A Deep Dive into Metal Fabric Solution

Introduction: Navigating the Global Market for metal fabric

In the ever-evolving landscape of global commerce, sourcing high-quality metal fabric presents a unique challenge for B2B buyers. With its diverse applications in architecture, automotive, and industrial sectors, understanding the nuances of metal fabric is crucial for making informed purchasing decisions. This guide serves as a comprehensive resource, exploring various types of metal fabric, their specific applications, and essential considerations for supplier vetting. We delve into critical factors such as material selection, cost analysis, and innovative design options that can significantly enhance your projects.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including emerging markets such as Nigeria and Brazil—will find actionable insights tailored to their needs. This guide empowers you to navigate the complexities of sourcing metal fabric, equipping you with the knowledge to identify reliable suppliers and negotiate favorable terms. By understanding the intricacies of metal fabric—from flexible designs to rigid structures—you can optimize your procurement strategy and ensure your projects are not only aesthetically pleasing but also structurally sound.

Whether you are looking to enhance architectural features with stunning metallic mesh or require robust materials for industrial applications, this guide is designed to facilitate your journey in the global market for metal fabric.

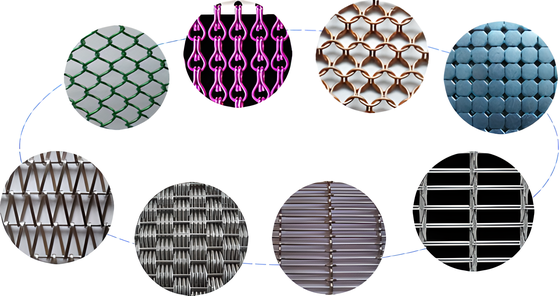

Understanding metal fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible Cable Fabric | Composed of precision wire cable, allowing flexibility in one or both directions. | Wall coverings, partitions, railings, enclosures | Pros: Lightweight, versatile designs. Cons: May require specific framing for installation. |

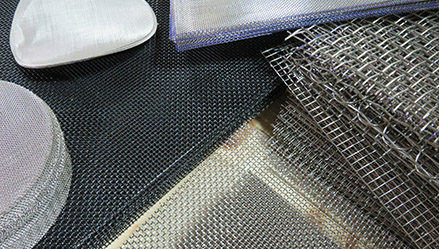

| Rigid Metal Mesh | Constructed from solid wires in both warp and weft directions, providing stiffness. | Architectural facades, security applications, fencing | Pros: High durability and strength. Cons: Less adaptable to complex shapes. |

| Acoustic Mesh Panels | Integrates sound-absorbing materials, designed to reduce noise. | Auditoriums, conference rooms, theaters | Pros: Enhances sound quality, aesthetically pleasing. Cons: Can be more expensive than standard options. |

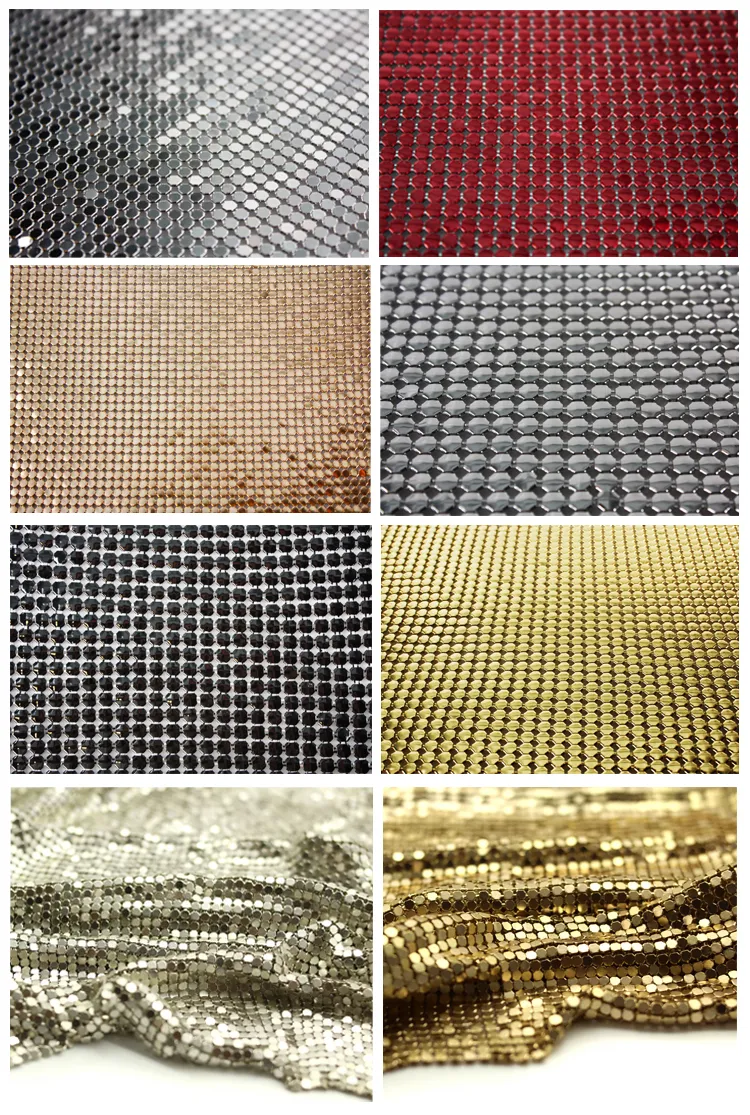

| Metallic Fabric | Available in various materials like polyester and PET, often with metallic finishes. | Fashion, upholstery, decorative applications | Pros: Eye-catching appearance, diverse applications. Cons: May not be suitable for high-stress environments. |

| Expanded Metal | Features a diamond-shaped pattern, allowing airflow while maintaining strength. | Grating, safety barriers, walkways | Pros: Lightweight yet strong; excellent for drainage. Cons: Limited aesthetic appeal for some applications. |

