.

Comparison Table

| Comparison Aspect | Oxidizer For Pools | UV Water Treatment System | Mineral Sanitizer |

|---|---|---|---|

| Performance | Highly effective in killing bacteria and algae; restores water clarity. | Destroys microorganisms without chemicals; effective against bacteria and viruses. | Reduces chlorine usage; eliminates algae and bacteria; softer feel to water. |

| Cost | Moderate to high; varies by product type (liquid, powder, etc.). | High initial investment; lower ongoing costs due to reduced chemical usage. | Moderate cost; savings on chlorine may offset initial investment. |

| Ease of Implementation | Simple application; requires following dosage instructions. | Requires professional installation; ongoing maintenance needed. | Easy to install; compatible with existing systems; less frequent maintenance. |

| Maintenance | Regular application required; monitoring of chemical levels is necessary. | Minimal maintenance; occasional bulb replacement needed. | Requires periodic checks and occasional mineral replenishment. |

| Best Use Case | Ideal for routine shock treatments and addressing high bather loads. | Best for commercial pools or high-usage residential pools needing chemical-free sanitation. | Suitable for residential pools wanting to reduce chlorine levels while maintaining cleanliness. |

Detailed Breakdown of Alternatives

What are the Benefits and Drawbacks of UV Water Treatment Systems?

UV water treatment systems utilize ultraviolet light to neutralize bacteria and viruses. This method is effective in providing chemical-free sanitation, making it particularly attractive for environmentally conscious users. The primary advantage is the significant reduction in chemical usage, which can lead to lower overall pool maintenance costs. However, the initial investment can be high, and the system requires professional installation. Regular maintenance, including bulb replacement, is also essential to ensure optimal performance.

How Do Mineral Sanitizers Work and What Are Their Pros and Cons?

Mineral sanitizers use natural minerals, such as silver and copper, to maintain water quality. They help reduce the need for chlorine, providing a softer feel to the water while effectively controlling algae and bacteria. This approach is generally easy to implement and integrates well with existing filtration systems. However, while mineral sanitizers can lower chlorine requirements, they may not completely eliminate the need for traditional sanitizers in high-demand situations, potentially leading to additional costs.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate solution for pool maintenance, B2B buyers should consider their specific operational requirements, including pool size, usage frequency, and local regulations. For high-traffic pools, traditional oxidizers may still offer the most reliable performance. In contrast, businesses looking to reduce chemical usage and appeal to eco-conscious clients might lean towards UV systems or mineral sanitizers. Ultimately, the decision should align with budget constraints, maintenance capabilities, and desired water quality outcomes. By carefully weighing these factors, buyers can make informed decisions that enhance their pool management strategies.

Essential Technical Properties and Trade Terminology for oxidizer for pools

What Are the Key Technical Properties of Pool Oxidizers?

-

Active Ingredient Concentration

The concentration of active ingredients in pool oxidizers, such as chlorine or potassium peroxymonosulfate, is critical for efficacy. Typically, chlorine-based oxidizers range from 50-70% active content, while non-chlorine alternatives might contain around 42.8% active oxygen. This specification directly impacts the product’s ability to eliminate contaminants and maintain water clarity, which is essential for meeting health and safety regulations in various markets. -

pH Level

The pH level of oxidizers is a vital property that influences their effectiveness. Most pool oxidizers are formulated to have a pH of around 6.5 to 8.5, aligning with optimal pool water pH levels. Products that deviate from this range can lead to chemical imbalances, potentially causing skin irritation or damage to pool surfaces. For B2B buyers, understanding pH compatibility ensures seamless integration into existing pool maintenance programs. -

Stability and Shelf Life

The stability of oxidizers affects their performance and safety. Chlorine-based oxidizers generally have a shelf life of 3-5 years when stored correctly, while non-chlorine options may vary. A longer shelf life minimizes waste and allows for bulk purchasing, which is crucial for B2B operations in regions with varying demand levels. Buyers should prioritize products with clear storage guidelines and expiration dates to maintain quality. -

Dosage Recommendations

Recommended dosages, typically expressed in parts per million (ppm), are essential for effective use. For example, chlorine oxidizers often recommend dosages of 5-10 ppm for shock treatment. Understanding these guidelines helps buyers in different regions ensure compliance with local regulations and optimize water treatment processes, reducing the risk of over-treatment or under-treatment. -

Compatibility with Other Chemicals

Many oxidizers are designed to work synergistically with other pool chemicals, such as algaecides and pH balancers. This compatibility is crucial for B2B buyers who may offer comprehensive pool maintenance solutions. Ensuring that oxidizers do not negatively react with other products can enhance overall pool care efficiency and customer satisfaction.

