A Deep Dive into Hdpe Foam Solution

Introduction: Navigating the Global Market for hdpe foam

In today’s dynamic global marketplace, sourcing high-density polyethylene (HDPE) foam presents unique challenges for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. With its exceptional durability, lightweight nature, and versatility, HDPE foam is integral to various applications, from packaging sensitive electronics to providing insulation in construction projects. However, navigating the complexities of supply chains, material specifications, and cost considerations can often prove daunting.

This comprehensive guide aims to empower B2B buyers by offering a detailed exploration of HDPE foam, including its various types, applications, and critical factors for supplier vetting. Readers will gain insights into the properties that make HDPE foam a preferred choice across industries, alongside practical advice on pricing structures and procurement strategies. Whether you are looking to purchase HDPE foam for automotive parts, medical equipment, or construction materials, this guide serves as a valuable resource to help you make informed purchasing decisions.

By equipping yourself with the knowledge contained within these pages, you can confidently navigate the global market for HDPE foam, ensuring that you select the right materials to meet your business needs while optimizing costs and enhancing product performance. With a focus on actionable insights, this guide is tailored to help you thrive in today’s competitive landscape.

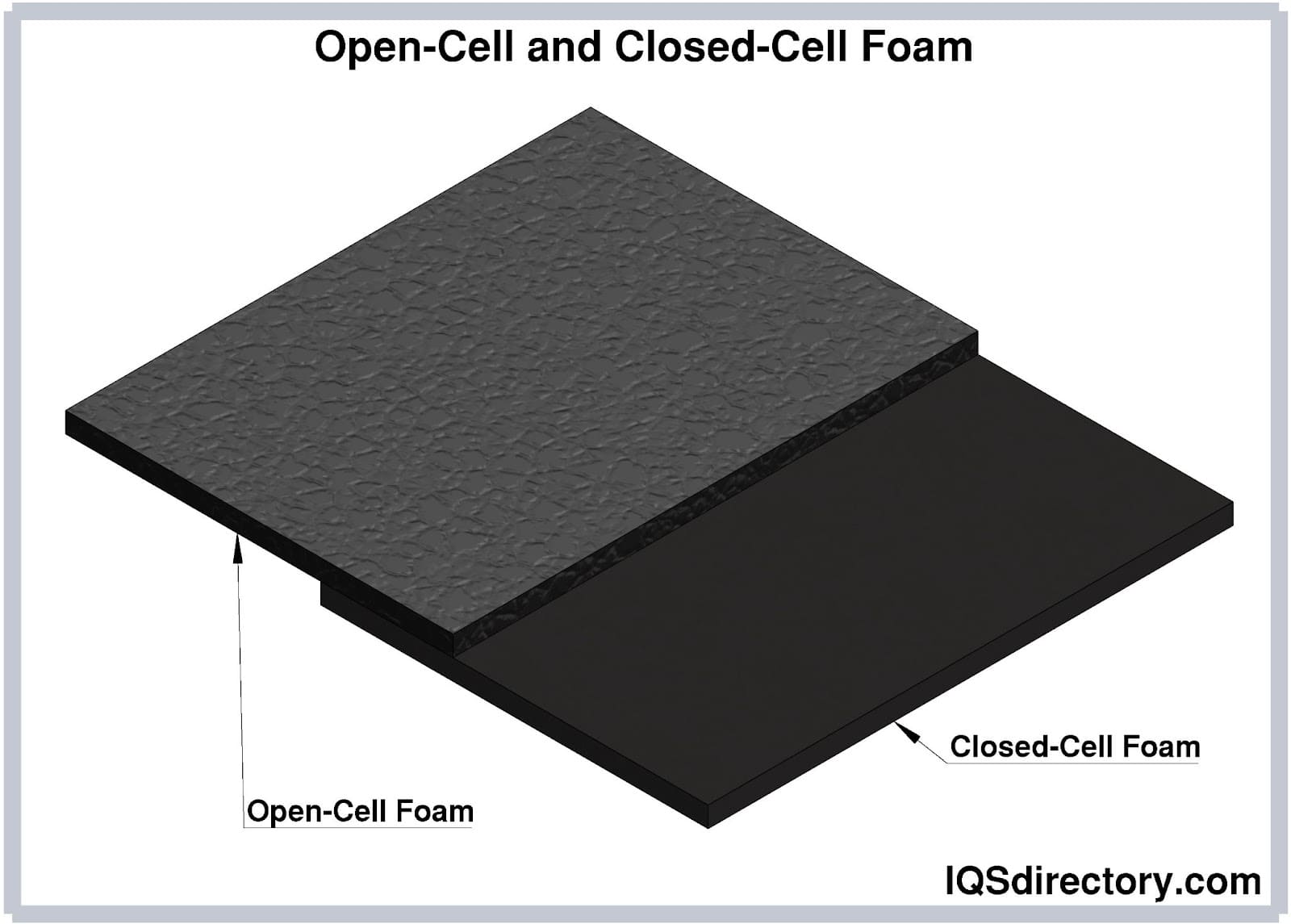

Understanding hdpe foam Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

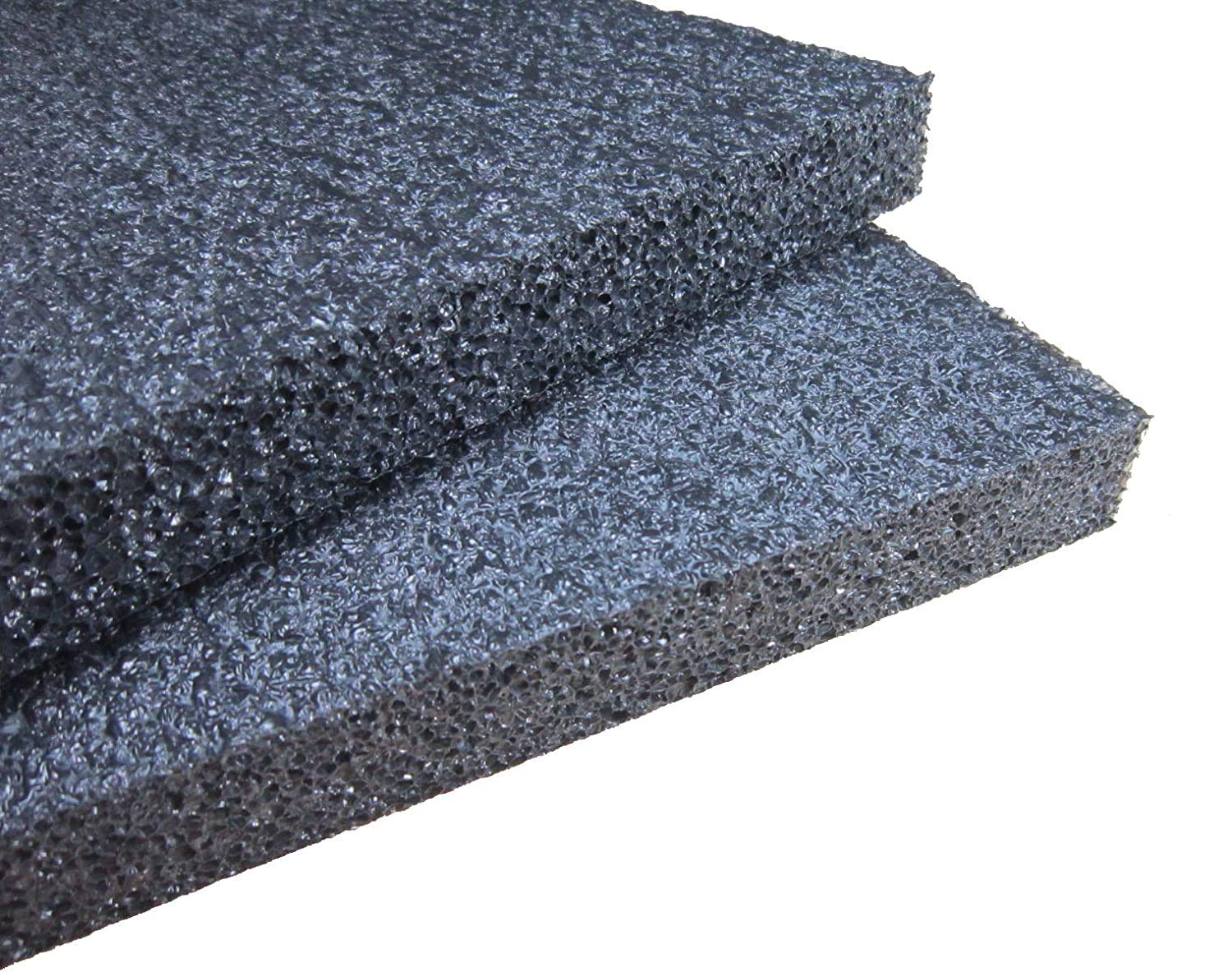

| Standard HDPE Foam | Lightweight, closed-cell structure, low moisture absorption | Packaging, construction, insulation | Pros: Durable, moisture-resistant. Cons: Limited cushioning for heavy items. |

| Anti-Static HDPE Foam | Electrically conductive, prevents static build-up | Electronics packaging, sensitive equipment | Pros: Protects against static damage. Cons: Higher cost than standard foam. |

| High-Density HDPE Foam | Increased density for enhanced strength and durability | Automotive parts, industrial applications | Pros: Superior strength-to-weight ratio. Cons: Heavier than other foam types. |

| Textured HDPE Foam | Surface texture for better grip and handling | Sports equipment, consumer goods | Pros: Improved grip and aesthetics. Cons: May be more expensive due to manufacturing complexity. |

| Custom Fabricated HDPE Foam | Tailored dimensions and properties for specific needs | Specialized packaging, bespoke solutions | Pros: Meets unique project specifications. Cons: Longer lead times and potential higher costs. |

What Are the Characteristics of Standard HDPE Foam?

Standard HDPE foam is known for its lightweight and closed-cell structure, making it an ideal choice for various applications such as packaging and insulation. Its low moisture absorption enhances its dimensional stability, particularly in outdoor or humid environments. For B2B buyers, understanding the specific density and thickness options available is crucial, as these factors can affect performance in different applications. This foam type is cost-effective, but it may not provide sufficient cushioning for heavier items.

How Does Anti-Static HDPE Foam Protect Sensitive Equipment?

Anti-static HDPE foam is specifically designed to prevent static electricity build-up, making it essential for packaging electronics and sensitive equipment. This foam variant incorporates additives that dissipate electrostatic charges, thereby safeguarding delicate components during shipping and handling. Buyers should consider the specific anti-static properties and certifications when purchasing, as these can vary. While offering significant protection, this foam type tends to be more expensive than standard options, necessitating a cost-benefit analysis for budget-conscious businesses.

Why Choose High-Density HDPE Foam for Industrial Applications?