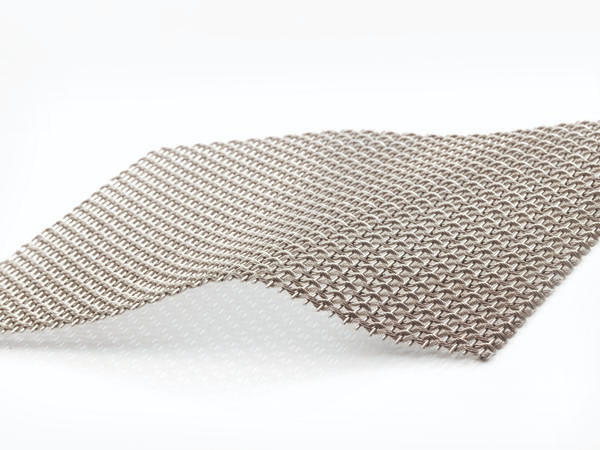

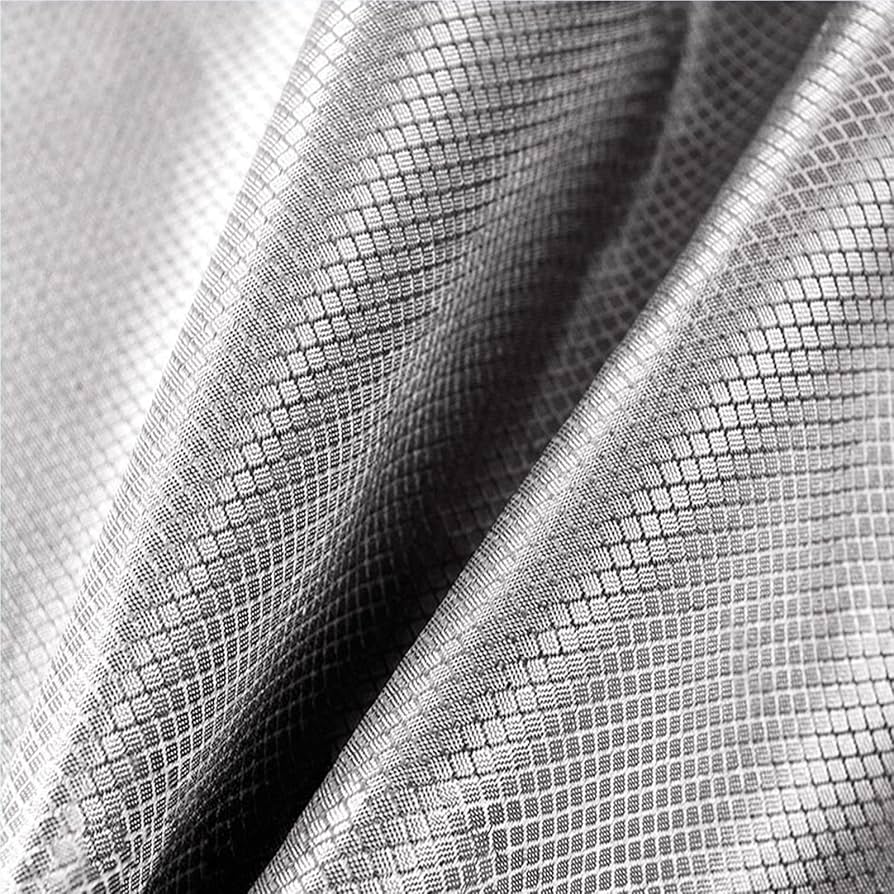

What Are the Characteristics of Flexible Cable Fabric in Metal Applications?

Flexible cable fabric is a versatile option made from precision wire cables, providing adaptability in design and application. This type can be flexible in one or both directions, making it suitable for diverse uses such as wall coverings, partitions, and railings. When purchasing, buyers should consider the specific framing requirements, as the installation may necessitate custom solutions. Additionally, the lightweight nature allows for easier handling and installation, which can be advantageous for large projects.

How Does Rigid Metal Mesh Differ from Other Metal Fabrics?

Rigid metal mesh is characterized by its solid wire construction, offering high durability and strength. It is typically used in architectural facades, security applications, and fencing where structural integrity is paramount. Buyers should note that while rigid mesh provides excellent strength, its inflexibility may limit its use in projects requiring complex shapes or configurations. The long-term value comes from its robustness, making it a sound investment for high-traffic or security-sensitive environments.

Illustrative image related to metal fabric

What Are the Advantages of Acoustic Mesh Panels?

Acoustic mesh panels incorporate sound-absorbing materials, making them ideal for environments where sound control is crucial, such as auditoriums and conference rooms. These panels not only enhance sound quality but also add an aesthetic element to the space. However, their advanced design often comes at a higher cost compared to traditional metal fabrics. Buyers should evaluate their sound management needs and budget constraints when considering these options, as the investment can lead to significant improvements in acoustic performance.

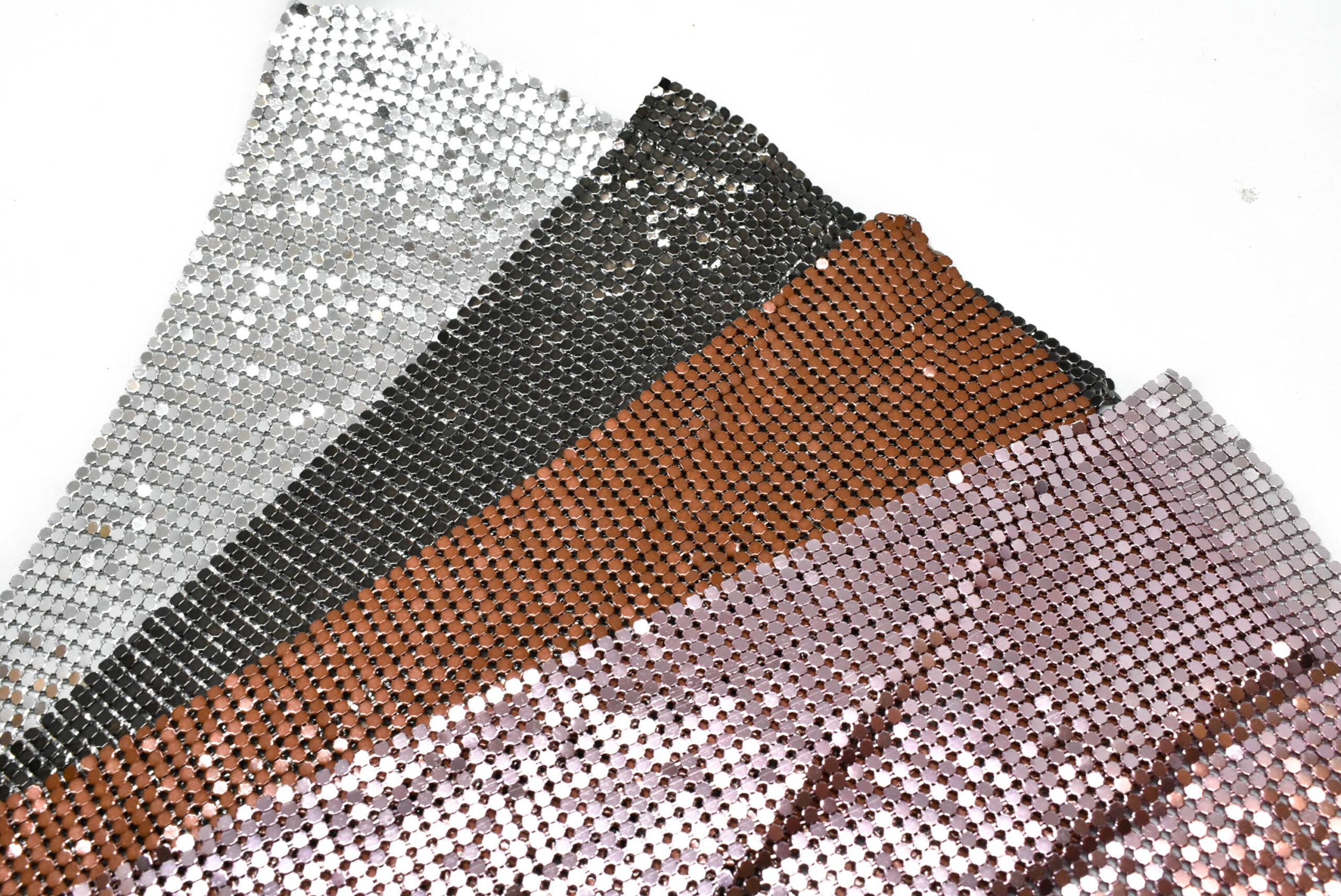

In What Scenarios Would Metallic Fabric Be Most Effective?

Metallic fabric, often made from materials like polyester and PET, is popular in fashion and decorative applications due to its striking appearance. Its versatility allows for use in upholstery and various design elements. While the eye-catching finish can elevate a project, buyers must consider that metallic fabrics may not withstand high-stress environments as effectively as other types. Therefore, it is essential to assess the intended application and durability requirements when selecting this fabric.

Why Is Expanded Metal a Practical Choice for Structural Applications?

Expanded metal features a diamond-shaped pattern that allows for airflow while maintaining strength, making it suitable for grating, safety barriers, and walkways. Its lightweight yet robust nature enables effective drainage and reduces the risk of slipping. However, the aesthetic appeal may be limited for certain applications, which buyers should keep in mind. When considering expanded metal, it is crucial to evaluate the balance between functionality and appearance to ensure it meets project requirements effectively.

