A Deep Dive into Machine Labels Solution

Introduction: Navigating the Global Market for machine labels

In the complex landscape of global manufacturing, sourcing the right machine labels can pose a significant challenge for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. The demand for durable, compliant, and versatile labeling solutions is at an all-time high, driven by the need for operational efficiency, safety, and regulatory compliance. This guide aims to demystify the myriad options available for machine labels, from barcode labels to safety and hazardous material labels, ensuring that your sourcing decisions are informed and strategic.

Within these pages, you will find a comprehensive overview of the various types of machine labels, their applications across different industries, and essential insights into supplier vetting processes. We will also delve into cost considerations and best practices for integrating these labels into your operations, empowering you to make decisions that align with your business goals. By addressing the unique challenges faced by international B2B buyers, particularly those in countries like Nigeria and Vietnam, this guide serves as a vital resource. It equips you with the knowledge needed to navigate supplier landscapes confidently and select machine labels that meet your specific requirements, ensuring your operations are both efficient and compliant.

Understanding machine labels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Barcode Labels | Scannable codes for inventory tracking | Warehousing, Logistics, Retail | Pros: Efficient tracking, reduces errors; Cons: Requires scanner investment. |

| Electrical Labels | Identifies electrical components and safety hazards | Manufacturing, Construction, Maintenance | Pros: Enhances safety, compliance; Cons: May fade in harsh environments. |

| Hazardous Material Labels | Indicates presence of hazardous substances | Chemical, Pharmaceutical, Laboratory | Pros: Vital for safety, regulatory compliance; Cons: Can be costly for small quantities. |

| Safety Labels | Communicates safety instructions or warnings | Industrial, Construction, Warehousing | Pros: Promotes workplace safety; Cons: Overuse can lead to label fatigue. |

| Pipe Markers | Identifies pipe contents, flow direction, and hazards | Oil & Gas, Water Treatment, Manufacturing | Pros: Improves maintenance efficiency; Cons: Limited to specific applications. |

What Are Barcode Labels and Their B2B Benefits?

Barcode labels are essential for businesses that require efficient inventory management and tracking. These labels use scannable codes, which can be easily read by barcode scanners, streamlining the process of tracking products through various stages of the supply chain. They are particularly suitable for warehousing, logistics, and retail environments. When purchasing barcode labels, B2B buyers should consider compatibility with existing scanning equipment and the durability of the labels under different environmental conditions.

Why Are Electrical Labels Important for B2B Operations?

Electrical labels are crucial for identifying electrical components and ensuring safety within industrial and construction settings. These labels often include information about voltage, current, and safety warnings, helping to prevent accidents and ensure compliance with safety regulations. When selecting electrical labels, buyers should assess their resistance to environmental factors such as heat, moisture, and chemical exposure, as these can affect label longevity and effectiveness.