High-density HDPE foam is characterized by its increased density, providing enhanced strength and durability, which is particularly advantageous in demanding applications such as automotive parts and industrial machinery. Its superior strength-to-weight ratio allows for efficient load-bearing while maintaining a lightweight profile. B2B buyers should assess the specific density requirements for their applications, as higher density options may come at a premium. This foam type is ideal for environments where durability and performance are critical, despite being heavier than other foam types.

What Are the Benefits of Textured HDPE Foam?

Textured HDPE foam features a surface designed to enhance grip and handling, making it suitable for sports equipment and consumer goods. The texture not only adds aesthetic value but also improves the user experience by providing better control. When sourcing this foam type, buyers should consider the texture patterns available and how they align with their product requirements. While textured options may incur higher manufacturing costs, the benefits in terms of usability and market appeal often justify the investment.

How Can Custom Fabricated HDPE Foam Meet Specific Needs?

Custom fabricated HDPE foam allows businesses to tailor dimensions and properties to meet unique project specifications. This flexibility is particularly beneficial for specialized packaging solutions or bespoke applications where standard sizes may not suffice. B2B buyers should be aware of the lead times and potential costs associated with custom orders, as these can vary significantly based on complexity. While this option can enhance product fit and protection, careful planning is required to ensure that specifications align with production capabilities.

Key Industrial Applications of hdpe foam

| Industry/Sector | Specific Application of hdpe foam | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Packaging | Protective packaging for electronics | Reduces damage during transport, enhancing product integrity | Density, anti-static properties, and custom sizes are crucial. |

| Automotive | Interior cushioning and soundproofing | Improves passenger comfort and reduces noise levels | Thickness, durability, and compliance with safety standards needed. |

| Construction | Insulation and moisture barrier in buildings | Enhances energy efficiency and moisture control | Thermal resistance, moisture absorption rates, and local regulations. |

| Medical Devices | Padding for medical equipment | Ensures safety and protection for sensitive devices | Biocompatibility and compliance with health regulations are essential. |

| Sports Equipment | Impact-absorbing layers in protective gear | Increases safety and performance for athletes | Weight, flexibility, and shock absorption properties must be evaluated. |

How is HDPE Foam Used in Packaging?

In the packaging industry, HDPE foam is utilized for protective packaging, especially for sensitive electronics. Its lightweight and shock-absorbing properties help reduce damage during transport, ensuring that products reach their destination intact. B2B buyers should consider sourcing HDPE foam with specific densities and anti-static properties to cater to electronics. Additionally, international buyers must be aware of shipping regulations and packaging standards that vary by region, particularly in Africa and South America.

Illustrative image related to hdpe foam

What Role Does HDPE Foam Play in Automotive Applications?

In the automotive sector, HDPE foam serves as interior cushioning and soundproofing material, enhancing passenger comfort and reducing noise levels. Its high strength-to-weight ratio makes it an ideal choice for automotive manufacturers looking to optimize vehicle performance without compromising safety. Buyers in this sector should focus on sourcing HDPE foam that meets automotive industry standards and consider factors like thickness and durability to ensure compliance with safety regulations prevalent in markets like Saudi Arabia and Europe.

