A Deep Dive into Membrane Switches Solution

Introduction: Navigating the Global Market for membrane switches

Navigating the complex landscape of membrane switches can be daunting for international B2B buyers, particularly when sourcing reliable and high-quality components for diverse applications. With their unique construction and capabilities, membrane switches are pivotal in industries such as automotive, aerospace, and medical devices. However, the challenge often lies in identifying the right supplier that not only meets stringent quality standards but also aligns with specific regional requirements.

This comprehensive guide delves into the various types of membrane switches, including tactile and non-tactile options, and their respective applications across multiple sectors. It addresses critical aspects such as supplier vetting processes, cost considerations, and the advantages of integrating advanced features like backlighting and graphic overlays. By exploring these elements, this guide equips B2B buyers from Africa, South America, the Middle East, and Europe—regions characterized by distinct market dynamics and regulatory frameworks—with the insights needed to make informed purchasing decisions.

Whether you are looking to enhance user interface designs or improve product durability, understanding the nuances of membrane switches will empower your business to thrive in the global market. This guide serves as a vital resource to streamline your sourcing process, ensuring that you select the right membrane switch solutions tailored to your operational needs.

Understanding membrane switches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tactile Membrane Switches | Provides physical feedback (click or snap) upon actuation | Automotive, Aerospace, Medical Devices | Pros: Enhanced user experience, customizable feedback; Cons: May have a shorter lifespan than non-tactile versions. |

| Non-Tactile Membrane Switches | No physical feedback; relies on visual/auditory indicators | Consumer Electronics, Industrial Equipment | Pros: Highly durable, sealed against environmental factors; Cons: Lacks direct tactile feedback, which may affect usability. |

| SnapMax® Actuators | Unique magnetic technology for actuation | High-traffic environments, Medical Devices | Pros: Long lifespan, minimal wear and tear; Cons: Higher initial cost compared to traditional actuators. |

| Dual Circuit Switches | Two circuit layers with air gap for actuation | Medical Equipment, Control Panels | Pros: Reliable performance, customizable configurations; Cons: More complex design can lead to increased production time. |

| Polyester Dome Switches | Uses conductive ink and thermoformed plastic for actuation | Consumer Products, Home Appliances | Pros: Cost-effective, lightweight design; Cons: May not provide the same durability as metal dome switches. |

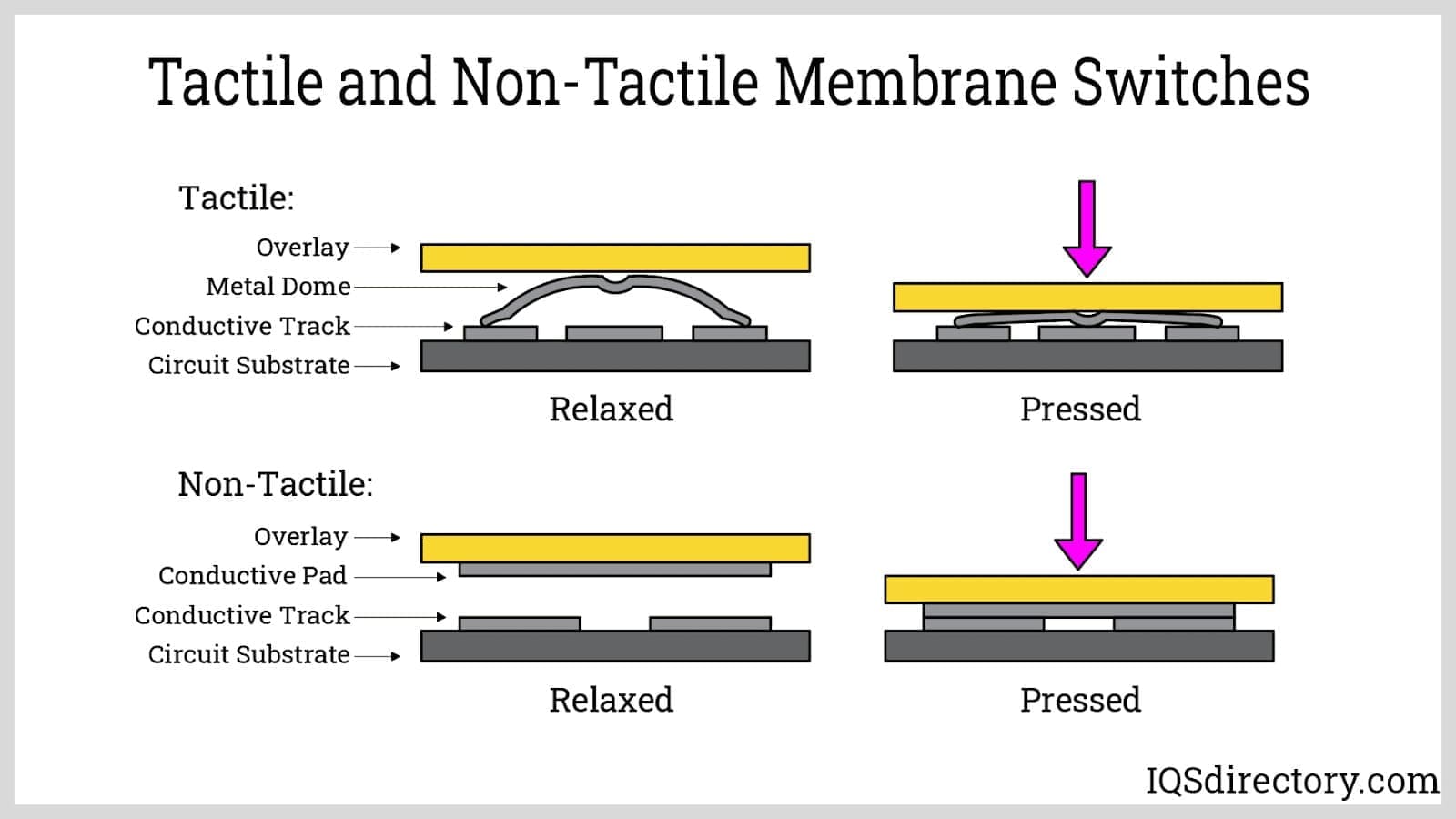

What Are the Characteristics of Tactile Membrane Switches?

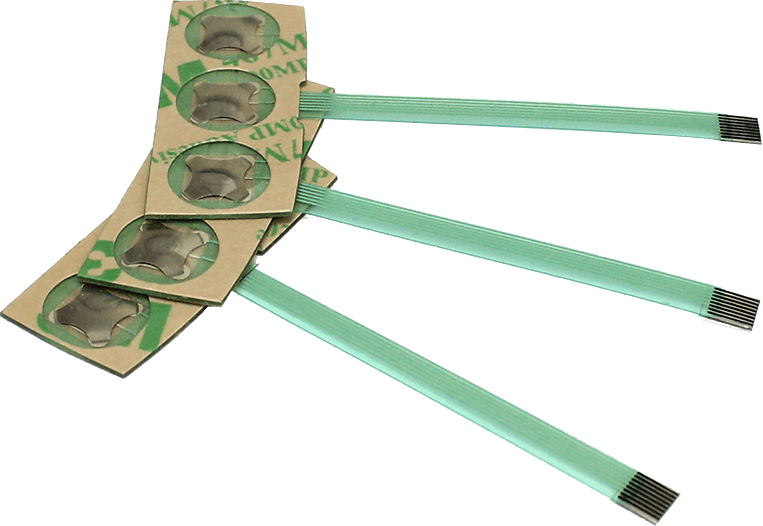

Tactile membrane switches are designed to provide immediate feedback to users through physical sensations such as a click or snap when pressed. This feature is essential in applications where user interaction is frequent, such as in automotive and aerospace controls. The customization options available for tactile switches allow businesses to fine-tune the feedback characteristics, making them suitable for specialized applications. When purchasing, buyers should consider the balance between tactile feedback and the expected lifespan, as these switches may wear out faster than non-tactile variants.

