A Deep Dive into Multi-18650 Backup Battery Case Solution

Introduction: Navigating the Global Market for multi-18650 backup battery case

As global demand for portable power solutions continues to rise, the challenge of sourcing a reliable multi-18650 backup battery case becomes increasingly paramount for B2B buyers. Whether you operate in the electronics, automotive, or renewable energy sectors, the need for effective storage and protection of lithium-ion batteries cannot be overstated. This comprehensive guide will delve into the diverse types of multi-18650 battery cases available in the market, their various applications across industries, and crucial factors to consider when vetting suppliers.

Our analysis extends to cost considerations, ensuring that international buyers from regions such as Africa, South America, the Middle East, and Europe—specifically Germany and Nigeria—are equipped with the insights necessary to make informed purchasing decisions. By addressing key challenges such as safety, durability, and compliance with regional regulations, this guide serves as a vital resource for businesses looking to optimize their battery management strategies.

Empowering B2B buyers with actionable insights, this guide not only highlights the importance of choosing the right battery case but also provides a roadmap for navigating the complexities of the global market. With a focus on quality, reliability, and cost-effectiveness, you will be better positioned to enhance your operational efficiency and ensure the longevity of your battery assets.

Understanding multi-18650 backup battery case Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Plastic Case | Durable, impact-resistant plastic, holds multiple batteries | Vaping, photography, general battery storage | Pros: Cost-effective, lightweight. Cons: Limited waterproofing. |

| Waterproof Battery Case | Sealed design with gasket for moisture protection | Outdoor equipment, emergency kits | Pros: Protects against water damage. Cons: Slightly higher cost. |

| Modular Storage Case | Customizable inserts for various battery types | Military, field operations, emergency services | Pros: Versatile, accommodates different battery sizes. Cons: Bulkier. |

| Silicone Battery Sleeve | Soft, flexible material that protects against impacts | Consumer electronics, portable devices | Pros: Lightweight, easy to carry. Cons: Less rigid protection. |

| Magnetic Closure Flask Case | Magnetic closure for secure transport, stylish design | Retail, promotional products, unique branding | Pros: Attractive, secure. Cons: Limited storage capacity. |

What are the Characteristics of Standard Plastic Cases for Multi-18650 Batteries?

Standard plastic cases are a common choice for B2B buyers looking for reliable battery storage solutions. These cases are made from durable, impact-resistant plastic, allowing them to hold multiple 18650 batteries securely. Their compact design makes them suitable for various applications, including vaping and photography. When considering a purchase, buyers should weigh the cost-effectiveness and lightweight nature of these cases against their limited waterproofing capabilities, which may not be ideal for all environments.

How Do Waterproof Battery Cases Enhance Battery Protection?

Waterproof battery cases are specifically designed with sealed gaskets to prevent moisture from damaging the batteries inside. This feature is crucial for businesses that operate in outdoor environments or require reliable emergency kits. The added layer of protection ensures that batteries remain functional even in adverse weather conditions. While these cases tend to be slightly more expensive, the investment can be justified by the increased durability and reliability they offer.

Why Choose Modular Storage Cases for Versatile Battery Needs?

Modular storage cases provide a customizable solution for businesses needing to transport various battery types. With interchangeable inserts, these cases can accommodate not only 18650 batteries but also other sizes like CR123 and AA. This versatility is particularly advantageous for military and emergency services that require different batteries for various equipment. Although they may be bulkier than standard cases, the flexibility and capacity for organization make them a preferred choice for many B2B applications.

What Are the Benefits of Using Silicone Battery Sleeves?

Silicone battery sleeves offer a lightweight and flexible alternative to traditional hard cases. These sleeves provide basic protection against impacts, making them suitable for consumer electronics and portable devices. They are easy to carry, which is beneficial for businesses that prioritize mobility. However, buyers should note that while silicone sleeves are convenient, they may not provide the same level of rigid protection as more robust options.

How Do Magnetic Closure Flask Cases Stand Out in the Market?

Magnetic closure flask cases combine functionality with aesthetic appeal, making them popular among retailers and promotional product companies. These cases not only secure the batteries effectively but also serve as stylish branding tools. While they offer an attractive design, buyers should consider the limited storage capacity compared to bulkier cases. For businesses looking to make a statement while providing battery protection, magnetic closure flasks can be an excellent choice.

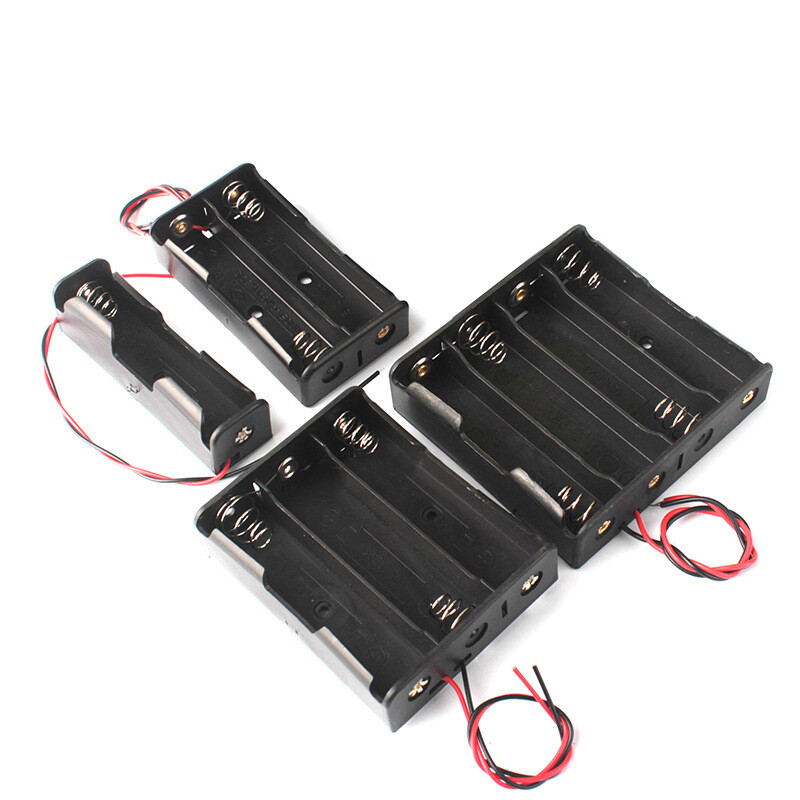

Illustrative image related to multi-18650 backup battery case

Key Industrial Applications of multi-18650 backup battery case

| Industry/Sector | Specific Application of multi-18650 backup battery case | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Energy storage solutions for solar and wind systems | Ensures reliable power supply and backup capabilities | Durability, weather resistance, and modular options |