Key Industrial Applications of metal fabric

| Industry/Sector | Specific Application of metal fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architecture & Design | Decorative Wall Panels | Enhances aesthetic appeal and provides durability | Material options (stainless steel, aluminum), custom designs, and finishes |

| Automotive | Grilles and Ventilation Covers | Improves airflow while maintaining structural integrity | Corrosion resistance, weight considerations, and compliance with safety standards |

| Construction | Safety Barriers and Fencing | Provides security and visibility in construction sites | Compliance with local regulations, flexibility in design, and durability against environmental factors |

| Industrial Equipment | Filtration Systems | Enhances efficiency by allowing optimal airflow and preventing contamination | Mesh size, material compatibility, and resistance to chemicals |

| Interior Design | Acoustic Panels | Reduces noise levels while adding a modern touch | Acoustic performance specifications, aesthetic options, and installation requirements |

How is Metal Fabric Used in Architecture & Design?

In the architecture and design sector, metal fabric is often utilized for decorative wall panels. These panels not only enhance the aesthetic appeal of spaces but also provide a durable and low-maintenance surface. For international buyers, particularly in regions like Africa and South America, sourcing options should include various material finishes, such as stainless steel or aluminum, to suit diverse architectural styles. Custom designs can also be requested to meet specific project requirements, ensuring that the panels align with the overall vision.

Illustrative image related to metal fabric

What Role Does Metal Fabric Play in Automotive Applications?

In the automotive industry, metal fabric is commonly employed in grilles and ventilation covers. These components are essential for improving airflow to engines while maintaining the structural integrity of vehicles. Buyers in this sector should prioritize corrosion-resistant materials that can withstand harsh environmental conditions. Additionally, compliance with safety standards is crucial, as automotive applications often face rigorous testing and regulation.

Why is Metal Fabric Important for Construction Safety?

Metal fabric serves a critical role in construction through its application in safety barriers and fencing. These solutions provide essential security and visibility on construction sites, helping to prevent unauthorized access and accidents. For international buyers, it is important to consider local regulations regarding construction safety, as well as the flexibility in design that metal fabric offers. Durability against environmental factors, such as rust and corrosion, is also a key consideration for long-term use.

How Does Metal Fabric Enhance Industrial Equipment Efficiency?

In industrial settings, metal fabric is extensively used in filtration systems. Its design allows for optimal airflow while preventing contamination, thereby enhancing operational efficiency. Buyers should focus on mesh size and material compatibility to ensure that the metal fabric meets specific filtration requirements. Additionally, resistance to chemicals is crucial for applications in industries such as pharmaceuticals and food processing, where cleanliness and safety are paramount.

What Benefits Does Metal Fabric Provide in Interior Design?

Metal fabric is increasingly popular in interior design for its application in acoustic panels. These panels effectively reduce noise levels in spaces, making them ideal for offices, restaurants, and public venues. International buyers should consider acoustic performance specifications to ensure that the chosen metal fabric meets the soundproofing needs of their projects. Furthermore, the aesthetic options available allow for creative installations that enhance the overall design of a space.

3 Common User Pain Points for ‘metal fabric’ & Their Solutions

Scenario 1: Navigating Customization Challenges with Metal Fabric

The Problem: B2B buyers often face the challenge of sourcing metal fabric that meets specific project requirements, such as unique dimensions, colors, and textures. For instance, a construction company may need a flexible metal fabric that not only fits certain architectural specifications but also complements the aesthetic of the building. The lack of available options can lead to delays in project timelines and increased costs due to rework or modifications.

Illustrative image related to metal fabric

The Solution: To effectively navigate these customization challenges, buyers should engage directly with manufacturers and suppliers who specialize in bespoke solutions. It’s essential to initiate discussions about specific project needs early in the procurement process. Request samples of different alloys, colors, and textures to evaluate compatibility with your project. Additionally, leveraging advanced technology like CAD (Computer-Aided Design) can help visualize how different fabric options will integrate into your design. Establishing a clear line of communication with suppliers about your customization requirements will not only expedite the process but also ensure that the final product aligns perfectly with your vision.

Scenario 2: Addressing Durability Concerns in Harsh Environments

The Problem: For businesses operating in demanding environments—such as oil and gas, mining, or coastal areas—durability is a critical concern when selecting metal fabrics. These conditions can lead to accelerated wear and corrosion, making it essential for buyers to choose materials that can withstand such challenges. A failure to do so can result in costly repairs, safety hazards, and disruptions in operations.

The Solution: To address durability concerns, buyers should prioritize sourcing high-quality metal fabrics made from corrosion-resistant materials, such as stainless steel or specialized alloys. It is vital to conduct thorough research into the specific environmental conditions where the metal fabric will be used. Request certifications or test results from suppliers that demonstrate the fabric’s performance against factors like UV exposure, moisture, and chemical resistance. Furthermore, consider investing in protective coatings or treatments that can enhance the longevity of the fabric. Building a partnership with a supplier that offers ongoing support and guidance regarding maintenance can also help mitigate long-term risks associated with durability.

Scenario 3: Managing Costs Without Compromising Quality

The Problem: B2B buyers frequently grapple with the challenge of balancing cost constraints with the need for high-quality metal fabrics. In industries such as construction and manufacturing, budget overruns can occur when low-cost materials lead to premature failures or safety issues. This creates a dilemma where buyers must choose between affordability and reliability, often resulting in subpar outcomes.

The Solution: To manage costs effectively while ensuring quality, buyers should adopt a strategic sourcing approach. Begin by conducting a thorough cost-benefit analysis that evaluates not just the initial price of the metal fabric, but also its lifecycle costs, including maintenance and replacement. Collaborate with suppliers to explore bulk purchasing options or long-term contracts that may yield cost savings. Additionally, consider investing in higher-quality fabrics that, while more expensive upfront, will ultimately reduce costs associated with repairs and replacements. Engaging in supplier negotiations to explore value-added services, such as installation support or technical guidance, can further enhance the overall value proposition without significantly impacting the budget.

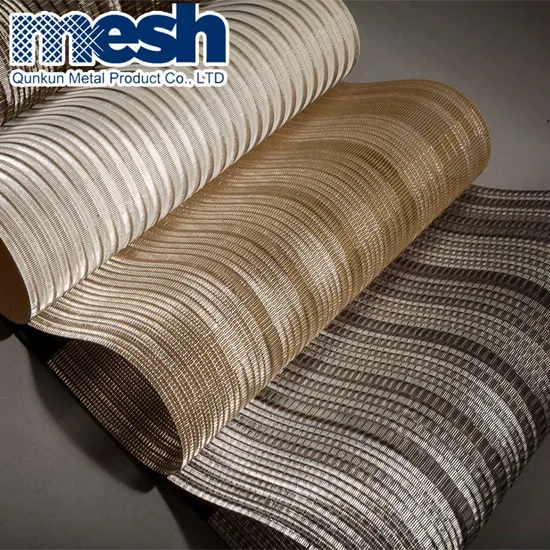

Strategic Material Selection Guide for metal fabric

What Are the Key Properties of Common Materials Used in Metal Fabric?

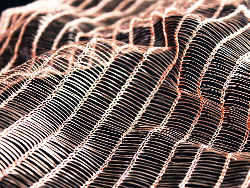

When selecting metal fabric for various applications, understanding the properties of the materials involved is crucial. Here, we analyze four common materials: stainless steel, aluminum, copper, and brass. Each material has unique characteristics that influence performance, durability, and cost.

