A Deep Dive into Latch Plastic Solution

Introduction: Navigating the Global Market for latch plastic

In the rapidly evolving global market, sourcing high-quality latch plastic components can present significant challenges for B2B buyers, particularly those operating in diverse sectors such as industrial, commercial, and agricultural applications. As manufacturers and suppliers expand their reach, understanding the nuances of latch plastic—from material types to specific applications—becomes crucial for making informed purchasing decisions. This comprehensive guide aims to illuminate the complexities surrounding latch plastic, covering essential topics such as various types of latches, their applications across different industries, supplier vetting processes, and cost considerations.

With a focus on international buyers from regions including Africa, South America, the Middle East, and Europe—such as Brazil and Vietnam—this guide is designed to empower decision-makers by providing actionable insights and strategies. By navigating the intricacies of the latch plastic market, buyers can enhance their procurement strategies, ensuring they select the most appropriate latching solutions for their specific needs. Whether you are looking to replace outdated components or seeking durable latches for new projects, our guide equips you with the knowledge to evaluate suppliers effectively and make cost-efficient choices. Dive in to discover how to optimize your latch plastic sourcing strategy and drive operational success.

Understanding latch plastic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Thermoplastic Latches | Made from materials like PVC or nylon; durable and lightweight. | Industrial settings, cabinets, appliances. | Pros: Cost-effective, resistant to chemicals. Cons: May not withstand extreme temperatures. |

| UHMW (Ultra High Molecular Weight) Latches | High impact strength and excellent weather resistance. | Agricultural equipment, outdoor fixtures. | Pros: Long-lasting, low friction. Cons: Higher initial cost compared to standard plastics. |

| ABS (Acrylonitrile Butadiene Styrene) Latches | Rigid and tough; good for high-impact applications. | Automotive, electronics, and consumer goods. | Pros: Excellent strength-to-weight ratio. Cons: Less UV resistance; may degrade over time in sunlight. |

| Polypropylene Latches | Flexible and resistant to fatigue; good chemical resistance. | Food processing, medical equipment. | Pros: Lightweight, affordable. Cons: Lower strength compared to other plastics. |

| Nylon Latches | Excellent abrasion resistance; can handle high loads. | Heavy machinery, transportation equipment. | Pros: Durable and versatile. Cons: Can absorb moisture, affecting performance. |

What Are the Characteristics of Thermoplastic Latches?

Thermoplastic latches are crafted from materials like PVC or nylon, making them both lightweight and durable. These latches are particularly suitable for industrial applications, such as securing cabinets and appliances. When considering a purchase, businesses should note that while thermoplastic latches are cost-effective and resistant to many chemicals, they may not perform well under extreme temperature conditions.

Why Choose UHMW Latches for Outdoor Applications?

UHMW latches are renowned for their high impact strength and exceptional weather resistance, making them ideal for agricultural equipment and outdoor fixtures. The long-lasting nature of UHMW latches ensures that they maintain functionality even in harsh environments. B2B buyers should consider the initial investment, as these latches tend to have a higher upfront cost, but their durability can lead to long-term savings.

What Makes ABS Latches Suitable for Automotive and Electronics?

ABS latches are characterized by their rigidity and toughness, making them an excellent choice for high-impact applications in industries like automotive and electronics. They offer a strong strength-to-weight ratio, which is crucial for performance-sensitive applications. However, buyers should be aware that ABS latches have limited UV resistance, which could lead to degradation over time if exposed to sunlight.

How Do Polypropylene Latches Benefit Food Processing?

Polypropylene latches are flexible and exhibit good chemical resistance, making them highly suitable for food processing and medical equipment. Their lightweight nature and affordability make them a popular choice among businesses looking to optimize costs. However, buyers should keep in mind that polypropylene latches may lack the strength of other materials, which could be a consideration depending on the application.

Why Are Nylon Latches Preferred for Heavy Machinery?

Nylon latches are known for their excellent abrasion resistance and ability to handle high loads, making them ideal for heavy machinery and transportation equipment. Their durability and versatility make them a favored choice in various industrial applications. However, potential buyers should consider that nylon can absorb moisture, which might affect its performance over time, particularly in humid environments.

Key Industrial Applications of latch plastic

| Industry/Sector | Specific Application of latch plastic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Industrial Lighting | Replacement latches for vapor proof fixtures | Enhances moisture protection, energy efficiency, and safety | Ensure compatibility with existing fixtures and materials used |

| Food Service Equipment | Latches for kitchen storage and refrigeration | Maintains hygiene and prevents contamination | Look for latches that meet food safety standards and resist corrosion |

| Agricultural Equipment | Latches on storage bins and trailers | Secures contents and prevents loss or spoilage | Consider durability and weather resistance for outdoor use |

| Automotive | Latches for vehicle compartments | Provides secure access and enhances safety | Evaluate weight capacity and material resilience against elements |

| Furniture Manufacturing | Cabinet and drawer latches | Improves functionality and user experience | Assess design compatibility and ease of installation |

How is latch plastic used in industrial lighting applications?