| Telecommunications | Backup power for remote communication towers | Maintains uptime and connectivity in remote locations | Size, weight, and ease of integration with existing systems |

| Medical Devices | Power supply for portable medical equipment | Ensures consistent operation of critical medical devices | Compliance with safety standards and battery longevity |

| Outdoor and Tactical Gear | Powering high-drain devices in field operations | Provides reliable energy for tools and equipment in the field | Waterproofing and rugged design for harsh environments |

| Consumer Electronics | Powering rechargeable devices like e-cigarettes | Offers a safe and organized way to store multiple batteries | Variety of sizes, colors, and protective features |

How is the multi-18650 backup battery case utilized in renewable energy applications?

In the renewable energy sector, multi-18650 backup battery cases are integral for storing energy generated from solar panels and wind turbines. These cases protect the batteries from environmental hazards, ensuring they remain functional and safe for long-term use. Businesses in this sector require cases that are durable and capable of withstanding extreme weather conditions, making sourcing from reputable suppliers critical. Additionally, modular designs allow for flexibility in energy storage configurations, catering to diverse project needs.

What role does the multi-18650 backup battery case play in telecommunications?

Telecommunications companies use multi-18650 backup battery cases to secure backup power for communication towers, especially in remote areas where electricity supply may be unreliable. These cases help maintain consistent connectivity during outages, which is vital for both business operations and emergency communications. Buyers in this sector should consider cases that are lightweight and easy to integrate into existing systems, while also ensuring they meet regulatory standards for safety and performance.

In what ways does the multi-18650 backup battery case support medical devices?

In the medical field, multi-18650 backup battery cases are crucial for powering portable medical equipment, such as defibrillators and diagnostic devices. These cases ensure that batteries are protected from damage and short circuits, which can be life-threatening in critical situations. When sourcing for medical applications, businesses must prioritize compliance with health regulations and focus on battery longevity to minimize replacement costs and ensure reliability.

Illustrative image related to multi-18650 backup battery case

How does the multi-18650 backup battery case enhance outdoor and tactical gear?

Outdoor and tactical industries rely on multi-18650 backup battery cases to power high-drain devices like flashlights, GPS units, and communication tools during field operations. The rugged design and waterproof features of these cases ensure that batteries remain functional in harsh environments, thus increasing operational efficiency. Buyers should seek cases that offer a secure fit for batteries and are designed for easy attachment to tactical gear, enhancing usability in the field.

Why is the multi-18650 backup battery case important for consumer electronics?

In the consumer electronics market, particularly for vaping devices, multi-18650 backup battery cases provide a safe and organized way to store multiple batteries. These cases prevent accidental discharges and physical damage, ensuring that users can rely on their devices without interruption. When sourcing these cases, businesses should consider options that offer various sizes and colors to cater to diverse consumer preferences while ensuring adequate protection features are in place.

3 Common User Pain Points for ‘multi-18650 backup battery case’ & Their Solutions

Scenario 1: Difficulty in Finding Reliable Suppliers for Multi-18650 Backup Battery Cases

The Problem: B2B buyers often encounter significant challenges when sourcing multi-18650 backup battery cases. In regions such as Africa and South America, where local suppliers may not offer a diverse selection, buyers may find themselves limited to low-quality options. This can lead to concerns about product reliability, safety during transportation, and potential damage to batteries, impacting overall operational efficiency. Furthermore, fluctuating import regulations and tariffs can complicate the procurement process, making it difficult to establish a consistent supply chain.

The Solution: To overcome these sourcing issues, buyers should consider leveraging online platforms that aggregate multiple suppliers, providing access to a wider range of products. Engaging in wholesale inquiries can also yield better pricing and higher-quality options. It’s advisable to conduct thorough due diligence on suppliers, including checking customer reviews and product certifications, to ensure they meet quality standards. Establishing relationships with manufacturers who specialize in battery cases can also lead to more favorable terms and custom solutions tailored to specific needs. Furthermore, collaborating with logistics providers familiar with international shipping can streamline the import process and mitigate regulatory hurdles.

Scenario 2: Challenges with Battery Case Durability and Protection

The Problem: A common pain point for businesses using multi-18650 backup battery cases is ensuring that the cases provide adequate protection for the batteries during transportation and storage. Industries such as telecommunications and renewable energy often require robust solutions to safeguard batteries from moisture, dust, and physical impacts. Buyers may experience frustration when cases fail to meet these standards, resulting in damaged batteries that can lead to operational disruptions and increased costs.

The Solution: To ensure optimal durability and protection, buyers should prioritize cases constructed from high-quality, impact-resistant materials such as polycarbonate or ABS plastic. Additionally, selecting cases with features like waterproof seals and internal padding can significantly enhance protection. It is also beneficial to conduct field tests of the cases under real-world conditions to validate their performance. Suppliers should be asked for certifications that confirm their products have been tested against industry standards for impact resistance and environmental exposure. Investing in training for staff on proper handling and storage techniques can further mitigate risks associated with battery damage.

