A Deep Dive into Injection Molding Companies In Ohio Solution

Introduction: Navigating the Global Market for injection molding companies in ohio

In today’s competitive landscape, sourcing high-quality injection molding companies in Ohio presents a significant challenge for international B2B buyers. Whether you are seeking reliable partners for producing precision-engineered components or looking to innovate your product line, understanding the nuances of the Ohio injection molding market is crucial. This guide serves as a comprehensive resource, detailing various types of injection molding services, applications across industries, and effective supplier vetting strategies.

The injection molding industry in Ohio boasts a rich tapestry of experienced manufacturers who excel in delivering customized solutions tailored to meet diverse business needs. By exploring essential factors such as cost considerations, quality standards, and production capabilities, this guide empowers decision-makers from Africa, South America, the Middle East, and Europe—countries like Vietnam and Germany—to make informed purchasing decisions.

With insights into the operational strengths of Ohio’s injection molding companies, buyers can navigate the complexities of the global market with confidence. Whether you require prototyping, rapid tooling, or full-scale production, this guide equips you with the knowledge necessary to forge successful partnerships, ensuring that your projects are executed to the highest standards of quality and efficiency.

Understanding injection molding companies in ohio Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Injection Molding | Tailored designs, flexibility in production volumes | Consumer goods, automotive parts | Pros: High customization; Cons: Longer lead times |

| Overmolding | Combines multiple materials into a single part | Electronics, medical devices | Pros: Enhanced functionality; Cons: Complex tooling |

| Rapid Injection Molding | Fast production cycles, ideal for prototyping | Product development, testing | Pros: Quick turnaround; Cons: Higher cost per unit |

| High-Volume Production | Focus on large-scale manufacturing, cost efficiency | Industrial components, packaging | Pros: Lower costs per unit; Cons: Less customization |

| Specialty Plastics Molding | Uses advanced materials for niche applications | Aerospace, military, medical | Pros: Superior performance; Cons: Limited supplier base |

What Are the Characteristics of Custom Injection Molding Companies in Ohio?

Custom injection molding companies in Ohio specialize in producing tailored plastic components that meet specific client needs. These companies are characterized by their ability to adapt designs and production volumes based on customer specifications, making them ideal for industries such as consumer goods and automotive. B2B buyers should consider factors like the company’s design capabilities and their experience with similar projects to ensure alignment with their requirements.

How Does Overmolding Benefit B2B Buyers?

Overmolding is a process where multiple materials are combined to create a single, integrated part. This technique is particularly advantageous for applications in electronics and medical devices, where enhanced functionality and ergonomic designs are crucial. When selecting a provider, buyers should evaluate their expertise in handling various materials and the complexity of the tooling required, which can impact lead times and costs.

Why Choose Rapid Injection Molding for Prototyping?

Rapid injection molding is designed for fast production cycles, making it an excellent choice for companies engaged in product development and testing. This method allows for quick adjustments and iterations, enabling businesses to refine their designs efficiently. However, buyers should be aware that while the turnaround is swift, the cost per unit may be higher than traditional methods, necessitating a careful assessment of budget versus speed.

What Are the Advantages of High-Volume Production Injection Molding?

High-volume production companies focus on manufacturing large quantities of plastic parts, making them highly cost-effective for industrial components and packaging solutions. The key advantage lies in the lower costs per unit, which can significantly benefit businesses looking to scale their operations. However, buyers should consider the trade-off in terms of customization, as these companies typically offer limited flexibility in design modifications.

When Should You Consider Specialty Plastics Molding?

Specialty plastics molding companies utilize advanced materials for niche applications, such as aerospace, military, and medical industries. These companies are known for producing high-performance components that meet stringent regulatory standards. Buyers should look for suppliers with a strong track record in their specific industry and an understanding of the unique challenges associated with specialty materials to ensure compliance and functionality.

Key Industrial Applications of injection molding companies in ohio

| Industry/Sector | Specific Application of Injection Molding Companies in Ohio | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of interior and exterior components | High precision and durability enhance vehicle performance | Certification standards (ISO, TS16949), material specifications |

| Consumer Goods | Manufacturing of packaging and containers | Cost-effective solutions with rapid production cycles | Customization options, sustainability of materials |

| Medical Devices | Creation of surgical instruments and diagnostic equipment | Compliance with stringent health regulations and reliability | Quality assurance processes, biocompatibility of materials |

| Electronics | Production of housings and connectors | Lightweight, durable parts improve device efficiency | Design complexity, integration with electronic components |

| Industrial Equipment | Fabrication of machine parts and assemblies | Enhanced performance and operational efficiency | Tolerance levels, material resistance to wear and tear |

How Are Injection Molding Companies in Ohio Impacting the Automotive Industry?

Injection molding companies in Ohio play a crucial role in the automotive sector by producing high-precision interior and exterior components, such as dashboards, panels, and trim pieces. These components must meet stringent durability and performance standards to withstand the rigors of daily use. For international buyers, especially from emerging markets, it’s vital to ensure that suppliers adhere to industry certifications like ISO and TS16949, which guarantee quality and reliability. Partnering with Ohio-based manufacturers offers the advantage of rapid prototyping and just-in-time production, reducing lead times and inventory costs.

