A Deep Dive into Multi 18650 Battery Case Solution

Introduction: Navigating the Global Market for multi 18650 battery case

Navigating the global market for multi 18650 battery cases presents a significant challenge for B2B buyers, particularly those seeking reliable storage solutions for lithium-ion batteries across diverse industries. As the demand for portable power continues to rise, sourcing durable and versatile battery cases becomes paramount for businesses in sectors ranging from electronics to renewable energy. This comprehensive guide delves into the various types of multi 18650 battery cases available, their applications, and the critical factors to consider when selecting a supplier.

Within this guide, international B2B buyers will find detailed insights on the specifications and features of various battery case options, alongside expert advice on supplier vetting processes. We will explore the cost implications associated with different types of battery cases, helping businesses make informed purchasing decisions that align with their operational needs and budget constraints.

Particularly for buyers in Africa, South America, the Middle East, and Europe—regions characterized by diverse market dynamics—this guide aims to empower stakeholders with the knowledge necessary to navigate the complexities of sourcing quality battery cases. By providing actionable insights and strategic recommendations, we equip businesses with the tools to optimize their procurement processes and ensure the secure storage of their critical battery supplies.

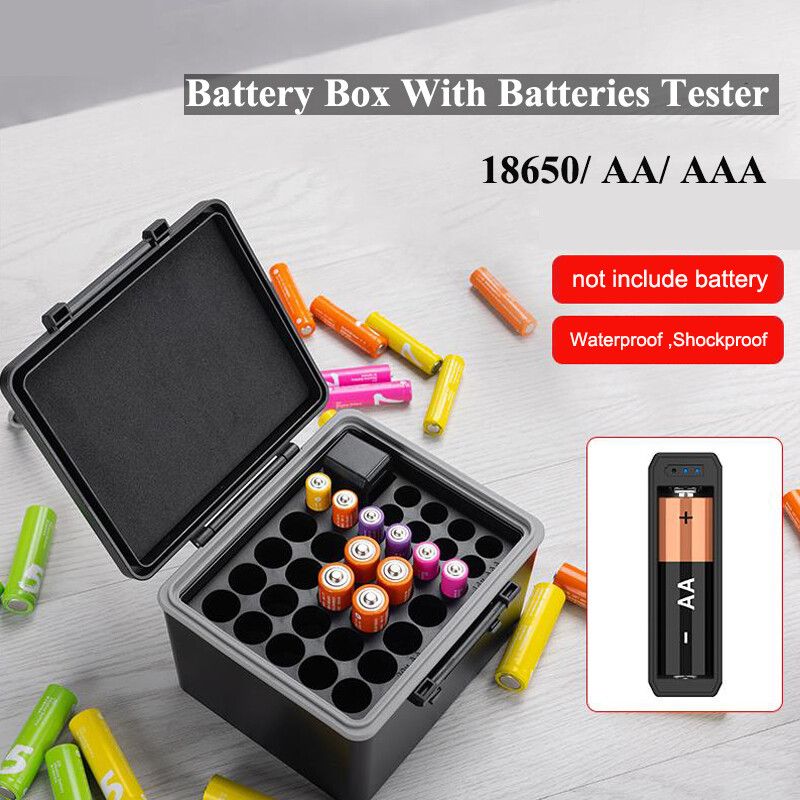

Understanding multi 18650 battery case Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Modular Battery Cases | Customizable inserts for various battery types | Tactical, outdoor, and emergency services | Pros: Versatile, durable, and waterproof. Cons: Higher initial cost. |

| Waterproof Battery Cases | Sealed design for moisture protection | Marine, outdoor equipment, and electronics | Pros: Protects against water damage. Cons: May be bulkier. |

| Stackable Battery Cases | Compact design allowing for vertical stacking | Retail, storage, and transportation | Pros: Space-efficient, easy to organize. Cons: Limited capacity per unit. |

| Silicone Battery Cases | Soft, flexible material providing shock resistance | Consumer electronics, DIY projects | Pros: Lightweight, protective, and inexpensive. Cons: Less rigid, can wear out faster. |

| Heavy-Duty Protective Cases | Robust construction for extreme conditions | Industrial, military, and rugged environments | Pros: High durability and impact resistance. Cons: Heavier and more costly. |

What Are Modular Battery Cases and Their B2B Relevance?

Modular battery cases are designed with interchangeable inserts that can accommodate various battery types, including multiple 18650 cells. This feature is particularly beneficial for businesses in tactical and outdoor sectors where flexibility in battery configuration is crucial. Buyers should consider the initial investment, as these cases tend to be more expensive but offer long-term value through their adaptability and durability.

Why Choose Waterproof Battery Cases for Specific Applications?

Waterproof battery cases are engineered to prevent moisture ingress, making them ideal for marine applications or outdoor electronics that may be exposed to rain or splashes. Businesses that operate in humid or wet environments should prioritize these cases. While they provide significant protection, buyers must balance the bulkiness against the need for portability in their operations.

How Do Stackable Battery Cases Improve Storage Efficiency?

Stackable battery cases allow for vertical organization, maximizing storage space in retail and transportation environments. Their compact design is advantageous for businesses looking to optimize inventory management. However, buyers should be aware that while they save space, they might limit the number of batteries that can be stored in a single unit.