Scenario 3: Complexity in Managing Battery Inventory and Tracking

The Problem: Many B2B buyers struggle with managing their battery inventory effectively, particularly when utilizing multi-18650 backup battery cases. As businesses grow and their battery needs become more complex, keeping track of battery types, charge status, and expiration dates can become cumbersome. This lack of organization can lead to wasted resources, such as using expired batteries or overstocking unnecessary quantities, which ultimately affects profitability and operational efficiency.

Illustrative image related to multi-18650 backup battery case

The Solution: Implementing an inventory management system specifically designed for battery tracking can streamline this process. Buyers should look for solutions that allow for easy labeling and categorization of batteries within cases, such as using adhesive labels or color-coded patches to denote charge status. Additionally, integrating a digital inventory system can help track battery usage and expiration dates, sending alerts when batteries are nearing their end of life. Training staff on the importance of maintaining accurate inventory records and conducting regular audits can further enhance efficiency. For businesses with larger fleets, exploring modular battery cases that allow for easy customization and organization can help maintain order and clarity in inventory management.

Strategic Material Selection Guide for multi-18650 backup battery case

When selecting materials for multi-18650 backup battery cases, it is essential to consider properties that impact performance, durability, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of these cases: Polypropylene (PP), Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), and Ethylene Vinyl Acetate (EVA).

What are the Key Properties of Polypropylene for Battery Cases?

Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and lightweight nature. It can withstand temperatures ranging from -20°C to 100°C, making it suitable for various environmental conditions. Additionally, PP has a low moisture absorption rate, which is beneficial for protecting batteries from humidity.

Pros and Cons:

The primary advantage of polypropylene is its cost-effectiveness and ease of manufacturing, which allows for high-volume production. However, its impact resistance is lower than that of other materials, which may pose a risk in rugged applications. For international buyers, PP is widely accepted and compliant with various standards, including ASTM and ISO.

Illustrative image related to multi-18650 backup battery case

How Does Polycarbonate Enhance Battery Case Durability?

Polycarbonate is a robust thermoplastic known for its high impact resistance and transparency. It can endure extreme temperatures, with a range from -40°C to 120°C. This material is also flame-retardant, adding an extra layer of safety for lithium-ion batteries.

Pros and Cons:

The key advantage of polycarbonate is its durability, making it ideal for applications that require high protection levels. However, it tends to be more expensive than other materials and can be more complex to manufacture. Buyers from regions like Europe may prefer polycarbonate for its compliance with stringent safety standards, such as REACH and RoHS.

What Role Does Acrylonitrile Butadiene Styrene Play in Battery Cases?

Acrylonitrile Butadiene Styrene (ABS) is another thermoplastic commonly used for battery cases. It offers good impact resistance and can handle temperatures between -20°C and 80°C. ABS is known for its rigidity and toughness, making it suitable for applications requiring structural integrity.

Pros and Cons:

The main advantage of ABS is its balance between cost and performance, making it a popular choice for various consumer electronics. However, it is less resistant to UV light and may degrade over time if exposed to sunlight. For international buyers, ABS is often compliant with ASTM standards, making it a reliable choice for regions with established regulatory frameworks.

Why is Ethylene Vinyl Acetate a Good Choice for Battery Cases?

Ethylene Vinyl Acetate (EVA) is a copolymer known for its flexibility and resilience. It can withstand temperatures from -40°C to 80°C and has excellent shock absorption properties, which is critical for protecting batteries during transport.

Illustrative image related to multi-18650 backup battery case

Pros and Cons:

EVA’s flexibility makes it suitable for applications requiring a snug fit around batteries, enhancing protection against physical damage. However, its lower temperature resistance compared to other materials may limit its use in extreme environments. Buyers in Africa and South America may find EVA appealing due to its lightweight nature and cost-effectiveness, particularly for portable applications.

Summary Table of Material Selection for Multi-18650 Backup Battery Cases

| Material | Typical Use Case for multi-18650 backup battery case | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | General-purpose battery storage | Cost-effective and lightweight | Lower impact resistance | Low |

| Polycarbonate (PC) | High-durability applications | Excellent impact resistance and flame-retardant | Higher cost and manufacturing complexity | High |

| Acrylonitrile Butadiene Styrene (ABS) | Consumer electronics and portable devices | Good balance of cost and performance | Less UV resistance | Medium |

| Ethylene Vinyl Acetate (EVA) | Flexible and portable battery cases | Excellent shock absorption and flexibility | Limited temperature resistance | Low |

In conclusion, selecting the right material for multi-18650 backup battery cases involves balancing performance, cost, and compliance with international standards. Each material has unique properties that cater to different applications, making it crucial for B2B buyers to assess their specific needs and regional regulations when making a decision.

In-depth Look: Manufacturing Processes and Quality Assurance for multi-18650 backup battery case

What Are the Key Stages in the Manufacturing Process of Multi-18650 Backup Battery Cases?

The manufacturing process for multi-18650 backup battery cases involves several critical stages, each designed to ensure the final product meets high standards of safety, durability, and usability. Understanding these stages is essential for B2B buyers, especially those sourcing from diverse global markets such as Africa, South America, the Middle East, and Europe.

1. Material Preparation

The first step in manufacturing involves selecting the right materials, which typically include high-quality, impact-resistant plastics like polycarbonate or ABS. These materials are chosen for their durability, lightweight properties, and ability to withstand various environmental conditions.

Illustrative image related to multi-18650 backup battery case

Once selected, the materials undergo preparation, which may include drying to remove moisture, cutting into manageable sizes, and mixing with additives to enhance properties such as UV resistance or fire retardancy. Quality control begins here, as suppliers must ensure that the materials meet specific criteria, such as tensile strength and thermal stability.

2. Forming Techniques: How Are Multi-18650 Battery Cases Shaped?

The forming stage is where raw materials are transformed into the desired shape of the battery case. Common techniques include:

- Injection Molding: This is the most prevalent method for producing plastic battery cases. Molten plastic is injected into molds to create precise shapes. The process allows for high volume production with consistent quality.