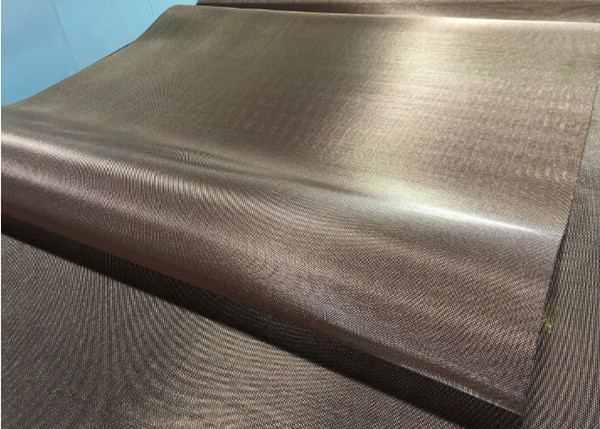

How Does Stainless Steel Perform in Metal Fabric Applications?

Stainless steel is renowned for its exceptional corrosion resistance, making it suitable for a wide range of environments, especially those exposed to moisture or chemicals. It typically withstands temperatures up to 1,600°F (870°C) without losing structural integrity. The durability of stainless steel ensures a long lifespan, which is a significant advantage for B2B buyers looking for cost-effective solutions over time.

Illustrative image related to metal fabric

However, the manufacturing complexity of stainless steel can lead to higher initial costs compared to other materials. While its strength is a benefit, it may not be suitable for applications requiring high flexibility, as it is generally more rigid. Buyers in regions like Africa and South America should consider local availability and compliance with international standards such as ASTM for corrosion resistance.

What Advantages Does Aluminum Offer for Metal Fabric?

Aluminum is lightweight yet strong, making it a popular choice for applications where weight is a critical factor, such as in aerospace or automotive industries. Its excellent corrosion resistance, particularly when anodized, enhances its longevity, while its thermal and electrical conductivity is beneficial for specific applications.

The primary drawback of aluminum is its lower strength compared to stainless steel, which may limit its use in heavy-duty applications. Additionally, while aluminum is generally more affordable, the cost can increase significantly if specialized coatings are required for enhanced performance. International buyers should ensure compliance with standards like JIS for aluminum products, especially in markets like the Middle East.

Illustrative image related to metal fabric

Why Is Copper Considered in Metal Fabric Applications?

Copper is known for its superior electrical and thermal conductivity, making it ideal for applications in electronics and heat exchangers. Its natural antimicrobial properties also make it suitable for environments requiring hygiene, such as hospitals and food processing facilities.

However, copper is prone to corrosion in certain environments, which can limit its application without protective coatings. Additionally, the cost of copper is relatively high, which may deter budget-conscious buyers. For international buyers, understanding the local market for copper and compliance with relevant standards is essential, particularly in Europe, where regulations may be stricter.

What Role Does Brass Play in Metal Fabric Solutions?

Brass, an alloy of copper and zinc, offers a unique combination of strength and corrosion resistance. It is often used in decorative applications due to its attractive appearance and is also suitable for plumbing and electrical fittings due to its excellent machinability.

The downside of brass is its susceptibility to dezincification in certain environments, which can compromise its integrity over time. Additionally, while brass is generally more affordable than stainless steel, it can be more expensive than aluminum. Buyers should consider the specific application requirements and local standards when selecting brass, especially in regions with varying environmental conditions like Nigeria and Brazil.

Summary Table of Material Properties for Metal Fabric

| Material | Typical Use Case for metal fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Architectural applications, industrial use | Excellent corrosion resistance | Higher initial cost, less flexible | High |

| Aluminum | Aerospace, automotive, and structural applications | Lightweight and good corrosion resistance | Lower strength compared to steel | Medium |

| Copper | Electronics, heat exchangers, plumbing | Superior conductivity, antimicrobial properties | Prone to corrosion, high cost | High |

| Brass | Decorative fittings, plumbing, electrical | Attractive appearance, good machinability | Susceptible to dezincification | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions tailored to their specific application needs and regional standards.

Illustrative image related to metal fabric

In-depth Look: Manufacturing Processes and Quality Assurance for metal fabric

What Are the Key Stages in the Manufacturing Process of Metal Fabric?

The manufacturing process of metal fabric involves several critical stages that ensure the final product meets the desired specifications. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, such as stainless steel or other alloys. The chosen materials undergo thorough inspection to ensure they meet specific standards. This stage may also involve cutting the metal into appropriate shapes and sizes for further processing.

-

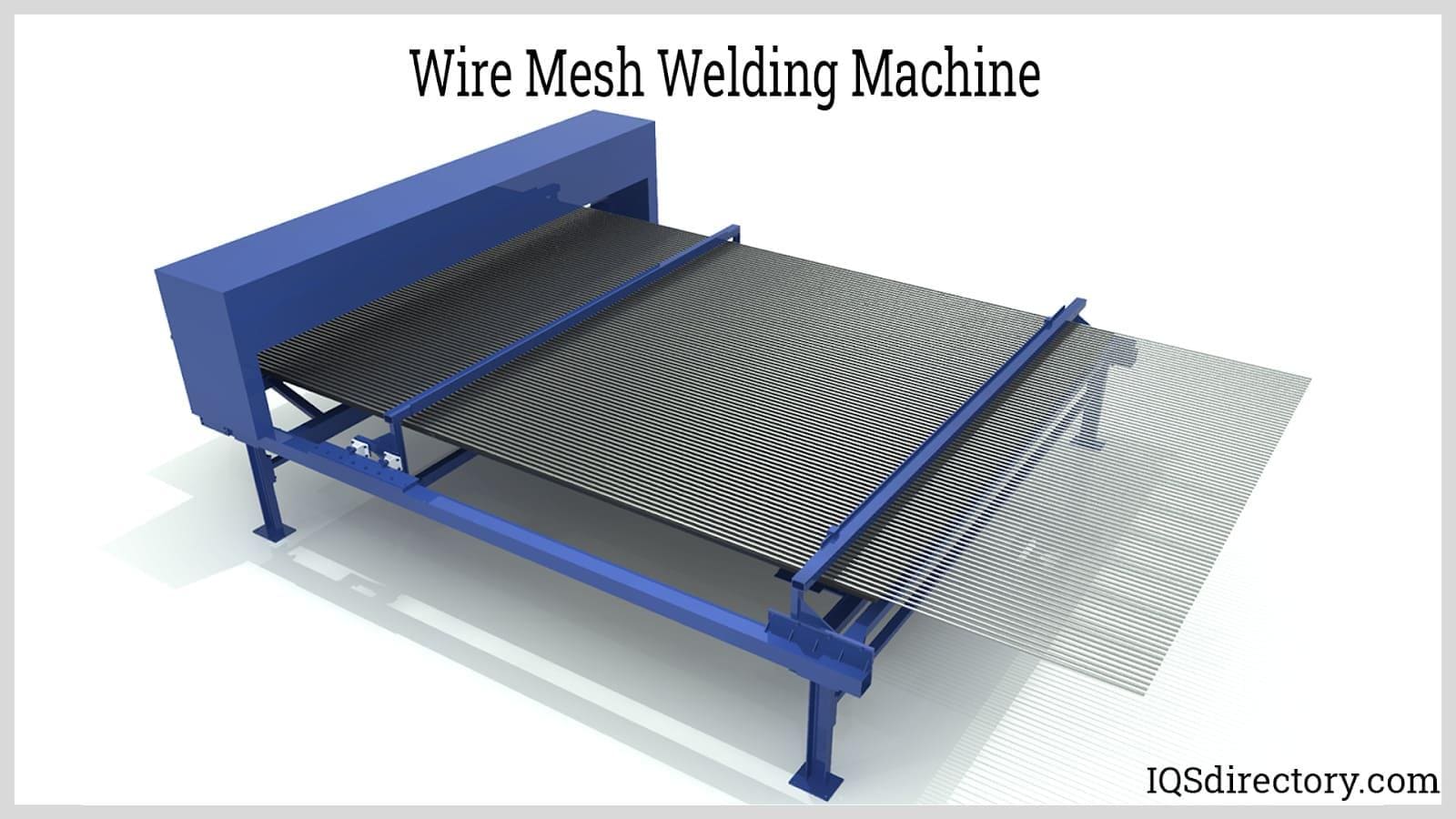

Forming: This stage utilizes various techniques, such as weaving or mesh formation, to create the desired fabric structure. For instance, flexible metal fabrics may be produced through a combination of precision wire cables woven in the warp direction and solid wires in the weft direction. The forming process can also include techniques like stamping or laser cutting, depending on the design requirements.

