A Deep Dive into Kimona Pole Hanger Metal Hook Solution

Introduction: Navigating the Global Market for kimona pole hanger metal hook

In today’s competitive retail landscape, sourcing high-quality kimona pole hanger metal hooks can significantly enhance garment display and organization. As businesses strive to create appealing environments that showcase their products effectively, the challenge of finding durable, functional, and aesthetically pleasing hangers becomes paramount. This guide offers a comprehensive exploration of the kimona pole hanger metal hook, detailing its various types, applications, and the advantages it provides to both residential and commercial users.

Within these pages, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe will find valuable insights on selecting the right hanger for their specific needs. We will cover essential factors such as material quality, design variations, and weight capacity, as well as tips for vetting suppliers and understanding pricing structures. By equipping decision-makers with the knowledge to navigate the global market effectively, this guide empowers businesses to make informed purchasing decisions that enhance their operational efficiency and product presentation.

Whether you are a boutique owner in Vietnam looking to optimize your display space or a fashion retailer in Nigeria aiming to preserve delicate fabrics, the kimona pole hanger metal hook is an indispensable tool for your business. Join us as we unlock the secrets to effective garment storage and display solutions tailored for a diverse global audience.

Understanding kimona pole hanger metal hook Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Metal Hooks | Minimalist design, suitable for various garments | Retail, home use, laundry facilities | Pros: Cost-effective, versatile. Cons: Limited protection for delicate items. |

| Rotating Hooks | Adjustable design for easy garment access | Retail displays, clothing exhibitions | Pros: Enhances accessibility, saves space. Cons: May be more complex to install. |

| Padded Hangers | Soft padding for protection of delicate fabrics | High-end boutiques, specialty clothing stores | Pros: Prevents damage to garments. Cons: Higher cost, may require more maintenance. |

| Heavy-Duty Designs | Reinforced for heavy garments like coats | Industrial, hospitality, uniform storage | Pros: High weight capacity, durable. Cons: Bulkier, may require more space. |

| Decorative Hangers | Aesthetic designs for visual appeal | Fashion shows, retail showcases | Pros: Enhances brand presentation. Cons: Typically higher price point, less functional. |

What Are the Characteristics of Standard Metal Hooks?

Standard metal hooks are designed with a minimalist approach, making them suitable for a variety of garments, from casual wear to formal attire. Their robust construction ensures durability, making them ideal for everyday use in both retail and home environments. B2B buyers should consider the cost-effectiveness of these hooks, as they provide a practical solution without compromising quality. However, they may lack the protective features needed for delicate fabrics, which could be a consideration for businesses specializing in high-end clothing.

How Do Rotating Hooks Enhance Accessibility?

Rotating hooks are engineered to allow easy access to garments, making them particularly beneficial for retail displays and clothing exhibitions. Their adjustable design facilitates a more organized and space-efficient layout, which can enhance customer experience. B2B buyers should evaluate the installation complexity and ensure that their display areas can accommodate these hooks. While they offer significant advantages in accessibility, their installation may require additional time and effort compared to standard models.

Why Choose Padded Hangers for Delicate Fabrics?

Padded hangers come with soft cushioning that protects delicate fabrics from damage, making them an excellent choice for high-end boutiques and specialty clothing stores. Their design helps maintain the shape of garments, reducing the risk of creasing or stretching. B2B buyers focused on quality and customer satisfaction should consider these hangers, despite their higher price point. It’s essential to weigh the benefits of garment preservation against the potential for increased costs and maintenance.

What Makes Heavy-Duty Designs Essential for Specific Industries?

Heavy-duty designs are tailored for garments that require extra support, such as coats and uniforms. Their reinforced structure makes them suitable for industrial and hospitality settings where durability is paramount. B2B buyers should assess the weight capacity and space requirements when selecting these hangers, as they can be bulkier than standard options. Despite their size, their longevity and strength make them a worthwhile investment for businesses handling heavier clothing items.

How Do Decorative Hangers Contribute to Brand Presentation?

Decorative hangers offer an aesthetic appeal that can significantly enhance brand presentation at fashion shows and retail showcases. These hangers come in various styles and finishes that can align with a brand’s identity. B2B buyers should consider the visual impact of these hangers, as they can attract customers and elevate the overall shopping experience. However, it’s important to note that decorative hangers often come at a higher price point, which may not be feasible for all budgets.

Key Industrial Applications of kimona pole hanger metal hook

| Industry/Sector | Specific Application of kimona pole hanger metal hook | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Displaying garments in boutiques and department stores | Enhances visual merchandising and customer engagement | Durability, aesthetic appeal, and ease of access for customers |

| Hospitality | Organizing guest robes and uniforms in hotels and spas | Improves guest experience and garment care | Resistance to humidity and weight capacity for heavy garments |

| Fashion Design | Showcasing collections during fashion shows and exhibitions | Provides professional presentation of designs | Customization options for branding and color preferences |

| Home Organization | Storing and displaying traditional clothing in households | Maximizes space and preserves garment quality | Compatibility with various closet sizes and styles |

| Cultural Exhibits | Hanging traditional garments in museums or cultural events | Enhances cultural representation and preservation | Robust construction for long-term use and ease of setup |

How is the kimona pole hanger metal hook used in the retail industry?

In retail settings, the kimona pole hanger metal hook is utilized for displaying garments in an appealing manner. By providing a sturdy and aesthetically pleasing way to showcase clothing, these hooks enhance visual merchandising strategies. Retailers benefit from increased customer engagement as garments are easily accessible and well-presented. For international B2B buyers, it is crucial to consider the durability and design of the hooks, ensuring they align with the store’s branding and can withstand high traffic environments.