How Do Non-Tactile Membrane Switches Operate?

Non-tactile membrane switches operate without providing physical feedback, relying instead on visual or auditory signals to indicate activation. This type of switch is often used in consumer electronics and industrial equipment, where durability and sealing against environmental factors are paramount. Buyers should consider the longevity and durability of these switches, as they typically endure more actuations than tactile switches. However, the lack of tactile feedback may not be suitable for all applications, particularly those requiring precise user interaction.

What Sets SnapMax® Actuators Apart?

SnapMax® actuators use a patented magnetic technology that enhances performance and durability. These actuators are particularly beneficial in high-traffic environments, such as medical devices and control panels, where reliability is critical. The absence of mechanical wear makes SnapMax® actuators a smart investment for businesses aiming for longevity. However, the higher initial cost may be a consideration for budget-conscious buyers, who must weigh the long-term benefits against upfront expenses.

What Are the Advantages of Dual Circuit Switches?

Dual circuit switches feature two circuit layers separated by an air gap, allowing for reliable actuation without tactile feedback. These switches are commonly employed in medical equipment and control panels, where precision and dependability are essential. Buyers should focus on the customization options available, as these switches can be tailored to meet specific application requirements. However, the complexity of dual circuit designs may lead to longer production times, which could impact project timelines.

Illustrative image related to membrane switches

Why Choose Polyester Dome Switches?

Polyester dome switches utilize conductive ink and thermoformed plastic to create a lightweight and cost-effective solution. They are suitable for a variety of consumer products and home appliances, offering a balance between performance and price. Buyers should consider the application environment, as polyester dome switches may not offer the same durability as their metal counterparts. However, their affordability makes them an attractive option for high-volume projects where cost efficiency is essential.

Key Industrial Applications of membrane switches

| Industry/Sector | Specific Application of membrane switches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Control panels for dashboards and infotainment | Enhanced user experience with customizable interfaces | Compliance with automotive standards, durability under extreme conditions |

| Medical Devices | User interfaces for diagnostic equipment | Improved hygiene and ease of cleaning | Biocompatibility, regulatory compliance, and reliability in critical applications |

| Aerospace | Cabin control systems | Lightweight design contributing to fuel efficiency | High-performance materials, resistance to environmental factors |

| Industrial Equipment | Machinery control interfaces | Streamlined operations with intuitive user interfaces | Customizability, robustness, and integration with existing systems |

| Consumer Electronics | Remote controls and home appliance interfaces | Improved usability and aesthetic appeal | Design flexibility, tactile feedback options, and cost-effectiveness |

How Are Membrane Switches Used in the Automotive Industry?

In the automotive sector, membrane switches are integral to control panels in dashboards and infotainment systems. These switches allow manufacturers to create sleek, customizable interfaces that enhance user interaction. They solve issues related to space constraints and aesthetic design while offering durability against vibrations and moisture. Buyers in this sector must ensure that the switches comply with rigorous automotive standards and can withstand extreme temperature fluctuations and wear over time, particularly in regions with diverse climates such as Africa and the Middle East.

What Role Do Membrane Switches Play in Medical Devices?

Membrane switches are extensively used in medical devices, particularly for user interfaces in diagnostic and monitoring equipment. Their smooth surfaces promote hygiene, making them easier to clean and maintain, which is crucial in healthcare settings. The ability to provide tactile feedback while ensuring durability under frequent use addresses common challenges in medical environments. International buyers should prioritize sourcing switches that meet biocompatibility standards and regulatory requirements, ensuring reliability in critical health applications across varying regions, including Europe and South America.

How Are Membrane Switches Beneficial in Aerospace Applications?

In aerospace, membrane switches are utilized in cabin control systems, where their lightweight design contributes significantly to overall fuel efficiency. These switches offer a high degree of customization, enabling manufacturers to design user-friendly interfaces that accommodate complex functionalities. They address challenges such as space limitations and the need for reliability in demanding environments. Buyers must consider sourcing switches that are made from high-performance materials to ensure they can withstand extreme pressure changes and temperature variations typical of aerospace applications, especially in regions like Saudi Arabia and Europe.

Why Are Membrane Switches Important for Industrial Equipment?

Membrane switches find critical applications in machinery control interfaces within industrial equipment. They streamline operations by providing intuitive user interfaces that enhance productivity and reduce training time for operators. The robust nature of these switches solves issues related to dirt and moisture ingress, which can be common in industrial environments. Buyers should focus on customizability and the ability to integrate seamlessly with existing systems, ensuring that the switches can withstand the rigors of industrial use, particularly in regions with challenging operational conditions like South America and Africa.

Illustrative image related to membrane switches

What Are the Advantages of Using Membrane Switches in Consumer Electronics?