-

Assembly: After the forming stage, individual components may be assembled into larger sections or custom designs. This stage may involve welding, soldering, or using mechanical fasteners to ensure durability and structural integrity.

-

Finishing: The final stage involves applying surface treatments such as coatings, plating, or polishing to enhance aesthetics and protect against corrosion. This step may also include quality checks to ensure the fabric meets the required specifications for strength, flexibility, and visual appeal.

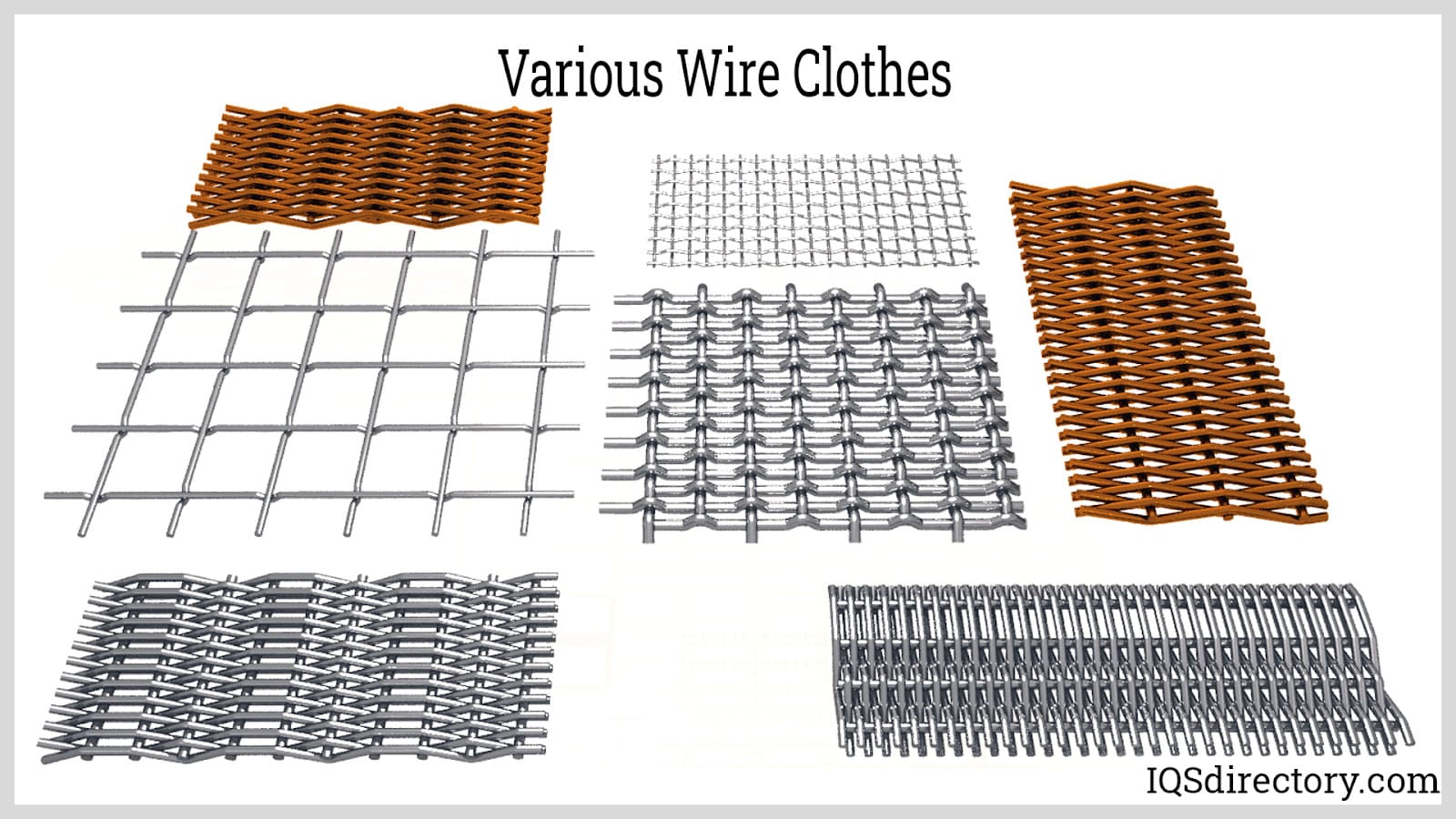

Which Techniques Are Commonly Used in Metal Fabric Production?

Various techniques are employed in the production of metal fabrics, each contributing to the unique properties of the final product.

-

Weaving: This is the most common technique for creating flexible metal fabrics. The weaving process allows for different patterns and densities, resulting in fabrics that can be tailored to specific applications, such as architectural designs or industrial uses.

-

Laser Cutting: This technique is often used to achieve intricate designs and precise dimensions. Laser cutting allows for greater flexibility in design while maintaining high levels of accuracy.

-

Coating and Plating: Surface treatments can enhance the durability and aesthetic qualities of metal fabrics. Techniques such as powder coating or anodizing provide additional protection against environmental factors, ensuring longevity in various applications.

What Quality Control Standards Should B2B Buyers Consider?

Quality assurance is paramount in the metal fabric industry, particularly for international B2B buyers who require consistent quality across different suppliers. Understanding the relevant quality control standards can help buyers assess potential suppliers effectively.

-

International Standards: Compliance with standards such as ISO 9001 is critical for ensuring a quality management system is in place. This standard emphasizes continual improvement and customer satisfaction, which are essential for B2B transactions.

-

Industry-Specific Certifications: Depending on the application, other certifications may be relevant. For instance, the CE mark indicates conformity with European health, safety, and environmental protection standards, while API standards are essential for products used in the oil and gas sector.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that each stage meets the required standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): Before production begins, materials are inspected to ensure they meet specifications. This includes checking for defects in raw materials and verifying certification documents.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic inspections are conducted to monitor production quality. This includes checking dimensions, structural integrity, and adherence to specifications at various stages.

-

Final Quality Control (FQC): After the production is complete, the final product undergoes a thorough inspection. This includes testing for durability, flexibility, and other performance metrics relevant to the intended application.

What Common Testing Methods Are Employed in Metal Fabric Quality Assurance?

Several testing methods are employed to verify the quality of metal fabrics, ensuring they meet industry standards and customer expectations. Common methods include:

Illustrative image related to metal fabric

-

Tensile Testing: This method evaluates the strength and flexibility of the fabric, providing insights into how the material will perform under stress.

-

Corrosion Resistance Testing: For fabrics intended for outdoor or industrial applications, corrosion resistance tests are essential to ensure longevity in harsh environments.

