A Deep Dive into Hardware Cloth 6 Solution

Introduction: Navigating the Global Market for hardware cloth 6

In the ever-evolving landscape of global trade, sourcing hardware cloth 6 can pose significant challenges for international B2B buyers. As businesses in Africa, South America, the Middle East, and Europe strive to meet their operational needs, understanding the nuances of this versatile product becomes essential. Hardware cloth 6 serves a multitude of applications, from securing gardens against pests to reinforcing structures in agricultural and construction projects. However, navigating the complexities of material specifications, supplier reliability, and pricing can be daunting.

This comprehensive guide aims to demystify the hardware cloth market by exploring various types, applications, and critical factors to consider when sourcing. We will delve into the specifics of gauge sizes, material compositions, and the myriad uses of hardware cloth across different industries. Moreover, we will provide actionable insights on how to effectively vet suppliers, ensuring that buyers can confidently select partners who align with their quality standards and logistical requirements.

By empowering B2B buyers with the knowledge to make informed purchasing decisions, this guide seeks to streamline the sourcing process for hardware cloth 6. With a focus on practical solutions tailored to the unique challenges faced by businesses in regions such as Nigeria and Vietnam, we aim to facilitate successful transactions that enhance operational efficiency and drive growth.

Understanding hardware cloth 6 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized Steel Hardware Cloth | Durable, rust-resistant, available in various mesh sizes | Agricultural fencing, garden protection | Pros: Long lifespan, strong against corrosion. Cons: Can be heavier and more difficult to work with. |

| PVC Coated Hardware Cloth | Coated with PVC for added protection and aesthetics | Garden fencing, animal enclosures | Pros: Enhanced durability, visually appealing. Cons: Higher cost compared to uncoated options. |

| Stainless Steel Hardware Cloth | High resistance to rust and corrosion, very strong | Industrial applications, high-end gardens | Pros: Exceptional longevity, ideal for harsh environments. Cons: Most expensive option. |

| Aluminum Hardware Cloth | Lightweight, resistant to rust, easy to cut and handle | Temporary fencing, craft projects | Pros: Easy to work with, good for DIY applications. Cons: Less durable than steel options. |

| Copper Hardware Cloth | Unique aesthetic, natural anti-corrosive properties | Decorative applications, pest barriers | Pros: Attractive finish, effective against pests. Cons: Limited availability and higher price point. |

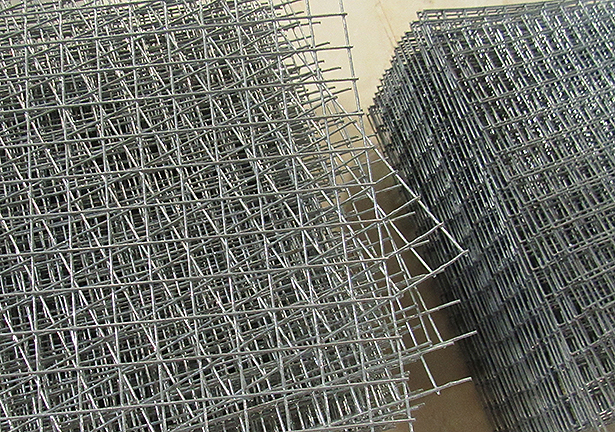

What are the Key Characteristics of Galvanized Steel Hardware Cloth?

Galvanized steel hardware cloth is one of the most common types used in various applications. Known for its durability, it features a protective zinc coating that helps prevent rust and corrosion, making it suitable for outdoor use. The mesh size typically ranges from 1/4 inch to 1/2 inch, providing flexibility for different projects. B2B buyers should consider its strength and longevity, especially for agricultural fencing and garden protection, where exposure to the elements is a concern.

How Does PVC Coated Hardware Cloth Enhance Durability?

PVC coated hardware cloth adds an extra layer of protection to the galvanized steel, enhancing its resistance to corrosion and wear. This type is particularly popular for garden fencing and animal enclosures, as the PVC coating also provides an aesthetically pleasing finish. When purchasing, businesses should evaluate the cost-effectiveness of the coating versus the longevity it offers, as it can be more expensive than standard galvanized options.

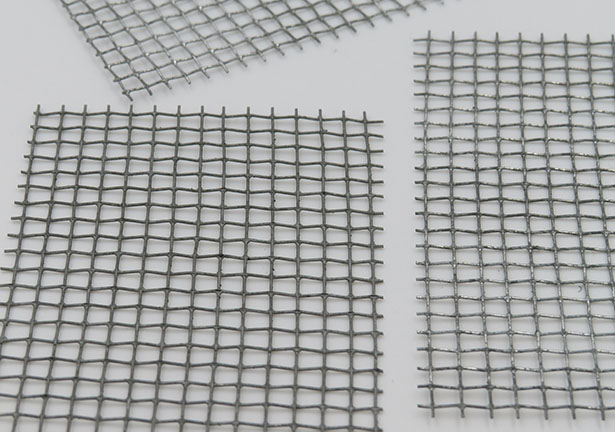

Illustrative image related to hardware cloth 6

Why Choose Stainless Steel Hardware Cloth for Industrial Applications?

Stainless steel hardware cloth is favored in environments where corrosion resistance is critical, such as food processing plants or coastal areas. This type is incredibly strong and can withstand harsh conditions, making it suitable for high-end gardens and industrial applications. While it comes at a higher price point, its longevity and reliability make it a worthwhile investment for B2B buyers focused on durability.

What Advantages Does Aluminum Hardware Cloth Offer for Temporary Projects?

Aluminum hardware cloth is lightweight and easy to handle, making it ideal for temporary fencing and various craft projects. It is resistant to rust, but its strength is not on par with steel options. B2B buyers should consider its application carefully, as it is best suited for short-term use or less demanding environments where ease of installation is a priority.

