A Deep Dive into Medical Equipment Leak Detection System Solution

Introduction: Navigating the Global Market for medical equipment leak detection system

In the ever-evolving landscape of healthcare, sourcing a reliable medical equipment leak detection system presents a significant challenge for international B2B buyers. Ensuring that medical devices maintain their integrity is paramount, as leaks can lead to catastrophic consequences for patient safety and regulatory compliance. This comprehensive guide delves into the critical aspects of medical equipment leak detection systems, covering various types, applications, supplier vetting processes, and cost considerations.

For businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe—ranging from Nigeria to Germany—understanding these elements is crucial. The guide empowers B2B buyers by providing actionable insights into selecting the right leak detection solutions tailored to their unique operational needs. By examining the standards that govern medical device safety, the implications of regulatory compliance, and the latest technological advancements in leak detection, this resource equips decision-makers with the knowledge needed to make informed purchasing decisions.

Navigating the complexities of medical equipment leak detection not only enhances product reliability and safety but also fosters long-term operational efficiency and cost-effectiveness. This guide serves as a vital tool for manufacturers and distributors aiming to elevate their quality assurance processes and maintain a competitive edge in the global market.

Understanding medical equipment leak detection system Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pressure Decay Testing | Measures pressure drop over time to detect leaks. | Catheters, infusion pumps, blood bags | Pros: Non-invasive, reliable for sealed devices. Cons: May not detect very small leaks. |

| Vacuum Decay Testing | Utilizes vacuum to identify leaks by measuring pressure changes. | Implantable devices, syringes, blister packs | Pros: Highly sensitive, effective for complex shapes. Cons: Requires more setup and calibration. |

| Burst Testing | Tests the maximum pressure a device can withstand before failure. | Packaging, medical bags, balloon catheters | Pros: Assesses structural integrity, easy to interpret. Cons: Can damage the product if not calibrated correctly. |

| Occlusion Testing | Checks for blockages or leaks in fluid delivery systems. | IV bags, dialysis machines, medical tubing | Pros: Directly related to functionality, quick results. Cons: Limited to fluid-carrying components. |

| Helium Leak Testing | Uses helium as a tracer gas to find leaks in sealed systems. | Ventilators, high-precision medical devices | Pros: Extremely sensitive, can detect minuscule leaks. Cons: More costly and requires specialized equipment. |

What Are the Characteristics of Pressure Decay Testing Systems?

Pressure decay testing systems are designed to monitor the pressure within a sealed medical device over a specific time period. If a leak is present, the pressure will drop, indicating a failure. This method is widely used for devices like catheters and infusion pumps, where maintaining an airtight seal is critical for patient safety. Buyers should consider the testing environment and the specific pressure ranges of their products, as this method is effective for non-invasive testing but may not detect very small leaks.

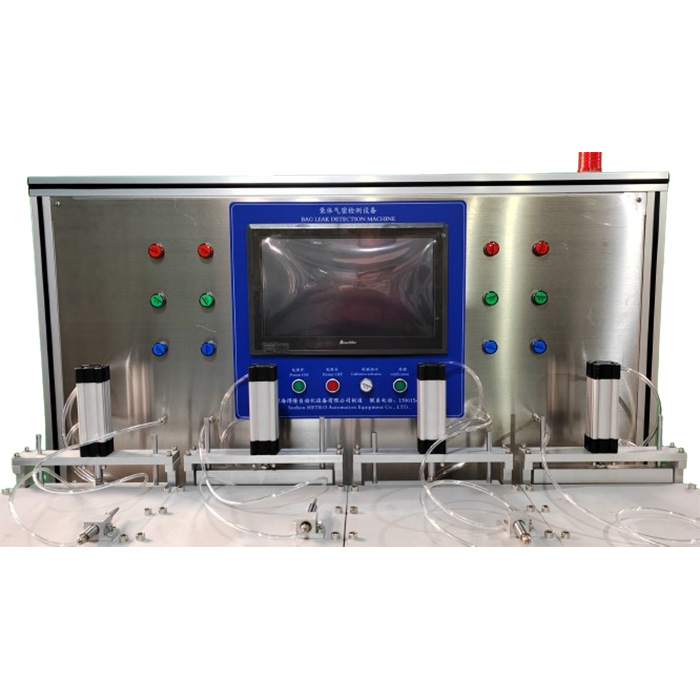

Illustrative image related to medical equipment leak detection system

How Does Vacuum Decay Testing Work for Medical Devices?

Vacuum decay testing creates a vacuum around the medical device and measures the pressure change over time. This method is particularly suitable for complex shapes or implantable devices, as it can detect even the smallest leaks. B2B buyers should evaluate their production processes and the level of sensitivity required for their devices. While this method is highly effective, it necessitates careful setup and calibration to ensure accurate results.

Why Choose Burst Testing for Medical Equipment?

Burst testing is a straightforward method that evaluates the maximum pressure a device can withstand before rupture. This testing is essential for ensuring the structural integrity of packaging and medical bags. While it provides easy-to-interpret results, buyers must ensure that the calibration is precise to avoid damaging the product during testing. It is ideal for manufacturers focusing on the safety and reliability of their products under pressure.

What Is the Role of Occlusion Testing in Medical Device Functionality?

Occlusion testing is designed to identify blockages or leaks in fluid delivery systems, making it crucial for devices such as IV bags and dialysis machines. This method allows manufacturers to ensure that fluids are delivered accurately without leaks. Buyers should prioritize this testing for components that are directly involved in patient care. Although it yields quick results, its application is limited to fluid-carrying devices.

When Is Helium Leak Testing the Best Option?

Helium leak testing employs helium as a tracer gas to detect leaks in sealed systems. This method is particularly effective for high-precision medical devices like ventilators. Its sensitivity allows for the detection of even the smallest leaks, making it ideal for critical applications. However, buyers should be aware of the higher costs associated with this testing method and the need for specialized equipment. It is essential for manufacturers who prioritize the integrity of their devices in high-stakes environments.

