A Deep Dive into Hydrologic Lift Solution

Introduction: Navigating the Global Market for hydrologic lift

In today’s global economy, sourcing effective hydrologic lift solutions presents a unique challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. As industries seek to optimize productivity and enhance operational safety, understanding the nuances of hydrologic lift technology becomes paramount. This guide delves into various types of hydraulic lifts, their applications across different sectors, and essential supplier vetting processes, enabling buyers to navigate the complexities of this market with confidence.

The comprehensive scope of this guide encompasses critical factors such as cost analysis, performance specifications, and safety features, ensuring that international buyers can make informed purchasing decisions. By providing insights into the advantages and disadvantages of different lift types, including hydraulic elevators and scissor lifts, this resource aims to equip decision-makers with the knowledge needed to select the most suitable solutions for their specific operational needs.

Whether you are based in Nigeria, Brazil, or elsewhere, this guide serves as a vital tool for enhancing your procurement strategy, ensuring compliance with local regulations, and ultimately driving your business success in an increasingly competitive marketplace. Unlock the potential of hydrologic lift systems and elevate your operations to new heights with the insights provided herein.

Understanding hydrologic lift Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

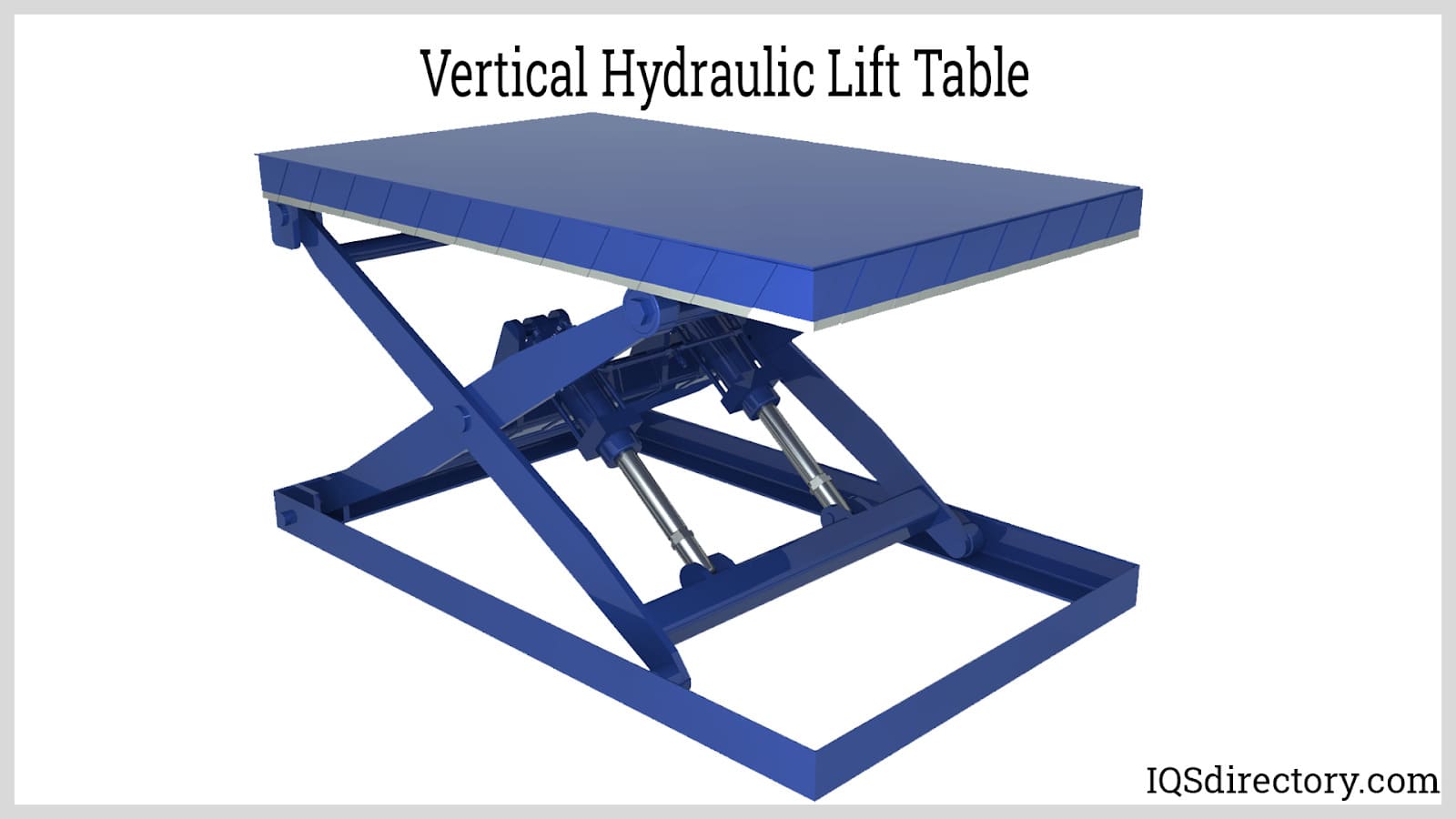

| Hydraulic Scissor Lift | Compact design, vertical lifting, stable platform | Warehousing, construction, maintenance | Pros: Versatile, safe, good for tight spaces. Cons: Limited height and speed compared to other lifts. |

| Electric Order Picker Lift | Designed for picking orders at height | Retail, distribution centers | Pros: Efficient for order fulfillment, reduces manual labor. Cons: Battery life can limit operation time. |

| Drivable Vertical Mast Lift | Can be driven while elevated, 360-degree rotation | Maintenance, construction, warehousing | Pros: Highly maneuverable, suitable for small spaces. Cons: Higher cost, requires skilled operators. |

| Mini Scissor Lift | Smaller footprint, ideal for indoor use | Retail, small maintenance jobs | Pros: Easy to transport, good for limited spaces. Cons: Lower weight capacity than larger models. |

| MRO Telescoping Lift | Extends to significant heights, portable | Industrial maintenance, construction | Pros: Reaches high areas, easy to maneuver. Cons: More expensive, requires regular maintenance. |

What Are the Key Characteristics of Hydraulic Scissor Lifts?

Hydraulic scissor lifts are characterized by their ability to elevate platforms using a crisscross mechanism that provides stability. They are ideal for applications requiring vertical lifting in warehouses, construction sites, and maintenance tasks. Buyers should consider the lift’s height capacity, weight restrictions, and safety features. The compact design allows for operation in tight spaces, making it a preferred choice for urban environments.

How Do Electric Order Picker Lifts Enhance Efficiency in Warehousing?

Electric order picker lifts are specialized for order fulfillment, enabling workers to pick items from elevated positions. They are particularly beneficial in retail and distribution centers where efficiency is paramount. When purchasing, businesses should evaluate battery life, load capacity, and ease of operation. While these lifts streamline processes and reduce manual labor, potential buyers should also consider the impact of battery maintenance on operational efficiency.

What Makes Drivable Vertical Mast Lifts a Versatile Option?

Drivable vertical mast lifts offer the ability to maneuver while elevated, providing flexibility in various applications such as maintenance and construction. Their 360-degree rotation capability allows for easy navigation in confined spaces. Buyers should assess the lift’s height range, weight capacity, and operator training requirements. Although they are more expensive, their versatility and maneuverability can lead to increased productivity.