In the industrial lighting sector, latch plastic is commonly utilized in vapor proof fixtures. These fixtures are essential in environments exposed to moisture, such as kitchens and outdoor areas. The primary function of latch plastic in this scenario is to replace worn or damaged latches, ensuring a tight seal that prevents moisture and contaminants from entering the fixture. This not only extends the life of the lighting equipment but also enhances energy efficiency and reduces electrical hazards. For international buyers, sourcing latches that are compatible with specific fixture models and materials is crucial for maintaining operational efficiency.

What role does latch plastic play in food service equipment?

In food service environments, latch plastic is vital for securing kitchen storage units and refrigeration systems. The use of high-quality plastic latches ensures that storage containers remain sealed, preventing contamination and maintaining hygiene standards. This is particularly important in regions where food safety regulations are stringent. Buyers should prioritize latches made from materials that are resistant to corrosion and easy to clean, as these factors significantly contribute to compliance with health regulations and overall operational effectiveness.

Illustrative image related to latch plastic

How does latch plastic benefit agricultural equipment?

In agriculture, latch plastic is often found in storage bins and trailers, where it plays a critical role in securing contents. By providing a reliable fastening solution, latch plastic helps prevent loss or spoilage of valuable materials, such as seeds and harvested crops. Buyers in this sector should consider the durability and weather resistance of latch plastic to ensure it can withstand outdoor conditions and heavy usage, especially in regions with varying climates.

Why is latch plastic important in the automotive industry?

Latch plastic is extensively used in automotive applications, particularly for securing compartments and access points in vehicles. These latches provide secure access while enhancing overall safety and convenience for users. For B2B buyers, it is essential to evaluate the weight capacity of latch plastic components and their resilience to environmental factors like temperature fluctuations and moisture. Sourcing latches that meet automotive standards can significantly impact vehicle reliability and user satisfaction.

How does latch plastic improve furniture manufacturing?

In furniture manufacturing, latch plastic is utilized in cabinets and drawers to enhance functionality. By ensuring that these components close securely, latch plastic improves user experience and product reliability. Buyers should assess design compatibility with existing furniture lines and the ease of installation when selecting latch plastic solutions. This is particularly important for international manufacturers looking to maintain quality and consistency across diverse markets.

3 Common User Pain Points for ‘latch plastic’ & Their Solutions

Scenario 1: Durability Issues in Harsh Environments

The Problem: B2B buyers often face significant challenges when sourcing latches for applications in harsh environments, such as outdoor facilities or industrial settings. These latches may be exposed to moisture, temperature fluctuations, and corrosive substances, leading to rapid degradation. This not only compromises the functionality of the latches but also increases the maintenance costs and potential safety hazards associated with equipment failure. Buyers might find themselves repeatedly replacing latches, which disrupts operations and impacts the bottom line.

The Solution: To address these concerns, it’s crucial to select latches made from high-performance plastic materials that offer superior weather resistance and durability. Look for latches specifically designed for harsh environments, such as those made from UV-stabilized or impact-resistant thermoplastics. Additionally, consider suppliers who can provide detailed specifications on the materials used, including resistance to specific chemicals or temperatures. By investing in quality latches tailored for tough conditions, businesses can enhance their equipment’s longevity, reduce replacement frequency, and ultimately save on maintenance costs.

Scenario 2: Compatibility Challenges with Existing Systems

The Problem: Many B2B buyers encounter compatibility issues when trying to replace or upgrade latches in existing systems. This can arise from variations in size, mounting configurations, or latch mechanisms. Incompatible latches can lead to installation delays, increased labor costs, and potential operational disruptions. Furthermore, the lack of standardized sizes and specifications across manufacturers can complicate the sourcing process, leaving buyers frustrated and uncertain about their options.

The Solution: To mitigate compatibility challenges, buyers should conduct a thorough assessment of their current latch systems before making a purchase. This includes measuring existing latches and understanding the mounting requirements of the application. When sourcing new latches, it’s advisable to consult with manufacturers who offer customization options or have a range of adjustable latches. Additionally, using a reliable supplier who provides comprehensive technical support can help buyers ensure that the new latches will fit seamlessly into their existing infrastructure. By taking these steps, businesses can streamline the replacement process and avoid costly installation errors.

Illustrative image related to latch plastic

Scenario 3: High Costs of Frequent Replacements

The Problem: Frequent latch failures can lead to escalating costs for businesses, particularly in industries where latches are crucial for safety and functionality, such as in transportation or manufacturing. Constantly replacing latches not only adds to direct material costs but also incurs additional labor expenses and potential downtime in operations. This issue is exacerbated when buyers opt for cheaper, lower-quality latches, resulting in a cycle of failures and replacements that can strain budgets.

The Solution: To combat high replacement costs, buyers should consider investing in high-quality latches designed for durability and reliability. Conducting a cost-benefit analysis can be beneficial, comparing the initial investment of premium latches against the long-term savings from reduced replacements and maintenance. Additionally, exploring bulk purchasing options or establishing long-term contracts with suppliers can yield significant discounts and ensure a steady supply of reliable latches. Implementing a preventive maintenance program that includes regular inspections can further extend the lifespan of latches, ensuring they perform optimally over time. By taking a proactive approach, businesses can achieve substantial savings while enhancing operational efficiency.

Strategic Material Selection Guide for latch plastic

What Are the Key Properties of Common Materials Used for Latch Plastics?