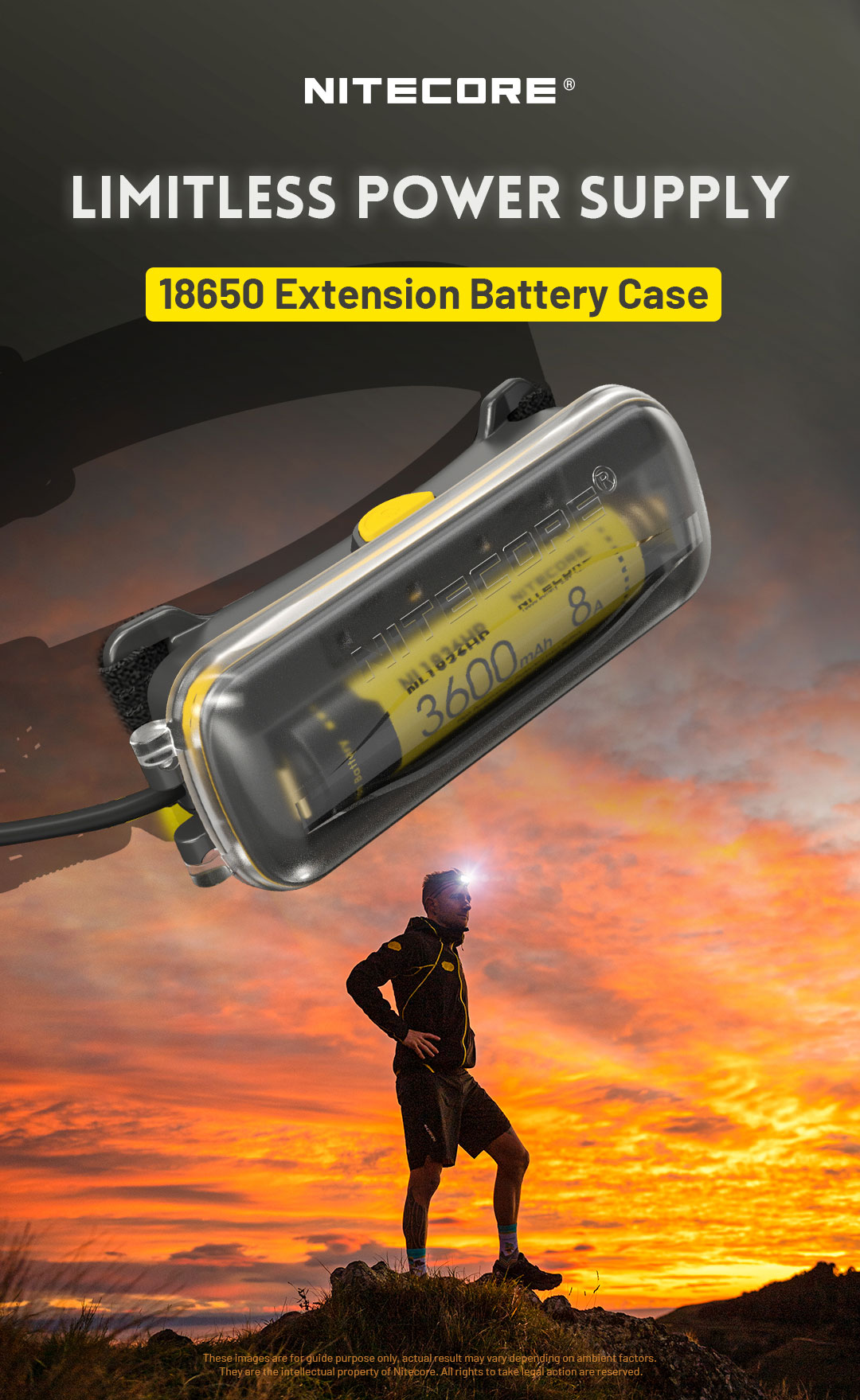

Illustrative image related to multi 18650 battery case

What Advantages Do Silicone Battery Cases Offer for Consumer Electronics?

Silicone battery cases are lightweight and flexible, providing shock resistance that is particularly useful for consumer electronics and DIY projects. These cases are cost-effective and easy to handle, appealing to businesses that require a quick and budget-friendly solution. However, their less rigid structure may lead to quicker wear compared to more robust options.

Why Invest in Heavy-Duty Protective Cases for Rugged Environments?

Heavy-duty protective cases are built to withstand extreme conditions, making them suitable for industrial or military applications. Their robust construction ensures that batteries remain safe during transport in challenging environments. While they offer superior durability, buyers should consider the trade-off in terms of weight and cost, as these cases are generally heavier and more expensive than standard options.

Key Industrial Applications of multi 18650 battery case

| Industry/Sector | Specific Application of multi 18650 battery case | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Energy storage solutions for solar and wind systems | Enhanced battery management and protection in remote installations | Need for waterproof and durable cases to withstand environmental conditions |

| Telecommunications | Backup power systems for communication devices | Reliable power supply ensuring continuous operation during outages | Lightweight and compact designs for easy integration into existing systems |

| Medical Equipment | Portable medical devices and emergency equipment | Safe storage and transport of batteries for life-saving devices | Compliance with international safety standards and regulations |

| Consumer Electronics | High-performance gadgets and tools | Protection against physical damage and moisture, prolonging battery life | Customization options for branding and specific battery configurations |

| Defense and Security | Tactical equipment for military and law enforcement | Quick access and secure storage for essential battery types in the field | Rugged construction to endure harsh conditions and military specifications |

How are Multi 18650 Battery Cases Used in Renewable Energy Applications?

In the renewable energy sector, multi 18650 battery cases are essential for energy storage solutions, particularly in solar and wind systems. These cases provide robust protection against environmental factors, ensuring batteries remain functional in remote locations. They mitigate risks associated with battery damage during transportation and installation, which is crucial for maintaining energy supply continuity. For international buyers, sourcing cases that are waterproof and durable is vital, especially in regions with extreme weather conditions.

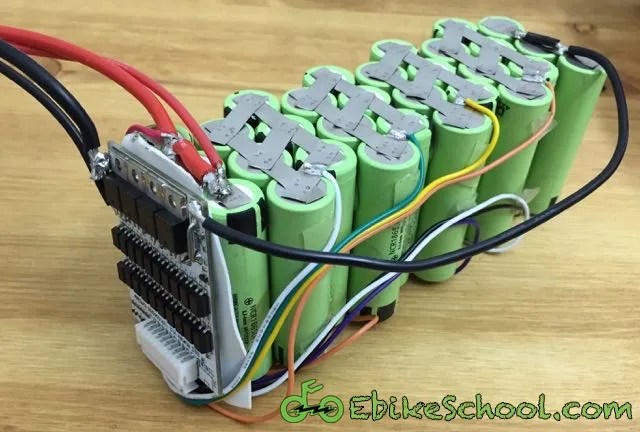

Illustrative image related to multi 18650 battery case

What Role Do Multi 18650 Battery Cases Play in Telecommunications?

Telecommunications companies utilize multi 18650 battery cases to support backup power systems for communication devices. In scenarios where power outages can disrupt services, these cases ensure that batteries are securely stored and easily accessible. This reliability is paramount for maintaining communication lines, especially in remote or underserved areas. Buyers should focus on lightweight and compact designs that can be seamlessly integrated into existing systems without adding significant bulk.

Why are Multi 18650 Battery Cases Important in Medical Equipment?

In the medical field, multi 18650 battery cases are critical for the safe storage and transport of batteries used in portable medical devices and emergency equipment. These cases protect batteries from physical damage and ensure they remain operational when needed most. Compliance with international safety standards is a key consideration for buyers, as it ensures the reliability and safety of life-saving devices in various healthcare settings across different regions.

How Do Multi 18650 Battery Cases Benefit Consumer Electronics?

Consumer electronics manufacturers leverage multi 18650 battery cases to enhance the performance and longevity of high-performance gadgets and tools. These cases safeguard batteries from moisture and physical impacts, which can otherwise lead to reduced efficiency or failure. Customization options for branding and specific battery configurations are also attractive to B2B buyers in this sector, allowing them to tailor products to their market needs.

What Are the Advantages of Multi 18650 Battery Cases in Defense and Security?

In defense and security applications, multi 18650 battery cases are utilized for storing tactical equipment batteries. These cases provide quick access and secure storage, which is essential for military and law enforcement operations. The rugged construction of these cases ensures they can withstand harsh conditions and meet military specifications. Buyers in this sector must prioritize sourcing solutions that offer durability and functionality to support critical operations effectively.