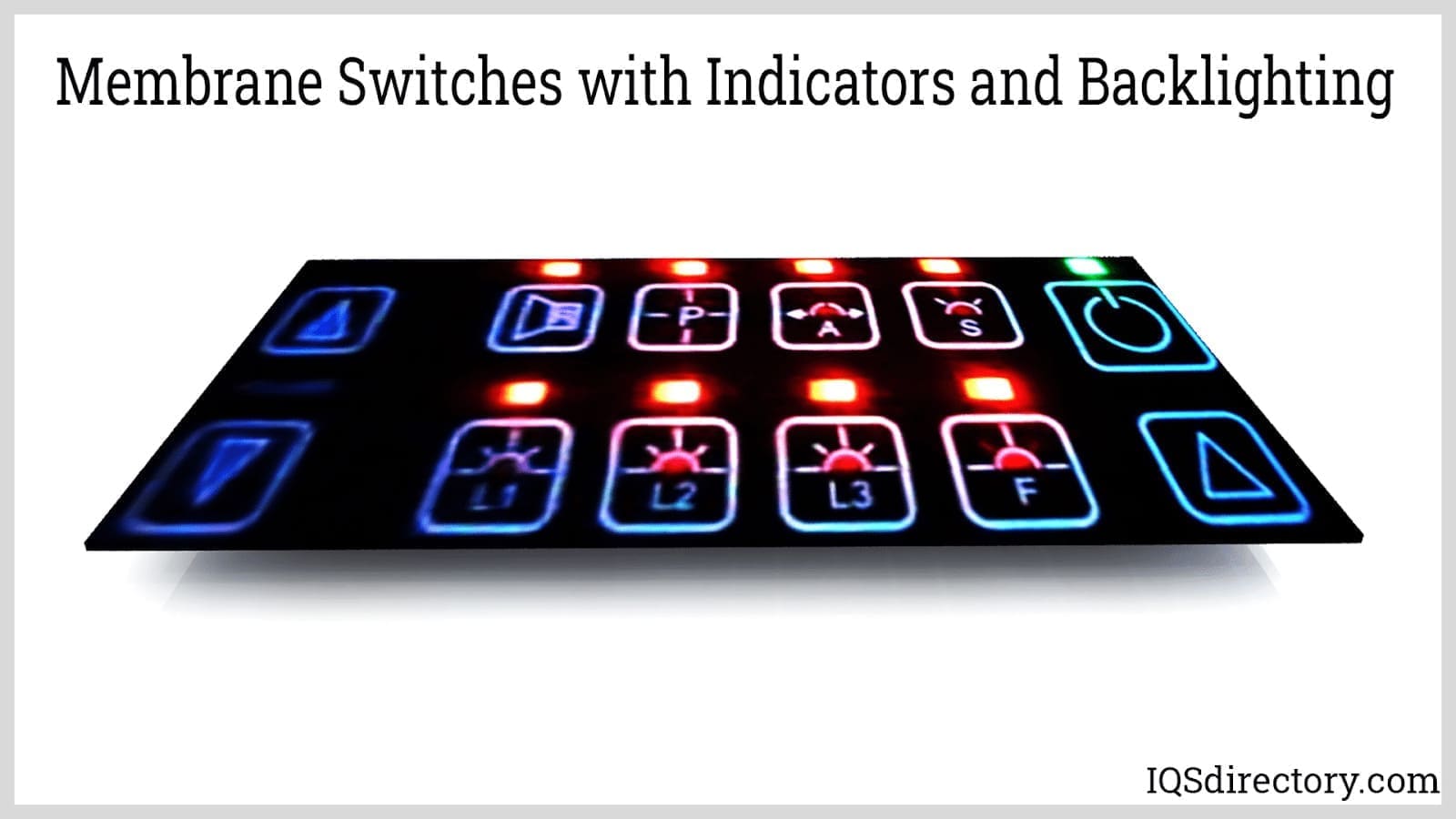

In the realm of consumer electronics, membrane switches are commonly found in remote controls and interfaces for home appliances. Their design flexibility allows manufacturers to create attractive, user-friendly products that enhance usability. The tactile feedback provided by certain membrane switches improves user interaction, addressing common usability issues. When sourcing for this application, businesses should consider the aesthetic requirements, cost-effectiveness, and options for backlighting to cater to diverse consumer preferences across various international markets.

3 Common User Pain Points for ‘membrane switches’ & Their Solutions

Scenario 1: Difficulty in Customization for Unique Applications

The Problem: Many B2B buyers encounter challenges when it comes to customizing membrane switches for specific applications. For instance, a manufacturer in the automotive sector may require membrane switches that not only fit into limited spaces but also withstand extreme temperatures and harsh environments. The overwhelming number of options—such as different actuator types, materials, and thicknesses—can make the decision-making process daunting, leading to potential delays in production and increased costs if errors occur.

The Solution: To effectively navigate customization, buyers should collaborate closely with manufacturers from the initial design phase. Engaging with an experienced supplier who understands industry-specific requirements can streamline this process. It’s crucial to provide detailed specifications, including environmental conditions, actuation force, and tactile feedback preferences. Utilizing prototyping services offered by manufacturers allows for testing and refining designs before mass production. This not only ensures that the final product meets the intended application but also helps in avoiding costly adjustments later in the production line.

Illustrative image related to membrane switches

Scenario 2: Concerns About Durability and Longevity

The Problem: A common pain point for B2B buyers is the concern over the durability and lifespan of membrane switches, especially in high-usage environments like medical devices or industrial machinery. Buyers may have experienced failures with previous switches that led to operational downtime, negatively impacting productivity and increasing repair costs. This can create hesitation when selecting membrane switches, as the fear of investing in an unreliable product looms large.

The Solution: To address durability concerns, buyers should prioritize sourcing membrane switches that are tested and certified for the specific industry standards relevant to their applications. Requesting information on the expected lifecycle and performance metrics can provide insights into the reliability of the switches. Additionally, exploring options such as non-tactile membrane switches, which typically offer greater durability due to their sealed design, can be beneficial. Buyers should also ensure that their suppliers offer warranties or guarantees, providing an added layer of assurance regarding the longevity of the product.

Scenario 3: Integration with Existing Systems

The Problem: Buyers often face challenges when integrating new membrane switches with existing electronic systems. This scenario frequently arises in sectors such as consumer electronics or industrial automation, where seamless communication between components is crucial. Without proper compatibility, buyers may find themselves dealing with additional costs related to system upgrades or modifications, which can be frustrating and time-consuming.

The Solution: To facilitate smooth integration, it is essential for buyers to conduct thorough compatibility assessments before selecting membrane switches. This involves gathering detailed specifications of the existing systems, including voltage requirements and circuit layouts. Establishing a clear line of communication with the membrane switch manufacturer can aid in identifying compatible options and even lead to customized solutions tailored to the current system architecture. It’s also advisable to utilize flexible circuit options that can easily adapt to various interfaces, thus minimizing integration issues and ensuring a more straightforward implementation process.

Strategic Material Selection Guide for membrane switches

What Are the Key Materials Used in Membrane Switches?

When selecting materials for membrane switches, understanding their properties and suitability for specific applications is crucial for B2B buyers. Here, we analyze four common materials used in membrane switches: polyester, polycarbonate, metal, and silicone rubber. Each material has distinct characteristics that can significantly impact performance, durability, and cost.

Polyester: A Versatile and Cost-Effective Option

Polyester is widely used in membrane switches due to its excellent clarity and durability. It typically withstands temperatures ranging from -40°C to 120°C and has good chemical resistance, making it suitable for a variety of environments.

Pros: Polyester is relatively inexpensive and easy to manufacture, allowing for rapid prototyping and high-volume production. Its flexibility and strength make it ideal for applications requiring a thin profile.

Cons: While durable, polyester can be prone to scratching and may not be suitable for environments with extreme temperatures or harsh chemicals.

Impact on Application: Polyester is often used in consumer electronics and medical devices, where clarity and tactile feedback are essential.

Considerations for International Buyers: Compliance with international standards such as ASTM and JIS is critical. Buyers from regions like Africa and South America should ensure that their suppliers can meet local regulatory requirements.

Illustrative image related to membrane switches

Polycarbonate: Enhanced Durability and Clarity

Polycarbonate is another popular choice for membrane switches, known for its high impact resistance and optical clarity. It can handle temperatures from -40°C to 120°C, similar to polyester, but offers superior durability against physical impacts.

Pros: Polycarbonate provides excellent resistance to UV light and chemicals, making it suitable for outdoor applications. It also allows for intricate designs and graphics.

Cons: The manufacturing process for polycarbonate can be more complex and costly than polyester, especially for custom designs.

Impact on Application: This material is ideal for industrial applications, automotive controls, and outdoor equipment, where durability and visibility are paramount.

Considerations for International Buyers: Buyers should be aware of the specific certifications required in their regions, particularly in Europe, where CE marking may be necessary.

Metal: Robustness and Longevity

Metal components, such as stainless steel or aluminum, are often incorporated into membrane switches for added durability and tactile feedback. These materials can withstand extreme temperatures and harsh environments.

Pros: Metal offers exceptional durability, corrosion resistance, and a premium feel, making it suitable for high-end applications.

Illustrative image related to membrane switches

Cons: The cost of metal components is significantly higher, and the manufacturing process can be more complex, leading to longer lead times.

Impact on Application: Metal is commonly used in medical devices and industrial machinery, where a robust interface is critical.

Considerations for International Buyers: Compliance with industry-specific regulations, such as those in the automotive or aerospace sectors, is essential for buyers in the Middle East and Europe.

Silicone Rubber: Flexibility and User Comfort

Silicone rubber is often used in tactile membrane switches, providing a soft touch and excellent flexibility. It can operate effectively in a temperature range of -60°C to 200°C, making it suitable for extreme environments.

Pros: Silicone rubber is highly durable and resistant to UV light, ozone, and extreme temperatures. It also offers excellent tactile feedback, enhancing user experience.

Cons: The initial cost of silicone rubber can be higher, and its manufacturing process may require specialized equipment.

Impact on Application: This material is ideal for medical devices and consumer electronics, where user comfort and durability are critical.

Considerations for International Buyers: Buyers should ensure that silicone rubber components meet local health and safety regulations, especially in medical applications.

Summary Table of Material Selection for Membrane Switches

| Material | Typical Use Case for membrane switches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Consumer electronics, medical devices | Cost-effective and flexible | Prone to scratching | Low |

| Polycarbonate | Industrial applications, automotive | High impact resistance | Higher manufacturing complexity | Med |

| Metal | Medical devices, industrial machinery | Exceptional durability | Higher cost and complexity | High |

| Silicone Rubber | Medical devices, consumer electronics | Excellent tactile feedback | Higher initial cost | Med |

This guide provides a comprehensive overview of material selection for membrane switches, helping B2B buyers make informed decisions based on application requirements and regional considerations.