When selecting materials for latch plastics, it’s essential to consider the specific properties that will affect performance in various applications. The most common materials include Polypropylene (PP), Polycarbonate (PC), Nylon (PA), and Acrylonitrile Butadiene Styrene (ABS). Each of these materials has unique characteristics that impact their suitability for different environments and applications.

How Does Polypropylene (PP) Perform in Latch Applications?

Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and lightweight nature. It typically performs well in temperatures ranging from -20°C to 100°C and is resistant to moisture, making it ideal for outdoor and humid applications.

Pros: Polypropylene is cost-effective, easy to mold, and has good fatigue resistance, which is beneficial for latches that undergo repeated use.

Cons: However, it has lower impact resistance compared to other materials and can become brittle at lower temperatures, limiting its use in colder climates.

Impact on Application: PP is suitable for applications involving exposure to chemicals but may not be the best choice for high-impact environments.

Considerations for International Buyers: Buyers in regions with varying climates, such as Africa and South America, should consider the temperature range of their application and potential chemical exposure. Compliance with local standards such as ASTM or ISO is also crucial.

What Benefits Does Polycarbonate (PC) Offer for Latch Plastics?

Polycarbonate is known for its exceptional impact resistance and optical clarity. It can withstand temperatures from -40°C to 120°C, making it suitable for demanding environments.

Pros: Its high strength and durability make it an excellent choice for security applications where breakage could be a concern.

Cons: However, polycarbonate can be more expensive than other plastics and may require more complex manufacturing processes.

Impact on Application: PC latches are ideal for high-stress applications, such as in automotive or industrial settings, where safety and durability are paramount.

Considerations for International Buyers: Buyers should be aware of the higher costs associated with polycarbonate and ensure that their suppliers meet international standards for safety and durability.

Why Choose Nylon (PA) for Latch Plastics?

Nylon is a versatile material that offers excellent tensile strength and abrasion resistance. It typically operates effectively between -40°C and 120°C.

Pros: Nylon latches are lightweight and have good chemical resistance, making them suitable for a variety of applications, including automotive and industrial uses.

Cons: The main downside is that nylon can absorb moisture, which may lead to dimensional changes over time, potentially affecting latch performance.

Impact on Application: Nylon is particularly effective in applications where flexibility and strength are required, but moisture exposure must be carefully managed.

Considerations for International Buyers: Buyers should consider the moisture levels in their specific regions, particularly in humid climates like those in parts of Africa and South America, and ensure compliance with relevant industry standards.

What Are the Advantages of Using Acrylonitrile Butadiene Styrene (ABS) in Latch Plastics?

ABS is a popular choice for latch plastics due to its balance of strength, toughness, and cost-effectiveness. It typically operates within a temperature range of -20°C to 80°C.

Pros: ABS is easy to process and offers good impact resistance and surface finish, making it suitable for consumer products.

Cons: However, it is less resistant to UV light and may degrade in outdoor applications unless treated.

Impact on Application: ABS is well-suited for indoor applications where aesthetic appearance and durability are important, but its limitations in UV resistance must be considered for outdoor uses.

Illustrative image related to latch plastic

Considerations for International Buyers: Buyers should evaluate the environmental conditions of their target markets, especially in sunny regions, and ensure that their ABS products comply with local standards.

Summary Table of Material Selection for Latch Plastics

| Material | Typical Use Case for latch plastic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Chemical exposure applications | Cost-effective and lightweight | Lower impact resistance | Low |

| Polycarbonate (PC) | Security applications | Exceptional impact resistance | Higher cost and manufacturing complexity | High |

| Nylon (PA) | Automotive and industrial uses | Excellent tensile strength and abrasion resistance | Moisture absorption can affect performance | Medium |

| Acrylonitrile Butadiene Styrene (ABS) | Indoor consumer products | Good impact resistance and aesthetic finish | Poor UV resistance for outdoor applications | Medium |

This guide provides a comprehensive overview of common materials used in latch plastics, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for latch plastic

What Are the Key Stages in the Manufacturing Process of Latch Plastic?

The manufacturing process for latch plastic involves several critical stages, each designed to ensure that the final product meets high standards of quality and functionality.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing latch plastic is the selection and preparation of raw materials. Commonly used materials include thermoplastics such as polycarbonate and polyethylene due to their durability and resistance to environmental factors. Suppliers typically source these materials from reputable manufacturers who adhere to international quality standards.

Once the raw materials are procured, they undergo a series of processes, including drying to remove moisture and milling to achieve the desired particle size. This preparation is crucial as it directly impacts the molding and forming stages, ensuring consistency in the final product.

How Are Plastic Latches Formed?

The forming stage is where the actual shape of the latch is created. This can be accomplished through several techniques, including injection molding, blow molding, and extrusion.

-

Injection Molding: This is the most common method used for producing latch plastics. The prepared material is heated and injected into a mold under high pressure. This technique allows for high precision and can produce complex shapes, making it ideal for latches that require specific design features.

-

Blow Molding: Often used for hollow latches, this method involves inflating a heated plastic tube within a mold to form the desired shape.

-

Extrusion: While less common for latches, this technique may be used for producing flat or elongated components that are later cut to size.

Each method has its advantages and is selected based on the design requirements, production volume, and cost considerations.

