A Deep Dive into Menards Paneling Solution

Introduction: Navigating the Global Market for menards paneling

In today’s competitive landscape, sourcing high-quality menards paneling can be a significant challenge for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. With diverse applications ranging from residential renovations to commercial projects, understanding the various types of paneling available and their specific uses is crucial for making informed purchasing decisions. This guide provides a comprehensive overview of menards paneling, including insights into different styles, materials, and applications, as well as practical advice on supplier vetting and cost considerations.

Navigating the complexities of sourcing menards paneling requires a strategic approach. This guide is designed to empower B2B buyers by offering actionable insights into the global market, equipping them with the knowledge to evaluate suppliers effectively and make cost-efficient purchases. From understanding the benefits of engineered wood panel siding to exploring prefinished options that enhance aesthetic appeal and durability, this resource aims to facilitate informed decisions that align with project needs and budget constraints.

By leveraging this guide, buyers can confidently navigate the global market for menards paneling, ensuring they procure the right products that meet their specifications while also considering local regulations and market dynamics. Whether you are based in Brazil, Vietnam, or elsewhere, this guide serves as your go-to resource for optimizing your paneling procurement strategy.

Understanding menards paneling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plywood Panel Siding | Available in various thicknesses and patterns, durable | Residential and commercial siding | Pros: Cost-effective, versatile; Cons: May require regular maintenance. |

| Engineered Wood Paneling | Made from composite materials, moisture resistant | High-humidity areas, commercial spaces | Pros: Enhanced durability, eco-friendly; Cons: Higher initial cost. |

| Beaded Paneling | Features a decorative groove pattern, aesthetic appeal | Interior walls, accent features | Pros: Attractive design, easy installation; Cons: Limited color options. |

| Prefinished Panels | Factory-finished, ready-to-install | Quick renovations, DIY projects | Pros: Saves time, consistent quality; Cons: Less customization available. |

| Decorative Mouldings | Various styles, enhances paneling aesthetics | Residential interiors, commercial decor | Pros: Adds elegance, diverse styles; Cons: Additional cost and installation complexity. |

What Are the Key Characteristics of Plywood Panel Siding?

Plywood panel siding is known for its robustness and versatility, making it suitable for both residential and commercial applications. It comes in various thicknesses and groove patterns, allowing for customization based on project requirements. B2B buyers should consider its cost-effectiveness and ease of installation, though they must also be aware of the potential need for regular maintenance to ensure longevity, especially in adverse weather conditions.

How Does Engineered Wood Paneling Stand Out?

Engineered wood paneling is composed of composite materials, which provide enhanced moisture resistance. This makes it an ideal choice for high-humidity environments, such as kitchens and bathrooms, as well as commercial spaces where durability is crucial. While it may have a higher upfront cost compared to traditional wood, its longevity and eco-friendly manufacturing process can offer significant value for B2B buyers looking for sustainable options.

Why Choose Beaded Paneling for Interior Design?

Beaded paneling is characterized by its decorative groove patterns, which add aesthetic appeal to interior walls. This type of paneling is particularly popular for accent walls and decorative features in both residential and commercial settings. B2B buyers should note its ease of installation and attractive design; however, the range of color options may be limited, which could impact design flexibility.

What Advantages Do Prefinished Panels Offer?

Prefinished panels are factory-finished and ready for installation, making them an excellent choice for quick renovations and DIY projects. Their consistent quality and time-saving characteristics appeal to B2B buyers looking for efficiency. However, the trade-off may be limited customization options, which could restrict design choices for specific projects.

How Can Decorative Mouldings Enhance Paneling?

Decorative mouldings serve to enhance the overall aesthetics of paneling, offering a variety of styles that can elevate both residential interiors and commercial decor. While they add elegance and sophistication, B2B buyers should consider the additional costs and installation complexity that come with integrating mouldings into their projects. This investment can significantly improve the perceived value of a space, making it a worthwhile consideration for many buyers.

Key Industrial Applications of menards paneling

| Industry/Sector | Specific Application of menards paneling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Interior Wall Finishing | Enhances aesthetics and insulation, reducing energy costs | Sourcing moisture-resistant options for humid climates |

| Hospitality | Decorative Wall Panels in Hotels | Creates inviting atmospheres, improving guest experience | Need for durable, easy-to-clean finishes |

| Retail | Display and Merchandising Fixtures | Increases product visibility and enhances customer engagement | Customization options for branding and design preferences |

| Residential Renovation | DIY Home Improvement Projects | Cost-effective solution for quick renovations | Availability of various styles to match diverse tastes |

| Educational Institutions | Acoustic Panels for Classrooms | Improves sound quality and learning environments | Compliance with safety regulations and acoustic standards |

How is Menards Paneling Used in the Construction Industry?

In the construction sector, menards paneling is widely utilized for interior wall finishing. Its variety of styles and finishes allows builders to enhance the aesthetic appeal of residential and commercial spaces. Additionally, certain types of paneling can provide insulation benefits, contributing to energy efficiency. For international buyers, especially in regions with high humidity, sourcing moisture-resistant paneling is critical to prevent mold and deterioration.