Why Choose Mini Scissor Lifts for Small Spaces?

Mini scissor lifts are designed for indoor use, making them perfect for tasks in retail environments or small maintenance jobs. Their smaller footprint allows for easy transportation and access to tight areas. When considering a mini scissor lift, businesses should focus on weight capacity and overall height. While they are cost-effective and easy to use, their lower weight capacity compared to larger models may limit their application.

What Are the Advantages of MRO Telescoping Lifts in Industrial Settings?

MRO telescoping lifts are notable for their ability to reach significant heights, making them essential for industrial maintenance and construction projects. Their portability and ease of maneuvering enhance their appeal. Buyers should consider the lift’s maximum reach, weight limits, and maintenance requirements. Although these lifts come with a higher price tag, their capacity to access elevated areas efficiently can justify the investment in safety and productivity.

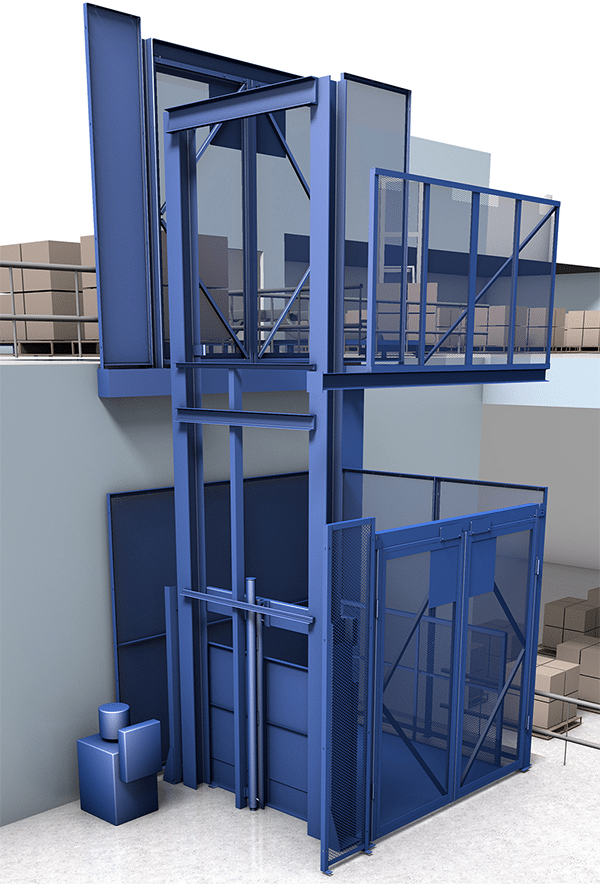

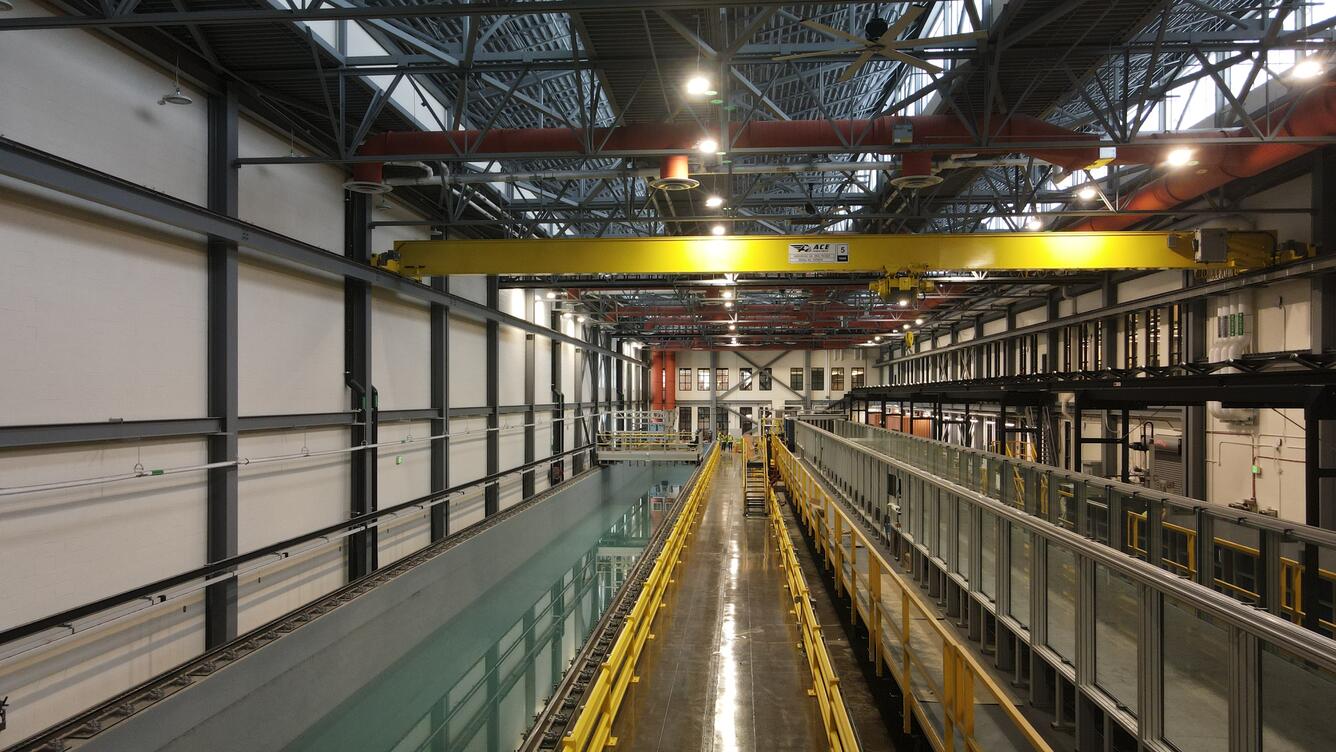

Illustrative image related to hydrologic lift

Key Industrial Applications of hydrologic lift

| Industry/Sector | Specific Application of hydrologic lift | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Access to elevated work areas for maintenance and installation | Enhances worker safety and productivity, reduces downtime | Compliance with safety standards, load capacity, terrain adaptability |

| Warehousing | Vertical lifting of heavy goods between floors | Increases efficiency in inventory management and retrieval | Space requirements, weight limits, ease of maneuverability |

| Oil & Gas | Lifting equipment to offshore platforms or drilling sites | Facilitates safe and efficient operations in challenging environments | Corrosion resistance, hydraulic fluid compatibility, reliability |

| Manufacturing | Transporting heavy machinery and components within plants | Streamlines production processes and minimizes manual handling risks | Customization for specific loads, maintenance requirements, safety features |

| Retail | Elevating stock for inventory management in large stores | Improves accessibility and organization of products, enhancing customer experience | Size and weight capacity, ease of use, compliance with safety regulations |

How is Hydrologic Lift Used in Construction Projects?

In the construction sector, hydrologic lifts are essential for providing safe access to elevated areas, such as scaffolding and rooftops. They enable workers to perform tasks like installing HVAC systems or conducting maintenance safely. This application solves the problem of limited access to heights, reducing the risk of falls and accidents. Buyers in this sector should consider compliance with local safety regulations, the lift’s load capacity, and its ability to navigate various terrains, particularly in regions like Nigeria or Brazil where construction sites may have diverse conditions.