What Happens During the Assembly of Latch Plastic Components?

After the latching components are formed, they may undergo assembly. This stage can involve the integration of various parts, such as hinges, locking mechanisms, and seals, depending on the latch design.

Automated assembly lines are often used to improve efficiency and consistency. However, manual assembly may also be employed for more intricate designs or where precision is paramount.

Quality checks during assembly are vital to ensure that each component fits correctly and functions as intended.

What Finishing Processes Are Applied to Latch Plastics?

The finishing stage enhances the product’s appearance and prepares it for final inspection. This can include processes such as surface treatment, painting, or coating to improve aesthetics and durability.

For example, some latch plastics may receive a UV-resistant coating to protect against sun damage, particularly important for products intended for outdoor use.

Additionally, finishing may involve deburring and polishing to eliminate sharp edges and improve user safety.

How Is Quality Assurance Implemented in Latch Plastic Manufacturing?

Quality assurance (QA) is a critical aspect of latch plastic manufacturing, ensuring that products meet both customer expectations and international standards.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers of latch plastics often adhere to various international quality standards. The ISO 9001 standard is widely recognized and focuses on quality management systems, emphasizing continuous improvement and customer satisfaction.

Additionally, industry-specific certifications may be relevant, such as CE marking for products sold in Europe, which indicates compliance with health, safety, and environmental protection standards. For manufacturers supplying to the oil and gas sector, API (American Petroleum Institute) standards may also apply, particularly for latches used in hazardous environments.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves systematic checks at various stages of the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This stage inspects raw materials and components before they enter production. It ensures that suppliers meet specified quality criteria.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken to verify that production processes maintain quality standards. This can involve measuring dimensions, testing material properties, and assessing functionality.

-

Final Quality Control (FQC): After production, the finished latches undergo rigorous testing to ensure they meet all design specifications and performance criteria before being shipped to customers.

What Testing Methods Are Commonly Used for Latch Plastics?

Various testing methods are employed to validate the quality and performance of latch plastics. Common tests include:

- Mechanical Testing: Evaluates strength, flexibility, and impact resistance.

- Environmental Testing: Assesses durability under various conditions, such as exposure to UV light, moisture, and temperature fluctuations.

- Functional Testing: Ensures that the latch operates as intended, including locking mechanisms and ease of use.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential.

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits can provide valuable insights into a manufacturer’s quality assurance processes. Buyers should consider:

-

Requesting Quality Assurance Documentation: Suppliers should provide evidence of their compliance with relevant quality standards, including ISO certifications and quality control reports.

-

Third-Party Inspections: Engaging independent inspection agencies can help verify that manufacturing processes and final products meet specified quality standards.

-

Site Visits: Whenever feasible, visiting the manufacturing site allows buyers to assess the production environment, equipment, and adherence to quality practices firsthand.

What Nuances Should International Buyers Consider in Quality Control?

International buyers should be aware of the potential differences in quality standards and practices across regions. For instance, while European manufacturers may have stringent CE marking requirements, suppliers in other regions may not. Understanding these nuances is critical for ensuring that products meet the necessary safety and performance standards in the buyer’s market.

In conclusion, the manufacturing processes and quality assurance for latch plastics involve intricate stages and rigorous testing to meet international standards. B2B buyers must engage actively with suppliers to ensure quality and performance that align with their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch plastic’

When sourcing latch plastic for your business, it’s essential to follow a structured approach to ensure quality, efficiency, and cost-effectiveness. This guide provides a checklist to help you navigate the procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the latches you need. Consider factors such as size, material, load capacity, and environmental resistance (e.g., moisture, chemicals). This step is crucial as it sets the foundation for your sourcing process, ensuring that the products meet your operational needs.

- Material Requirements: Specify whether you need standard plastic or a more durable option like UHMW for impact resistance.

- Compliance Standards: Identify any industry-specific standards or certifications that the latches must meet.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reliable suppliers of latch plastic. Look for manufacturers with a proven track record in producing quality products.

- Supplier Directories: Utilize online platforms and directories that specialize in industrial hardware.

- Local and International Suppliers: Consider both local and international options to compare pricing and availability.

Step 3: Evaluate Supplier Certifications

Before making a decision, verify that potential suppliers have the necessary certifications. Certifications can indicate quality management and adherence to safety standards.

- ISO Certifications: Look for ISO 9001 or similar certifications that demonstrate quality management systems.

- Material Safety Data Sheets (MSDS): Ensure they provide MSDS for the materials used in their products.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the latch plastic products. Testing samples allows you to assess quality, durability, and fit for your application.

- Quality Assessment: Check for defects, flexibility, and overall build quality.

- Compatibility Testing: Ensure the samples meet your specific operational requirements.

Step 5: Review Pricing and Payment Terms

Analyze the pricing structures offered by each supplier. This step is important to ensure that you are getting a fair deal while considering the quality of the product.

- Bulk Discounts: Inquire about volume pricing or discounts for bulk orders.

- Payment Terms: Understand payment terms and conditions, including any upfront costs or credit options.

Step 6: Check References and Customer Feedback

Before finalizing your supplier choice, check references and customer feedback. This can provide insight into the supplier’s reliability and product performance.