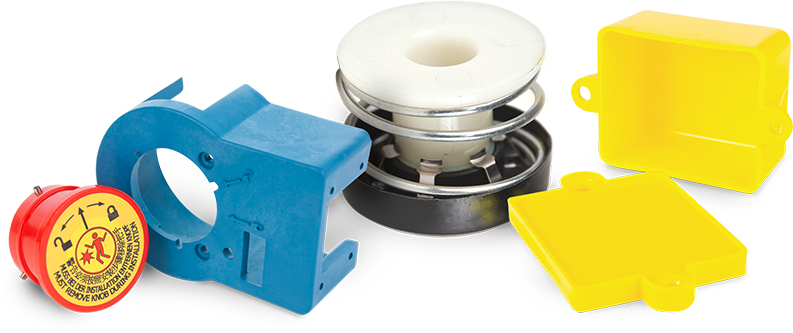

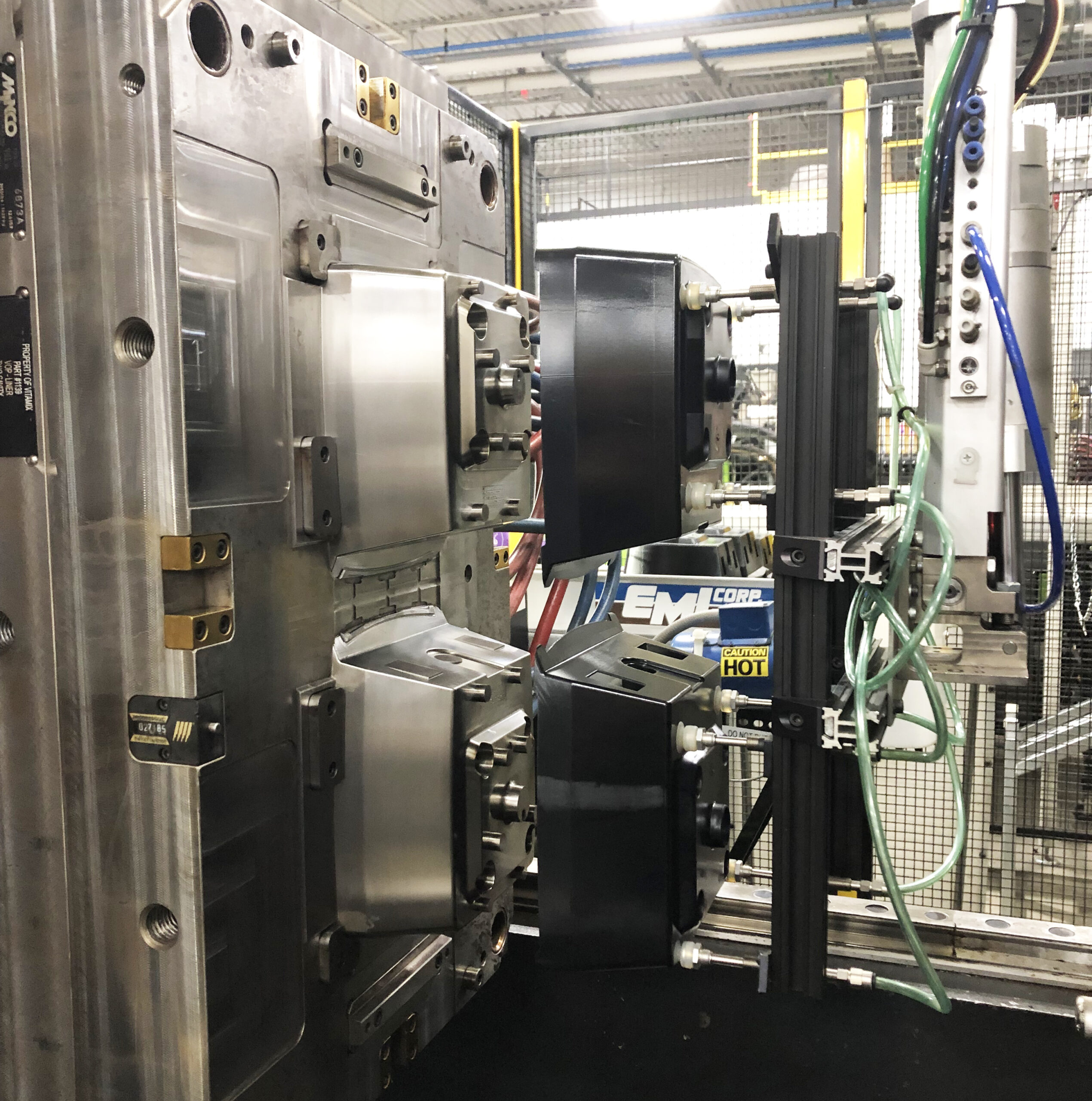

Illustrative image related to injection molding companies in ohio

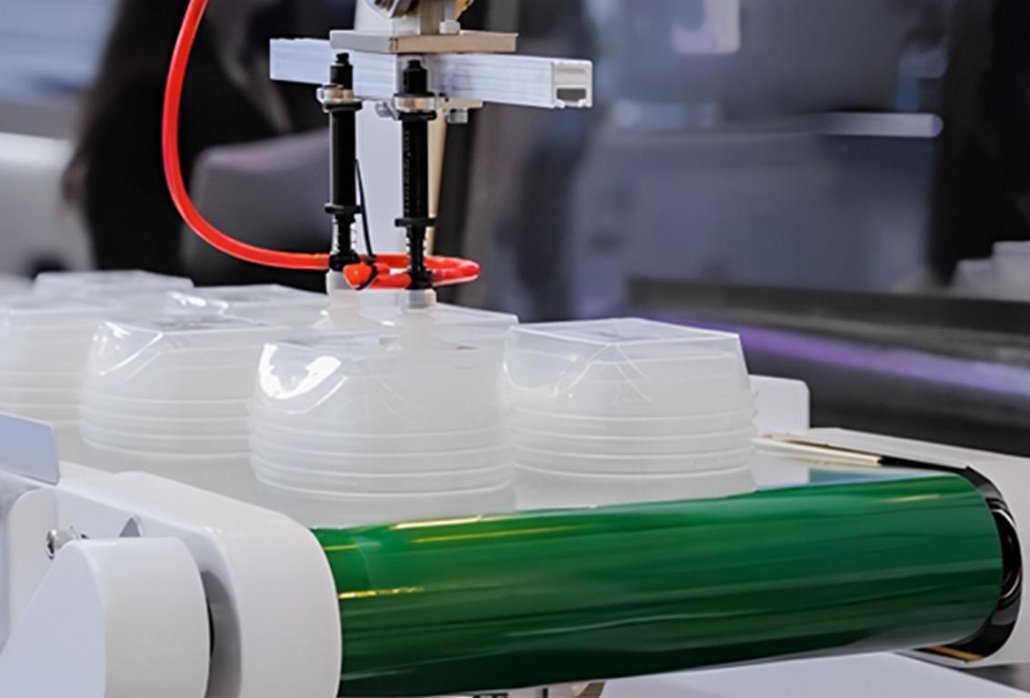

What Are the Benefits of Injection Molding for Consumer Goods Packaging?

In the consumer goods sector, injection molding companies in Ohio provide efficient manufacturing solutions for packaging and containers. This process allows for the creation of complex shapes and designs that are both visually appealing and functional. The rapid production cycles offered by these companies enable businesses to respond quickly to market demands, ensuring that products are available to consumers without delay. Buyers should consider customization options and the sustainability of materials used, as eco-friendly packaging is increasingly important in global markets.

How Do Injection Molding Solutions Support the Medical Device Sector?

The medical device industry relies heavily on injection molding for the production of surgical instruments and diagnostic equipment. Companies in Ohio specialize in creating components that comply with rigorous health regulations, ensuring that products are both safe and effective. For international buyers, understanding the quality assurance processes and the biocompatibility of materials is essential when sourcing medical components. Ohio’s manufacturers provide a reliable supply chain that can adapt to the specific needs of healthcare providers, enhancing patient outcomes through innovative design and production techniques.

Why Is Injection Molding Important for the Electronics Industry?