How is HDPE Foam Applied in Construction?

In construction, HDPE foam is often used as insulation and moisture barriers within buildings. Its low moisture absorption helps maintain dimensional stability in humid environments, contributing to energy efficiency and moisture control. For international B2B buyers, understanding local building codes and thermal resistance requirements is crucial when sourcing HDPE foam for construction applications. Buyers should also consider the foam’s compatibility with other building materials to ensure optimal performance.

Why is HDPE Foam Important for Medical Devices?

HDPE foam is essential in the medical sector for padding sensitive medical equipment. It provides a protective layer that minimizes the risk of damage during transport and handling, ensuring patient safety. Buyers in this field must prioritize sourcing biocompatible HDPE foam that complies with health regulations. Understanding the specific requirements for medical applications, such as sterilization compatibility, is also vital for international buyers looking to source materials for diverse healthcare markets.

Illustrative image related to hdpe foam

How Does HDPE Foam Enhance Sports Equipment?

In the sports equipment industry, HDPE foam is integrated into protective gear as an impact-absorbing layer. This enhances safety and performance for athletes by reducing the risk of injury during play. B2B buyers should evaluate the weight and flexibility of the foam to ensure it meets the specific demands of different sports. Additionally, sourcing from reliable manufacturers that adhere to safety standards is essential for ensuring the quality and reliability of sports equipment in markets across Europe and the Middle East.

3 Common User Pain Points for ‘hdpe foam’ & Their Solutions

Scenario 1: Difficulty in Sourcing Consistent Quality HDPE Foam

The Problem:

B2B buyers often face challenges in sourcing HDPE foam that consistently meets their quality standards. Variations in density, thickness, and overall material properties can lead to significant discrepancies in product performance. For industries such as automotive or packaging, where precise specifications are crucial, receiving inconsistent quality can result in increased costs due to wasted materials and production delays. Buyers may also struggle with suppliers who lack transparency in their manufacturing processes, making it hard to ascertain whether the HDPE foam will meet their project requirements.

The Solution:

To overcome sourcing challenges, buyers should establish strong relationships with reputable suppliers who provide detailed specifications for their HDPE foam products. Requesting samples before placing bulk orders can help verify quality and consistency. Additionally, buyers should prioritize suppliers who utilize standardized production processes and possess relevant certifications, such as ISO standards, which ensure adherence to quality benchmarks. Implementing a robust quality assurance protocol upon receipt of materials can also help identify any inconsistencies early, allowing for timely resolutions with the supplier. Regular communication and feedback loops with suppliers can further enhance product quality over time.

Scenario 2: Misunderstanding the Application of HDPE Foam in Packaging

The Problem:

Many B2B buyers may not fully understand how to effectively apply HDPE foam in their packaging solutions, leading to inadequate protection for shipped goods. This lack of knowledge can result in damaged products during transit, customer dissatisfaction, and increased costs associated with returns and replacements. Buyers often struggle with selecting the right density and thickness for their specific applications, which can vary significantly based on the fragility and weight of the items being packaged.

The Solution:

To ensure optimal use of HDPE foam in packaging, buyers should start by conducting a thorough analysis of the items they need to protect. Understanding the weight, fragility, and shipping conditions will guide the selection of the appropriate density and thickness. Suppliers often provide technical datasheets and application guidelines that can serve as valuable resources. Additionally, engaging in consultation with packaging engineers or foam experts can provide insights into the best practices for using HDPE foam effectively. Investing in custom-cut solutions may also be beneficial, as tailored foam packaging can enhance product protection and reduce shipping costs.

Scenario 3: Environmental Concerns Regarding HDPE Foam Disposal

The Problem:

As sustainability becomes a priority for many businesses, B2B buyers face increasing pressure to address the environmental impact of their materials, including HDPE foam. Concerns about the recyclability of foam products and the potential for contributing to plastic waste can deter companies from choosing HDPE foam, even when its properties align well with their needs. This hesitation can lead to missed opportunities for using a versatile material that, when managed properly, can be environmentally friendly.

The Solution:

Buyers should actively seek suppliers who offer HDPE foam that is either recyclable or made from recycled materials. Many manufacturers have implemented recycling programs that allow businesses to return used foam for processing. Establishing a waste management plan that incorporates recycling options will not only help mitigate environmental impact but also enhance corporate social responsibility. Furthermore, buyers can consider using HDPE foam in applications where its longevity and durability can offset its environmental footprint. By educating their teams about proper disposal and recycling practices, businesses can confidently use HDPE foam while promoting sustainability within their operations.

Strategic Material Selection Guide for hdpe foam

What Are the Key Properties of HDPE Foam?

HDPE foam, or high-density polyethylene foam, is recognized for its unique properties that make it suitable for a variety of applications. Its closed-cell structure provides excellent moisture resistance, making it ideal for environments where exposure to water is a concern. Additionally, HDPE foam exhibits a high strength-to-weight ratio, ensuring that it remains lightweight while still offering significant durability and impact resistance. This material can withstand a wide range of temperatures, typically from -40°F to 180°F (-40°C to 82°C), which is crucial for applications in diverse climates, especially in regions like Africa and the Middle East.

