A Deep Dive into Mini Plastic Babies Solution

Introduction: Navigating the Global Market for mini plastic babies

In the dynamic landscape of international trade, sourcing mini plastic babies presents unique challenges for B2B buyers seeking to capitalize on their growing popularity in party supplies, educational tools, and promotional products. These whimsical items, often used in baby showers, games, and crafts, have seen a surge in demand across diverse markets, from Africa to South America and the Middle East to Europe. This guide aims to equip buyers with essential insights into the various types of mini plastic babies available, their applications, and strategies for effective supplier vetting.

Understanding the nuances of sourcing these products is crucial for making informed purchasing decisions. Buyers will benefit from a comprehensive overview that covers material quality, safety standards, and pricing structures, ensuring that they can navigate the complexities of global procurement. Additionally, this guide will delve into the importance of aligning with suppliers who not only meet quality expectations but also demonstrate reliability and ethical practices.

By providing actionable strategies and key considerations, this resource empowers international B2B buyers to make confident choices in their sourcing journey, ultimately enhancing their competitive edge in the market. Whether you are targeting niche markets in Germany or Brazil, the insights gained here will facilitate smarter investments in mini plastic babies, ensuring you stay ahead in a vibrant and evolving marketplace.

Understanding mini plastic babies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Soft Mini Babies | Made from soft plastic; typically 1.5 inches | Party favors, craft projects, decorations | Pros: Safe for children, versatile use. Cons: Limited durability compared to hard plastics. |

| Hard Plastic Babies | Rigid construction; various sizes available | Educational tools, collectibles, promotional items | Pros: Durable, long-lasting. Cons: May not be suitable for all age groups due to choking hazards. |

| Themed Mini Babies | Custom designs based on themes (e.g., holidays) | Event decorations, themed parties | Pros: Enhances event aesthetics, unique appeal. Cons: Higher cost for customization. |

| Glow-in-the-Dark Babies | Luminescent feature for visibility in dark | Halloween decorations, night events | Pros: Eye-catching, fun for themed events. Cons: Limited use cases outside specific events. |

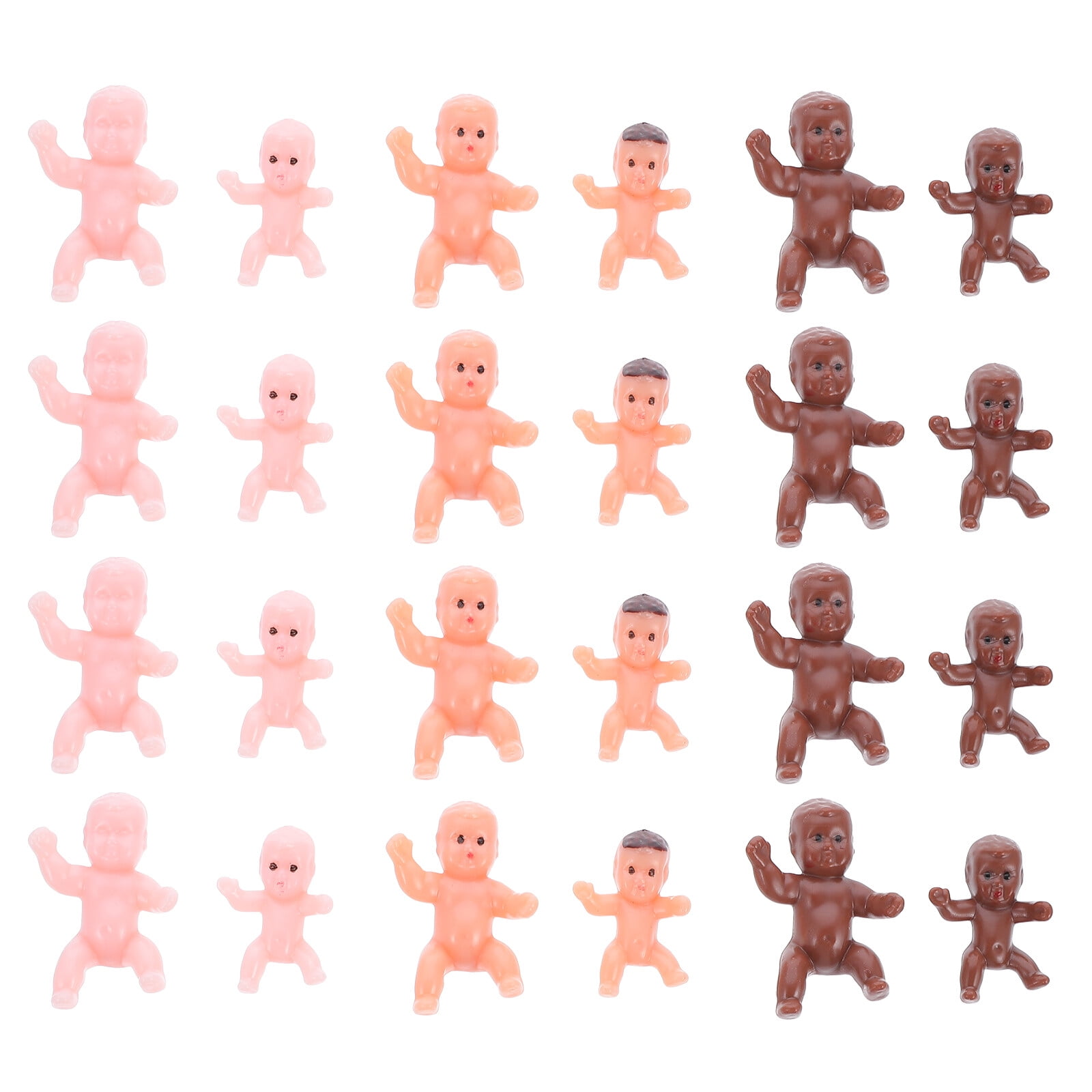

| Multi-Ethnic Babies | Diverse representations of ethnic backgrounds | Inclusivity in events, educational purposes | Pros: Promotes diversity, suitable for various cultural events. Cons: Higher production costs may apply. |

What Are the Key Characteristics of Soft Mini Babies?

Soft mini babies are typically made from a soft plastic material that is safe for children and easy to handle. Measuring around 1.5 inches, these miniatures are often used as playful party favors at baby showers or for craft projects. Their versatility makes them appealing for various applications, from cake decorations to educational tools. When purchasing, B2B buyers should consider the safety certifications and the material’s food safety standards, especially if intended for use in food-related settings.