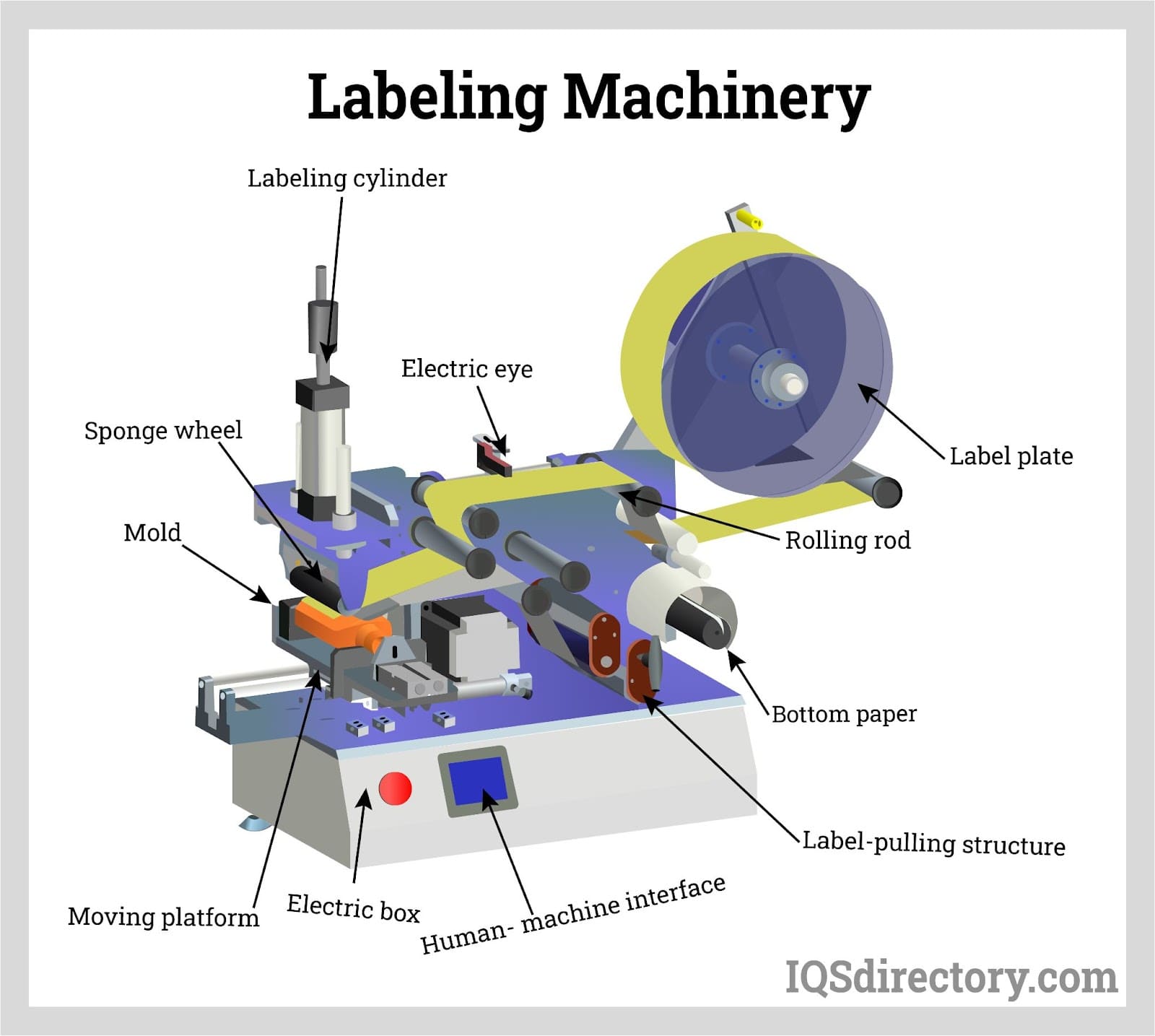

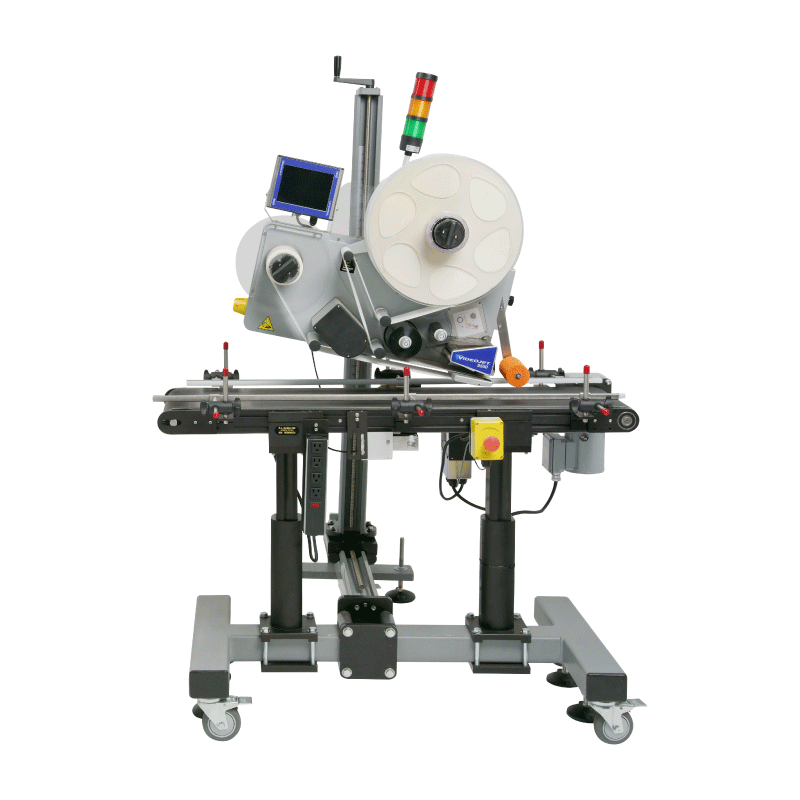

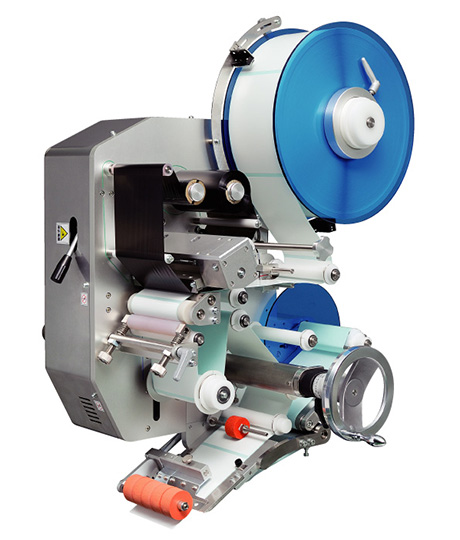

Illustrative image related to machine labels

How Do Hazardous Material Labels Enhance Workplace Safety?

Hazardous material labels are designed to inform employees and emergency responders about the presence of dangerous substances. They are vital in industries like chemicals, pharmaceuticals, and laboratories, where safety is paramount. These labels must comply with specific regulations, such as OSHA and GHS, which dictate their design and content. Buyers should evaluate the labels’ durability and visibility, especially in environments where exposure to chemicals might degrade standard labels.

What Role Do Safety Labels Play in Industrial Environments?

Safety labels communicate essential safety instructions or warnings, helping to create a safer workplace environment. They are widely used in industrial, construction, and warehousing settings to inform workers about potential hazards and required safety measures. When considering safety labels, B2B buyers should think about the clarity of the messaging, the label’s adherence to safety standards, and its ability to withstand the specific conditions of their environment to ensure long-lasting effectiveness.

Why Are Pipe Markers Essential for Efficient Operations?

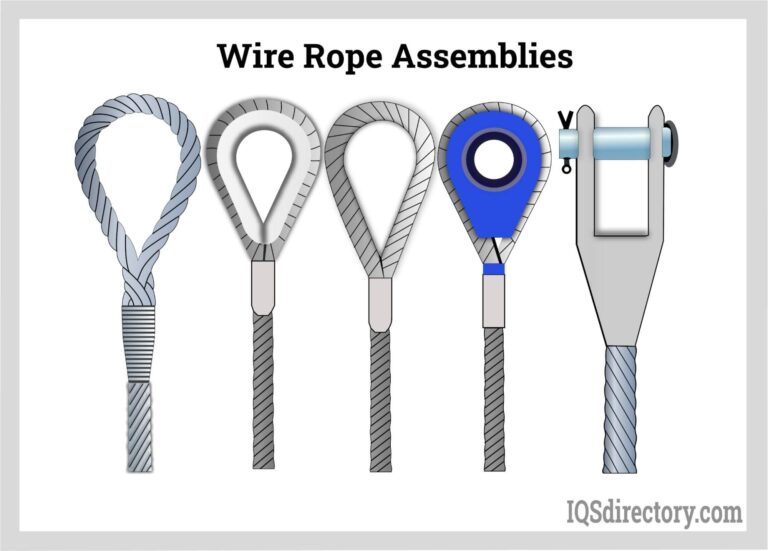

Pipe markers are specialized labels that identify the contents of pipes, flow direction, and associated hazards. They are particularly useful in industries such as oil and gas, water treatment, and manufacturing, where clear identification is necessary for maintenance and safety. Buyers should consider the materials used for pipe markers to ensure they are resistant to environmental factors such as UV exposure and moisture, which can compromise their visibility and effectiveness over time.