- Thermoforming: Used for creating thin-walled cases, this method involves heating plastic sheets until pliable and then forming them over molds. While not as common for battery cases, it is useful for certain design specifications.

Both methods require careful temperature and pressure control to ensure the integrity of the final product.

Illustrative image related to multi-18650 backup battery case

3. Assembly: What Does the Assembly Process Involve?

After forming, the individual components of the battery case are assembled. This can include adding features such as compartments for the batteries, latches, or seals for waterproofing.

Assembly may involve:

- Ultrasonic Welding: A technique used to join plastic parts without adhesives, ensuring a strong bond that maintains the integrity of the case.

- Screw Assembly: For cases that require additional strength or replaceable components, screws may be used to secure parts together.

Quality checks during assembly ensure that each component fits correctly and meets design specifications.

4. Finishing: How Is the Final Product Enhanced?

The finishing stage enhances the product’s appearance and functionality. This can involve:

- Surface Treatment: Techniques such as sanding, polishing, or applying coatings to improve aesthetics and durability.

- Labeling and Branding: Printing or attaching labels that provide important information about the battery case, including safety warnings and brand identity.

Finishing processes are critical as they impact the product’s marketability and compliance with international standards.

Illustrative image related to multi-18650 backup battery case

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance (QA) is an integral part of the manufacturing process for multi-18650 backup battery cases. It ensures that the products meet both international standards and customer expectations.

Relevant International Standards for Quality Assurance

B2B buyers should be aware of the following standards:

- ISO 9001: This standard focuses on quality management systems (QMS) and is essential for manufacturers to demonstrate their commitment to quality. Compliance ensures systematic processes are in place for continuous improvement.

- CE Marking: Required for products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In some cases, particularly for battery storage in specialized applications, adherence to API standards can be crucial, particularly in industries such as oil and gas.

Key Quality Control Checkpoints: What to Expect?

Quality control is typically segmented into several checkpoints:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early. This can include monitoring temperature and pressure during forming, as well as dimensional checks during assembly.

- Final Quality Control (FQC): The final product undergoes a thorough inspection before shipping. This includes functional tests, visual inspections, and packaging verification.

Common Testing Methods: How Are Products Tested?

Testing methods may include:

- Electrical Testing: Ensuring that the battery case can handle the electrical load without failure.

- Mechanical Testing: Assessing impact resistance and durability under various conditions.

- Environmental Testing: Checking performance against moisture, temperature fluctuations, and UV exposure.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is critical for B2B buyers, especially when sourcing internationally. Here are actionable steps:

-

Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing and quality assurance processes. This can be done through on-site visits or third-party audit services.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results and compliance certifications.

-

Third-Party Inspections: Engaging third-party inspection services can help verify that products meet agreed-upon standards before shipment.

-

Understanding Certification Nuances: Buyers should be aware of specific certification requirements in their regions. For example, European markets may have stricter compliance needs compared to those in Africa or South America.

Conclusion: Why Understanding Manufacturing and Quality Assurance Matters

For B2B buyers sourcing multi-18650 backup battery cases, a comprehensive understanding of the manufacturing process and quality assurance measures is vital. Not only does this knowledge help in selecting reliable suppliers, but it also ensures the safety and performance of the products in various applications. By prioritizing quality and compliance, businesses can protect their investments and maintain customer satisfaction across international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘multi-18650 backup battery case’

Introduction

In the competitive landscape of battery solutions, sourcing a reliable multi-18650 backup battery case is essential for businesses aiming to ensure optimal performance and safety in their operations. This guide provides a practical checklist to aid B2B buyers in making informed decisions when procuring these cases, ensuring that they meet both technical requirements and business needs.

Illustrative image related to multi-18650 backup battery case

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of a successful procurement process. Consider factors such as the number of batteries the case will hold, dimensions, material (e.g., impact-resistant plastic), and whether you need features like waterproofing or modular inserts. Clearly defined specifications will help streamline your search for suitable suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in multi-18650 backup battery cases. Look for companies with a solid reputation in the industry and positive customer reviews. Utilize online marketplaces and industry-specific directories to compile a list of potential partners, focusing on those that have experience with clients in your target regions, such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. This is crucial for ensuring that the products meet safety and quality regulations, especially in regions with strict import laws. Check for certifications such as ISO 9001 for quality management systems or relevant safety certifications that apply to battery storage products.

Illustrative image related to multi-18650 backup battery case

Step 4: Request Samples for Quality Assessment

Once you have narrowed down your options, request samples of the battery cases. Assess the quality of materials, design, and functionality firsthand. This step is essential to confirm that the cases can withstand the rigors of your intended use, whether it’s for transportation, storage, or field applications.

Step 5: Inquire About Customization Options

Consider whether you need customized solutions to better meet your operational needs. Many suppliers offer options for branding, color variations, or specialized compartments for different battery types. Discuss these possibilities with potential suppliers to ensure the product aligns with your brand and usage requirements.

Step 6: Review Pricing and Payment Terms

Once you have identified suitable suppliers, compare pricing structures and payment terms. Ensure that the costs are competitive while also reflecting the quality of the product. Pay attention to factors such as minimum order quantities, bulk discounts, and payment options to find a deal that works for your budget and cash flow.

Illustrative image related to multi-18650 backup battery case

Step 7: Finalize Logistics and Delivery Expectations

After selecting a supplier, clarify logistics regarding shipping and delivery timelines. Understanding the lead times and shipping costs associated with your order is vital for planning and inventory management. Ensure that the supplier can meet your deadlines and inquire about their return policy in case the products do not meet your expectations upon arrival.

By following this checklist, B2B buyers can navigate the procurement process more effectively, ensuring they secure high-quality multi-18650 backup battery cases that meet their operational needs.

Comprehensive Cost and Pricing Analysis for multi-18650 backup battery case Sourcing

What Are the Key Cost Components in Sourcing Multi-18650 Backup Battery Cases?