Illustrative image related to membrane switches

In-depth Look: Manufacturing Processes and Quality Assurance for membrane switches

What Are the Main Stages in the Manufacturing Process of Membrane Switches?

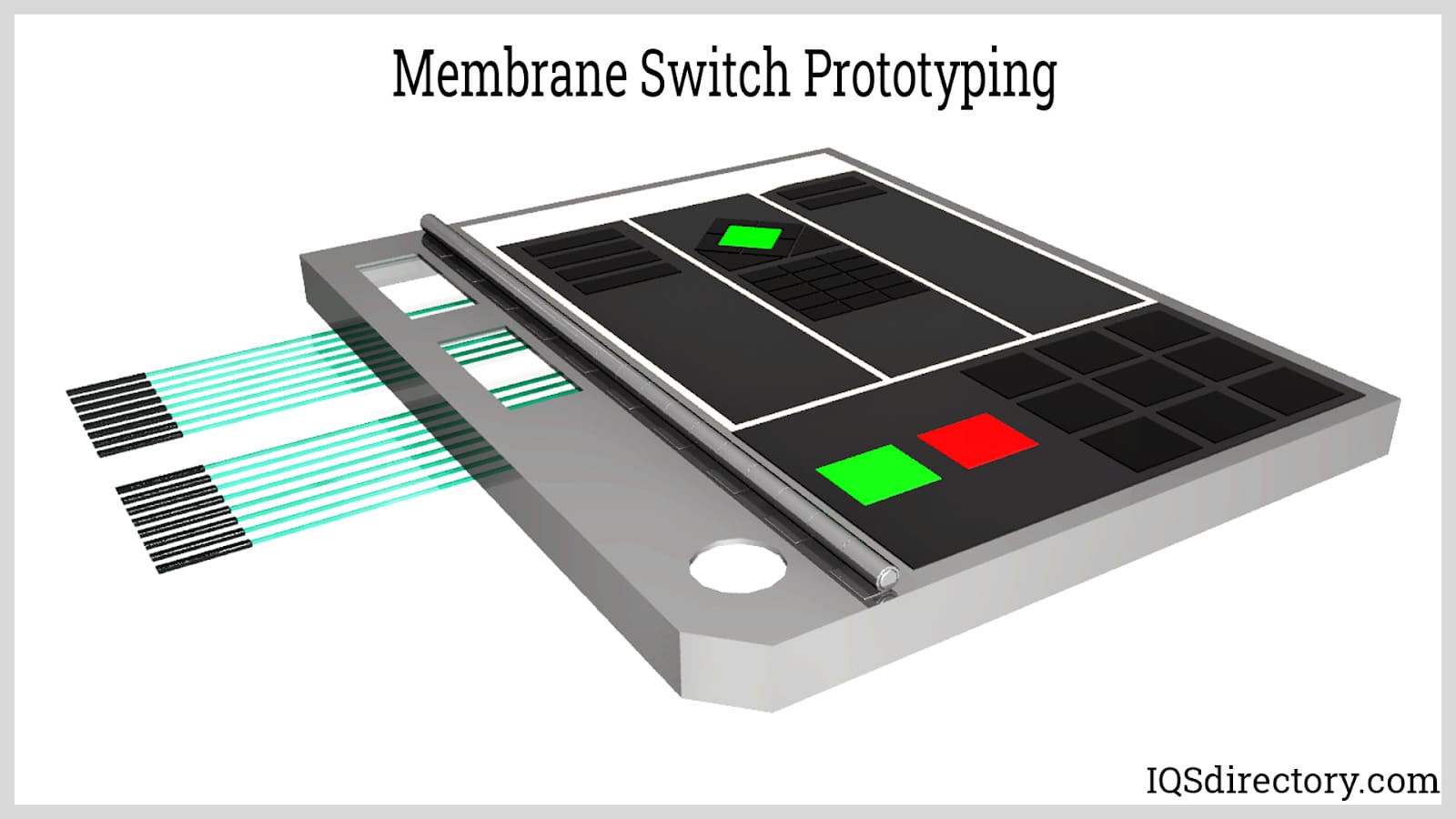

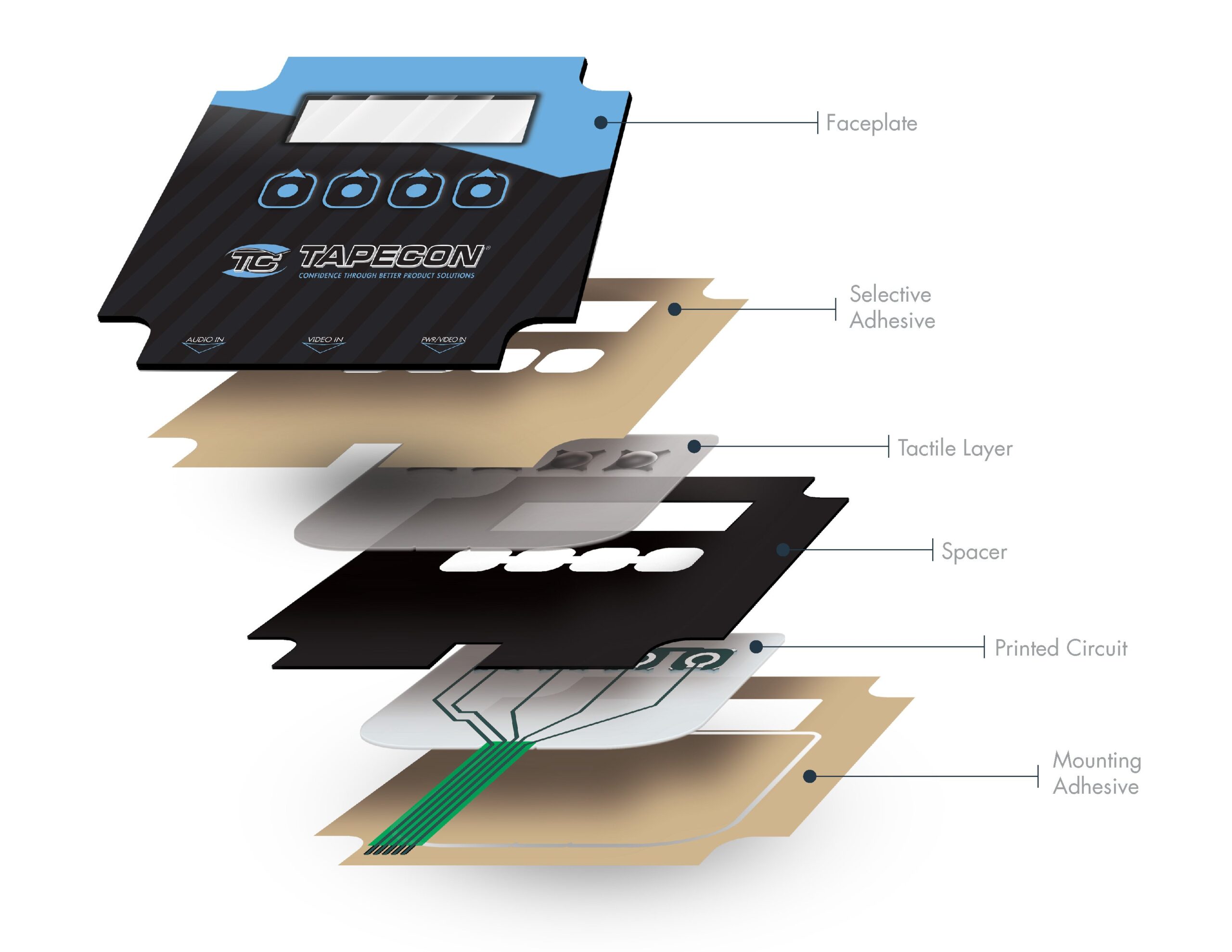

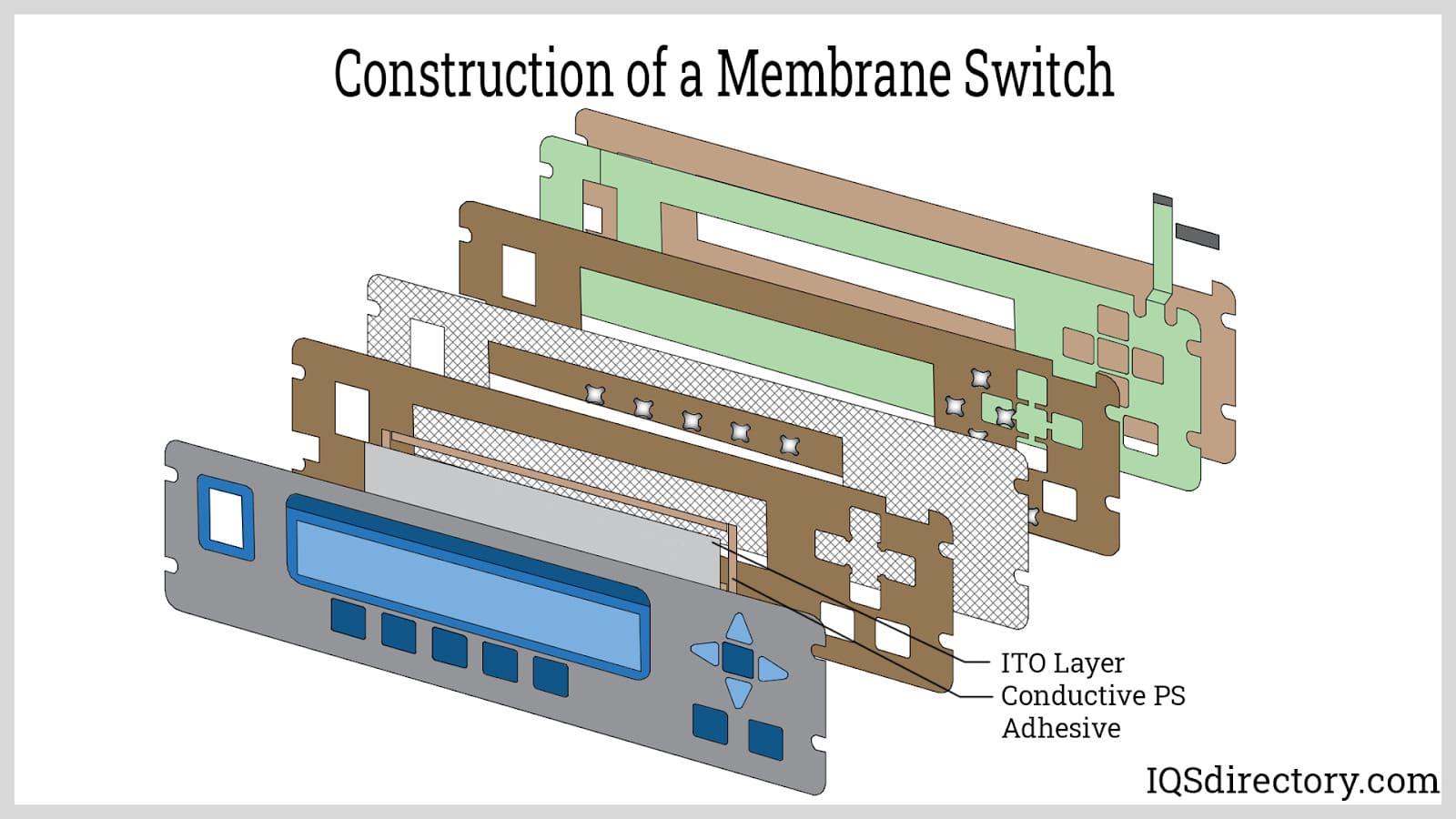

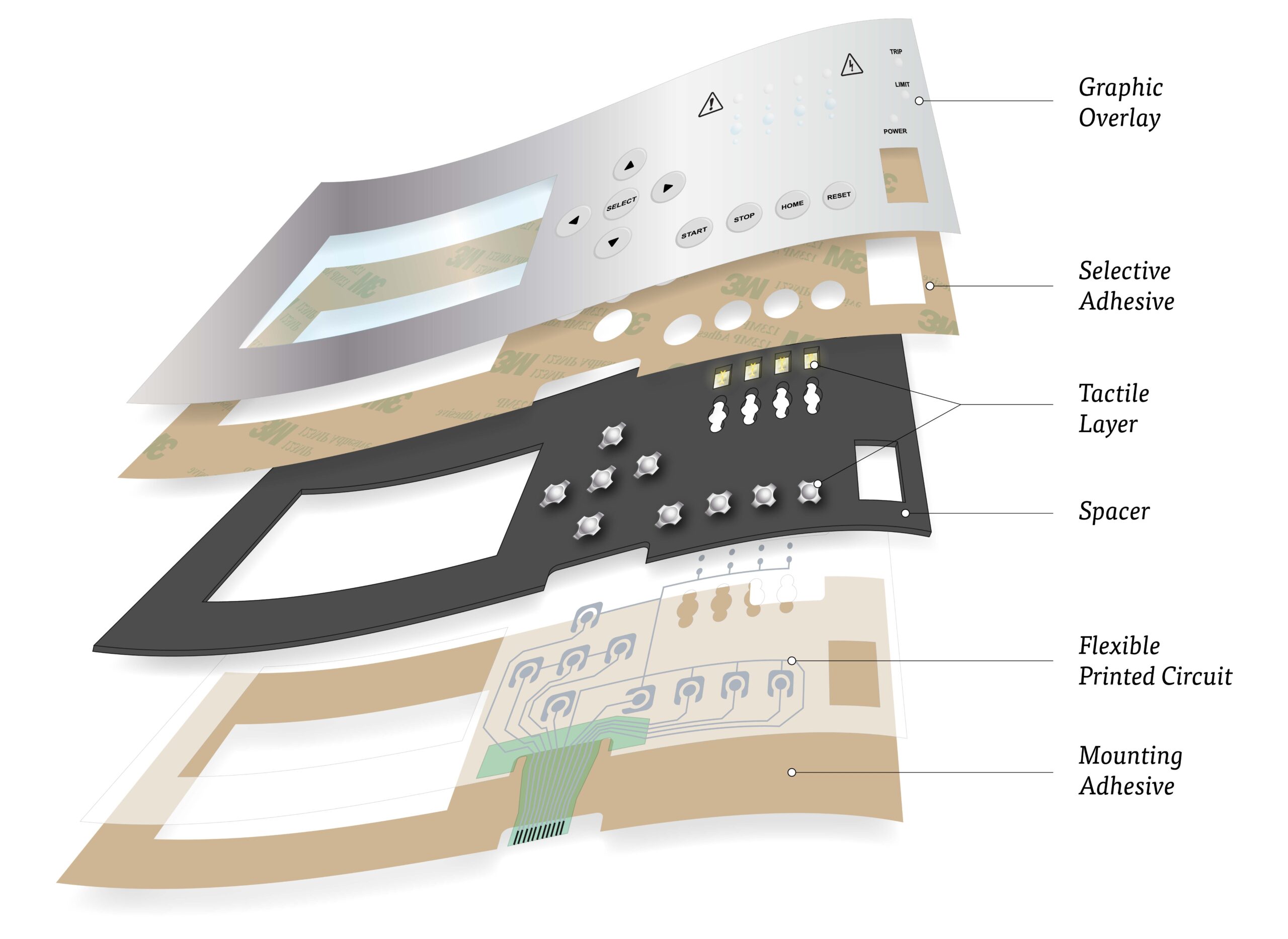

The manufacturing process for membrane switches is intricate, requiring precision at every stage. The process typically unfolds in four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials such as polyester films, adhesives, and conductive inks. Suppliers must ensure that materials meet specific standards for durability and functionality, especially when catering to demanding industries like automotive and medical devices. Proper inventory management and material testing are essential to prevent defects in the final product.