Key Industrial Applications of machine labels

| Industry/Sector | Specific Application of Machine Labels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Equipment Identification and Maintenance Labels | Enhances safety and compliance by clearly identifying machinery. | Durability, adhesion properties, and resistance to harsh environments. |

| Food and Beverage | Hazardous Material and Safety Labels | Ensures compliance with health regulations and prevents accidents. | Compliance with local regulations, food-safe materials, and clarity of information. |

| Automotive | Wire and Cable Labels | Prevents miswiring and ensures efficient assembly processes. | Resistance to heat and chemicals, along with easy readability. |

| Pharmaceuticals | Laboratory Labels | Facilitates accurate tracking and compliance in lab environments. | Chemical resistance, durability, and the ability to withstand sterilization processes. |

| Construction | Pipe Markers and Safety Labels | Promotes safety on job sites by clearly marking hazards and utilities. | Weather resistance, visibility, and compliance with local safety standards. |

How Are Machine Labels Used in Manufacturing and What Problems Do They Solve?

In the manufacturing sector, machine labels are vital for equipment identification and maintenance. These labels help in the clear identification of machinery, which is essential for safety protocols and compliance with industry regulations. By using durable labels that can withstand harsh environments, manufacturers can minimize accidents and enhance operational efficiency. International buyers should consider labels with aggressive adhesion and resistance to chemicals, as these factors greatly influence their longevity in a factory setting.

What Role Do Machine Labels Play in the Food and Beverage Industry?

In the food and beverage industry, machine labels are critical for ensuring safety and compliance with health regulations. Hazardous material and safety labels are used to inform staff of potential dangers and to comply with legal requirements. These labels must be made from food-safe materials and designed for clarity, as they provide essential information that can prevent accidents and health violations. Buyers from regions like Africa and South America should prioritize suppliers who understand local regulations and can provide compliant labeling solutions.

How Are Machine Labels Beneficial in the Automotive Sector?

In the automotive industry, wire and cable labels are essential for preventing miswiring during assembly processes. Clear labeling ensures that components are correctly connected, which is crucial for vehicle safety and performance. Labels must be resistant to heat and chemicals, given the demanding conditions in which they are used. Buyers should look for suppliers who offer customizable options to meet specific needs, ensuring that labels are easily readable and durable throughout the vehicle’s lifespan.

Why Are Laboratory Labels Important in Pharmaceuticals?

Pharmaceutical companies rely heavily on laboratory labels for accurate tracking and compliance. These labels facilitate the organization of samples and reagents, ensuring that all materials are correctly identified. The ability to withstand sterilization processes and resist chemicals is crucial for laboratory labels. International buyers should seek out manufacturers that specialize in compliant labeling solutions tailored for the pharmaceutical industry, particularly those that understand the stringent requirements of various regulatory bodies.

Illustrative image related to machine labels

How Do Pipe Markers and Safety Labels Enhance Safety in Construction?

In construction, pipe markers and safety labels are crucial for promoting safety on job sites. These labels clearly mark hazards and utility lines, helping to prevent accidents and injuries. The labels must be weather-resistant and highly visible to ensure they remain effective in outdoor environments. When sourcing these labels, buyers should focus on suppliers who can provide options that comply with local safety standards, ensuring that they meet the specific needs of their construction projects.

3 Common User Pain Points for ‘machine labels’ & Their Solutions

Scenario 1: Difficulty in Label Durability Under Harsh Conditions

The Problem: Many B2B buyers face the challenge of ensuring that machine labels remain intact and legible in harsh environments. Industries such as manufacturing, construction, and food processing frequently deal with extreme temperatures, moisture, and chemical exposure. Labels that peel, fade, or become illegible can lead to safety hazards and compliance issues, ultimately affecting operational efficiency and product quality. This problem is compounded in regions with high humidity or temperature fluctuations, where inadequate labeling can disrupt workflows and lead to costly errors.

The Solution: To address this issue, buyers should prioritize sourcing labels specifically designed for harsh environments. When selecting machine labels, look for features such as aggressive adhesion, heat resistance, and washdown capabilities. For instance, labels made from durable materials like polyester or vinyl are often best suited for these applications. Additionally, consider using labels that are resistant to chemicals and UV light. Conduct a thorough analysis of the specific environmental conditions in your facility and collaborate with suppliers who can provide samples for testing. This approach ensures that the labels you choose will withstand the rigors of your operational environment.

Scenario 2: Inconsistent Labeling Leading to Operational Inefficiencies

The Problem: In many organizations, inconsistent labeling practices can create confusion and lead to operational inefficiencies. When workers encounter different labeling formats, colors, or languages, it can slow down processes, increase the risk of errors, and ultimately compromise safety. This problem is especially prevalent in multicultural environments or where multiple teams are involved in the same workflow, leading to misunderstandings and miscommunication.

Illustrative image related to machine labels

The Solution: Establishing a standardized labeling system is crucial for overcoming this pain point. Create a labeling guideline that includes specifications for label size, color coding, font types, and language requirements. Collaborate with your team to ensure that everyone understands and adheres to these standards. Utilize label printing software that allows for easy customization and consistency across various labels. Additionally, consider implementing visual aids or training sessions to reinforce the importance of consistent labeling practices. This not only enhances communication but also fosters a safer and more efficient work environment.