In the electronics sector, Ohio-based injection molding companies are vital for producing lightweight and durable housings, connectors, and other components. These parts are essential for improving the efficiency and functionality of electronic devices. Buyers from diverse markets need to focus on design complexity and how these components can integrate seamlessly into their products. The ability of Ohio manufacturers to deliver high-quality, precision-engineered parts can significantly enhance the performance of electronic devices, making them a preferred sourcing option for international clients.

How Can Injection Molding Benefit Industrial Equipment Manufacturers?

Injection molding is integral to the industrial equipment sector, where companies in Ohio manufacture machine parts and assemblies that enhance operational efficiency. The precision offered by injection molding allows for the creation of complex geometries that can withstand heavy use. International buyers must evaluate tolerance levels and the material’s resistance to wear and tear when sourcing these components. Collaborating with Ohio manufacturers ensures access to advanced technologies and expertise, resulting in high-performance parts that meet the specific demands of industrial applications.

3 Common User Pain Points for ‘injection molding companies in ohio’ & Their Solutions

Scenario 1: Delays in Production Timeline

The Problem: Many international B2B buyers experience significant frustration when dealing with injection molding companies in Ohio due to unexpected delays in production timelines. These delays can stem from various issues such as equipment malfunctions, material shortages, or inefficient communication between the supplier and the client. This not only affects the buyer’s supply chain but can also lead to missed deadlines, resulting in financial penalties and loss of customer trust.

The Solution: To mitigate this challenge, buyers should establish a transparent communication protocol with their chosen injection molding company. Before finalizing any contract, it is crucial to inquire about the company’s production capabilities, including their backup plans for potential disruptions. Setting clear expectations regarding timelines and regular updates can help manage and align production schedules. Additionally, incorporating performance metrics into the contract can incentivize the injection molding company to adhere to agreed timelines. Lastly, consider diversifying your supplier base; having alternative suppliers can safeguard against unforeseen delays.

Scenario 2: Quality Control Issues with Molding Products

The Problem: A common pain point for B2B buyers is the inconsistency in the quality of injection molded products. Buyers may receive parts that do not meet the required specifications, leading to complications in assembly, functionality, and overall product integrity. This inconsistency can arise from variations in the molding process, material quality, or inadequate quality assurance measures.

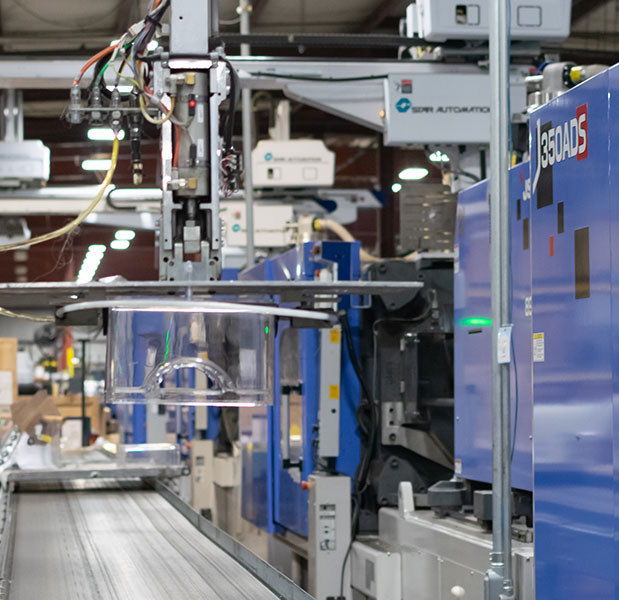

Illustrative image related to injection molding companies in ohio

The Solution: To address quality control issues, buyers should prioritize working with injection molding companies that have robust quality assurance processes in place. Before partnering, request detailed information about their quality control measures, including their inspection protocols and certifications (like ISO standards). Furthermore, engage in a collaborative design process during the initial stages of product development. Utilizing prototyping services can allow for early detection of potential issues and enable adjustments before mass production begins. Establishing a comprehensive feedback loop will also ensure continuous improvement and adherence to quality standards.

Scenario 3: Difficulties in Customization and Design Adaptation

The Problem: International buyers often face challenges when needing customized injection molded products that meet specific design criteria. Many companies may have rigid processes that do not easily accommodate changes or unique specifications, leading to frustration and potential project delays. This lack of flexibility can hinder innovation and the development of tailored solutions that meet the buyer’s precise needs.

The Solution: To overcome challenges with customization, buyers should seek out injection molding companies in Ohio that specialize in flexible manufacturing and have a proven track record of adapting to client specifications. When initiating contact, clearly articulate your design requirements and ask for examples of past projects where they successfully customized products. Establishing a partnership with a company that values innovation and collaboration can facilitate a more agile response to design changes. Additionally, utilizing advanced technologies such as 3D printing for prototyping can help visualize and refine designs before moving to full-scale production, ensuring that the final product aligns perfectly with the buyer’s expectations.

Strategic Material Selection Guide for injection molding companies in ohio

When selecting materials for injection molding, companies in Ohio must consider a variety of factors that affect the performance, cost, and suitability of the end products. Here, we analyze four common materials used in injection molding, focusing on their properties, advantages, limitations, and specific considerations for international B2B buyers.

What Are the Key Properties of Polypropylene (PP) in Injection Molding?

Polypropylene (PP) is a widely used thermoplastic in injection molding due to its excellent chemical resistance and low density. It has a temperature rating of approximately 100°C (212°F) and can withstand moderate pressure. Its low moisture absorption makes it suitable for various applications, including automotive parts and consumer goods.

Pros & Cons: The primary advantage of PP is its cost-effectiveness and versatility, making it ideal for mass production. However, it can be less durable than other materials, especially in high-temperature applications. Additionally, while PP is easy to mold, its lower impact resistance may limit its use in applications requiring high strength.

Impact on Application: PP is compatible with various media, making it suitable for packaging, automotive, and household products. However, it may not be the best choice for applications requiring high structural integrity or exposure to extreme temperatures.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local regulations regarding plastic materials. Standards like ASTM and ISO are commonly referenced, and familiarity with these can facilitate smoother transactions.

How Does Polycarbonate (PC) Perform in Injection Molding Applications?

Polycarbonate (PC) is known for its exceptional clarity and impact resistance, making it a preferred choice for applications such as safety glasses and automotive components. It can withstand temperatures up to 135°C (275°F) and offers good dimensional stability.

Pros & Cons: The key advantage of PC is its high strength-to-weight ratio, which makes it suitable for demanding applications. However, it is generally more expensive than PP and can be prone to scratching unless treated with a hard coating. Additionally, PC is more complex to process, requiring careful temperature control during molding.

Impact on Application: PC’s excellent optical properties make it ideal for applications requiring transparency, such as light covers and lenses. Its high impact resistance is crucial for safety applications, but its susceptibility to UV degradation may necessitate additives for outdoor use.