What Role Does Menards Paneling Play in the Hospitality Sector?

In the hospitality industry, menards paneling serves as decorative wall panels in hotels and restaurants. These panels create inviting environments that enhance the overall guest experience. Durable finishes that are easy to clean are essential for maintaining aesthetics, especially in high-traffic areas. B2B buyers in this sector should prioritize sourcing paneling that meets durability and maintenance standards, ensuring longevity and guest satisfaction.

Illustrative image related to menards paneling

How Can Retail Businesses Benefit from Menards Paneling?

Retailers leverage menards paneling for display and merchandising fixtures, which significantly increases product visibility and customer engagement. By utilizing eye-catching designs and finishes, businesses can create an appealing shopping environment that encourages purchases. For B2B buyers, customization options are vital, allowing retailers to align paneling with their branding and design preferences, ultimately enhancing the shopping experience.

Why is Menards Paneling Ideal for Residential Renovation Projects?

Menards paneling is an excellent choice for DIY home improvement projects, offering a cost-effective solution for quick renovations. Homeowners can easily install paneling to refresh spaces, add character, or improve insulation. For international buyers, the availability of various styles ensures that diverse tastes are catered to, making it easier to find suitable options for different markets.

How Does Menards Paneling Enhance Educational Institutions?

In educational settings, menards paneling is often used as acoustic panels in classrooms to improve sound quality and create conducive learning environments. This application is crucial for minimizing noise distractions and enhancing focus. B2B buyers in this sector must consider compliance with safety regulations and acoustic standards when sourcing paneling to ensure a safe and effective learning atmosphere.

3 Common User Pain Points for ‘menards paneling’ & Their Solutions

Scenario 1: Sourcing Quality Paneling for Diverse Markets

The Problem: B2B buyers from international markets often face challenges in sourcing quality paneling that meets local regulations and standards. For example, a buyer from Brazil may struggle to find Menards paneling that adheres to specific fire safety or environmental guidelines. Additionally, language barriers and different measurement systems can complicate the ordering process, leading to delays and potential compliance issues.

The Solution: To navigate these challenges, buyers should first conduct thorough research on local building codes and standards relevant to paneling materials. Collaborating with local consultants or industry experts can provide insights into specific requirements. When sourcing from Menards, utilize their extensive product specifications and technical data sheets to ensure compliance. Additionally, consider reaching out to Menards’ customer service for assistance in understanding product attributes in relation to local regulations. Utilizing a bilingual sourcing agent can also mitigate language barriers, ensuring accurate communication and documentation throughout the procurement process.

Scenario 2: Managing Installation Challenges with Paneling

The Problem: B2B buyers often encounter difficulties during the installation of Menards paneling, particularly in large-scale projects. Issues such as misalignment, inadequate surface preparation, and improper handling can lead to costly delays and rework. For example, a construction firm in the Middle East may face challenges in ensuring that paneling is installed correctly in high-humidity environments, risking warping or mold growth.

The Solution: To ensure successful installation, it is crucial to develop a comprehensive installation plan that includes detailed guidelines tailored to the specific environmental conditions of the project. Buyers should invest in training for their installation teams, focusing on best practices for handling and installing Menards paneling. Menards offers installation resources, including video tutorials and manuals, which can be beneficial. Additionally, consider engaging with experienced contractors who have successfully worked with similar materials in similar environments to gain practical insights. Implementing a quality control checklist during installation can also help catch issues early, preventing costly errors.

Scenario 3: Addressing Aesthetic and Functional Requirements

The Problem: Buyers often struggle to balance aesthetic preferences with functional requirements when selecting Menards paneling. For instance, a design firm in Europe might want to achieve a modern look while ensuring that the paneling is durable and easy to maintain. This often leads to confusion over which products will fulfill both aesthetic and practical needs, risking client satisfaction and project success.

The Solution: To address this pain point, B2B buyers should start by clearly defining the project’s aesthetic goals alongside functional requirements. Conducting a thorough review of Menards’ diverse paneling options can help identify products that meet both needs. Creating mood boards or sample boards can aid in visualizing how different paneling options align with the desired aesthetic. Furthermore, engaging with Menards’ design consultants can provide valuable insights into product performance, maintenance needs, and style compatibility. By leveraging these resources, buyers can ensure that the selected paneling not only meets design expectations but also stands up to practical use, thereby enhancing customer satisfaction.

Strategic Material Selection Guide for menards paneling

When selecting materials for Menards paneling, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in Menards paneling, focusing on their properties, advantages, disadvantages, and specific considerations for international markets.

What Are the Key Properties of Plywood in Menards Paneling?