Scenario 3: Challenges in Compliance with Regulatory Standards

The Problem: Compliance with industry regulations and safety standards is a significant concern for B2B buyers when it comes to machine labels. Many industries, particularly those dealing with hazardous materials or operating in regulated environments, must adhere to strict labeling requirements. Failure to comply can result in hefty fines, legal issues, and damage to a company’s reputation. Buyers often struggle to keep up with changing regulations and ensuring that their labels meet these standards.

The Solution: To navigate the complexities of compliance, B2B buyers should stay informed about the relevant regulations affecting their industry. Establish a regular review process to assess and update labeling practices as regulations evolve. Partnering with suppliers who specialize in regulatory compliance can also be beneficial; they can provide insights into the latest requirements and help source compliant labels. Additionally, consider investing in labeling software that includes regulatory templates to simplify the design process. By proactively managing compliance, you not only reduce the risk of penalties but also enhance your organization’s credibility and operational integrity.

Strategic Material Selection Guide for machine labels

What are the Key Properties of Common Materials Used for Machine Labels?

When selecting materials for machine labels, it is crucial to consider their properties, as these directly affect performance in various environments. Here, we analyze four common materials: polyester, vinyl, polyimide, and paper.

Polyester: A Versatile Choice for Durability

Polyester labels are known for their excellent durability and resistance to various environmental factors. They can withstand high temperatures (up to 120°C) and are resistant to moisture, chemicals, and UV light. This makes polyester an ideal choice for industrial applications where labels are exposed to harsh conditions.

Illustrative image related to machine labels

Pros: The material’s durability ensures longevity, reducing the frequency of label replacements. It also offers good print quality, making it suitable for detailed graphics and barcodes.

Cons: Polyester labels can be more expensive than other materials. Additionally, their manufacturing process may involve more complexity, which can affect lead times.

Impact on Application: Polyester labels are compatible with a wide range of media, including thermal transfer and inkjet printing. However, buyers should ensure that the chosen printing method aligns with the label’s surface properties.

Illustrative image related to machine labels

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and South America should also consider local climate conditions, as high humidity can affect label adhesion.

Vinyl: Cost-Effective and Flexible

Vinyl labels are often used for indoor applications due to their flexibility and cost-effectiveness. They can handle moderate temperatures and are resistant to moisture, making them suitable for less demanding environments.

Pros: Vinyl labels are relatively inexpensive and easy to produce, making them ideal for short-run applications. Their flexibility allows them to adhere well to curved surfaces.

Illustrative image related to machine labels

Cons: However, vinyl is less durable than polyester and may degrade faster under UV exposure. This limits its use in outdoor applications.

Impact on Application: Vinyl labels are compatible with various printing technologies, but their lower durability may necessitate more frequent replacements in harsh environments.

Considerations for International Buyers: Buyers should be aware of local regulations regarding material safety and environmental impact, especially in regions with stringent compliance requirements.

Polyimide: High-Performance for Extreme Conditions

Polyimide labels excel in extreme temperature environments, withstanding temperatures up to 260°C. This makes them suitable for applications in aerospace, electronics, and other high-tech industries.

Illustrative image related to machine labels

Pros: Their high-temperature resistance and chemical stability make polyimide labels ideal for applications that involve exposure to harsh chemicals and extreme conditions.

Cons: The cost of polyimide labels is generally higher than other materials, and their manufacturing process can be complex, leading to longer lead times.

Impact on Application: Polyimide labels are compatible with thermal transfer printing but may require specific inks to ensure adhesion and durability.

Considerations for International Buyers: Companies in high-tech sectors in Europe and the Middle East should ensure that polyimide labels meet industry-specific standards, such as IPC for electronics.

Paper: The Economical Option for Short-Term Use

Paper labels are a common choice for temporary applications, such as inventory management and shipping labels. They are lightweight and cost-effective, making them ideal for short-term use.

Pros: The low cost and ease of printing make paper labels suitable for many applications, especially where durability is not a primary concern.

Cons: Paper labels are less resistant to moisture and chemicals, leading to potential degradation in challenging environments.

Impact on Application: While paper labels can be printed using various methods, they are best suited for indoor use where exposure to moisture and chemicals is minimal.

Considerations for International Buyers: Buyers should consider the environmental impact of paper labels and ensure compliance with local regulations regarding paper waste and recycling.

Summary Table of Material Selection for Machine Labels

| Material | Typical Use Case for machine labels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Industrial applications | Excellent durability and UV resistance | Higher cost and manufacturing complexity | High |

| Vinyl | Indoor applications | Cost-effective and flexible | Less durable under UV exposure | Low |

| Polyimide | High-tech industries | High-temperature resistance | Higher cost and longer lead times | High |

| Paper | Temporary labels | Economical and easy to print | Poor resistance to moisture | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for machine labels

What Are the Main Stages of Manufacturing Machine Labels?

The manufacturing process of machine labels involves several key stages that ensure both quality and functionality. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to machine labels

-

Material Preparation: The first step is selecting the appropriate materials, which can vary based on the label’s intended use—such as heat resistance for machinery or chemical resistance for hazardous materials. Common materials include vinyl, polyester, and paper. These materials are sourced based on their durability and suitability for specific environments.

-

Forming: Once the materials are prepared, they undergo forming processes. This may involve cutting the material into specific shapes and sizes, often using advanced techniques such as die-cutting or laser cutting. Precision is critical in this stage to ensure that the labels fit the machines they are intended for and can withstand the operational conditions.

-

Assembly: After forming, the labels are assembled. This can include adding adhesive backing, applying laminates for additional protection, or integrating other features such as barcodes or QR codes. Automation plays a significant role in this stage, where machines can apply labels at high speeds while maintaining accuracy.

-

Finishing: The final stage involves quality checks and additional treatments. Labels may undergo processes like UV coating or thermal transfer printing, which enhance their durability and legibility. This step ensures that the labels not only meet aesthetic requirements but also comply with industry standards.