When sourcing multi-18650 backup battery cases, several cost components must be considered. The main components include:

-

Materials: The choice of materials directly affects the cost. High-quality, durable plastics or waterproof materials can increase upfront costs but may reduce long-term expenses related to replacements or damages.

-

Labor: Labor costs vary significantly depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this can be offset by potential quality issues.

-

Manufacturing Overhead: This includes utilities, rent, and administrative costs associated with the production facility. Efficient manufacturing processes can help keep these costs down.

-

Tooling: The initial investment in molds and tooling can be substantial, particularly for custom designs. This cost is typically amortized over large production runs.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability but can add to manufacturing costs. International buyers should consider suppliers with certifications (e.g., ISO) that indicate adherence to quality standards.

-

Logistics: Shipping and handling costs, including insurance and tariffs, must be factored in, especially for international transactions. The choice of Incoterms can significantly influence these logistics costs.

-

Margin: Suppliers typically apply a profit margin that reflects their operational costs, market demand, and competitive landscape.

How Do Price Influencers Affect Multi-18650 Battery Case Costs?

Several factors influence the pricing of multi-18650 battery cases:

-

Volume/MOQ: Bulk purchasing can lead to significant cost savings. Suppliers often provide discounts for higher minimum order quantities (MOQs), making it beneficial for buyers to forecast demand accurately.

-

Specifications/Customization: Custom designs, colors, or features (like waterproofing) can increase costs. Buyers should evaluate whether these customizations justify the additional expense based on their target market’s needs.

-

Materials Quality/Certifications: Premium materials and certifications for safety (such as UL certification) enhance product value but come at a higher price. Buyers should assess the balance between cost and quality to ensure they meet regulatory requirements in their markets.

-

Supplier Factors: The reputation and reliability of suppliers play a critical role in pricing. Established suppliers with a proven track record may charge more, but their reliability can save costs related to defects or delays.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They dictate who is responsible for shipping, insurance, and tariffs, which can affect the total landed cost of the product.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing?

To maximize cost-efficiency when sourcing multi-18650 battery cases, consider the following tips:

-

Negotiate Wisely: Engage in negotiations with suppliers to secure better pricing, especially for larger orders. Highlighting long-term partnership potential can incentivize suppliers to offer more competitive rates.

-

Evaluate Total Cost of Ownership (TCO): Assess not just the purchase price but also the long-term costs associated with maintenance, shipping, and potential replacements. A cheaper initial price might lead to higher TCO if quality is compromised.

-

Understand Pricing Nuances for International Markets: Different regions may have varying expectations regarding quality, delivery times, and pricing structures. For example, European buyers may prioritize certifications and quality assurance, while buyers in emerging markets might focus on cost-effectiveness.

-

Be Aware of Currency Fluctuations: For international transactions, currency volatility can impact pricing. Consider locking in prices or negotiating terms that account for potential fluctuations.

Disclaimer on Indicative Prices

Pricing for multi-18650 backup battery cases can vary widely based on the aforementioned factors. The prices provided by suppliers are indicative and may fluctuate based on market conditions, demand, and supplier capabilities. It is advisable for buyers to obtain detailed quotes and conduct thorough market research before making purchasing decisions.

Alternatives Analysis: Comparing multi-18650 backup battery case With Other Solutions

Understanding Alternatives for Multi-18650 Backup Battery Cases

In the realm of battery storage solutions, it’s essential for businesses to evaluate multiple options to ensure they choose the most effective and economical method for their specific requirements. The multi-18650 backup battery case is a popular choice for safely storing lithium-ion batteries, but several alternatives may also serve similar purposes. This analysis compares the multi-18650 backup battery case with two viable alternatives: the CellVault-5M Modular Battery Storage and the standard protective battery case for 18650 batteries.

Illustrative image related to multi-18650 backup battery case

Comparison Table

| Comparison Aspect | Multi-18650 Backup Battery Case | CellVault-5M Modular Battery Storage | Standard Protective Battery Case |

|---|---|---|---|

| Performance | High, protects multiple batteries | Customizable, accommodates various batteries | Good, secure for 4 batteries |

| Cost | Low-cost option (approx. $1-$10) | Higher cost ($46.74 – $96.23) | Low-cost (approx. $2-$5) |

| Ease of Implementation | Simple and straightforward | Requires selection of inserts | Very easy to use |

| Maintenance | Minimal; just clean occasionally | Low; modular inserts may need replacing | Low; generally durable |

| Best Use Case | General storage for multiple 18650 batteries | Field use, requiring various battery types | Everyday carry for vapers, photographers |

Detailed Breakdown of Alternatives

CellVault-5M Modular Battery Storage

The CellVault-5M offers a highly customizable solution for storing not only 18650 batteries but also various other battery types. Its modular inserts allow users to adapt the storage configuration according to their needs, making it particularly useful for professionals who rely on multiple battery types in the field. The waterproof design and durable construction provide additional security. However, its higher price point may deter some buyers who are looking for a more cost-effective solution.

Standard Protective Battery Case

The standard protective battery case is a more affordable option designed to securely hold up to four 18650 batteries. Made from impact-resistant plastic, it effectively prevents short circuits and protects batteries from moisture and dust. This simplicity makes it an attractive choice for everyday users like vapers and photographers. However, its limited capacity and lack of additional features may not meet the needs of users requiring storage for multiple battery types.

Conclusion: Choosing the Right Battery Storage Solution

When selecting a battery storage solution, B2B buyers should consider their specific operational requirements, budget constraints, and the environments in which they will use the batteries. The multi-18650 backup battery case is a highly economical option for straightforward storage of multiple batteries, while the CellVault-5M is ideal for users needing a versatile and rugged solution for various battery types. The standard protective battery case serves as a reliable, low-cost alternative for those focused on basic battery protection. By analyzing these alternatives, businesses can make informed decisions that align with their operational needs and financial goals.