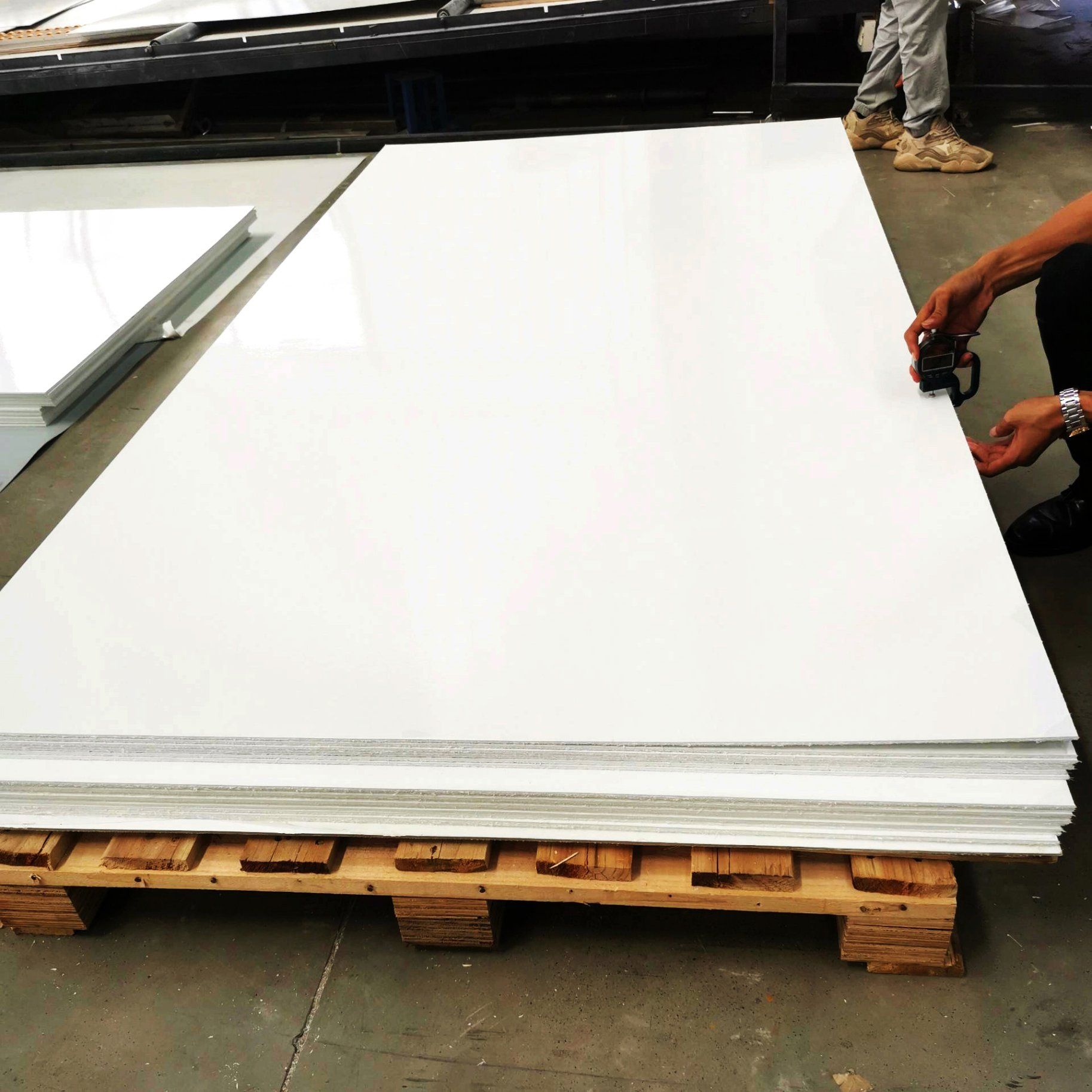

Plywood is a popular choice for paneling due to its layered construction, which enhances strength and stability. It typically exhibits good temperature resistance and can withstand moderate pressure, making it suitable for various applications. Plywood’s moisture resistance varies based on the type, with marine-grade options offering superior protection against humidity.

Pros: Plywood is relatively durable, cost-effective, and easy to work with, allowing for straightforward installation and customization. It is also available in various finishes, making it versatile for different aesthetic needs.

Cons: While plywood is generally durable, it can be susceptible to water damage if not properly treated. Additionally, lower-quality plywood may warp or delaminate over time, which could impact long-term performance.

Impact on Application: Plywood is compatible with a range of adhesives and finishes, making it suitable for both residential and commercial projects. However, buyers should ensure that the specific plywood type meets local building codes.

Considerations for International Buyers: Compliance with standards such as ASTM or DIN is crucial, particularly in regions like Europe and South America. Buyers should also consider the availability of treated plywood to meet humidity challenges in tropical areas like Africa and Southeast Asia.

How Does MDF Compare as a Material for Menards Paneling?

Medium Density Fiberboard (MDF) is another common material for paneling, known for its smooth surface and ability to hold paint and finishes well. MDF is produced from wood fibers, which are compressed and bonded with adhesives, giving it a uniform density.

Pros: MDF is highly versatile, allowing for intricate designs and finishes. Its smooth surface is ideal for painting, providing a high-quality aesthetic finish. It is also less prone to warping compared to solid wood.

Cons: MDF is less durable than plywood and can be more susceptible to moisture damage. It also has a lower weight-bearing capacity, which may limit its application in structural settings.