What Role Does Hydrologic Lift Play in Warehousing Operations?

Hydrologic lifts are vital in warehousing for transporting goods between different levels. They facilitate the vertical movement of inventory, enabling efficient organization and retrieval processes. This application addresses the challenge of handling heavy items that may pose safety risks if moved manually. B2B buyers in this sector need to assess the lift’s space requirements and weight limits, especially in densely packed warehouses common in South America and Europe, ensuring that the lift can operate effectively within their specific layout.

How Does Hydrologic Lift Enhance Operations in Oil & Gas?

In the oil and gas industry, hydrologic lifts are used to transport equipment and materials to offshore platforms and drilling sites. This application is crucial for maintaining operational efficiency in challenging environments, where safety is paramount. It addresses the logistical difficulties of moving heavy loads over water and rough terrain. Buyers should prioritize sourcing lifts that offer corrosion resistance and compatibility with hydraulic fluids, as these factors are critical for reliability in harsh conditions typical of the Middle East and offshore operations.

In What Ways Does Hydrologic Lift Benefit Manufacturing Facilities?

Hydrologic lifts streamline the movement of heavy machinery and components within manufacturing plants. This application enhances production efficiency by minimizing manual handling risks and reducing the potential for workplace injuries. It also allows for the quick repositioning of equipment, which is vital for maintaining workflow. Buyers in the manufacturing sector should look for customization options to accommodate specific loads and consider the lift’s maintenance requirements to ensure longevity and consistent performance.

How is Hydrologic Lift Used in Retail Environments?

In retail, hydrologic lifts assist in elevating stock for better visibility and accessibility in large stores. This application enhances customer experience by ensuring that products are organized and easy to reach, while also improving inventory management efficiency. Retailers need to consider the lift’s size, weight capacity, and compliance with safety regulations to ensure it meets operational needs. In regions like Africa and Europe, where retail spaces can vary significantly, understanding these factors is crucial for successful implementation.

3 Common User Pain Points for ‘hydrologic lift’ & Their Solutions

Scenario 1: Challenges in Ensuring Operator Safety with Hydraulic Lifts

The Problem: Safety is a paramount concern for B2B buyers utilizing hydraulic lifts. In many industries, such as construction and warehousing, the risk of accidents can be significant. Buyers often struggle with ensuring that operators are adequately trained to use these lifts safely. Inadequate training can lead to serious injuries or even fatalities, not only causing harm to employees but also exposing companies to legal liabilities and increased insurance costs. Moreover, frequent turnover in staff can exacerbate this issue, as new operators may not be familiar with safety protocols.

The Solution: To address safety concerns, buyers should invest in comprehensive training programs that go beyond basic operational guidelines. Collaborating with manufacturers or third-party safety consultants to create tailored training modules can significantly enhance operator competency. These programs should include hands-on training sessions, safety simulations, and assessments to ensure that operators are well-versed in using hydraulic lifts. Additionally, implementing regular safety audits and refresher courses can help maintain high safety standards. Equipping lifts with advanced safety features, such as emergency stop buttons and tilt sensors, can further mitigate risks, ensuring a safer working environment for all employees.

Scenario 2: Dealing with Hydraulic Lift Maintenance Costs and Downtime

The Problem: Another common pain point for B2B buyers is managing the maintenance costs and downtime associated with hydraulic lifts. Over time, hydraulic systems can develop leaks or require part replacements, leading to unexpected expenses and project delays. This is particularly challenging for businesses operating in regions with limited access to specialized maintenance services or replacement parts, such as some areas in Africa or South America. The financial strain of these issues can affect overall operational efficiency and profitability.

The Solution: To minimize maintenance costs and downtime, buyers should adopt a proactive maintenance strategy. This includes establishing a scheduled maintenance program that involves regular inspections and servicing of hydraulic lifts. Buyers can partner with local service providers who specialize in hydraulic systems to ensure timely repairs and access to spare parts. Implementing a condition monitoring system can also help identify potential issues before they escalate, allowing for scheduled repairs instead of emergency fixes. Additionally, investing in higher-quality hydraulic lifts that come with warranties and robust support from manufacturers can reduce long-term operational costs and enhance reliability.

Scenario 3: Navigating the Complexity of Choosing the Right Hydraulic Lift

The Problem: Selecting the appropriate hydraulic lift can be a daunting task for B2B buyers, especially when considering varying load capacities, lift heights, and operational environments. Buyers often face confusion regarding which specifications best meet their needs, leading to the risk of purchasing equipment that does not perform optimally for their specific applications. This challenge is compounded in international markets where buyers may not have a clear understanding of local regulations or standards.

The Solution: To streamline the selection process, buyers should conduct a thorough needs assessment that includes an analysis of their specific operational requirements. Engaging with lift manufacturers or experienced consultants can provide valuable insights into the types of hydraulic lifts that best suit their applications. Buyers should also request demonstrations or trial periods to evaluate different models before making a purchase. Furthermore, staying informed about local regulations and compliance standards is crucial. Building relationships with local suppliers can offer additional guidance and support, ensuring that the chosen hydraulic lift aligns with both operational needs and safety regulations.

Strategic Material Selection Guide for hydrologic lift

What Are the Key Materials for Hydrologic Lifts?

When selecting materials for hydrologic lifts, it’s essential to consider their properties, advantages, and limitations. This analysis will focus on four common materials: steel, aluminum, composite materials, and stainless steel. Each material offers distinct characteristics that can significantly influence the performance and suitability of hydrologic lifts in various applications.

How Does Steel Perform in Hydrologic Lift Applications?

Steel is a widely used material in the construction of hydrologic lifts due to its high strength and durability. It typically has a temperature rating of up to 300°F and can withstand significant pressure, making it suitable for heavy-duty applications. The primary advantage of steel is its robustness, allowing for high payload capacities and longevity. However, steel is prone to corrosion, particularly in humid or wet environments, which can lead to maintenance challenges and reduced lifespan.

For international B2B buyers, especially in regions like Africa and South America, compliance with local standards such as ASTM or DIN is crucial. Buyers should also consider the availability of protective coatings to enhance corrosion resistance, which may add to manufacturing complexity and costs.

What Advantages Does Aluminum Offer for Hydrologic Lifts?

Aluminum is another popular choice for hydrologic lifts, primarily due to its lightweight nature and excellent corrosion resistance. With a temperature rating similar to steel, aluminum can handle various environmental conditions effectively. The lightweight property of aluminum allows for easier maneuverability and reduced energy consumption during operation.

However, aluminum’s lower strength compared to steel means it may not be suitable for extremely heavy loads. Additionally, the cost of aluminum can be higher than that of steel, which may deter some buyers. For international buyers, understanding local market prices and availability is vital, as aluminum may be subject to import tariffs in certain regions.

Why Consider Composite Materials for Hydrologic Lifts?

Composite materials, such as fiberglass or carbon fiber, are increasingly being utilized in hydrologic lifts due to their high strength-to-weight ratio and exceptional resistance to corrosion. These materials can operate effectively in extreme temperatures and are often used in specialized applications where traditional materials may fail.

The primary advantage of composites is their lightweight nature, which enhances portability and reduces energy consumption. However, the manufacturing complexity and higher costs associated with composite materials can be significant drawbacks. For buyers in regions like the Middle East, where specific applications may require advanced materials, it is essential to assess the availability and compliance with local standards.