Essential Technical Properties and Trade Terminology for multi-18650 backup battery case

What Are the Key Technical Properties of a Multi-18650 Backup Battery Case?

When considering a multi-18650 backup battery case, several technical properties are critical for ensuring optimal performance, safety, and usability in various applications. Below are essential specifications that international B2B buyers should understand:

1. Material Grade

The material used in the construction of battery cases significantly impacts durability and safety. Most cases are made from high-quality, impact-resistant plastics like polycarbonate or ABS (Acrylonitrile Butadiene Styrene). These materials not only provide robustness against physical damage but also prevent chemical reactions with the lithium-ion batteries they house. For buyers, selecting a case with superior material ensures longevity and protects against battery leakage or explosion.

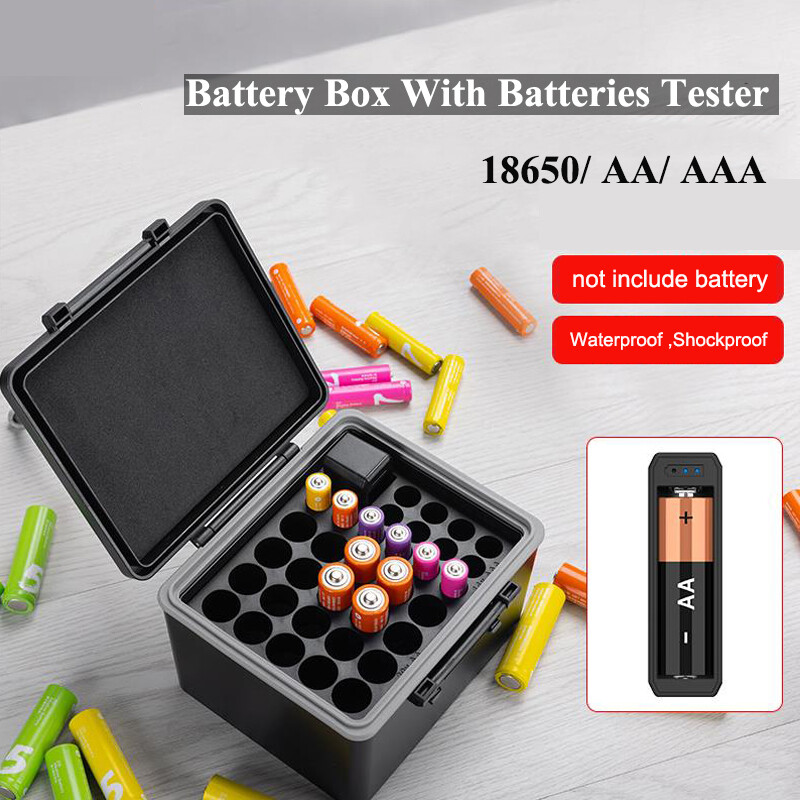

2. Capacity (Number of Cells)

The capacity of a battery case, often denoted by the number of cells it can accommodate (e.g., 2, 4, or 8 cells), is a fundamental specification. This directly correlates to the energy storage and the intended application of the case. For instance, a case designed for four 18650 batteries is ideal for users who require extended battery life for devices like flashlights or vape pens. Understanding capacity helps buyers match their energy needs with the right product.

3. Waterproof Rating

A battery case’s waterproof rating is crucial for users operating in wet environments. Cases may be rated using the Ingress Protection (IP) classification, such as IP67, which indicates complete dust protection and the ability to withstand submersion in water up to one meter for a limited time. Buyers in regions prone to moisture, like parts of Africa and South America, should prioritize waterproof features to ensure battery safety and performance.

4. Short Circuit Protection

Many modern battery cases include built-in short circuit protection, which safeguards against accidental contact between battery terminals. This feature is vital as it prevents potential fires or explosions, particularly in high-drain applications. Buyers should inquire about this safety feature to mitigate risks associated with lithium-ion battery use.

Illustrative image related to multi-18650 backup battery case

5. Weight and Portability

The weight of the battery case is also an important consideration, particularly for users who need to carry spare batteries frequently. Lightweight cases made from advanced materials can enhance portability without compromising protection. Buyers should evaluate their transport needs and choose cases that balance weight and durability.

What Are Common Trade Terminology and Jargon Related to Battery Cases?

Understanding industry terminology is essential for effective communication and negotiation in the B2B market for battery cases. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For battery cases, OEMs often create custom designs based on the specifications provided by their clients. This term is crucial for buyers looking for tailored solutions to meet specific application needs.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is particularly relevant for B2B buyers looking to purchase battery cases in bulk. Understanding MOQ helps businesses plan their inventory and budget effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to invite them to bid on specific products or services. In the context of battery cases, an RFQ would detail the required specifications and quantities, allowing suppliers to provide competitive pricing. This process is essential for sourcing the best deals.

Illustrative image related to multi-18650 backup battery case

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers in the shipping process. Understanding these terms helps buyers anticipate costs and risks associated with transportation, ensuring smoother transactions when importing battery cases from different regions.

5. Li-ion (Lithium-ion)

Li-ion refers to a type of rechargeable battery that is commonly used in consumer electronics and electric vehicles. Knowledge of Li-ion technology is essential for buyers as it influences the choice of battery cases, ensuring compatibility and safety.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing multi-18650 backup battery cases, ultimately enhancing their operations and product offerings.

Navigating Market Dynamics and Sourcing Trends in the multi-18650 backup battery case Sector

What Are the Current Market Dynamics and Key Trends Influencing the Multi-18650 Backup Battery Case Sector?

The multi-18650 backup battery case market is experiencing robust growth driven by several global trends. As the demand for rechargeable lithium-ion batteries continues to rise across various sectors, including renewable energy, consumer electronics, and electric vehicles, the need for efficient and reliable battery storage solutions has become critical. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should note the increasing preference for battery cases that offer enhanced durability, waterproofing, and modular designs. These features not only ensure safety but also cater to the diverse needs of industries ranging from telecommunications to military applications.