How Do Hard Plastic Babies Differ from Other Types?

Hard plastic babies are characterized by their rigid construction, which offers durability and a longer lifespan compared to softer variants. These products come in various sizes and can be used as educational tools, collectibles, or promotional items. B2B buyers should evaluate the intended use carefully, as hard plastic babies may pose choking hazards for young children. Additionally, bulk purchasing options can provide cost savings for businesses looking to stock these items for resale or events.

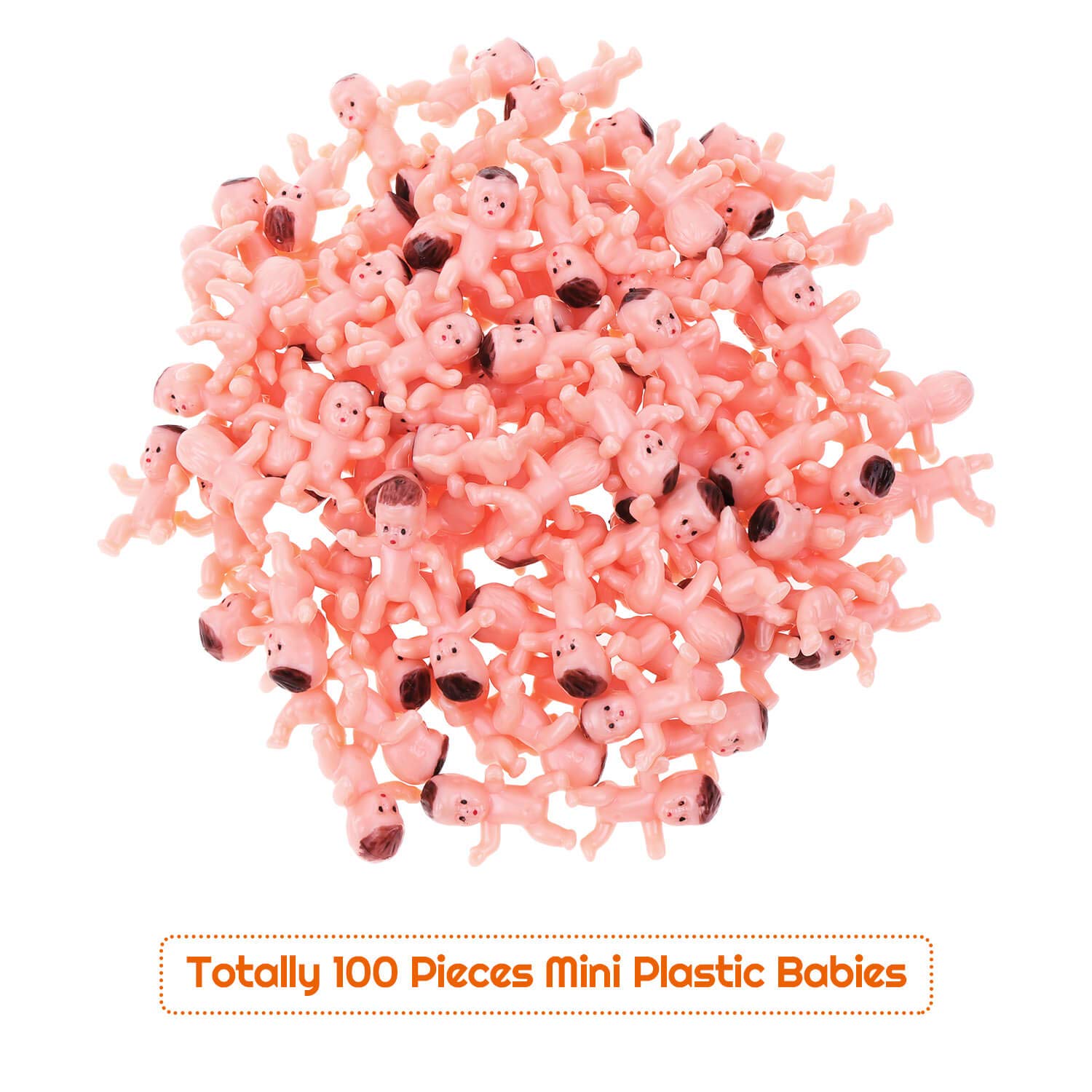

Illustrative image related to mini plastic babies

Why Choose Themed Mini Babies for Events?

Themed mini babies are custom-designed to fit specific themes, such as holidays or special occasions. This customization allows businesses to enhance the aesthetic appeal of events, making them more memorable for attendees. When considering purchasing themed mini babies, B2B buyers should weigh the benefits of unique designs against the potential higher costs associated with customization. These items can serve as excellent conversation starters and memorable keepsakes for guests.

What Are the Benefits of Glow-in-the-Dark Babies?

Glow-in-the-dark babies offer a distinctive feature that makes them particularly appealing for nighttime events such as Halloween parties. Their luminescent quality adds an element of fun and excitement, drawing attention in dark settings. However, B2B buyers should keep in mind that their use may be limited to specific occasions. When sourcing these items, it’s essential to ensure they meet safety standards, especially if they will be used around children.

How Do Multi-Ethnic Babies Promote Inclusivity?

Multi-ethnic babies are designed to represent diverse ethnic backgrounds, promoting inclusivity in various settings. These miniatures can be particularly valuable in educational contexts or cultural events, allowing for a broader representation of communities. B2B buyers should consider the cultural relevance of these items in their target markets, as well as the potential for higher production costs. Investing in multi-ethnic mini babies can enhance a brand’s reputation for social responsibility and inclusivity.

Key Industrial Applications of mini plastic babies

| Industry/Sector | Specific Application of mini plastic babies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Event Planning | Party Favors for Baby Showers | Increases customer engagement and memorable experiences | Ensure compliance with safety standards; consider bulk purchasing for cost efficiency |

| Retail & E-commerce | Novelty Items for Online Sales | Attracts customers with unique product offerings | Focus on supplier reliability and shipping times for international markets |

| Educational Supplies | Teaching Aids for Early Childhood Education | Enhances learning through interactive play | Source from manufacturers with educational product certifications |

| Marketing & Promotions | Unique Giveaway Items for Brand Awareness | Differentiates brand in competitive markets | Evaluate customization options and minimum order quantities |

| Crafting & DIY Projects | Supplies for Arts and Crafts | Provides creative opportunities for various demographics | Look for diverse color options and packaging for retail display |

How Are Mini Plastic Babies Used in Event Planning?