Considerations for International Buyers: Buyers from Europe and the Middle East should be aware of compliance with standards like DIN and EN, which govern the use of plastics in various applications. Understanding these standards can help in selecting the right supplier.

What Are the Advantages of Acrylonitrile Butadiene Styrene (ABS)?

Acrylonitrile Butadiene Styrene (ABS) is a popular thermoplastic known for its toughness and impact resistance. It can withstand temperatures up to 80°C (176°F) and offers good chemical resistance.

Pros & Cons: ABS is favored for its ease of machining and excellent surface finish, making it ideal for consumer products and electronic housings. However, it can be more expensive than PP and may not perform well in high-temperature environments. Additionally, ABS is less environmentally friendly, as it is not biodegradable.

Illustrative image related to injection molding companies in ohio

Impact on Application: ABS is widely used in applications ranging from toys to automotive parts due to its durability and aesthetic appeal. However, its thermal limitations may restrict its use in high-heat applications.

Considerations for International Buyers: Buyers from regions like Vietnam and Germany should consider environmental regulations regarding the use of ABS and look for suppliers who adhere to sustainability practices.

What Makes Polyethylene Terephthalate (PET) a Preferred Choice?

Polyethylene Terephthalate (PET) is a thermoplastic polyester known for its strength and thermal stability. It can withstand temperatures up to 70°C (158°F) and is commonly used in packaging and textile applications.

Pros & Cons: PET’s primary advantage is its recyclability, making it an environmentally friendly option. It offers excellent clarity and barrier properties. However, it can be more expensive than other materials and may require specialized processing techniques.

Impact on Application: PET is ideal for food and beverage packaging due to its safety and barrier properties. However, its processing requirements may complicate production for some manufacturers.

Considerations for International Buyers: Buyers should be aware of recycling regulations in their regions, especially in Europe, where sustainability is a significant concern. Familiarity with compliance standards can help in selecting the right materials and suppliers.

Summary Table

| Material | Typical Use Case for injection molding companies in ohio | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Automotive parts, consumer goods | Cost-effective and versatile | Lower durability in high-temp applications | Low |

| Polycarbonate (PC) | Safety glasses, automotive components | High strength-to-weight ratio | More expensive and complex to process | High |

| Acrylonitrile Butadiene Styrene (ABS) | Toys, electronic housings | Toughness and impact resistance | Thermal limitations and less eco-friendly | Medium |

| Polyethylene Terephthalate (PET) | Food and beverage packaging | Recyclable and excellent barrier properties | Higher processing complexity | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, emphasizing the importance of material properties and compliance with regional standards. Understanding these factors can lead to more informed purchasing decisions and successful partnerships with Ohio-based injection molding companies.

In-depth Look: Manufacturing Processes and Quality Assurance for injection molding companies in ohio

What Are the Main Stages of the Injection Molding Manufacturing Process?

The injection molding process is a sophisticated technique employed by Ohio-based companies to produce high-quality plastic components. This process typically involves several key stages, each critical to ensuring the final product meets stringent quality and performance standards.

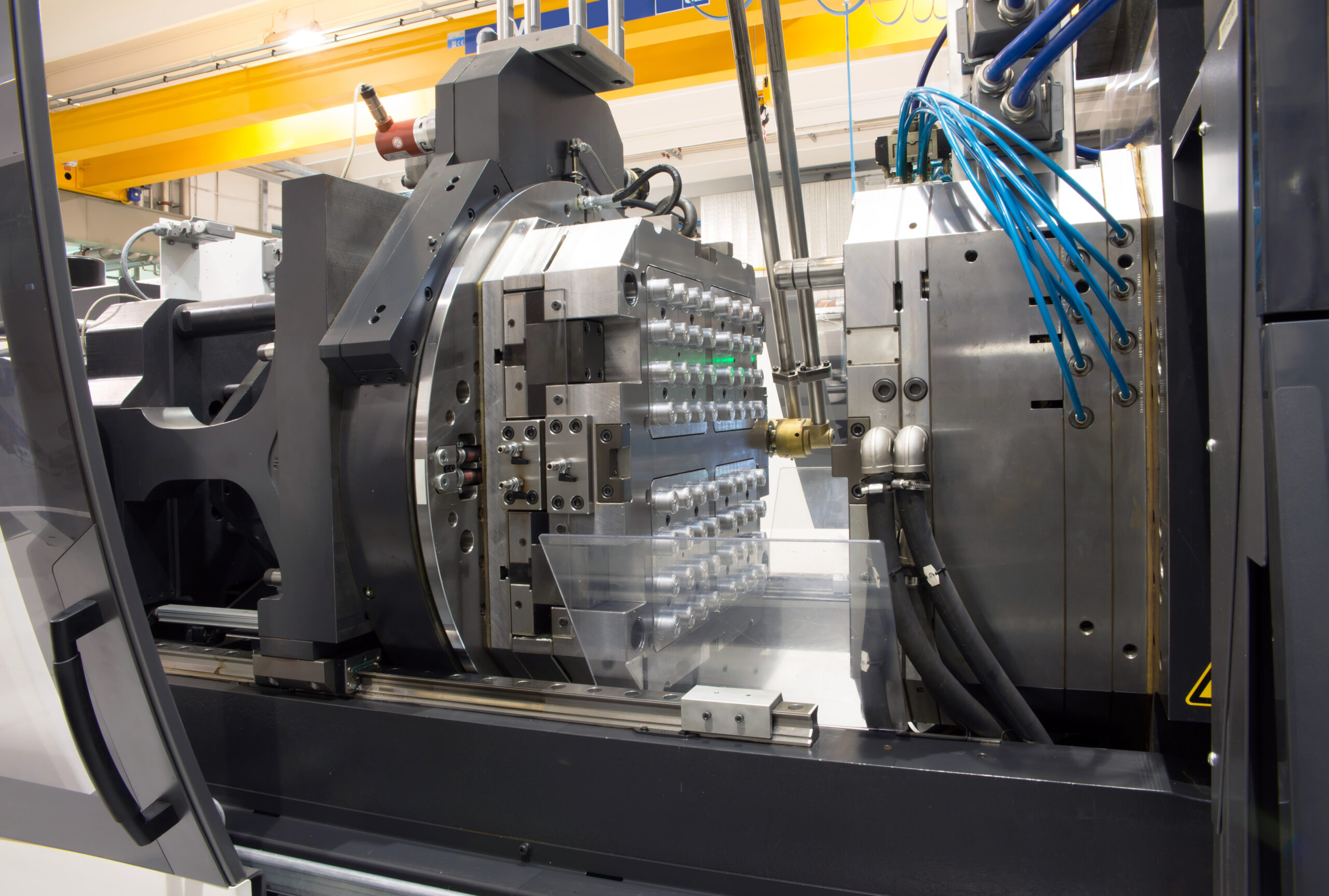

Illustrative image related to injection molding companies in ohio

-

Material Preparation: The first stage involves selecting the appropriate thermoplastic resin or thermoset material, which is then dried and blended as necessary. Material preparation is crucial, as moisture content and material consistency directly affect the quality of the molded parts. Advanced companies often utilize automated systems for material handling to ensure precision and efficiency.