What Role Does Stainless Steel Play in Hydrologic Lift Design?

Stainless steel is renowned for its corrosion resistance and durability, making it an excellent choice for hydrologic lifts exposed to harsh environments. It typically has a high temperature and pressure rating, allowing for versatile applications. The main advantage of stainless steel is its longevity and low maintenance requirements, which can lead to cost savings over time.

However, stainless steel is generally more expensive than carbon steel and aluminum, which may pose budget constraints for some buyers. Additionally, the weight of stainless steel can limit its application in scenarios where lightweight materials are preferred. International buyers should be aware of the specific grades of stainless steel that comply with local regulations to ensure optimal performance.

Summary Table of Material Selection for Hydrologic Lifts

| Material | Typical Use Case for hydrologic lift | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Lightweight lifts for easy transport | Excellent corrosion resistance | Lower strength than steel | High |

| Composite | Specialized applications in harsh environments | High strength-to-weight ratio | High manufacturing complexity | High |

| Stainless Steel | Environments requiring corrosion resistance | Low maintenance and longevity | Higher cost compared to other metals | High |

This strategic material selection guide provides B2B buyers with valuable insights into the properties and implications of various materials for hydrologic lifts. Understanding these factors can help in making informed decisions that align with specific operational requirements and regional compliance standards.

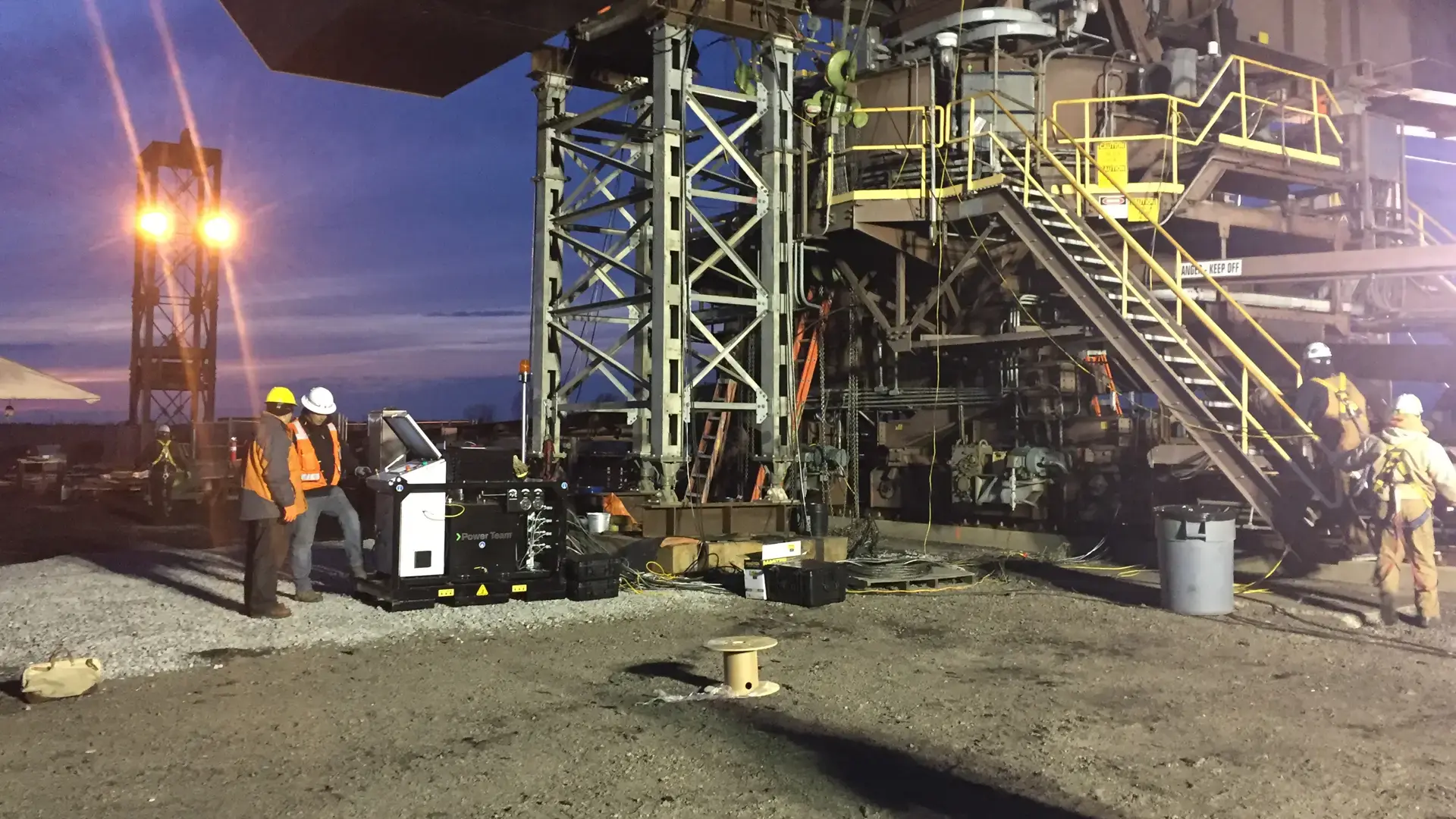

Illustrative image related to hydrologic lift

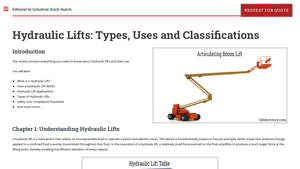

In-depth Look: Manufacturing Processes and Quality Assurance for hydrologic lift

What Are the Main Stages of Manufacturing Hydrologic Lifts?

The manufacturing process of hydrologic lifts involves several key stages that ensure the final product is both functional and safe for use. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Hydrologic Lifts?

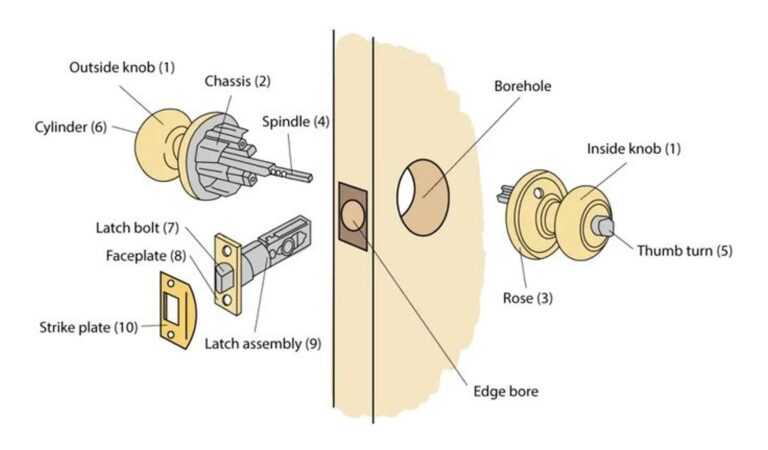

The first step in manufacturing hydrologic lifts is material preparation. Manufacturers typically utilize high-strength steel, aluminum, and other durable materials to ensure the lift can support significant weight and withstand rigorous use. The materials undergo quality checks to ensure they meet specified standards. Common preparations include cutting, bending, and machining the metal to create the necessary components, such as lift frames, platforms, and hydraulic cylinders.