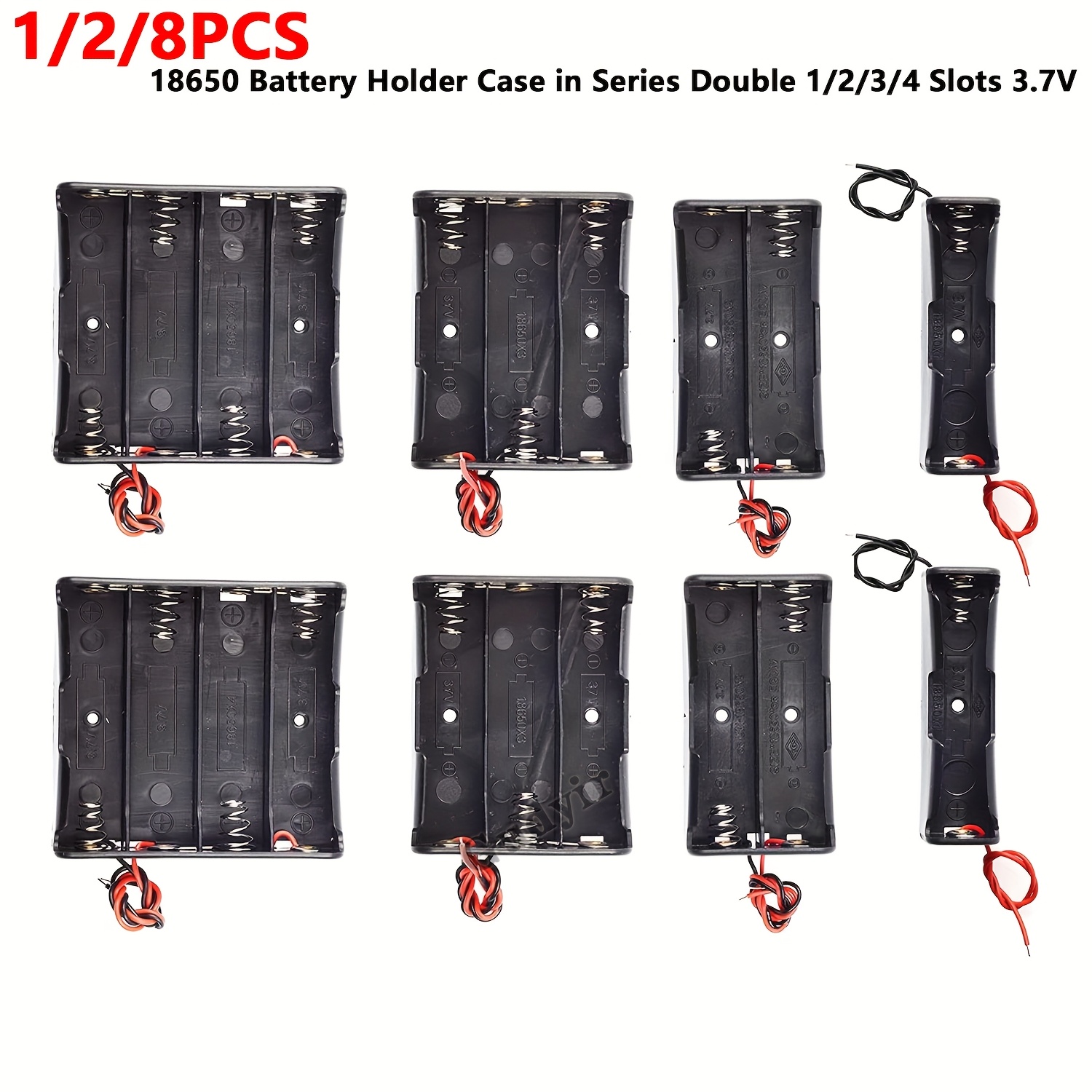

Illustrative image related to multi 18650 battery case

3 Common User Pain Points for ‘multi 18650 battery case’ & Their Solutions

Scenario 1: The Challenge of Inconsistent Battery Storage Solutions

The Problem: B2B buyers often struggle with the inconsistent quality and design of multi 18650 battery cases available in the market. This inconsistency can lead to significant operational inefficiencies. For example, a buyer may purchase a bulk order of battery cases that do not fit their specific battery models or fail to provide adequate protection against moisture and impact. Such discrepancies can disrupt the workflow, especially for companies that depend on reliable power sources for their equipment in demanding environments like construction sites or outdoor operations.

The Solution: To overcome this challenge, buyers should conduct thorough research and specify their requirements clearly when sourcing multi 18650 battery cases. Engaging with manufacturers who offer customizable options can ensure that the cases fit the specific dimensions and protection needs of their batteries. Additionally, opting for cases with proven waterproof and shock-resistant features can safeguard batteries against environmental hazards. Requesting samples before bulk purchases can also provide firsthand insights into the product’s quality, ensuring it meets the operational demands of the buyer’s environment.

Scenario 2: Navigating Compliance and Safety Regulations

The Problem: Many B2B buyers, particularly in regions with strict safety regulations like Europe, face the daunting task of ensuring that the multi 18650 battery cases they purchase comply with local laws and international standards. Non-compliance can lead to costly penalties, product recalls, and damage to a company’s reputation. Moreover, navigating these regulations can be overwhelming, especially for businesses without dedicated compliance teams.

The Solution: To address compliance concerns, buyers should proactively educate themselves about the relevant safety standards applicable to battery storage in their region. This includes understanding certifications such as UN38.3 for transportation and IEC62133 for safety. Collaborating with suppliers that are transparent about their compliance processes and can provide documentation is critical. Buyers should also consider investing in cases that feature built-in safety mechanisms, such as thermal protection and over-discharge prevention, which not only comply with regulations but also enhance overall safety in usage.

Scenario 3: Managing Inventory and Logistics Challenges

The Problem: Efficient inventory management is a significant pain point for B2B buyers who handle multi 18650 battery cases. The need to maintain optimal stock levels while managing varying demand can lead to either excess inventory, which ties up capital, or shortages that disrupt operations. Additionally, coordinating logistics for battery storage solutions can be cumbersome, especially for businesses operating across multiple regions.