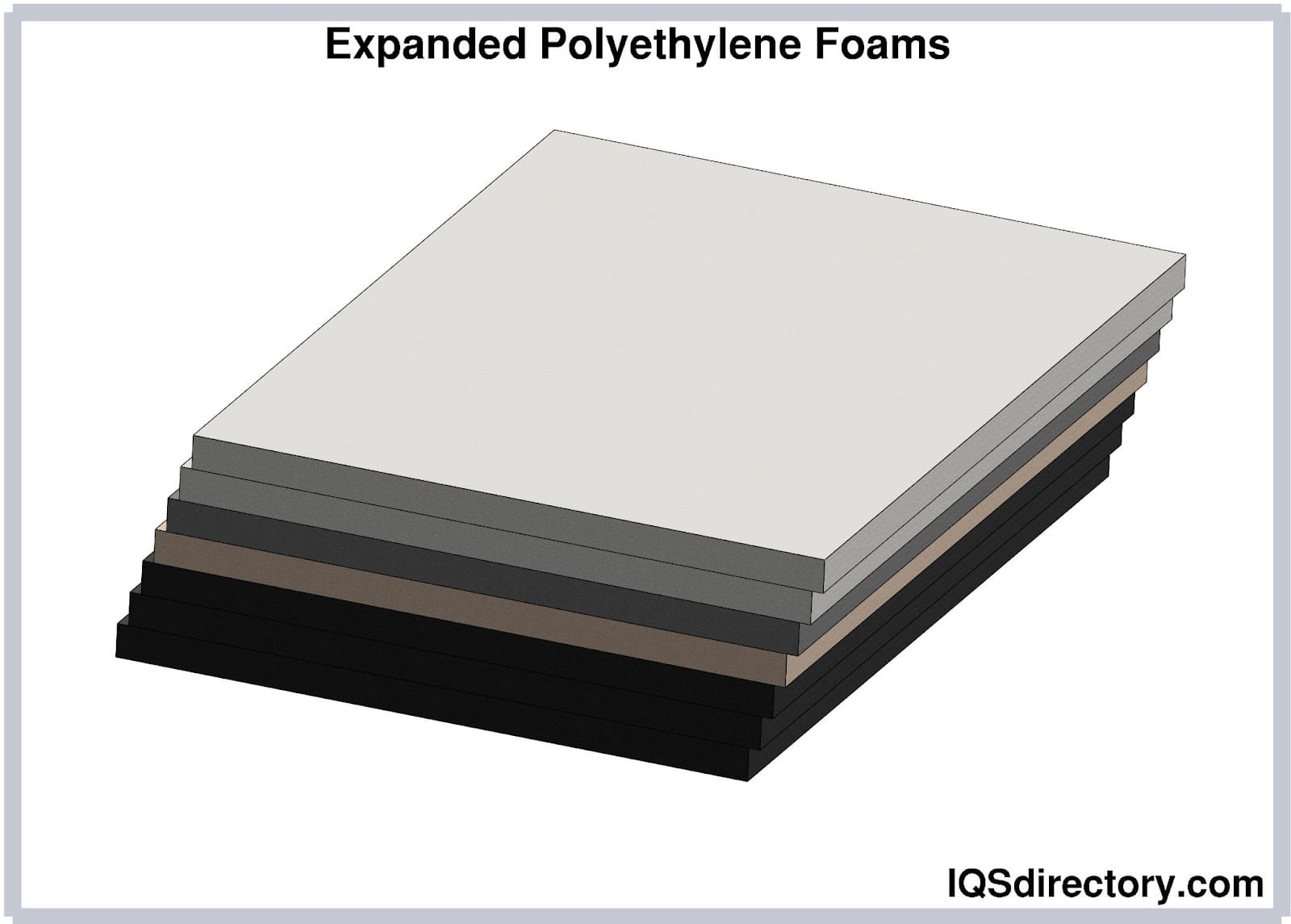

Illustrative image related to hdpe foam

What Are the Advantages and Disadvantages of HDPE Foam?

When considering HDPE foam for B2B applications, it is essential to weigh its advantages against potential drawbacks.

Advantages:

– Durability: HDPE foam is resistant to chemicals, moisture, and UV radiation, which prolongs its lifespan in outdoor and industrial settings.

– Cost-Effectiveness: While the initial cost may be moderate, the longevity and reduced maintenance needs make it a cost-effective choice in the long run.

– Manufacturing Flexibility: HDPE can be easily molded into various shapes and sizes, allowing for tailored solutions that meet specific project requirements.

Disadvantages:

– Molding Complexity: The manufacturing process can be more complex compared to other foams, requiring specialized equipment and expertise.

– Limited Temperature Resistance: Although HDPE foam performs well within a specific temperature range, it may not be suitable for extreme thermal environments.

– Environmental Concerns: While HDPE is recyclable, the recycling infrastructure may not be uniformly available in all regions, particularly in developing markets.

How Does HDPE Foam Impact Specific Applications?

The application of HDPE foam varies widely based on its properties. In packaging, its shock-absorbing qualities protect delicate items during transport. In construction, its moisture resistance makes it ideal for insulation and protective barriers. Additionally, its compatibility with various chemicals makes it suitable for industrial applications, such as storage containers for hazardous materials. For international buyers, understanding the specific media compatibility is crucial, especially in sectors like automotive and electronics, where material integrity is paramount.

What Should International B2B Buyers Consider When Selecting HDPE Foam?

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, several considerations are vital:

- Compliance with Standards: Ensure that the HDPE foam meets local and international standards such as ASTM, DIN, or JIS. This is particularly important for industries like automotive and construction, where safety and performance regulations are stringent.

- Availability of Recycling Options: In regions with limited recycling facilities, consider the environmental impact of using HDPE foam and explore suppliers that offer take-back programs.

- Cultural Preferences: Different regions may have specific preferences regarding color, texture, and density. Understanding these preferences can enhance product acceptance and marketability.

Summary Table of HDPE Foam Materials

| Material | Typical Use Case for hdpe foam | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| HDPE Foam Sheets | Packaging and insulation | High strength-to-weight ratio | Limited temperature resistance | Medium |

| Anti-Static HDPE Foam | Electronics packaging | Protects sensitive components from static | Higher manufacturing complexity | High |

| Textured HDPE Foam | Sports and recreational equipment | Enhanced grip and durability | May not be suitable for all applications | Medium |

| Colored HDPE Foam | Aesthetic applications in design | Customizable appearance | Potentially higher costs for custom colors | Medium |

This strategic material selection guide provides valuable insights for B2B buyers, facilitating informed decisions when sourcing HDPE foam for diverse applications across various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for hdpe foam

What Are the Main Stages in the Manufacturing Process of HDPE Foam?

The manufacturing process of HDPE (High-Density Polyethylene) foam involves several critical stages that ensure the final product meets industry standards and customer requirements. Here’s a breakdown of the main stages:

1. Material Preparation

The first step involves selecting high-quality HDPE resin, which is often in pellet form. This resin is subjected to quality checks to ensure it meets specifications regarding density, moisture content, and other properties. The resin may also be blended with additives to enhance specific characteristics, such as UV resistance, color, or anti-static properties.

2. Forming

The forming stage is where the actual shaping of the foam occurs. This can be done using several techniques, including:

-

Extrusion: In this method, the resin is melted and forced through a die to create sheets or rolls of foam. This process allows for continuous production and can be adjusted to create various thicknesses and densities.

-

Molding: For more complex shapes, molding techniques such as structural foam molding or blow molding can be employed. These methods allow for the creation of intricate designs while maintaining the lightweight and durable characteristics of HDPE foam.

3. Assembly

While HDPE foam products are often used as standalone items, they may sometimes require assembly with other components. This can include layering different types of foam, adhering them to other materials, or incorporating them into larger systems. Adhesives and bonding techniques are applied to ensure a secure and durable assembly.

4. Finishing

The finishing stage includes several processes to enhance the product’s appearance and functionality. This may involve cutting the foam to specific dimensions, surface treatment for improved aesthetics, and the application of protective coatings. Additionally, products may undergo further quality checks to ensure they meet customer specifications.

Illustrative image related to hdpe foam

How Is Quality Assurance Implemented in HDPE Foam Production?

Quality assurance is critical in the manufacturing of HDPE foam to ensure that products are consistent, reliable, and safe for use in various applications. Here are key aspects of quality assurance in this industry:

Relevant International Standards

Compliance with international quality standards is essential for maintaining credibility in global markets. ISO 9001 is one of the most recognized quality management standards and focuses on meeting customer and regulatory requirements. Other standards that may be applicable include:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Certification: Relevant for manufacturers supplying the oil and gas industry, ensuring that products meet specific performance and safety criteria.