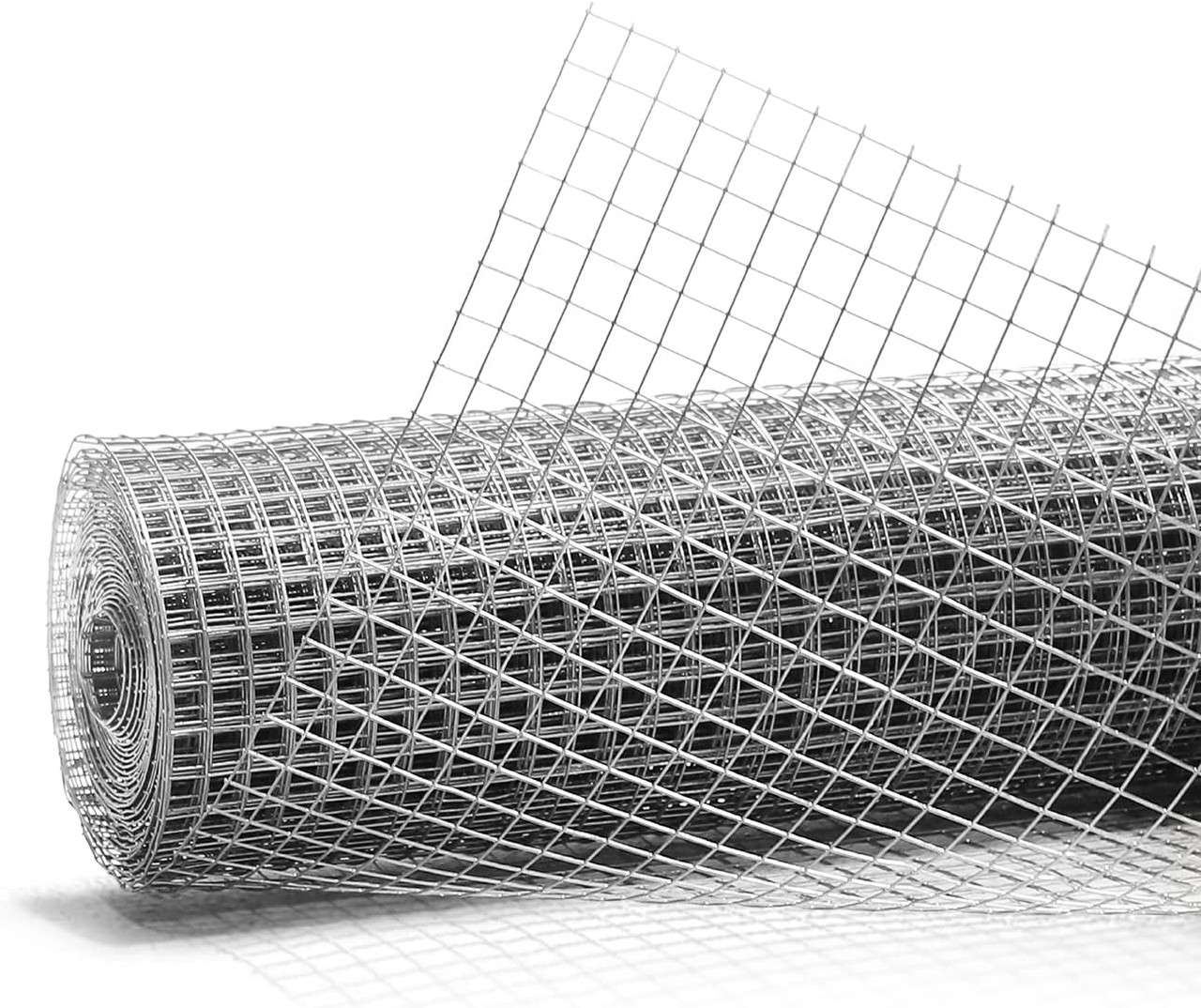

In What Situations Would Copper Hardware Cloth Be the Preferred Choice?

Copper hardware cloth is not only functional but also aesthetically pleasing, often used in decorative applications or as a pest barrier. Its natural anti-corrosive properties make it effective against pests, but its availability can be limited, and it tends to be on the pricier side. Businesses should weigh its decorative benefits against practicality when considering it for projects.

Key Industrial Applications of hardware cloth 6

| Industry/Sector | Specific Application of hardware cloth 6 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop Protection Fencing | Shields crops from pests, enhancing yield | Gauge and mesh size for specific pest types; corrosion resistance for longevity. |

| Construction | Reinforcement in Concrete and Masonry | Improves structural integrity and durability | Material compatibility with local construction standards; sourcing from reliable suppliers. |

| Animal Husbandry | Enclosures for Poultry and Small Livestock | Provides safe and secure housing for animals | Strength of material to withstand animal behavior; appropriate mesh size to prevent escapes. |

| Landscaping and Gardening | Soil Sifting and Root Protection | Facilitates healthy plant growth while deterring pests | Ease of installation; UV resistance for outdoor applications. |

| Home Improvement and DIY | Craft Projects and Home Repairs | Versatile use for various projects, enhancing creativity | Availability in various sizes; ease of cutting and handling for DIY projects. |

How is hardware cloth 6 utilized in agriculture for crop protection?

In the agricultural sector, hardware cloth 6 is primarily used as a fencing solution to protect crops from small animals and pests. The mesh size is designed to deter critters while allowing air and light to reach the plants. This application is crucial for farmers looking to maximize their yield by minimizing crop damage. International buyers should consider the gauge and mesh size based on the specific types of pests prevalent in their region, as well as the corrosion resistance of the material to ensure longevity in varying climates.

What role does hardware cloth 6 play in construction for reinforcement?

In construction, hardware cloth 6 serves as an essential reinforcement material for concrete and masonry projects. It enhances the structural integrity of walls and slabs, providing additional strength to withstand various loads. Builders and contractors must ensure that the material complies with local construction standards and regulations. Sourcing from reputable suppliers is vital to guarantee the quality and reliability of the hardware cloth, particularly in regions with stringent building codes.

