A Deep Dive into Kenworth Build And Price Solution

Introduction: Navigating the Global Market for kenworth build and price

In today’s competitive landscape, sourcing the right trucks for your operations can be a daunting challenge. For international B2B buyers seeking to navigate the complexities of the Kenworth build and price process, understanding how to customize trucks to meet specific operational needs is crucial. This guide offers a comprehensive exploration of Kenworth’s diverse range of vehicles, detailing various models—including heavy-duty and medium-duty trucks—and their applications across different industries.

We delve into the intricacies of truck specifications, providing insights on engine types, transmission options, and other critical components that influence performance and cost. Additionally, we address the importance of vetting suppliers to ensure reliability and support in the purchasing process. By equipping buyers with knowledge about pricing structures, financing options, and potential return on investment, this guide empowers decision-makers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia—to make informed purchasing decisions.

Whether you are looking to enhance your fleet’s efficiency or meet stringent regulatory standards, understanding how to build and price a Kenworth truck tailored to your unique needs is essential for driving business success in a global market.

Understanding kenworth build and price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

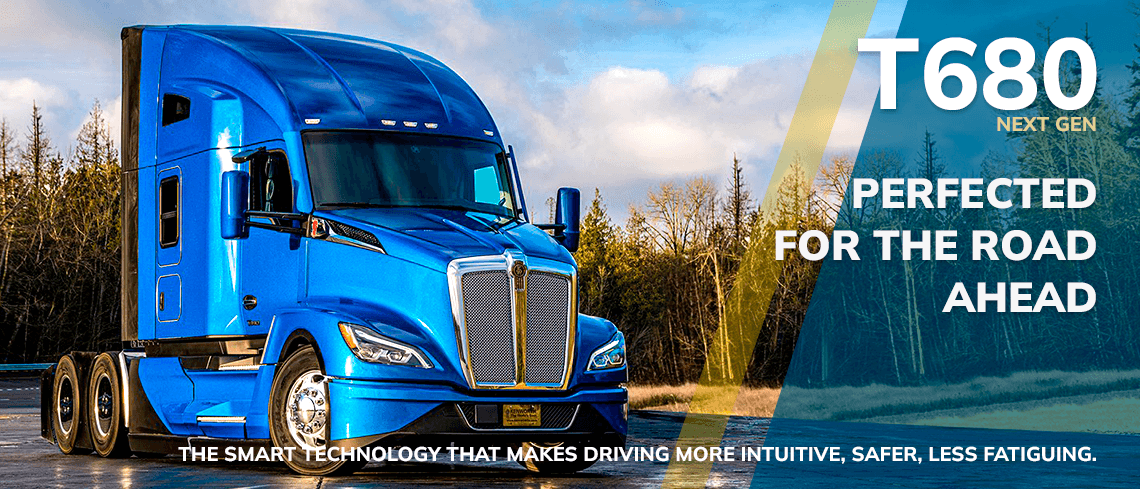

| T680 | Aerodynamic design, customizable interior, advanced fuel efficiency | Long-haul transport, freight | Pros: Excellent fuel economy, driver comfort. Cons: Higher initial investment. |

| T880 | Robust chassis, versatile configurations, high payload capacity | Construction, heavy hauling | Pros: Durable for tough jobs, customizable. Cons: May require more maintenance. |

| W900 | Classic design, customizable features, strong engine options | Long-distance hauling, specialty | Pros: Iconic styling, powerful performance. Cons: Less fuel-efficient than newer models. |

| K270/K370 | Compact size, medium-duty applications, flexible configurations | Urban delivery, regional transport | Pros: Maneuverable in tight spaces, good for city driving. Cons: Limited payload compared to heavy-duty trucks. |

| C500 | Heavy-duty construction, high towing capacity, rugged design | Heavy-haul, off-road applications | Pros: Built for extreme conditions, customizable for various tasks. Cons: Higher operational costs. |

What are the Characteristics of the Kenworth T680?

The Kenworth T680 is known for its aerodynamic design, which enhances fuel efficiency and reduces operational costs. It features a customizable interior, allowing B2B buyers to tailor the truck to their drivers’ needs. This model is ideal for long-haul transport and freight applications, where comfort and efficiency are paramount. When considering the T680, businesses should weigh its higher initial investment against the long-term fuel savings and driver satisfaction it can provide.

Illustrative image related to kenworth build and price

How Does the Kenworth T880 Stand Out in Heavy-Duty Applications?

The Kenworth T880 is engineered for durability and versatility, making it suitable for construction and heavy hauling. With a robust chassis and the ability to accommodate various configurations, it can handle demanding tasks. Its high payload capacity is a significant advantage for businesses that require reliable performance in tough environments. However, potential buyers should consider the maintenance needs, as the truck may require more upkeep compared to lighter models.

Why Choose the Kenworth W900 for Specialty Hauling?

The W900 offers a classic design with powerful engine options, catering to long-distance hauling and specialty applications. Its customizable features allow businesses to adapt the truck to specific requirements, enhancing its utility. While the W900 is favored for its iconic styling and performance, buyers should be aware that it may not be as fuel-efficient as newer models, which could impact overall operating costs.

What Advantages Do the Kenworth K270/K370 Provide for Urban Logistics?