Key Industrial Applications of medical equipment leak detection system

| Industry/Sector | Specific Application of medical equipment leak detection system | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Device Manufacturing | Testing of catheters and surgical instruments | Ensures patient safety by preventing contamination and device failure | Compliance with ISO 13485 and local regulations, testing accuracy |

| Pharmaceutical Packaging | Leak testing of blister packs and vials | Maintains sterility and efficacy of medications | Integration with existing production lines, automation options |

| Hospital Equipment Maintenance | Leak detection in ventilators and infusion pumps | Enhances operational reliability and patient safety | Durability and ease of maintenance, support and training services |

| Diagnostics and Imaging Devices | Testing of MRI and ultrasound equipment | Reduces downtime and increases diagnostic accuracy | Compatibility with various diagnostic technologies, precision |

| Implantable Devices | Leak testing of pacemakers and cochlear implants | Ensures long-term reliability and patient safety | Advanced technology for hermetic sealing, international certifications |

How is the Medical Equipment Leak Detection System Used in Medical Device Manufacturing?

In medical device manufacturing, leak detection systems are critical for testing devices such as catheters and surgical instruments. These devices must remain sterile and function correctly to ensure patient safety. By implementing robust leak testing protocols, manufacturers can identify potential defects that could compromise the integrity of the device. Buyers in this sector should prioritize sourcing equipment that complies with international standards like ISO 13485, ensuring their products meet regulatory requirements across different markets, including Africa and Europe.

Illustrative image related to medical equipment leak detection system

What Role Does Leak Detection Play in Pharmaceutical Packaging?

In the pharmaceutical industry, leak detection systems are vital for testing blister packs and vials. These packaging solutions must maintain sterility to preserve the effectiveness of medications. By ensuring that packaging is leak-proof, companies can prevent contamination and ensure patient safety. When sourcing leak detection systems, businesses should consider automation options that seamlessly integrate with existing production lines to enhance efficiency and reduce operational costs.

How Does Leak Detection Benefit Hospital Equipment Maintenance?

Leak detection systems are essential for maintaining hospital equipment such as ventilators and infusion pumps. These systems help ensure that devices operate reliably, minimizing the risk of failure during critical medical procedures. Regular leak testing can enhance patient safety and operational efficiency within healthcare facilities. Buyers should look for durable systems that require minimal maintenance and come with robust support services to ensure continuous operation.

Why is Leak Testing Important for Diagnostics and Imaging Devices?

In the diagnostics and imaging sector, leak detection systems are used to test MRI and ultrasound equipment. Ensuring these devices are free from leaks is crucial for maintaining their operational reliability and accuracy in diagnostics. A malfunction could lead to incorrect diagnoses, negatively impacting patient outcomes. Buyers should focus on sourcing precision testing equipment compatible with various technologies to meet the diverse needs of diagnostic applications.

How Does Leak Testing Enhance the Reliability of Implantable Devices?

Leak detection systems play a vital role in ensuring the reliability of implantable devices such as pacemakers and cochlear implants. These devices must be hermetically sealed to prevent fluid ingress, which could compromise their functionality and pose risks to patient safety. Manufacturers should seek advanced leak testing technologies that offer high precision and comply with international certifications, ensuring the long-term safety of their products in global markets.

3 Common User Pain Points for ‘medical equipment leak detection system’ & Their Solutions

Scenario 1: Ensuring Patient Safety with Reliable Leak Detection

The Problem:

In the medical equipment sector, patient safety is paramount. Buyers often face the daunting challenge of ensuring that devices such as infusion pumps, catheters, and blood bags are leak-proof to prevent contamination and protect patients. A single leak can lead to catastrophic consequences, including infections or device malfunctions during critical procedures. This concern is amplified in regions where access to immediate medical care may be limited, making the stakes even higher for healthcare providers. Additionally, ensuring compliance with international standards such as ISO 13485 can complicate the procurement process, especially for buyers unfamiliar with specific testing requirements.

The Solution:

To address these challenges, buyers should prioritize sourcing leak detection systems designed specifically for medical devices. When selecting a system, look for equipment that offers multiple testing methods, such as pressure decay and vacuum decay tests, to ensure comprehensive leak detection. Ensure that the chosen system complies with regulatory standards to facilitate smoother audits and inspections. Engaging with suppliers who provide training and support can also enhance your team’s ability to conduct effective leak testing, thereby boosting overall patient safety. Regular maintenance and calibration of the detection systems will further ensure their reliability and accuracy over time.

Scenario 2: Reducing Manufacturing Costs through Effective Leak Testing

The Problem:

Manufacturers of medical devices often grapple with high costs associated with product recalls, warranty claims, and repairs due to undetected leaks. These financial burdens can be particularly impactful for companies operating in emerging markets where profit margins are already tight. Buyers may find it challenging to justify the upfront investment in leak detection systems when they are focused on minimizing operational costs, even though the long-term savings can be substantial.

The Solution:

Investing in advanced leak detection technology can dramatically reduce manufacturing costs. When selecting a leak detection system, opt for solutions that allow for high-capacity testing and the ability to test multiple devices simultaneously. This efficiency can significantly decrease production time and costs associated with returns or repairs. Furthermore, implementing a robust quality control process that includes regular leak testing can help identify issues early in the manufacturing process, mitigating the risk of costly recalls. Consider partnering with suppliers who offer comprehensive service agreements, ensuring that your equipment is maintained and calibrated properly, which will extend its lifespan and enhance productivity.

Scenario 3: Navigating Regulatory Compliance in Diverse Markets

The Problem:

For B2B buyers in the medical equipment sector, navigating the complex landscape of regulatory compliance can be overwhelming, especially when dealing with international markets. Different regions, such as Europe, Africa, and South America, have varying standards and requirements for medical device testing. This inconsistency can lead to complications in the supply chain, delayed product launches, and potential legal liabilities if compliance is not met.

The Solution:

To effectively manage regulatory compliance, buyers should invest in leak detection systems that are versatile and adaptable to different market standards. When sourcing equipment, prioritize suppliers who have a proven track record of understanding and adhering to international regulations. This partnership can provide invaluable insights into local compliance requirements, helping to streamline the certification process. Additionally, developing a thorough understanding of the specific regulations in each market can guide procurement decisions. Regular training sessions for staff on compliance-related topics and leak testing protocols can also bolster your organization’s ability to meet regulatory demands and ensure successful market entry.