Quality Control Checkpoints

Quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. Any material that does not meet the required specifications is rejected.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and ensure they adhere to predetermined quality standards. This includes checking the consistency of density, thickness, and other physical properties.

-

Final Quality Control (FQC): Once the products are completed, they undergo final inspections to verify that they meet all specified requirements. This includes dimensional checks, visual inspections, and performance testing.

What Common Testing Methods Are Used for HDPE Foam?

Various testing methods are employed to assess the quality and performance characteristics of HDPE foam. Key testing methods include:

Illustrative image related to hdpe foam

-

Density Testing: This determines the weight per unit volume of the foam, which is essential for applications requiring specific strength and buoyancy characteristics.

-

Compression Testing: This evaluates the foam’s ability to withstand loads without deformation, critical for packaging and protective applications.

-

Thermal Conductivity Testing: Important for applications where temperature control is crucial, this test measures how well the foam insulates against heat transfer.

-

Flammability Testing: Assessing the foam’s reaction to fire is vital for compliance with safety regulations in many industries.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying supplier quality control is crucial to ensure product reliability. Here are several methods to consider:

Conducting Audits

One effective way to assess a supplier’s quality control processes is to conduct on-site audits. This allows buyers to evaluate the manufacturing processes, quality assurance practices, and overall operational standards firsthand.

Requesting Quality Assurance Reports

Buyers should request detailed quality assurance reports from suppliers, including documentation of testing methods, results, and compliance with relevant standards. This transparency can help buyers understand the quality measures in place.

Utilizing Third-Party Inspection Services

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These agencies can conduct inspections and audits, offering insights into the supplier’s adherence to quality standards.

Illustrative image related to hdpe foam

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate several nuances when it comes to quality control in HDPE foam production. Key considerations include:

-

Cultural Differences: Understanding the local manufacturing culture can impact quality expectations. Buyers should be aware of variations in production practices and quality standards across different regions.

-

Regulatory Compliance: Different countries may have specific regulations governing product safety and environmental impact. Buyers need to ensure that their suppliers comply with these regulations to avoid legal issues.

-

Logistical Challenges: Shipping products internationally can introduce risks related to quality. Buyers should work closely with suppliers to establish robust packaging and transportation methods to minimize damage during transit.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for HDPE foam is essential for B2B buyers. By leveraging this knowledge, buyers can make informed decisions and establish strong partnerships with reliable suppliers in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hdpe foam’

In the dynamic world of sourcing HDPE foam, having a structured approach is essential for making informed decisions. This guide will walk you through the critical steps to effectively procure HDPE foam, ensuring that you find the right products and suppliers for your business needs.

Step 1: Define Your Technical Specifications

Before beginning the procurement process, it’s crucial to outline your specific requirements for HDPE foam. Consider factors such as density, thickness, color, and intended application. Clearly defined specifications will help you communicate effectively with suppliers and ensure you receive products that meet your needs.

- Density Requirements: Identify the weight and load-bearing capacity needed for your application.

- Thickness and Size: Determine the dimensions required for your specific project.

- Application Context: Understand whether the foam will be used for packaging, insulation, or other purposes.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of HDPE foam. Look for companies that specialize in foam products and have a proven track record in your industry. A diverse supplier base can provide you with options and leverage in negotiations.

Illustrative image related to hdpe foam

- Supplier Reputation: Check online reviews, testimonials, and case studies to gauge supplier reliability.

- Industry Experience: Prioritize suppliers with experience in your specific application area, whether it’s automotive, packaging, or construction.

Step 3: Evaluate Supplier Certifications

Ensure that your chosen suppliers possess the necessary certifications and compliance standards relevant to your industry. This step is vital to guarantee product quality and safety.

- ISO Certifications: Look for ISO 9001 certification, which indicates a commitment to quality management.

- Material Safety Data Sheets (MSDS): Request MSDS to understand the safety and handling guidelines for HDPE foam.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the HDPE foam. Testing these samples will allow you to assess their quality, performance, and suitability for your specific applications.

- Quality Assessment: Check for consistency in density, texture, and other technical specifications.

- Performance Testing: Evaluate how the foam performs under conditions similar to your intended use.

Step 5: Compare Pricing and Terms

Once you have identified potential suppliers and tested their products, compare pricing structures and terms. This step is crucial for ensuring you get the best value for your investment.

- Total Cost of Ownership: Consider not just the unit price but also shipping costs, minimum order quantities, and potential discounts for bulk purchases.

- Payment Terms: Look for favorable payment terms that align with your cash flow requirements.

Step 6: Establish Communication and Support Channels

Effective communication with your supplier is key to a successful partnership. Establish clear channels for ongoing support and inquiries related to your orders.

- Point of Contact: Ensure you have a dedicated contact person for your account.

- Support Availability: Verify that the supplier offers responsive customer service and support for any issues that may arise.

Step 7: Finalize Your Order and Monitor Delivery

Once you have selected your supplier and agreed on terms, finalize your order. Keep track of the delivery process to ensure that the products arrive on time and in the expected condition.

Illustrative image related to hdpe foam

- Order Confirmation: Confirm all details in writing, including specifications, quantities, and delivery timelines.

- Delivery Inspection: Upon receipt, inspect the products immediately to ensure they meet your specifications before accepting the shipment.

By following these steps, you can navigate the complexities of sourcing HDPE foam with confidence, ensuring that you make well-informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for hdpe foam Sourcing

What Are the Key Cost Components in HDPE Foam Sourcing?

When sourcing HDPE foam, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The raw material cost significantly influences the pricing of HDPE foam. Variations in the price of high-density polyethylene due to market fluctuations can impact overall costs. Buyers should consider sourcing from regions with stable pricing or local suppliers to mitigate risks.

-

Labor: Labor costs vary by region and can affect the overall price of HDPE foam. In countries with higher labor costs, the price per unit may increase. Buyers should evaluate the labor market conditions in the supplier’s location to understand potential cost implications.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, maintenance, and administrative costs. Efficient manufacturing processes can lower overhead costs, which may translate to better pricing for buyers.

-

Tooling: The initial investment in molds and tools for foam production can be significant, especially for customized products. Buyers should inquire about tooling costs, particularly if they require specific shapes or sizes, as these can add to the initial purchase price.

-

Quality Control (QC): Ensuring the quality of HDPE foam is crucial, particularly for applications in sensitive industries like automotive or electronics. QC processes add to manufacturing costs, but they are necessary for maintaining product integrity and compliance with industry standards.

-

Logistics: Shipping costs can vary greatly depending on the distance and method of transportation. For international buyers, understanding Incoterms is vital to determine who bears the costs and risks during shipping, which can impact the final price.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s business model, market competition, and relationship with the buyer.

What Factors Influence HDPE Foam Pricing for B2B Buyers?

Several factors can influence the pricing of HDPE foam, particularly for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often lead to volume discounts, making it advantageous for buyers to consolidate orders when possible.