The Kenworth K270 and K370 are compact trucks designed for medium-duty applications, making them ideal for urban delivery and regional transport. Their smaller size allows for greater maneuverability in tight city spaces, which is a crucial consideration for businesses operating in congested areas. However, while they are excellent for city driving, their payload capacity is limited compared to heavy-duty alternatives, which could affect logistics strategies.

Illustrative image related to kenworth build and price

In What Scenarios is the Kenworth C500 the Best Choice?

The Kenworth C500 is built for heavy-duty construction and off-road applications, featuring a rugged design and high towing capacity. This model excels in extreme conditions, making it a preferred choice for businesses involved in heavy-haul operations. While its capabilities are impressive, buyers should consider the higher operational costs associated with this model, including fuel and maintenance, to ensure it aligns with their business objectives.

Key Industrial Applications of kenworth build and price

| Industry/Sector | Specific Application of kenworth build and price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Custom heavy-duty trucks for site operations | Enhanced durability and efficiency in rugged environments | Engine specifications, payload capacity, and customization options |

| Logistics and Freight | Long-haul trucks for regional transportation | Improved fuel efficiency and driver comfort | Aerodynamic design, fuel tank capacity, and maintenance support |

| Mining | Specialized trucks for material transportation | Increased productivity and reduced downtime | Heavy-duty specifications, off-road capabilities, and safety features |

| Agriculture | Versatile trucks for transporting goods | Adaptability to various terrains and load types | Engine power, suspension systems, and agricultural attachments |

| Waste Management | Custom refuse trucks for waste collection | Enhanced operational efficiency and reduced emissions | Body design, waste handling capabilities, and compliance with local regulations |

How is ‘Kenworth Build and Price’ Used in the Construction Industry?

In the construction sector, the ‘Kenworth build and price’ tool is crucial for businesses needing heavy-duty trucks tailored for site operations. Buyers can specify features such as reinforced chassis, robust suspension systems, and high payload capacities to navigate challenging terrains. This customization ensures that the trucks can withstand the demanding conditions typical of construction sites, enhancing operational efficiency and reducing maintenance costs. International buyers from regions like Africa and South America, where infrastructure varies, particularly benefit from this adaptability.

What are the Benefits of Kenworth Trucks in Logistics and Freight?

For logistics and freight companies, the ‘Kenworth build and price’ configurator allows for the selection of long-haul trucks optimized for fuel efficiency and driver comfort. Buyers can choose aerodynamic designs and engine options that significantly reduce fuel consumption, which is a critical cost factor in transportation. Additionally, features such as advanced telematics and maintenance support enhance vehicle longevity and performance. This is particularly important for B2B buyers in Europe and the Middle East, where regulations on emissions and fuel efficiency are stringent.

How Does Kenworth Cater to the Mining Sector?

In the mining industry, the ‘Kenworth build and price’ feature enables the creation of specialized trucks designed for material transportation. Buyers can specify heavy-duty components that enhance durability and off-road performance, ensuring reliability in harsh environments. This customization is vital for maximizing productivity and minimizing downtime, which directly impacts profitability. Companies in regions with significant mining operations, like South America, require trucks that can handle specific load types and terrains, making this configurator an invaluable tool.

Illustrative image related to kenworth build and price

Why is ‘Build and Price’ Important for Agricultural Applications?

Agricultural businesses benefit from the versatility offered by the ‘Kenworth build and price’ tool, allowing them to configure trucks for various transport tasks, such as delivering produce or transporting equipment. Buyers can select engine power and suspension systems that suit different terrains, ensuring adaptability and efficiency. This is particularly beneficial for international buyers in Africa, where agricultural operations may face diverse environmental challenges, requiring reliable and customizable transport solutions.

How is Waste Management Enhanced Through Custom Kenworth Trucks?

The waste management sector utilizes the ‘Kenworth build and price’ configurator to create custom refuse trucks tailored for efficient waste collection. Buyers can specify body designs and waste handling capabilities that align with local regulations and operational requirements. The ability to integrate features that reduce emissions is particularly valuable in urban areas, where compliance with environmental standards is essential. This level of customization ensures that waste management companies can operate efficiently and sustainably, making it a vital consideration for B2B buyers in Europe and the Middle East.

3 Common User Pain Points for ‘kenworth build and price’ & Their Solutions

Scenario 1: Difficulty in Customizing Trucks for Specific Needs

The Problem: Many B2B buyers find it challenging to navigate the extensive customization options available when using the ‘Kenworth Build and Price’ tool. With a myriad of choices for engines, transmissions, and other specifications, it can be overwhelming to determine the best configuration for their unique operational needs. Buyers, especially those in industries such as construction or long-haul trucking, may fear making costly mistakes that could affect performance and profitability.

The Solution: To effectively utilize the ‘Kenworth Build and Price’ tool, buyers should first conduct a thorough analysis of their operational requirements. This includes understanding the types of loads they will carry, the terrains they will navigate, and their fuel efficiency goals. Engaging with Kenworth’s knowledgeable sales representatives can provide valuable insights into which specifications will yield optimal performance for specific applications. Additionally, buyers can leverage the truck configurator feature to visualize different options in real-time, ensuring that they can adjust specifications as needed before finalizing their orders. By collaborating closely with dealers and utilizing the configurator effectively, buyers can confidently create a truck tailored precisely to their business needs.