-

Forming: Once the materials are prepared, they undergo forming processes, which may include printing graphic overlays and creating circuit layers. Techniques such as screen printing or digital printing are commonly employed to ensure high-resolution graphics. Additionally, forming processes may involve embossing or die-cutting to create tactile feedback in switches. The choice of technique can significantly affect the switch’s aesthetics and functionality.

-

Assembly: The assembly stage is where the layered components come together. This stage typically utilizes pressure-sensitive adhesives to bond layers, ensuring that the switches maintain their integrity over time. Advanced techniques like automated assembly lines can enhance efficiency and reduce human error. Quality checks during assembly are crucial, as any misalignment or improper adhesion can lead to functional failures.

-

Finishing: The final stage involves applying protective coatings and conducting final assembly checks. This might include lamination for added durability and scratch resistance. Additionally, the finishing stage often incorporates testing to ensure that the switches meet specified performance criteria before shipping.

How Do Quality Assurance Practices Enhance Membrane Switch Manufacturing?

Quality assurance (QA) is integral to the manufacturing of membrane switches, ensuring that products meet both international standards and customer expectations. Manufacturers typically adhere to various quality frameworks, such as ISO 9001, which outlines requirements for a quality management system.

-

Relevant International Standards: Compliance with international standards like ISO 9001 is critical. This certification demonstrates a commitment to quality management practices that enhance customer satisfaction and operational efficiency. Additionally, industry-specific certifications such as CE for electronics and API for certain applications may be required depending on the end-use of the membrane switches.

-

Quality Control Checkpoints: Effective QA involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This phase inspects raw materials to ensure they meet the required specifications before production begins.

– In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC helps identify defects early, reducing waste and ensuring that corrective actions can be taken promptly.

– Final Quality Control (FQC): This critical checkpoint assesses the finished product, ensuring it meets all design specifications and performance standards before shipment. -

Common Testing Methods: Various testing methods are employed to validate the functionality and durability of membrane switches. These may include:

– Electrical testing to verify circuit integrity.

– Environmental testing to assess performance under extreme conditions (temperature, humidity).

– Mechanical testing to evaluate the switch’s tactile response and life cycle.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is paramount. Here are actionable steps to ensure that suppliers maintain high standards:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality management systems. Buyers should request access to their quality management documentation, including ISO certifications and internal audit reports.

-

Review Quality Reports: Suppliers should provide regular quality reports detailing performance metrics, defect rates, and corrective actions taken. These reports serve as a transparent communication tool, allowing buyers to assess supplier reliability.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can add an additional layer of assurance. These inspectors can conduct independent assessments of the manufacturing processes and final products, ensuring that they meet specified standards.

-

Understand Regional Certification Nuances: Different regions may have specific certification requirements that impact product acceptance. Buyers should familiarize themselves with these nuances, especially when sourcing from manufacturers in regions like the Middle East or Africa, where local certifications may also play a critical role.

What Are the Challenges in Quality Assurance for International B2B Buyers?

International B2B buyers face unique challenges regarding quality assurance in the membrane switch industry. Understanding these challenges can help buyers make informed decisions when selecting suppliers.

-

Cultural Differences: Variations in business practices and quality expectations across regions can complicate the procurement process. Buyers should establish clear communication channels and set explicit quality expectations to mitigate misunderstandings.

-

Logistical Complexities: Shipping products across borders introduces risks, including damage during transit and delays. Buyers should work with suppliers who have robust logistics management systems in place to minimize these risks.

-

Regulatory Compliance: Ensuring compliance with both local and international regulations can be daunting. Buyers should be proactive in understanding the regulatory landscape of both their home market and the supplier’s region to avoid compliance issues.

-

Technological Advancements: Rapid advancements in technology may result in a gap between supplier capabilities and buyer expectations. Engaging in continuous dialogue about technological updates can help ensure that suppliers remain competitive and capable of meeting evolving demands.

By understanding the manufacturing processes, quality assurance practices, and challenges associated with sourcing membrane switches, B2B buyers can make more informed decisions, ultimately leading to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘membrane switches’

To assist international B2B buyers in procuring membrane switches, this guide offers a practical checklist to streamline the sourcing process. Membrane switches are critical components in various applications, from consumer electronics to industrial controls, making informed procurement essential.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure that the membrane switches meet your application requirements. Consider factors such as the switch type (tactile vs. non-tactile), environmental conditions (water resistance, temperature range), and integration needs (backlighting, graphic overlays). This step helps avoid costly mistakes and ensures compatibility with existing systems.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and innovations in membrane switch technology. This includes advancements in materials, manufacturing processes, and design capabilities. Understanding these trends can help you make better decisions and potentially leverage new technologies that enhance user experience or reduce costs.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product samples, and case studies relevant to your industry. Look for suppliers with a proven track record in manufacturing membrane switches that comply with international quality standards, such as ISO certifications. Engaging with references from similar businesses can provide valuable insights into supplier reliability.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers you consider have the necessary certifications and comply with industry standards relevant to your region. This may include certifications for quality (ISO 9001), safety (UL, CE), and environmental regulations (RoHS). Compliance not only guarantees quality but also mitigates risks associated with regulatory non-conformity.

Step 5: Request Prototypes and Samples

Before finalizing an order, request prototypes or samples of the membrane switches. Testing these samples will allow you to evaluate their functionality, durability, and overall performance. This hands-on assessment is vital for confirming that the switches meet your specifications and expectations, ultimately reducing the risk of issues post-production.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, it’s time to negotiate terms and pricing. Discuss bulk pricing, lead times, payment terms, and warranty conditions. Ensure that you have a clear understanding of all costs involved, including shipping and handling, to avoid unexpected expenses later on.

Step 7: Establish Quality Control Measures

Before placing a large order, outline quality control measures that the supplier must adhere to during production. This includes regular inspections, testing protocols, and reporting procedures. Establishing these measures ensures that the final products meet your quality standards and specifications consistently.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing membrane switches more effectively, ensuring that they select the right products for their specific needs while minimizing risks associated with procurement.

Illustrative image related to membrane switches

Comprehensive Cost and Pricing Analysis for membrane switches Sourcing

What Are the Key Cost Components in Membrane Switch Manufacturing?

When sourcing membrane switches, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of substrates, adhesives, and conductive inks significantly impacts costs. For example, polyester and polycarbonate materials vary in price based on durability and flexibility. Incorporating features like tactile feedback mechanisms, such as metal domes or SnapMax actuators, also influences material costs.

-

Labor: Skilled labor is essential for the precision required in membrane switch manufacturing. The labor cost can vary by region, with countries offering lower wages potentially providing cost advantages. However, this must be balanced with the skills and expertise needed to ensure high-quality production.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, equipment maintenance, and facility expenses. Overhead can vary widely based on the manufacturer’s location and operational efficiency.

-

Tooling: Custom tooling for specialized designs can add significant upfront costs. However, these costs can be amortized over larger production runs, making it beneficial to consider volume when negotiating tooling fees.

-

Quality Control: Ensuring compliance with industry standards (e.g., ISO certifications) incurs costs related to testing and inspections. High-quality switches that meet stringent regulations will typically command a higher price but can lead to long-term savings by reducing failure rates.

-

Logistics: Shipping and handling costs can vary based on the distance, shipping method, and volume. International shipping may also involve customs duties and tariffs, which should be factored into the total cost.

-

Margin: The profit margin added by manufacturers typically depends on their market position, brand reputation, and the perceived value of their products.