What Are Common Trade Terms Related to Pool Oxidizers?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that may be marketed under another company’s brand. In the pool chemical industry, understanding OEM relationships can help B2B buyers identify reliable suppliers that can offer high-quality oxidizers that meet their specific needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the context of pool oxidizers, knowing the MOQ is crucial for B2B buyers to manage inventory effectively and ensure cost-efficiency, especially when dealing with multiple suppliers across regions. -

RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For buyers in the pool chemicals market, issuing an RFQ for oxidizers allows them to compare prices, delivery times, and product specifications, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers in the pool chemical sector, as they dictate shipping responsibilities, risk management, and cost allocations, which are crucial for successful cross-border transactions. -

Technical Data Sheet (TDS)

A TDS provides detailed information about a product’s properties, applications, and handling instructions. For pool oxidizers, this document helps B2B buyers assess compatibility with existing products, ensuring they make informed decisions regarding chemical use and safety measures. -

SDS (Safety Data Sheet)

An SDS outlines the hazards associated with chemical products, including oxidizers. This document is essential for B2B buyers to ensure compliance with health and safety regulations and to provide necessary training for employees handling these chemicals. Understanding the SDS is critical for risk management and ensuring safe operations in pool maintenance.

Navigating Market Dynamics and Sourcing Trends in the oxidizer for pools Sector

What Are the Current Market Dynamics and Key Trends Affecting the Oxidizer for Pools Sector?

The global market for pool oxidizers is witnessing significant growth, driven by increasing consumer awareness of water quality and health standards. As pool ownership rises in regions such as Africa, South America, and the Middle East, the demand for effective oxidizing agents is surging. Key trends include a shift towards non-chlorine oxidizers, which are gaining popularity due to their ability to maintain water clarity without the strong odors associated with traditional chlorine products. This is especially relevant in markets like Germany and Saudi Arabia, where environmental regulations and consumer preferences are evolving.

Emerging technologies in water treatment are also reshaping the sourcing landscape for oxidizers. Automated dosing systems and digital water testing solutions are becoming standard, enhancing efficiency and accuracy in pool maintenance. B2B buyers are increasingly looking for suppliers that offer integrated solutions rather than standalone products, which can streamline operations and reduce costs. Furthermore, as online purchasing becomes more prevalent, suppliers are adapting their sales strategies to include e-commerce platforms, making it easier for international buyers to source products.

How Can Sustainability and Ethical Sourcing Impact B2B Purchases of Pool Oxidizers?

Sustainability is becoming a pivotal factor in the purchasing decisions of B2B buyers in the pool chemicals sector. The environmental impact of pool maintenance products is under scrutiny, with a growing emphasis on reducing chemical runoff and promoting eco-friendly alternatives. Buyers are increasingly seeking oxidizers that are biodegradable or derived from renewable resources, such as potassium peroxymonosulfate, which offers effective oxidation without the negative environmental footprint associated with traditional chlorine.

Ethical sourcing practices are equally important. B2B buyers are prioritizing suppliers who adhere to transparent supply chains and ethical labor practices. Certifications such as EcoLabel or Green Seal can serve as indicators of a supplier’s commitment to sustainability. By choosing products that meet these standards, buyers not only fulfill their corporate social responsibility but also cater to a growing segment of environmentally conscious consumers.

What Is the Historical Context of the Oxidizer for Pools Market?

The use of oxidizers in pool maintenance dates back several decades, evolving from simple chlorine-based solutions to more sophisticated formulations. Initially, chlorine was the primary method for sanitizing pool water, but concerns over its byproducts and health implications led to the development of alternative oxidizers. The introduction of non-chlorine products in the late 20th century marked a significant shift in the industry, allowing pool owners to maintain water quality without harsh chemicals.

Over the years, the market has continued to adapt to changing consumer preferences and regulatory standards. Innovations in formulation and application have made oxidizers more effective and user-friendly, leading to increased adoption across various regions. Today, as the focus on health, safety, and sustainability intensifies, the oxidizer for pools sector stands at a critical juncture, poised for further growth and transformation.

Frequently Asked Questions (FAQs) for B2B Buyers of oxidizer for pools

-

How do I solve issues with pool water clarity?

To address pool water clarity issues, regular oxidation is essential. Using oxidizers helps eliminate organic contaminants introduced by swimmers and environmental factors. For effective results, choose products that comply with local regulations and recommended dosages. Consider options like chlorine-based shock or non-chlorine oxidizers, depending on your pool type and maintenance routine. Establishing a consistent schedule for oxidation treatments can significantly enhance water clarity and reduce the burden on sanitizers. -

What is the best oxidizer for maintaining pool water quality?

The best oxidizer for maintaining pool water quality depends on your specific needs and pool type. Chlorine-based oxidizers are effective for traditional pools, while non-chlorine options, such as potassium peroxymonosulfate, provide fast-acting solutions that allow swimming shortly after application. Evaluate factors like pool usage, water conditions, and local climate when selecting an oxidizer. Engaging with suppliers who offer a range of products can help you make informed decisions tailored to your pool maintenance requirements. -

What should I consider when vetting suppliers of pool oxidizers?