Scenario 2: Concerns Over Long Lead Times for Custom Builds

The Problem: One of the most significant pain points for international B2B buyers is the concern about long lead times associated with custom truck builds. In regions like Africa and South America, where transportation infrastructure can be unreliable, delays in receiving essential vehicles can severely disrupt business operations. Buyers often worry about how long they will have to wait for their trucks to be delivered, especially when they have pressing projects that require immediate logistical support.

The Solution: To mitigate concerns regarding lead times, buyers should engage in proactive communication with Kenworth dealers regarding the estimated timelines for their specific configurations. It’s advisable to request a detailed production schedule and inquire about any potential bottlenecks that could cause delays. Buyers should also consider placing orders well in advance of peak seasons or project demands, allowing for ample time to address any unexpected issues. Furthermore, exploring the availability of pre-configured models that meet general specifications can provide quicker alternatives without compromising on quality or performance. Establishing a reliable relationship with a local dealer can also facilitate faster responses and enhance the overall purchasing experience.

Scenario 3: Navigating Import Regulations and Compliance Issues

The Problem: For B2B buyers in regions with strict import regulations, such as the Middle East and parts of Europe, understanding compliance requirements can be daunting. Buyers may face challenges related to emissions standards, vehicle specifications, and documentation needed for customs clearance. This can lead to delays in truck delivery, unexpected costs, and even the risk of non-compliance penalties, which can be particularly frustrating for businesses aiming to maintain operational efficiency.

Illustrative image related to kenworth build and price

The Solution: To navigate these complexities, it is crucial for buyers to conduct thorough research on local import regulations specific to their region. Engaging with legal or compliance experts who specialize in vehicle imports can provide essential guidance on meeting necessary requirements. Buyers should also utilize the resources available through Kenworth’s dealer network, which often has experience dealing with local regulations and can assist with preparing the required documentation. Additionally, buyers should consider working with logistics companies that have expertise in international transportation, ensuring that all compliance measures are met before the truck arrives. By proactively addressing these regulatory challenges, buyers can streamline the import process and avoid costly delays.

Strategic Material Selection Guide for kenworth build and price

What Are the Key Materials for Kenworth Truck Manufacturing?

When selecting materials for Kenworth trucks, it’s crucial to consider their properties, advantages, and limitations, particularly from an international B2B perspective. Here are four common materials used in the construction of Kenworth trucks, along with insights that cater to buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

How Does Steel Perform in Kenworth Truck Applications?

Steel is a primary material used in truck frames and chassis due to its high strength and durability. It typically exhibits excellent temperature and pressure ratings, making it suitable for heavy-duty applications. Steel’s corrosion resistance can be enhanced through galvanization or coatings, which is vital in regions with high humidity or saline environments.

Pros: Steel offers superior strength, making it ideal for heavy loads. It is also cost-effective and widely available, which simplifies procurement for international buyers.

Illustrative image related to kenworth build and price

Cons: The weight of steel can be a disadvantage in fuel efficiency, and its susceptibility to corrosion without protective coatings can lead to increased maintenance costs.

Impact on Application: Steel is compatible with various media, including hydraulic fluids and fuels, making it a versatile choice for truck components.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN for structural integrity. In regions like Nigeria or Saudi Arabia, where environmental conditions may vary, selecting the right steel grade is essential.

What Role Does Aluminum Play in Truck Manufacturing?

Aluminum is increasingly used in truck manufacturing due to its lightweight nature and resistance to corrosion. It is particularly beneficial in applications where weight reduction is critical for enhancing fuel efficiency.

Pros: Aluminum’s lightweight properties lead to better fuel economy and payload capacity. It also offers excellent corrosion resistance, reducing maintenance needs.

Cons: The cost of aluminum is generally higher than that of steel, and its manufacturing processes can be more complex, requiring specialized techniques.

Impact on Application: Aluminum is suitable for components exposed to corrosive environments, such as fuel tanks and body panels, enhancing longevity.

Illustrative image related to kenworth build and price

Considerations for International Buyers: Buyers must be aware of the specific grades of aluminum that meet international standards. In markets like Europe, compliance with EU regulations on material sourcing and recycling is crucial.

Why Is Composite Material Gaining Popularity in Truck Design?

Composite materials, including fiberglass and carbon fiber, are becoming popular in truck design for their high strength-to-weight ratio and resistance to environmental factors.

Pros: Composites can significantly reduce vehicle weight, improving fuel efficiency. They also offer excellent resistance to corrosion and environmental degradation.

Illustrative image related to kenworth build and price

Cons: The initial manufacturing cost of composite materials can be high, and they may not be suitable for all truck applications due to their brittleness.

Impact on Application: Composites are ideal for non-structural components, such as body panels, where weight savings are paramount.

Considerations for International Buyers: Buyers should consider local manufacturing capabilities for composites, as not all regions may have the technology or expertise to work with these materials effectively.

Illustrative image related to kenworth build and price

What About Rubber and Polymer Materials?

Rubber and polymers are essential for various truck components, including tires, seals, and hoses. They provide flexibility and resistance to wear and tear.

Pros: These materials are cost-effective and can be engineered to meet specific performance criteria, such as temperature and chemical resistance.

Cons: Rubber and polymers can degrade over time due to UV exposure and extreme temperatures, necessitating regular replacements.

Impact on Application: Suitable for components that require flexibility and resilience, rubber is critical in ensuring the longevity of moving parts.