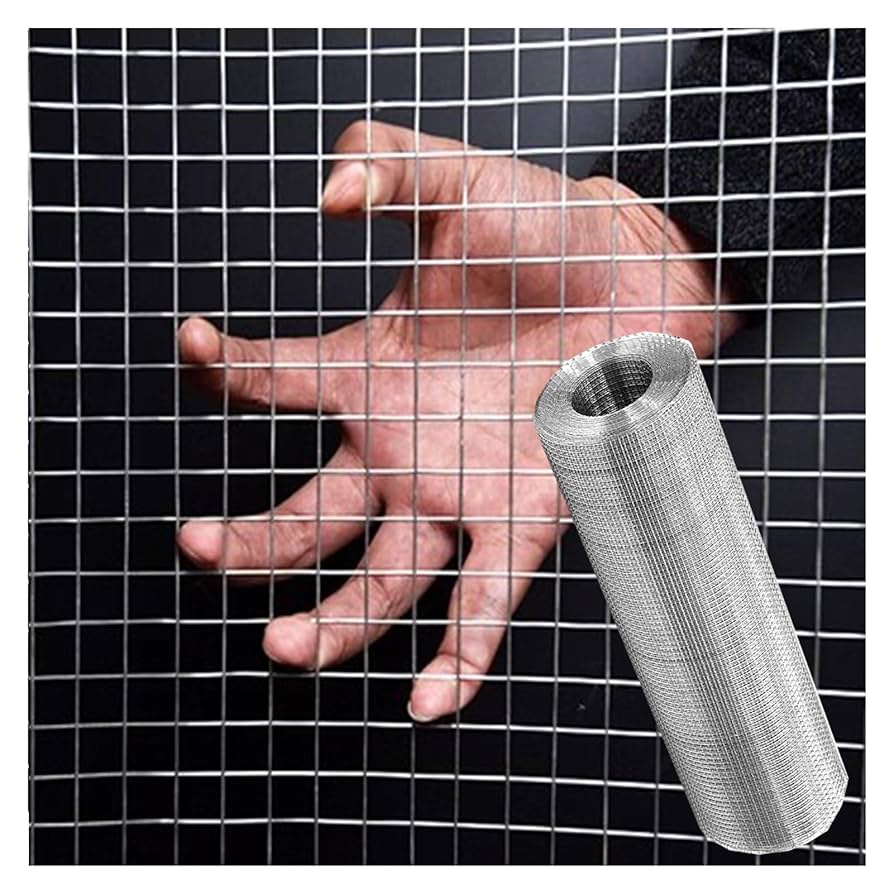

Illustrative image related to hardware cloth 6

How does hardware cloth 6 contribute to animal husbandry?

For animal husbandry, hardware cloth 6 is widely used to create secure enclosures for poultry and small livestock. Its robust structure prevents animals from escaping while protecting them from predators. Buyers in this sector should focus on the strength of the material, ensuring it can withstand the behavior of the animals housed. Additionally, the mesh size is critical to prevent smaller animals from getting trapped or escaping, making it essential to choose the right specifications based on the livestock type.

In what ways is hardware cloth 6 beneficial for landscaping and gardening?

In landscaping and gardening, hardware cloth 6 is employed for soil sifting and root protection. It acts as a barrier that allows roots to grow while deterring pests from damaging the plants. This application is particularly beneficial for gardeners looking to cultivate healthy plants without chemical pesticides. Buyers should consider the UV resistance of the material, especially in regions with high sun exposure, to ensure that it maintains its integrity over time.

How can hardware cloth 6 enhance home improvement and DIY projects?

Hardware cloth 6 is a versatile material in home improvement and DIY projects, used for crafting and repairs. Its lightweight yet durable nature allows for easy handling and cutting, making it ideal for various creative applications. Buyers should look for availability in different sizes to accommodate their specific project needs. Additionally, the ease of installation and adaptability to different environments makes it a popular choice among DIY enthusiasts, particularly in regions where innovative home solutions are sought after.

Illustrative image related to hardware cloth 6

3 Common User Pain Points for ‘hardware cloth 6’ & Their Solutions

Scenario 1: Sourcing Durable Hardware Cloth for Agricultural Use

The Problem: B2B buyers in agriculture often struggle to find durable hardware cloth that withstands harsh environmental conditions, particularly in regions with extreme weather. For instance, in parts of Africa and South America, buyers may face challenges with products that rust or degrade quickly, leading to frequent replacements. This not only disrupts operations but also increases costs and affects productivity. Moreover, the variety of mesh sizes available can make it difficult for buyers to select the right product to protect their crops from pests without hindering airflow or water drainage.

The Solution: To ensure the procurement of high-quality hardware cloth, buyers should look for products made from galvanized steel with a heavy-duty PVC coating, which provides excellent rust resistance and durability. When sourcing, consider suppliers that provide detailed specifications, including gauge, mesh size, and corrosion resistance ratings. For agricultural applications, a mesh size of 1/2 inch is typically effective for keeping out small animals while allowing for proper ventilation. Additionally, establishing a relationship with local suppliers can provide insights into the best-performing products in specific regions. Regular quality checks and maintenance of the installed hardware cloth can also prolong its lifespan, ensuring it remains effective against pests.

Scenario 2: Implementing Effective Pest Control Solutions

The Problem: Many businesses, particularly those in horticulture and landscaping, face significant challenges with pest infestations that threaten their operations. The inability to find a reliable barrier that is both effective and aesthetically pleasing can lead to crop damage and increased costs. For instance, a landscaping company in the Middle East may find that traditional fencing does not adequately prevent small rodents and birds from accessing their plants, resulting in substantial losses.