-

Visual Inspection: A thorough visual inspection is often the first line of defense against defects. Inspectors look for inconsistencies in weaving, surface defects, and overall aesthetics.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several proactive steps to verify the quality control practices of potential suppliers.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control systems, and adherence to industry standards. This firsthand observation can provide critical insights into the supplier’s capabilities.

-

Quality Assurance Reports: Requesting documentation on quality control processes and testing results can help buyers verify compliance with international and industry-specific standards. These reports should detail the testing methods used, results, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent assessments can provide unbiased evaluations of the supplier’s quality control practices and product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control in different regions is essential for successful transactions.

-

Cultural Differences: Different regions may have varying standards and practices regarding quality assurance. It is crucial for buyers to familiarize themselves with local practices and expectations to ensure smooth communication and effective collaboration.

-

Regulatory Compliance: Buyers must be aware of the regulatory requirements specific to their industry and region. This includes understanding local certifications, import regulations, and any additional documentation required for compliance.

-

Supply Chain Considerations: The complexity of international supply chains can impact quality control. Buyers should consider factors such as lead times, transportation conditions, and customs regulations, which can all affect product quality upon arrival.

By comprehensively understanding the manufacturing processes and quality assurance measures in the metal fabric industry, B2B buyers can make informed decisions, ensuring they select suppliers that meet their quality expectations while adhering to international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal fabric’

Introduction

Navigating the procurement of metal fabric can be complex, especially for international B2B buyers. This practical sourcing guide provides a step-by-step checklist to streamline your decision-making process, ensuring you acquire the right materials for your specific needs. By following these steps, you can make informed choices that align with your project requirements and business goals.

Illustrative image related to metal fabric

1. Define Your Technical Specifications

Start by clearly outlining the technical specifications of the metal fabric you need. Consider factors such as material type (e.g., stainless steel, aluminum), weave pattern, flexibility, and weight. Defining these specifications upfront helps in narrowing down suppliers who can meet your exact requirements and reduces the risk of mismatched products.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers of metal fabric. Look for companies with a strong reputation in the industry, particularly those that specialize in your specific type of fabric. Utilize online directories, industry forums, and trade shows to gather a list of suppliers, paying attention to their experience and client testimonials.

3. Evaluate Supplier Certifications

Verify that potential suppliers possess relevant certifications that guarantee quality and compliance with industry standards. Certifications such as ISO 9001 or specific material certifications indicate that the supplier adheres to rigorous quality management systems. These credentials can provide peace of mind regarding product reliability and safety.

Illustrative image related to metal fabric

4. Request Samples for Evaluation

Before making a bulk order, request samples of the metal fabric to evaluate its quality and suitability. Assess the samples for texture, durability, and compliance with your specifications. This step is crucial as it allows you to physically inspect the product and ensures it meets your standards before finalizing the purchase.

5. Assess Production Capabilities and Lead Times

Inquire about the supplier’s production capabilities and lead times to ensure they can meet your project timelines. Understanding their manufacturing processes, capacity, and any potential delays helps you plan accordingly. A supplier with the ability to scale production quickly can be advantageous for large projects or urgent needs.

6. Negotiate Terms and Pricing

Engage in discussions about pricing, payment terms, and delivery schedules. Be clear about your budget constraints and explore options for bulk discounts or long-term contracts. Negotiating favorable terms can significantly impact your overall project costs and enhance your partnership with the supplier.

Illustrative image related to metal fabric

7. Finalize the Order and Confirm Logistics

Once you have selected a supplier, finalize the order by confirming all details, including specifications, pricing, and delivery timelines. Ensure that logistics are arranged for shipping, especially if dealing with international suppliers. Clear communication during this stage is essential to prevent misunderstandings and ensure a smooth procurement process.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing metal fabric, ensuring that they secure high-quality materials that meet their specific needs.

Comprehensive Cost and Pricing Analysis for metal fabric Sourcing

What Are the Key Cost Components in Metal Fabric Sourcing?

When sourcing metal fabric, understanding the underlying cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The choice of metal—such as stainless steel, aluminum, or custom alloys—significantly impacts the cost. Additionally, variations in surface treatments and finishes can add to the material costs.

Labor: Labor costs can vary based on the complexity of the fabrication process and the skill level required. In regions with higher labor costs, such as Europe, this can affect overall pricing.

Illustrative image related to metal fabric

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance of machinery. Efficient production processes can help minimize overhead and lower costs.

Tooling: Initial tooling costs can be significant, especially for custom designs. Buyers should consider these costs as part of the total investment, particularly for low-volume orders.

Quality Control: Rigorous QC processes ensure that the final products meet specifications. However, enhanced QC measures can lead to increased costs, which should be factored into pricing.

Logistics: Transportation and shipping costs are critical, especially for international orders. Factors like distance, mode of transport, and customs duties can add to logistics expenses.

Margin: Finally, suppliers typically include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Affect Metal Fabric Costs?

Several factors can influence the pricing of metal fabric, which buyers should carefully consider:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating favorable terms for bulk purchases can yield significant savings.

Specifications and Customization: Custom designs and specifications can increase costs due to additional labor and tooling requirements. Buyers should balance their need for customization with cost considerations.

Illustrative image related to metal fabric

Material Quality and Certifications: Higher-quality materials and necessary certifications (like ISO or CE) can lead to increased costs. Buyers should assess whether these certifications are essential for their application.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their proven track record, while newer entrants might offer lower prices to capture market share.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining responsibilities in shipping and logistics. Terms like CIF (Cost, Insurance, and Freight) can affect the final price and total cost of ownership.

What Are the Best Practices for Negotiating Metal Fabric Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing:

Illustrative image related to metal fabric

-

Research and Compare: Collect quotes from multiple suppliers to understand market rates. This information empowers buyers to negotiate from a position of strength.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Suppliers may be more willing to offer discounts or flexible payment terms to established clients.

-

Evaluate Total Cost of Ownership: Consider not just the upfront cost but also long-term factors like maintenance, durability, and potential resale value. This broader perspective can justify a higher initial investment for superior quality.

-

Be Transparent About Needs: Clearly communicate your requirements and constraints. Suppliers may offer tailored solutions that align with your budget.

-

Understand Pricing Nuances: Familiarize yourself with local economic conditions, currency fluctuations, and import duties that may affect pricing. This knowledge helps in negotiating more effectively.

Conclusion: What Should Buyers Keep in Mind?

While the prices of metal fabrics can vary widely based on the factors discussed, it is essential for buyers to approach sourcing with a comprehensive understanding of the cost structure and pricing influencers. Each project’s specifics can lead to significant variations in price, making it crucial to conduct thorough research and engage in strategic negotiation. Always remember to consult multiple suppliers and consider the total cost of ownership to make informed decisions.

Disclaimer: Prices mentioned are indicative and can fluctuate based on market conditions, material availability, and other external factors.

Alternatives Analysis: Comparing metal fabric With Other Solutions

Exploring Alternatives to Metal Fabric: A Comparative Analysis

In the realm of architectural and interior design, metal fabric stands out for its aesthetic appeal and functional versatility. However, various alternative solutions can also fulfill similar roles, each with unique characteristics that may align better with specific project requirements. This analysis will compare metal fabric with two notable alternatives: traditional textiles and perforated metal sheets, focusing on aspects critical to B2B buyers.

| Comparison Aspect | Metal Fabric | Traditional Textiles | Perforated Metal Sheets |

|---|---|---|---|

| Performance | High strength, flexibility | Moderate strength, less durable | Very strong, rigid |

| Cost | Mid to high | Low to mid | Mid to high |

| Ease of Implementation | Moderate complexity | Easy to install | Moderate to complex |

| Maintenance | Low maintenance | Moderate maintenance required | Low maintenance |

| Best Use Case | Aesthetic wall coverings, partitions | Upholstery, drapery | Architectural facades, safety barriers |

What Are the Pros and Cons of Traditional Textiles as an Alternative?