What Forming Techniques Are Used in Hydrologic Lift Production?

Forming techniques play a crucial role in shaping the components of hydrologic lifts. Common methods include:

- Welding: This is essential for joining parts of the lift frame and ensuring structural integrity.

- Hydraulic Pressing: Used to form metal sheets into specific shapes for platforms and other parts.

- CNC Machining: This precision technique is employed to create intricate components that require exact specifications.

These techniques not only enhance the strength of the lifts but also ensure they can operate smoothly and safely under various conditions.

How Is the Assembly of Hydrologic Lifts Conducted?

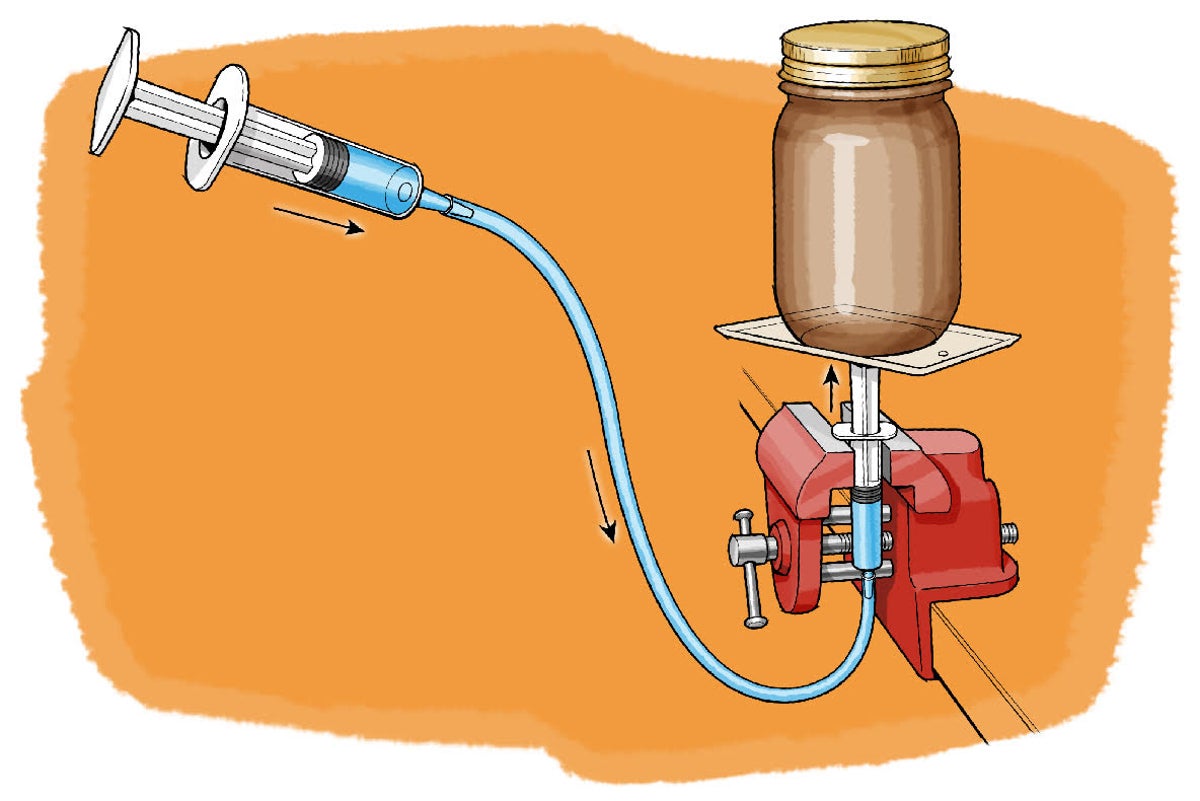

Once the components are formed, they move to the assembly stage. This stage involves:

- Component Integration: All parts, including hydraulic systems, controls, and safety features, are assembled. This is where the lift begins to take its functional form.

- System Calibration: Hydraulic systems are tested and calibrated to ensure proper pressure and functionality. This step is critical for the lift’s performance and safety.

- Installation of Safety Features: Safety mechanisms, such as emergency stops and velocity fuses, are integrated into the lift to comply with industry standards.

The assembly process is often carried out in a clean environment to prevent contamination and ensure precision.

Illustrative image related to hydrologic lift

What Finishing Processes Are Applied to Hydrologic Lifts?

After assembly, finishing processes are applied to enhance both aesthetics and durability. These processes typically include:

- Surface Treatment: Components may be coated with protective finishes to prevent rust and wear. Common treatments include powder coating or galvanization.

- Quality Inspection: Each lift undergoes thorough inspection to ensure that all components are properly installed and functioning as intended.

Finishing not only improves the appearance of the lift but also extends its lifespan, making it a more valuable investment for buyers.

What Quality Assurance Standards Are Relevant for Hydrologic Lifts?

Quality assurance is paramount in the manufacturing of hydrologic lifts. Several international standards govern the quality and safety of these products, making them crucial for B2B buyers to understand.

Illustrative image related to hydrologic lift

Which International Standards Should B2B Buyers Be Aware Of?

- ISO 9001: This standard sets the criteria for a quality management system and is essential for ensuring consistent quality in manufacturing processes.

- CE Marking: Required in Europe, CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For lifts used in specific industries, such as oil and gas, compliance with American Petroleum Institute (API) standards may be necessary.

Understanding these standards helps buyers ensure that the products they purchase are safe, reliable, and compliant with regional regulations.

What Are the Key Quality Control Checkpoints in Hydrologic Lift Manufacturing?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process. The primary QC checkpoints include:

What Is Incoming Quality Control (IQC)?

Incoming Quality Control (IQC) involves inspecting raw materials before they enter the production line. This step ensures that all materials meet the required specifications and quality standards. By catching potential issues early, manufacturers can avoid costly rework and delays.

Illustrative image related to hydrologic lift

How Is In-Process Quality Control (IPQC) Conducted?

In-Process Quality Control (IPQC) occurs during the manufacturing stages. This involves:

- Regular Inspections: Quality inspectors monitor the production process to ensure adherence to standards.

- Functional Testing: Components may be tested for functionality as they are assembled, helping to identify any defects early.

IPQC is vital for maintaining high standards throughout the manufacturing process, ensuring that issues are resolved before final assembly.

What Is Final Quality Control (FQC)?

Final Quality Control (FQC) is conducted after assembly and finishing. This stage involves comprehensive testing of the completed lifts, including:

- Load Testing: Lifts are subjected to weight tests to verify their lifting capacities.

- Safety Feature Testing: All safety mechanisms are tested to ensure they function correctly under various scenarios.

FQC ensures that only lifts that meet all quality and safety standards are delivered to customers.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control processes is crucial. Here are several methods to ensure that suppliers maintain high standards:

What Are the Best Practices for Supplier Audits?

Conducting supplier audits can provide insights into the manufacturing and quality assurance processes. Buyers should look for:

Illustrative image related to hydrologic lift

- Documentation of Quality Management Systems: Suppliers should provide evidence of compliance with ISO 9001 and other relevant standards.

- Production Processes: Understanding the supplier’s manufacturing process helps buyers assess reliability.

How Can Buyers Request Quality Reports?