In the event planning industry, mini plastic babies serve as humorous and playful party favors, particularly for baby showers. They can be incorporated into treat bags, cake decorations, or used in games, enhancing the overall theme of the event. This not only creates memorable experiences for attendees but also encourages engagement, making events more enjoyable. Buyers should consider compliance with safety standards, especially regarding choking hazards, and look for suppliers who offer bulk purchasing options to optimize costs.

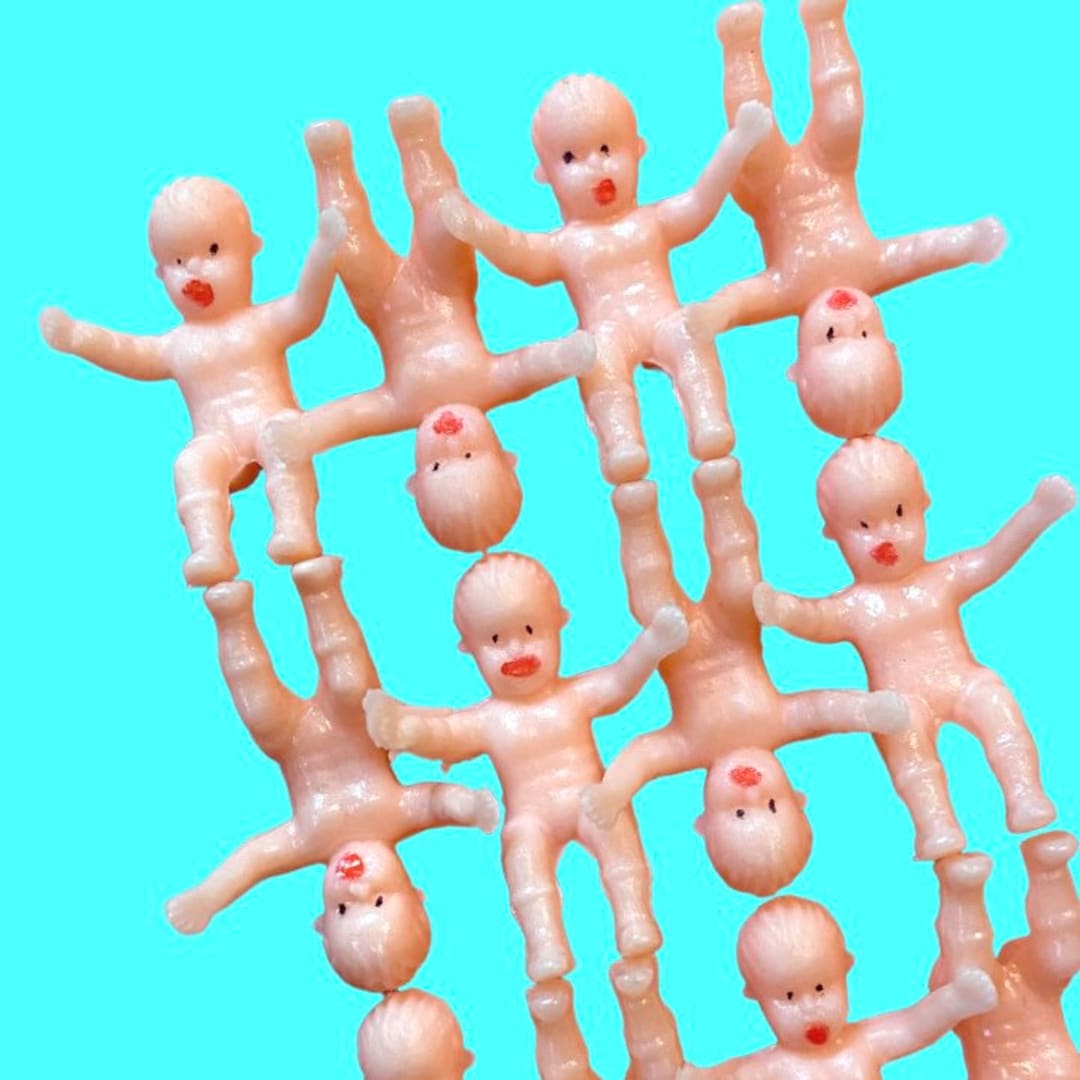

Illustrative image related to mini plastic babies

What Role Do Mini Plastic Babies Play in Retail & E-commerce?

Retailers and e-commerce businesses leverage mini plastic babies as novelty items that attract customers looking for unique gifts or party supplies. Their quirky appeal can enhance online product offerings, driving sales through impulse buys. For international B2B buyers, it’s crucial to source from reliable manufacturers who can guarantee timely delivery, especially when catering to seasonal demand spikes. Understanding local market preferences can also guide product selection to ensure relevance and appeal.

How Can Mini Plastic Babies Be Effective Teaching Aids?

In educational settings, particularly in early childhood education, mini plastic babies are utilized as teaching aids that facilitate interactive learning. They can be used in role-playing scenarios, helping children develop social skills and understand concepts related to family and community. Buyers in this sector should prioritize sourcing from manufacturers who provide educational certifications to ensure the toys meet safety and developmental standards, particularly in diverse markets across Africa and South America.

How Do Mini Plastic Babies Enhance Marketing & Promotions?

Marketing teams often use mini plastic babies as unique giveaway items to enhance brand awareness. These items can create a memorable association with the brand, particularly when they tie into specific campaigns or events. For international buyers, evaluating customization options, such as branding the plastic babies with company logos, can maximize their promotional impact. Additionally, understanding minimum order quantities and lead times is essential for effective planning and execution of marketing strategies.

Why Are Mini Plastic Babies Popular in Crafting & DIY Projects?

In the crafting and DIY sector, mini plastic babies are popular supplies for a variety of projects, from scrapbook embellishments to themed decorations. Their versatility allows crafters to incorporate them into diverse creations, appealing to a wide range of demographics. Buyers should seek suppliers that offer a variety of colors and packaging options to cater to retail display needs. Ensuring consistent quality and availability can also support ongoing crafting trends and customer satisfaction.

3 Common User Pain Points for ‘mini plastic babies’ & Their Solutions

Scenario 1: Navigating Safety Compliance for Mini Plastic Babies

The Problem: B2B buyers often face significant challenges when it comes to ensuring that products comply with safety regulations. This is particularly critical for items like mini plastic babies, which may be used as party favors or in games but pose a choking hazard for young children. Buyers must navigate complex regulations that vary by region, such as the EU’s EN71 standard for toy safety or the U.S. Consumer Product Safety Commission (CPSC) guidelines. Failure to comply can lead to serious liabilities, including product recalls, fines, and damage to brand reputation.