Which Quality Assurance Standards Are Relevant for Machine Labels?

Quality assurance (QA) is crucial in the manufacturing of machine labels, especially for B2B buyers who require reliability and compliance with international standards. Key standards include:

-

ISO 9001: This is a widely recognized standard for quality management systems (QMS). Compliance with ISO 9001 ensures that the manufacturer follows a structured approach to quality assurance, which includes documentation, process control, and continuous improvement.

-

CE Marking: For labels used in machinery within the European market, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly relevant for buyers in Europe.

-

API Standards: The American Petroleum Institute (API) sets standards for labels used in the oil and gas industry. Compliance ensures that labels can withstand the harsh conditions often found in these environments.

What Are the Key Quality Control Checkpoints in Machine Label Production?

Quality control (QC) checkpoints are integral to ensuring that machine labels meet specified standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the raw materials used for label production. Materials are inspected for compliance with specifications before they enter the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves monitoring specific stages of production to identify any deviations from the quality standards. This may include checking the precision of cuts and the consistency of adhesive application.

-

Final Quality Control (FQC): Once labels are completed, FQC ensures that the final products meet all specifications. This includes visual inspections, testing adhesion strength, and verifying print quality.

What Common Testing Methods Are Used in Machine Label Quality Assurance?

Testing methods for machine labels are diverse and tailored to the materials and intended use of the labels. Common methods include:

-

Adhesion Testing: This evaluates how well the label adheres to surfaces under various conditions. It can involve peel tests or shear tests to ensure durability.

-

Environmental Testing: Labels are subjected to extreme conditions, such as high temperatures, humidity, and exposure to chemicals, to evaluate their performance in real-world applications.

-

Print Quality Testing: This involves checking the legibility and clarity of printed information, including barcodes and QR codes, to ensure they meet industry standards.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For B2B buyers, particularly in international markets, verifying a supplier’s QC measures is essential. Here are several ways to conduct this verification:

Illustrative image related to machine labels

-

Supplier Audits: Conducting audits on-site or remotely can provide insights into a supplier’s manufacturing processes and quality assurance practices. This is an effective way to assess compliance with international standards.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the QC measures in place. These reports should outline testing methods, results, and any corrective actions taken in case of non-compliance.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be crucial for ensuring compliance with international standards and for mitigating risks.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control and certification. Variations in standards across regions, such as different regulations in Africa, South America, the Middle East, and Europe, require buyers to stay informed about local compliance requirements.

-

Regional Certifications: Buyers should familiarize themselves with certifications that are specific to their region. For instance, in Africa, compliance with local safety standards may be required, while buyers in Europe might prioritize CE marking.

-

Cultural Considerations: Understanding cultural nuances can also play a role in quality assurance. Different regions may have varying expectations regarding quality and service, influencing how QC measures are implemented and communicated.

-

Supply Chain Transparency: Ensuring transparency in the supply chain is crucial for maintaining quality standards. Buyers should inquire about the traceability of materials and the supplier’s adherence to ethical sourcing practices.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing machine labels, ensuring they receive products that meet their specific needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘machine labels’

In the competitive landscape of industrial manufacturing, sourcing the right machine labels is crucial for operational efficiency and regulatory compliance. This guide provides a structured checklist to assist B2B buyers in making informed procurement decisions, ensuring that the labels meet both functional and regulatory requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for your machine labels is the foundation of a successful procurement process. Consider factors such as size, material, adhesive type, and durability to ensure the labels can withstand the operational environment. For example, if labels will be exposed to extreme temperatures or harsh chemicals, opt for heat-resistant or washdown-resistant options.

Step 2: Research Label Applications and Compliance Standards

Understanding the specific applications for your labels is essential. Different industries have varying compliance requirements, especially for safety and hazardous material labeling. Familiarize yourself with local and international standards (e.g., ISO, OSHA) that may apply to your products to ensure compliance and avoid potential penalties.

Illustrative image related to machine labels

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to gauge their reliability and quality. Look for suppliers with proven track records in your industry and request documentation such as company profiles, case studies, and references. Checking for certifications like ISO 9001 can also indicate a supplier’s commitment to quality.

Step 4: Request Samples for Testing

Once you’ve narrowed down potential suppliers, request samples of their machine labels for testing. This step is vital to assess the quality, adhesion, and printability of the labels in real-world conditions. Evaluate how well the samples adhere to different surfaces and ensure that the print quality meets your standards.

Step 5: Compare Pricing and Terms of Service

Pricing is a critical factor, but it shouldn’t be the only consideration. Compare quotes from different suppliers, taking note of the value offered in terms of quality and service. Additionally, review the terms of service, including lead times, minimum order quantities, and return policies, to avoid unexpected costs.

Step 6: Check for Customization Options

Customization may be necessary to meet specific branding or operational needs. Inquire about the supplier’s ability to provide custom sizes, colors, or designs. Ensure they can accommodate your unique requirements while maintaining quality and compliance with relevant standards.

Step 7: Finalize Your Order and Establish Communication

Once you’ve selected a supplier, finalize your order details and establish a clear line of communication. Document all specifications and expectations in a formal agreement to ensure alignment. Regular communication can help address any issues that arise during the production and delivery process, ensuring a smoother procurement experience.

By following this checklist, B2B buyers can navigate the complexities of sourcing machine labels effectively, ensuring that their operational needs are met while maintaining compliance and quality standards.

Illustrative image related to machine labels

Comprehensive Cost and Pricing Analysis for machine labels Sourcing

What Are the Key Cost Components in Sourcing Machine Labels?

When sourcing machine labels, it is essential to understand the various cost components that contribute to the final price. These components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margin.

-

Materials: The choice of materials directly impacts the cost. Labels can be made from different substrates such as vinyl, polyester, or paper, each with varying costs based on durability and application. For example, labels intended for harsh environments may require heat or chemical resistance, increasing material costs.