What role does the kimona pole hanger metal hook play in the hospitality sector?

In the hospitality industry, the kimona pole hanger metal hook serves as an efficient solution for organizing guest robes and staff uniforms. Hotels and spas can utilize these hooks to maintain a tidy and professional appearance while ensuring that garments are preserved in excellent condition. For B2B buyers in this sector, sourcing options should focus on rust-resistant materials that can withstand humid environments and the weight capacity to support heavy garments, ensuring longevity and reliability in guest services.

How do fashion designers benefit from using kimona pole hanger metal hooks?

Fashion designers often employ the kimona pole hanger metal hook during fashion shows and exhibitions to showcase their collections. These hooks allow for a professional presentation of garments, ensuring that delicate fabrics maintain their shape and integrity. Buyers in the fashion sector should prioritize customization options that reflect their brand identity, as well as the hook’s ability to securely hold various garment types without risk of damage. This attention to detail can significantly enhance the overall impact of a designer’s showcase.

In what ways can the kimona pole hanger metal hook assist in home organization?

For home organization, the kimona pole hanger metal hook provides an elegant solution for storing traditional clothing, such as kimonos and robes. This product maximizes space in closets and ensures that garments are kept wrinkle-free and in pristine condition. International buyers, particularly those from regions with limited storage solutions, should consider the adaptability of these hooks to various home styles and their capacity to support different garment weights, making them a valuable addition to any household.

How is the kimona pole hanger metal hook utilized in cultural exhibits?

In cultural exhibits, the kimona pole hanger metal hook is essential for displaying traditional garments in a way that honors their heritage. Museums and cultural institutions can use these hooks to enhance the visibility of exhibits while ensuring the preservation of delicate fabrics. Buyers in this sector should focus on sourcing robust hooks that can accommodate the weight of historical garments and provide ease of setup for temporary displays, ensuring that cultural artifacts are showcased effectively and respectfully.

3 Common User Pain Points for ‘kimona pole hanger metal hook’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Hanger for Specific Garments

The Problem: Many B2B buyers, especially in the fashion retail and hospitality sectors, face challenges when selecting the appropriate kimona pole hanger metal hook for different garment types. For instance, a boutique owner may struggle with choosing hangers that can support heavy winter coats while also being suitable for delicate silk garments. The fear of damaging high-value clothing items or mismanaging inventory can lead to hesitation in purchasing, ultimately affecting sales and customer satisfaction.

The Solution: To effectively address this issue, buyers should consider a multi-tiered approach to sourcing hangers. First, assess the weight and fabric types of the garments that will be displayed. Opt for heavy-duty kimona pole hangers for robust items like coats, ensuring they can support 20-30 pounds without bending. For delicate items, padded or specialty hangers are essential to maintain garment shape and prevent damage. When negotiating with suppliers, request samples to evaluate the strength and design before making bulk purchases. Additionally, incorporating a diverse range of hanger types in your inventory allows for greater flexibility and responsiveness to customer needs.

Scenario 2: Managing Space Optimization in Retail and Storage Areas

The Problem: Retailers and storage facilities often encounter space constraints that hinder efficient garment organization. In smaller boutiques or warehouses, the lack of space can lead to cluttered displays and difficulty in locating specific items. This disorganization can frustrate staff and customers alike, impacting sales and the overall shopping experience.

The Solution: To optimize space, consider using kimona pole hanger metal hooks strategically. Implement vertical storage solutions by installing multiple poles at varying heights to maximize vertical space. This technique allows for more hangers in less area and creates an appealing display for customers. Additionally, choose hangers with a compact design that can accommodate multiple garments without taking up excess room. Encourage staff to regularly rotate and refresh displays to prevent overcrowding and keep the space visually appealing. Employing a systematic approach to garment placement based on size and type can also streamline operations, making it easier to locate items quickly.

Scenario 3: Concerns Over Durability in Various Environments

The Problem: B2B buyers operating in humid or outdoor environments often worry about the longevity of their kimona pole hanger metal hooks. For example, retailers in tropical climates may find that standard hangers corrode or weaken over time, leading to increased replacement costs and potential damage to garments. This is a valid concern, especially when dealing with high-quality or delicate fabrics that require careful handling.

The Solution: When sourcing kimona pole hanger metal hooks, prioritize those made from rust-resistant materials, such as stainless steel or aluminum with protective coatings. This choice ensures durability and longevity, even in humid conditions. Additionally, consider investing in hangers designed explicitly for outdoor use if applicable, as these often feature enhanced weather resistance. When negotiating with suppliers, inquire about warranty options and product longevity guarantees. Implementing a routine maintenance check on the hangers can also prolong their lifespan; regularly inspect for signs of wear or corrosion and replace any compromised hangers promptly. By being proactive about durability, businesses can safeguard their investments and maintain a high standard of garment care.

Strategic Material Selection Guide for kimona pole hanger metal hook

What Are the Best Materials for Kimona Pole Hanger Metal Hooks?

Selecting the right material for kimona pole hanger metal hooks is crucial for ensuring durability, functionality, and aesthetic appeal. Below, we analyze four common materials used in the manufacturing of these hooks, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand various temperatures and pressures. It is typically rated for use in environments with humidity and exposure to moisture, making it suitable for diverse climates.