Illustrative image related to kenworth build and price

Considerations for International Buyers: Buyers must ensure that rubber products meet local safety and performance standards, particularly in regions with extreme weather conditions.

Summary of Material Selection for Kenworth Trucks

| Material | Typical Use Case for kenworth build and price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Truck frames and chassis | High strength and cost-effective | Heavier, susceptible to corrosion | Medium |

| Aluminum | Body panels and fuel tanks | Lightweight, corrosion-resistant | Higher cost, complex manufacturing | High |

| Composite | Non-structural components | Reduced weight, excellent resistance | High initial cost, brittleness | High |

| Rubber/Polymer | Tires, seals, and hoses | Cost-effective, flexible | Degradation over time | Low |

This strategic material selection guide provides an overview of critical materials used in Kenworth truck manufacturing, offering valuable insights for international B2B buyers looking to make informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for kenworth build and price

What Are the Main Stages in the Manufacturing Process of Kenworth Trucks?

The manufacturing process for Kenworth trucks is a multi-stage operation that emphasizes precision, quality, and customization. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to kenworth build and price

-

Material Preparation: The first step involves sourcing high-quality materials that meet strict industry standards. Steel, aluminum, and composites are typically used, chosen for their durability and performance characteristics. These materials undergo rigorous quality checks to ensure they comply with international standards such as ISO 9001, which governs quality management systems.

-

Forming: This stage involves shaping the raw materials into specific components using advanced techniques like stamping, machining, and welding. CNC (Computer Numerical Control) machines are commonly employed for precision cutting and shaping, ensuring that parts fit together perfectly during assembly. The forming process also includes the fabrication of critical components such as frames, axles, and body panels.

-

Assembly: Once the components are prepared, they move to the assembly line, where skilled workers and robotic systems work in tandem. Each truck is assembled according to customer specifications, allowing for a high degree of customization. The assembly process includes installing engines, transmissions, and electrical systems, with checkpoints to verify that each component meets quality standards.

-

Finishing: The final stage focuses on aesthetics and protective coatings. This includes painting, polishing, and applying decals. Kenworth employs advanced finishing techniques that not only enhance the truck’s appearance but also improve durability against harsh weather conditions, especially important for international buyers operating in diverse climates.

How Does Quality Assurance Ensure High Standards in Kenworth Trucks?

Quality assurance is integral to Kenworth’s manufacturing process, ensuring that every truck meets rigorous safety and performance standards. The company adheres to both international and industry-specific quality standards, such as ISO 9001 and CE marking.

-

International Standards: ISO 9001 provides a framework for consistent quality management, ensuring that processes are continuously improved and that customer satisfaction is prioritized. Compliance with these standards is crucial for B2B buyers, as it assures them of the reliability and performance of their investment.

-

Industry-Specific Standards: In addition to ISO certifications, Kenworth also aligns with other relevant standards such as API (American Petroleum Institute) for trucks used in oil and gas industries. These certifications indicate that products meet specific safety and performance criteria applicable to the industry.

What Are the Key Quality Control Checkpoints in Kenworth’s Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure the final product meets quality standards. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. Materials are tested for compliance with specifications and standards, ensuring that only the best components are used in the manufacturing process.

-

In-Process Quality Control (IPQC): During assembly, multiple inspections occur to ensure that each component is correctly installed and functioning as intended. This includes testing electrical systems, engine performance, and structural integrity at various stages of assembly.

-

Final Quality Control (FQC): Before a truck is delivered to a customer, it undergoes a comprehensive final inspection. This includes a road test to evaluate performance, safety checks, and visual inspections for cosmetic issues. Only after passing these tests is the truck deemed ready for delivery.

What Testing Methods Are Commonly Used to Ensure Quality in Kenworth Trucks?

Kenworth employs a variety of testing methods to validate the quality and performance of its trucks. Common testing methods include:

Illustrative image related to kenworth build and price

-

Dynamic Testing: Trucks are subjected to dynamic tests that simulate real-world conditions. This includes evaluating handling, braking, and engine performance under various loads and terrains.

-

Static Testing: Components are also tested in static conditions, such as pressure tests for fuel systems and strength tests for structural components. This ensures that each part meets the necessary safety and performance standards.

-

Environmental Testing: Given the diverse climates in which Kenworth trucks operate, environmental testing is critical. Trucks are tested for corrosion resistance, heat tolerance, and other factors that may affect performance in extreme conditions.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to ensure reliable partnerships. Here are actionable steps buyers can take:

-

Conduct Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s quality control processes. Buyers should consider scheduling these audits to assess compliance with international standards.

-

Request Documentation: Suppliers should provide detailed documentation of their quality management systems, including ISO certifications, quality control reports, and records of past inspections and tests.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspectors can offer an unbiased evaluation of the supplier’s manufacturing and quality control processes. This is particularly valuable for buyers who may not have the expertise to assess these factors internally.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate specific nuances when it comes to quality control in the manufacturing of Kenworth trucks. These include:

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers should ensure that the trucks meet local standards, which may differ from those in the supplier’s country.

-

Cultural Considerations: Understanding cultural differences in business practices can aid in establishing effective communication and expectations regarding quality.