- Case Studies: Request case studies from suppliers that demonstrate their work with similar businesses.

- Online Reviews: Look for reviews or testimonials on third-party websites to gauge customer satisfaction.

Step 7: Finalize the Contract and Place Your Order

After thorough evaluation, finalize your contract with the chosen supplier. Ensure that all agreed-upon terms, including delivery timelines and warranty information, are clearly documented.

- Contract Details: Clearly outline specifications, payment terms, and delivery schedules.

- Follow-Up: Maintain communication with the supplier throughout the production and delivery process to address any issues promptly.

By following these steps, B2B buyers can ensure a well-informed procurement process for latch plastic, leading to successful partnerships and product outcomes.

Comprehensive Cost and Pricing Analysis for latch plastic Sourcing

What Are the Key Cost Components in Plastic Latch Manufacturing?

When sourcing plastic latches, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and margins.

-

Materials: The choice of plastic (e.g., thermoplastics) significantly impacts costs. Higher-grade materials may offer better durability and weather resistance but will increase the unit price. For instance, common plastics like polypropylene or ABS are more cost-effective compared to high-performance polymers.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs, such as certain areas in Africa or South America, may provide competitive pricing but could also present challenges in skill levels and quality assurance.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility operations. Efficient manufacturing processes and technologies can reduce overhead, leading to more competitive pricing.

-

Tooling: Initial tooling costs for molds and dies can be substantial, particularly for custom designs. Buyers should consider these costs in their overall budget, especially if they require unique specifications.

-

Quality Control (QC): Ensuring that the latches meet industry standards and certifications can add to the cost. However, investing in quality control can reduce long-term expenses related to returns and warranty claims.

-

Logistics: Transportation costs depend on the location of the supplier and the buyer. International shipments may incur additional fees due to customs and tariffs, impacting overall costs.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. This margin can vary based on market conditions and competition.

What Influences the Pricing of Plastic Latches?

Several factors can affect the pricing of plastic latches, particularly for international buyers. Understanding these influencers can help buyers make informed decisions.

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts. Buyers should inquire about MOQs and potential price breaks for larger orders to optimize costs.

-

Specifications and Customization: Customized latches may incur additional costs for design and tooling. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Latches that comply with specific industry standards (like UL or CE certifications) may be priced higher due to the rigorous testing and quality assurance processes involved.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is crucial for pricing. Different Incoterms can shift costs and risks, impacting the overall price of the latches.

What Are Effective Buyer Tips for Sourcing Plastic Latches?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance sourcing efficiency:

-

Negotiate Wisely: Leverage your purchasing power, especially for larger orders. Suppliers may be open to negotiations on price, terms, and conditions.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and replacement costs. Cheaper latches may lead to higher long-term costs if they fail prematurely.

-

Understand Pricing Nuances: Be aware of local market conditions, currency fluctuations, and import duties that may affect pricing. Researching local suppliers can also reveal competitive options.

-

Request Samples: Before committing to a large order, request samples to evaluate quality and performance. This can prevent costly mistakes down the line.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better terms, priority service, and insights into upcoming product developments or cost-saving opportunities.

Disclaimer on Indicative Prices

Prices for plastic latches can vary widely based on specifications, supplier practices, and market conditions. The figures mentioned in various contexts are indicative and should not be considered fixed. Always seek quotes directly from suppliers for the most accurate pricing.

Alternatives Analysis: Comparing latch plastic With Other Solutions

Exploring Alternatives to Latch Plastic: A Comprehensive Comparison

In the industrial and commercial sectors, the choice of latching solutions is critical for ensuring the reliability and safety of equipment and installations. While latch plastic is widely used due to its cost-effectiveness and versatility, there are several alternative solutions worth considering. This analysis compares latch plastic against metal latches and magnetic catches, which also serve the purpose of securing closures in various applications.

| Comparison Aspect | Latch Plastic | Metal Latches | Magnetic Catches |

|---|---|---|---|

| Performance | Good; weather-resistant and durable | Excellent; high strength and longevity | Moderate; depends on magnet strength |

| Cost | Low (typically $1.95-$4.95) | Medium to High (typically $5-$30) | Low to Medium (typically $2-$5) |

| Ease of Implementation | Easy; requires minimal tools | Moderate; may require more tools and skills | Very Easy; typically self-adhesive or simple install |

| Maintenance | Low; resistant to corrosion and wear | Moderate; can rust or corrode if not treated | Low; minimal upkeep needed |

| Best Use Case | General applications in humid environments | Heavy-duty applications in demanding environments | Light-duty applications, cabinets, or doors |

What Are the Pros and Cons of Metal Latches?

Metal latches, such as those made from stainless steel or aluminum, offer superior strength and durability compared to plastic options. They are ideal for high-stress environments, such as industrial machinery and heavy-duty storage solutions. However, they can be more expensive and may require additional maintenance to prevent rust and corrosion. Their installation can also be more complex, often necessitating specialized tools. Overall, metal latches are best suited for applications where strength and security are paramount.

How Do Magnetic Catches Compare to Latch Plastic?