Pros & Cons: The durability of stainless steel ensures a long lifespan, making it a preferred choice for both residential and commercial applications. However, it tends to be more expensive than other materials, which may impact budget constraints for some buyers. Manufacturing complexity can also be higher due to the need for specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of media, including heavy garments like coats and suits, without bending or warping. It also maintains the integrity of delicate fabrics, making it ideal for high-end retail environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or DIN for durability and safety. The demand for rust-resistant products is high in humid climates, making stainless steel an attractive option.

2. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can handle moderate temperatures and is often treated with anodized coatings for enhanced durability.

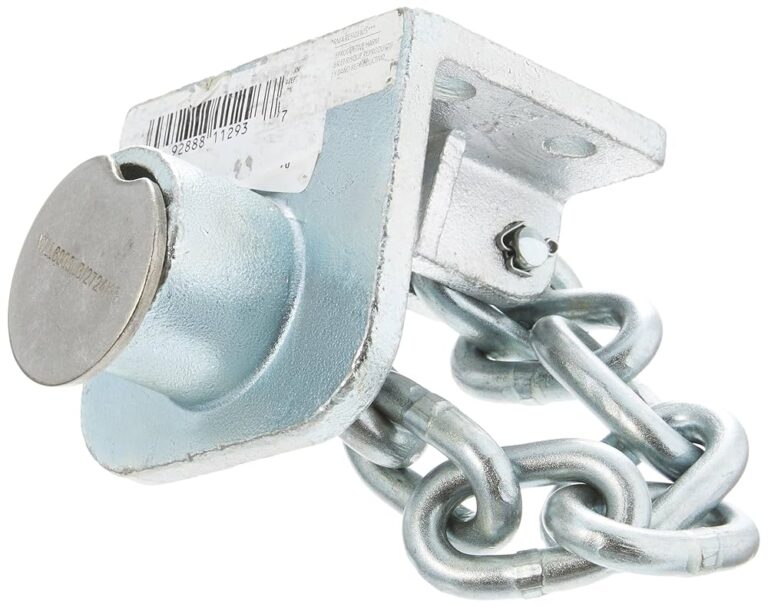

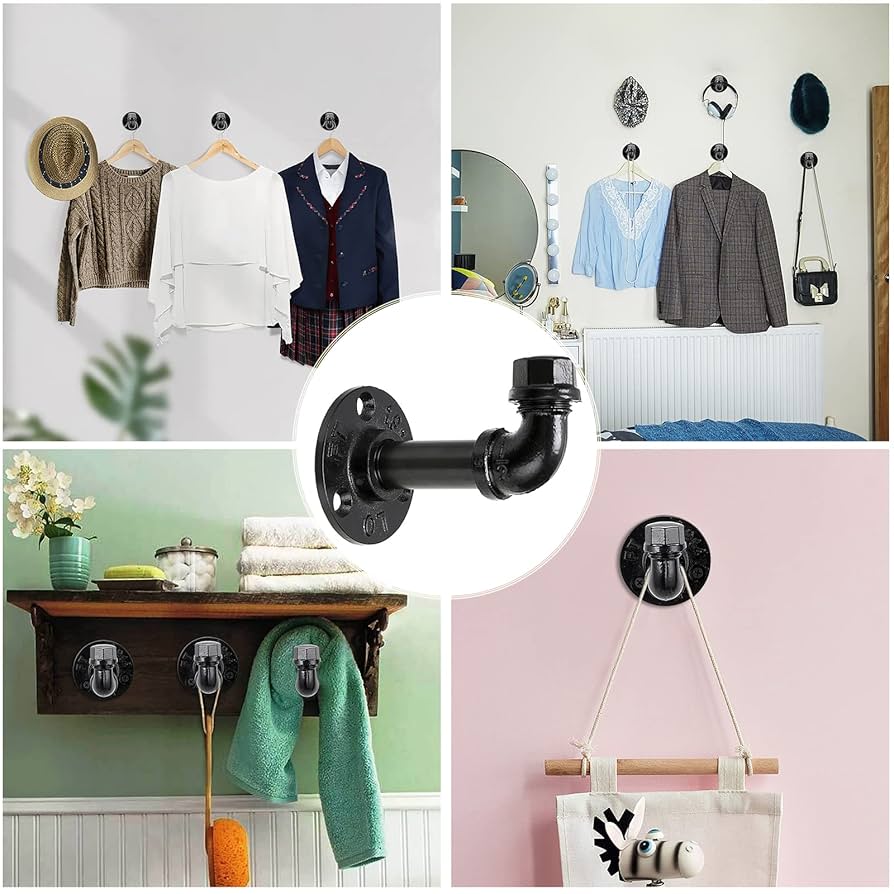

Illustrative image related to kimona pole hanger metal hook

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which makes it easy to handle and install. However, it may not support as much weight as stainless steel, limiting its use for heavier garments. Additionally, while aluminum is generally less expensive, it can be prone to denting and scratching.

Impact on Application: Aluminum hooks are suitable for lighter garments and are often used in home settings or for temporary displays. They are less ideal for heavy-duty applications but work well in environments where weight is a concern.

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer aluminum for its lightweight properties, especially in regions where transport costs are a factor. Compliance with local manufacturing standards is essential to ensure quality and safety.

3. Carbon Steel

Key Properties: Carbon steel offers high strength and durability, making it suitable for heavy-duty applications. However, it is less resistant to corrosion compared to stainless steel and aluminum unless coated.