-

Logistics and Supply Chain: The global supply chain can introduce complexities in quality control. Buyers should consider how transportation and handling may affect the integrity of the product and incorporate additional checks if necessary.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions and ensure they are investing in high-quality, reliable Kenworth trucks tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kenworth build and price’

The following practical sourcing guide outlines the essential steps for international B2B buyers interested in procuring Kenworth trucks through the ‘build and price’ process. This checklist will help ensure that you make informed decisions, leading to optimal investment in your fleet.

Illustrative image related to kenworth build and price

Step 1: Define Your Technical Specifications

Understanding your operational requirements is crucial. Begin by identifying the specific application for which the truck will be used—be it heavy-duty transport, construction, or regional hauling.

– Consider factors such as engine type, transmission, and axle configurations.

– Clearly outline your requirements to facilitate accurate quotes from suppliers.

Step 2: Research Kenworth Models

Familiarize yourself with the various Kenworth models available. Each model, such as the T680, W990, or T880, is designed for specific applications and comes with distinct features.

– Review model specifications, performance metrics, and user reviews to gauge suitability for your needs.

– Leverage online resources, including the Kenworth website and truck configurators, to visualize options and configurations.

Step 3: Utilize the Truck Configurator

Take advantage of Kenworth’s online truck configurator tool to customize your truck. This interactive feature allows you to select various options, including cab style, engine, and additional features.

– Experiment with different configurations to find the optimal setup that meets your operational needs.

– Save and print your configurations to discuss them with your dealer, ensuring that all your preferences are documented.

Step 4: Evaluate Potential Suppliers

Before finalizing your order, conduct thorough evaluations of potential suppliers. Look for established dealers with a proven track record in your region.

– Request company profiles, case studies, and references from other businesses in your industry.

– Ensure the dealer is part of Kenworth’s PremierCare Gold Certified network for quality after-sales support.

Step 5: Verify Supplier Certifications

Confirm that the suppliers you are considering have the necessary certifications and licenses. This is vital for ensuring compliance with local regulations and industry standards.

– Check for certifications such as ISO or any local governmental approvals that might apply to heavy-duty vehicles.

– A certified dealer typically indicates a commitment to quality and customer satisfaction.

Step 6: Discuss Financing and Warranty Options

Engage in discussions regarding financing and warranty options with your dealer. Understanding these aspects can significantly affect your total cost of ownership.

– Inquire about leasing versus purchasing, as well as any financing plans that might be available.

– Evaluate warranty coverage details to ensure you have support for maintenance and repairs post-purchase.

Step 7: Finalize Your Order and Schedule Delivery

Once you have evaluated your options and are satisfied with your choice, finalize your order with the supplier.

– Confirm all specifications, pricing, and delivery timelines before signing contracts.

– Consider scheduling a delivery date that aligns with your operational needs to avoid disruptions in your fleet’s functionality.

Illustrative image related to kenworth build and price

By following this step-by-step guide, you can navigate the Kenworth build and price process effectively, ensuring that you procure the right vehicles tailored to your specific business requirements.

Comprehensive Cost and Pricing Analysis for kenworth build and price Sourcing

What Are the Key Cost Components in Kenworth Build and Price Sourcing?

When sourcing Kenworth trucks through the build and price model, understanding the cost structure is crucial. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly affects the overall cost. High-quality steel, aluminum, and advanced composites, which enhance durability and reduce weight, may increase initial expenses but lead to long-term savings through fuel efficiency and lower maintenance costs.

-

Labor: Skilled labor is essential for assembling Kenworth trucks. Labor costs can fluctuate based on geographic location and local wage standards. Understanding labor market conditions in your sourcing region can help in forecasting costs.

-

Manufacturing Overhead: This encompasses expenses related to running the manufacturing facility, including utilities, equipment depreciation, and administrative costs. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Custom tooling for specific configurations or modifications can add to the initial costs. However, investing in specialized tooling can improve production efficiency and quality, ultimately benefiting the buyer.

-

Quality Control: Rigorous QC processes ensure that each truck meets Kenworth’s high standards, which can increase costs but also reduce the risk of defects and enhance reliability.

-

Logistics: Transportation costs from the manufacturing facility to the buyer’s location can vary significantly. Factors such as distance, mode of transport, and regional tariffs should be considered in the total cost analysis.

-

Margin: The profit margin for manufacturers and dealers typically reflects the complexity of the build and the market demand. Understanding these margins can help buyers negotiate better pricing.

How Do Price Influencers Impact Kenworth Build and Price Sourcing?

Several factors can influence the pricing of Kenworth trucks, including volume or minimum order quantities (MOQ), specifications and customization options, material choices, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Larger orders often lead to discounted pricing due to economies of scale. Buyers should assess their purchasing strategy to leverage volume discounts.

-

Specifications and Customization: Custom-built trucks tailored to specific operational needs can incur additional costs. The more unique the specifications, the higher the potential price. Buyers should carefully evaluate the necessity of custom features against their budget.

-

Materials: The choice of materials directly impacts both cost and quality. Premium materials may command higher prices but can offer better performance and longevity, leading to lower total ownership costs.

-

Quality/Certifications: Trucks that meet specific industry standards or certifications may be priced higher due to the assurance of quality and reliability. Buyers should consider the long-term benefits of investing in certified vehicles.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer better warranties and support, justifying a higher price point.

-

Incoterms: Understanding the agreed Incoterms is essential, as they dictate who bears the cost and risk at each stage of the shipping process. This can significantly affect the overall cost of procurement.