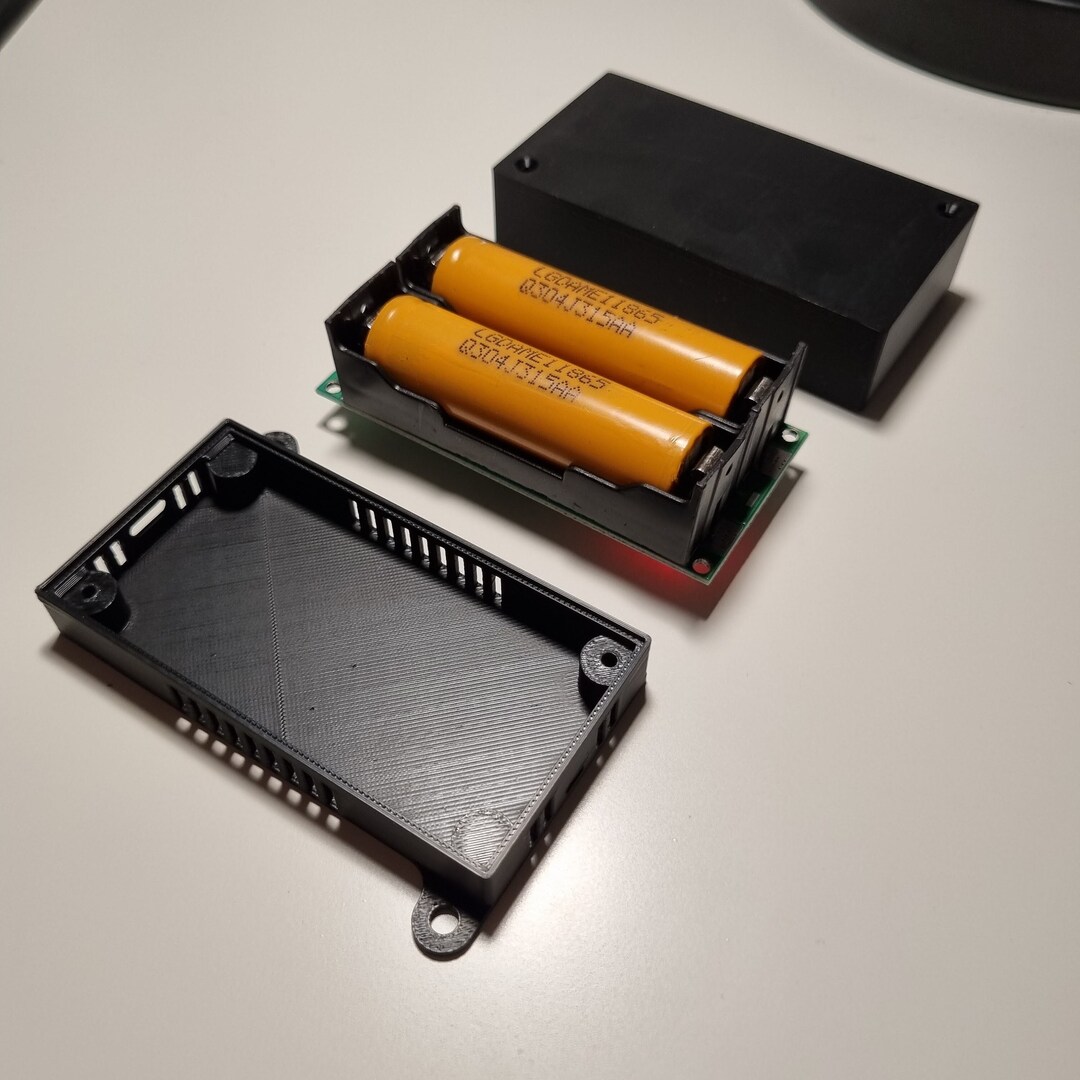

Illustrative image related to multi 18650 battery case

The Solution: Implementing an inventory management system tailored for battery storage can alleviate these logistical challenges. Buyers should look for suppliers who offer flexible order quantities and just-in-time delivery options, which can help maintain an optimal inventory level without overcommitting resources. Utilizing data analytics to track usage patterns can also provide insights into demand forecasting, enabling businesses to adjust their orders proactively. Furthermore, establishing partnerships with local distributors can streamline logistics and reduce shipping costs, ensuring that battery cases are always available when needed without incurring unnecessary delays.

Strategic Material Selection Guide for multi 18650 battery case

What are the Key Materials for Multi 18650 Battery Cases?

When selecting materials for multi 18650 battery cases, it is crucial to consider properties such as durability, weight, cost, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of these battery cases: polypropylene, polycarbonate, aluminum, and silicone.

How Does Polypropylene Perform in Multi 18650 Battery Cases?

Polypropylene (PP) is a thermoplastic polymer known for its excellent chemical resistance and lightweight properties. It typically has a temperature rating of around 100°C and can withstand moderate pressures.

Pros: Polypropylene is cost-effective and easy to mold, making it suitable for high-volume production. It is also resistant to moisture and many chemicals, which is essential for battery storage.

Illustrative image related to multi 18650 battery case

Cons: While it has good impact resistance, polypropylene can become brittle at lower temperatures and is less durable than some other materials.

Impact on Application: Its chemical resistance makes it suitable for environments where exposure to various substances is expected. However, it may not be the best choice for extreme conditions.

Considerations for International Buyers: Compliance with ASTM and ISO standards is essential, especially in regions like Africa and South America, where regulatory requirements may vary. Buyers should ensure that the material meets local environmental regulations.

Illustrative image related to multi 18650 battery case

What Benefits Does Polycarbonate Offer for Battery Cases?

Polycarbonate (PC) is a high-performance thermoplastic known for its clarity and impact resistance. It can withstand temperatures up to 120°C and has excellent dimensional stability.

Pros: Polycarbonate is highly durable and resistant to impact, making it ideal for rugged applications. Its transparency allows for easy visibility of the battery status.

Cons: It is more expensive than polypropylene and can be prone to scratching. Additionally, it may require more complex manufacturing processes.

Impact on Application: The high durability and temperature resistance make polycarbonate suitable for applications requiring robust protection, such as outdoor or industrial environments.

Considerations for International Buyers: Buyers from Europe and the Middle East should look for compliance with EU regulations regarding materials in contact with batteries. Understanding local certifications can help ensure market acceptance.

How Does Aluminum Compare as a Material for Battery Cases?

Aluminum is a lightweight metal known for its strength and corrosion resistance. It has a high melting point, making it suitable for high-temperature applications.

Pros: Aluminum provides excellent protection against physical damage and offers a premium feel. It is also recyclable, appealing to environmentally conscious buyers.

Cons: The cost of aluminum is higher than that of plastics, and it may require additional coatings to enhance corrosion resistance in certain environments.

Impact on Application: Aluminum cases are ideal for high-end products where durability and aesthetics are critical. They can withstand harsh conditions, making them suitable for outdoor applications.

Considerations for International Buyers: Buyers should ensure that the aluminum used complies with relevant international standards, such as ASTM for materials and ISO for manufacturing processes. This is particularly important in regions with strict import regulations, like Europe.

What Role Does Silicone Play in Multi 18650 Battery Cases?

Silicone is a flexible polymer known for its excellent temperature resistance and chemical stability. It can operate effectively in a temperature range of -60°C to 200°C.

Pros: Silicone provides good cushioning and protection against shocks and vibrations, making it ideal for portable battery cases. It is also resistant to UV light and ozone.

Cons: Silicone can be more expensive than traditional plastics and may not offer the same level of structural integrity as rigid materials.

Impact on Application: Its flexibility and cushioning properties make silicone suitable for applications where mobility and protection from impact are essential.

Illustrative image related to multi 18650 battery case

Considerations for International Buyers: Compliance with food-grade and safety standards is crucial, particularly in markets like Africa and South America, where regulations may differ. Buyers should verify that the silicone used is free from harmful substances.