Buyers should request quality reports from suppliers that detail their QC processes, testing outcomes, and compliance with industry standards. These documents serve as proof of the supplier’s commitment to quality.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide an objective assessment of the supplier’s manufacturing and QC processes. These inspections can verify compliance with international standards and ensure that products meet the required specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regional Standards: Different regions may have varying standards and regulations. Buyers must ensure that suppliers are compliant with local requirements.

- Cultural Differences: Understanding cultural attitudes towards quality and safety can influence the buyer-supplier relationship. Open communication about expectations is essential.

- Logistics and Transportation: Quality control should extend to the logistics process, ensuring that products are protected during shipping to maintain their integrity.

By being aware of these nuances, B2B buyers can make informed decisions and establish successful partnerships with suppliers of hydrologic lifts.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydrologic lift’

The following guide serves as a comprehensive checklist for B2B buyers looking to procure hydrologic lifts. It aims to streamline the sourcing process by outlining critical steps to ensure the selection of the right equipment and supplier.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for your hydrologic lift. Consider factors such as lift capacity, height range, and power source (hydraulic or electric). Establishing these parameters will help narrow down your options and ensure that the equipment meets your operational needs.

Step 2: Identify Your Application Requirements

Understand the specific applications for which the hydrologic lift will be used. Will it be for warehouse logistics, construction, or maintenance tasks? Different applications may require unique features such as portability, terrain adaptability, or load capacity. This clarity will assist in selecting a lift that enhances productivity and safety in your operations.

Illustrative image related to hydrologic lift

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, product catalogs, and client references, especially from businesses in similar sectors or regions. Assess their reputation, reliability, and experience in the industry to ensure you are partnering with a credible supplier who can deliver high-quality equipment.

Step 4: Check Compliance and Safety Standards

Ensure that the hydrologic lifts you are considering comply with relevant safety standards and regulations. Look for certifications such as OSHA compliance in the U.S. or CE marking in Europe. Safety features like velocity fuses, carriage enclosures, and interlock mechanisms are essential to minimize risks associated with lift operations.

Step 5: Compare Pricing and Total Cost of Ownership

Obtain detailed quotes from multiple suppliers and compare not only the initial purchase price but also the total cost of ownership. Consider factors such as maintenance costs, warranty provisions, and the availability of spare parts. A lower upfront cost may not always translate to better value if ongoing expenses are high.

Illustrative image related to hydrologic lift

Step 6: Request Demonstrations and Trials

If possible, arrange for product demonstrations or trials before finalizing your purchase. This hands-on experience allows you to assess the lift’s functionality, ease of use, and suitability for your specific tasks. It also provides an opportunity to evaluate customer support and training offered by the supplier.

Step 7: Finalize Your Procurement Process

Once you have gathered all necessary information and made your selection, finalize your procurement process. Review the terms and conditions, including delivery timelines, payment options, and post-purchase support. Ensure that you have a clear understanding of the logistics involved in the installation and maintenance of the hydrologic lift.

By following these steps, B2B buyers can make informed decisions when sourcing hydrologic lifts, ensuring they select the right equipment and supplier to meet their operational needs effectively.

Illustrative image related to hydrologic lift

Comprehensive Cost and Pricing Analysis for hydrologic lift Sourcing

What Are the Key Cost Components in Hydrologic Lift Manufacturing?

When sourcing hydrologic lifts, understanding the cost structure is crucial. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. High-grade steel or aluminum may increase upfront expenses but provide better durability and safety. Additionally, hydraulic components, such as pumps and cylinders, can vary in price based on quality and supplier.

-

Labor: Labor costs can fluctuate based on geographic location and skill level. In regions like Africa or South America, lower labor costs may benefit manufacturers, but this can also affect quality and production timelines.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, facility maintenance, and administrative expenses. Overhead rates can differ widely between regions, influencing the final price.

-

Tooling: Custom tooling for specific lift designs can incur substantial costs. Buyers should consider whether they require standard models or custom solutions, as this will affect both initial and long-term expenses.

-

Quality Control (QC): Investing in rigorous QC processes ensures that the lifts meet safety standards and operational efficiency. However, this comes at a cost, which can vary based on the certifications required (e.g., OSHA, ISO).

-

Logistics: Transportation costs can add significant overhead, especially for international buyers. Factors such as shipping methods, tariffs, and local regulations will influence logistics expenses.

-

Margin: Finally, suppliers will add a profit margin to cover their costs and generate revenue. This margin can vary widely based on competition and market demand.

What Price Influencers Should Buyers Consider?

Several factors can influence the pricing of hydrologic lifts, including:

-

Volume/MOQ: Bulk orders typically come with discounts. Buyers should assess their needs to leverage economies of scale effectively.

-

Specifications and Customization: Custom lifts tailored to specific applications will generally cost more than standard models. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher quality materials and compliance with certifications can increase costs but are essential for safety and longevity.

-

Supplier Factors: Supplier reputation, reliability, and after-sales support can affect pricing. Established suppliers may charge higher prices due to their proven track record.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) is crucial for calculating total costs. Incoterms dictate who bears the risk and cost of transportation.

How Can Buyers Negotiate for Better Pricing?

Negotiation is a critical skill for B2B buyers, especially in international markets. Here are some tips:

-

Research and Preparation: Understand market rates and competitor pricing before entering negotiations. This knowledge provides leverage.

-

Build Relationships: Establishing long-term partnerships with suppliers can lead to more favorable pricing and terms.

-

Focus on Total Cost of Ownership (TCO): Consider all costs associated with the lift over its lifecycle, including maintenance and operational expenses. This holistic view can justify a higher upfront investment for lower long-term costs.

-

Leverage Local Knowledge: Utilize local agents or experts who understand regional nuances and can assist in negotiations.

-

Be Flexible: Being open to different specifications or materials can enable cost savings. For example, opting for a less expensive hydraulic system could reduce overall costs.

What Are the Pricing Nuances for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, and the Middle East, must navigate unique pricing challenges. Currency fluctuations, import tariffs, and varying regional demand can significantly impact costs. Additionally, understanding local regulations and compliance standards is essential to avoid unexpected expenses. It’s advisable for buyers to consult with local experts to ensure they are well-informed about the nuances of pricing in their specific markets.

Illustrative image related to hydrologic lift

Disclaimer Regarding Indicative Prices

Prices for hydrologic lifts can vary significantly based on the factors discussed above. The prices mentioned in the reference materials are indicative and may not reflect current market conditions or specific supplier quotes. Buyers are encouraged to seek multiple quotes and conduct thorough due diligence when sourcing lifts to ensure they receive the best value for their investment.

Alternatives Analysis: Comparing hydrologic lift With Other Solutions

Introduction: Evaluating Alternatives to Hydrologic Lift Solutions

In the realm of material handling and lifting solutions, businesses often seek alternatives to hydrologic lifts due to varying operational needs, budget constraints, and specific application requirements. Evaluating different technologies can help B2B buyers identify the most effective solution that aligns with their goals, whether that involves efficiency, safety, or cost-effectiveness.