Traditional textiles offer a low-cost alternative with easy installation, making them suitable for quick projects. They provide a wide range of colors and patterns, allowing for creative expression in interior design. However, their performance can be compromised in terms of durability and strength compared to metal fabric. Textiles may require more maintenance, such as cleaning and potential replacement, especially in high-traffic or outdoor settings.

How Do Perforated Metal Sheets Compare to Metal Fabric?

Perforated metal sheets are an excellent alternative for projects requiring high strength and rigidity. They can serve similar aesthetic purposes as metal fabric but are more suited for applications where structural integrity is paramount, such as architectural facades or safety barriers. The cost is often comparable to metal fabric, but installation can be more complex due to the need for precise fitting and support structures. Maintenance is generally low, making perforated sheets a durable option, but they lack the flexibility and aesthetic versatility of metal fabric.

Illustrative image related to metal fabric

How Can B2B Buyers Decide on the Right Solution?

When choosing between metal fabric and its alternatives, B2B buyers should consider several factors. First, evaluate the specific performance requirements of the project; for instance, if flexibility and aesthetic appeal are priorities, metal fabric may be the best choice. Conversely, if budget constraints are significant, traditional textiles might suffice, especially for interior applications. For projects needing durability and structural support, perforated metal sheets could be more appropriate.

Ultimately, the decision should align with the project’s goals, budget, and the desired aesthetic. Engaging with suppliers to understand the specific benefits and applications of each option can further guide the selection process, ensuring the chosen solution meets both functional and aesthetic needs.

Essential Technical Properties and Trade Terminology for metal fabric

What Are the Key Technical Properties of Metal Fabric?

Understanding the critical technical properties of metal fabric is essential for B2B buyers to make informed purchasing decisions. Here are some of the most important specifications:

-

Material Grade

The grade of the metal used in fabric, such as stainless steel, aluminum, or copper, significantly influences durability, corrosion resistance, and aesthetic appeal. For instance, stainless steel is highly resistant to rust and tarnishing, making it ideal for outdoor applications. Buyers should verify the material grade to ensure it meets specific project requirements, especially in harsh environments. -

Open Area Percentage

This refers to the ratio of the open spaces in the fabric to the total area. It is a crucial property for applications requiring airflow or visibility. A higher open area percentage can improve ventilation, making it suitable for architectural and industrial uses. Buyers should consider this specification to align with functional requirements, such as acoustics or light transmission. -

Weight and Thickness

The weight of the metal fabric (often measured in pounds per square foot) and its thickness directly affect its strength and rigidity. Lighter fabrics may be easier to handle and install but might not provide the same structural support as heavier options. Buyers should assess the weight and thickness in relation to the intended application, ensuring the fabric can withstand environmental stresses. -

Flexibility vs. Rigidity

Metal fabrics can be categorized as flexible, semi-flexible, or rigid. Flexible fabrics are ideal for applications requiring adaptability and can accommodate various shapes and surfaces. Rigid fabrics, on the other hand, provide structural stability, making them suitable for load-bearing applications. Understanding the flexibility level needed for a specific project can guide buyers in selecting the right type of metal fabric. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. Precise tolerances are critical in applications where fit and finish are paramount. For example, when designing architectural elements, small deviations can affect installation and aesthetics. Buyers should discuss tolerance requirements with suppliers to ensure compatibility with their projects. -

Surface Finish Options

The finish of metal fabric can vary, including options like brushed, polished, or powder-coated. Different finishes can enhance aesthetics and protect against corrosion. Buyers should choose a finish that aligns with both functional and design objectives, as it impacts not only appearance but also maintenance requirements.

What Are Common Trade Terms Related to Metal Fabric?

Familiarity with industry jargon is crucial for navigating the procurement process effectively. Here are some common terms that B2B buyers should know:

Illustrative image related to metal fabric

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the metal fabric industry, OEMs often provide custom solutions tailored to specific applications. Understanding this term helps buyers identify potential suppliers capable of meeting their unique requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is vital for budget-conscious buyers, as it affects pricing and inventory management. Knowing the MOQ can help businesses plan their purchases and avoid excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For metal fabric buyers, issuing an RFQ can facilitate comparison shopping and ensure they receive competitive pricing. It is an essential step in the procurement process. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms can help buyers clarify shipping responsibilities, insurance, and payment terms, minimizing misunderstandings during the procurement process. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. It is a crucial factor for project planning, especially in industries where timely delivery is essential. Buyers should inquire about lead times to ensure that products arrive when needed, preventing project delays. -

Certification Standards

Certification standards, such as ISO or ASTM, indicate that a product meets specific quality and safety criteria. Buyers should verify that suppliers adhere to relevant certification standards to ensure the metal fabric’s reliability and performance in their applications.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that they select the right metal fabric for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the metal fabric Sector

What Are the Key Market Dynamics and Trends Shaping the Metal Fabric Sector?

The global metal fabric market is witnessing significant transformation driven by factors such as urbanization, technological advancements, and increasing demand for sustainable building materials. In regions like Africa and South America, rapid infrastructure development is propelling demand for durable and versatile metal fabrics. This trend is complemented by the Middle East’s focus on luxury and aesthetically pleasing architectural designs, which frequently employ metal fabrics for both functional and decorative purposes. In Europe, stricter regulations on building materials’ sustainability and environmental impact are influencing sourcing decisions, encouraging international buyers to seek out suppliers who can provide compliant and innovative solutions.

Emerging technologies such as automation in manufacturing processes are enhancing production efficiency and reducing costs, making metal fabrics more accessible to a broader market. Furthermore, the rise of e-commerce platforms enables international B2B buyers to source metal fabrics from suppliers around the globe, facilitating competitive pricing and a wider selection of materials, including custom alloys and finishes. Buyers must also stay attuned to shifts in consumer preferences, particularly the growing inclination towards customizable and multifunctional products, which can lead to greater market differentiation and customer loyalty.

How Is Sustainability and Ethical Sourcing Reshaping the Metal Fabric Supply Chain?

The importance of sustainability in the metal fabric sector cannot be overstated. As environmental concerns become increasingly pressing, B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices. The production of metal fabrics can significantly impact the environment, particularly in terms of resource extraction and energy consumption. Hence, buyers should evaluate suppliers based on their adherence to sustainable practices, such as using recycled materials and minimizing waste during production.

Illustrative image related to metal fabric

Ethical sourcing is another critical aspect that international buyers must consider. Establishing partnerships with suppliers who uphold fair labor practices and transparency in their supply chains is essential for maintaining a positive brand image and meeting regulatory requirements. Certifications such as ISO 14001 for environmental management and LEED for sustainable building practices can serve as indicators of a supplier’s commitment to sustainability. As the market evolves, buyers who integrate sustainability into their sourcing strategies will not only comply with regulations but also appeal to a growing demographic of environmentally-conscious consumers.

What Is the Historical Context of Metal Fabric Usage in B2B Markets?

The use of metal fabric dates back centuries, evolving from simple wire mesh applications in construction and industry to sophisticated architectural designs in modern buildings. Historically, metal fabrics were primarily used for functional purposes, such as security and ventilation. However, advancements in technology and weaving techniques have transformed metal fabrics into versatile design elements, suitable for a variety of applications, including interior design, façade cladding, and artistic installations.

In recent years, the integration of technology into the manufacturing process has allowed for greater customization and flexibility in design, enabling metal fabrics to meet the specific needs of diverse industries. As international B2B buyers navigate the complexities of this sector, understanding the evolution of metal fabric usage will provide valuable insights into market trends and future opportunities for innovation and collaboration.