Illustrative image related to multi-18650 backup battery case

Emerging trends indicate a shift towards modular and customizable solutions. Products like the CellVault-5M highlight the growing demand for storage systems that can adapt to various battery types and configurations. Furthermore, technological advancements are leading to the integration of smart features, such as temperature monitoring and RFID tracking, which enhance inventory management and operational efficiency. B2B buyers should also be aware of the competitive pricing strategies being employed, as manufacturers strive to balance quality with affordability to capture market share in developing regions.

How Is Sustainability and Ethical Sourcing Shaping the Multi-18650 Backup Battery Case Market?

Sustainability is becoming a pivotal factor in the sourcing of multi-18650 backup battery cases. The environmental impact of battery production and disposal is prompting B2B buyers to prioritize products made from recycled or eco-friendly materials. Companies are increasingly seeking partnerships with manufacturers who demonstrate a commitment to reducing their carbon footprint through sustainable practices and materials.

Ethical sourcing is also gaining traction, as global consumers demand transparency in supply chains. B2B buyers are encouraged to look for suppliers who hold certifications related to sustainability, such as ISO 14001, which signifies effective environmental management systems. Furthermore, the use of biodegradable packaging and non-toxic materials in the production of battery cases is becoming a standard expectation among buyers. By aligning with suppliers that prioritize sustainability and ethical sourcing, companies can enhance their brand reputation while contributing positively to the environment.

What Has Been the Evolution of the Multi-18650 Backup Battery Case Market?

The evolution of the multi-18650 backup battery case market reflects the broader technological advancements within the battery industry. Initially, battery cases were primarily designed for basic protection and storage. However, as the adoption of lithium-ion batteries surged, so did the complexity of their applications. Early models were simple plastic enclosures, but advancements in materials and design have led to the development of cases that offer impact resistance, waterproofing, and modular functionality.

Over the years, the market has seen a diversification of products catering to various needs, from casual consumers to specialized industries. This evolution underscores the importance of innovation in meeting the growing demands for safety, portability, and versatility in battery storage solutions. Today, manufacturers are not only focused on functionality but also on creating aesthetically pleasing designs that appeal to a broader audience, thus enhancing market competitiveness.

Illustrative image related to multi-18650 backup battery case

Frequently Asked Questions (FAQs) for B2B Buyers of multi-18650 backup battery case

-

How do I select the right multi-18650 backup battery case for my business needs?

Choosing the right multi-18650 backup battery case involves assessing your specific requirements, such as the number of batteries you need to store, the level of protection required (e.g., waterproof, impact-resistant), and any environmental considerations. Additionally, consider the dimensions and weight of the case for transportability. If your applications include critical operations, opt for cases that offer modular designs for flexibility. Engaging with suppliers for samples can also help you evaluate the product’s quality and suitability before making bulk purchases. -

What are the benefits of using modular battery cases for 18650 batteries?

Modular battery cases provide customizable storage solutions, allowing you to tailor the configuration based on your specific battery types and quantities. This flexibility is particularly useful for businesses requiring various battery sizes. Modular designs often feature additional compartments that can help differentiate between charged and depleted batteries, enhancing operational efficiency. Furthermore, these cases are typically built with durable materials, ensuring protection against impacts and environmental conditions, making them ideal for field use. -

What should I consider regarding the minimum order quantity (MOQ) when sourcing battery cases?

When sourcing multi-18650 backup battery cases, the MOQ is a crucial factor that can significantly impact your purchasing strategy. Different suppliers have varying MOQs based on production capabilities and inventory management. It’s essential to negotiate terms that align with your business needs, especially if you are a small to medium-sized enterprise. Additionally, consider the potential for bulk discounts, as purchasing larger quantities can often lead to cost savings, allowing for better inventory management. -

How can I ensure the quality of multi-18650 battery cases from international suppliers?

To ensure the quality of battery cases from international suppliers, conduct thorough due diligence. Request samples to assess the material quality and construction standards. Look for suppliers with ISO certifications or industry-specific standards that guarantee product reliability. Additionally, consider third-party quality assurance services for inspections before shipment. Establishing clear quality control agreements and guidelines can also help maintain product standards throughout the manufacturing process. -

What are the typical payment terms when sourcing battery cases internationally?

Payment terms can vary significantly among suppliers, but common practices include a deposit (often 30%) upon order confirmation, with the balance payable before shipping. Some suppliers may offer letters of credit or escrow services to safeguard transactions. It’s advisable to clarify payment methods accepted, such as bank transfers, PayPal, or trade credit, and to ensure that you understand the implications of currency fluctuations on pricing. Negotiating favorable terms that suit your cash flow can enhance your financial planning. -

What logistics considerations should I keep in mind when importing battery cases?

When importing multi-18650 battery cases, consider shipping methods (air vs. sea) based on urgency and budget. Ensure compliance with international shipping regulations, particularly for lithium-ion batteries, which may have specific handling requirements. Work with reliable freight forwarders who can provide insights into customs procedures and potential tariffs. Additionally, factor in lead times for production and shipping to avoid disruptions in your supply chain, and explore options for tracking shipments for better visibility. -

How do I vet suppliers for multi-18650 battery cases?

To vet suppliers effectively, start by researching their reputation through online reviews, industry forums, and trade associations. Request references from previous clients to gauge their reliability and service quality. Evaluate their production capabilities by visiting their facilities if possible, or conducting virtual tours. Additionally, review their compliance with safety and quality standards, and ensure they have robust customer support for post-purchase assistance. Building a relationship with suppliers can also foster trust and better communication. -

Can I customize my multi-18650 backup battery cases for branding purposes?

Yes, many suppliers offer customization options for multi-18650 backup battery cases, allowing you to add your branding, such as logos or specific colors. Customization can enhance your brand visibility and create a unique product offering. When discussing customization, inquire about the minimum order quantities, additional costs, and lead times involved. Ensure that the customization does not compromise the case’s functionality or quality, and request samples of customized products before placing large orders.