Strategic Material Selection Guide for medical equipment leak detection system

What Materials Are Commonly Used in Medical Equipment Leak Detection Systems?

When selecting materials for medical equipment leak detection systems, it is crucial to consider their properties, advantages, and limitations. The following analysis focuses on four common materials: stainless steel, silicone rubber, polycarbonate, and fluoropolymers. Each material has unique characteristics that influence its performance in leak detection applications.

How Does Stainless Steel Perform in Leak Detection Systems?

Stainless steel is widely used in medical equipment due to its excellent strength, durability, and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for various leak testing environments. Stainless steel’s non-reactive nature ensures that it does not contaminate the media being tested, which is critical in medical applications.

Illustrative image related to medical equipment leak detection system

Pros: Stainless steel offers exceptional durability and longevity, reducing the need for frequent replacements. Its resistance to corrosion and high temperatures makes it ideal for rigorous testing scenarios.

Cons: The primary drawback is its higher cost compared to other materials. Additionally, manufacturing complex shapes can be challenging, which may increase production time and costs.

Impact on Application: Stainless steel is compatible with a wide range of media, including gases and liquids, making it versatile for different leak detection scenarios.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and ISO for stainless steel grades. Countries like Germany have stringent regulations regarding material quality, which may affect procurement decisions.

What Role Does Silicone Rubber Play in Medical Equipment Leak Detection?

Silicone rubber is another popular choice for sealing and gaskets in leak detection systems. It exhibits excellent flexibility and can maintain its integrity across a wide temperature range. Silicone rubber is also resistant to aging and UV exposure, making it suitable for long-term applications.

Pros: Its flexibility allows for effective sealing even in irregular shapes or surfaces. Silicone is also relatively low-cost and easy to manufacture, making it a practical choice for many applications.

Cons: While silicone rubber is durable, it may not withstand high-pressure environments as effectively as metals. It can also be susceptible to certain chemicals, which may limit its applicability in specific media.

Impact on Application: Silicone rubber is ideal for applications involving low-pressure gas or liquid testing, where flexibility and sealing capability are paramount.

Considerations for International Buyers: Buyers should verify the silicone’s compliance with medical-grade standards, especially in regions with strict regulations like Europe. Understanding the specific chemical compatibility is also essential.

Illustrative image related to medical equipment leak detection system

How Do Polycarbonates Contribute to Leak Detection Systems?

Polycarbonate is a robust thermoplastic known for its high impact resistance and optical clarity. In leak detection systems, polycarbonate can be used for housings and components that require transparency for visual inspection.

Pros: Polycarbonate is lightweight and can be molded into complex shapes, which can enhance design flexibility. Its high impact resistance makes it suitable for environments where mechanical stress is a concern.

Cons: Polycarbonate may not offer the same level of chemical resistance as other materials, which can limit its use in certain applications. It is also more susceptible to scratching, which can affect visibility over time.

Impact on Application: Polycarbonate is particularly useful in applications where visibility is crucial, such as monitoring fluid levels or detecting leaks visually.

Considerations for International Buyers: Buyers should ensure that polycarbonate components meet relevant standards for medical devices, as some regions may have specific requirements for materials used in patient-contact applications.

What Advantages Do Fluoropolymers Offer in Leak Detection Systems?

Fluoropolymers, such as PTFE (Teflon), are known for their exceptional chemical resistance and low friction properties. These materials are ideal for applications involving aggressive chemicals or extreme temperatures.

Illustrative image related to medical equipment leak detection system

Pros: Fluoropolymers are highly durable and can withstand a wide range of chemicals, making them suitable for various leak detection scenarios. Their non-stick properties also facilitate easier cleaning and maintenance.

Cons: The primary limitation of fluoropolymers is their higher cost compared to other materials. Additionally, they can be more challenging to process, which may increase manufacturing complexity.

Impact on Application: Fluoropolymers are particularly beneficial in applications involving corrosive substances, ensuring the integrity of the leak detection system.

Considerations for International Buyers: Buyers must consider the certification of fluoropolymer materials for medical use, especially in regions with strict compliance requirements. Understanding the specific chemical compatibility is crucial for ensuring safety and effectiveness.

Summary Table of Material Selection for Medical Equipment Leak Detection Systems

| Material | Typical Use Case for medical equipment leak detection system | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components and fittings in leak testers | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Silicone Rubber | Seals and gaskets in low-pressure applications | Excellent flexibility and low cost | Limited high-pressure performance | Medium |

| Polycarbonate | Housings and visual inspection components | Lightweight and high impact resistance | Susceptible to scratching and chemicals | Medium |

| Fluoropolymers | Seals in corrosive environments | Exceptional chemical resistance | Higher cost and processing complexity | High |

This guide provides insights into the strategic selection of materials for medical equipment leak detection systems, helping international B2B buyers make informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for medical equipment leak detection system

What Are the Main Stages in the Manufacturing Process of Medical Equipment Leak Detection Systems?

The manufacturing process of medical equipment leak detection systems involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring the reliability and functionality of the final product.

-

Material Preparation: This initial stage focuses on sourcing high-quality materials that meet industry standards. Common materials include various plastics, metals, and elastomers, selected for their durability and resistance to environmental factors. Suppliers should provide certifications confirming that materials comply with international standards such as ISO 13485, which is essential for medical device manufacturing.

-

Forming: In this stage, materials are shaped into the required components using techniques such as injection molding, extrusion, or CNC machining. For leak detection systems, precision is paramount. Manufacturers employ advanced technology to ensure that components are formed accurately, minimizing the risk of defects that could affect performance.

-

Assembly: After forming, components are assembled into the final product. This process may involve manual assembly or automated systems, depending on the complexity and volume of the devices being produced. Quality assurance measures, such as real-time monitoring of assembly processes, are critical to ensuring that each unit is assembled correctly and meets design specifications.

-

Finishing: The final stage involves applying surface treatments, coatings, or additional quality checks to ensure that the product is ready for distribution. This may include sterilization processes for components that will come into contact with patients. Final inspections are conducted to verify that the leak detection systems are free from defects and function as intended.

Which Quality Control Standards Are Relevant for Medical Equipment Leak Detection Systems?