Illustrative image related to mini plastic babies

The Solution: To address these compliance issues, buyers should prioritize sourcing from manufacturers who provide clear documentation of their safety standards and certifications. When selecting suppliers, ask for test reports that confirm adherence to relevant safety regulations. Additionally, consider conducting your own risk assessments based on the intended use of the mini plastic babies. Implementing a robust quality control process that includes periodic checks of incoming inventory can also mitigate risks. If you are planning to market these products in multiple regions, consider consulting with a legal expert who specializes in product safety regulations to ensure comprehensive compliance.

Scenario 2: Managing Inventory and Supply Chain Challenges

The Problem: B2B buyers often struggle with inventory management and supply chain issues, especially when dealing with seasonal items like mini plastic babies, which may see spikes in demand during events such as baby showers, gender reveal parties, or other celebrations. These fluctuations can lead to either stockouts, resulting in lost sales, or overstocking, which ties up capital and increases storage costs.

The Solution: To effectively manage inventory, buyers should adopt a data-driven approach to forecasting demand. Utilize historical sales data and analytics to predict peak seasons for mini plastic babies. Collaborating closely with suppliers to establish a just-in-time inventory system can help ensure that you have adequate stock without overcommitting. Additionally, consider implementing an inventory management software that can automate stock level tracking and trigger reorders based on predefined thresholds. This proactive strategy will not only help maintain optimal inventory levels but also enhance overall operational efficiency.

Scenario 3: Differentiating Product Offerings in a Competitive Market

The Problem: The market for mini plastic babies can be saturated, making it difficult for B2B buyers to differentiate their product offerings and attract customers. Competing on price alone often leads to diminished margins, while a lack of unique selling propositions (USPs) can result in lower sales and reduced brand loyalty.

The Solution: To stand out in the crowded marketplace, buyers should explore customization options for mini plastic babies. This could include offering a wider variety of colors, designs, or even personalized features that appeal to specific customer segments. For instance, providing ethnic diversity in the mini plastic baby designs can resonate with a broader audience, particularly in regions with varied cultural representations. Additionally, consider bundling these products with related items, such as themed party supplies or games, to create attractive packages that encourage larger purchases. Investing in targeted marketing campaigns that highlight these unique offerings can further enhance visibility and customer engagement, driving increased sales and brand recognition.

Strategic Material Selection Guide for mini plastic babies

What Are the Common Materials Used for Mini Plastic Babies?

When selecting materials for mini plastic babies, international B2B buyers must consider various factors including durability, safety, cost, and compliance with local regulations. The most common materials used in the production of these items include PVC, ABS, Polypropylene, and Thermoplastic Elastomers (TPE). Each material has distinct properties and suitability for different applications.

How Does PVC Perform in Mini Plastic Baby Production?

Polyvinyl Chloride (PVC) is a widely used plastic known for its versatility and cost-effectiveness. It has good mechanical strength and can withstand a range of temperatures, making it suitable for various applications. PVC is resistant to chemicals and moisture, which is beneficial for products that may come into contact with food or beverages.

Pros: PVC is relatively inexpensive and easy to mold, allowing for intricate designs. Its durability ensures that the mini plastic babies can withstand rough handling, which is particularly important in party settings or as toys.

Cons: The primary drawback of PVC is its environmental impact, as it is not biodegradable. Additionally, certain formulations can release harmful chemicals if not properly manufactured, which raises safety concerns for end-users.

Considerations for International Buyers: Compliance with safety standards such as ASTM F963 (USA) and EN71 (Europe) is crucial. Buyers in regions like Africa and South America may also need to consider local regulations regarding the use of PVC.

What Advantages Does ABS Offer for Mini Plastic Babies?

Acrylonitrile Butadiene Styrene (ABS) is another popular material for mini plastic babies. It boasts excellent impact resistance and toughness, making it suitable for products that are frequently dropped or handled.

Pros: ABS is known for its strength and rigidity, which contributes to the longevity of the product. It can be easily colored and finished, allowing for vibrant designs that appeal to consumers.

Cons: ABS is generally more expensive than PVC, which may affect pricing strategies for B2B buyers. It also has a lower temperature resistance compared to PVC, which can limit its applications in extreme conditions.

Considerations for International Buyers: Buyers should ensure that ABS products meet the necessary safety standards, particularly in Europe where regulations are stringent. Importers should also consider the cost implications of sourcing ABS compared to other materials.

Illustrative image related to mini plastic babies

How Does Polypropylene Compare for Mini Plastic Babies?

Polypropylene (PP) is a lightweight and flexible material that is increasingly popular in toy manufacturing. It has good chemical resistance and is less prone to cracking compared to other plastics.

Pros: PP is food-safe and can be sterilized, making it an excellent choice for products that may come into contact with food or beverages. Its lightweight nature also reduces shipping costs.

Cons: While PP is durable, it may not offer the same level of impact resistance as PVC or ABS. Additionally, it can be more challenging to color and finish, which may limit design options.

Illustrative image related to mini plastic babies

Considerations for International Buyers: Compliance with food safety regulations is essential for buyers in the food and beverage sectors. In Europe, EN71 compliance is particularly important for toys, while buyers in Africa may need to navigate varying local standards.

Why Choose Thermoplastic Elastomers (TPE) for Mini Plastic Babies?

Thermoplastic Elastomers (TPE) combine the properties of rubber and plastic, offering flexibility and resilience. TPE is often used for products that require a soft touch or a rubber-like feel.

Pros: TPE is highly durable and can withstand repeated bending and stretching without losing its shape. It is also non-toxic, making it a safe option for children’s toys.

Cons: The primary limitation of TPE is its cost, which is generally higher than that of other plastics. Additionally, TPE can be more complex to process, which may increase manufacturing lead times.

Illustrative image related to mini plastic babies

Considerations for International Buyers: Buyers should ensure that TPE products comply with international safety standards. In regions like the Middle East and South America, understanding local regulations regarding materials is crucial for successful market entry.

Summary Table of Material Selection for Mini Plastic Babies

| Material | Typical Use Case for mini plastic babies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General toy production and party favors | Cost-effective and durable | Environmental impact and safety concerns | Low |

| ABS | High-quality toys with intricate designs | Strong and impact-resistant | Higher cost and lower temperature resistance | Med |

| Polypropylene | Food-safe applications and lightweight toys | Food-safe and sterilizable | Limited impact resistance | Med |

| Thermoplastic Elastomers (TPE) | Soft-touch toys and flexible products | Non-toxic and highly durable | Higher cost and complex processing | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of common materials used in the production of mini plastic babies. Understanding these factors will help inform purchasing decisions and ensure compliance with local regulations, ultimately leading to successful product offerings in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for mini plastic babies

What Are the Main Stages of Manufacturing Mini Plastic Babies?