-

Labor: Labor costs encompass the wages for workers involved in the production process. Automation can reduce labor costs, but the initial investment in machinery may offset these savings.

-

Manufacturing Overhead: This includes utilities, rent, and other indirect costs associated with production. Efficient manufacturing processes can help lower these overhead costs.

-

Tooling: The cost of creating custom dies or molds for label production can be significant, especially for unique shapes or designs. This cost is typically amortized over a larger volume of production.

-

Quality Control (QC): Ensuring labels meet industry standards and customer specifications incurs additional costs. Investing in robust QC processes can prevent costly errors and returns.

-

Logistics: Shipping costs can vary greatly depending on the distance, weight, and packaging requirements. International buyers should consider Incoterms to clarify responsibilities for shipping costs and risks.

-

Supplier Margin: Suppliers will include a margin on top of their costs. Understanding the competitive landscape can help buyers negotiate better pricing.

How Do Price Influencers Affect Machine Labels Sourcing?

Several factors influence the pricing of machine labels, which international buyers must consider:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Suppliers often provide discounts for larger orders, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom designs or specialized features will increase costs. Buyers should weigh the necessity of customization against the potential for higher expenses.

-

Materials and Quality Certifications: Labels with specific certifications (e.g., UL, CE) may carry a premium. Buyers must evaluate if these certifications are necessary for their application.

-

Supplier Factors: The reliability and reputation of a supplier can influence pricing. Established suppliers may charge more but offer better quality and service.

-

Incoterms: Understanding the implications of Incoterms is crucial for international transactions. These terms dictate who is responsible for shipping costs and risks, which can affect the overall pricing structure.

What Are Effective Buyer Tips for Negotiating Machine Labels Pricing?

B2B buyers should adopt strategic approaches when negotiating prices for machine labels:

-

Leverage Bulk Purchases: If feasible, consolidate orders to meet MOQs, which can help secure volume discounts.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with quality, durability, and potential returns. A cheaper label may lead to higher costs down the line if it fails to meet operational requirements.

-

Research and Compare: Gather quotes from multiple suppliers and compare not only prices but also the value offered in terms of quality, delivery times, and customer service.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, shipping arrangements, and pricing structures. Building a good relationship with suppliers can lead to more favorable terms.

-

Be Aware of Pricing Nuances: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations and import duties that can affect overall costs.

Conclusion

Understanding the comprehensive cost structure and pricing influencers in sourcing machine labels is critical for B2B buyers. By focusing on key cost components, negotiating effectively, and considering the total cost of ownership, buyers can make informed purchasing decisions that align with their operational needs. Always keep in mind that prices may vary widely based on specific requirements and supplier capabilities, so thorough research and negotiation are essential.

Alternatives Analysis: Comparing machine labels With Other Solutions

Introduction to Alternatives for Machine Labels

When it comes to labeling machinery and equipment, businesses have various options available. While machine labels are a popular choice due to their versatility and reliability, it is essential to explore alternative solutions that may offer unique advantages. This analysis compares machine labels with two viable alternatives: digital signage and RFID tagging, providing insights into their performance, costs, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Machine Labels | Digital Signage | RFID Tagging |

|---|---|---|---|

| Performance | Durable, weather-resistant, and customizable for various environments. | High visibility and dynamic content capabilities. | Accurate tracking and inventory management. |

| Cost | Generally low-cost per label, depending on material and printer used. | Higher initial investment for hardware and software, plus ongoing content management costs. | Moderate to high cost depending on tags and readers. |

| Ease of Implementation | Simple to print and apply; minimal training required. | Requires technical knowledge for setup and maintenance. | Installation of readers and tags can be complex, requires training. |

| Maintenance | Low maintenance; only requires replacement when damaged or outdated. | High maintenance due to software updates and hardware issues. | Moderate maintenance; tags may need replacement, but readers require less frequent attention. |

| Best Use Case | Ideal for safety, compliance, and identification in industrial settings. | Best for environments needing real-time updates and information display. | Perfect for inventory management and tracking assets in large facilities. |

Detailed Breakdown of Alternatives

Digital Signage

Digital signage offers businesses a visually engaging way to convey information. It excels in environments where real-time updates are crucial, such as manufacturing floors or retail spaces. The dynamic nature of digital signage allows companies to display multiple messages, which can be beneficial for promotions or safety alerts. However, the initial investment can be significant, and ongoing costs for content management can add up. Additionally, technical expertise is required for setup and maintenance, which may deter some organizations.

Illustrative image related to machine labels

RFID Tagging

RFID (Radio Frequency Identification) tagging provides a sophisticated solution for tracking and managing assets. This technology is particularly advantageous in warehouses and large manufacturing plants where inventory management is critical. RFID tags can streamline operations by automating the tracking process, reducing human error, and improving efficiency. However, the costs can be moderate to high, especially when considering the need for readers and the infrastructure to support them. Furthermore, the implementation can be complex, requiring trained personnel to manage the system effectively.

Conclusion: How to Choose the Right Solution for Your Business Needs

Selecting the right labeling solution depends on various factors unique to each business. B2B buyers should consider their specific operational requirements, budget constraints, and the environment in which the labels will be used. Machine labels offer a cost-effective, low-maintenance option suitable for many industrial applications, while digital signage and RFID tagging provide advanced features that may be more beneficial for businesses requiring real-time updates or sophisticated asset tracking. By carefully evaluating these alternatives, buyers can make informed decisions that align with their operational goals and enhance efficiency.

Essential Technical Properties and Trade Terminology for machine labels

What Are the Key Technical Properties of Machine Labels?