Magnetic catches provide a unique alternative that operates on a simple mechanism. They are exceptionally easy to install and can be affixed with adhesive or screws, making them ideal for quick setups. While they are effective for securing lightweight doors and cabinet closures, their holding power is reliant on the strength of the magnets used. In environments where moisture or heavy use is a concern, magnetic catches may not provide the same level of security and durability as latch plastic or metal latches. They are best used in applications where aesthetics and convenience are more important than heavy-duty performance.

Conclusion: How Should B2B Buyers Choose the Right Latching Solution?

When selecting a latching solution, B2B buyers should assess their specific needs based on application requirements, environmental conditions, and budget constraints. Latch plastic is an excellent choice for cost-sensitive projects requiring moderate durability and resistance to moisture. In contrast, metal latches are preferable for applications demanding maximum strength and security. Magnetic catches can be ideal for light-duty applications where ease of installation is critical. By evaluating these factors, buyers can make an informed decision that aligns with their operational goals and enhances overall efficiency.

Essential Technical Properties and Trade Terminology for latch plastic

What Are the Key Technical Properties of Latch Plastic?

When selecting latch plastic for various applications, understanding the technical properties is crucial for ensuring product reliability and performance. Here are several key specifications to consider:

1. Material Grade

The material grade refers to the type of thermoplastic used in manufacturing latches, which can include materials like polycarbonate, polypropylene, or nylon. Each material has distinct properties such as impact resistance, flexibility, and temperature tolerance. Choosing the right material grade is essential for ensuring that the latch can withstand specific environmental conditions, particularly in industrial settings where exposure to chemicals or extreme temperatures may occur.

2. Tolerance

Tolerance defines the permissible limit of variation in dimensions and is critical in ensuring that latches fit securely and function properly. In a B2B context, precise tolerances reduce the risk of failure in applications where latches must engage or disengage smoothly. Maintaining tight tolerances is especially important for OEMs (Original Equipment Manufacturers) who require consistent quality across large production runs.

3. Load Capacity

Load capacity indicates the maximum weight or force that a latch can securely hold without failing. This property is vital for applications in industrial, commercial, and domestic settings, where the failure of a latch could lead to safety hazards or damage. Buyers must match the load capacity of the latch to the specific requirements of their application to ensure durability and reliability.

4. UV Resistance

For latches used in outdoor applications, UV resistance is a critical property that prevents degradation from prolonged sunlight exposure. Latches with high UV resistance maintain structural integrity and color stability, which is essential for aesthetic and functional longevity. B2B buyers should prioritize UV-resistant materials when sourcing latches for outdoor use.

5. Weather Resistance

Weather resistance refers to the ability of latch plastic to withstand various environmental conditions, including moisture, temperature fluctuations, and exposure to chemicals. This property is particularly important in regions with extreme weather conditions, where latches may be exposed to rain, snow, or humidity. Selecting weather-resistant latches ensures that they will perform reliably over time, reducing maintenance costs and downtime.

Which Trade Terms Should B2B Buyers Understand When Sourcing Latch Plastic?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are key terms relevant to latch plastic procurement:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products for other businesses to sell under their brand. In the context of latch plastic, OEMs often require specific designs and material properties to meet their customers’ standards. Understanding the OEM relationship can help buyers navigate product customization and compatibility issues.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it can affect inventory management and cash flow. Knowing the MOQ helps companies plan their purchases and negotiate better pricing terms.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products. When sourcing latch plastic, issuing an RFQ allows buyers to compare costs, lead times, and material specifications from multiple suppliers, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping and logistics. Understanding Incoterms is crucial for B2B transactions, as they outline who bears the risk and costs associated with transportation, insurance, and customs clearance. This knowledge helps buyers mitigate risks in international shipping.

5. Lead Time

Lead time refers to the amount of time it takes for a supplier to fulfill an order from the moment it is placed until it is delivered. For latch plastic, understanding lead times is essential for project planning and ensuring that production schedules are met without delays.

Illustrative image related to latch plastic

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing latch plastic, ensuring they select the right products for their specific needs while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the latch plastic Sector

What are the Current Market Dynamics and Key Trends in the Latch Plastic Sector?

The latch plastic sector is experiencing dynamic shifts driven by various global factors. A primary driver is the increasing demand for lightweight, durable, and cost-effective fastening solutions across industries such as construction, automotive, and consumer goods. As international markets expand, B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly sourcing plastic latches due to their versatility and superior performance compared to traditional metal options.

Emerging technologies, such as 3D printing, are revolutionizing the production of plastic latches, enabling rapid prototyping and customization that meet specific client needs. This trend is particularly appealing to buyers looking for tailored solutions that enhance product efficiency and reduce lead times. Furthermore, the rise of e-commerce platforms is simplifying the purchasing process, allowing businesses to access a broader range of suppliers and products with just a few clicks.

Market dynamics are also influenced by regional economic conditions and trade policies. For instance, buyers in Brazil and Vietnam may benefit from favorable trade agreements that lower import tariffs on plastic components, making it economically viable to source high-quality products from established manufacturers. Additionally, the ongoing push for improved safety standards in industrial applications is prompting companies to invest in high-performance latches that ensure durability and security in challenging environments.

How is Sustainability and Ethical Sourcing Affecting the Latch Plastic Market?