Impact on Application: MDF is particularly suited for decorative wall paneling and interior applications where aesthetics are prioritized over structural integrity.

Considerations for International Buyers: Buyers should be aware of the formaldehyde emissions associated with MDF and ensure compliance with local regulations, especially in regions with strict environmental standards, such as Europe.

What Are the Benefits of Vinyl Paneling in Menards Offerings?

Vinyl paneling is gaining popularity due to its durability and low maintenance requirements. Made from polyvinyl chloride (PVC), vinyl panels are resistant to moisture, making them ideal for areas prone to humidity.

Pros: Vinyl paneling is highly resistant to stains, fading, and moisture, making it suitable for various environments, including bathrooms and kitchens. Its lightweight nature simplifies installation.

Cons: While vinyl is durable, it may not have the same aesthetic appeal as natural wood or high-quality finishes. Additionally, it can be less environmentally friendly due to its plastic composition.

Impact on Application: Vinyl panels are excellent for commercial applications where durability and ease of maintenance are prioritized over aesthetics.

Considerations for International Buyers: Buyers should verify that vinyl products meet local safety and environmental standards, particularly in regions with stringent regulations regarding plastic materials.

How Does Engineered Wood Stand Out in Menards Paneling?

Engineered wood products, such as laminated veneer lumber (LVL) or oriented strand board (OSB), offer a balance of performance and cost. These materials are designed for specific applications, providing enhanced strength and stability.

Illustrative image related to menards paneling

Pros: Engineered wood is designed to resist warping and splitting, offering superior durability compared to traditional wood. It is also often more cost-effective, making it an attractive option for large-scale projects.

Cons: The manufacturing process can be complex, and engineered wood may not be suitable for all aesthetic applications, particularly where a natural wood look is desired.

Impact on Application: Engineered wood is ideal for structural applications and can be used in environments where moisture resistance is critical.

Illustrative image related to menards paneling

Considerations for International Buyers: Compliance with international standards is essential, and buyers should ensure that engineered wood products are certified for use in their specific markets.

Summary Table of Material Selection for Menards Paneling

| Material | Typical Use Case for menards paneling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plywood | Structural and decorative paneling | Durable and versatile | Susceptible to water damage | Medium |

| MDF | Decorative interior paneling | Smooth finish for painting | Less durable, moisture-sensitive | Medium |

| Vinyl | Moisture-prone areas | Highly resistant to stains and moisture | Aesthetic limitations | Low |

| Engineered Wood | Structural applications | Superior durability and cost-effective | May lack natural wood aesthetics | Medium |

This guide provides a comprehensive overview of materials available for Menards paneling, offering valuable insights for international B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for menards paneling

What Are the Main Stages in the Manufacturing Process of Menards Paneling?

The manufacturing process of Menards paneling encompasses several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential to producing high-quality paneling products suitable for a variety of applications.

Illustrative image related to menards paneling

Material Preparation

The journey begins with the selection and preparation of raw materials, predominantly wood-based products like plywood and engineered wood. The materials undergo rigorous sorting to eliminate defects, ensuring only the highest quality inputs are used. This stage may include drying the wood to optimal moisture levels, which is crucial for preventing warping and ensuring durability.

Forming Techniques

Once prepared, the materials are cut and formed into specific sizes and shapes. Advanced machinery is employed for precision cutting, ensuring consistency across all panels. Techniques such as laminating may be used to enhance the strength and aesthetic appeal of the paneling. For example, laminated panels can offer moisture resistance, making them suitable for diverse environments, including humid conditions often found in tropical regions.

Assembly Processes

During the assembly phase, the individual components of the paneling are brought together. This may involve gluing, pressing, or fastening different layers, depending on the panel type. Automated assembly lines are commonly used to enhance efficiency and ensure a uniform product. Quality checks are integrated at this stage to catch any inconsistencies before moving to the finishing phase.

Finishing Techniques

The finishing process involves sanding, painting, or applying protective coatings to enhance the paneling’s appearance and performance. This stage is vital for achieving the desired aesthetic, whether it’s a natural wood finish or a more modern painted look. Advanced finishing techniques also help in providing moisture and UV resistance, which is particularly relevant for markets in regions like Africa and South America, where climate considerations are paramount.

Illustrative image related to menards paneling

How is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance is a fundamental component of the manufacturing process for Menards paneling, ensuring that products meet both internal and international standards. The quality control framework typically includes several checkpoints throughout the manufacturing journey.

International Standards and Industry Certifications

Menards paneling adheres to various international standards such as ISO 9001, which emphasizes quality management systems and continuous improvement. Additionally, industry-specific certifications like CE marking (for products sold in Europe) and API standards (for specific applications) are important. These certifications not only ensure product safety and performance but also enhance credibility with B2B buyers.

Quality Control Checkpoints

Quality control is segmented into several key checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any defective materials are rejected to prevent issues down the line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to monitor the production flow. This includes verifying dimensions, strength, and other critical parameters.