The Solution: To combat pest issues effectively, consider using hardware cloth as a protective barrier around gardens and plant beds. The 1/4 inch mesh size is particularly effective for excluding small pests while remaining visually unobtrusive. When implementing this solution, ensure that the cloth is installed securely to the ground to prevent any gaps that pests might exploit. Using stakes or burying the edges of the cloth can enhance its effectiveness. Furthermore, pairing hardware cloth with other pest deterrents, such as natural repellents or companion planting, can create a comprehensive pest management strategy. Regular monitoring and maintenance will also help in identifying any wear and tear that could compromise the barrier’s effectiveness.

Scenario 3: Versatile Applications for Construction and Home Improvement

The Problem: Construction companies often require versatile materials that can serve multiple functions in various projects. Many buyers find it difficult to identify the right type of hardware cloth that can be utilized for different applications, such as insulation, fencing, and even decorative projects. For example, a contractor in Europe may need hardware cloth for both reinforcing structures and creating enclosures for pets, leading to confusion over which product best meets their diverse needs.

The Solution: To address this challenge, buyers should consider hardware cloth as a multifunctional tool in their inventory. Products with a 1/2 inch mesh size can be utilized for animal enclosures, while finer mesh options (like 1/4 inch) can serve well in applications requiring more protection, such as soil sifting or as a barrier for insulation. When purchasing, it is beneficial to work with suppliers who offer bulk purchasing options or custom cuts to meet specific project requirements. Additionally, educating staff on the various applications of hardware cloth can enhance its usage across projects. Providing clear guidelines on installation and maintenance can also help maximize the value derived from this versatile material, ensuring it meets the needs of various applications effectively.

Strategic Material Selection Guide for hardware cloth 6

What Are the Key Materials Used for Hardware Cloth 6?

When selecting hardware cloth 6, understanding the materials used is crucial for ensuring optimal performance in various applications. Below, we analyze four common materials: galvanized steel, stainless steel, aluminum, and PVC-coated wire. Each material has unique properties, advantages, and limitations that can influence their suitability for specific projects.

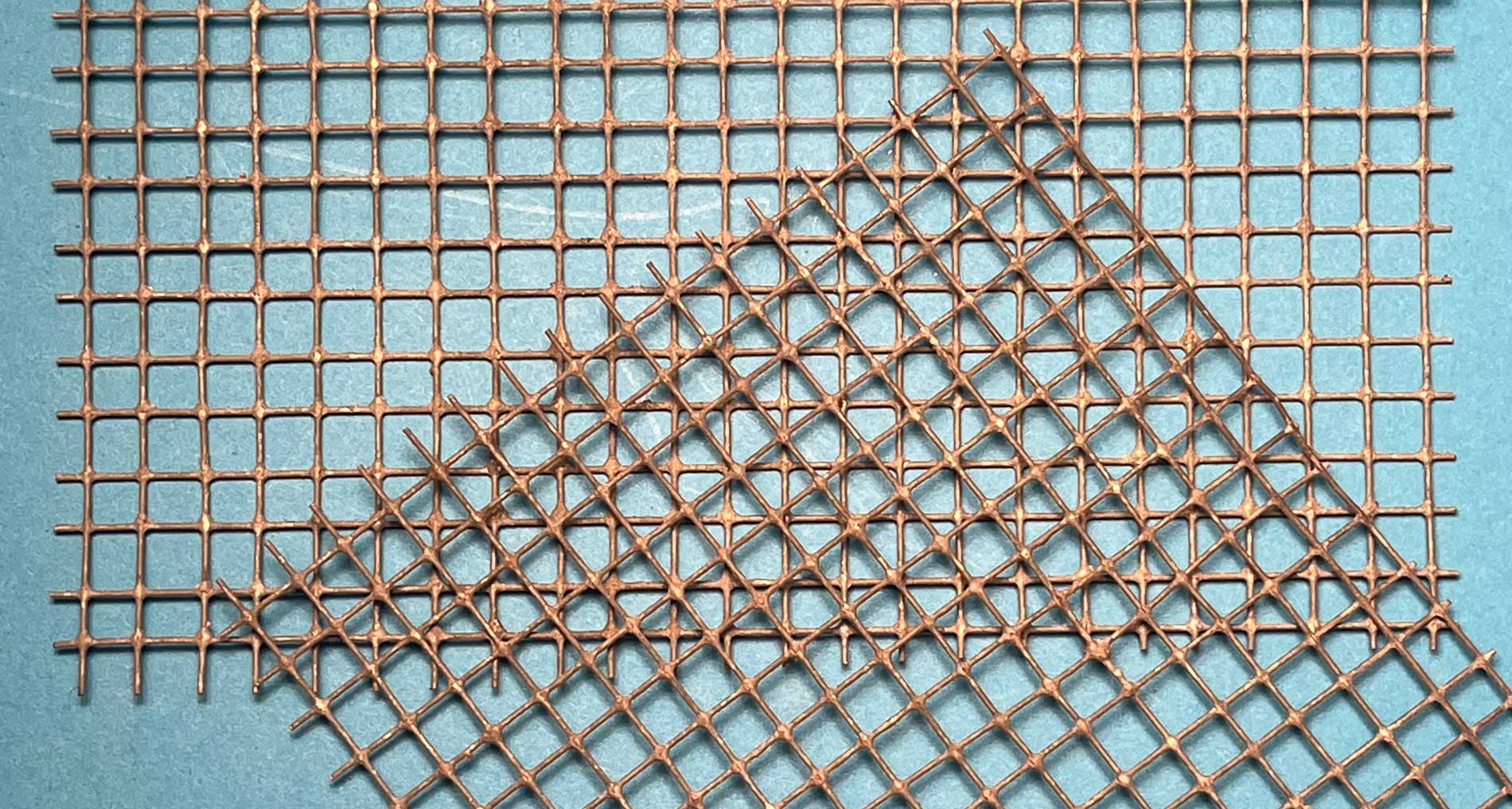

How Does Galvanized Steel Perform in Hardware Cloth 6 Applications?