Illustrative image related to metal fabric

Frequently Asked Questions (FAQs) for B2B Buyers of metal fabric

-

How do I choose the right type of metal fabric for my project?

Selecting the appropriate metal fabric involves understanding your specific application requirements, such as structural support, aesthetic appeal, and environmental conditions. Consider factors like flexibility (e.g., flexible vs. rigid fabric), material composition (e.g., stainless steel vs. aluminum), and the open area percentage, which affects light and air flow. Reviewing past projects where similar materials were used can provide insight into what works best in your industry, whether it’s architecture, automotive, or decorative applications. -

What are the benefits of using metal fabric in construction and design?

Metal fabric offers numerous advantages, including durability, aesthetic versatility, and low maintenance. It can enhance the visual appeal of buildings and structures while providing essential functions like safety and privacy. Additionally, metal fabrics are resistant to corrosion and can withstand extreme weather conditions, making them ideal for both indoor and outdoor applications. Their lightweight nature also simplifies installation, reducing labor costs. -

What customization options are available for metal fabric products?

Many suppliers offer extensive customization options, including different alloys, colors, textures, and patterns. You can often specify the weave type, wire diameter, and open area percentage to meet your design and functional requirements. Additionally, inquire about cutting and finishing services that can provide tailored solutions for your specific project needs. Ensure to communicate your exact specifications during the ordering process to avoid discrepancies. -

What are the minimum order quantities (MOQs) for metal fabric products?

Minimum order quantities can vary significantly between suppliers, depending on the material and customization options. Typically, MOQs range from a few square meters for standard products to larger quantities for custom orders. It’s essential to discuss your project scope with potential suppliers to determine whether they can accommodate your needs without excessive costs. Some suppliers may offer flexibility for first-time buyers or larger projects. -

How can I vet potential suppliers for metal fabric?

To vet suppliers, conduct thorough research by checking their industry reputation, customer reviews, and case studies. Request samples to assess product quality and craftsmanship firsthand. Additionally, inquire about their manufacturing processes, certifications (such as ISO), and compliance with international standards. Establishing clear communication regarding lead times, pricing, and after-sales support is crucial for building a reliable partnership. -

What are the typical payment terms for international orders of metal fabric?

Payment terms can vary widely based on the supplier and the buyer’s relationship. Common arrangements include upfront payments, net 30, or letter of credit for larger orders. It’s advisable to clarify payment terms before placing an order to avoid misunderstandings. Ensure you understand any additional costs associated with shipping and customs duties, which may impact the total expenditure. -

How can I ensure quality assurance (QA) for my metal fabric orders?

Implementing a quality assurance process is essential to ensure you receive the correct products that meet your specifications. Request detailed product specifications and certifications from your supplier. Consider conducting inspections at the manufacturing facility or requiring third-party quality checks before shipment. Establish a clear return policy for defective or non-conforming products to protect your investment. -

What logistics considerations should I keep in mind when importing metal fabric?

When importing metal fabric, consider factors such as shipping methods, lead times, and customs regulations in your country. Choose a reliable freight forwarder experienced in handling metal products to ensure smooth transport and compliance with international trade laws. Additionally, be prepared for potential delays due to customs clearance and ensure all documentation is accurate and complete to minimize disruptions. Understanding the logistics landscape will help you plan better and avoid costly delays.

Top 7 Metal Fabric Manufacturers & Suppliers List

1. GKD – Baltic Flexible Stainless Steel Fabric

Domain: gkdmetalfabrics.com

Registered: 2000 (25 years)

Introduction: {“name”: “Baltic”, “material”: “Stainless Steel”, “type”: “Flexible”, “weight”: “1.6 psf”, “max_width”: “26′”, “applications”: [“Ceilings”, “Covering”, “Enclosures”, “Partitions”, “Railing”, “Specialties”], “projects”: [“Ascot Racecourse”, “Bulthaup”, “Chapel of St. Lawrence”, “Jinhua Globe”, “Museum of Islamic Art”, “National Gallery Victoria”, “Victoria Theatre and Concert Hall”, “Dubai Opera”, …

2. McNICHOLS – Wire Mesh Products

Domain: mcnichols.com

Introduction: This company, McNICHOLS – Wire Mesh Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Fabric Wholesale Direct – Metallic Fabrics

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Metallic Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Inntex – Dream11 Steel

Domain: inntex.com

Registered: 2002 (23 years)

Introduction: Products: Metal Fabrics for Design

Applications: curtains, paneling, upholstery, ceilings, metal fabric ceilings, interlayers for laminated glass. Suitable for indoors or outdoors.

1. Dream11 – steel: Shiny fabric made of pure stainless steel. Very flexible, drapable and ladderproof. Used for curtains, panels, upholstery, ceilings, chairs, outdoor.

2. Dream11 – brass: Fabric made of brass wire wi…

5. Metal Fabric – Architectural Mesh Designs

Domain: in.pinterest.com

Registered: 2009 (16 years)

Introduction: Metal fabric, including various types of architectural metal mesh designs such as perforated metal panels, expanded metal mesh, and wire mesh. Related interests include industrial design elements like metal facades, stair railings, cladding systems, and metal gates. Specific applications mentioned are for buildings such as stadiums, factories, and hospitals, as well as interior design elements lik…

6. Cascade Architectural – Fabricoil® Coiled Wire Fabric

Domain: cascade-architectural.com

Registered: 2014 (11 years)

Introduction: Fabricoil® coiled wire fabric is an architectural-grade woven wire mesh material available in aluminum, steel, stainless steel, copper-clad steel, or solid brass. It offers flexible and rigid characteristics, is affordable, and suitable for various interior and exterior applications. The fabric has translucency, providing energy efficiency, solar control, space sculpting, partitioning, security, a…

7. Generation Store – Metal Mesh Fabric

Domain: generationstore.com

Registered: 2000 (25 years)

Introduction: Metal Mesh Fabric – Sequin Cloth

– Usage: Decorative mesh for interior design, clothing design, visual merchandising, wall/ceiling treatments, curtains, clothing/bag/shoe design, draping, table dressing, etc.

– Material: Made of aluminum flakes and rings

– Characteristics: Durable, flexible, unique texture

– Available Colors: Silver, Gold, Copper

– Customization: Available for specific size cuts

-…

Strategic Sourcing Conclusion and Outlook for metal fabric

What Are the Key Takeaways for B2B Buyers in Metal Fabric Sourcing?

In the dynamic landscape of metal fabric sourcing, strategic partnerships and informed decision-making are paramount. The versatility of metal fabrics, such as flexible cable mesh and rigid options, allows for a wide range of applications—from architectural features to functional enclosures. As international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it’s crucial to engage with suppliers who offer diverse materials, customization options, and robust support throughout the procurement process.

Why Is Strategic Sourcing Essential for Your Business?

Strategic sourcing not only optimizes procurement costs but also enhances product quality and sustainability. By carefully selecting suppliers who prioritize innovation and compliance with global standards, businesses can ensure they receive high-performance materials that align with their specific project needs. This proactive approach mitigates risks associated with supply chain disruptions and fluctuating market conditions.

How Can You Prepare for the Future of Metal Fabric Procurement?

As the demand for sustainable and aesthetically pleasing materials continues to grow, staying ahead of trends will be essential. Consider exploring new technologies and materials that enhance the performance and durability of metal fabrics. We encourage you to take action now—connect with reputable suppliers, assess your sourcing strategies, and position your business to leverage the exciting opportunities within the metal fabric market. The future is bright for those who strategically navigate this evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to metal fabric

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.