Quality control (QC) in the manufacturing of medical equipment leak detection systems is governed by several international and industry-specific standards. Understanding these standards is vital for B2B buyers seeking reliable suppliers.

-

ISO 9001: This standard focuses on quality management systems and is applicable across various industries, including medical devices. It emphasizes continuous improvement and customer satisfaction, ensuring that manufacturers maintain high-quality standards throughout the production process.

-

ISO 13485: Specifically tailored for medical devices, this standard outlines the requirements for a comprehensive quality management system that ensures consistent design, development, production, and delivery of medical devices. Compliance with ISO 13485 is crucial for manufacturers aiming to enter international markets.

-

CE Marking: For products sold in Europe, obtaining a CE mark indicates that the equipment meets European health, safety, and environmental protection standards. This certification is essential for ensuring market access and is often a requirement for medical devices.

-

API Standards: For devices that involve pharmaceutical applications, adherence to API (Active Pharmaceutical Ingredients) standards is necessary. These standards ensure that the materials used in manufacturing are safe and effective for their intended use.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that each product meets regulatory and performance standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the manufacturing process. Suppliers must provide documentation proving compliance with relevant standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves monitoring and testing components as they are being produced. This may include visual inspections, dimensional checks, and functional testing to identify any issues early in the process.

-

Final Quality Control (FQC): Once the product is assembled, FQC involves comprehensive testing to ensure that the leak detection system performs as required. This may include leak testing under various conditions to verify that the device maintains its integrity.

Which Testing Methods Are Commonly Used in Quality Assurance?

Testing methods play a crucial role in verifying the performance and safety of medical equipment leak detection systems. Common methods include:

-

Pressure Decay Testing: This method involves subjecting the device to a specific pressure and monitoring for any drop in pressure, indicating a leak. It is widely used due to its simplicity and effectiveness.

-

Vacuum Decay Testing: Similar to pressure decay testing, this method creates a vacuum around the device and measures any changes in pressure. It is particularly useful for detecting minute leaks in sealed systems.

-

Burst Testing: This technique tests the maximum pressure the device can withstand before failure. It is essential for ensuring that the equipment can handle operational pressures without compromising safety.

-

Flow Testing: This method assesses the flow rates through the device to ensure that it meets specified performance criteria. It is particularly relevant for devices that rely on fluid movement.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of suppliers to ensure compliance with industry standards and reliability of products. Key actions include:

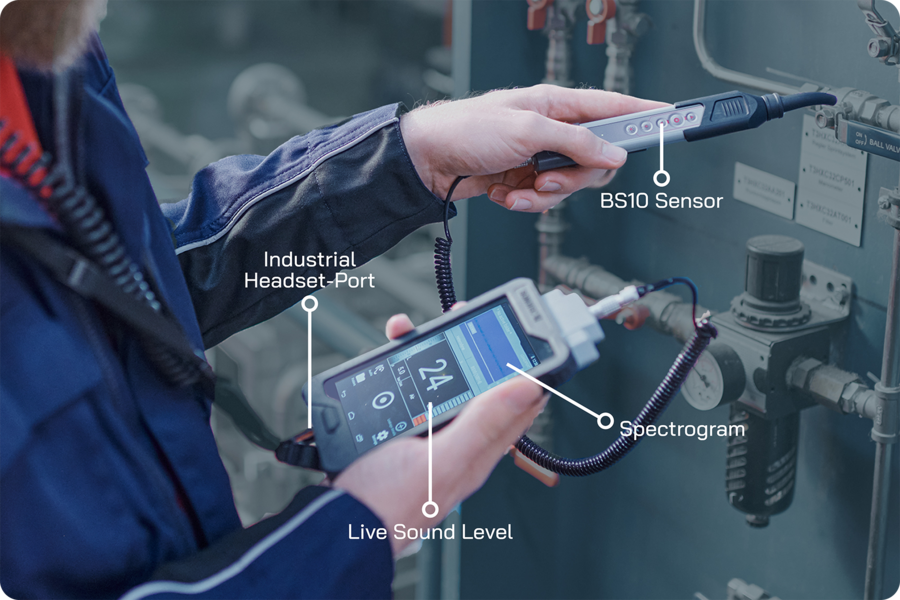

Illustrative image related to medical equipment leak detection system

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control processes, and compliance with relevant standards. Audits can provide insights into the supplier’s operational practices and commitment to quality.

-

Reviewing Quality Control Reports: Buyers should request detailed quality control reports that outline testing methodologies, results, and compliance with standards. These reports provide transparency and assurance regarding the reliability of the products.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an additional layer of verification. These agencies can conduct independent assessments of the manufacturing processes and product quality.

-

Certifications and Compliance Documentation: Buyers should verify that suppliers possess the necessary certifications and compliance documentation. This includes ISO certifications, CE marking, and any other relevant industry-specific certifications.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

-

Regulatory Differences: Different regions have varying regulatory requirements. Buyers must familiarize themselves with local regulations in their target markets to ensure compliance.

-

Cultural Factors: Communication and business practices can vary significantly across cultures. Building strong relationships with suppliers may require understanding these cultural nuances.

-

Logistical Challenges: Importing medical devices can involve complex logistics, including customs regulations and transportation conditions. Buyers should ensure that suppliers have robust logistics practices in place to prevent damage during transit.

-

Market-Specific Needs: Different markets may have unique demands or standards. Buyers should communicate their specific needs clearly to ensure that suppliers can meet these requirements effectively.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures for medical equipment leak detection systems is vital for B2B buyers. By focusing on quality standards, testing methods, and supplier verification processes, buyers can make informed decisions that enhance patient safety and regulatory compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘medical equipment leak detection system’

When sourcing a medical equipment leak detection system, it’s vital to have a clear and structured approach. This guide serves as a checklist to help international B2B buyers navigate the complexities of procurement in the medical device sector. The goal is to ensure that the selected equipment meets both regulatory standards and operational needs, ultimately safeguarding patient safety and enhancing product reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Identify the specific types of medical devices that require leak testing and the relevant testing methods—such as pressure decay or vacuum decay. This will help narrow down options to systems that can effectively meet your needs.