Summary Table of Material Selection for Multi 18650 Battery Cases

| Material | Typical Use Case for multi 18650 battery case | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | General-purpose battery storage | Lightweight and cost-effective | Brittle at low temperatures | Low |

| Polycarbonate | Rugged, outdoor applications | High durability and impact resistance | More expensive and prone to scratching | Med |

| Aluminum | High-end, premium battery cases | Excellent protection and aesthetics | Higher cost and may require coatings | High |

| Silicone | Portable, flexible battery cases | Good cushioning and temperature resistance | More expensive and less rigid | Med |

This strategic material selection guide provides actionable insights for international B2B buyers, enabling informed decisions when sourcing multi 18650 battery cases that meet their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for multi 18650 battery case

What Are the Key Stages in the Manufacturing Process of Multi 18650 Battery Cases?

The manufacturing process for multi 18650 battery cases involves several critical stages, ensuring that the final product meets the high standards required for safety and functionality. The primary phases include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in manufacturing is selecting high-quality materials. Most battery cases are made from durable polymers, such as polycarbonate or ABS (Acrylonitrile Butadiene Styrene), which provide excellent protection against impact and environmental factors. Material testing is crucial at this stage, as it assesses the thermal and electrical properties of the materials to ensure they can safely house lithium-ion batteries.

-

Forming: The forming stage involves shaping the selected materials into the desired case structure. This is typically achieved through injection molding, where heated material is injected into a mold. This process allows for high precision and repeatability in producing cases with consistent dimensions. Advanced techniques like blow molding or thermoforming may also be utilized, depending on the design specifications.

-

Assembly: Following the forming process, the individual components are assembled. This may include adding features such as waterproof seals, ventilation ports, or modular inserts for battery organization. Automated assembly lines are often employed to enhance efficiency and reduce labor costs. Quality checks during assembly ensure that all components fit correctly and function as intended.

-

Finishing: The final stage is finishing, which may involve surface treatments such as painting, coating, or adding textures for better grip. This stage not only enhances aesthetics but also improves the durability and usability of the battery cases. Final inspections are conducted to verify that the finishing meets the specified standards.

How Is Quality Assurance Ensured During Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for multi 18650 battery cases, ensuring that the products meet international standards and industry regulations. Implementing effective QA measures can significantly enhance a manufacturer’s reputation and customer satisfaction.

-

Relevant International Standards: Compliance with international standards such as ISO 9001 is essential. This standard focuses on quality management systems and continuous improvement. In addition to ISO, certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for energy-related products may also be applicable. These certifications indicate that the products have been tested and verified to meet stringent safety and performance criteria.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint inspects raw materials upon receipt to ensure they meet predefined specifications. Any defective materials are rejected at this stage to prevent issues later in the production process.

– In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves regular checks at various stages to monitor production parameters. This helps in identifying defects early and reduces waste.

– Final Quality Control (FQC): Once the battery cases are fully assembled and finished, FQC is conducted to ensure that the final products meet all specifications and quality standards. This includes functional tests and visual inspections. -

Common Testing Methods for Battery Cases: Various testing methods are employed to validate the integrity and safety of multi 18650 battery cases. These may include:

– Drop Tests: Assess the case’s resistance to impact.

– Waterproof Testing: Ensures that the seals function correctly under specified conditions.

– Thermal Stability Tests: Evaluates how well the case withstands high temperatures, which is critical for lithium-ion battery safety.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is paramount. Here are several strategies to ensure robust supplier QA practices:

-

Conducting Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Audits should assess compliance with international standards, production capabilities, and the overall quality management system in place.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including records of inspections, test results, and any corrective actions taken for non-compliance. These reports can help buyers evaluate the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. This is particularly useful for buyers who may not have the resources to conduct on-site audits themselves.

-

Understanding QC/CERT Nuances for International Buyers: Different regions may have specific regulatory requirements or certifications that must be adhered to. Buyers should be aware of these nuances to ensure compliance and avoid potential legal issues. For instance, products sold in the European market must meet CE certification requirements, while products in the U.S. may need to comply with UL standards.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for multi 18650 battery cases is essential for B2B buyers. By familiarizing themselves with the manufacturing stages, quality control checkpoints, and verification methods, buyers can make informed decisions and select suppliers that ensure safety, reliability, and compliance with international standards. This knowledge not only enhances their procurement strategy but also contributes to building long-term partnerships with reliable manufacturers in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘multi 18650 battery case’

Introduction

Sourcing a multi 18650 battery case is critical for businesses that rely on lithium-ion batteries for their operations. This guide provides a step-by-step checklist to help B2B buyers effectively navigate the procurement process, ensuring they select a case that meets their specific needs while also considering factors like quality, compliance, and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in your sourcing process. Consider the number of batteries the case must hold, the required durability, and any environmental factors such as moisture or temperature extremes. Knowing your needs upfront will streamline the selection process and help eliminate unsuitable options.

Illustrative image related to multi 18650 battery case

- Battery Capacity: Determine how many 18650 batteries the case must accommodate.

- Protection Level: Assess whether you need waterproofing, shock resistance, or other protective features.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in battery cases. Look for companies with a proven track record in your industry or region, and gather information about their product offerings and reputation. This step will help ensure you’re working with a reliable source.

- Industry Experience: Prioritize suppliers with experience in your specific market.

- Product Range: Ensure they offer a variety of cases to meet your specifications.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier choice, verify their certifications and compliance with international standards. Certifications such as ISO, CE, or RoHS can indicate a commitment to quality and safety in manufacturing practices. This step is crucial for minimizing risks associated with product failures or regulatory issues.

- Quality Assurance: Check for documented quality control processes.

- Safety Compliance: Ensure compliance with safety regulations relevant to your region.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the multi 18650 battery cases you’re considering. Testing these samples will provide insights into their build quality, usability, and how well they meet your specifications. This hands-on evaluation can significantly influence your final decision.

- Durability Testing: Assess the case’s performance under different conditions.

- User Experience: Evaluate ease of use, such as battery insertion and removal.

Step 5: Compare Pricing and Terms

Collect pricing information from your shortlisted suppliers and compare their offers. Look beyond the initial cost; consider factors such as shipping fees, bulk order discounts, and payment terms. This comprehensive approach will help you make a cost-effective decision that aligns with your budget.

- Total Cost of Ownership: Factor in long-term costs, including maintenance or replacement.

- Flexible Payment Options: Seek suppliers who offer favorable payment terms that can support your cash flow.

Step 6: Assess Customer Support and Warranty

Strong customer support can be a significant advantage when sourcing battery cases. Evaluate the level of support offered by each supplier, including warranty terms and after-sales service. A responsive supplier can provide valuable assistance in case of issues with the product.

Illustrative image related to multi 18650 battery case

- Warranty Coverage: Understand what is covered under the warranty and for how long.

- Response Time: Assess how quickly the supplier responds to inquiries or issues.

Step 7: Finalize and Place Your Order

Once you have evaluated all factors, finalize your supplier choice and place your order. Ensure that all terms are clearly documented in a purchase agreement, covering delivery schedules, quality expectations, and payment terms. This step solidifies your relationship with the supplier and sets the foundation for future transactions.

- Contract Details: Ensure all agreed-upon terms are included in the contract.

- Delivery Schedule: Confirm timelines to avoid delays in your operations.

By following this checklist, B2B buyers can confidently source a multi 18650 battery case that meets their operational needs while ensuring quality and reliability in their supply chain.