-

Forming: This is the core of the injection molding process, where the prepared material is heated until molten and injected into a pre-designed mold under high pressure. The mold is engineered to the exact specifications of the desired part, and this stage can include various techniques such as overmolding or insert molding, which allows for the integration of multiple materials into a single product.

-

Cooling and Solidifying: Once the material fills the mold, it is allowed to cool and solidify. This phase is vital for dimensional accuracy and part integrity. Cooling times can vary based on material properties and part geometry, and advanced cooling systems may be implemented to optimize cycle times.

-

Assembly: After the parts are ejected from the mold, they may require further assembly. This could include adding components, decorating, or performing secondary operations such as machining or surface finishing. This stage enhances the functionality and aesthetics of the final product.

-

Finishing: The final stage involves any additional processes needed to meet customer specifications, such as surface treatment, painting, or printing. Companies in Ohio may utilize techniques like ultrasonic welding or laser marking to provide the finishing touches that enhance product appeal.

How Do Injection Molding Companies in Ohio Ensure Quality Assurance?

Quality assurance (QA) is paramount in the injection molding industry, particularly for international B2B buyers who demand compliance with global standards. Ohio injection molding companies implement comprehensive QA practices to ensure their products meet industry expectations.

What International Standards Do Ohio Injection Molding Companies Follow?

Many injection molding companies in Ohio adhere to internationally recognized quality management standards, such as ISO 9001. This certification demonstrates a company’s commitment to quality management principles, including customer focus, process approach, and continuous improvement. Additional industry-specific certifications may include CE marking for European markets or API standards for sectors like oil and gas.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated at various stages of the injection molding process:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and conformity to specifications before they enter the production process. This step is crucial to prevent defects from the outset.

-

In-Process Quality Control (IPQC): During the molding process, regular checks are conducted to monitor parameters such as temperature, pressure, and cycle times. This ensures that the molding conditions remain optimal and any deviations are addressed promptly.

-

Final Quality Control (FQC): After production, finished parts undergo rigorous testing to verify that they meet the required specifications. This can include dimensional inspections, visual checks, and functional tests.

What Common Testing Methods Are Used in Quality Assurance?

To ensure product reliability and performance, Ohio injection molding companies employ various testing methods, including:

Illustrative image related to injection molding companies in ohio

-

Dimensional Inspection: Using precision measuring tools, companies verify that parts meet specified tolerances.

-

Mechanical Testing: This may involve tensile strength tests, impact tests, and fatigue tests to assess material performance under different conditions.

-

Visual Inspection: Automated and manual inspections are conducted to identify surface defects or inconsistencies.

-

Functional Testing: This assesses whether the product performs its intended function within the specified parameters.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control measures of potential suppliers is essential to mitigate risks associated with product quality. Here are several strategies:

-

Supplier Audits: Conducting on-site audits can provide insight into a supplier’s manufacturing processes, quality management systems, and overall capabilities. Buyers should consider the frequency and thoroughness of these audits.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers assess product consistency and compliance with standards. These reports should include results from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services offers an unbiased evaluation of a supplier’s quality systems. These inspections can be particularly beneficial for buyers unfamiliar with local practices or standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing from Ohio injection molding companies, international buyers should be aware of several nuances in quality control:

-

Cultural Differences: Different regions may have varying approaches to quality management. Understanding these differences can aid in establishing effective communication and expectations.

-

Regulatory Compliance: Buyers from regions like Africa or the Middle East should ensure that their suppliers comply with local regulations and international standards relevant to their markets.

-

Documentation and Certification: Buyers should verify that suppliers provide appropriate documentation, including certificates of compliance, test reports, and quality assurance protocols. This documentation is critical for ensuring that products meet both local and international standards.

In summary, Ohio injection molding companies are equipped with advanced manufacturing processes and robust quality assurance systems. By understanding these practices, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their quality and performance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘injection molding companies in ohio’

In today’s global market, sourcing injection molding companies in Ohio can be a strategic move for international B2B buyers. This practical guide aims to streamline your procurement process, ensuring you select a partner that meets your specific needs and quality standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly define your technical specifications. This includes understanding the materials, dimensions, tolerances, and production volumes required for your project. A well-documented specification not only aids in accurate quotations but also ensures that potential suppliers understand your exact requirements, minimizing the risk of miscommunication.

Step 2: Research Potential Suppliers

Conduct comprehensive research to compile a list of potential injection molding companies in Ohio. Utilize online directories, industry forums, and referrals from colleagues to identify reputable suppliers. When researching, consider their industry experience, service offerings, and customer reviews. This foundational knowledge will serve as a basis for deeper evaluations later in the process.

Step 3: Evaluate Supplier Certifications

✅ Verify Supplier Certifications

Quality assurance is paramount in injection molding. Look for suppliers who hold relevant certifications such as ISO 9001 or IATF 16949, which indicate adherence to international quality management standards. Additionally, inquire about their quality control processes and how they ensure product consistency, as this reflects their commitment to delivering high-quality solutions.

Step 4: Request Quotes and Compare

Once you have a shortlist of potential suppliers, request detailed quotes from each. Ensure that the quotes include all relevant costs, such as tooling, materials, and shipping. Comparing these quotes not only helps in understanding the market rates but also reveals how each company values transparency and customer service. Look for any hidden costs or terms that could affect your final decision.

Step 5: Assess Production Capabilities

It’s crucial to understand each supplier’s production capabilities. Inquire about their machinery, technology, and the scalability of their operations. A supplier with advanced technology and sufficient capacity can accommodate future growth or changes in your production needs. Additionally, assess their lead times to ensure they can meet your project deadlines.

Illustrative image related to injection molding companies in ohio

Step 6: Check References and Past Projects

Before finalizing your decision, ask for references and case studies from past clients. This will provide insights into the supplier’s reliability and quality of service. Contacting previous clients can reveal valuable information about the supplier’s communication, problem-solving abilities, and overall satisfaction.

Step 7: Establish Clear Communication Channels

Finally, ensure that there are clear communication channels established with your chosen supplier. Discuss how you will manage project updates, feedback, and any potential issues that may arise during production. Effective communication is vital for a successful partnership and can significantly impact project outcomes.

By following this step-by-step checklist, B2B buyers can confidently navigate the procurement process for injection molding companies in Ohio, ensuring they select a partner that aligns with their quality standards and operational needs.

Comprehensive Cost and Pricing Analysis for injection molding companies in ohio Sourcing

What are the Key Cost Components in Ohio’s Injection Molding Sector?