When selecting machine labels, understanding their technical properties is vital for ensuring compliance, durability, and functionality in various industrial environments. Here are some critical specifications to consider:

-

Material Grade

Machine labels can be made from various materials, including polyester, vinyl, and polypropylene. The material grade affects the label’s durability, resistance to chemicals, and ability to withstand harsh environmental conditions. For instance, polyester labels are often preferred for outdoor use due to their UV resistance, while vinyl labels offer excellent flexibility and adhesion. -

Adhesive Type

The choice of adhesive is crucial for the label’s longevity and performance. Options include permanent, removable, and repositionable adhesives. Permanent adhesives are ideal for long-term applications, ensuring labels stay securely attached in demanding conditions. Removable adhesives allow for easy repositioning without leaving residue, which is beneficial for temporary labeling needs. -

Temperature Tolerance

Labels must withstand temperature extremes, ranging from low to high heat. Heat-resistant labels are designed to endure elevated temperatures without degrading, making them suitable for applications near machinery or in ovens. Conversely, low-temperature labels remain effective in cold environments, such as freezers or refrigeration units. -

Printability

Printability refers to how well a label can accept different printing methods, such as thermal transfer or inkjet printing. This property is essential for customization, allowing businesses to include variable data like barcodes or QR codes. Labels that are laser markable can provide additional versatility for on-demand printing solutions. -

Durability Ratings

Durability is often measured through resistance to wear, tear, and environmental factors. Labels may come with ratings for scratch resistance, water resistance, and chemical resistance. Understanding these ratings helps buyers select labels that will endure specific conditions, reducing replacement costs and downtime. -

Finish Options

The finish of a label, whether matte, glossy, or textured, impacts its visibility and aesthetic appeal. A matte finish may reduce glare, making it easier to read in bright conditions, while a glossy finish can enhance color vibrancy. The choice of finish can also affect the label’s performance, influencing adhesion and resistance properties.

What Are Common Trade Terms Used in the Machine Label Industry?

Familiarizing yourself with trade terminology can streamline communication and improve negotiation processes. Here are several key terms frequently encountered in the machine label sector:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are marketed by another company. In the context of machine labels, buyers often work with OEMs to ensure that labels meet specific requirements for equipment branding or compliance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and cost efficiency. Larger orders often lead to better pricing, but buyers must balance this with their actual needs. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and terms for specific products or services. In the context of machine labels, an RFQ can help buyers compare options, negotiate better rates, and ensure they are getting the best value. -

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in global transactions. Understanding these terms is vital for buyers dealing with international suppliers, as they clarify shipping costs, delivery responsibilities, and risk management. -

Lead Time

Lead time refers to the period between placing an order and receiving the products. Knowing the lead time for machine labels is essential for planning and ensuring that production schedules are met without delays. -

Compliance Standards

Compliance standards refer to regulations that labels must meet, such as safety or environmental standards. Familiarity with these standards is crucial for avoiding legal issues and ensuring that products are suitable for their intended applications.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions regarding machine labels, ensuring they select the right products for their specific applications while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the machine labels Sector

What Are the Current Market Dynamics and Key Trends in the Machine Labels Sector?

The global machine labels market is experiencing significant growth driven by various factors, including the rise of automation and the need for efficient inventory management. As businesses increasingly adopt Industry 4.0 technologies, the demand for clear, durable, and functional labeling solutions is escalating. This trend is particularly pronounced in sectors such as manufacturing, logistics, and healthcare, where labels play a critical role in product identification, safety compliance, and operational efficiency.

Emerging technologies such as digital printing, RFID labeling, and smart labels are reshaping the sourcing landscape. These innovations enable companies to customize labels on demand, reduce waste, and enhance traceability. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are leveraging these advancements to improve supply chain visibility and ensure compliance with local regulations. Additionally, the increasing importance of e-commerce is driving the need for effective labeling solutions that facilitate seamless shipping and returns.

The competitive nature of the market means that international buyers must stay informed about new entrants and pricing strategies. Collaborating with suppliers that offer innovative solutions and robust support services can provide a distinct advantage. As buyers navigate these dynamics, understanding regional market nuances and consumer preferences will be vital for successful sourcing.

How Can Sustainability and Ethical Sourcing Impact the Machine Labels Sector?

Sustainability is becoming a critical consideration in the procurement of machine labels, driven by both regulatory pressures and consumer demand for environmentally responsible products. The production of labels can have a notable environmental impact, particularly concerning the materials used and waste generated. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability through the use of eco-friendly materials, such as recycled paper and biodegradable plastics.

Ethical sourcing practices are equally essential, as buyers seek to ensure that their suppliers adhere to fair labor practices and environmental standards. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 can signal a supplier’s commitment to sustainable practices. Implementing a robust ethical sourcing strategy not only mitigates risks associated with supply chain disruptions but also enhances brand reputation and customer loyalty.

Illustrative image related to machine labels

Furthermore, as businesses pursue sustainability goals, they often seek suppliers who can provide innovative labeling solutions that minimize waste. This includes options like self-laminating labels and those made from low-impact materials. By aligning procurement strategies with sustainability objectives, B2B buyers can contribute to a more responsible supply chain while still achieving their operational needs.

What Is the Historical Context of Machine Labels in B2B Transactions?

The evolution of machine labels can be traced back to the industrial revolution when the need for product identification became paramount. Initially, labels were manually created, often leading to inconsistencies and errors. With the advent of digital printing in the late 20th century, businesses gained the ability to produce high-quality, customized labels quickly and efficiently.

As industries have advanced, so too have the technologies and materials used in labeling. The introduction of thermal transfer printing and RFID technology has enabled companies to enhance their labeling capabilities significantly. Today, machine labels serve not only practical functions but also contribute to branding and consumer engagement, reflecting the broader trends of automation and digitalization in manufacturing and logistics.

In summary, understanding the historical context of machine labels helps B2B buyers appreciate the technological advancements that have shaped the current market and informs their sourcing decisions in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of machine labels

-

How do I choose the right machine labels for my application?