-

Final Quality Control (FQC): Before packaging, finished products undergo a final inspection to ensure they meet all quality standards. This may involve visual inspections, performance testing, and compliance checks against certification requirements.

What Testing Methods Are Commonly Used in Quality Assurance for Paneling?

A variety of testing methods are employed to ensure the quality and performance of Menards paneling. These methods are designed to evaluate different aspects of the product, from structural integrity to surface finish.

Illustrative image related to menards paneling

Common Testing Methods

– Moisture Content Testing: This is essential for wood products to prevent issues such as warping or mold growth. Moisture meters are often used to ensure that the wood’s moisture content is within acceptable limits.

-

Strength Testing: Panels are subjected to various strength tests, including bending and compression tests, to ensure they can withstand typical loads and stresses encountered in real-world applications.

-

Adhesion Testing: For laminated panels, adhesion strength is critical. Tests are conducted to ensure that the layers bond securely, which is vital for durability and performance.

-

Surface Finish Inspection: Visual inspections and gloss measurements are performed to ensure that the finish meets aesthetic standards and is free from defects.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. There are several methods buyers can employ to ensure that they are partnering with reputable manufacturers.

Supplier Audits

Conducting supplier audits is a proactive way to assess a manufacturer’s quality control practices. This may involve visiting the manufacturing facility, reviewing quality management systems, and examining production processes firsthand.

Quality Control Reports

Requesting detailed quality control reports can provide insights into the supplier’s quality assurance practices. These reports should outline testing methodologies, results, and compliance with international standards.

Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct thorough inspections and testing, providing unbiased reports on product quality and compliance.

Illustrative image related to menards paneling

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers must be aware of certain nuances that can impact quality control and product delivery.

Cultural and Regulatory Differences

Cultural differences may affect communication and expectations regarding quality standards. Understanding local regulations and compliance requirements is crucial, as they can vary significantly from one region to another.

Logistical Considerations

Shipping and handling can affect product quality, particularly for paneling materials sensitive to moisture and temperature changes. Buyers should discuss shipping methods and storage conditions with suppliers to ensure products arrive in optimal condition.

Long-Term Relationships

Building long-term relationships with suppliers can facilitate better communication regarding quality issues and improvements. Regular feedback and collaboration can lead to enhanced product quality and innovation over time.

Illustrative image related to menards paneling

In conclusion, understanding the manufacturing processes and quality assurance measures for Menards paneling is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘menards paneling’

This guide serves as a practical checklist for B2B buyers looking to procure Menards paneling. By following these steps, international buyers can streamline their sourcing process, ensuring they obtain quality products that meet their specific needs.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the paneling you need. Consider factors such as size, thickness, material type (e.g., plywood, engineered wood), and finish. Defining these parameters upfront helps in narrowing down options and avoids misunderstandings with suppliers.

Step 2: Research Menards Paneling Products

Familiarize yourself with the range of paneling products available at Menards. Explore categories such as wall paneling, plywood panel siding, and prefinished panels to understand the offerings. This knowledge allows you to identify products that align with your project requirements and budget constraints.

Step 3: Evaluate Potential Suppliers

Before making a purchase, assess potential suppliers thoroughly. Request detailed company profiles, product catalogs, and references from similar industry buyers. This step is crucial for establishing trust and ensuring that the supplier can meet your quality and delivery expectations.

- Check Certifications: Verify that the suppliers hold relevant certifications that align with international quality standards. This is particularly important for buyers in regions with strict import regulations.

Step 4: Request Samples

Always ask for samples of the paneling products you are considering. This allows you to evaluate the material quality, finish, and texture firsthand. Assessing samples before placing a large order mitigates risks associated with product discrepancies and enhances overall satisfaction.

Step 5: Negotiate Terms and Conditions

Once you identify a suitable supplier, initiate discussions on pricing, payment terms, and delivery schedules. Clearly outline your expectations regarding lead times and potential penalties for delays. A well-structured agreement protects both parties and fosters a positive working relationship.

Step 6: Verify Logistics and Shipping Arrangements

Ensure that you understand the logistics involved in shipping the paneling to your location. Confirm shipping methods, costs, and estimated delivery times. This step is vital for international buyers, as it can significantly impact project timelines and budget.

Step 7: Establish Quality Control Procedures

Implement quality control measures to ensure the paneling received meets your specifications. Define acceptance criteria and inspection processes for incoming shipments. This proactive approach helps to address any issues before they affect your project, safeguarding your investment.

Illustrative image related to menards paneling

By following this checklist, B2B buyers can efficiently navigate the procurement process for Menards paneling, ensuring they make informed decisions that meet their project needs and standards.

Comprehensive Cost and Pricing Analysis for menards paneling Sourcing

What Are the Key Cost Components in Menards Paneling Sourcing?

When evaluating the cost structure for sourcing Menards paneling, several critical components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of paneling selected—be it plywood, engineered wood, or moisture-resistant variants—greatly affects material costs. Prices may vary based on the source, availability, and quality of the raw materials used.