- Consider device types: Catheters, blood bags, and infusion pumps may each require different testing parameters.

- Understand testing standards: Familiarize yourself with international standards like ISO 13485 that govern medical device manufacturing.

Step 2: Evaluate Regulatory Compliance

Regulatory compliance is non-negotiable in the medical industry. Ensure that the leak detection systems you are considering comply with local and international regulations, such as those set by the FDA or EMA.

- Request documentation: Obtain certificates of compliance and quality assurance reports from suppliers.

- Assess testing capabilities: Verify that the equipment can provide evidence of maintaining device integrity under expected conditions.

Step 3: Assess Supplier Experience and Expertise

Before making a commitment, it’s crucial to vet suppliers thoroughly. Look for companies with extensive experience in the medical device sector and a proven track record in leak testing solutions.

- Check references: Request case studies or testimonials from clients in similar markets or industries.

- Inquire about support: Assess the level of technical support and training offered, ensuring that your team can operate the equipment efficiently.

Step 4: Review Technological Features

Examine the technological features of the leak detection systems. Consider aspects such as sensitivity, speed, and the range of testing capabilities.

- Look for automation: Automated systems can enhance efficiency and reduce human error.

- Evaluate data reporting: Ensure that the system provides comprehensive data reporting features for tracking quality control metrics.

Step 5: Conduct a Cost-Benefit Analysis

A thorough cost-benefit analysis will help determine the overall value of the leak detection system. Factor in initial purchase costs, operational expenses, and potential savings from reduced recalls or warranty claims.

- Calculate long-term savings: Consider how effective leak detection can minimize costs associated with product failures.

- Compare options: Obtain quotes from multiple suppliers to ensure competitive pricing without compromising quality.

Step 6: Plan for Integration and Training

Integration of new equipment into existing processes is critical for operational success. Consider how the leak detection system will fit into your current workflow and the training required for staff.

Illustrative image related to medical equipment leak detection system

- Assess compatibility: Ensure the new system can seamlessly integrate with existing quality control processes.

- Organize training sessions: Plan for comprehensive training to maximize the efficiency and effectiveness of the new equipment.

Step 7: Establish a Maintenance Schedule

Regular maintenance is essential to ensure the longevity and reliability of leak detection systems. Establish a maintenance schedule with your supplier to keep the equipment in optimal working condition.

- Request maintenance support: Inquire about warranty terms and after-sales service options.

- Document maintenance activities: Keep records of all maintenance and calibration activities to comply with regulatory requirements.

By following these steps, B2B buyers can effectively source a medical equipment leak detection system that meets stringent quality standards while enhancing patient safety and operational efficiency.

Comprehensive Cost and Pricing Analysis for medical equipment leak detection system Sourcing

What Are the Key Cost Components of Medical Equipment Leak Detection Systems?

When sourcing medical equipment leak detection systems, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The quality of materials used in manufacturing leak detection systems significantly affects pricing. High-grade components that ensure reliability and precision often come at a premium. For instance, specialized sensors and durable casings designed to withstand rigorous testing environments can increase initial costs but enhance long-term reliability.

-

Labor: Labor costs vary depending on the complexity of the technology and the skill level required for production. Advanced systems may require specialized technicians for assembly, calibration, and maintenance, which can drive up labor expenses.

-

Manufacturing Overhead: This encompasses the costs associated with the production facility, utilities, and general administration. Companies adhering to international standards like ISO 13485 may incur higher overhead due to stringent compliance processes.

-

Tooling: The initial setup for manufacturing, including molds and fixtures, can be a significant one-time investment. Buyers should consider the amortization of these costs over the expected product lifespan.

-

Quality Control (QC): Rigorous testing and quality assurance processes are essential in the medical field. The costs associated with QC are vital to ensure compliance with safety standards, which can influence overall pricing.

-

Logistics: Transportation and warehousing costs can vary significantly based on the destination. International shipping may require additional considerations, such as customs duties and insurance, impacting the total cost.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure sustainable operations. This margin can vary based on market competition, brand reputation, and the perceived value of the technology.

How Do Price Influencers Affect the Cost of Leak Detection Systems?

Several factors influence the pricing of medical equipment leak detection systems:

-

Volume/MOQ: Larger orders often result in lower per-unit costs due to economies of scale. Buyers should assess their needs and consider negotiating minimum order quantities (MOQ) to optimize costs.

-

Specifications/Customization: Custom features tailored to specific applications can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses while ensuring that the system meets their operational needs.

-

Materials and Quality Certifications: Systems built with high-quality materials and recognized certifications (e.g., FDA, CE marking) may command higher prices. However, these certifications can also justify the investment by ensuring compliance and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge more, but they often provide better support and warranty services.

-

Incoterms: The terms of shipping and delivery can significantly affect the final cost. Buyers should be aware of the Incoterms used to negotiate responsibilities for transportation, insurance, and customs duties.

What Buyer Tips Can Help Optimize Cost-Efficiency?

To maximize cost-efficiency when sourcing medical equipment leak detection systems, consider the following strategies:

-

Negotiate Terms: Engage in discussions about pricing, MOQ, and payment terms. Suppliers may offer discounts for bulk purchases or longer contract commitments.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. A lower upfront cost may lead to higher TCO if the system requires frequent repairs or replacements.

-

Research International Pricing Nuances: Understand the market dynamics in specific regions, such as Africa, South America, the Middle East, and Europe. Economic conditions, currency fluctuations, and local regulations can all influence pricing.

-

Leverage Local Partnerships: Establishing relationships with local distributors or representatives can facilitate better pricing and support, particularly in regions with complex import regulations.

Conclusion

In the competitive landscape of medical equipment leak detection systems, a comprehensive understanding of cost components, pricing influencers, and strategic buying tips is essential for B2B buyers. By evaluating these factors meticulously, organizations can make informed decisions that align with their operational needs and budget constraints. While indicative pricing may vary, a focus on quality, compliance, and supplier reliability will ensure long-term value and patient safety in the medical sector.