What Are the Best Buyer Tips for Negotiating Kenworth Pricing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, employing strategic negotiation tactics can yield favorable outcomes.

Illustrative image related to kenworth build and price

-

Negotiate Wisely: Engage in discussions with multiple dealers to compare offers and establish a baseline for negotiations. Leverage information about your competitors’ pricing strategies to strengthen your position.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the upfront price. Consider fuel efficiency, maintenance costs, and resale value when evaluating the overall investment.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, taxes, and tariffs. Familiarize yourself with these nuances to make informed decisions.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better terms and conditions over time. Consider loyalty and volume as leverage for future negotiations.

-

Stay Informed on Market Trends: Keep abreast of industry trends, technological advancements, and regulatory changes that may affect pricing. This knowledge can provide a competitive edge in negotiations.

Disclaimer

The pricing analysis provided here is indicative and subject to change based on market conditions, supplier policies, and specific buyer requirements. Always consult with a Kenworth dealer or authorized distributor for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing kenworth build and price With Other Solutions

Exploring Alternative Solutions to Kenworth Build and Price

When considering the purchase of commercial trucks, particularly in international markets, buyers often seek alternatives to the established Kenworth build and price solution. Understanding these alternatives can help businesses make informed decisions that align with their operational needs, budget constraints, and specific application requirements.

| Comparison Aspect | Kenworth Build And Price | Alternative 1: Freightliner Custom Build | Alternative 2: Volvo Trucks Configurator |

|---|---|---|---|

| Performance | High fuel efficiency, customizable specifications for various applications | Strong focus on fuel economy and driver comfort, especially in long-haul | Excellent performance in safety and ergonomics, optimized for urban and regional transport |

| Cost | Competitive pricing with a focus on long-term ROI | Generally lower upfront costs but may have higher maintenance costs | Higher initial investment but potentially lower total cost of ownership due to fuel savings |

| Ease of Implementation | User-friendly online configurator; accessible dealer network for support | Simple online configurator; however, dealer availability can vary by region | User-friendly interface with extensive customization options, but dealer support may not be as widespread |

| Maintenance | Strong after-sales support through PremierCare network | Good support, but parts may be less accessible in some regions | Excellent maintenance programs, though parts can be pricier |

| Best Use Case | Versatile for heavy-duty applications, ideal for customized needs | Best for fleets requiring rapid deployment with standard specifications | Excellent for companies prioritizing safety and technology in urban settings |

Detailed Breakdown of Alternatives

Freightliner Custom Build

Freightliner offers a robust custom build option that appeals to businesses looking for a balance between performance and cost. With a focus on long-haul trucking, Freightliner trucks are designed for optimal fuel efficiency, which can translate into significant savings over time. However, while they may have lower initial costs, maintenance expenses can add up, particularly if spare parts are not readily available in specific regions. Freightliner’s dealer network is generally accessible, but may not be as comprehensive as Kenworth’s in some areas.

Volvo Trucks Configurator

Volvo’s configurator is another viable alternative, especially for companies that prioritize safety and driver comfort. Volvo trucks are known for their advanced safety features and ergonomic designs, making them suitable for urban and regional transport applications. The initial purchase price can be higher than Kenworth’s offerings, but the total cost of ownership could be lower, thanks to fuel efficiency and strong resale values. However, potential buyers should consider that while Volvo provides excellent support, parts may come at a premium, impacting ongoing maintenance costs.

Illustrative image related to kenworth build and price

Conclusion: How to Choose the Right Solution

For B2B buyers, selecting the right truck solution involves evaluating both Kenworth and its alternatives in terms of performance, cost, ease of implementation, and maintenance. Each option has its strengths and weaknesses, making it essential for businesses to align their choice with specific operational needs and financial capabilities. Factors such as the intended application, regional dealer support, and long-term maintenance costs should play a crucial role in the decision-making process. Ultimately, understanding the nuances of each solution will empower buyers to make an informed investment that enhances their operational efficiency and drives profitability.

Essential Technical Properties and Trade Terminology for kenworth build and price

What Are the Key Technical Specifications for Kenworth Trucks?

When considering a Kenworth truck for your business needs, understanding the critical technical specifications is essential. Here are some key properties to evaluate:

1. Engine Options

The choice of engine is paramount, affecting performance, fuel efficiency, and emissions. Kenworth offers a variety of engines, including the PACCAR MX-13 and Cummins engines. These engines can be configured for different horsepower ratings (commonly between 370 to 600 hp) and torque outputs (up to 2,050 lb-ft). Selecting the right engine is crucial for ensuring the truck meets your operational demands while optimizing fuel costs.

2. Transmission Types

Transmission plays a vital role in a truck’s drivability and efficiency. Kenworth trucks feature various transmission options, including manual, automatic, and automated manual transmissions (AMTs). The choice between these can impact not only the ease of operation but also the fuel consumption and maintenance costs. For instance, AMTs can enhance fuel efficiency and reduce driver fatigue, making them suitable for long-haul operations.

Illustrative image related to kenworth build and price

3. Axle Configurations

Understanding axle configurations is important for load distribution and vehicle stability. Kenworth offers different axle options, including single, tandem, and tridem configurations. The choice of axles will depend on the type of cargo and the truck’s intended use, influencing payload capacity and overall vehicle performance.