Sustainability is no longer just a buzzword; it has become a critical consideration for B2B buyers in the latch plastic sector. The environmental impact of plastic production, particularly in terms of waste and pollution, is prompting companies to seek more sustainable alternatives. This trend is driving demand for latches made from recycled plastics or bio-based materials that minimize ecological footprints.

Buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing practices. This includes verifying that materials are sourced responsibly and that production processes adhere to environmental regulations. Certifications such as ISO 14001 for environmental management and the Global Recycling Standard (GRS) are gaining traction, providing buyers with assurance that their suppliers are committed to sustainable practices.

Moreover, the shift towards circular economy principles is influencing product design in the latch sector. Companies are focusing on developing latches that are not only durable but also recyclable at the end of their lifecycle, thus reducing waste. This focus on sustainability is not only beneficial for the planet but also enhances brand reputation and can lead to increased customer loyalty among environmentally conscious consumers.

Illustrative image related to latch plastic

What is the Brief Evolution of the Latch Plastic Sector Relevant for B2B Buyers?

The latch plastic sector has evolved significantly over the past few decades, transitioning from simple mechanical devices to sophisticated fastening solutions that leverage advanced materials and technologies. Initially, latches were predominantly made from metal, which posed challenges in terms of weight and corrosion resistance. However, the introduction of thermoplastic materials revolutionized the industry by offering lightweight, durable, and corrosion-resistant alternatives.

As industries began to recognize the benefits of plastic latches, their applications expanded beyond traditional uses in cabinetry and furniture to encompass automotive, aerospace, and industrial sectors. Innovations in manufacturing processes, such as injection molding and 3D printing, have further enhanced the design and functionality of latches, allowing for more complex shapes and configurations that meet specific customer needs.

Today, the latch plastic sector is characterized by a focus on sustainability and efficiency, reflecting broader industry trends towards responsible sourcing and manufacturing. For B2B buyers, understanding this evolution is crucial for making informed purchasing decisions that align with current market demands and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of latch plastic

-

How do I solve issues with worn or damaged plastic latches?

To address problems with worn or damaged plastic latches, consider replacing them rather than replacing the entire fixture. This approach not only extends the life of your equipment but also enhances its performance. When sourcing replacements, ensure they are compatible with your existing fixtures. Opt for high-quality plastic latches that provide durability and a secure seal against moisture and contaminants. Additionally, evaluate suppliers that offer warranties or guarantees on their products to ensure you are making a sound investment. -

What is the best type of plastic latch for industrial applications?

For industrial applications, thermoplastic latches are often the best choice due to their durability and resistance to environmental factors. Look for latches made from materials like polycarbonate or nylon, which offer superior strength and impact resistance. Additionally, consider latches designed specifically for moisture-prone environments, such as vapor-proof latches, to enhance performance and safety. It’s also beneficial to consult with suppliers who can provide detailed specifications and testing certifications to ensure they meet your industry standards. -

What should I consider when vetting suppliers for plastic latches?

When vetting suppliers for plastic latches, assess their reputation, manufacturing capabilities, and quality assurance processes. Look for suppliers with a proven track record in your specific industry, as they will better understand your needs. Request samples to evaluate product quality, and inquire about certifications such as ISO standards. Additionally, consider their communication efficiency and customer service responsiveness, as these factors can significantly impact your ongoing relationship. -

What are the typical minimum order quantities (MOQs) for plastic latches?

Minimum order quantities for plastic latches can vary significantly based on the supplier and the complexity of the product. Generally, MOQs range from as low as 50 units to several thousand, especially for customized latches. It’s important to discuss your specific requirements with potential suppliers to negotiate favorable terms, particularly if you are a smaller business or testing a new product line. Some suppliers may offer flexibility in MOQs for first-time orders or bulk purchases. -

What payment terms should I expect when sourcing plastic latches internationally?

Payment terms for international purchases of plastic latches typically include options such as advance payment, letter of credit, or payment upon delivery. Standard practices may require a deposit upfront, especially for custom orders, with the balance due before shipment. Always clarify payment terms in advance to avoid misunderstandings, and consider using secure payment methods to protect your financial interests. Engaging with suppliers familiar with international trade can also help navigate currency exchange and payment processing issues. -

How can I ensure quality assurance for plastic latches?

To ensure quality assurance for plastic latches, request detailed information about the supplier’s quality control processes. Inquire whether they conduct regular testing for durability, environmental resistance, and compliance with industry standards. Consider asking for certifications or third-party testing results to verify product quality. Establishing a clear quality agreement before placing an order can also help set expectations and provide a framework for addressing any quality issues that may arise. -

What logistics considerations should I keep in mind when sourcing plastic latches?

When sourcing plastic latches, logistics considerations are crucial. Evaluate the shipping options available, including air freight for faster delivery or sea freight for cost savings on larger orders. Consider the supplier’s location and any potential customs regulations that may affect shipping times and costs. Additionally, ensure that the supplier can provide proper packaging to prevent damage during transit. It’s also wise to establish a clear timeline for delivery and plan for any potential delays. -

Are there customization options available for plastic latches?

Many suppliers offer customization options for plastic latches, allowing you to tailor the design, size, and color to meet your specific needs. Customization can enhance functionality and branding, making your products stand out. When discussing customization, provide detailed specifications and consider the implications for lead times and costs. Be sure to confirm the supplier’s capability to produce prototypes before full-scale production to ensure the final product meets your requirements.