The manufacturing process for mini plastic babies involves several key stages that ensure the final product meets the required quality standards while being cost-effective. Understanding these stages is essential for B2B buyers who want to ensure their suppliers maintain high manufacturing standards.

Material Preparation: What Raw Materials Are Used?

The primary raw material for mini plastic babies is high-density polyethylene (HDPE) or low-density polyethylene (LDPE). These plastics are favored due to their durability, flexibility, and safety for consumer use. The first stage involves sourcing and preparing these materials, which are often delivered in pellet form. Suppliers must ensure that the materials are free from contaminants and meet international safety standards, especially for products intended for children.

Illustrative image related to mini plastic babies

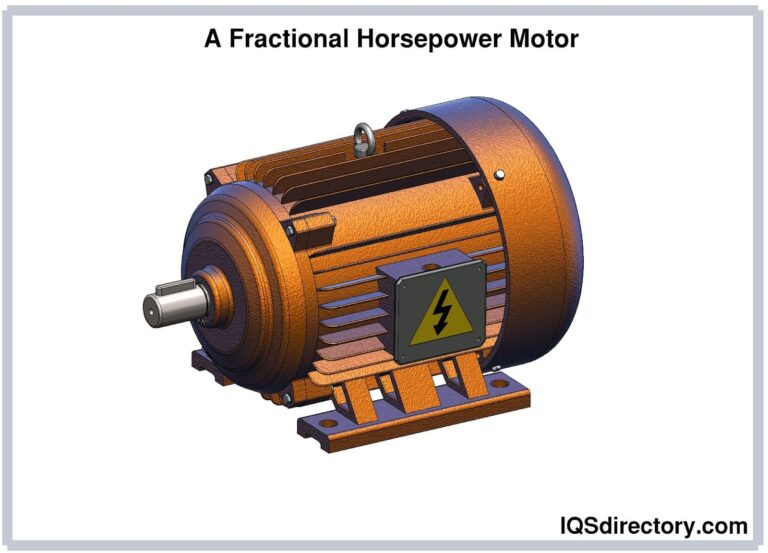

How Are Mini Plastic Babies Formed?

The forming stage typically employs injection molding, a common technique for creating plastic products. In this process, plastic pellets are heated until they melt, then injected into a mold that shapes the mini plastic babies. The molds are designed to create various colors and features, allowing for customization based on market demand. This stage is crucial because it determines the initial quality and dimensional accuracy of the products.

What Is the Assembly Process for Mini Plastic Babies?

In most cases, mini plastic babies are produced as a single molded piece, eliminating the need for extensive assembly. However, if additional components are involved (like accessories or packaging), this stage will ensure that all parts fit correctly and securely. The assembly may also include printing or labeling, which must adhere to safety regulations, particularly for products aimed at children.

How Is Finishing Achieved in Manufacturing?

Finishing touches in the manufacturing process involve quality checks and aesthetic enhancements. This could include polishing, painting, or applying any surface coatings. For mini plastic babies, it is vital to ensure that any finishes used are non-toxic and comply with food safety regulations if the products will be used in food-related applications, such as cake decorations.

What Are the Key Quality Assurance Standards for Mini Plastic Babies?

Quality assurance is critical in the manufacturing of mini plastic babies. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that suppliers maintain consistent quality in their processes.

What International Standards Should Buyers Be Aware Of?

-

ISO 9001: This standard focuses on quality management systems, emphasizing continuous improvement and customer satisfaction. It is crucial for buyers to verify that their suppliers are ISO-certified.

-

CE Marking: For buyers in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. It is particularly relevant for toys and products intended for children.

-

ASTM F963: This standard is essential in the United States for toy safety, covering various aspects such as material safety, mechanical hazards, and labeling.

-

API Standards: For products used in medical or healthcare settings, adherence to API standards ensures that the materials used are safe and effective.

What Are the Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integral to ensuring that the mini plastic babies produced meet all necessary standards. Key QC checkpoints include:

Illustrative image related to mini plastic babies

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers should ensure that the materials meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested to ensure that the production is on track and that any deviations from quality standards are addressed immediately.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection ensures that they meet all quality and safety standards. This includes checking for defects, ensuring proper labeling, and confirming compliance with relevant certifications.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, ensuring that suppliers adhere to stringent quality control processes is paramount. Here are several strategies to verify supplier QC:

-

Supplier Audits: Conducting regular audits of suppliers can help identify potential quality issues before they affect your supply chain. Audits should evaluate the manufacturer’s adherence to ISO standards and their overall quality management practices.

-

Quality Reports: Request detailed quality reports from suppliers that outline their QC processes, test results, and any corrective actions taken. This documentation provides transparency and can help build trust between buyers and suppliers.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be conducted at various stages of the manufacturing process to ensure compliance with international standards.

What Are the Unique QC Considerations for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must consider additional nuances in QC:

-

Cultural and Regulatory Differences: Different regions may have varying safety standards and regulatory requirements. Buyers should familiarize themselves with local regulations and ensure that suppliers can comply.

-

Logistics and Shipping: Quality can be affected during transportation. Buyers should consider the entire supply chain and ensure that products are handled and stored appropriately to prevent damage.

-

Language Barriers: Effective communication is crucial in quality assurance. Buyers should ensure that all documentation, including safety data sheets and quality reports, is available in a language that is understandable to both parties.

Conclusion

Understanding the manufacturing processes and quality assurance practices for mini plastic babies is essential for B2B buyers looking to ensure product safety and compliance. By focusing on material preparation, forming, assembly, and finishing, along with adhering to international quality standards, buyers can make informed decisions when selecting suppliers. Implementing rigorous quality control measures and verifying supplier practices will ultimately lead to better product quality and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini plastic babies’

The following practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure mini plastic babies. This guide will help you navigate the procurement process efficiently, ensuring you find high-quality products that meet your business needs.

Step 1: Define Your Product Specifications

Clearly outline the specifications for the mini plastic babies you need. Consider factors such as size, material, colors, and any specific design features. Defining these criteria upfront ensures that you source products that align with your intended use, whether for party decorations, games, or craft projects.