How Do Price Influencers Affect Membrane Switch Costs?

Several factors can influence the pricing of membrane switches, making it essential for buyers to consider them during negotiations.

-

Volume/MOQ: The minimum order quantity (MOQ) often dictates pricing. Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to determine the most cost-effective order size.

-

Specifications and Customization: Customized solutions may involve higher costs due to unique tooling and design requirements. Standardized products, in contrast, can be sourced at lower prices.

-

Material Quality and Certifications: High-quality materials and industry certifications can increase costs but are critical for applications in sectors like aerospace or medical devices. Buyers must weigh the benefits of investing in certified products against budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding international shipping terms (Incoterms) is crucial for accurate cost calculations. Different terms can affect who bears the shipping and insurance costs, impacting the overall price.

What Buyer Tips Can Enhance Cost-Efficiency in Membrane Switch Sourcing?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, implementing strategic approaches can enhance cost-efficiency.

Illustrative image related to membrane switches

-

Negotiation: Engage suppliers in discussions about pricing flexibility, especially for larger orders or long-term contracts. Building relationships can lead to better terms and discounts.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also long-term costs, including maintenance, operational efficiency, and potential downtime due to switch failures. Investing in quality products can reduce TCO significantly.

-

Understand Pricing Nuances: Be aware of regional pricing variations due to labor costs, material availability, and economic conditions. Buyers should conduct market research to ensure they are not overpaying based on local pricing norms.

-

Leverage Technology: Utilize online platforms and procurement tools to compare prices and supplier capabilities efficiently. This can streamline the sourcing process and uncover competitive pricing options.

While indicative prices can vary widely based on the factors discussed, thorough research and strategic negotiations can lead to better sourcing outcomes in the membrane switch market.

Alternatives Analysis: Comparing membrane switches With Other Solutions

Exploring Alternatives to Membrane Switches: A Comparative Analysis

When considering the best interface solutions for electronic devices, membrane switches are a popular choice due to their simplicity, versatility, and cost-effectiveness. However, various alternatives can meet similar needs, each with distinct advantages and drawbacks. This analysis compares membrane switches with two alternative technologies: capacitive touch switches and mechanical switches, providing insights for B2B buyers seeking the most suitable solution for their applications.

| Comparison Aspect | Membrane Switches | Capacitive Touch Switches | Mechanical Switches |

|---|---|---|---|

| Performance | Reliable for low to medium use cases | High sensitivity and responsiveness | Excellent tactile feedback |

| Cost | Generally low-cost | Moderate to high-cost | Varies widely, can be low or high |

| Ease of Implementation | Easy to design and install | Requires specific PCB design and setup | Simple installation, but bulkier |

| Maintenance | Low maintenance due to sealing | Minimal maintenance, but sensitive | Higher maintenance due to wear |

| Best Use Case | Consumer electronics, medical devices | Modern interfaces, smartphones, tablets | Industrial machinery, automotive |

What Are the Pros and Cons of Capacitive Touch Switches?

Capacitive touch switches utilize the electrical properties of the human body to detect touch. They offer a sleek, modern interface that is highly sensitive and can support multi-touch gestures. One of their primary advantages is the absence of moving parts, which enhances durability and reduces maintenance needs. However, they can be more expensive than membrane switches and may require careful design to mitigate false activations in environments with moisture or dirt. Their reliance on specific PCB configurations can complicate implementation, making them less ideal for projects with tight deadlines or budget constraints.

How Do Mechanical Switches Compare in Terms of Functionality?

Mechanical switches are a traditional option known for their reliability and tactile feedback. These switches provide a clear click or resistance when pressed, which can enhance user experience in applications where tactile response is crucial. They are commonly used in industrial settings where durability and reliability are paramount. However, mechanical switches can be bulkier and may require more maintenance over time due to wear and tear, especially in high-usage applications. Their cost can vary significantly based on the type and quality, making them suitable for specific applications where performance outweighs cost considerations.

Making the Right Choice: Which Solution Fits Your Needs?

For B2B buyers, the decision to choose between membrane switches, capacitive touch switches, and mechanical switches should be based on several factors, including the specific application, budget, and desired user experience. Membrane switches are a strong choice for applications requiring a low-cost and low-maintenance solution, particularly in consumer electronics or medical devices. In contrast, capacitive touch switches may be more suitable for modern devices that benefit from sleek interfaces, while mechanical switches excel in environments demanding high reliability and tactile feedback.

By carefully evaluating the unique requirements of your project and the characteristics of each alternative, you can make an informed decision that aligns with your operational goals and user expectations.

Essential Technical Properties and Trade Terminology for membrane switches

What Are the Key Technical Properties of Membrane Switches?

Understanding the critical specifications of membrane switches is essential for making informed purchasing decisions. Here are some of the most important technical properties to consider:

1. Material Grade

Membrane switches are typically constructed from materials like polyester (PET) or polycarbonate (PC). The choice of material affects durability, clarity, and resistance to environmental factors such as moisture and UV light. For B2B buyers, selecting the right material grade ensures that the membrane switch can withstand the specific conditions of its intended application, such as automotive or medical environments.

2. Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the membrane switch components. Precise tolerances are crucial for ensuring that switches fit correctly into their designated panels and function reliably. In B2B contexts, high tolerance levels can reduce manufacturing waste and minimize the risk of product failure, leading to cost savings and enhanced customer satisfaction.

Illustrative image related to membrane switches

3. Actuation Force

Actuation force is the amount of pressure required to activate a switch. This specification can vary widely among tactile and non-tactile membrane switches. Understanding actuation force is essential for designing user-friendly interfaces that meet ergonomic standards, particularly in sectors like healthcare, where ease of use is critical.

4. Cycle Life

Cycle life indicates the number of times a membrane switch can be actuated before it fails. This property is particularly important for applications requiring frequent use. A longer cycle life translates to lower replacement costs and higher reliability, making it a key consideration for B2B buyers looking to minimize long-term operational expenses.

5. Environmental Sealing

Environmental sealing refers to the switch’s ability to resist moisture, dust, and other contaminants. Membrane switches can be designed to meet various IP (Ingress Protection) ratings, which specify their resistance to environmental factors. For buyers in industries like food processing or pharmaceuticals, ensuring adequate sealing is vital to maintain compliance with health and safety standards.

Illustrative image related to membrane switches

What Are Common Trade Terms Used in the Membrane Switch Industry?

Familiarity with industry jargon can facilitate smoother transactions and better understanding between buyers and suppliers. Here are some key trade terms relevant to membrane switches:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of membrane switches, an OEM may design custom switches that are then integrated into larger systems, such as medical devices or automotive dashboards.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is particularly significant for B2B transactions, as it helps buyers understand the minimum investment required to procure membrane switches, especially for custom designs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. In the membrane switch industry, submitting an RFQ allows buyers to compare costs and specifications from multiple manufacturers, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is crucial for B2B buyers, as they clarify who bears the risk and costs associated with shipping membrane switches, ensuring smooth logistics and compliance with trade regulations.

5. Tactile vs. Non-Tactile

This terminology distinguishes between two main types of membrane switches. Tactile switches provide physical feedback upon actuation, while non-tactile switches do not. Understanding this difference is vital for buyers seeking to enhance user interaction with their products.

By grasping these technical properties and trade terms, B2B buyers can make more informed choices regarding membrane switches, ensuring that their selections align with both their operational needs and strategic goals.

Illustrative image related to membrane switches

Navigating Market Dynamics and Sourcing Trends in the membrane switches Sector

What Are the Current Market Trends Impacting Membrane Switches?