Illustrative image related to kimona pole hanger metal hook

Pros & Cons: The main advantage of carbon steel is its cost-effectiveness and ability to support heavy garments. However, its susceptibility to rust and corrosion can be a significant drawback, especially in humid or wet environments. Proper coatings can mitigate this issue, but they add to manufacturing complexity.

Impact on Application: Carbon steel hooks are ideal for commercial settings where heavy garments are frequently hung. However, they may require more maintenance to ensure longevity, particularly in challenging climates.

Considerations for International Buyers: Buyers from humid regions should be cautious when selecting carbon steel products and ensure they have appropriate protective coatings. Understanding local compliance standards is crucial to avoid issues with product quality.

Illustrative image related to kimona pole hanger metal hook

4. Plastic Composites

Key Properties: Plastic composites are lightweight, resistant to moisture, and can be molded into various shapes. They are often designed to mimic the look of metal while providing a more affordable option.

Pros & Cons: The affordability and versatility of plastic composites make them attractive for budget-conscious buyers. However, they typically lack the durability and strength of metal options, which can limit their application for heavier garments.

Impact on Application: These hooks are best suited for lightweight clothing and casual settings. They are often used in homes or temporary displays where aesthetics are less critical than functionality.

Considerations for International Buyers: Buyers should be aware of the environmental impact of plastic products and consider compliance with local regulations regarding plastic use. In regions like Africa, where sustainability is increasingly valued, opting for recyclable materials may be beneficial.

Illustrative image related to kimona pole hanger metal hook

Summary Table

| Material | Typical Use Case for kimona pole hanger metal hook | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy garments, high-end retail displays | Excellent durability and rust resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight garments, home settings | Lightweight and easy to handle | Limited weight capacity | Medium |

| Carbon Steel | Heavy-duty commercial applications | Cost-effective and strong | Prone to rust without coatings | Low |

| Plastic Composites | Casual settings, lightweight clothing | Affordable and versatile | Less durable than metal options | Low |

This detailed analysis should assist international B2B buyers in making informed decisions regarding the material selection for kimona pole hanger metal hooks, ensuring they choose the best option for their specific needs and applications.

In-depth Look: Manufacturing Processes and Quality Assurance for kimona pole hanger metal hook

What are the Main Stages of Manufacturing a Kimona Pole Hanger Metal Hook?

Manufacturing a kimona pole hanger metal hook involves several critical stages that ensure the final product meets durability and functionality standards. Understanding these stages can help B2B buyers assess the quality and reliability of potential suppliers.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing kimona pole hanger metal hooks is selecting high-quality raw materials. Common materials include stainless steel, aluminum, and other metals known for their strength and corrosion resistance. These materials are sourced from reputable suppliers to ensure they meet industry standards. Before processing, the materials undergo inspection to check for defects, impurities, and overall quality. This initial quality control (IQC) step is crucial in maintaining the integrity of the final product.

Forming: How Are the Hooks Shaped?

Once the materials are prepared, the next stage is forming. This process typically involves techniques such as stamping, bending, and welding.

-

Stamping: Sheets of metal are cut and shaped into the desired hook form using high-pressure stamping machines. This method allows for high-volume production while maintaining precision.

-

Bending: After stamping, the metal pieces are bent to create the hook shape. This can be done using hydraulic or mechanical bending machines, which ensure consistent angles and shapes.

-

Welding: In some designs, parts may need to be welded together for added strength. Automated welding systems are often employed to ensure uniformity and strength in the joints.

Assembly: How Are the Components Brought Together?

In the assembly stage, various components of the kimona pole hanger metal hook are put together. This can involve attaching the metal hook to a pole or integrating additional features such as rotating mechanisms or padding.

-

Manual Assembly: Skilled workers may be involved in the assembly process to ensure that each product meets quality standards. They check for fit, alignment, and overall craftsmanship.

-

Automated Assembly: For larger production runs, automated assembly lines can be utilized. These lines speed up production and minimize human error, ensuring consistent quality across batches.

Finishing: What Processes Enhance Aesthetic and Functional Qualities?

The final stage of manufacturing is finishing, which enhances both the aesthetic appeal and the functional properties of the kimona pole hanger metal hook.

-

Surface Treatment: Common treatments include powder coating or anodizing, which provide a protective layer against rust and scratches while allowing for various color options.

-

Quality Inspection: After finishing, hooks are inspected for surface defects, coating uniformity, and overall appearance. This inspection serves as a part of the in-process quality control (IPQC) to catch any issues before the product moves to the next phase.

What International Standards and Quality Assurance Practices Are Relevant?

Quality assurance is paramount in the manufacturing of kimona pole hanger metal hooks, especially for international B2B buyers who may have specific compliance requirements.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers typically adhere to several international quality standards to ensure their products are safe and reliable:

-

ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers looking to demonstrate their commitment to quality. Compliance with ISO 9001 indicates that the manufacturer follows consistent processes and continuously improves their operations.

-

CE Marking: For products sold in the European market, CE marking signifies compliance with health, safety, and environmental protection standards. This is particularly relevant for B2B buyers in Europe who must ensure that the products meet these requirements.

-

API Specifications: If the hooks are intended for specialized uses, such as in industrial or heavy-duty settings, compliance with American Petroleum Institute (API) standards may also be necessary.

What Quality Control Checkpoints Are Essential?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure that the kimona pole hanger metal hooks meet specified standards:

-

Incoming Quality Control (IQC): This involves checking raw materials upon arrival at the manufacturing facility to confirm they meet required specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples are taken to verify that each stage adheres to quality standards. This includes checks during material forming, assembly, and finishing.