Comparison Table

| Comparison Aspect | Hydrologic Lift | Electric Lift | Mechanical Lift |

|---|---|---|---|

| Performance | Moderate lifting speed; limited height | Fast lifting speed; can reach high elevations | Unlimited lifting capability; very fast |

| Cost | Generally lower installation cost; moderate maintenance costs | Higher initial cost; lower ongoing maintenance | Higher upfront investment; low maintenance |

| Ease of Implementation | Requires a hydraulic system setup; moderate complexity | Simple installation; requires electrical setup | Requires significant structural support; complex |

| Maintenance | Needs regular oil checks; potential for leaks | Minimal maintenance; check electrical components | Low maintenance; very durable |

| Best Use Case | Ideal for low-rise buildings and warehouses | Best for high-rise buildings and quick access | Suitable for heavy loads and continuous use |

Detailed Breakdown of Alternatives

Electric Lift

Electric lifts utilize powered motors to raise and lower loads, offering a faster lifting speed compared to hydrologic lifts. They are particularly advantageous in environments where space is limited, as they can operate without requiring a separate machine room. While the initial investment may be higher, the low maintenance costs and efficient operation often justify the expense for businesses focused on high-rise applications. However, electric lifts may not be suitable for very heavy loads and can be limited by electrical infrastructure availability.

Mechanical Lift

Mechanical lifts are engineered for heavy-duty applications and can accommodate unlimited vertical rises, making them an excellent choice for large industrial settings. They operate on a mechanical system that provides rapid lifting capabilities, ideal for environments where time is of the essence. Despite their higher initial costs and the need for robust structural support, mechanical lifts require minimal ongoing maintenance, making them a long-term investment. However, they may not be suitable for businesses with limited floor space or those needing a solution for lighter loads.

Conclusion: Choosing the Right Lifting Solution for Your Business Needs

Selecting the appropriate lifting solution depends on various factors, including the specific operational requirements, budget constraints, and the physical environment of your facility. Hydrologic lifts may be ideal for businesses focused on cost-effectiveness and moderate lifting needs, while electric lifts can cater to those requiring speed and efficiency in high-rise settings. Mechanical lifts are suited for heavy-duty applications where rapid lifting is crucial. By thoroughly assessing these alternatives, B2B buyers can make informed decisions that align with their operational goals and enhance productivity in their organizations.

Essential Technical Properties and Trade Terminology for hydrologic lift

What Are the Key Technical Properties of Hydrologic Lifts?

Understanding the critical specifications of hydrologic lifts is essential for B2B buyers to make informed decisions that enhance operational efficiency and safety. Here are some vital technical properties to consider:

-

Load Capacity

The load capacity of a hydrologic lift indicates the maximum weight it can safely handle, typically expressed in pounds or kilograms. This specification is crucial for ensuring that the lift can accommodate the intended materials or personnel without risk of overload. For instance, a lift with a capacity of 2,500 lbs is suitable for heavy machinery, while lighter models may be used for smaller tasks. -

Lift Height

The lift height defines how high the platform can elevate, which is often a key factor in selecting the appropriate equipment for tasks such as maintenance or construction. A lift with a maximum height of 30 feet is ideal for accessing high ceilings in warehouses or large construction sites. Understanding lift height is essential for ensuring the equipment fits the operational environment. -

Power Source

Hydrologic lifts can operate using various power sources, including electric, diesel, or manual. The choice of power source impacts operational costs, efficiency, and environmental considerations. Electric models may be more suitable for indoor use due to lower emissions, while diesel lifts are often preferred for outdoor applications where mobility and power are critical. -

Safety Features

Safety features such as emergency stop buttons, guardrails, and tilt sensors are vital for protecting operators and preventing accidents. A lift equipped with advanced safety mechanisms can reduce liability and ensure compliance with local regulations. Buyers should prioritize models that meet or exceed safety standards relevant to their industry. -

Material Grade

The material grade of the lift’s construction—often steel or aluminum—affects durability, weight, and maintenance needs. Higher-grade materials can provide longer service life and withstand harsher environments, which is particularly important for industries such as construction and manufacturing where equipment is subject to heavy use. -

Operational Speed

The operational speed indicates how quickly the lift can ascend or descend. This specification is particularly important in fast-paced environments where time efficiency is critical. A lift that operates smoothly at a speed of 100 feet per minute can significantly enhance productivity in material handling tasks.

What Are Common Trade Terms Related to Hydrologic Lifts?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several common terms related to hydrologic lifts:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hydrologic lifts, OEM parts may be necessary for repairs or upgrades, ensuring compatibility and performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it can influence purchasing decisions and inventory management, especially for smaller companies. -

RFQ (Request for Quotation)

An RFQ is a formal document soliciting price quotes from suppliers for specific products or services. Buyers should utilize RFQs when seeking competitive pricing and detailed specifications from multiple vendors, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the shipping of goods. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, which is essential for international transactions. -

Hydraulic Fluid

Hydraulic fluid is the medium used in hydraulic systems to transfer power. The choice of hydraulic fluid affects the lift’s performance and maintenance needs, making it essential for buyers to understand its properties, such as viscosity and compatibility with materials. -

Maintenance Schedule

A maintenance schedule outlines the regular service intervals for hydrologic lifts to ensure optimal performance and safety. Buyers should prioritize manufacturers that provide clear maintenance guidelines, as this can prevent costly downtime and extend the equipment’s lifespan.

By grasping these technical properties and trade terminologies, B2B buyers can make strategic decisions that enhance their operations while ensuring compliance and safety in the use of hydrologic lifts.

Navigating Market Dynamics and Sourcing Trends in the hydrologic lift Sector

What Are the Key Market Drivers and Trends in the Hydrologic Lift Sector?

The hydrologic lift sector is experiencing significant growth driven by urbanization, industrial expansion, and technological advancements. Global demand for efficient material handling solutions is surging, particularly in developing regions like Africa and South America, where infrastructure projects are on the rise. Countries such as Nigeria and Brazil are investing heavily in construction and logistics, increasing the need for reliable lift systems that enhance productivity while ensuring worker safety.

Emerging technologies, such as IoT integration and automation, are reshaping sourcing trends in the hydrologic lift market. Buyers are increasingly seeking lifts equipped with smart technology that offers real-time data analytics for maintenance and performance monitoring. This trend is particularly relevant for B2B buyers looking to optimize operational efficiency and reduce downtime. Additionally, the rise of e-commerce and warehousing solutions is pushing the demand for vertical lifting systems that can handle diverse payloads and adapt to various operational environments.

Moreover, suppliers are focusing on customizable solutions to meet specific industry needs, allowing buyers to source equipment that aligns with their unique operational requirements. As competition intensifies, international buyers are encouraged to evaluate suppliers based on their innovation, reliability, and service capabilities, ensuring they partner with manufacturers that can support their growth in a dynamic market landscape.

How Can Sustainability and Ethical Sourcing Impact the Hydrologic Lift Sector?

In today’s business climate, sustainability and ethical sourcing have become critical considerations for B2B buyers in the hydrologic lift sector. The environmental impact of hydraulic systems—particularly concerning oil leaks and energy consumption—has prompted buyers to seek solutions that prioritize eco-friendliness. Suppliers are increasingly adopting ‘green’ certifications and materials, aligning their products with international sustainability standards.

For instance, manufacturers are now utilizing recyclable materials in their lift designs and implementing energy-efficient hydraulic systems that minimize carbon footprints. Buyers should prioritize suppliers who demonstrate a commitment to sustainability, as this not only enhances brand reputation but can also lead to cost savings through reduced energy consumption and waste.