When vetting suppliers of pool oxidizers, assess their reputation, product quality, and compliance with international regulations. Look for suppliers with certifications like ISO or those adhering to local environmental standards. Request samples to evaluate product performance and check customer reviews or testimonials. Additionally, ensure they have robust customer service and support systems to assist with your inquiries and issues during the procurement process. -

What are the typical minimum order quantities (MOQ) for pool oxidizers?

Minimum order quantities (MOQ) for pool oxidizers can vary significantly based on the supplier and product type. Generally, MOQs can range from 100 kg for bulk chemicals to several pallets for packaged products. Discuss your requirements with suppliers to negotiate MOQs that align with your purchasing strategy. Establishing a long-term partnership may also provide flexibility in order sizes, especially if you have consistent demand. -

What payment terms are commonly offered by international suppliers?

International suppliers may offer a range of payment terms, including upfront payments, letters of credit, and net payment terms (e.g., net 30 or net 60 days). It’s essential to clarify these terms before finalizing any agreements. Ensure you understand any associated fees, currency exchange rates, and the implications for cash flow management. Establishing a good relationship with suppliers can sometimes lead to more favorable payment options over time. -

How do I ensure quality assurance for pool oxidizers?

To ensure quality assurance for pool oxidizers, request detailed product specifications, safety data sheets (SDS), and compliance certifications from your suppliers. Consider conducting third-party testing or quality audits, especially for bulk orders. Establish a clear return policy for defective products and maintain open communication with suppliers regarding quality control measures. Regularly review and assess supplier performance to ensure they consistently meet your quality standards. -

What logistics considerations should I keep in mind when importing pool oxidizers?

When importing pool oxidizers, logistics considerations include shipping methods, customs clearance, and regulatory compliance in your destination country. Choose a reliable freight forwarder experienced in handling chemical shipments to navigate these complexities. Ensure that all necessary documentation, such as bills of lading and import permits, are in order. Also, factor in lead times and potential delays caused by inspections or regulatory checks to plan your inventory effectively. -

Can I customize pool oxidizer formulations to meet specific needs?

Many suppliers offer customization options for pool oxidizers, allowing you to tailor formulations based on specific water chemistry or environmental conditions. Discuss your requirements with potential suppliers and inquire about their ability to create custom blends or packaging. Keep in mind that custom formulations may require minimum order quantities and longer lead times. Collaborating closely with suppliers can help ensure the final product meets your unique specifications and performance standards.

Top 2 Oxidizer For Pools Manufacturers & Suppliers List

1. Poolife® – Shock & Oxidizer Products

Domain: fronheiser.com

Registered: 1999 (26 years)

Introduction: Shock & Oxidizer products from poolife® are designed to maintain healthy pool water by killing bacteria, controlling algae, and destroying organic contaminants. They comply with EPA dosage recommendations, delivering between 5-10 ppm of available chlorine. The calcium hypochlorite based shock products do not cause overstabilization with prolonged use. Available products include: 1 GLN Liquid Chlor…

2. Fiesta Pools and Spas – BAQUACIL Swimming Pool Oxidizer

Domain: fiestapoolsandspas.com

Registered: 2000 (25 years)

Introduction: BAQUACIL Swimming Pool Oxidizer is a chlorine-free liquid oxidizer formulated with specially-stabilized hydrogen peroxide (27%). It is designed to clarify pool water by removing swimmer waste and other contaminants. Recommended usage is weekly as Step two in the three-step BAQUACIL® CDX® System. The dosage is 1 gallon per 10,000 gallons of pool water per month. The product is not compatible with c…

Strategic Sourcing Conclusion and Outlook for oxidizer for pools

In conclusion, strategic sourcing of oxidizers for pools is vital for maintaining optimal water quality and ensuring a safe swimming environment. Buyers should prioritize products that effectively eliminate contaminants, support sustainable practices, and comply with local regulations. Understanding the differences between chlorine and non-chlorine options can aid in selecting the most suitable products for specific market needs, particularly in diverse regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to oxidizer for pools

Investing in reliable suppliers who offer a range of oxidizers, such as potassium peroxymonosulfate and stabilized hydrogen peroxide, can enhance the overall performance of pool maintenance programs. Additionally, fostering partnerships with manufacturers that prioritize innovation and eco-friendly solutions will not only improve customer satisfaction but also drive long-term profitability.

As international B2B buyers navigate this dynamic market, leveraging these insights will empower them to make informed purchasing decisions. The future of pool maintenance hinges on strategic sourcing—seize the opportunity to enhance your product offerings and elevate your business’s competitive edge. Engage with suppliers today to ensure your pool chemical solutions are as effective and sustainable as possible.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to oxidizer for pools

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.