-

Final Quality Control (FQC): Before products are packaged and shipped, they undergo final inspections. This includes testing for weight capacity, checking for defects, and ensuring that the product matches design specifications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should implement several strategies to verify the quality control processes of potential suppliers, particularly when sourcing from international markets.

What Audit Methods Can Be Employed?

Conducting audits is a critical step in ensuring that suppliers meet quality standards. Buyers can use the following methods:

-

Supplier Audits: Requesting on-site audits can help assess the manufacturing processes, quality control measures, and overall operational efficiency.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing capabilities and quality control practices.

What Documentation Should Be Requested?

When evaluating suppliers, B2B buyers should ask for relevant documentation, including:

-

Quality Assurance Reports: These documents outline the results of various quality checks and tests performed throughout the manufacturing process.

-

Certificates of Compliance: Suppliers should provide documentation that verifies compliance with international standards such as ISO 9001 or CE marking.

-

Testing Reports: Requesting reports from third-party labs that have tested the hooks for durability, weight capacity, and material quality can provide additional assurance.

What Are the Unique Quality Control Considerations for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe may encounter unique challenges and considerations when ensuring quality control in their sourcing efforts.

-

Cultural Differences: Understanding cultural differences in business practices can aid in communication and expectations regarding quality. Building strong relationships with suppliers can lead to better outcomes.

-

Regulatory Compliance: Buyers must be aware of specific regulations in their home countries that may affect the import of metal products, including tariffs, trade restrictions, and safety standards.

-

Logistics and Shipping: Ensuring that quality control measures extend to shipping and logistics is essential. Buyers should verify that products are packaged correctly to prevent damage during transit.

By understanding the manufacturing processes and quality assurance practices involved in producing kimona pole hanger metal hooks, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only enhances procurement strategies but also contributes to building long-term, reliable partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kimona pole hanger metal hook’

Introduction

Sourcing kimona pole hanger metal hooks effectively is essential for businesses looking to enhance their garment storage solutions. This guide provides a structured checklist to help B2B buyers navigate the procurement process, ensuring that they select high-quality products that meet their specific needs. By following these steps, you can streamline your sourcing efforts and make informed purchasing decisions.

Step 1: Identify Your Requirements

Before diving into the sourcing process, clearly define your needs. Consider the types of garments you will hang, the volume of hooks required, and the specific environments (e.g., retail, home, or industrial) where they will be used. This clarity will guide your selection and help in communicating effectively with suppliers.

- Types of garments: Will you need hooks for delicate fabrics or heavier items?

- Quantity: How many units do you need for your operations?

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for companies that specialize in metal garment hangers and have a solid reputation in the industry. A well-established supplier is more likely to provide reliable products and services.

Illustrative image related to kimona pole hanger metal hook

- Online directories: Use platforms like Alibaba, ThomasNet, or local trade directories.

- Industry recommendations: Ask for referrals from industry contacts or trade associations.

Step 3: Evaluate Supplier Certifications

Ensure that your selected suppliers have the necessary certifications that indicate quality and compliance with international standards. This step is vital for maintaining product integrity and ensuring safety, especially when dealing with metal products.

- ISO certifications: Look for suppliers with ISO 9001 for quality management systems.

- Safety standards: Verify compliance with local and international safety regulations.

Step 4: Request Product Samples

Before placing a large order, request samples of the kimona pole hanger metal hooks. Testing samples allows you to assess their durability, design, and suitability for your specific needs. This step can prevent costly mistakes and ensure that the products meet your expectations.

- Material quality: Check for rust resistance and overall sturdiness.

- Design features: Ensure the hooks accommodate the intended garments without causing damage.

Step 5: Compare Pricing and Terms

Once you have gathered samples and evaluated potential suppliers, compare pricing and payment terms. While it may be tempting to choose the cheapest option, consider the overall value, including product quality and supplier reliability.

- Bulk discounts: Inquire about pricing tiers for larger orders.

- Payment flexibility: Assess payment terms that suit your cash flow needs.

Step 6: Negotiate Contract Terms

After selecting a supplier, negotiate the contract terms to ensure they align with your business objectives. This includes delivery schedules, warranty conditions, and after-sales support. A well-structured agreement will protect both parties and establish clear expectations.

- Delivery timelines: Confirm lead times that fit your inventory needs.

- Warranty and returns: Ensure you have a clear understanding of the return policy for defective items.

Step 7: Establish a Communication Plan

Finally, set up a communication plan with your supplier to facilitate ongoing dialogue. Regular communication helps address any issues that may arise during the order process and ensures that you stay informed about product updates or changes.

- Point of contact: Designate a specific contact person for ease of communication.

- Regular check-ins: Schedule periodic updates to discuss order status and future needs.

By following this checklist, B2B buyers can effectively source kimona pole hanger metal hooks that meet their operational needs while ensuring quality and reliability in their supply chain.

Comprehensive Cost and Pricing Analysis for kimona pole hanger metal hook Sourcing

Understanding the cost structure and pricing analysis for kimona pole hanger metal hooks is crucial for B2B buyers looking to source these products efficiently. This guide provides insights into the various cost components, price influencers, and practical tips for negotiating and optimizing purchasing decisions.

What Are the Key Cost Components in Sourcing Kimona Pole Hanger Metal Hooks?