-

Specifications and Customization: Custom specifications, such as thickness, density, and color, can lead to increased costs. Buyers should balance the need for customization with budget constraints.

-

Material Quality and Certifications: The quality of HDPE foam and any relevant certifications (e.g., FDA approval for food-grade applications) can affect pricing. Buyers should ensure they are sourcing materials that meet their quality requirements while considering the cost implications.

-

Supplier Factors: The reputation, reliability, and experience of the supplier can influence pricing. Established suppliers may charge a premium for their services due to their proven track record.

How Can B2B Buyers Optimize Their HDPE Foam Sourcing Costs?

To maximize cost efficiency in sourcing HDPE foam, buyers should consider the following strategies:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders. Building long-term relationships can lead to better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as shipping, handling, and potential wastage during production to understand the true cost of ownership.

-

Understand Pricing Nuances for International Transactions: For buyers in Africa, South America, the Middle East, and Europe, currency fluctuations, import duties, and tariffs can impact pricing. It’s essential to factor these into the overall cost analysis.

-

Stay Informed About Market Trends: Keeping abreast of changes in the HDPE market, such as new suppliers entering the market or shifts in raw material prices, can help buyers make informed purchasing decisions.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific requirements. It is advisable for buyers to conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing.

Illustrative image related to hdpe foam

Alternatives Analysis: Comparing hdpe foam With Other Solutions

Exploring Alternatives to HDPE Foam: A Comprehensive Comparison

In today’s market, B2B buyers face an array of options when selecting materials for their projects. Understanding the alternatives to HDPE foam can help businesses make informed decisions based on performance, cost, and application suitability. Below, we compare HDPE foam with two viable alternatives: Polyethylene Foam and Expanded Polystyrene (EPS) Foam.

| Comparison Aspect | HDPE Foam | Polyethylene Foam | Expanded Polystyrene (EPS) Foam |

|---|---|---|---|

| Performance | High strength-to-weight ratio; low moisture absorption; good impact resistance | Lightweight; excellent shock absorption; resistant to chemicals | Lightweight; good thermal insulation; lower compressive strength |

| Cost | Moderate cost, varies by thickness and density | Generally lower cost; varies by density | Typically lower cost; price can vary based on density and thickness |

| Ease of Implementation | Requires cutting tools for customization; easy to handle | Easily cut and shaped; versatile for various applications | Lightweight and easy to handle, but can be brittle and requires careful handling |

| Maintenance | Low maintenance; resistant to mold and chemicals | Low maintenance; resistant to moisture and chemicals | Low maintenance; can degrade over time if exposed to UV light |

| Best Use Case | Ideal for structural applications, chemical containers, and impact-resistant packaging | Suitable for packaging, cushioning, and insulation | Best for thermal insulation, lightweight packaging, and construction applications |

In-Depth Analysis of Alternatives

Polyethylene Foam

Polyethylene foam is a versatile, lightweight material known for its excellent shock absorption capabilities. It is often used in packaging and cushioning applications due to its ability to protect fragile items during transport. One significant advantage of polyethylene foam is its cost-effectiveness, making it an attractive option for businesses operating on tight budgets. However, while it offers good durability, it may not match the strength and moisture resistance of HDPE foam, which could be a limiting factor for certain applications.

Expanded Polystyrene (EPS) Foam

EPS foam is widely recognized for its thermal insulation properties and lightweight nature. It is often utilized in construction and packaging sectors, particularly for items that require thermal protection. The primary benefits of EPS include its low cost and ease of handling, which can lead to reduced shipping costs. However, EPS foam has a lower compressive strength compared to HDPE and can be more susceptible to damage from physical impacts. Additionally, exposure to UV light can degrade EPS over time, making it less suitable for long-term outdoor applications.

Making the Right Choice for Your Needs

When choosing between HDPE foam and its alternatives, B2B buyers should consider several factors, including the specific requirements of their application, budget constraints, and the material’s long-term performance. For projects demanding high durability and moisture resistance, HDPE foam is a superior choice. Conversely, if cost is a significant concern and the application is less demanding, polyethylene foam or EPS may provide adequate protection and insulation.

Ultimately, understanding the unique properties of each material will empower buyers to select the most suitable solution for their specific needs, ensuring optimal performance and cost-efficiency in their projects.

Essential Technical Properties and Trade Terminology for hdpe foam

What Are the Key Technical Properties of HDPE Foam?

When considering HDPE foam for your business applications, understanding its essential technical properties is crucial for making informed purchasing decisions. Here are some of the most critical specifications you should be aware of:

1. Material Grade

Material grade refers to the specific formulation of HDPE foam, which can affect its density, strength, and application suitability. Common grades include standard HDPE and specialized formulations designed for enhanced performance in specific environments. Selecting the appropriate material grade ensures that the foam meets the requirements for durability, flexibility, and resistance to environmental factors, which is vital for industries such as packaging, construction, and automotive.

2. Density

Density is a measure of mass per unit volume and is a key indicator of the foam’s strength and cushioning properties. HDPE foam densities typically range from 1.2 to 9.0 pounds per cubic foot. Higher density foams offer greater impact resistance and durability, making them suitable for heavy-duty applications, while lower density options are more lightweight and flexible for less demanding uses. Understanding the density of the foam allows buyers to match the product to their specific application needs.

3. Thickness

Thickness refers to the foam’s physical depth and can vary based on the intended application. Common thicknesses for HDPE foam range from 0.25 inches to over 2 inches. The thickness of the foam can significantly impact its insulation properties, shock absorption, and weight-bearing capacity. Buyers need to consider the thickness that will provide the necessary protection or insulation for their specific use cases.

4. Impact Resistance

Impact resistance is the ability of HDPE foam to absorb and dissipate energy from impacts, which is essential in applications such as packaging fragile items or in protective gear. HDPE foam is known for its high impact strength, making it an ideal choice for industries that require reliable cushioning and protection against shocks. This property is particularly important for businesses involved in shipping and transportation.

5. Moisture Resistance

HDPE foam exhibits low moisture absorption, making it dimensionally stable in wet environments. This characteristic is crucial for applications exposed to humidity or liquids, such as marine or outdoor uses. Moisture resistance helps maintain the integrity of the foam over time, preventing mold and mildew growth, which is a significant concern for businesses in humid climates.

What Are Common Trade Terms Related to HDPE Foam?

Understanding the terminology used in the HDPE foam industry can streamline communication and negotiations. Here are some essential terms to familiarize yourself with:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of HDPE foam, an OEM might provide custom foam solutions tailored for specific applications or products. Knowing whether a supplier operates as an OEM can help businesses identify potential partners for specialized projects.