Alternatives Analysis: Comparing medical equipment leak detection system With Other Solutions

Exploring Alternatives to Medical Equipment Leak Detection Systems

In the realm of medical device manufacturing, ensuring product integrity is paramount. While medical equipment leak detection systems are widely recognized for their effectiveness, several alternative solutions also exist. This analysis will compare these alternatives based on key performance indicators, helping international B2B buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Medical Equipment Leak Detection System | Alternative 1: Pressure Decay Testing | Alternative 2: Helium Leak Testing |

|---|---|---|---|

| Performance | High sensitivity; detects small leaks effectively | Moderate sensitivity; effective for larger leaks | Extremely high sensitivity; detects very small leaks |

| Cost | Moderate to high initial investment; operational costs vary | Lower initial cost; minimal operational costs | High initial investment; requires specialized equipment |

| Ease of Implementation | Generally requires training and setup | Simple setup; user-friendly | Complex setup; requires specialized training |

| Maintenance | Requires regular calibration and maintenance | Minimal maintenance needed | High maintenance due to equipment complexity |

| Best Use Case | Ideal for a wide range of medical devices, especially critical care | Suitable for non-critical applications | Best for high-stakes environments where precision is critical |

Analyzing Pressure Decay Testing as an Alternative

Pressure decay testing is a widely used method that involves pressurizing a device and monitoring the pressure drop over time to identify leaks. One of the primary advantages of this method is its lower initial cost and ease of setup, making it an attractive option for many manufacturers. However, it has limitations in sensitivity, particularly for smaller leaks, which may not be detected. This method is best suited for non-critical applications where the consequences of a leak are less severe, such as in general packaging or some non-invasive devices.

Evaluating Helium Leak Testing as a Viable Alternative

Helium leak testing is known for its exceptional sensitivity, capable of detecting leaks as small as a few parts per billion. This method utilizes helium as a tracer gas, making it highly effective in applications where maintaining sterility and integrity is crucial, such as in implantable devices. However, helium leak testing comes with a significant initial investment and requires specialized equipment and training. Maintenance can also be demanding due to the complexity of the systems involved. This technique is best suited for high-stakes environments, like surgical instruments or critical care devices, where even the smallest leak can have serious implications.

How Can B2B Buyers Choose the Right Solution?

When selecting a leak detection system, B2B buyers must consider several factors, including the specific requirements of their medical devices, regulatory compliance needs, and the potential consequences of undetected leaks. Assessing performance characteristics, cost implications, and the operational environment will aid in making a well-informed choice. For instance, while pressure decay testing may suffice for general applications, helium leak testing may be necessary for devices where precision is non-negotiable. Ultimately, understanding the unique needs of their operations and the regulatory landscape in their region will guide buyers toward the most effective solution.

Illustrative image related to medical equipment leak detection system

Essential Technical Properties and Trade Terminology for medical equipment leak detection system

What Are the Key Technical Properties of Medical Equipment Leak Detection Systems?

Understanding the technical specifications of medical equipment leak detection systems is crucial for B2B buyers in the medical device sector. Here are some essential properties to consider:

1. Material Grade

The material grade of leak detection systems significantly affects their durability and reliability. Common materials include stainless steel and high-grade polymers, which resist corrosion and degradation. For B2B buyers, selecting equipment made from high-quality materials ensures longevity and minimizes the risk of failures that could compromise patient safety.

2. Leak Rate Sensitivity

This specification indicates the smallest leak that the system can detect, typically measured in cc/min or Pa. A lower leak rate sensitivity means the system can identify even minute leaks, which is critical for devices like catheters or implantable devices. For manufacturers, this precision helps ensure compliance with regulatory standards and enhances product reliability.

3. Testing Pressure Range

The testing pressure range defines the limits within which the system can operate effectively. Systems designed for high-pressure applications, such as infusion pumps, must accurately simulate operational conditions. Understanding this range is essential for B2B buyers to ensure compatibility with the intended medical devices, thereby preventing costly errors during production.

4. Number of Testing Channels

The number of channels in a leak detection system determines its throughput and efficiency. Systems with multiple channels can conduct simultaneous tests, significantly speeding up the quality control process. For manufacturers, investing in multi-channel systems can lead to increased productivity and lower operational costs.

5. Calibration and Verification Standards

Calibration ensures that the equipment operates accurately over time. Look for systems that comply with international standards like ISO 13485, which assures quality management in medical device manufacturing. Adhering to these standards is vital for B2B buyers to maintain regulatory compliance and avoid potential liabilities.

6. User Interface and Automation

An intuitive user interface and automation features enhance usability, reducing training time for staff. Automated systems can minimize human error and increase testing consistency. For B2B buyers, prioritizing equipment with advanced user interfaces can lead to better operational efficiency and reliability in testing.

What Are Common Trade Terms in Medical Equipment Leak Detection?

Understanding industry jargon is essential for effective communication in the procurement process. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the medical device industry, OEMs often provide leak detection systems tailored to specific client needs. For B2B buyers, working with reputable OEMs can ensure high-quality products that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers to understand as it affects inventory management and cash flow. Knowing the MOQ can help buyers negotiate better terms and plan their purchases more effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. It is essential for comparing costs and services from different manufacturers. B2B buyers should utilize RFQs to ensure they receive competitive pricing and understand the full scope of what suppliers offer.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and tariffs. Familiarity with these terms is vital for B2B buyers engaged in cross-border procurement to mitigate risks and clarify obligations.

5. TQM (Total Quality Management)

TQM is a management approach focused on continuous improvement in all aspects of a business, including quality control processes. For manufacturers, implementing TQM principles can enhance product reliability and customer satisfaction, making it an important consideration during the procurement of leak detection systems.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting medical equipment leak detection systems, ultimately enhancing the safety and effectiveness of medical devices.

Illustrative image related to medical equipment leak detection system

Navigating Market Dynamics and Sourcing Trends in the medical equipment leak detection system Sector

What are the Current Market Dynamics and Key Trends in Medical Equipment Leak Detection Systems?

The global market for medical equipment leak detection systems is experiencing significant growth, driven by several key factors. Increasing regulatory scrutiny surrounding medical device safety and the rising awareness of patient safety standards are paramount. Compliance with international quality standards, such as ISO 13485, is essential for manufacturers to ensure their products meet rigorous safety and efficacy requirements. This demand is particularly pronounced in emerging markets in Africa and South America, where healthcare infrastructure is rapidly developing, and the need for reliable medical devices is critical.