When sourcing kimona pole hanger metal hooks, several cost components contribute to the overall price:

-

Materials: The primary material for these hooks is metal, often stainless steel or aluminum, which ensures durability. The choice of material impacts the cost significantly, with higher-grade metals typically resulting in a higher price.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs can offer competitive pricing, but it’s essential to balance this with the quality of workmanship.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, which may be passed on to buyers.

-

Tooling: Initial tooling costs for molds and machinery can be substantial, particularly for customized designs. Buyers should consider whether they require standard or custom hooks, as this will affect the tooling investment.

-

Quality Control (QC): Ensuring that each batch meets quality standards incurs costs. Buyers should prioritize suppliers with robust QC processes, as this can prevent costly returns or replacements.

-

Logistics: Shipping and handling costs can vary widely based on distance, weight, and chosen shipping methods. International buyers should be aware of import duties and potential delays in transit.

-

Margin: Suppliers typically mark up prices to cover their costs and achieve profit margins. Understanding the average margin in the industry can aid in evaluating supplier pricing.

How Do Price Influencers Impact the Cost of Kimona Pole Hanger Metal Hooks?

Several factors can influence the final price of kimona pole hanger metal hooks:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for bulk orders. Understanding the MOQ can help buyers negotiate better terms and lower per-unit costs.

-

Specifications and Customization: Customized hooks, including specific finishes or branding options, can lead to increased costs. Buyers should assess whether customization is necessary for their market.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as ISO or environmental standards) can affect pricing. Buyers should evaluate the importance of these factors for their end-use.

-

Supplier Reputation and Reliability: Established suppliers may charge a premium for their reliability and quality assurance. Researching supplier histories and customer reviews can provide insights into value versus cost.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can affect the overall cost structure. Understanding these terms helps buyers calculate total expenses, including shipping and insurance.

What Are the Best Tips for Negotiating and Sourcing Kimona Pole Hanger Metal Hooks?

B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost-efficiency:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Building a relationship with suppliers can lead to better deals over time.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs, including maintenance, replacements, and potential shipping fees. A lower upfront cost might not be the best value if quality is compromised.

-

Consider Regional Suppliers: Sourcing from local suppliers can reduce shipping costs and lead times. This is particularly relevant for international buyers facing logistical challenges.

-

Be Informed on Pricing Nuances: Different regions may have varying pricing structures based on local economic conditions and market demand. Understanding these nuances can aid in making more informed purchasing decisions.

-

Request Samples: Before committing to large orders, request samples to evaluate quality and suitability. This can prevent costly mistakes in bulk purchases.

Disclaimer

Prices for kimona pole hanger metal hooks can fluctuate based on market conditions, availability, and supplier negotiations. This analysis provides indicative pricing and cost structures; actual prices may vary. Always conduct thorough market research and supplier evaluations before making purchasing decisions.

Alternatives Analysis: Comparing kimona pole hanger metal hook With Other Solutions

Exploring Alternative Garment Hanging Solutions: A Comparative Analysis

In the realm of garment storage and display, selecting the right solution is crucial for both functionality and aesthetics. While the kimona pole hanger metal hook offers unique advantages, there are alternative solutions available that may better suit specific needs. This analysis compares the kimona pole hanger metal hook with two viable alternatives: traditional wooden hangers and modern adjustable garment racks.

Comparison Table

| Comparison Aspect | Kimona Pole Hanger Metal Hook | Traditional Wooden Hanger | Adjustable Garment Rack |

|---|---|---|---|

| Performance | Excellent for delicate fabrics; prevents wrinkling | Good for light garments; may stretch heavier items | Highly versatile; supports various garment types |

| Cost | Moderate to high investment | Low to moderate cost | Moderate cost; can vary based on size and features |

| Ease of Implementation | Simple to install; requires minimal setup | Ready to use; no installation needed | Requires assembly; may need tools for setup |

| Maintenance | Low maintenance; rust-resistant options available | Prone to wear; needs occasional replacement | Moderate; needs regular cleaning and adjustment |

| Best Use Case | Ideal for retail displays and delicate garments | Suitable for home closets; classic choice | Great for seasonal storage, events, or flexible display options |

Detailed Breakdown of Alternatives

Traditional Wooden Hanger

Traditional wooden hangers are a staple in garment storage, known for their aesthetic appeal and sturdiness. They are often less expensive than metal options and readily available in various designs. However, they may not provide the same level of support for heavier garments, leading to stretching over time. Additionally, wooden hangers can absorb moisture and may not be suitable for humid environments. For buyers looking for a cost-effective and classic solution for light clothing, wooden hangers are a viable option.

Adjustable Garment Rack

Adjustable garment racks are designed for versatility, allowing users to change the height and width as needed. This solution is particularly beneficial for businesses that require flexibility in their display setups, such as during seasonal sales or events. While they can accommodate a wide range of garments, the assembly process may require tools and time, making them less convenient for immediate use. Additionally, they may need regular maintenance to ensure stability. For B2B buyers focused on dynamic display options and seasonal storage, adjustable garment racks provide a flexible solution.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a garment hanging solution, B2B buyers must consider various factors such as performance, cost, ease of implementation, and maintenance. The kimona pole hanger metal hook excels in preserving delicate fabrics and providing a stylish display, making it ideal for retail settings. In contrast, traditional wooden hangers offer a classic and cost-effective option for home use, while adjustable garment racks provide the flexibility required for dynamic business environments. By assessing specific needs and priorities, buyers can make an informed decision that enhances their garment storage and display strategy.