4. Suspension Types

The suspension system affects ride quality, handling, and load capacity. Kenworth provides options such as air ride and leaf spring suspensions. Air ride suspensions can provide a smoother ride and better weight distribution, which is beneficial for transporting sensitive cargo. The choice of suspension should align with the specific operational requirements to enhance performance and driver comfort.

5. Fuel Tank Capacity

Fuel tank size is crucial for operational efficiency, especially for long-haul routes. Kenworth trucks come with various fuel tank capacities, generally ranging from 50 to 150 gallons. A larger fuel tank can reduce the frequency of refueling stops, leading to increased productivity. Evaluating your typical route distances will help determine the appropriate fuel tank size for your fleet.

6. Weight Ratings

Understanding the Gross Vehicle Weight Rating (GVWR) is essential for compliance and safety. Kenworth trucks have varying GVWRs, typically ranging from 26,000 to 80,000 pounds, depending on the model. Choosing a truck with the appropriate GVWR ensures that your fleet operates within legal limits while meeting your hauling needs.

What Are Common Trade Terms in the Kenworth Truck Industry?

Familiarity with industry jargon is vital for effective communication and negotiation in the truck purchasing process. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

This term refers to the company that manufactures the original parts for the vehicle. In the context of Kenworth, it signifies the quality and compatibility of parts used in the trucks. Working with an OEM ensures that you receive genuine components that meet specific performance standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management, especially when planning to purchase multiple trucks or parts.

3. RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to request pricing and terms from suppliers. In the context of Kenworth, submitting an RFQ can help you obtain competitive pricing for the trucks and options you need, ensuring that you make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery terms. Familiarity with these terms is essential when negotiating contracts, as they clarify who bears the risk and costs at various stages of shipping.

Illustrative image related to kenworth build and price

5. Tare Weight

Tare weight refers to the weight of the truck without any cargo. Knowing the tare weight helps businesses calculate the maximum payload they can transport while ensuring compliance with weight regulations.

6. Aftermarket Support

This term encompasses all services provided after the initial sale, including parts, maintenance, and repair services. Kenworth’s PremierCare Gold Certified dealer network exemplifies strong aftermarket support, ensuring that your trucks remain operational and efficient throughout their lifecycle.

Understanding these technical specifications and trade terms will empower B2B buyers to make informed decisions when purchasing Kenworth trucks, ultimately leading to optimized fleet performance and cost savings.

Illustrative image related to kenworth build and price

Navigating Market Dynamics and Sourcing Trends in the kenworth build and price Sector

What Are the Key Market Dynamics and Trends Influencing Kenworth Build and Price?

The Kenworth build and price sector is experiencing significant transformation driven by global economic shifts, technological advancements, and changing customer preferences. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are witnessing an uptick in demand for heavy-duty and medium-duty trucks that emphasize fuel efficiency, reliability, and customization. Factors such as urbanization, increased freight demand, and infrastructure development are propelling the market forward.

Emerging technologies, including telematics and connected vehicle systems, are becoming integral in the purchasing decision process. These technologies allow businesses to monitor vehicle performance in real-time, enhancing operational efficiency and reducing downtime. Furthermore, the rise of online configurators, such as the Kenworth T680 Truck Configurator, allows buyers to visualize and customize their trucks according to specific operational needs, streamlining the procurement process.

As international trade expands, so does the necessity for versatile and robust vehicles capable of navigating diverse terrains and regulatory environments. Buyers are increasingly looking for trucks that can be tailored to meet local market demands, including those related to emissions standards and fuel types. This creates an opportunity for manufacturers to innovate and differentiate their offerings in a competitive landscape.

How Are Sustainability and Ethical Sourcing Influencing Kenworth Build and Price?

Sustainability has emerged as a critical concern in the trucking industry, influencing both purchasing decisions and supplier relationships. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their environmental impact through sustainable practices. This includes the use of eco-friendly materials, energy-efficient manufacturing processes, and trucks that comply with stringent emissions regulations.

In the Kenworth build and price sector, buyers are encouraged to seek out trucks equipped with ‘green’ certifications, such as those meeting EPA standards or utilizing alternative fuel technologies. This not only enhances corporate social responsibility but also aligns with the growing consumer demand for sustainable products. Furthermore, ethical sourcing is vital; suppliers who ensure fair labor practices and responsible sourcing of materials are becoming more desirable partners.

The shift towards sustainability is also reflected in the growing interest in electric and hybrid trucks. Kenworth’s developments in zero-emission vehicles, like the T680E, signify a market trend towards cleaner transportation solutions. B2B buyers who invest in such technologies not only contribute to environmental preservation but also benefit from potential cost savings in fuel and maintenance over time.

What Is the Historical Context of Kenworth in the Trucking Industry?

Kenworth has a rich history rooted in innovation and quality, dating back to its founding in 1923. Initially focused on producing custom-built trucks, the company quickly gained a reputation for durability and performance, which resonated with businesses requiring reliable transportation solutions. Over the decades, Kenworth has evolved to embrace technological advancements, from introducing aerodynamic designs to integrating cutting-edge engine technologies.

As the demand for specialized trucks grew, Kenworth adapted its offerings to include a diverse range of vehicles, catering to various sectors such as construction, logistics, and heavy haulage. The introduction of the PACCAR Powertrain technology and the Connected TruckTech+ system exemplifies Kenworth’s commitment to enhancing operational efficiency and user experience.