Illustrative image related to hdpe foam

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For HDPE foam, MOQs can vary based on the supplier and the type of foam being purchased. Understanding MOQs helps buyers plan their purchases effectively, ensuring they meet supplier requirements while optimizing inventory levels.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific quantities and specifications of products. In the HDPE foam industry, submitting an RFQ is a common step for buyers seeking competitive pricing and terms. Providing detailed specifications in an RFQ can lead to better pricing and more tailored solutions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is essential for B2B buyers dealing with international suppliers of HDPE foam, as they dictate shipping costs, risk transfer, and delivery points. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who bears the costs and risks during transportation.

5. Lead Time

Lead time is the period between placing an order and receiving the product. In the HDPE foam industry, lead times can vary based on the complexity of the order and the supplier’s production capabilities. Understanding lead times is critical for effective inventory management and project planning, especially in industries that require just-in-time delivery.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing HDPE foam, ensuring they select the right products for their specific needs while navigating the complexities of international trade.

Illustrative image related to hdpe foam

Navigating Market Dynamics and Sourcing Trends in the hdpe foam Sector

What Are the Key Trends and Market Dynamics Impacting the HDPE Foam Sector?

The HDPE foam market is witnessing significant growth driven by the increasing demand for lightweight and durable packaging solutions across various industries, including automotive, construction, and electronics. As global supply chains recover from recent disruptions, international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, are prioritizing reliable sourcing strategies. Notably, the shift toward e-commerce has amplified the need for efficient packaging solutions that HDPE foam offers, such as its excellent shock absorption and moisture resistance.

Emerging technologies are reshaping sourcing dynamics, with digital platforms facilitating easier access to suppliers and products. Businesses are increasingly using online marketplaces and e-procurement tools to streamline their purchasing processes. Additionally, the trend towards customization is on the rise, as buyers seek tailored foam solutions that meet specific application requirements. This customization trend is particularly relevant for industries like automotive and construction, where precise dimensions and material properties are crucial.

Furthermore, the market is influenced by regional factors such as economic growth in emerging markets, which is driving construction and manufacturing activities. For instance, countries like Brazil and Saudi Arabia are investing heavily in infrastructure, creating new opportunities for HDPE foam suppliers. Buyers should remain attuned to these market dynamics to enhance their procurement strategies and ensure they are sourcing from the most competitive and reliable suppliers.

How Is Sustainability Influencing the Sourcing of HDPE Foam in B2B Transactions?

Sustainability has emerged as a pivotal consideration for B2B buyers in the HDPE foam sector. The environmental impact of plastic production and waste management has prompted companies to seek sustainable alternatives. As a result, the demand for HDPE foam products made from recycled materials is on the rise. Suppliers that prioritize sustainability and offer eco-friendly HDPE foam solutions are gaining traction in the market, appealing to environmentally conscious buyers.

Ethical sourcing is becoming increasingly important as companies recognize the benefits of transparent supply chains. Buyers are encouraged to partner with suppliers who demonstrate responsible sourcing practices, including adherence to environmental regulations and fair labor standards. Certifications such as ISO 14001 for environmental management and the Forest Stewardship Council (FSC) certification for sustainable materials can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the push for greener products extends to the design and production processes. Innovations in HDPE foam manufacturing that reduce energy consumption and waste are gaining attention. B2B buyers should actively seek out suppliers who are investing in sustainable practices, as this not only enhances brand reputation but also aligns with the growing consumer demand for environmentally responsible products.

What Is the Historical Context of HDPE Foam in the B2B Market?

The evolution of HDPE foam can be traced back to the development of polyethylene in the 1930s, with high-density polyethylene (HDPE) emerging as a preferred material due to its advantageous properties. Initially used in packaging and insulation, HDPE foam’s versatility has led to its adoption across various sectors, including automotive, medical, and construction.

Over the decades, advancements in manufacturing techniques have improved the quality and performance of HDPE foam, making it an integral part of modern supply chains. The introduction of closed-cell technology enhanced its durability and moisture resistance, further expanding its applications. As industries increasingly prioritize lightweight and high-performance materials, HDPE foam has established itself as a key player in the global market.

In summary, understanding the market dynamics, sustainability trends, and historical context of HDPE foam is essential for B2B buyers looking to make informed sourcing decisions. By leveraging this knowledge, businesses can better navigate the complexities of the supply chain and position themselves for success in an evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of hdpe foam

-

How do I solve supply chain issues when sourcing HDPE foam internationally?

To address supply chain issues while sourcing HDPE foam, it’s crucial to establish strong relationships with suppliers who have a proven track record in international logistics. Conduct thorough due diligence to verify their reliability and capacity to meet your demands. Consider diversifying your supplier base to mitigate risks associated with geopolitical events or natural disasters. Utilize technology for real-time tracking of shipments and ensure clear communication regarding lead times and potential delays. Additionally, work closely with freight forwarders familiar with customs regulations in your target regions. -

What is the best type of HDPE foam for packaging sensitive electronics?

For packaging sensitive electronics, anti-static HDPE foam is highly recommended due to its ability to prevent static discharge, which can damage electronic components. Look for HDPE foam sheets with a density of at least 1.7LB, as they provide adequate cushioning and protection during transit. Additionally, consider custom-cut options to fit your specific products perfectly, ensuring maximum safety. Ensure that the supplier can provide certifications confirming the foam’s anti-static properties to meet industry standards. -

What are the minimum order quantities (MOQs) for HDPE foam products?

Minimum order quantities for HDPE foam can vary significantly depending on the supplier and the specific product being ordered. Typically, MOQs range from 100 to 500 units for standard sizes and specifications. For custom foam solutions, the MOQ may increase due to the additional manufacturing processes involved. It is advisable to communicate your needs clearly with potential suppliers to negotiate MOQs that align with your project requirements while ensuring cost-effectiveness. -

How can I ensure quality assurance (QA) for my HDPE foam orders?

To ensure quality assurance for HDPE foam, establish a set of clear specifications and standards before placing your order. Request samples from suppliers to assess the quality and suitability of their products. Additionally, inquire about their QA processes, including any certifications such as ISO 9001. Consider implementing third-party inspections for large orders, especially when sourcing from international suppliers. Regular audits of your suppliers can also help maintain quality standards over time. -

What payment terms should I expect when sourcing HDPE foam internationally?

Payment terms for international sourcing of HDPE foam can vary based on supplier policies and the relationship you establish. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Letter of Credit (LC) is often used for larger transactions to mitigate risks. Be sure to discuss and negotiate payment terms that are favorable to your cash flow while ensuring security for both parties. -

How do I vet suppliers for HDPE foam in different regions?

Vetting suppliers for HDPE foam involves a multi-step process. Start by researching potential suppliers online, checking their reviews and ratings on B2B platforms. Request references from their previous clients to gauge reliability. Evaluate their production capabilities, certifications, and compliance with international standards. If possible, conduct site visits or virtual inspections to assess their facilities. Establish clear communication to understand their responsiveness and willingness to accommodate your needs. -

What are the logistics considerations when importing HDPE foam?