Illustrative image related to mini plastic babies

- Size and Dimensions: Common sizes range from 1 to 2 inches.

- Material Quality: Ensure the plastic is durable and non-toxic, especially if the products will be used in environments where children are present.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. Look for manufacturers or wholesalers with a proven track record in producing mini plastic items. Utilize online marketplaces, industry directories, and trade shows to gather a list of potential vendors.

- Market Presence: Assess the supplier’s reputation in the industry.

- Product Range: Ensure they offer a variety of mini plastic babies to meet diverse needs.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers meet relevant safety and quality standards. This is particularly important when sourcing products that may be used by or around children.

- Safety Certifications: Check for compliance with international safety standards, such as ASTM or EN71.

- Quality Assurance: Inquire about their quality control processes to ensure consistency in product quality.

Step 4: Request Samples

Always request samples before finalizing a bulk order. This allows you to assess the product quality and suitability for your market.

- Material Inspection: Evaluate the feel, durability, and safety of the samples.

- Color and Design Verification: Ensure that the samples match your specifications in terms of color and design.

Step 5: Understand Pricing and Terms

Clarify pricing structures and terms of sale with potential suppliers. Understanding the financial aspects is crucial for budgeting and financial planning.

Illustrative image related to mini plastic babies

- Bulk Pricing: Inquire about discounts for larger orders.

- Payment Terms: Discuss payment methods and timelines to avoid any future misunderstandings.

Step 6: Assess Shipping and Delivery Options

Evaluate shipping options and delivery timelines. This is essential to ensure that you receive your products when needed, particularly for time-sensitive events like parties or promotions.

- Shipping Methods: Ask about available shipping methods and associated costs.

- Delivery Times: Confirm estimated delivery times based on your location and the supplier’s capabilities.

Step 7: Establish a Communication Plan

Set up a clear communication channel with your chosen supplier. Effective communication is vital for addressing any questions or issues that may arise during the procurement process.

- Contact Points: Designate specific contacts for sales, support, and logistics.

- Regular Updates: Agree on a schedule for updates regarding order status and any potential delays.

By following this checklist, B2B buyers can streamline their sourcing process for mini plastic babies, ensuring they procure products that meet their quality, safety, and budgetary requirements.

Comprehensive Cost and Pricing Analysis for mini plastic babies Sourcing

What Are the Key Cost Components in Sourcing Mini Plastic Babies?

When sourcing mini plastic babies, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The cost of raw materials, such as plastic resin, significantly impacts the overall price. The choice between high-quality, food-safe plastics and standard options can affect costs and should align with the intended use—whether for decorations, games, or crafts.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower wage standards might offer competitive pricing, but this could influence quality and lead times.

-

Manufacturing Overhead: This includes utilities, rent, and other operational costs incurred during production. Buyers should inquire about how these costs are calculated and what percentage they contribute to the final price.

-

Tooling: Initial tooling costs for molds can be substantial, especially for custom designs. This is typically a one-time expense but should be factored into the pricing for bulk orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures product safety and quality, especially for items used in children’s products. Higher QC standards may increase costs but can mitigate risks associated with product recalls.

-

Logistics: Shipping and handling costs can vary widely based on the origin of the goods and the destination. International shipping logistics often involve additional fees such as customs duties and tariffs.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the expected margin can help buyers negotiate better deals.

How Do Price Influencers Affect Sourcing Decisions for Mini Plastic Babies?

Several factors influence pricing that B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to maximize cost efficiency.

-

Specifications and Customization: Custom designs or unique specifications can increase production costs. Buyers should balance the desire for customization with budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., safety standards) can increase costs but are essential for products aimed at children. Buyers should prioritize quality to avoid potential liabilities.

-

Supplier Factors: The supplier’s location, reputation, and reliability can impact pricing. It’s advisable to conduct thorough research and consider suppliers with a proven track record.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) can influence total costs. Buyers should clarify responsibilities for shipping, insurance, and tariffs to avoid unexpected expenses.

What Negotiation Tips Can Help B2B Buyers Secure Better Pricing?

To achieve cost efficiency, B2B buyers should adopt strategic negotiation techniques:

-

Leverage Volume Discounts: When possible, consolidate orders to meet MOQ requirements and negotiate bulk pricing.

-

Research Market Prices: Stay informed about current market rates and competitor pricing to strengthen your negotiating position.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs related to quality, durability, and potential replacements.

-

Build Relationships with Suppliers: Establishing long-term partnerships can lead to better pricing, priority service, and more favorable terms.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local manufacturers can reduce shipping costs and lead times.

What Pricing Nuances Should International Buyers Be Aware Of?

International B2B buyers, particularly in regions like Africa, South America, and Europe, should be aware of several nuances:

Illustrative image related to mini plastic babies

-

Currency Fluctuations: Exchange rate volatility can affect pricing. It’s wise to agree on pricing in a stable currency or include clauses to address significant fluctuations.

-

Import Duties and Taxes: Understand the local regulations regarding import duties, taxes, and compliance to avoid unexpected costs.

-

Cultural Sensitivities: Be mindful of cultural preferences and safety regulations that might influence product specifications and marketing strategies.

Conclusion

The sourcing of mini plastic babies entails a multifaceted cost and pricing landscape. By understanding the various components and influencers, B2B buyers can make informed decisions that align with their budget and quality requirements. Always approach negotiations with a clear strategy and a comprehensive understanding of the total cost implications to ensure successful sourcing outcomes.

Alternatives Analysis: Comparing mini plastic babies With Other Solutions

Introduction to Alternative Solutions for Mini Plastic Babies

When considering party favors, decorations, or novelty items, mini plastic babies have established themselves as a popular choice. However, various alternatives can serve similar purposes, appealing to different market needs. This section compares mini plastic babies with alternative solutions, evaluating their performance, cost, ease of implementation, maintenance, and best use cases. By examining these options, B2B buyers can make informed decisions tailored to their specific requirements.