-

Labor: Labor costs encompass both direct labor associated with manufacturing the paneling and indirect costs related to workforce management. In regions with higher labor costs, these expenses can significantly impact overall pricing.

-

Manufacturing Overhead: This includes expenses related to the factory operations, such as utilities, equipment maintenance, and administrative costs. Understanding these overheads helps buyers anticipate potential pricing fluctuations.

-

Tooling: Investments in specialized equipment for production can lead to higher initial costs but may improve efficiency and reduce per-unit costs in the long run.

-

Quality Control: Ensuring the paneling meets industry standards and certifications is essential. This may involve additional costs related to testing and compliance.

-

Logistics: Transportation costs, including shipping and handling, are crucial, especially for international buyers. Incoterms play a significant role here, dictating who bears the cost and risk during shipping.

-

Margin: Suppliers will typically add a margin to cover their costs and generate profit. Understanding the typical margin range can aid in negotiations.

How Do Price Influencers Affect Menards Paneling Costs?

Several factors influence the pricing of Menards paneling, crucial for international B2B buyers to consider:

Illustrative image related to menards paneling

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Bulk purchases often yield discounts, making it advantageous for buyers to negotiate larger orders if feasible.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should weigh the benefits of customization against potential price hikes.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., moisture-resistant, eco-friendly) can lead to increased costs but may offer long-term value through durability and compliance with international standards.

-

Supplier Factors: The reputation, reliability, and location of the supplier can influence costs. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is vital for international transactions, as they determine cost responsibility and risk.

What Are Effective Buyer Tips for Sourcing Menards Paneling?

To enhance cost-efficiency in sourcing Menards paneling, consider the following strategies:

-

Negotiation: Don’t shy away from negotiating prices. Suppliers often have flexibility in pricing, especially for larger orders. Building a rapport with suppliers can yield better terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term implications of paneling choices. Consider factors like durability, maintenance, and energy efficiency.

-

Understand Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can affect overall costs. Establishing a clear understanding of the total landed cost is critical.

-

Conduct Market Research: Investigate various suppliers and compare prices and offerings. Knowledge of market trends can empower buyers during negotiations.

Disclaimer on Pricing

The prices discussed in this analysis are indicative and may vary based on the supplier, region, and market conditions. It is recommended to obtain quotes from multiple suppliers to ensure competitive pricing and optimal sourcing strategies.

Alternatives Analysis: Comparing menards paneling With Other Solutions

Exploring Alternative Solutions to Menards Paneling for B2B Buyers

In the realm of construction and interior design, choosing the right wall paneling solution is crucial for achieving both aesthetic appeal and functional performance. While Menards paneling offers a range of products suitable for various applications, it is essential to consider other alternatives that may better meet specific project needs, especially for international B2B buyers. This analysis compares Menards paneling with other viable solutions, helping decision-makers make informed choices.

| Comparison Aspect | Menards Paneling | Alternative 1: PVC Wall Panels | Alternative 2: Gypsum Board Panels |

|---|---|---|---|

| Performance | Durable, moisture-resistant options available | Highly durable, water-resistant, easy to clean | Good insulation properties, fire-resistant |

| Cost | Mid-range pricing, competitive options | Generally lower initial cost | Cost-effective but installation may increase total cost |

| Ease of Implementation | Requires basic carpentry skills | Simple installation with adhesive or clips | Requires professional installation for best results |

| Maintenance | Requires periodic cleaning and upkeep | Minimal maintenance, resistant to stains | Regular painting or finishing needed to maintain appearance |

| Best Use Case | Ideal for residential and light commercial | Best for high-moisture areas like bathrooms | Suitable for commercial buildings needing fire safety |

What Are the Pros and Cons of PVC Wall Panels?

PVC wall panels are increasingly popular in various applications, particularly in high-moisture environments like bathrooms and kitchens. Their primary advantage lies in their resistance to water, stains, and mildew, making them easy to clean and maintain. The lightweight nature of PVC panels allows for simple installation, often requiring just adhesive or clips. However, while the initial cost may be lower than Menards paneling, the aesthetic appeal may not match that of traditional wood or engineered paneling, which could be a consideration for high-end projects.

How Do Gypsum Board Panels Compare to Menards Paneling?

Gypsum board panels, commonly known as drywall, are widely used in commercial construction due to their excellent fire-resistance properties. They offer good insulation and can create a smooth surface for painting or finishing. While gypsum board is cost-effective in terms of material, the installation process can be labor-intensive, requiring skilled professionals to achieve optimal results. Additionally, these panels may not be as moisture-resistant as Menards paneling, making them less suitable for humid environments unless treated appropriately.

How Can B2B Buyers Choose the Right Paneling Solution?

When selecting a wall paneling solution, B2B buyers should evaluate their specific project requirements, including environmental conditions, budget constraints, and desired aesthetics. Menards paneling provides a reliable and aesthetically pleasing option for a variety of settings, while alternatives like PVC and gypsum board panels offer unique benefits that may better suit certain applications. Consideration of installation complexity, long-term maintenance needs, and performance characteristics will guide buyers to the most appropriate choice for their projects. Ultimately, the right paneling solution can enhance both functionality and design, contributing to the overall success of a project.