When sourcing injection molding services in Ohio, understanding the cost structure is vital for international B2B buyers. The primary components contributing to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of resin significantly influences costs. Commodity plastics like polypropylene are generally less expensive than specialty materials such as polycarbonate or engineered thermoplastics. Buyers should consider the long-term implications of material selection on durability and performance.

-

Labor: Skilled labor is essential in injection molding, affecting both the quality of the finished product and the cost. Ohio has a robust manufacturing workforce, but labor costs can vary based on the complexity of the project and the level of expertise required.

-

Manufacturing Overhead: This includes utilities, equipment depreciation, and facility costs. Ohio injection molding companies often have modern facilities equipped with advanced technology, which can lead to higher overhead but also enhances efficiency and precision.

-

Tooling: Tooling is a significant upfront investment in injection molding. Costs vary based on the complexity of the mold, with intricate designs requiring more sophisticated tooling that increases initial expenses but can reduce per-unit costs in high-volume production runs.

-

Quality Control (QC): A rigorous QC process is essential to ensure product consistency and compliance with industry standards. Companies that invest in advanced QC measures may charge higher prices, but this can lead to lower defect rates and reduced costs in the long run.

-

Logistics: Shipping costs can vary depending on the destination, mode of transport, and volume of orders. For international buyers, understanding Incoterms is crucial for clarifying responsibility for shipping costs and risks.

-

Margin: The profit margin typically reflects the supplier’s market position, reputation, and the value-added services they provide. Expect a range of margins, with established companies potentially charging more for their reliability and expertise.

How Do Volume and Customization Affect Pricing in Injection Molding?

Volume and customization are two of the most influential factors on pricing. Most Ohio injection molding companies offer tiered pricing structures based on the volume of orders. Higher order volumes often lead to lower per-unit costs due to economies of scale. Conversely, low minimum order quantities (MOQs) may result in higher costs per unit, particularly for customized designs.

Customization also plays a pivotal role in determining costs. Highly tailored projects require more extensive design work, which can elevate costs significantly. Buyers should clearly communicate their specifications and explore options that balance customization with cost-effectiveness.

What Should International B2B Buyers Consider for Cost-Efficiency?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the Total Cost of Ownership (TCO) is critical. This includes not only the initial cost of production but also shipping, tariffs, and potential delays.

-

Negotiation: Establishing a good relationship with suppliers can facilitate better pricing. Engage in discussions about volume discounts, payment terms, and the possibility of long-term contracts to secure favorable rates.

-

Cost-Efficiency: Evaluate different suppliers based on their production capabilities, quality certifications, and past performance. A supplier with a robust track record may charge more upfront but can reduce long-term costs through fewer defects and faster turnaround times.

-

Pricing Nuances: Be aware that prices can fluctuate based on market conditions, material availability, and currency exchange rates. Always request detailed quotes that include all potential costs to avoid surprises.

Conclusion

Navigating the cost structure and pricing of injection molding services in Ohio requires careful consideration of multiple factors. By understanding the key components and leveraging negotiation strategies, international buyers can secure cost-effective solutions that meet their manufacturing needs. Always engage suppliers in open dialogue to clarify expectations and ensure alignment on project goals.

Alternatives Analysis: Comparing injection molding companies in ohio With Other Solutions

When considering manufacturing solutions, especially for plastic parts, B2B buyers often explore various alternatives to injection molding. This analysis compares injection molding companies in Ohio with other viable solutions, enabling international buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Injection Molding Companies In Ohio | 3D Printing | Blow Molding |

|---|---|---|---|

| Performance | High precision and repeatability | Varies; good for complex designs | High speed for hollow parts |

| Cost | Moderate to high setup costs | Lower initial costs, high per unit | Moderate setup costs, efficient for large runs |

| Ease of Implementation | Requires significant setup | Quick setup, minimal tooling | Moderate complexity in setup |

| Maintenance | Regular maintenance needed | Low maintenance | Requires specific maintenance |

| Best Use Case | High-volume production, complex parts | Prototyping, small batches | Large-scale production of containers |

What Are the Advantages and Disadvantages of 3D Printing as an Alternative?

3D printing, or additive manufacturing, offers flexibility in design and rapid prototyping capabilities. It is ideal for creating complex geometries that might be challenging to achieve with traditional methods. The initial investment is relatively low, making it accessible for small-scale projects. However, the cost per unit can be higher for larger production runs, making it less economical for mass production compared to injection molding. Additionally, the material options can be limited based on the printer technology used.

How Does Blow Molding Compare to Injection Molding?

Blow molding is a process primarily used for creating hollow plastic products, such as bottles. It is highly efficient for high-volume production, offering faster cycle times than injection molding when producing large quantities. The setup costs are moderate, making it a viable option for businesses looking to produce large batches of similar items. However, it lacks the precision and versatility offered by injection molding, particularly for complex parts, which may limit its application in certain industries.

Illustrative image related to injection molding companies in ohio

What Should B2B Buyers Consider When Choosing Between These Solutions?

Choosing the right manufacturing solution depends on various factors, including production volume, part complexity, and budget constraints. Injection molding companies in Ohio offer robust solutions for high-volume needs, ensuring quality and consistency in production. In contrast, 3D printing is advantageous for rapid prototyping and low-volume runs with intricate designs. Blow molding is best suited for businesses focused on producing hollow forms at scale.

In conclusion, B2B buyers should assess their specific needs, including the type of product, production volume, and budget, before making a decision. Understanding the strengths and weaknesses of each alternative will empower international buyers to select the most suitable manufacturing method for their projects, ensuring efficiency and quality in their operations.

Essential Technical Properties and Trade Terminology for injection molding companies in ohio

What Are the Essential Technical Properties Relevant to Injection Molding?

Understanding the critical specifications in injection molding is vital for B2B buyers to ensure they select the right partner for their manufacturing needs. Here are some of the key technical properties:

Illustrative image related to injection molding companies in ohio

1. Material Grade

Material grade refers to the specific type of plastic used in the injection molding process, such as ABS, polycarbonate, or polypropylene. Each material possesses unique physical properties, including strength, flexibility, and thermal resistance. For B2B buyers, selecting the correct material grade is crucial as it directly impacts the performance and durability of the final product.

2. Tolerance

Tolerance indicates the allowable deviation from a specified dimension. In injection molding, tight tolerances are essential for ensuring that parts fit together correctly in their intended application. For international buyers, particularly those in precision-driven industries like automotive or aerospace, understanding tolerance specifications can be a deciding factor in product quality and compatibility.

3. Cycle Time

Cycle time is the duration it takes to complete one injection molding cycle, from the injection of material to the ejection of the molded part. Shorter cycle times can significantly improve production efficiency and reduce costs. B2B buyers should consider cycle times when evaluating potential manufacturers, as it can affect lead times and overall project timelines.