Essential Technical Properties and Trade Terminology for kimona pole hanger metal hook

What Are the Key Technical Properties of Kimona Pole Hanger Metal Hooks?

When considering the purchase of kimona pole hanger metal hooks, understanding their technical properties is crucial for ensuring that they meet the specific needs of your business. Here are several critical specifications to keep in mind:

1. Material Grade

The material grade primarily determines the strength and durability of the kimona pole hanger. Common materials include stainless steel and aluminum. Stainless steel is preferred for its rust resistance and longevity, making it ideal for humid environments. Aluminum, while lighter, may not provide the same level of durability but is suitable for less demanding applications. Selecting the right material grade is vital for minimizing replacement costs and ensuring that the hangers withstand daily use.

2. Weight Capacity

Weight capacity refers to the maximum load that a hanger can support without deforming or breaking. Most kimona pole hanger metal hooks can accommodate between 20 to 30 pounds, depending on their design and construction. Understanding the weight capacity is essential for businesses that handle heavy garments, ensuring that the hangers will safely support their inventory without risk of damage.

3. Tolerance Levels

Tolerance levels indicate the allowable deviation from specified dimensions during manufacturing. For kimona pole hangers, tight tolerances are critical to ensure a precise fit on display poles and to maintain the structural integrity of the hanger. Inaccurate tolerances can lead to issues such as instability or difficulty in hanging garments. Businesses should seek suppliers that can guarantee strict adherence to tolerance levels to ensure quality and consistency.

4. Surface Finish

The surface finish of kimona pole hangers impacts both aesthetics and functionality. Common finishes include powder coating, anodizing, and polishing. A powder-coated finish can provide additional protection against scratches and corrosion, while polished surfaces offer a sleek, modern look. Choosing the right surface finish is important not only for visual appeal but also for the longevity of the product, particularly in high-traffic retail environments.

5. Pole Diameter Compatibility

This specification refers to the diameter of the pole on which the hanger will be mounted. Kimona pole hangers come in various designs that fit different pole sizes, typically ranging from 1 to 2 inches in diameter. It is crucial for businesses to confirm the compatibility of hangers with existing display systems to avoid operational disruptions.

What Are Common Trade Terms Related to Kimona Pole Hanger Metal Hooks?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of kimona pole hangers, businesses often work with OEMs to create custom designs or private-label products. Understanding OEM relationships can provide opportunities for tailored solutions and better pricing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is significant for B2B buyers as it can affect inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases effectively, ensuring they can meet demand without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes for specified goods or services. For businesses interested in kimona pole hanger metal hooks, submitting an RFQ can lead to competitive pricing and better terms. It’s a vital step in the procurement process that allows for informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping arrangements. Understanding Incoterms is crucial for international buyers, as they define who is responsible for shipping costs, insurance, and risk during transit. This knowledge helps mitigate potential disputes and enhances logistical planning.

Illustrative image related to kimona pole hanger metal hook

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing kimona pole hanger metal hooks, ensuring they select the right products for their needs while navigating the complexities of international trade effectively.

Navigating Market Dynamics and Sourcing Trends in the kimona pole hanger metal hook Sector

What Are the Current Market Dynamics and Key Trends for Kimona Pole Hanger Metal Hooks?

The global market for kimona pole hanger metal hooks is witnessing significant growth, driven by increasing consumer demand for durable and aesthetically pleasing garment storage solutions. Key markets in Africa, South America, the Middle East, and Europe are becoming increasingly receptive to innovative products that blend functionality with design. In particular, countries like Nigeria and Vietnam are experiencing a surge in retail and home improvement sectors, creating new opportunities for manufacturers and suppliers of kimona pole hangers.

Emerging B2B tech trends such as e-commerce platforms and digital supply chain management are reshaping sourcing strategies. Buyers are increasingly turning to online marketplaces and specialized suppliers for procurement, allowing for greater flexibility and access to a wider range of products. Furthermore, the integration of data analytics is enabling companies to forecast demand more accurately, ensuring that inventory levels align with market needs.

Additionally, there is a growing trend towards customization, with businesses looking for products that can be tailored to their specific requirements, including branding options and unique designs. This demand for personalization is prompting manufacturers to adopt more agile production processes. As a result, international buyers should focus on suppliers who can offer both standard and customized solutions to meet diverse market needs.

Illustrative image related to kimona pole hanger metal hook

How Is Sustainability and Ethical Sourcing Shaping the Kimona Pole Hanger Metal Hook Market?

Sustainability and ethical sourcing are increasingly becoming focal points for international B2B buyers in the kimona pole hanger metal hook sector. The environmental impact of manufacturing processes has led to a heightened awareness among businesses, prompting them to seek suppliers who prioritize sustainable practices. Many buyers are now looking for products made from recycled materials or those that are certified for their eco-friendliness.

Ethical supply chains are not only important for reducing environmental footprints but also for enhancing brand reputation. Companies that can demonstrate a commitment to sustainability are more likely to attract customers and foster loyalty. Therefore, it is essential for buyers to engage with manufacturers who adhere to recognized sustainability standards and can provide documentation for their sourcing practices.

Moreover, certifications such as ISO 14001 (Environmental Management) and the use of green materials can serve as vital indicators of a supplier’s commitment to sustainability. As the market continues to evolve, the emphasis on ethical sourcing will likely become a key differentiator for businesses looking to gain a competitive edge in the kimona pole hanger metal hook sector.

What Is the Historical Context of Kimona Pole Hanger Metal Hooks Relevant to B2B Buyers?