Today, Kenworth stands as a leader in the heavy and medium-duty truck market, recognized for its ability to meet the unique needs of international B2B buyers. This history of adaptability and innovation positions Kenworth as a trusted partner for businesses seeking tailored solutions in the evolving landscape of commercial transportation.

Illustrative image related to kenworth build and price

Frequently Asked Questions (FAQs) for B2B Buyers of kenworth build and price

-

How do I customize my Kenworth truck to meet specific operational needs?

Customizing your Kenworth truck involves selecting various components based on your business requirements. You can choose from a range of options including engine types, transmission systems, axle configurations, and body styles. Additionally, you can specify the interior and exterior colors, as well as other features like fuel tank capacity and specialized equipment. Collaborating with a knowledgeable Kenworth dealer can help you design a truck tailored to your specific operational needs, ensuring maximum efficiency and performance. -

What are the payment terms typically offered for purchasing Kenworth trucks?

Payment terms for Kenworth trucks can vary based on the dealer and your creditworthiness. Generally, options may include upfront payments, financing plans, or leasing agreements. International buyers should inquire about specific terms, including down payments, interest rates, and repayment schedules. It’s advisable to discuss these options with your local dealer or financial institution to ensure a payment plan that aligns with your cash flow and budgetary constraints. -

What is the minimum order quantity (MOQ) for Kenworth trucks in international trade?

The minimum order quantity for Kenworth trucks can depend on the dealer and the specific model you wish to purchase. Typically, larger orders may qualify for discounts or favorable financing terms. For international buyers, it’s essential to communicate with your dealer to understand any MOQ requirements and to explore bulk purchasing options that may benefit your business. -

How can I ensure quality assurance when buying Kenworth trucks internationally?

To ensure quality assurance, consider purchasing from authorized Kenworth dealers who adhere to the company’s rigorous standards. Request documentation such as inspection reports and warranties to verify the truck’s condition and specifications. Additionally, conducting pre-purchase inspections and arranging for third-party assessments can provide extra assurance of the vehicle’s quality and compliance with your operational needs. -

What logistics considerations should I keep in mind when importing Kenworth trucks?

Importing Kenworth trucks involves several logistics considerations, including shipping methods, customs clearance, and delivery timelines. Ensure that you have a reliable freight forwarder familiar with automotive imports to handle transportation and paperwork. It’s also crucial to understand the import regulations and tariffs in your destination country to avoid unexpected delays or costs. Planning ahead will help streamline the process and ensure timely delivery. -

What are the advantages of using the Kenworth Build and Price tool?

The Kenworth Build and Price tool allows you to customize your truck online, providing a visual representation of your selections. This interactive tool helps streamline the decision-making process by allowing you to experiment with different configurations and options. Once satisfied, you can print your specifications or send them directly to your local dealer, facilitating a smoother ordering process that aligns with your business’s unique requirements. -

How do I vet suppliers for Kenworth trucks in international markets?

Vetting suppliers involves researching their reputation, customer reviews, and industry experience. Look for authorized Kenworth dealers with a strong presence in your region. It’s also beneficial to request references from other businesses that have purchased trucks from them. Engaging in direct communication can help you assess their responsiveness and willingness to support your needs, ultimately ensuring a reliable partnership. -

What support services are available after purchasing Kenworth trucks?

After purchasing a Kenworth truck, buyers can access a range of support services, including maintenance, repairs, and parts supply through Kenworth’s PremierCare Gold Certified dealer network. This network is committed to providing efficient service and minimizing downtime. Additionally, many dealers offer training programs for operators and fleet managers to enhance the use and maintenance of the trucks, ensuring long-term operational success.

Top 3 Kenworth Build And Price Manufacturers & Suppliers List

1. Youngstown Kenworth – Customized Trucks

Domain: youngstownkenworth.com

Registered: 1999 (26 years)

Introduction: Customize your truck with Youngstown Kenworth. Options include: specific applications, heavy-haul, construction, over-the-road, specialized chassis. Customization options include engines, transmissions, suspensions, tire sizes & brands, fuel tank capacity, paint color, interior options, factory-installed accessories, power take-off, and more. Thousands of options available for ordering based on us…

2. International – Custom Build Solutions

Domain: international.com

Registered: 1998 (27 years)

Introduction: This company, International – Custom Build Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Facebook – Beige T880

Strategic Sourcing Conclusion and Outlook for kenworth build and price

In today’s competitive landscape, the importance of strategic sourcing in the procurement of Kenworth trucks cannot be overstated. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, are presented with unique opportunities to leverage Kenworth’s customizable options tailored to specific operational needs. By strategically sourcing from Kenworth’s extensive lineup—including models like the T680 and T880—buyers can ensure they are investing in vehicles that maximize efficiency, fuel savings, and overall performance.

The Kenworth Truck Configurator empowers buyers to visualize their ideal truck, thus streamlining the decision-making process. Engaging with local dealers facilitates deeper discussions around specifications and financing options, ensuring alignment with both immediate and long-term business goals.

As the market continues to evolve, embracing innovations such as zero-emission technologies and advanced diagnostics through Connected TruckTech+ will be pivotal. We encourage international buyers to explore these advancements and engage with Kenworth’s PremierCare Gold Certified dealer network for unparalleled support. Take the next step in optimizing your fleet—invest in Kenworth trucks that not only meet your current requirements but also position your business for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.