Furthermore, establishing ethical supply chains is essential for mitigating risks associated with sourcing practices. Buyers are encouraged to conduct due diligence to ensure their suppliers uphold fair labor practices and environmental stewardship. By fostering partnerships with ethically responsible manufacturers, businesses can enhance their corporate social responsibility profiles and appeal to a growing segment of environmentally-conscious consumers.

Illustrative image related to hydrologic lift

What Is the Historical Context of Hydrologic Lifts Relevant to B2B Buyers?

The evolution of hydrologic lifts can be traced back to early mechanical lifting devices, which laid the groundwork for modern hydraulic systems. The introduction of hydraulic technology in the late 19th century revolutionized vertical transportation, allowing for more efficient lifting capabilities compared to traditional mechanical systems. As urbanization progressed, the demand for reliable and space-efficient lifting solutions grew, paving the way for hydraulic lifts to become a staple in commercial and industrial applications.

Today, hydraulic lifts are preferred for their ability to handle heavy loads while occupying less space, making them ideal for high-rise buildings and manufacturing facilities. For B2B buyers, understanding this evolution highlights the importance of selecting lift systems that not only meet current operational demands but also anticipate future advancements in technology and efficiency. The historical context also underscores the ongoing need for compliance with safety regulations and standards, ensuring that equipment remains safe and reliable for end-users.

Frequently Asked Questions (FAQs) for B2B Buyers of hydrologic lift

-

How do I choose the right hydrologic lift for my business needs?

Selecting the appropriate hydrologic lift requires an assessment of your specific operational requirements. Consider factors such as the lift’s maximum height, load capacity, and intended application—whether it’s for warehouse shelving, construction sites, or maintenance tasks. Additionally, evaluate the available space for installation and maneuverability. Engage with suppliers to understand the various models, customization options, and safety features. It’s also beneficial to review compliance with local regulations to ensure the lift meets safety standards in your region. -

What are the key safety features to look for in a hydrologic lift?

Safety is paramount when choosing a hydrologic lift. Look for features such as emergency stop buttons, anti-tipping mechanisms, and velocity fuses that prevent uncontrolled descent. Additionally, ensure that the lift has a sturdy enclosure and interlock gates to prevent accidental falls. Compliance with international safety standards, such as ASME B20.1, is crucial. Regular maintenance and operator training should also be prioritized to minimize risks associated with lift operation. -

What are the minimum order quantities (MOQ) for hydrologic lifts?

Minimum order quantities can vary widely among suppliers, often depending on the lift model and customization requirements. Typically, manufacturers may require a MOQ ranging from one unit for standard models to several units for custom designs. It’s advisable to discuss your needs with potential suppliers to negotiate favorable terms. Bulk orders may also attract discounts, making it beneficial to consider future demand when placing an order. -

How do I vet suppliers when sourcing hydrologic lifts?

Supplier vetting is essential for ensuring quality and reliability. Start by checking the supplier’s reputation through reviews and testimonials from previous clients. Request references and case studies that demonstrate their experience in the hydrologic lift industry. Additionally, verify their certifications and compliance with international safety standards. Conducting factory visits or requesting virtual tours can provide insight into their manufacturing processes and quality control measures. -

What payment terms should I expect when purchasing hydrologic lifts?

Payment terms can vary among suppliers but typically include options like upfront deposits, net 30/60/90 days, or letters of credit for larger transactions. Always clarify payment methods accepted, whether it’s bank transfers, credit cards, or escrow services. Negotiating favorable terms is crucial, especially for international transactions, to ensure cash flow management. Be aware of any additional costs such as shipping fees, customs duties, and taxes that may affect the total price. -

What are the logistics considerations when importing hydrologic lifts?

Logistics for importing hydrologic lifts involve several key factors. First, confirm the shipping method, whether by sea, air, or land, based on urgency and cost. Understand the customs regulations and documentation required in your country to avoid delays. Collaborating with a reliable freight forwarder can simplify the process, ensuring compliance and smooth transit. It’s also important to factor in lead times for production and shipping to align with your operational schedules. -

Can hydrologic lifts be customized to fit specific operational needs?

Yes, many manufacturers offer customization options for hydrologic lifts. Custom features can include modifications to height, load capacity, and operational controls tailored to your specific applications. Discuss your requirements with potential suppliers to explore available options. Customization may involve additional lead time and costs, so it’s important to plan ahead and communicate clearly with the supplier regarding your exact specifications. -

What quality assurance measures should be in place for hydrologic lifts?

Quality assurance is critical in the manufacturing of hydrologic lifts. Ensure that suppliers have robust QA processes that include material inspections, performance testing, and adherence to international standards. Request documentation of quality certifications and any third-party testing results. Ongoing maintenance and operational training should also be emphasized to uphold performance standards. Establishing a warranty or service agreement can further safeguard your investment in hydrologic lifts.

Top 3 Hydrologic Lift Manufacturers & Suppliers List

1. TP Supply Co – Hydraulic Lift Tables

Domain: tpsupplyco.com

Registered: 2004 (21 years)

Introduction: Hydraulic Lift Tables for Material Handling, available in various capacities including 2000 lbs, 3000 lbs, 4000 lbs, 5000 lbs, 6000 lbs, and 8000 lbs. Product categories include Double Scissor Lift, Dual Scissor Lifts, Low Profile Floor Height Lift, Standard-Duty Scissor Lifts, Tandem Scissor Lift, and Wide Base Lift Tables. Contact information for assistance: Call (877) 302-2337 or Chat Now!

2. Auto Body Toolmart – Vehicle Lifts

Domain: autobodytoolmart.com

Registered: 1998 (27 years)

Introduction: Vehicle Lifts – Hydraulic Car Lifts – Auto Body Toolmart offers a variety of vehicle lifts including Two-Post Lifts, Four-Post Lifts, Scissor Lifts, Alignment Lifts, and Parking Lifts, along with Lift Accessories.

3. IQS Directory – Hydraulic Lifts

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Hydraulic lifts are mechanisms that utilize incompressible fluid to operate a piston and elevate a load, based on Pascal’s principle. They consist of major components including a piston, cylinder, oil reservoir, pump, and valve. Hydraulic lifts are known for their efficiency, reliability, and low maintenance operation. They are cost-effective, space-efficient, and capable of handling heavy loads. …

Strategic Sourcing Conclusion and Outlook for hydrologic lift

As global demand for efficient lifting solutions continues to rise, strategic sourcing in the hydrologic lift sector becomes paramount for international B2B buyers. By investing in high-quality hydraulic lifts, companies can enhance productivity, streamline operations, and improve workplace safety. Key takeaways include understanding the advantages of hydraulic systems—such as cost-effectiveness and space efficiency—while remaining mindful of their limitations, including maintenance needs and operational speed.

For businesses operating in diverse markets like Africa, South America, the Middle East, and Europe, it is crucial to align sourcing strategies with local regulations and industry standards. Building relationships with reliable suppliers who emphasize safety and compliance can significantly mitigate risks associated with hydraulic lift operations.

Looking ahead, the evolution of technology in hydraulic systems promises even greater efficiency and sustainability. As you evaluate your sourcing options, consider partnering with manufacturers that prioritize innovation and environmental responsibility. Seize this opportunity to elevate your business operations by integrating advanced hydrologic lift solutions that meet the demands of a competitive global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.