Technological advancements are also reshaping the landscape of leak detection systems. Innovations such as automated testing equipment and advanced leak testing methodologies, including pressure decay and vacuum decay techniques, are becoming more prevalent. These technologies not only enhance the accuracy of leak detection but also improve efficiency in the manufacturing process, reducing costs and time-to-market for new medical devices. Furthermore, the integration of Industry 4.0 principles, including data analytics and the Internet of Things (IoT), allows manufacturers to optimize their testing processes and monitor device integrity in real-time.

International B2B buyers, particularly from regions like Germany and Nigeria, should note the growing trend towards sourcing suppliers who can offer both advanced technology and regulatory compliance. The shift towards automation in leak testing is expected to continue, making it imperative for manufacturers to invest in state-of-the-art equipment that meets evolving industry standards. Additionally, partnerships with suppliers that possess local expertise can facilitate smoother entry into diverse markets, ensuring adherence to specific regulatory requirements and cultural considerations.

How is Sustainability Impacting the Sourcing of Medical Equipment Leak Detection Systems?

Sustainability is increasingly influencing B2B procurement strategies in the medical equipment sector, including leak detection systems. As environmental regulations tighten globally, companies are under pressure to adopt sustainable practices throughout their supply chains. This includes sourcing materials that are not only high-performing but also environmentally friendly. Buyers are encouraged to seek suppliers who prioritize sustainable manufacturing processes and utilize eco-friendly materials in their products.

The importance of ethical supply chains cannot be overstated. Manufacturers are increasingly held accountable for the environmental impact of their operations, which includes the lifecycle of their products. By partnering with suppliers who are committed to sustainable practices, companies can enhance their brand reputation and appeal to a growing demographic of environmentally conscious consumers and healthcare providers. Certifications such as ISO 14001 for environmental management and the use of recyclable or biodegradable materials in leak detection systems can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the move towards circular economy principles, where products are designed for reuse and recycling, is gaining traction. B2B buyers should consider how suppliers are addressing these principles, as this not only benefits the environment but can also lead to cost savings through reduced waste and resource efficiency.

What is the Historical Context of Medical Equipment Leak Detection Systems?

The evolution of medical equipment leak detection systems can be traced back to the increasing complexity of medical devices and the corresponding need for rigorous quality assurance. In the early stages, basic manual testing methods were sufficient; however, as medical technology advanced, so did the demands for precision and reliability. The introduction of automated leak testing equipment in the late 20th century marked a significant turning point, enabling manufacturers to conduct more extensive testing with greater accuracy.

Over the past two decades, the focus on patient safety and regulatory compliance has intensified, leading to the development of sophisticated testing methodologies that align with international standards. The integration of digital technologies into leak detection processes is a more recent trend, providing manufacturers with the tools needed to enhance quality control and meet the ever-evolving requirements of the healthcare sector. This historical context underscores the importance of ongoing innovation and adaptability in the medical equipment leak detection industry, ensuring that it continues to meet the needs of a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of medical equipment leak detection system

-

How do I choose the right leak detection system for my medical devices?

Choosing the right leak detection system involves assessing your specific needs, including the types of devices you manufacture and the regulatory standards you must meet. Consider systems that offer flexibility in testing methods such as pressure decay, vacuum decay, and burst tests. Additionally, ensure the equipment complies with international quality standards like ISO 13485, which is critical for medical device safety. Engage with suppliers who can provide tailored solutions and have expertise in your device category to ensure you select the most effective system for your operations. -

What are the key features to look for in a medical equipment leak detection system?

When selecting a leak detection system, prioritize features such as accuracy, speed, and versatility. Look for systems that can handle multiple testing methods and have a user-friendly interface for ease of operation. Advanced systems should also include automated testing capabilities and real-time data reporting to enhance efficiency. Additionally, consider the capacity for customization to align with your specific manufacturing processes and the ability to integrate with existing quality control systems. -

What are the regulatory requirements for medical device leak testing in international markets?

Regulatory requirements for medical device leak testing vary by region. In Europe, compliance with CE marking and ISO 13485 is essential, while in the USA, FDA regulations govern the approval of medical devices. Familiarize yourself with the specific standards applicable to your target markets, as non-compliance can lead to product recalls and legal repercussions. Working with suppliers who understand these regulations can help ensure your products meet necessary quality and safety standards before entering the market. -

How can I ensure the quality of the leak detection system I purchase?

To ensure quality, source equipment from reputable manufacturers with a proven track record in the medical device sector. Request certifications, such as ISO 13485, and ask for documentation on their quality control processes. Consider conducting on-site visits to assess their manufacturing capabilities and quality assurance practices. Additionally, seek customer testimonials and case studies to gauge the reliability and performance of the equipment in real-world applications. -

What is the typical minimum order quantity (MOQ) for leak detection systems?

Minimum order quantities for leak detection systems can vary significantly by supplier and product type. Many manufacturers offer flexible MOQs, especially for initial purchases or custom solutions. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Additionally, consider the implications of MOQ on your cash flow and inventory management, especially when entering new markets or scaling production. -

What payment terms should I expect when sourcing leak detection systems internationally?

Payment terms can differ based on the supplier’s policies and the nature of the transaction. Common arrangements include upfront payments, deposits with the balance due upon shipment, or net payment terms after delivery. For international transactions, consider factors such as currency fluctuations and transfer fees. Always clarify payment terms during negotiations and consider using secure payment methods to protect your investment. -

How do I assess the reliability of a supplier for leak detection systems?

Assessing supplier reliability involves several steps. Start by evaluating their industry experience and expertise in medical device leak testing. Request references from other clients, particularly those in your industry, to gain insight into their service quality. Look for suppliers who provide comprehensive customer support and training for their equipment. Additionally, check for certifications and adherence to international quality standards, which are indicators of a supplier’s commitment to quality. -

What logistics considerations should I keep in mind when importing leak detection systems?