Comprehensive Cost and Pricing Analysis for multi 18650 battery case Sourcing

What Are the Key Cost Components for Sourcing Multi 18650 Battery Cases?

When assessing the cost structure for multi 18650 battery cases, several critical components come into play. Materials form the backbone of the cost, with choices ranging from standard plastics to high-grade polymers that provide durability and protection against environmental factors. The selection of materials not only impacts the initial cost but also influences the long-term performance of the product.

Labor costs are another significant factor, especially in regions where labor rates vary dramatically. The complexity of manufacturing processes, such as injection molding or custom machining, can lead to fluctuations in labor costs.

Manufacturing overhead encompasses utilities, maintenance, and indirect labor, which should be factored into the overall pricing. Tooling costs can also be substantial, particularly for custom designs or specialized molds, and these costs are typically amortized over large production runs.

Illustrative image related to multi 18650 battery case

Quality Control (QC) measures are essential in maintaining product reliability and safety, especially for battery cases that may be used in critical applications. Implementing stringent QC processes can add to the cost but ultimately protects the brand and customer satisfaction.

Finally, logistics costs, including shipping and handling, can vary based on the destination and mode of transport. It’s crucial for buyers to consider these costs when evaluating total expenditures.

How Do Price Influencers Affect the Sourcing of Multi 18650 Battery Cases?

Several factors influence the pricing of multi 18650 battery cases. Volume and Minimum Order Quantity (MOQ) are significant; larger orders often yield lower per-unit prices due to economies of scale. Buyers should negotiate favorable terms based on their projected needs.

Specifications and customization also play a role. Custom designs or features, such as additional waterproofing or modular inserts, can drive up costs. Buyers should weigh the benefits of these features against their budget constraints.

Illustrative image related to multi 18650 battery case

Material quality and certifications are critical considerations, especially in markets that demand compliance with international safety standards. Higher-quality materials and certifications generally lead to higher prices, but they can also enhance the product’s marketability and reliability.

Supplier factors, including reputation and reliability, can also affect pricing. Established suppliers may charge a premium for their experience and track record, while newer entrants may offer lower prices to gain market share.

The choice of Incoterms can significantly impact total costs. For instance, terms like FOB (Free on Board) place shipping responsibilities on the buyer, which can lead to increased logistics costs if not carefully managed.

Illustrative image related to multi 18650 battery case

What Are Some Effective Buyer Tips for Sourcing Multi 18650 Battery Cases?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance sourcing effectiveness. Begin with negotiation; leveraging volume commitments can lead to better pricing and terms. Always ask for discounts on bulk orders or long-term contracts.

Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, potential duties, and the lifespan of the product. Investing in higher-quality cases may incur higher upfront costs but can lead to savings in replacement and warranty claims over time.

Pricing nuances for international buyers must be understood; currency fluctuations and local taxes can affect final costs. Buyers should also be aware of any tariffs or trade agreements that could impact pricing.

Illustrative image related to multi 18650 battery case

Lastly, always request sample products before committing to large orders. Testing samples can help ascertain quality and suitability, ensuring that the final product meets expectations without incurring additional costs related to returns or replacements.

Disclaimer

The pricing and cost components discussed are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always verify current prices with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing multi 18650 battery case With Other Solutions

Exploring Alternatives to the Multi 18650 Battery Case

In the realm of battery storage and management, the multi 18650 battery case stands out as a robust solution for organizing and protecting lithium-ion cells. However, various alternatives exist, each offering unique advantages and limitations. This analysis will compare the multi 18650 battery case against modular battery storage systems and individual battery cases, providing B2B buyers with actionable insights into the best storage solutions for their needs.

| Comparison Aspect | Multi 18650 Battery Case | Modular Battery Storage System | Individual Battery Cases |

|---|---|---|---|

| Performance | High capacity, durable | Customizable, versatile | Basic protection, low capacity |

| Cost | Moderate ($25-$100) | Higher ($46-$96) | Low ($0.50-$10 per case) |

| Ease of Implementation | Easy to use | Requires setup/configuration | Very easy (ready to use) |

| Maintenance | Minimal upkeep required | Moderate (depends on use) | Low (replace when damaged) |

| Best Use Case | Field operations, tactical | Versatile applications, travel | Everyday use, low-demand scenarios |

What Are the Benefits and Drawbacks of Modular Battery Storage Systems?

Modular battery storage systems, like the CellVault-5M, provide a flexible approach to battery management. They are designed to accommodate various battery sizes and types, making them suitable for users who require a tailored solution for diverse battery needs. The main advantage is their customization potential, allowing users to mix and match battery types based on specific operational requirements. However, the higher cost and slightly more complex setup may deter some users, particularly those looking for a straightforward solution.

How Do Individual Battery Cases Compare?

Individual battery cases are the simplest alternative, often made from lightweight materials and offering basic protection for single or double batteries. Their affordability makes them an attractive option for budget-conscious buyers or those who need a minimalistic approach to battery storage. However, their limitations in capacity and protection make them less suitable for users in demanding environments. They are best for everyday use where high performance and durability are not critical.

Illustrative image related to multi 18650 battery case

Conclusion: Which Battery Storage Solution Is Right for Your Business?

Choosing the right battery storage solution hinges on your specific operational needs. For businesses that require high-capacity, durable storage for multiple batteries in challenging environments, the multi 18650 battery case is a wise investment. Alternatively, if flexibility and customization are paramount, a modular battery storage system may be the best fit, despite the higher upfront costs. On the other hand, if the requirement is for basic, low-cost solutions for occasional use, individual battery cases offer a practical option. By evaluating performance, cost, and use case scenarios, B2B buyers can make informed decisions that align with their operational requirements.

Essential Technical Properties and Trade Terminology for multi 18650 battery case

What Are the Key Technical Properties of Multi 18650 Battery Cases?

When selecting a multi 18650 battery case, understanding its technical properties is essential for ensuring safety, durability, and compatibility with your battery management needs. Here are some critical specifications that buyers should consider:

-

Material Grade

The material used in the construction of battery cases is paramount. Common materials include high-density polyethylene (HDPE), polypropylene, and durable polymers. These materials provide robust protection against physical impacts and environmental factors. For B2B buyers, sourcing cases made from high-quality materials ensures longevity and reliability, which is crucial for industries relying on battery-powered equipment. -

Waterproof Rating

The waterproof rating indicates the level of moisture protection offered by the case. This is often measured using the Ingress Protection (IP) code, such as IP67, which signifies dust-tight protection and immersion in water up to 1 meter for 30 minutes. For businesses operating in challenging environments, a high waterproof rating is essential to prevent battery degradation and potential hazards. -

Capacity and Configuration

Multi 18650 battery cases come with varying capacities, typically accommodating two to eight cells. Understanding the configuration options—such as series or parallel arrangements—is crucial for applications needing specific voltage outputs or run times. B2B buyers should evaluate their power requirements to select a case that optimally supports their energy needs. -

Safety Features

Integrated safety features, such as short-circuit protection, thermal insulation, and secure locking mechanisms, enhance the safety of battery storage. Cases with these features minimize risks associated with lithium-ion batteries, such as overheating and fires. Businesses must prioritize these safety aspects to protect personnel and assets. -

Modular Inserts

Many multi 18650 battery cases offer modular inserts that allow for customization of battery configurations. This flexibility is beneficial for businesses that use different types of batteries or require quick reconfiguration for various applications. Understanding the availability and compatibility of these inserts can significantly impact operational efficiency. -

Weight and Portability

The weight of the battery case affects its portability, especially for mobile applications. Lightweight materials that do not compromise on durability are preferred. For companies that transport equipment frequently, a balance between protection and portability is critical.