Galvanized steel is one of the most commonly used materials for hardware cloth due to its excellent corrosion resistance. The galvanization process involves coating the steel with zinc, which protects it from rust and extends its lifespan significantly, often exceeding 10 years under normal conditions.

Pros: Galvanized steel is durable, cost-effective, and readily available. It is suitable for various applications, including fencing, garden protection, and animal enclosures.

Cons: However, it can be prone to rust if the coating is damaged. Additionally, galvanized steel may not perform well in highly acidic environments.

Illustrative image related to hardware cloth 6

For international buyers, especially in regions like Africa and South America, compliance with local standards such as ASTM or DIN is essential. Buyers should ensure that the galvanized steel meets these standards to avoid issues with durability and performance.

What Are the Benefits of Using Stainless Steel for Hardware Cloth 6?

Stainless steel offers superior corrosion resistance compared to galvanized steel, making it ideal for applications in harsh environments or where hygiene is a concern, such as food processing and pharmaceuticals.

Pros: Its durability and aesthetic appeal make it suitable for both functional and decorative applications. Stainless steel hardware cloth can withstand extreme temperatures and is resistant to rust and staining.

Cons: The primary drawback is its higher cost compared to galvanized options. Additionally, while it is easier to work with than other materials, it requires specialized tools for cutting and installation.

Illustrative image related to hardware cloth 6

International buyers should consider the specific grades of stainless steel (such as 304 or 316) based on their application needs and local availability. Compliance with international standards is critical for ensuring product quality.

How Does Aluminum Stack Up for Hardware Cloth 6 Uses?

Aluminum is lightweight and resistant to corrosion, making it a viable option for hardware cloth applications where weight is a concern, such as in portable fencing or temporary structures.

Pros: Its lightweight nature makes it easy to handle and install. Aluminum also does not rust, providing a longer lifespan in outdoor applications.

Cons: However, aluminum is less durable than steel and can be more susceptible to physical damage. It is also generally more expensive than galvanized steel.

For international buyers, especially in the Middle East, the lightweight nature of aluminum can be advantageous in regions where transport costs are a concern. Compliance with local standards is also essential to ensure quality.

What Role Does PVC Coating Play in Hardware Cloth 6?

PVC-coated wire combines the benefits of metal with a protective plastic layer, enhancing corrosion resistance and aesthetic appeal. This coating is particularly useful in environments where exposure to moisture and chemicals is common.

Pros: The PVC coating provides additional protection against rust and enhances the wire’s lifespan. It is also available in various colors, making it suitable for decorative applications.

Illustrative image related to hardware cloth 6

Cons: The main limitation is that the coating can wear off over time, especially in high-traffic areas. Additionally, the initial cost can be higher due to the added manufacturing process.

International buyers should ensure that the PVC coating meets local environmental regulations and standards, particularly in Europe, where compliance with REACH regulations may be necessary.

Summary Table of Material Properties for Hardware Cloth 6

| Material | Typical Use Case for hardware cloth 6 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Garden fencing, animal enclosures | Excellent corrosion resistance | Prone to rust if coating is damaged | Low |

| Stainless Steel | Food processing, decorative fencing | Superior corrosion resistance | Higher cost, requires specialized tools | High |

| Aluminum | Portable fencing, temporary structures | Lightweight and easy to install | Less durable, more susceptible to damage | Medium |

| PVC-Coated Wire | Decorative fencing, moisture-prone areas | Enhanced corrosion resistance | Coating can wear off over time | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in hardware cloth 6, enabling informed decisions based on application needs, environmental conditions, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hardware cloth 6

What Are the Main Stages of the Manufacturing Process for Hardware Cloth 6?

The manufacturing process for hardware cloth 6 primarily involves several critical stages: material preparation, forming, assembly, and finishing. Each of these stages plays a vital role in ensuring the final product meets both functional and quality standards.