Choosing the right machine labels requires understanding your specific application and environment. Consider factors such as the material of the label (e.g., vinyl, polyester), the print method (thermal transfer, inkjet), and the conditions the labels will face (humidity, temperature, exposure to chemicals). Additionally, ensure the labels meet regulatory requirements for safety and identification in your industry. Consult with suppliers who can provide samples and technical data sheets to help you make an informed decision. -

What is the best labeling solution for harsh environments?

For harsh environments, look for labels designed with aggressive adhesion and durability in mind. Heat-resistant, washdown-resistant, and chemical-resistant labels are ideal for industries such as manufacturing, food processing, and pharmaceuticals. Suppliers often offer specialized materials that withstand extreme temperatures and moisture, ensuring longevity and legibility. Request samples to test their performance in your specific conditions before making a bulk purchase. -

What are the customization options available for machine labels?

Customization options for machine labels can include size, shape, color, text, and graphics. Many suppliers offer printing services that allow you to incorporate your company logo, barcodes, or specific text requirements. Additionally, you can choose from various materials and finishes to suit your branding and operational needs. Discuss your specific requirements with potential suppliers to explore their capabilities and ensure they can meet your customization requests. -

What is the minimum order quantity (MOQ) for machine labels?

Minimum order quantities for machine labels can vary significantly between suppliers. Some may have a low MOQ of 100 labels, while others might require orders in the thousands, especially for custom designs. It’s advisable to inquire about MOQs when sourcing suppliers to ensure they align with your purchasing needs. Additionally, larger orders may provide cost savings, so consider your long-term label requirements when negotiating. -

How can I ensure the quality of machine labels before purchase?

To ensure quality, request samples from potential suppliers to assess the label material, adhesion, and print quality. Look for certifications that verify compliance with industry standards relevant to your application. Additionally, inquire about the supplier’s quality assurance processes, including testing methods and return policies. Reviews and testimonials from other customers can also provide insights into the supplier’s reliability and product performance. -

What payment terms should I negotiate with suppliers?

When negotiating payment terms, consider options such as net 30, net 60, or even upfront payments depending on your relationship with the supplier. It’s essential to establish terms that align with your cash flow and inventory needs. Some suppliers may offer discounts for early payments, while others may require a deposit for custom orders. Always clarify payment methods accepted (e.g., bank transfer, credit card) and any potential fees associated with international transactions. -

What logistics considerations should I keep in mind when sourcing machine labels?

Logistics considerations include shipping times, costs, and customs regulations, especially for international orders. Discuss with your supplier the expected lead times for production and delivery, as well as options for expedited shipping if necessary. Familiarize yourself with any import duties or taxes that may apply to your region. Establishing a reliable logistics partner can also help streamline the process and ensure timely receipt of your labels. -

How can I vet suppliers for machine labels effectively?

To vet suppliers, start by researching their reputation in the industry through online reviews, case studies, and referrals from other businesses. Request references and conduct background checks to assess their reliability and quality of service. Evaluate their certifications and compliance with relevant industry standards. A site visit or virtual meeting can also provide insights into their operational capabilities and customer service approach, ensuring they meet your expectations.

Top 4 Machine Labels Manufacturers & Suppliers List

1. MyAssetTag – Custom Equipment ID Tags

Domain: myassettag.com

Registered: 2004 (21 years)

Introduction: Equipment ID Tags from MyAssetTag are durable metal or plastic tags featuring sequential barcodes or numbers. They can be customized with a starting number or personalized text and design. The modular design allows for color coding by equipment type or purchase year. Metal tags, made from anodized aluminum, are designed to last longer than the equipment they label. Free shipping is available on or…

2. MySafetyLabels – Machine Safety Labels

Domain: mysafetylabels.com

Registered: 2007 (18 years)

Introduction: Machine Safety Labels help protect workers from preventable injuries during machine operation and maintenance. They comply with official laws and regulations, promoting safety and caution in hazardous environments. Key features include:

– Premium adhesive for easy application on clean surfaces (flat and curved).

– Durable vinyl labels available in various sizes.

– Designed according to OSHA and AN…

3. Maverick Label – Custom Industrial Labels

Domain: mavericklabel.com

Registered: 2000 (25 years)

Introduction: Custom Industrial Labels and Equipment Labels with free shipping. $100 off orders over $500 with code SAVE100 (offer ends 9/19/25). Products include asset tags, equipment labels, graphic overlays, domed labels, custom tape, blank roll labels, bumper stickers, cannabis labels, custom roll labels, custom pouches, die cut stickers, shipping labels, floor graphic decals, foil & embossed labels, hard h…

4. MPOF – Custom Equipment Labels

Domain: mpofcinci.com

Registered: 1997 (28 years)

Introduction: Custom Equipment Labels and Identification Tags designed for durability and longevity, suitable for various applications including industrial, aerospace, and military. Available in metal and plastic options, pre-printed with variable data, barcodes, or customizable using metal blanks. Products include Metalphoto® labels, plastic labels, industrial labels, security tags, compliance tags, and more. …

Strategic Sourcing Conclusion and Outlook for machine labels

In summary, the strategic sourcing of machine labels is pivotal for enhancing operational efficiency and compliance across industries. By selecting high-quality labels tailored to specific applications—such as safety, inventory, and automation—businesses can mitigate risks, ensure regulatory compliance, and streamline processes. The diverse range of label materials and printing technologies available today empowers companies to make informed choices that align with their unique operational needs.

Illustrative image related to machine labels

As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, embracing strategic sourcing practices will not only optimize your supply chain but also foster long-term partnerships with reputable manufacturers. Investing in reliable labeling solutions can significantly reduce operational downtime and improve product traceability, ultimately leading to enhanced customer satisfaction.

Looking ahead, it is essential to stay abreast of technological advancements in labeling solutions. By leveraging innovations such as automated labeling systems and eco-friendly materials, you can position your business for future success. Take proactive steps today to evaluate your labeling needs and connect with trusted suppliers who can help you elevate your operational standards. The journey towards a more efficient and compliant labeling system starts with you.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.