Essential Technical Properties and Trade Terminology for menards paneling

What Are the Essential Technical Properties of Menards Paneling?

When sourcing paneling products from Menards, understanding key technical properties is crucial for ensuring that the selected materials meet project requirements and performance standards. Here are some critical specifications to consider:

-

Material Grade

Material grade refers to the quality classification of the paneling, which affects durability, appearance, and cost. Higher-grade materials often offer better resistance to wear, moisture, and pests. For B2B buyers, selecting the appropriate material grade can impact long-term maintenance costs and overall project success. -

Thickness

The thickness of paneling affects its strength and insulation properties. Common thicknesses for Menards paneling include 3/8″, 1/2″, and 5/8″. Thicker panels generally provide better sound insulation and structural support, making them suitable for commercial applications where durability is essential. -

Moisture Resistance

Moisture-resistant paneling is critical for applications in humid environments or areas prone to water exposure. Menards offers products specifically designed to withstand moisture, which can prevent warping and mold growth. For international buyers, especially from humid climates, this property is essential for ensuring longevity and performance. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in dimensions and properties. Accurate tolerance levels are crucial for ensuring that panels fit together correctly during installation. For B2B buyers, understanding tolerance can help prevent costly rework and delays in projects. -

Finish Type

The finish type affects the aesthetic appeal and maintenance of the paneling. Menards offers various finishes, including natural wood, painted, and laminated options. Choosing the right finish can enhance the visual quality of the project and impact long-term maintenance requirements. -

Fire Rating

Fire ratings classify the fire resistance of paneling materials. Some Menards paneling products are treated to provide enhanced fire resistance, making them suitable for commercial buildings where safety regulations are stringent. Understanding fire ratings is crucial for compliance with local building codes and ensuring occupant safety.

What Are Common Trade Terms Related to Menards Paneling?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms relevant to sourcing paneling:

Illustrative image related to menards paneling

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the specifications provided by another company. In the context of paneling, an OEM might create custom designs or specifications for specific projects, allowing for tailored solutions. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to ensure that they can meet their project requirements without overcommitting to excess inventory. -

RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. This process is essential for comparing costs and terms from multiple suppliers, allowing for informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs, which is crucial for B2B buyers engaged in cross-border procurement. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to delivery. Understanding lead times is critical for project planning, especially for international buyers who may face longer shipping durations. -

Certification Standards

Certification standards indicate that a product meets specific industry criteria for safety, quality, or environmental impact. B2B buyers should look for paneling that complies with relevant certification standards to ensure compliance and enhance marketability.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing Menards paneling, ensuring that they select the right materials for their projects.

Navigating Market Dynamics and Sourcing Trends in the menards paneling Sector

What Are the Key Market Drivers and Trends in the Menards Paneling Sector?

The menards paneling sector is influenced by several global drivers that shape its market dynamics. Increased urbanization and infrastructure development in regions like Africa, South America, and the Middle East are driving demand for wall paneling solutions. As countries invest in housing and commercial projects, there is a growing need for versatile and cost-effective materials, such as plywood and engineered wood panels. Additionally, the rise of remote work has prompted a surge in home renovations, further boosting the demand for aesthetic and functional paneling options.

Emerging technologies are also transforming sourcing strategies. The adoption of digital platforms for procurement is becoming prevalent, enabling international B2B buyers to access a wider range of products and suppliers. Enhanced data analytics tools allow companies to forecast demand more accurately and streamline their supply chains, reducing lead times and costs. Moreover, sustainability considerations are influencing purchasing decisions, with buyers increasingly favoring suppliers that offer eco-friendly paneling options.

International buyers should remain aware of regional trends and preferences, as the demand for specific paneling types can vary significantly. For instance, in Europe, there is a marked preference for high-quality, durable materials that can withstand diverse climates, while markets in Brazil and Vietnam may prioritize affordability and ease of installation. Understanding these nuances is essential for developing effective sourcing strategies.

How Is Sustainability and Ethical Sourcing Reshaping the Menards Paneling Market?

Sustainability and ethical sourcing are becoming critical factors in the menards paneling sector. The environmental impact of paneling materials, particularly those derived from deforested areas, has raised concerns among consumers and businesses alike. As a result, international buyers are increasingly seeking suppliers who adhere to sustainable practices and offer certified materials.

Green certifications, such as Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI), are becoming essential in the sourcing process. These certifications ensure that the wood used in paneling products is sourced responsibly, minimizing environmental degradation and promoting forest conservation. Additionally, buyers are looking for products that incorporate recycled materials or innovative manufacturing processes that reduce waste.

Ethical supply chains are also gaining traction as businesses strive to ensure fair labor practices and transparency throughout their operations. Buyers should prioritize partnerships with manufacturers who demonstrate a commitment to social responsibility, as this not only enhances brand reputation but also meets the growing demand for ethical products in global markets.

What Is the Historical Context of Menards Paneling and Its Relevance to Today’s B2B Market?