Illustrative image related to hardware cloth 6

-

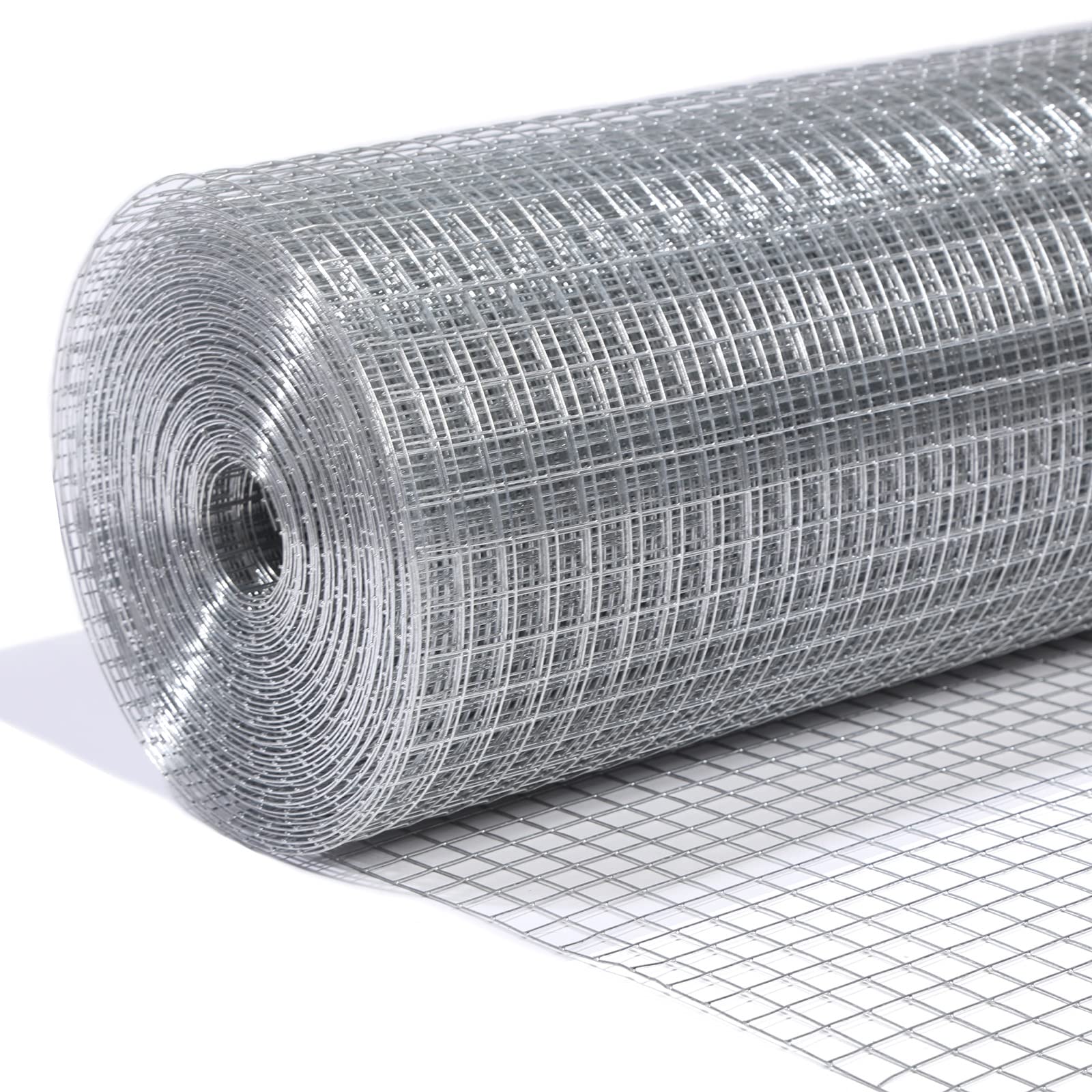

Material Preparation:

The first step in the manufacturing process involves sourcing high-quality raw materials, typically galvanized steel or stainless steel, which are chosen for their strength and corrosion resistance. The steel wire is then cut to the required length and diameter, depending on the specifications for the hardware cloth. This step may also include pre-treating the wire to enhance its durability against rust and other environmental factors. -

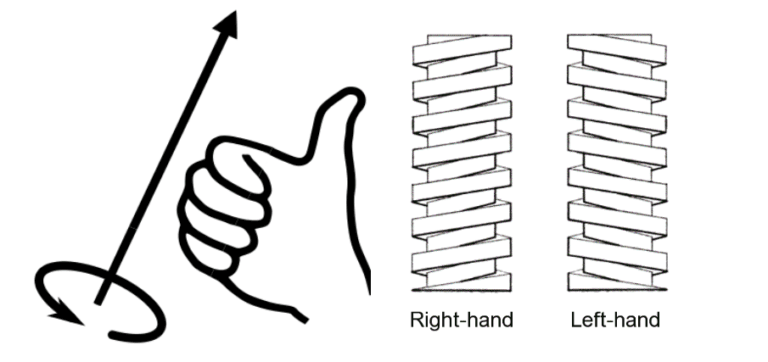

Forming:

After material preparation, the wire is subjected to a forming process where it is woven or welded into the desired mesh configuration. This is often achieved through machines that either weave the wire into a grid pattern or use welding techniques to bond the wires at intersections. For hardware cloth, mesh sizes typically range from 1/4 inch to 1/2 inch, which is essential for ensuring it effectively keeps out small pests while allowing air and light to pass through. -

Assembly:

Once the mesh is formed, it is cut into specific roll sizes, which are standard in the industry (e.g., 6′ x 50′). During assembly, various options for coating may also be applied. For instance, PVC coatings are commonly added to enhance the cloth’s weather resistance and aesthetic appeal. This step is crucial as it directly impacts the longevity and usability of the hardware cloth in different applications. -

Finishing:

The final stage involves applying protective finishes, such as additional galvanization or PVC coatings, to the hardware cloth. This is important for increasing resistance to rust, corrosion, and UV damage. The finished products are then packaged appropriately for shipment, ensuring they remain intact during transit.

How Is Quality Control Implemented in the Manufacturing of Hardware Cloth 6?

Quality control (QC) is an integral part of the manufacturing process for hardware cloth 6, ensuring that the products meet international and industry-specific standards. This QC process typically consists of several checkpoints and testing methods.

-

Relevant International Standards:

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems, and CE marking for products sold within the European Economic Area. These standards help ensure that the manufacturing processes are consistent and that the products meet safety and performance requirements. -

Quality Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility. Checks are made to ensure that the materials meet specified standards for size, strength, and corrosion resistance.

– In-Process Quality Control (IPQC): During the forming and assembly stages, regular inspections are conducted to monitor the manufacturing processes. This includes verifying mesh sizes, checking weld integrity, and confirming that coating processes are applied correctly.

– Final Quality Control (FQC): Once the hardware cloth is completed, a final inspection is conducted. This includes testing for mesh uniformity, checking for defects, and confirming that the product meets the required specifications before packaging. -

Common Testing Methods:

Various testing methods may be employed to assess the quality of hardware cloth. These include tensile strength tests, corrosion resistance tests, and dimensional accuracy checks. Some manufacturers also conduct visual inspections to identify any surface defects or inconsistencies in the coating.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial to ensure product reliability. Here are several actionable steps buyers can take:

-

Conduct Audits:

Buyers can conduct on-site audits of manufacturing facilities to assess the quality control processes firsthand. This allows for a comprehensive understanding of the manufacturing environment, including equipment, employee training, and adherence to quality standards. -

Request Quality Reports:

Suppliers should be able to provide documentation of their quality control processes, including IQC, IPQC, and FQC reports. These documents should outline the testing methods used, results of past inspections, and any corrective actions taken in case of non-compliance. -

Engage Third-Party Inspection Services:

Utilizing third-party inspection services can add an additional layer of assurance. These independent organizations can perform quality checks and audits on behalf of buyers, ensuring that the products meet specified standards before shipment. -

Understand Certification Nuances:

Different regions have varying certification requirements. For instance, CE marking is mandatory for products in the European market, while other regions may have their own specific standards. Buyers should be aware of these nuances to ensure compliance and avoid potential issues during importation.