Top 7 Latch Plastic Manufacturers & Suppliers List

1. LATCH-EG – White Plastic Latch

Domain: lightingplastics.com

Registered: 1998 (27 years)

Introduction: {“name”:”LATCH-EG White Plastic Latch for Vapor Tight Lens”,”price”:”$1.95″,”description”:”Replacing latches on a vapor proof light fixture improves protection against moisture and other contaminants, increases energy efficiency, reduces the risk of electrical hazards, and can be a cost-effective alternative to replacing the entire fixture.”,”sku”:”LATCH-EG”,”weight”:”2 oz”,”dimensions”:”1 × 3 × 2…

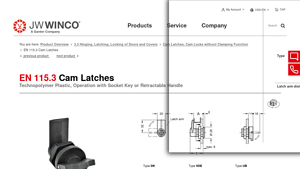

2. JW Winco – Cam Latches EN 115.3

Domain: jwwinco.com

Registered: 1997 (28 years)

Introduction: Cam Latches EN 115.3 by JW Winco

– Type: UB – With retractable handle, DK – With triangular spindle, VDE – With double bit

– Material: Technopolymer (Polyamide PA), Glass fiber reinforced

– Temperature resistance: up to 266 °F (130 °C)

– Color: Black, RAL 7021, matte finish

– Self-extinguishing: Yes

– Screw material: Stainless steel AISI 304

– Protection class: IP 65

– RoHS compliant: Yes

– Operat…

3. Latch Manufacturers – Plastic Latches

Domain: latchmanufacturers.com

Registered: 2015 (10 years)

Introduction: Plastic latches are devices used to fasten two surfaces securely in place, commonly manufactured from thermoplastic materials. They are utilized in industrial, commercial, domestic, and agricultural settings. Plastic latches are often used in applications that do not require high strength or durability, making them suitable for utility boxes, cabinets, and storage compartments. They provide impact…

4. American Plastics – Flat Black Plastic Luggage Handle

Domain: americanplastics.com

Registered: 1996 (29 years)

Introduction: [{‘name’: ‘Flat Black Plastic Luggage Handle 2″ Webbing on Each Side’, ‘sku’: ‘AP929’, ‘price’: ‘$4.19’}, {‘name’: ‘1″ Side Release Grizzly Buckle’, ‘sku’: ”, ‘price’: ‘From $1.63’}, {‘name’: ‘1.5″ Black Side Release Combo Buckle’, ‘sku’: ”, ‘price’: ‘$13.80’}, {‘name’: ‘Plastic Black Cord Lock’, ‘sku’: ‘AP611’, ‘price’: ‘$0.23’}, {‘name’: ‘Plastic 1″ Spa Safe Buckle’, ‘sku’: ‘APSPA-SAFE’, ‘pric…

5. Drotto – Replacement Plastic Plate for Catch–N–Release Latch

Domain: drottoproducts.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Replacement Plastic Plate or Cover for Drotto Catch–N–Release Boat Latch”, “price”: “$24.99 USD”, “colors_available”: [“Black”, “White”, “Blue”, “Gray”], “description”: “This is a replacement plastic plate for the top of the early model Drotto latches. Includes new plastic cover and mounting screws. This plate will only work on newer model Drotto Latches with a rounded base, and …

6. GlobalSpec – Electric Actuation Latches

Domain: globalspec.com

Registered: 1998 (27 years)

Introduction: Features: Electric / Electronic Actuation, Folding Handle (Drop), Inside Release, Key Lock, Mounting Holes / Slots, Padlockable, Recessed Latch Type; Types: Cam Latch, Compression Latch, Deadbolt Latch, Draw Latch / Tension Latch, Hasp Latch, Passenger Restraint Latch, Rotary Latch, Slam Latch; Materials: Iron, Rubber, Stainless Steel, Steel, Zinc; Multi Point System: Multi Point System; Operation…

7. Marine Depot Direct – Stainless Marine Hardware

Domain: marinedepotdirect.com

Registered: 2013 (12 years)

Introduction: This company, Marine Depot Direct – Stainless Marine Hardware, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for latch plastic

In the evolving landscape of latch plastic sourcing, strategic partnerships and informed decision-making are paramount. Buyers must recognize the dual benefits of sourcing high-quality plastic latches: enhancing operational efficiency while reducing long-term costs. By investing in durable and reliable latch solutions, organizations can significantly minimize maintenance and replacement expenses, particularly in demanding environments such as industrial, agricultural, and commercial settings.

The versatility of plastic latches offers opportunities across diverse sectors, from vapor-proof applications in lighting fixtures to secure cabinet solutions in kitchens and hospitals. As international markets grow, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for innovative and cost-effective solutions is on the rise. Strategic sourcing can facilitate access to top manufacturers and suppliers, ensuring that businesses stay competitive and responsive to market needs.

Looking ahead, it is crucial for B2B buyers to leverage these insights and actively engage with suppliers who prioritize quality, sustainability, and innovation. By doing so, organizations not only enhance their product offerings but also contribute to a more resilient supply chain. Start exploring your sourcing options today to secure the best solutions for your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.