Comparison Table

| Comparison Aspect | Mini Plastic Babies | Edible Cake Toppers | Plush Baby Toys |

|---|---|---|---|

| Performance | Eye-catching, versatile | Attractive, edible | Soft, cuddly, interactive |

| Cost | Low-cost (approx. $1.99) | Moderate ($3-$5 each) | Higher ($10-$20 each) |

| Ease of Implementation | Simple to distribute | Requires proper handling | Requires storage space |

| Maintenance | Minimal (clean and store) | Short shelf-life | Moderate (cleaning needed) |

| Best Use Case | Parties, crafts, games | Celebrations, parties | Gifts, comfort items |

Detailed Breakdown of Alternatives

Edible Cake Toppers

Edible cake toppers are an appealing alternative to mini plastic babies, particularly for cake decorations at events like baby showers. They provide a dual function of decoration and treat, enhancing the overall experience for guests. The main advantage of edible toppers is their ability to be a part of the celebration without the need for disposal, appealing to sustainability-minded consumers. However, they have a shorter shelf life and require proper handling and storage, which can complicate logistics for B2B buyers. Additionally, they can be more expensive than mini plastic babies, potentially impacting budget considerations.

Illustrative image related to mini plastic babies

Plush Baby Toys

Plush baby toys are another alternative that offers a tactile and comforting experience, especially for young children. These toys can serve as both party favors and gifts, providing a lasting keepsake for guests. Their softness and interactive nature can create a deeper emotional connection compared to mini plastic babies. However, plush toys are generally more expensive and require more storage space, which may not be feasible for all businesses. Additionally, they necessitate regular cleaning to maintain hygiene, adding to their maintenance requirements.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right alternative to mini plastic babies depends on the specific context and goals of the event or promotion. For budget-conscious buyers looking for a quick and easy solution, mini plastic babies remain an attractive option due to their low cost and minimal maintenance. Conversely, if the goal is to create a memorable experience with edible treats or comforting keepsakes, investing in edible cake toppers or plush toys may yield better long-term value. B2B buyers should carefully evaluate their audience, event type, and budget constraints to choose the most suitable solution for their needs.

Essential Technical Properties and Trade Terminology for mini plastic babies

What Are the Key Technical Properties of Mini Plastic Babies?

When sourcing mini plastic babies for various applications—from party favors to craft projects—buyers should consider several critical technical properties that ensure product quality and suitability for their intended use.

-

Material Composition

Mini plastic babies are typically made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC). HDPE is known for its strength and durability, making it suitable for products that may be subjected to wear and tear. PVC, on the other hand, offers versatility in color and shape but requires careful handling due to potential toxicity in lower-grade versions. Understanding the material composition is crucial for compliance with safety regulations, especially in markets with strict guidelines regarding children’s products. -

Dimensions and Tolerances

The standard size for mini plastic babies usually ranges around 1.5 inches in length. However, precise dimensions are essential for specific applications, such as games or decorative uses. Tolerances in manufacturing must be kept within ±0.1 inches to ensure uniformity, which is vital for packaging and display purposes. Buyers should confirm these specifications to avoid discrepancies that could affect product appeal. -

Color Fastness and Stability

Color stability refers to the ability of the mini plastic babies to maintain their color when exposed to various environmental conditions, including light and moisture. This property is critical for items used in outdoor settings or as long-term decorations. Buyers should seek products that have been tested for color fastness to ensure that they will not fade over time, thus enhancing customer satisfaction and product longevity. -

Food Safety Compliance

If mini plastic babies are used in food-related applications—such as cake decorations or party favors—they must be certified as food-safe. This involves compliance with international safety standards, including FDA regulations in the U.S. or the European Food Safety Authority (EFSA) guidelines. Ensuring food safety compliance mitigates liability risks and enhances brand reputation in markets where safety is paramount. -

Choking Hazard Warnings

Given their small size, mini plastic babies pose a choking hazard for young children. Proper labeling and compliance with safety standards regarding warnings are necessary to protect manufacturers from legal liabilities. Buyers should ensure that products come with appropriate warnings and are marketed according to age-appropriate guidelines.

What Are Common Trade Terms Related to Mini Plastic Babies?

Understanding trade terminology is essential for navigating B2B transactions effectively. Here are several key terms relevant to the procurement of mini plastic babies.

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of mini plastic babies, buyers may engage with OEMs to produce customized designs or colors that align with their branding strategy. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of product that a supplier is willing to sell. For mini plastic babies, MOQs can vary significantly depending on the manufacturer and can impact pricing and inventory management for buyers. Understanding MOQ is crucial for budgeting and supply chain planning. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specified products. When seeking mini plastic babies, an RFQ can help buyers compare prices, lead times, and terms of service from different suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international trade rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for international buyers of mini plastic babies to ensure clarity in transaction logistics and responsibilities. -

Lead Time

Lead time refers to the time it takes from placing an order to the delivery of goods. For mini plastic babies, understanding lead times is crucial for inventory management and planning seasonal promotions, especially in regions with varying shipping times.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance their purchasing strategy and ensure product quality in the competitive market for mini plastic babies.

Navigating Market Dynamics and Sourcing Trends in the mini plastic babies Sector

What Are the Current Market Dynamics for Mini Plastic Babies in B2B?

The mini plastic babies market is witnessing a significant transformation, driven by evolving consumer preferences and innovative sourcing trends. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly drawn to these products for various applications, including party favors, educational tools, and promotional items. The global market is expanding as mini plastic babies are integrated into diverse sectors such as event planning, education, and marketing, reflecting a growing trend toward playful and engaging products.

Emerging technologies are reshaping sourcing strategies, with a surge in online marketplaces facilitating easier access to suppliers. Buyers can now leverage data analytics to identify trends and forecast demand, allowing for more strategic purchasing decisions. Furthermore, the rise of e-commerce platforms enables buyers to source mini plastic babies directly from manufacturers, streamlining the supply chain and reducing costs. Key trends include customization options, where businesses can order products tailored to specific themes or branding requirements, enhancing their market appeal.

How Is Sustainability Shaping the Mini Plastic Babies Sector?

Sustainability has become a critical factor in sourcing mini plastic babies, as consumers and businesses alike become more environmentally conscious. The production of plastic products is under scrutiny due to its environmental impact, prompting buyers to seek suppliers committed to sustainable practices. This includes the use of recycled materials, eco-friendly production processes, and adherence to ethical sourcing standards.

B2B buyers should prioritize suppliers who hold relevant green certifications, such as ISO 14001 for environmental management or certifications for recycled content. Implementing sustainable sourcing practices not only mitigates environmental impact but also enhances brand reputation, appealing to a growing demographic of eco-conscious consumers. Additionally, transparency in the supply chain is essential, as buyers are increasingly interested in understanding the origins of the products they purchase.

What Is the Historical Context of Mini Plastic Babies in the Market?

The mini plastic babies category has evolved significantly since its inception, originally emerging as novelty items for party favors and games. Their popularity surged in the late 20th century, coinciding with a growing interest in themed events and creative party planning. Over the years, these products have diversified in design and application, finding utility in educational settings and as promotional tools in marketing campaigns.