What Are the Common Challenges in Quality Assurance for Hardware Cloth 6?

International B2B buyers may encounter several challenges related to quality assurance when sourcing hardware cloth. These challenges can include:

-

Variability in Standards: Different countries may have varying standards for materials and manufacturing processes. This can lead to discrepancies in product quality if suppliers are not well-versed in the specific requirements of the buyer’s region.

-

Supply Chain Issues: Delays or disruptions in the supply chain can affect the quality of raw materials and the overall manufacturing process. Buyers should establish clear communication channels with suppliers to monitor supply chain health and address any potential issues proactively.

-

Cultural Differences: Cultural differences in business practices and communication can pose challenges in ensuring quality. Building strong relationships with suppliers and understanding their operational practices can mitigate these challenges.

-

Market Fluctuations: Price fluctuations in raw materials can lead to compromises in quality if suppliers attempt to cut costs. Buyers should establish long-term contracts with suppliers to ensure consistent quality and pricing.

By understanding the manufacturing processes and quality assurance standards involved in hardware cloth 6 production, B2B buyers can make informed decisions that enhance their procurement strategies and ensure product reliability.

Illustrative image related to hardware cloth 6

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hardware cloth 6’

In the dynamic world of B2B procurement, sourcing hardware cloth 6 requires a strategic approach. This guide offers a practical checklist tailored for international buyers, ensuring that your sourcing process is efficient and effective. Follow these steps to secure high-quality hardware cloth that meets your needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, outline the specific requirements for the hardware cloth you need. Consider factors such as mesh size, gauge, length, and material (e.g., galvanized steel or PVC-coated). Defining these specifications will help you communicate effectively with suppliers and ensure you receive products that fit your intended applications, whether for fencing, gardening, or construction.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in hardware cloth. Look for companies with a strong reputation and extensive experience in the industry. Utilize online directories, trade shows, and industry forums to compile a list of manufacturers and distributors. Pay attention to their geographic reach, especially if you are sourcing from regions like Africa, South America, or Europe.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that your suppliers hold relevant certifications and adhere to industry standards. Certifications such as ISO 9001 demonstrate a commitment to quality management systems. Additionally, check for compliance with local regulations and environmental standards, especially if you’re operating in regions with stringent guidelines.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the hardware cloth from shortlisted suppliers. This step allows you to assess the quality, durability, and suitability of the products for your specific applications. Pay attention to the mesh size, gauge, and material finish to ensure they align with your technical specifications.

Step 5: Review Pricing Structures

Engage suppliers in discussions about pricing to understand their pricing structures. Inquire about bulk discounts, shipping costs, and payment terms. It’s important to compare prices across different suppliers, but remember that the lowest price does not always equate to the best value. Consider the overall quality and service offered alongside the cost.

Step 6: Check Customer Reviews and References

Investigate customer feedback on potential suppliers by reading online reviews and testimonials. Additionally, ask for references from previous clients who have sourced hardware cloth for similar projects. This information can provide insights into the supplier’s reliability, customer service, and product performance.

Step 7: Finalize Contracts and Agreements

Once you’ve selected a supplier, draft a detailed contract that outlines all terms of the agreement, including pricing, delivery schedules, and quality expectations. Make sure to include clauses for dispute resolution and warranties. A well-structured contract protects both parties and ensures a smooth procurement process.

Illustrative image related to hardware cloth 6

By following these steps, you can effectively navigate the complexities of sourcing hardware cloth 6, ensuring that you secure high-quality materials that meet your operational needs.

Comprehensive Cost and Pricing Analysis for hardware cloth 6 Sourcing

What Are the Key Cost Components for Sourcing Hardware Cloth 6?

When sourcing hardware cloth 6, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The most significant portion of the cost typically comes from the raw materials used in production. Hardware cloth is often made from galvanized steel or PVC-coated wire, which can vary in price based on market fluctuations and supplier contracts. Buyers should evaluate the quality of materials to ensure durability and compliance with any relevant standards.

-

Labor: Labor costs encompass wages for workers involved in manufacturing and assembly. Regions with lower labor costs may present opportunities for savings, but it’s essential to ensure that quality is not compromised.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and administrative costs associated with the production process. Efficient manufacturing practices can help reduce these costs.

-

Tooling: The initial investment in tools and machinery required to produce hardware cloth can be substantial. For custom orders, additional tooling may be necessary, impacting the overall cost.

-

Quality Control: Implementing rigorous quality control measures ensures that the final product meets specified standards. This can incur additional costs but is essential for maintaining product integrity, especially in competitive markets.

-

Logistics: Transportation costs are influenced by the distance from the manufacturing facility to the buyer, shipping methods, and local regulations. Efficient logistics planning can minimize these costs.

-

Margin: Suppliers will include a profit margin, which can vary based on market competition and demand. Understanding the typical margins in the industry can aid in negotiation.

How Do Price Influencers Impact Hardware Cloth 6 Sourcing?

Several factors influence the pricing of hardware cloth 6, and being aware of these can help buyers make better sourcing decisions.

-

Volume/MOQ: Purchasing in bulk often leads to discounts. Suppliers may have minimum order quantities (MOQs) that can affect pricing, so negotiating larger purchases can yield significant savings.

-

Specifications and Customization: Custom specifications, such as different mesh sizes or coatings, can lead to higher prices. Standard sizes and specifications typically have lower costs due to established production processes.