When importing leak detection systems, consider shipping costs, customs regulations, and import duties in your destination country. Ensure that your supplier provides all necessary documentation for customs clearance, including certificates of origin and compliance. It’s also crucial to select a reliable logistics partner familiar with handling medical equipment to avoid delays. Plan for potential lead times and arrange for proper storage conditions upon arrival to maintain equipment integrity before installation.

Top 9 Medical Equipment Leak Detection System Manufacturers & Suppliers List

1. ATEQ – Medical Device Leak Testing Solutions

Domain: ateq-leaktesting.com

Registered: 2012 (13 years)

Introduction: ATEQ designs testing equipment compliant with ISO 13485 for medical devices. Key features include:

– Ensures patient safety by maintaining airtight conditions to prevent contamination.

– Validates device functionality under specific pressure conditions.

– Supports regulatory compliance with FDA, EMA, and international health authorities.

– Acts as a quality control measure to ensure product re…

2. Uson – Sprint mD

Domain: uson.com

Registered: 1996 (29 years)

Introduction: Uson offers a range of medical device leak testing solutions designed for various applications in the medical industry. Key products include:

– **Sprint mD**: A compact, user-friendly leak tester available in single channel or configurable up to four channels for concurrent or sequential testing.

– **Optima vT**: A versatile leak tester suitable for multiple applications.

– **Vector Leak Test**…

3. Zaxis – Modular Air Leak Testers

Domain: zaxisinc.com

Registered: 1998 (27 years)

Introduction: Zaxis Z5 – Modular Air Leak Tester (5″) – New Product!; Zaxis Z8 – Modular Air Leak Tester (8″) – New Product!; Zaxis Isaac HD – Modular – Production Air Leak Tester (Medium) – Discontinued 03/31/25; Zaxis iKit – Semi Modular – Automation Air Leak Tester (Extra Small) – Discontinued 03/31/25; Zaxis PD – Basic – Entry Level Air Leak Tester (Small); VM3 Volumetric Air Leak Tester; Modular Air Leak T…

4. BeaconMedAES – MedGasScan Tool

Domain: beaconmedaes.com

Registered: 2003 (22 years)

Introduction: The MedGasScan tool utilizes advanced acoustic imaging to detect and quantify medical gas leaks in hard-to-access areas of pipeline systems. It detects ultrasonic sounds from gas and vacuum leaks, providing a precise acoustic image of the leak through an acoustic camera equipped with 124 microphones. This image is overlaid onto a digital photo, allowing visualization of leak size and location. The…

5. Water Alert – Leak Detection Solutions

Domain: wateralert.com

Registered: 1997 (28 years)

Introduction: Water Alert Standard Series includes multiple models (SS, SS-1, SS-2, SS-4, SS-5, SS-2100) designed for reliable water leak detection in healthcare facilities. Vandal Resistant Series (VR Series) is suitable for public restrooms and labs, featuring a programmable wash-down mode. Water Leak Sensor Cable is used for perimeter monitoring with sensors embedded every 3 feet. Standard series detectors o…

6. ATEQ – Leak Testing Instruments for Medical Devices

Domain: atequsa.com

Registered: 2000 (25 years)

Introduction: ATEQ offers a range of leak testing instruments for medical devices, which are customizable to meet specific testing parameters. The methods of leak testing include: 1. Air Bubble Method – a traditional method using water to detect leaks by submerging the device. 2. Pressure Decay Method – measures pressure changes in a pressurized device to identify leaks. 3. Vacuum Decay Method – detects leaks b…

7. VIC Leak Detection – Advanced Leak Test Systems

Domain: vicleakdetection.com

Registered: 2004 (21 years)

Introduction: VIC Leak Detection offers advanced leak test systems for medical devices, ensuring adherence to high-quality standards for patient safety and product reliability. Key technologies include mass flow and pressure decay methods, as well as tracer gases, providing precision and sensitivity in leak detection. The systems are customizable to meet specific testing requirements for various medical devices…

8. Pfeiffer Vacuum – Vacuum and Leak Detection Solutions

Domain: pfeiffer-vacuum.com

Registered: 1996 (29 years)

Introduction: Pfeiffer Vacuum offers vacuum and leak detection solutions specifically designed for the medical industry, focusing on safety, precision, and reliability. Key applications include:

– Helium leak detection (spraying) for ensuring the integrity of vacuum systems.

– Container Closure Integrity Testing (CCIT) to ensure sterile, leak-free packaging for pharmaceuticals.

– Residual gas analysis (RGA) to …

9. Cincinnati Test – Leak Detection Solutions

Domain: cincinnati-test.com

Registered: 1996 (29 years)

Introduction: Leak Detection Equipment, Leak Test Systems, Pressure Decay Test Systems, Differential Pressure Decay Leak Detection, Pressure Leak Test Gain Systems, Ultrasonic Leak Detection, Mass Flow Test Systems, Tracer Gas Leak Test Systems, Sniff Leak Testing, Nitrogen Purge Leak Testing, Hard Vacuum Helium Leak Test Systems, Function Test Systems, Calibration Test Systems, Dunk and Bubble Testing Systems,…

Strategic Sourcing Conclusion and Outlook for medical equipment leak detection system

What Are the Key Insights for Sourcing Medical Equipment Leak Detection Systems?

In conclusion, the strategic sourcing of medical equipment leak detection systems is critical for ensuring patient safety, regulatory compliance, and product reliability. As outlined, effective leak testing not only protects the integrity of medical devices but also enhances their longevity and reduces costs associated with product recalls and failures. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, prioritizing suppliers that adhere to international quality standards such as ISO 13485 can significantly influence product quality and market acceptance.

How Can You Leverage Strategic Sourcing for Competitive Advantage?

Investing in advanced leak detection technologies will not only meet regulatory obligations but also position your company as a leader in quality assurance within the medical device sector. By forging strong partnerships with reputable manufacturers and leveraging their expertise, you can ensure that your supply chain remains robust and responsive to market demands.

What Steps Should You Take Next?

As you move forward, evaluate your sourcing strategies and consider integrating state-of-the-art leak detection systems into your operations. This proactive approach will empower you to deliver high-quality medical devices that meet the rigorous standards of healthcare providers worldwide. Engage with leading suppliers to explore tailored solutions that align with your specific needs, ensuring a future of safety and reliability in the medical field.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.