Top 9 Multi-18650 Backup Battery Case Manufacturers & Suppliers List

1. IMR Batteries – 18650 Battery Cases

Domain: imrbatteries.com

Registered: 2014 (11 years)

Introduction: 18650 battery cases are protective enclosures designed to prevent short circuits, physical damage, and accidental exposure of lithium-ion batteries. They are made from impact-resistant plastic, flexible silicone, and reinforced waterproof materials. Available configurations include single, dual, and multi-battery options. Key features include short-circuit prevention, crush resistance, moisture pr…

2. Thyrm – CellVault-5M Modular Battery Storage

Domain: thyrm.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “CellVault-5M Modular Battery Storage”, “compatible_batteries”: [“AA”, “AAA”, “CR123”, “18350”, “18650”, “CR2032”, “1632”], “price_range”: “$46.74 – $96.23”, “features”: [“Customizable protection for lithium-ion batteries”, “8 modular inserts included”, “Extra wells for CR2032 batteries”, “Waterproof gasket seal”, “Integrated straps for MOLLE/webbing attachment”, “Lockable over-ce…

3. 18650 Battery Store – 4-Battery Storage Case

Domain: 18650batterystore.com

Registered: 2017 (8 years)

Introduction: {“Product Type”:”18650 Battery Storage Case”,”Capacity”:”Holds 4x 18650 Batteries”,”Material”:”Impact-Resistant Plastic”,”Color Options”:”Black / Transparent”,”Closure Mechanism”:”Secure Snap-Lock Lid”,”Protection Level”:”Short Circuit, Dust, Moisture, and Shock-Resistant”,”Dimensions”:”~90mm × 75mm × 25mm”,”Weight”:”~40g (Empty)”,”Key Features”:[“Secure Storage for 4x 18650 Batteries: Custom-fitt…

4. THYRM – CellVault Battery Storage

Domain: budgetlightforum.com

Registered: 2010 (15 years)

Introduction: This company, THYRM – CellVault Battery Storage, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. YA Powerbank – Versatile Charging Solution

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: YA Powerbank Q: A powerbank that supports removable 18650 cells, can be used as a powerbank and also acts as an 18650 charger at home/hotel. Preferred capacity is two or three cells. Currently using USB-A but anticipates moving to USB-C. Not intended for laptop charging; the largest device to charge is an iPad Pro. Previous powerbank had high self-discharge issues. Suggested alternatives include X…

6. Unbranded – Long Lasting 2x 9800mAh Battery Case

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Long Lasting 2x 9800mAh Battery + Replaceable 18650 Backup Battery Case for 18650; Condition: New; Brand: Unbranded; Type: Wall Charger; Compatible Brand: For 18650; Seller: Qik_Sara Store; Price: US $33.65; Shipping: Free USPS First Class; Returns: 30 days, seller pays for return shipping; Location: Diamond Bar, California, United States; Estimated Delivery: Between Fri, Sep 12 and Tue, Sep 16; Q…

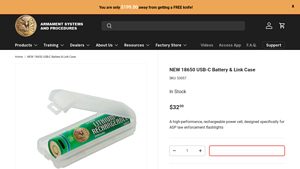

7. ASP – NEW 18650 USB-C Battery

Domain: asp-usa.com

Registered: 2003 (22 years)

Introduction: Product Name: NEW 18650 USB-C Battery & Link Case

SKU: 53057

Price: $32.00

Availability: In Stock

Description: A high-performance, rechargeable Lithium-Ion battery designed specifically for ASP law enforcement flashlights. Features an integrated USB-C charge port for in-light recharging and standalone charging. Includes a Link Case for safe storage and transport, with an interlocking design for or…

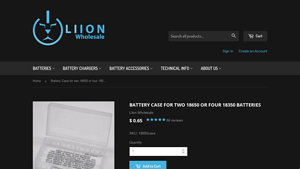

8. Liion – Battery Case for 18650/18350

Domain: liionwholesale.com

Registered: 2014 (11 years)

Introduction: Battery Case for two 18650 or four 18350 batteries. Price: $0.65 USD. SKU: 18650case. Fits 2 unprotected 18650 batteries or 4 unprotected 18350 batteries. Will not fit protected batteries. Made in China. Includes space for a 20mmx60mm or smaller label. Sold by the single, without batteries. Out of stock notification available. Discounts available for bulk purchases.

9. CandlePower Forums – DIY Bicycle Blinker Battery Holder

Domain: candlepowerforums.com

Registered: 2000 (25 years)

Introduction: 2 x 18650 Battery Holders; waterproof design; modded case from DX; uses Keystone battery contacts; parts used include Keystone #290, #209, #238/228; approximately $4 in parts; designed for DIY projects, specifically for bicycle blinkers; allows for easy removal of cells for charging; offers a fixed configuration with batteries in series (7.2v); potential for commercial sale; user-friendly with sol…

Strategic Sourcing Conclusion and Outlook for multi-18650 backup battery case

The strategic sourcing of multi-18650 backup battery cases is increasingly vital for international B2B buyers seeking reliable and cost-effective storage solutions. Key takeaways emphasize the importance of selecting cases that not only offer robust protection against impacts, moisture, and dust but also facilitate easy organization and transport of batteries. As demand grows across diverse sectors—from renewable energy to consumer electronics—investing in high-quality, customizable battery cases can enhance operational efficiency and safety.

Looking ahead, the market for battery storage solutions is expected to expand, driven by technological advancements and the need for sustainable energy solutions. International buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize partnerships with manufacturers who emphasize quality, innovation, and environmental responsibility. By strategically sourcing these essential components, businesses can ensure they are prepared for the evolving landscape of energy storage and usage.

Now is the time to reassess your battery storage strategies and align with suppliers who can meet your specific needs. Embrace this opportunity to enhance your product offerings and secure a competitive edge in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to multi-18650 backup battery case

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.