The membrane switches market is experiencing significant growth driven by various global factors. As industries increasingly adopt automation and digital interfaces, the demand for user-friendly, durable, and versatile input devices is on the rise. Key markets in Africa, South America, the Middle East, and Europe are particularly active, with rapid urbanization and industrialization leading to a surge in electronic device production. Countries like Saudi Arabia and Vietnam are investing heavily in manufacturing, further stimulating the demand for membrane switches, which are integral in sectors like automotive, aerospace, and medical devices.

Emerging trends include the integration of advanced technologies such as haptic feedback and touch-sensitive interfaces, enhancing user experience. Additionally, the customization of membrane switches to meet specific design and functional needs is becoming increasingly common. B2B buyers are also focusing on suppliers that offer a range of options, including tactile and non-tactile switches, various actuator types, and compatibility with graphic overlays. This flexibility allows businesses to create unique products tailored to their market demands, making it imperative for suppliers to stay ahead of the curve in innovation and customization.

How Can Sustainability and Ethical Sourcing Impact Membrane Switches Procurement?

As global awareness of environmental sustainability grows, B2B buyers are increasingly prioritizing suppliers who adhere to ethical sourcing practices. The production of membrane switches can have environmental impacts, from the materials used to the manufacturing processes employed. Buyers should seek manufacturers who utilize eco-friendly materials and processes, such as water-based adhesives and recyclable substrates, to minimize their carbon footprint.

Furthermore, certifications such as ISO 14001, which focuses on effective environmental management systems, can serve as indicators of a supplier’s commitment to sustainability. Ethical sourcing not only enhances a company’s brand image but also aligns with consumer preferences for environmentally responsible products. By choosing suppliers that prioritize sustainability, businesses can contribute to a greener supply chain while also meeting regulatory requirements that are increasingly being enforced in various markets.

What Is the Historical Context of Membrane Switches in B2B Markets?

The evolution of membrane switches dates back to the 1960s when they were first introduced as a cost-effective alternative to mechanical switches. Their development was driven by the need for more compact and reliable electronic interfaces. Over the decades, advancements in materials and manufacturing techniques have allowed for greater customization and functionality, leading to their widespread adoption across various industries.

Initially utilized mainly in consumer electronics, membrane switches have since found applications in critical sectors such as automotive and medical devices, where reliability and performance are paramount. Today, they are an essential component in sophisticated user interfaces, reflecting the ongoing technological advancements and the increasing complexity of electronic devices. As industries continue to evolve, membrane switches will play a crucial role in shaping future human-machine interactions.

Frequently Asked Questions (FAQs) for B2B Buyers of membrane switches

-

How do I choose the right membrane switch for my application?

Choosing the right membrane switch involves understanding your specific application requirements. Consider factors such as tactile feedback preferences (tactile vs. non-tactile), environmental conditions (e.g., moisture, temperature), and the desired lifespan of the switch. Additionally, evaluate the compatibility with graphic overlays and backlighting needs. Collaborating with a supplier that offers customization options can also ensure that the switch meets your design and functionality criteria. -

What are the key benefits of using membrane switches in industrial applications?

Membrane switches offer several advantages in industrial settings, including their compact design, resistance to dust and moisture, and ease of cleaning. They can be customized for various tactile feedback options, enhancing user experience. Additionally, membrane switches are often more cost-effective than traditional mechanical switches, providing durability with a long lifecycle, which is crucial for reducing maintenance costs in industrial environments. -

What customization options are available for membrane switches?

Customization options for membrane switches include various actuator types (metal domes, polyester domes), graphic overlays, colors, and sizes. You can also opt for features like backlighting, tactile feedback, and different layer configurations to meet specific needs. Discussing your requirements with manufacturers can help identify the best options to enhance functionality and aesthetics for your application. -

What is the minimum order quantity (MOQ) for membrane switches?

Minimum order quantities (MOQ) for membrane switches can vary significantly among suppliers. Generally, MOQs range from 100 to 1,000 units, depending on the complexity of the design and the manufacturing process. If you are a smaller business or a startup, consider discussing your needs with suppliers who may offer flexible MOQ options or prototyping services to accommodate your initial requirements. -

How do I vet potential suppliers of membrane switches?

Vetting suppliers involves evaluating their manufacturing capabilities, certifications (e.g., ISO 9001), and industry experience. Request samples of previous work to assess quality and reliability. Additionally, check for customer reviews and references, and inquire about their production processes, lead times, and warranty policies. Engaging in direct communication can also provide insights into their responsiveness and customer service quality. -

What payment terms should I expect when sourcing membrane switches internationally?

Payment terms for international orders can vary widely among suppliers. Common arrangements include upfront payments, partial payments with a balance due upon delivery, or payment upon receipt of goods. It’s essential to clarify these terms before finalizing your order. Consider using secure payment methods such as letters of credit or escrow services to protect your investment during international transactions. -

What quality assurance processes should I look for in membrane switch manufacturers?

Look for manufacturers that implement stringent quality assurance processes throughout production. This includes material inspections, functional testing, and adherence to international quality standards. A robust QA process should also involve final inspections before shipping to ensure that the switches meet specified requirements. Ask potential suppliers about their QA certifications and procedures to ensure product reliability. -

How are membrane switches typically shipped internationally, and what logistics should I consider?

Membrane switches are usually shipped via air or sea freight, depending on the volume and urgency of the order. When considering logistics, factor in lead times, shipping costs, and customs duties. Working with a supplier that has experience in international shipping can help streamline the process. Ensure that your supplier provides proper documentation for customs clearance to avoid delays upon arrival.

Top 3 Membrane Switches Manufacturers & Suppliers List

1. CSi Keyboards – Keypads

Domain: csikeyboards.com

Registered: 1997 (28 years)

Introduction: Keypads can be categorized into membrane switches and mechanical switches. Membrane keypads consist of pressure pads on a flat circuit with no separate moving parts, using electrical contact beneath the keys. Mechanical switches utilize metal domes for tactile feedback, which are made of stainless steel and act as momentary switch contacts. Membrane keypads are easier to clean and seal due to thei…

2. Loomia – Membrane Switch: Single Backlit Button

Domain: loomia.com

Registered: 2004 (21 years)

Introduction: {‘product_name’: ‘Loomia Membrane Switch: Single Backlit Button’, ‘price’: ‘$40.00’, ‘availability’: ‘Sold Out’, ‘description’: ‘A simple (mechanical) membrane switch with an embedded LED that completes a circuit when pressed. Can be used to create glowing icons or logos. Also available without backlighting.’, ‘features’: {‘seamless_integration’: ‘Soft user interfaces for modern, intuitive experie…

3. Butler Technologies – Membrane Switches

Domain: butlertechnologies.com

Registered: 1999 (26 years)

Introduction: Membrane switches are electrical devices that turn a circuit on and off, constructed of flexible layers over a printed circuit. They are used in various industries including medical, industrial controls, and consumer electronics. Membrane switches are momentary action switches, meaning circuits are open until a button is pressed. They are cost-effective, low profile, and can fulfill functions of t…

Strategic Sourcing Conclusion and Outlook for membrane switches

In conclusion, strategic sourcing of membrane switches presents a significant opportunity for international B2B buyers. These innovative components offer diverse applications across various industries, such as automotive, aerospace, and medical devices, driven by their unique construction and customizable features. The flexibility in design—from tactile feedback options to non-tactile configurations—enables businesses to tailor solutions that meet specific operational needs.

Understanding the intricacies of membrane switch technology, including actuator types and layer compositions, empowers buyers to make informed decisions that align with their product requirements. By leveraging the expertise of reputable manufacturers, companies can ensure high-quality production while adhering to stringent industry standards.

As global markets continue to evolve, the demand for reliable and efficient human interface solutions will only increase. For B2B buyers in Africa, South America, the Middle East, and Europe, now is the time to engage with suppliers who can provide both innovation and reliability. Explore partnerships that can elevate your product offerings and enhance user experience, positioning your business at the forefront of technological advancement in membrane switches.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to membrane switches

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.