The kimona pole hanger metal hook has its roots in traditional Japanese garment storage practices, where the preservation of delicate fabrics like kimonos was paramount. Originally crafted from wood, these hangers were designed to support the unique shapes and weights of traditional attire. Over time, advancements in material technology led to the introduction of metal hooks, enhancing durability and functionality.

Today, the evolution of the kimona pole hanger not only reflects changes in consumer preferences but also aligns with modern retail and home organization trends. Understanding this historical context can provide B2B buyers with insights into product quality and the craftsmanship involved in manufacturing. This knowledge can help buyers make informed decisions when sourcing kimona pole hanger metal hooks that meet both functional and aesthetic demands.

Overall, the combination of historical significance, current market dynamics, and a strong focus on sustainability makes the kimona pole hanger metal hook an attractive product for international B2B buyers seeking reliable and stylish storage solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of kimona pole hanger metal hook

-

How do I solve issues with garment slippage on kimona pole hanger metal hooks?

To prevent garments from slipping off kimona pole hanger metal hooks, consider using padded or rubberized hooks that provide better grip. Additionally, ensure the hanger is appropriately sized for the garments being stored, as a proper fit reduces slippage. Regularly inspect the hooks for wear and tear, as damaged hooks may not hold items securely. Implementing these strategies will enhance garment preservation and maintain an organized display. -

What is the best material for kimona pole hanger metal hooks?

The best material for kimona pole hanger metal hooks is typically stainless steel or aluminum due to their strength, durability, and rust resistance. Stainless steel offers excellent longevity, making it suitable for both humid and dry environments, while aluminum is lightweight and resistant to corrosion. When selecting a supplier, ensure they offer high-quality materials that can withstand the weight of heavier garments, ensuring long-term use in both residential and commercial settings. -

How can I ensure the quality of kimona pole hanger metal hooks from suppliers?

To ensure quality, request samples from potential suppliers before placing bulk orders. Look for certifications such as ISO or other quality management standards that indicate adherence to industry benchmarks. Additionally, ask for details about their manufacturing processes and materials used. Customer reviews and testimonials can also provide insights into the supplier’s reliability and product quality, helping you make an informed decision. -

What are the typical minimum order quantities (MOQs) for kimona pole hanger metal hooks?

Minimum order quantities for kimona pole hanger metal hooks can vary significantly based on the supplier and the specific product line. Generally, MOQs can range from 100 to 1,000 units. It’s advisable to discuss MOQs with potential suppliers to find a balance between your inventory needs and their production capabilities. Some suppliers may offer flexibility for first-time buyers or bulk orders, so it’s worth negotiating terms that suit your business model. -

What customization options are available for kimona pole hanger metal hooks?

Customization options often include variations in color, finish, and branding. Many suppliers offer a range of colors to match specific brand aesthetics or retail environments. You can also request custom designs or sizes to accommodate different garment types. When discussing customization, inquire about the associated costs, lead times, and minimum quantities required to ensure your order meets your specific branding needs. -

What payment terms should I expect when sourcing kimona pole hanger metal hooks internationally?

Payment terms for international orders typically vary by supplier and may include options such as upfront payments, partial payments, or letters of credit. Common practices involve a 30% deposit upon order confirmation and the remaining balance before shipment. Always clarify payment methods accepted, such as wire transfers or online payment platforms, and ensure you understand any currency exchange implications that may affect overall costs. -

How can I manage logistics effectively when importing kimona pole hanger metal hooks?

To manage logistics effectively, work with a reliable freight forwarder who understands international shipping regulations. Ensure you have a clear shipping plan that includes customs clearance and delivery timelines. Familiarize yourself with import duties and taxes that may apply to your order, and consider using Incoterms to specify responsibilities between you and the supplier regarding transportation and risk. Regular communication with your supplier can also streamline the process. -

What are the best practices for inspecting kimona pole hanger metal hooks upon arrival?

Upon arrival, conduct a thorough inspection of the kimona pole hanger metal hooks for any signs of damage or defects. Check for adherence to specifications such as size, material, and finish. It’s advisable to compare the received items against your order invoice and any provided samples. Document any discrepancies with photos and notes for potential claims. Establishing a clear inspection process helps maintain quality control and ensures customer satisfaction.

A Look at Kimona Pole Hanger Metal Hook Manufacturers & Suppliers

Could not verify enough suppliers for kimona pole hanger metal hook to create a list at this time.

Strategic Sourcing Conclusion and Outlook for kimona pole hanger metal hook

In the competitive landscape of garment storage solutions, the kimona pole hanger metal hook stands out as a superior choice for both residential and commercial applications. Its robust metal construction and innovative pole design not only provide enhanced durability but also ensure that delicate fabrics are preserved and displayed beautifully. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, strategic sourcing of these hangers can significantly enhance product offerings and customer satisfaction.

By focusing on quality, versatility, and aesthetics, businesses can differentiate themselves in a crowded market. Buyers should consider partnering with reliable suppliers who offer customization options and bulk purchasing discounts, ensuring they meet the specific needs of their clientele while optimizing costs.

Illustrative image related to kimona pole hanger metal hook

Looking ahead, as the demand for stylish and functional garment storage solutions continues to grow, investing in high-quality kimona pole hanger metal hooks will position businesses favorably in their respective markets. Now is the time to explore sourcing opportunities that will elevate your product line and drive sales. Engage with trusted manufacturers and distributors to secure the best options available, and ensure your business remains at the forefront of this evolving industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.