4. Surface Finish

Surface finish refers to the texture and appearance of the molded part. Various finishes can be achieved, from smooth to textured, depending on the mold design and processing conditions. A high-quality surface finish is often essential for aesthetic components or those requiring additional functionality, such as improved grip. Buyers should specify their surface finish requirements to ensure the final product meets their expectations.

5. Shrinkage Rate

The shrinkage rate is the percentage change in dimensions of a molded part as it cools and solidifies. This property is critical for ensuring that the final product matches the design specifications. Buyers must understand the shrinkage characteristics of the material used to ensure that parts will meet dimensional requirements after cooling.

Illustrative image related to injection molding companies in ohio

What Are the Common Trade Terms Used in the Injection Molding Industry?

Navigating the language of injection molding can be challenging for buyers. Here are some common trade terms that are essential for effective communication with manufacturers:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are then sold under another company’s brand name. Understanding OEM relationships is important for buyers looking to source components that will be integrated into larger systems or products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to produce or sell. This term is crucial for B2B buyers as it affects inventory management and cost efficiency. Knowing the MOQ helps buyers gauge whether a manufacturer can meet their production needs without incurring excessive costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This is a critical step in the procurement process, allowing buyers to compare offers from multiple manufacturers. A well-prepared RFQ can lead to better pricing and terms.

Illustrative image related to injection molding companies in ohio

4. Incoterms

Incoterms are a series of international commercial terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding Incoterms is vital for international transactions, as they clarify who bears the risk, cost, and responsibility for shipping and delivery.

5. Overmolding

Overmolding is a manufacturing process where a second material is molded over an existing molded part. This technique is often used to enhance the functionality or aesthetics of a product. Buyers should inquire about overmolding capabilities when looking for innovative solutions.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when selecting injection molding partners in Ohio, ensuring successful collaborations and high-quality product outcomes.

Navigating Market Dynamics and Sourcing Trends in the injection molding companies in ohio Sector

What Are the Current Market Dynamics and Key Trends in the Injection Molding Sector?

The injection molding industry in Ohio is experiencing a robust transformation driven by several global factors. A significant driver is the increasing demand for customized, high-quality plastic components across various sectors, including automotive, healthcare, and consumer goods. With the rise of Industry 4.0, businesses are leveraging advanced technologies such as automation, AI, and IoT to enhance production efficiency and product quality. This technological integration allows for rapid prototyping and shorter lead times, making Ohio an attractive location for international B2B buyers.

Moreover, sustainability is becoming a pivotal concern, shaping purchasing decisions. Companies are increasingly adopting eco-friendly practices and materials, driven by both regulatory pressures and consumer demand for greener products. This shift is particularly relevant for buyers from regions like Europe, where stringent environmental regulations are prevalent. As a result, Ohio injection molding companies are investing in sustainable practices, including the use of recycled materials and energy-efficient production processes.

Illustrative image related to injection molding companies in ohio

In addition, the global supply chain landscape is shifting. International buyers are seeking localized suppliers to mitigate risks associated with long-distance sourcing, such as delays and rising transportation costs. Ohio’s strategic location and its well-established manufacturing ecosystem make it an appealing choice for companies looking to streamline their supply chains while maintaining high-quality standards.

How Is Sustainability Influencing Ethical Sourcing in Injection Molding?

Sustainability and ethical sourcing are becoming integral to the injection molding industry in Ohio. Environmental impact considerations are prompting companies to adopt more sustainable practices. For B2B buyers, this means sourcing from manufacturers who prioritize eco-friendly materials and processes, thereby reducing their carbon footprint.

Ohio injection molding companies are increasingly utilizing bioplastics and recycled materials, which can significantly lower environmental impact compared to traditional plastics. Additionally, many of these companies are pursuing green certifications, such as ISO 14001, to demonstrate their commitment to sustainable practices. This certification not only enhances their marketability but also assures buyers of their adherence to environmental management standards.

Ethical supply chains are also gaining traction, with buyers looking for transparency and accountability in their sourcing decisions. Manufacturers that can provide detailed information about their sourcing practices, labor conditions, and environmental policies are more likely to attract international buyers who prioritize ethical considerations in their procurement processes. By focusing on sustainability and ethical sourcing, injection molding companies in Ohio can position themselves as leaders in a competitive global market.

Illustrative image related to injection molding companies in ohio

How Has the Injection Molding Industry Evolved Over Time?

The injection molding industry in Ohio has undergone significant evolution since its inception. Initially dominated by traditional manufacturing methods, the sector has embraced advanced technologies and innovative practices over the past few decades. The introduction of computer-aided design (CAD) and simulation software has revolutionized product development, allowing for more precise designs and efficient production processes.

In recent years, the emphasis on sustainability has further transformed the industry. Companies are now not only focused on operational efficiency but also on minimizing their environmental impact. This evolution reflects a broader trend within the manufacturing sector, where the integration of technology and sustainability is becoming essential for remaining competitive in a global marketplace.

The historical development of the injection molding industry in Ohio has positioned it as a key player in the U.S. manufacturing landscape, making it a prime destination for international B2B buyers seeking reliable partners in high-quality plastic production.

Frequently Asked Questions (FAQs) for B2B Buyers of injection molding companies in ohio

1. How do I choose the right injection molding company in Ohio?

When selecting an injection molding company in Ohio, consider factors such as industry expertise, production capabilities, and quality certifications. Review their portfolio to assess their experience with similar projects. Communication is key; choose a company that prioritizes customer service and offers clear channels for updates and feedback. Additionally, inquire about their technology and processes to ensure they align with your product requirements. Finally, check references and testimonials from previous clients to gauge reliability and performance.

2. What are the common minimum order quantities (MOQs) for injection molding services?

Minimum order quantities (MOQs) can vary significantly among injection molding companies. Typically, MOQs range from a few hundred to several thousand units, depending on the complexity of the part and the material used. For custom projects, it’s crucial to discuss your specific needs with the supplier, as some companies may accommodate lower MOQs for certain applications or offer flexible arrangements for larger orders. Always clarify MOQs upfront to avoid potential issues later in the production process.

3. How can I ensure quality assurance in injection molded products?

To ensure quality assurance in injection molded products, verify that the company adheres to recognized quality standards such as ISO 9001 or ISO 13485. Request details about their quality control processes, including inspection protocols and testing methods. It’s beneficial to ask for samples or prototypes before full-scale production, allowing you to assess product quality firsthand. Additionally, establish clear specifications and tolerances in your contract to ensure the final products meet your expectations.