When importing HDPE foam, logistics considerations include understanding shipping methods, transit times, and customs regulations in both the exporting and importing countries. Choose a reliable freight forwarder experienced in handling foam products, as they can provide insights into the best shipping routes and methods. Be aware of duties and taxes applicable to your imports, and ensure proper documentation is prepared to avoid delays at customs. Additionally, consider the environmental impact of your logistics choices, particularly for sustainability-focused buyers. -

Can HDPE foam be customized for specific applications?

Yes, HDPE foam can be customized for various applications. Many suppliers offer options for cutting, shaping, and even adding features such as adhesive backing or specific color coding to meet your needs. Customization can enhance the functionality of the foam for specific uses, such as specialized packaging, insulation, or cushioning. When discussing customization with suppliers, provide detailed specifications and expected performance characteristics to ensure the final product aligns with your application requirements.

Top 8 Hdpe Foam Manufacturers & Suppliers List

1. Foam By Mail – Polyethylene Foam Solutions

Domain: foambymail.com

Registered: 2000 (25 years)

Introduction: Polyethylene Foam is a cost-effective closed-cell foam product available in various formulations, including sheets, tubes, and cylinders. Key offerings include:

– Polyethylene Foam Sheets in densities ranging from 1.2LB to 9.0LB, available in multiple colors (Green, Blue, White, Pink) with prices starting from $5.99 to $36.99.

– Anti-Static Polyethylene Foam Sheets (1.7LB Pink) for shipping sensit…

2. ACi Plastics – HDPE Foamed Sheet

Domain: aciplastics.net

Registered: 1999 (26 years)

Introduction: {‘name’: ‘HDPE Foamed Sheet’, ‘dimensions’: ‘0.750 x 49 x 67’, ‘quantity’: ‘1’, ‘price’: ‘$120.07’, ‘sku’: ‘HDLBL07504967-1’, ‘category’: ‘Foam Board, HDPE, Mechanicals’, ‘type’: ‘Foamed’, ‘thickness’: ‘0.750’, ‘color’: ‘Light Blue’, ‘texture’: ‘Textured’, ‘width’: ’49’, ‘length’: ’67’, ‘weight’: ‘214 lbs’, ‘material’: ‘HDPE’, ‘features’: ‘Excellent impact resistance, high tensile strength, low mo…

3. Foam For You – 4lbs Density Polyethylene Planks

Domain: foamforyou.com

Registered: 2005 (20 years)

Introduction: Product Name: 4lbs Density Polyethylene Planks – Laminated

Price: $17.85

SKU: 4LBS Density Polyethylene Planks – Laminated

Color Options: Black, White

Available Thickness: 1/4″, 1/2″, 3/4″, 1″, 1-1/2″, 2″, 3″, 4″

Available Sizes: 24″ x 108″, 48″ x 108″

Shipping Cost: Usually higher than $23.00; a representative will contact for shipping above this amount.

Key Features:

– Optimal cushioning protec…

4. Foamty – PE & HDPE Foam Solutions

Domain: foamty.com

Registered: 2015 (10 years)

Introduction: {“Product Type”:”PE Foam, HDPE Foam Board, LDPE Foam Sheet, PE Foam Roller”,”Foaming Type”:”One / Two-stage foaming”,”Cell Structure”:”Open-cell & Close-cell”,”Standard Form”:”Block (can be coiled through processing)”,”Thickness”:”65~110mm”,”Customized Thickness”:”0.5mm~320mm”,”Density”:”11-130 kg/m3″,”Hardness”:”14-90 Shore C”,”Color”:”Customizable”,”Expansion Ratio”:”6-45″,”Temperature Resistanc…

5. The Foam Factory – Polyethylene Foam

Domain: thefoamfactory.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Polyethylene Foam”, “types”: [“Roll”, “Tubes”, “Sheets”], “thicknesses”: [“1/4”, “1/2”, “3/4”, “1”, “1-1/2”, “2”], “features”: [“Strong and resilient closed-cell foam”, “Shock-absorbing material”, “Available in sheets, cylinders, and tubes”, “Versatile applications”, “Anti-Static formulation for electronics”, “Made in the USA”], “characteristics”: [“Closed-cell, chemically cross-…

6. The Malibu Crew – Marine-Grade Materials

Domain: themalibucrew.com

Registered: 2005 (20 years)

Introduction: 1. HDPE (High-Density Polyethylene): A type of plastic that can be made smooth or textured. It is sturdy but may fade or chalk over time when exposed to sunlight. 2. King Starboard: A marine-grade material that includes UV inhibitors, making it more resistant to fading and chalking. It is considered a solid and reliable option for marine applications. 3. HDPE Foam: Suggested as a lighter alternati…

7. Penove – HDPE Foam Board

Domain: penove-desky.cz

Registered: 2018 (7 years)

Introduction: {“Product Name”: “HDPE Foam Board”,”Dimensions”: “2000 x 1200 x 50 mm”,”Material”: “Expanded Polyethylene (PE) Foam”,”Density”: “60 kg/m3″,”Features”: [“Lightweight”,”Flexible”,”Easy to handle”,”Waterproof”,”High variability”,”Dampens repeated impacts”,”Recyclable”],”Applications”: [“Corner and edge protection”,”Scratch and abrasion protection”,”Interleaving between products”,”Thermal and acoustic…

8. IQS Directory – Polyethylene Foam

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Polyethylene foam is a closed-cell thermoplastic foam known for its impact resistance, durability, and lightweight properties. It is impervious to air, moisture, and chemicals, making it suitable for various applications. Key types include: 1. Cross-Linked Polyethylene (XLPE) Foams: Durable, resistant to chemicals and moisture, enhanced thermal insulation, used in automotive, medical, and electron…

Strategic Sourcing Conclusion and Outlook for hdpe foam

What Are the Key Benefits of Strategic Sourcing for HDPE Foam?

In the dynamic landscape of HDPE foam sourcing, strategic partnerships and informed decision-making are paramount. By leveraging the unique properties of HDPE foam—such as its high strength-to-weight ratio, low moisture absorption, and versatility across multiple applications—international B2B buyers can enhance their product offerings while optimizing costs. This material is not only lightweight and durable but also resistant to environmental factors, making it an ideal choice for various sectors including automotive, packaging, and construction.

How Can International Buyers Maximize Their Sourcing Strategies?

For buyers in Africa, South America, the Middle East, and Europe, focusing on reliable suppliers who prioritize quality and sustainability can significantly impact business success. Establishing long-term relationships with manufacturers can lead to better pricing, tailored solutions, and improved supply chain efficiency. As global demand for eco-friendly materials rises, prioritizing suppliers who adopt sustainable practices will not only meet regulatory requirements but also enhance brand reputation.

What Should Be the Next Steps for B2B Buyers?

Looking ahead, the HDPE foam market presents promising opportunities for growth and innovation. As you strategize your sourcing approach, consider engaging with suppliers who offer customization options and can provide insights into emerging trends. By aligning your sourcing strategies with the evolving market landscape, you position your business for success in a competitive environment. Take action today by exploring partnerships that will drive value and sustainability in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.