Which Trade Terminology Should B2B Buyers Know When Purchasing Battery Cases?

Navigating the procurement of multi 18650 battery cases requires familiarity with specific industry jargon. Here are some essential terms:

Illustrative image related to multi 18650 battery case

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s end product. Understanding OEM relationships can help businesses ensure they are sourcing high-quality cases that meet specific requirements. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to manage inventory costs effectively and avoid overstocking. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other relevant information for specific products. B2B buyers should utilize RFQs to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms helps buyers understand shipping costs and liabilities, ultimately influencing the total cost of procurement. -

Lead Time

Lead time is the duration from the placement of an order to the delivery of the product. Understanding lead times is vital for inventory management and ensuring that supply chains remain uninterrupted. -

Certification Standards

Certification standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), indicate that a product has been tested for safety and compliance with regulatory requirements. For B2B buyers, ensuring that battery cases meet these standards is critical for compliance and safety assurance.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when procuring multi 18650 battery cases, ensuring that they meet their specific operational needs while mitigating risks.

Navigating Market Dynamics and Sourcing Trends in the multi 18650 battery case Sector

What Are the Key Market Trends Influencing the Multi 18650 Battery Case Sector?

The multi 18650 battery case market is experiencing robust growth driven by several global factors. The increasing adoption of lithium-ion batteries across various sectors, including consumer electronics, renewable energy, and electric vehicles, is a primary driver. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek reliable storage solutions, the demand for durable and versatile battery cases is on the rise. Customizable options, such as modular inserts for different battery types, are becoming increasingly popular, allowing users to adapt their storage solutions to specific needs.

Emerging technologies, particularly in smart manufacturing and IoT, are influencing sourcing trends. Buyers are now looking for suppliers who can offer innovative designs that not only protect the batteries but also integrate smart features like battery status indicators. Additionally, the rise of e-commerce platforms is reshaping how international buyers source these products, making it easier to compare prices and features across multiple suppliers.

Market dynamics are also shifting due to geopolitical factors and supply chain disruptions. Buyers must navigate fluctuating prices and availability while ensuring they maintain quality and compliance with international safety standards. As a result, strategic partnerships with manufacturers who prioritize reliability and innovation are becoming essential for B2B buyers.

How Is Sustainability Shaping Sourcing Decisions in the Multi 18650 Battery Case Sector?

Sustainability is becoming a pivotal consideration for B2B buyers sourcing multi 18650 battery cases. The environmental impact of battery production and disposal is prompting businesses to seek solutions that minimize ecological footprints. Buyers are increasingly favoring suppliers who utilize recycled materials and sustainable manufacturing processes. This trend is particularly relevant in regions like Europe, where stringent regulations on waste management and recycling are in place.

Illustrative image related to multi 18650 battery case

Ethical sourcing is also gaining traction, with buyers looking for transparent supply chains that prioritize fair labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management systems and those related to sustainable materials are becoming essential criteria in the supplier selection process. B2B buyers can enhance their brand reputation and appeal to eco-conscious consumers by ensuring their supply chains align with these values.

Moreover, the adoption of ‘green’ materials in battery case production, such as biodegradable plastics and recycled polymers, is becoming more common. This shift not only addresses environmental concerns but also meets the growing consumer demand for sustainable products. As sustainability continues to influence purchasing decisions, suppliers that can demonstrate their commitment to ethical practices and environmental responsibility will likely gain a competitive edge.

What Has Been the Evolution of the Multi 18650 Battery Case Market?

The evolution of the multi 18650 battery case market reflects broader technological advancements and changing consumer needs. Initially, battery cases were designed primarily for protection against physical damage. However, as the demand for lithium-ion batteries surged, particularly with the rise of portable electronics, manufacturers began innovating to offer multifunctional solutions.

The introduction of modular designs that allow for customization has marked a significant shift in the market, catering to the diverse needs of various industries, including military, medical, and outdoor recreation. The focus on safety, durability, and usability has led to the development of features like waterproof seals and lockable latches, addressing both consumer expectations and regulatory requirements.

As sustainability and ethical sourcing have gained importance, the market has also seen a shift towards environmentally friendly materials and practices. This evolution reflects a growing recognition of the need for responsible manufacturing in an increasingly interconnected global economy. As the market continues to evolve, B2B buyers can expect ongoing innovations aimed at enhancing both functionality and environmental responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of multi 18650 battery case

-

How do I choose the right multi 18650 battery case for my business needs?

Choosing the right multi 18650 battery case involves evaluating factors such as capacity, durability, and protection features. Consider the specific applications of the batteries you will be using—whether for consumer electronics, industrial applications, or medical devices. Look for cases with modular designs, as they offer flexibility to accommodate different battery sizes and configurations. Additionally, assess the material quality, water resistance, and locking mechanisms to ensure optimal protection during transport and storage. -

What is the best battery case for storing multiple 18650 batteries?

The best battery case for storing multiple 18650 batteries is one that combines durability, modularity, and protection. A case like the CellVault-5M offers customizable inserts for various battery sizes, ensuring safe storage and easy access. Look for features such as waterproof seals, robust construction materials, and labels for easy identification of charged and discharged batteries. Also, consider cases with integrated straps for secure attachment to gear during field operations. -

What are the typical minimum order quantities (MOQs) for multi 18650 battery cases?

Minimum order quantities (MOQs) for multi 18650 battery cases can vary significantly depending on the manufacturer and the specific product. Typically, MOQs may range from 100 to 1,000 units for bulk purchases. It’s essential to negotiate with suppliers, especially if you are looking to establish a long-term partnership. Consider your storage capacity and sales projections when determining how many units to order initially, as larger orders often result in better pricing. -

How can I vet suppliers for multi 18650 battery cases in international trade?

Vetting suppliers for multi 18650 battery cases involves several steps. Begin by researching potential suppliers through trade directories and industry forums. Look for reviews and testimonials from other businesses to gauge reliability. Request product samples to assess quality firsthand and check for compliance with international safety standards. Additionally, verify the supplier’s business licenses, certifications, and financial stability to ensure they can meet your long-term needs. -

What payment terms should I expect when sourcing multi 18650 battery cases internationally?

Payment terms for international sourcing of multi 18650 battery cases can vary widely. Common terms include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipping or upon delivery. Some suppliers may offer net payment terms, allowing you to pay 30-90 days after receipt of goods. It’s crucial to clarify these terms upfront and consider using secure payment methods like letters of credit or escrow services to protect your investment. -

What quality assurance measures should I implement when sourcing battery cases?