As the market continues to evolve, mini plastic babies are no longer just playful decorations; they have become versatile assets in various industries. The evolution of consumer trends towards personalization and sustainability is likely to further shape the future of this sector, providing opportunities for international B2B buyers to innovate and differentiate their offerings.

Illustrative image related to mini plastic babies

Frequently Asked Questions (FAQs) for B2B Buyers of mini plastic babies

-

How do I ensure the quality of mini plastic babies from suppliers?

To ensure quality, request product samples from potential suppliers before placing large orders. Look for certifications that indicate compliance with safety standards, such as ASTM or EN71, especially if they will be used in children’s products. Establish a quality assurance process that includes third-party inspections to verify the quality of materials and manufacturing practices. Additionally, reviewing customer feedback and ratings can provide insights into the supplier’s reliability and product quality. -

What is the best way to source mini plastic babies for my business?

The best way to source mini plastic babies is to identify reputable manufacturers or wholesalers with experience in producing similar products. Utilize online platforms such as Alibaba, Global Sources, or industry-specific trade fairs to connect with suppliers. It’s also beneficial to network with industry peers for recommendations. Always perform due diligence, including background checks on suppliers, to ensure they meet your quality and compliance standards. -

What are the common minimum order quantities (MOQs) for mini plastic babies?

MOQs for mini plastic babies typically range from 1,000 to 10,000 units, depending on the supplier and customization options. Lower MOQs may be available for standard products, while custom designs may require higher quantities to justify production costs. It’s essential to discuss your specific needs with suppliers to negotiate MOQs that align with your business model while considering the costs associated with larger orders. -

How can I customize mini plastic babies for my brand?

Customization options for mini plastic babies can include color variations, packaging design, and even unique shapes. Many manufacturers offer customizable molds for larger orders. To initiate the process, provide your design specifications and request a prototype to review before proceeding with mass production. Ensure to discuss lead times and costs associated with customization to plan your inventory effectively. -

What payment terms should I expect when sourcing mini plastic babies internationally?

Payment terms can vary widely among suppliers but are typically negotiated based on order size and the relationship established. Common terms include a 30% deposit upfront and the remaining 70% before shipment. Some suppliers may offer credit terms or letter of credit options for larger orders. Always clarify payment terms in the contract to avoid misunderstandings and ensure secure transactions. -

What are the shipping and logistics considerations for importing mini plastic babies?

Shipping and logistics for importing mini plastic babies involve selecting a reliable freight forwarder who understands international trade regulations. Consider shipping methods (air vs. sea) based on your budget and urgency. Be aware of customs duties and import taxes applicable in your country, which can affect overall costs. Ensure proper documentation is prepared to facilitate smooth customs clearance. -

How do I vet suppliers for mini plastic babies?

Vetting suppliers involves researching their business history, customer reviews, and production capabilities. Request references from previous clients and conduct site visits if possible. Verify certifications related to product safety and manufacturing practices. Engage in direct communication to assess their responsiveness and willingness to accommodate your requirements. A thorough vetting process helps mitigate risks associated with international sourcing. -

What safety standards should mini plastic babies comply with for international markets?

Mini plastic babies must comply with specific safety standards depending on the target market. For example, in the EU, they should adhere to EN71 standards, while in the U.S., they must meet ASTM F963 regulations. These standards govern aspects such as material safety, choking hazards, and flammability. Ensure your suppliers are knowledgeable about these regulations and can provide the necessary documentation to demonstrate compliance for your intended market.

Top 4 Mini Plastic Babies Manufacturers & Suppliers List

1. Hobby Lobby – Soft Mini Babies

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {‘name’: ‘Soft Mini Babies’, ‘sku’: ‘393033’, ‘original_price’: ‘$1.99’, ‘description’: ‘These Soft Mini Babies make a humorous party favor at a baby shower. Put these plastic babies in treat bags, on cakes, on cupcakes, and much more, or use them for craft projects! Celebrate in fun style!’, ‘dimensions’: ‘1.5″ x 1.13″‘, ‘material’: ‘Plastic’, ‘color’: ‘Peach, Yellow, Black & Blue’, ‘care_and_saf…

2. Pinterest – Miniature Baby Dolls

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Tiny plastic babies, measuring 1.25 inches long and 0.5 inches wide, featuring black painted hair. Ideal for baby showers and various crafts. Includes mini plastic sleeping babies and realistic miniature baby dolls made from clay and silicone, complete with tiny accessories like pacifiers and bottles.

3. Asbury Collegian – Tiny Plastic Babies

Domain: theasburycollegian.com

Registered: 2011 (14 years)

Introduction: Tiny plastic babies, created by sophomore Jonah Fern, are hidden around Asbury’s campus as part of a fun tradition. Over 150 neonate plastic figures have been distributed, encouraging students to find them as a de-stressing activity. The initiative has sparked a friendly competition among students, with some, like Madelyn Barren, actively collecting them. Fern plans to purchase more plastic babies…

4. Mini Plastic Babies – Bulk Options Available

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Mini Plastic Babies available in various quantities and prices. Examples include: 120 Mini Plastic Babies (1 Inch) for $16.99, 100pcs Tiny Plastic Mini Babies for $13.78, 60 Pieces Mini Plastic Babies for $11.27, and 48 Mini Babies for $7.99. All products are brand new with free delivery options. Suitable for baby shower games and party favors.

Strategic Sourcing Conclusion and Outlook for mini plastic babies

In the dynamic market for mini plastic babies, strategic sourcing emerges as a critical factor for international B2B buyers. Understanding the diverse applications—ranging from party favors to craft projects—enables businesses to tailor their sourcing strategies effectively. It is essential to recognize the importance of quality materials and compliance with safety standards, especially when targeting diverse markets across Africa, South America, the Middle East, and Europe.

Collaboration with reliable suppliers can facilitate access to innovative product designs that resonate with local cultural preferences. Additionally, leveraging e-commerce platforms for bulk purchases can enhance operational efficiency and reduce costs, ultimately improving profit margins.

Looking ahead, the market for mini plastic babies is poised for growth, driven by trends in event planning and creative crafts. International buyers are encouraged to explore new sourcing opportunities and consider expanding their product offerings to meet evolving consumer demands. By prioritizing strategic sourcing, businesses can not only enhance their competitive edge but also ensure long-term success in this vibrant market. Embrace these insights and take proactive steps toward optimizing your supply chain today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.