4. What payment terms should I expect when working with Ohio injection molding companies?

Payment terms can vary by supplier but typically include options such as upfront deposits, milestone payments, or net payment terms (e.g., Net 30, Net 60). For international transactions, consider additional factors such as currency exchange rates and potential tariffs. It’s advisable to discuss and negotiate payment terms upfront to ensure clarity and avoid any misunderstandings. Also, consider using secure payment methods or escrow services to protect your investment.

5. How can I customize my injection molded product design?

Customizing your injection molded product design starts with clear communication of your specifications and requirements. Most injection molding companies offer design assistance, including CAD modeling and prototyping services. Collaborate with their engineering team to refine your design for manufacturability, which can help reduce costs and lead times. Be prepared to provide detailed information on dimensions, materials, and any functional requirements to ensure the final product aligns with your vision.

6. What logistics considerations should I keep in mind when sourcing from Ohio?

When sourcing injection molding services from Ohio, consider logistics factors such as shipping costs, lead times, and customs regulations. Evaluate the proximity of the supplier to major transportation hubs to minimize shipping delays. For international shipments, familiarize yourself with import duties and taxes that may apply. Additionally, establish clear communication with your supplier about shipping methods and timelines to ensure a smooth delivery process.

7. What industries do Ohio injection molding companies typically serve?

Ohio injection molding companies serve a diverse range of industries, including automotive, consumer goods, healthcare, and electronics. Each sector has unique requirements regarding material properties, production volumes, and regulatory compliance. When selecting a supplier, ensure they have experience in your specific industry, as this can significantly impact the quality and efficiency of production. Additionally, inquire about their ability to meet industry standards and certifications relevant to your sector.

8. How do I handle disputes or issues with my injection molding supplier?

Handling disputes with your injection molding supplier should start with open and clear communication. Address the issue promptly and document all relevant details, including specifications, agreements, and timelines. Most suppliers will appreciate the opportunity to resolve problems amicably. If resolution is not achieved, refer to your contract for dispute resolution mechanisms, which may include mediation or arbitration. Establishing a positive relationship from the start can also help mitigate conflicts in the future.

Top 8 Injection Molding Companies In Ohio Manufacturers & Suppliers List

1. Ohio Precision Molding – Plastic Injection Molding Services

Domain: ohioprecisionmolding.com

Registered: 2000 (25 years)

Introduction: Ohio Precision Molding specializes in plastic injection molding, offering services that include product design and engineering, prototyping, rapid tooling, 3D printing, and production. The company emphasizes quality through a rigorous inspection process and aims for customer satisfaction by focusing on continuous improvement. Industries served include automotive, energy, consumer, and industrial s…

2. Injection Molded Plastics – Key Solutions

Domain: injection-molded-plastics.net

Registered: 2001 (24 years)

Introduction: Injection Molded Case, Injection Molded Part, Injection Molding, Insert Molding, Overmolding, Plastic Gear, Plastic Injection Molding, Plastic Molding, Plastic Overmolding, Prototype Injection Molding, Rapid Injection Molding, Reaction Injection Molding, Thermoplastic Molding.

3. Thogus – Precision Injection Molding Services

Domain: thogus.com

Registered: 2000 (25 years)

Introduction: Thogus offers precision injection molding services in Cleveland, Ohio, specializing in mid- to high-volume manufacturing. Their capabilities include custom plastic injection molding, engineering support, automation, tooling, secondary operations, and quality fittings. They work with a variety of materials, including commodity plastics, engineered resins, and custom resins, and provide services for…

4. Ohio Plastic Injection Molding – Key Manufacturers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Ohio Plastic Injection Molding Companies include Quality Plastics, LLC, GSH Industries, Inc., TyTek Industries, Hueter Toledo, Inc., Iten Industries, Plastic Enterprises Inc., Thogus Products Company, Ohio Precision Molding, Inc., Olan Plastics, Inc., American Engineering Group LLC, Automation Plastics, Deimling/jeliho Plastics, Inc., Esterle Mold & Machine Company, Inc., and Performance Plastics …

5. Molding Dynamics – Custom Plastic Injection Molding

Domain: moldingdynamics.net

Registered: 2004 (21 years)

Introduction: Custom Plastic Injection Molding services, specializing in engineering grade resins and various plastic molding capabilities. Key materials include ABS, Acetal, Acrylic, Nylons, PEEK, PEX, PP, PS, PET, PUR, PC, HDPE/LDPE/LLDPE, PPO, TPR, and TPE. Services offered include reshoring, tooling options, materials selection, overmolding, insert molding, project management, chrome plating, tooling transf…

6. Pleasant Precision, Inc. – Injection Molding Solutions

Domain: teamppi.com

Registered: 1998 (27 years)

Introduction: Pleasant Precision, Inc. is a full-service contract manufacturer specializing in injection molding and mold making. Key offerings include:

– High-quality parts with reduced lead times and lower production costs.

– IATF 16949:2016 certified quality management system.

– Advanced injection molding tools for high-quality thermoplastic parts.

– Secondary services such as assembly, kitting, welding, hea…

7. Promold Tech – Precision Injection Molding

Domain: promoldtech.com

Registered: 2002 (23 years)

Introduction: Progressive Molding Technologies, Inc. is an Ohio-based custom injection molder specializing in close-tolerance, precision injection molding of engineering plastics. They provide a service-oriented alternative for plastic injection molded products and services, utilizing scientific processing methods and automated molding cells to add value and reduce costs. The company offers full engineering ser…

8. Ferriot Inc. – Custom Injection Molding Solutions

Domain: ferriot.com

Registered: 1997 (28 years)

Introduction: Ferriot Inc. offers full-service engineering and custom injection molded parts, specializing in various injection molding processes including structural foam, gas assist injection, insert molding, overmolding, and large part injection molding. They provide services such as custom mold design, contract manufacturing, quality control, and value-added services like painting, decorating, pad printing,…

Strategic Sourcing Conclusion and Outlook for injection molding companies in ohio

As the injection molding industry in Ohio continues to thrive, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can leverage strategic sourcing to access high-quality plastic solutions. Ohio’s injection molding companies stand out for their commitment to innovation, precision, and customer satisfaction, ensuring that they meet diverse needs across various industries. By prioritizing quality standards and continuous improvement, these manufacturers not only enhance their service offerings but also build long-term partnerships with clients.

Investing in Ohio’s injection molding capabilities provides a competitive edge, enabling businesses to capitalize on advanced manufacturing processes and cutting-edge technologies. This is particularly vital for companies seeking reliable suppliers who can deliver timely and cost-effective solutions while adhering to stringent quality controls.

Looking ahead, international buyers are encouraged to explore the robust network of Ohio-based injection molding companies. Embracing these strategic partnerships will not only drive operational efficiencies but also foster innovation in product development. Connect with Ohio’s leading injection molding suppliers today to secure your place in a rapidly evolving global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to injection molding companies in ohio

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.