Implementing quality assurance (QA) measures involves setting clear specifications and standards for the battery cases you purchase. Request certifications from suppliers that demonstrate compliance with safety and performance standards, such as ISO 9001 or IEC 62133. Conduct regular inspections during production and before shipment, and consider third-party testing for critical components. Establish a return policy and warranty terms to address any defects or discrepancies that may arise post-purchase. -

What logistics considerations should I keep in mind when importing battery cases?

When importing multi 18650 battery cases, consider logistics factors such as shipping methods, customs regulations, and lead times. Assess whether air freight or sea freight is more suitable based on urgency and cost. Be aware of import duties, taxes, and any specific regulations related to battery transportation in your country. Work closely with your freight forwarder to ensure compliance with all shipping documentation and to streamline the customs clearance process. -

Can I customize the design of multi 18650 battery cases for my brand?

Yes, many manufacturers offer customization options for multi 18650 battery cases. You can often choose colors, logos, and specific features tailored to your brand’s requirements. Discuss your needs with potential suppliers to understand their capabilities regarding design modifications and the associated costs. Custom branding can enhance product visibility and differentiate your offerings in the competitive market, making it an attractive option for businesses looking to establish a unique identity.

Top 10 Multi 18650 Battery Case Manufacturers & Suppliers List

1. Thyrm – CellVault-5M Modular Battery Storage

Domain: thyrm.com

Registered: 2013 (12 years)

Introduction: CellVault-5M Modular Battery Storage for AA, AAA, CR123, 18350, 18650, CR2032, 1632. Price range: $46.74 – $96.23. Customizable protection for lithium-ion batteries with 8 modular inserts and extra wells for CR2032 batteries. Features include waterproof gasket seal, integrated straps for MOLLE/webbing, lockable over-center latch, and durable premium polymer construction. Available colors: Black, F…

2. 18650 Battery Store – Battery Cases

Domain: 18650batterystore.com

Registered: 2017 (8 years)

Introduction: Battery Cases available for various sizes and types including: 2x 18650 Battery Case – Black ($0.50), 18650 Battery Heavy Duty Protective Case 2x 18650 ($0.65), 14500 (AA) Battery Protective Case – 4x 14500 (AA) – Clear ($0.75), 18650 Battery Protective Case – 4x 18650 ($0.75), 26650 Battery Protective Case – 2x 26650 – Clear ($0.75), Chubby Gorilla Battery Case 2x 18650 ($0.99), Efest 26650 Batte…

3. IMR Batteries – 18650 Battery Cases

Domain: imrbatteries.com

Registered: 2014 (11 years)

Introduction: 18650 battery cases are protective enclosures designed to prevent short circuits, physical damage, and accidental exposure of lithium-ion batteries. They are made from impact-resistant plastic, flexible silicone, and reinforced waterproof materials. Storage capacities include single, dual, and multi-battery configurations. Key features include short-circuit prevention, crush resistance, moisture p…

4. MTM – Shotshell Cases

Domain: budgetlightforum.com

Registered: 2010 (15 years)

Introduction: This company, MTM – Shotshell Cases, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Illumn – Plastic 1 X 18650 Battery Case

Domain: illumn.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Plastic 1 X 18650 Battery Case”, “price”: “$0.55”, “availability”: “In stock”, “SKU”: “1 X 18650 Case”, “shipping_info”: “FREE SHIPPING ON DOMESTIC ORDERS OVER $75”, “store_location”: “760 Charcot Ave. San Jose, CA 95131”, “contact”: {“phone”: “(408) 800-1051”, “email”: “[email protected]”}, “business_hours”: “Monday – Friday 12:00PM – 5:00PM (PST) Closed – Sat. & Sun.”}

6. Reddit – Battery Holders for 69mm Protected 18650 Cells

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for battery holders compatible with protected 18650 cells that are 69mm in length. Standard holders are too short for these protected cells.

7. AsiaRF – 18650 Battery Holder 3 Slots

Domain: asiarf.com

Registered: 2003 (22 years)

Introduction: AsiaRF 18650 Battery Holder 3 Slots for 3.7V Batteries. Available in 1 Pack, 3 Pack, or 5 Pack options. Price: $8.00 (discounted to $5.00 for orders of 100+). Dimensions: 87mm x 60mm x 21mm. Features 10cm leads for easy connections. Designed for 18650 batteries (not included). Suitable for various electronic applications and DIY projects. Made of tough plastic material, easy to install with stainl…

8. CandlePower – 2 x 18650 Battery Holders

Domain: candlepowerforums.com

Registered: 2000 (25 years)

Introduction: Product: 2 x 18650 Battery Holders

Key Features:

– Waterproof case

– Modded design for easy DIY assembly

– Uses double battery contacts (Keystone #290, #209, #238/228)

– Soldered leads for user-friendly setup

– Designed for bicycle blinkers and light applications

– Longer than protected cells for easy housing of contacts

– Estimated cost: About $4 in parts (excluding postage)

9. Arduino – TP4056 Charging Solutions

Domain: forum.arduino.cc

Registered: 2005 (20 years)

Introduction: TP4056 charging board, 18650 lithium-ion batteries, charging multiple batteries, charging in series, battery protection chip, DIY power bank kits, maximum charge output of TP4056 is 4.2V, batteries must be of the same capacity, manufacturer, and chemistry.

10. Quality – 18650 Battery Case Holder

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Quality 18650 Battery Case Holder Storage Box 3.7V with Power Plug Multi Choice”, “Condition”: “New”, “Battery Holder Types Available”: [“2 Slot Holder 3.7V”, “3 Slot Holder 3.7V”, “4 Slot Holder 3.7V”], “Pack Quantities Available”: [“1 Pcs”, “2 Pcs”, “5 Pcs”], “Price”: “US $3.70”, “Shipping Cost”: “US $2.00”, “Shipping Origin”: “Greater China”, “Estimated Delivery”: “Between Wed…

Strategic Sourcing Conclusion and Outlook for multi 18650 battery case

In navigating the evolving landscape of multi 18650 battery cases, strategic sourcing emerges as a critical component for international B2B buyers. The adaptability and customization of products like the CellVault-5M demonstrate the growing demand for versatile solutions that can cater to diverse operational needs across various sectors. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who offer high-quality, durable battery cases that ensure safety and reliability in storage and transport.

Illustrative image related to multi 18650 battery case

Furthermore, understanding local market dynamics and regulatory requirements is essential for successful procurement. Sourcing from manufacturers who not only meet these criteria but also provide exceptional customer support will enhance supply chain resilience.

Looking ahead, the demand for multi 18650 battery cases is expected to rise as industries increasingly rely on portable power solutions. Buyers are encouraged to leverage this trend by establishing long-term partnerships with reputable suppliers. By doing so, they can ensure a steady supply of innovative battery storage solutions that meet their evolving needs. Embrace this opportunity to enhance your operational efficiency and secure a competitive edge in the marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to multi 18650 battery case