The history of menards paneling can be traced back to the development of engineered wood products in the mid-20th century, which revolutionized the construction and interior design industries. Initially, paneling was primarily viewed as a cost-effective alternative to traditional materials. However, over the decades, it has evolved into a versatile design element that caters to both aesthetic and functional needs.

Today, menards paneling reflects a blend of innovation and tradition, appealing to a diverse range of markets. As international B2B buyers explore paneling options, understanding this evolution is crucial. The shift towards customization and design flexibility in paneling products aligns with contemporary trends in interior design, making it an attractive option for modern projects. By recognizing the historical context, buyers can better appreciate the value and potential of menards paneling in their sourcing strategies.

Illustrative image related to menards paneling

Frequently Asked Questions (FAQs) for B2B Buyers of menards paneling

-

How do I choose the right paneling type for my project?

Selecting the right paneling involves assessing your project’s specific requirements, such as durability, moisture resistance, and aesthetic appeal. For commercial applications, engineered wood panels like LP® SmartSide® may be ideal due to their strength and weather resistance. Additionally, consider the installation environment; for areas exposed to high humidity, moisture-resistant options are preferable. Always consult with your suppliers about the best choices based on regional climate conditions and application needs. -

What are the most popular paneling styles for commercial use?

The most sought-after paneling styles for commercial projects include textured wood panels, beaded plywood, and prefinished panels. Textured wood panels offer a modern look, while beaded plywood provides a classic aesthetic. Prefinished panels save time on installation since they come ready to use. When sourcing for international projects, ensure the style aligns with local design trends and regulations, as these can vary significantly between regions. -

What are the minimum order quantities (MOQs) for Menards paneling?

Minimum order quantities for Menards paneling can vary based on the type of paneling and the supplier’s policies. Typically, MOQs range from a few hundred square feet to full truckloads. For international buyers, it’s advisable to communicate directly with suppliers to understand their MOQ terms and negotiate if necessary. Additionally, consolidating orders with other materials may help in meeting MOQs while maximizing shipping efficiency. -

What payment terms are typically offered for international purchases of paneling?

Payment terms can vary widely among suppliers, but common arrangements include upfront payments, 30% deposit with the balance on delivery, or net 30/60 days after delivery. For international transactions, consider using letters of credit or escrow services to mitigate risks. Always clarify payment methods accepted by the supplier and ensure that terms are documented in the purchase agreement to avoid misunderstandings. -

How can I ensure the quality of the paneling products I source?

To ensure product quality, request samples before committing to large orders. Additionally, verify the supplier’s certifications and quality assurance processes. Look for ISO certifications or other relevant quality standards that demonstrate a commitment to product excellence. Conducting factory visits or audits can provide deeper insights into manufacturing practices and help establish trust with your supplier. -

What are the logistics considerations for importing Menards paneling?

When importing paneling, consider shipping methods, customs regulations, and lead times. Options include sea freight for larger shipments or air freight for urgent deliveries. Research import duties and taxes applicable in your country, as these can significantly impact overall costs. Partnering with a logistics provider experienced in handling building materials can streamline the process and ensure compliance with local regulations. -

Can I customize paneling products to meet specific design needs?

Many suppliers, including Menards, offer customization options for paneling products. This can include size adjustments, finish variations, and specific textures. When discussing customization, provide detailed specifications and any design samples to ensure alignment with your vision. Keep in mind that customized orders may have longer lead times and potentially higher costs, so plan accordingly. -

What should I consider regarding paneling installation in different climates?

When installing paneling in diverse climates, consider factors such as moisture levels, temperature fluctuations, and exposure to sunlight. For humid regions, opt for moisture-resistant materials to prevent warping or mold growth. In colder climates, ensure proper insulation behind paneling to maintain energy efficiency. Always consult with local contractors familiar with climate-specific installation techniques to ensure optimal performance and longevity of the paneling.

A Look at Menards Paneling Manufacturers & Suppliers

Could not verify enough suppliers for menards paneling to create a list at this time.

Strategic Sourcing Conclusion and Outlook for menards paneling

In conclusion, the strategic sourcing of Menards paneling offers a myriad of opportunities for international B2B buyers. By leveraging a diverse range of products—from plywood panel siding to prefinished panels—buyers can enhance their project efficiency and quality. Understanding the unique specifications and applications of these materials is crucial for making informed purchasing decisions that align with regional construction standards and consumer preferences.

The value of strategic sourcing extends beyond merely acquiring materials; it encompasses building reliable supplier relationships, optimizing supply chains, and ensuring compliance with local regulations. As markets in Africa, South America, the Middle East, and Europe continue to evolve, buyers who engage proactively with suppliers can unlock competitive advantages, especially in meeting the demand for sustainable and innovative building solutions.

Looking ahead, we encourage international B2B buyers to explore Menards’ extensive catalog and consider the potential for collaboration. By integrating high-quality paneling solutions into your projects, you can not only elevate your offerings but also contribute to the growth of your business in a dynamic global marketplace. Embrace the possibilities that strategic sourcing presents and position your company for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.