-

Materials: The choice of material directly impacts the cost. For example, PVC-coated options may be more expensive than standard galvanized wire, but they offer added durability and aesthetic benefits.

-

Quality and Certifications: Products with higher quality certifications or warranties can command a premium price. Buyers should consider the long-term value of investing in higher-quality products versus cheaper alternatives.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers may offer better service and quality assurance, justifying higher costs.

-

Incoterms: Understanding the shipping terms (Incoterms) is vital as they dictate who bears the cost and risk during transport. This can significantly impact the total cost of acquisition.

What Are the Best Practices for Buyers in International Markets?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should adopt specific strategies when sourcing hardware cloth 6.

Illustrative image related to hardware cloth 6

-

Negotiation: Engage in open negotiations with suppliers regarding pricing and terms. Leverage volume commitments and long-term relationships to secure favorable terms.

-

Cost-Efficiency: Evaluate total cost of ownership (TCO), which includes purchase price, shipping, handling, and potential duties or tariffs. This approach provides a more accurate picture of the actual costs involved.

-

Pricing Nuances: Be aware of regional pricing differences and market conditions. Prices may vary significantly based on local economic factors, demand, and competition.

-

Cultural Considerations: Understanding cultural differences in negotiation styles and business practices can enhance communication and foster better relationships with suppliers.

-

Research and Due Diligence: Conduct thorough research on potential suppliers. Verify their credentials, quality certifications, and past performance to mitigate risks associated with international sourcing.

By taking these factors into account, B2B buyers can navigate the complexities of sourcing hardware cloth 6 effectively, ensuring that they secure quality products at competitive prices while minimizing risks associated with international trade.

Alternatives Analysis: Comparing hardware cloth 6 With Other Solutions

When considering the optimal solution for fencing and protective barriers, it’s crucial to analyze various alternatives to hardware cloth 6. Hardware cloth is a versatile material often used in agricultural, gardening, and construction applications. However, understanding other available options can help B2B buyers make informed decisions that align with their specific needs and operational contexts.

Comparison Table

| Comparison Aspect | Hardware Cloth 6 | Welded Wire Fencing | Plastic Garden Fencing |

|---|---|---|---|

| Performance | High durability; effective against small animals | Stronger against larger animals; long-lasting | Less durable; effective for lightweight barriers |

| Cost | Moderate ($0.25 – $0.50 per sq. ft.) | Higher ($1.00 – $2.00 per sq. ft.) | Low ($0.10 – $0.30 per sq. ft.) |

| Ease of Implementation | Requires tools for cutting and installation | Heavy; may need professional installation | Easy to install; often comes in rolls |

| Maintenance | Low; resistant to rust and corrosion | Low; galvanized options available | Moderate; may degrade under UV exposure |

| Best Use Case | Ideal for small animal barriers, gardening | Suitable for livestock containment and security fencing | Best for decorative or temporary garden use |

Detailed Breakdown of Alternatives

Welded Wire Fencing

Welded wire fencing offers robust performance against larger animals and provides a stronger overall structure than hardware cloth 6. It is often galvanized to resist rust, which extends its lifespan significantly. However, its installation can be more labor-intensive and may require professional assistance due to the weight and rigidity of the material. The cost is generally higher, but the strength and security it offers make it a preferred choice for livestock containment and long-term fencing solutions.

Plastic Garden Fencing

Plastic garden fencing serves as a lightweight and cost-effective alternative to hardware cloth 6. It is easy to install, often requiring minimal tools, making it accessible for DIY projects. While it is suitable for lightweight barriers and decorative purposes, it lacks the durability and strength of metal options. Over time, exposure to UV rays can degrade the material, reducing its effectiveness. This option is best suited for temporary fencing or decorative applications in gardens where high strength is not a priority.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right fencing solution depends on specific operational requirements, budget constraints, and intended use cases. Hardware cloth 6 is ideal for scenarios where small animal protection is paramount, offering a balance of durability and cost-effectiveness. In contrast, welded wire fencing is more appropriate for heavier-duty applications involving larger animals or security needs, albeit at a higher price point. For lighter applications, such as temporary garden barriers, plastic fencing can be an economical choice. B2B buyers should evaluate their unique circumstances, including environmental factors and long-term maintenance considerations, before making a final decision.

Essential Technical Properties and Trade Terminology for hardware cloth 6

What Are the Key Technical Properties of Hardware Cloth 6?

When sourcing hardware cloth, particularly the 6-foot variant, understanding its technical specifications is crucial for making informed purchasing decisions. Here are the essential properties to consider:

1. Material Composition

Hardware cloth is primarily made from galvanized steel, which is essential for durability and resistance to corrosion. The galvanized finish protects the metal from rust, ensuring longevity in various environmental conditions. For B2B buyers, choosing the right material grade can significantly affect the product’s lifespan and suitability for specific applications, such as fencing, gardening, or construction.

2. Mesh Size

The mesh size, commonly available in dimensions like 1/4 inch or 1/2 inch, dictates what can be kept out or contained. A smaller mesh size is ideal for preventing access by small animals, while larger sizes may suffice for larger livestock. Understanding the right mesh size is essential for buyers in agricultural or industrial sectors to ensure adequate protection and functionality.

3. Gauge (Wire Thickness)

The gauge indicates the thickness of the wire used in the hardware cloth, with lower numbers representing thicker wire. Common gauges for hardware cloth range from 19 to 23. A thicker gauge provides increased strength and resistance against bending or breaking, which is particularly important in high-stress applications. Buyers need to consider the gauge in relation to their specific use case and environmental conditions.

4. Roll Dimensions

Hardware cloth typically comes in various roll sizes, such as 6 feet by 50 feet. Knowing the roll dimensions helps buyers calculate how much material is needed for their project and can impact shipping costs and storage requirements. This specification is critical for planning and budgeting, especially for large-scale projects.

Illustrative image related to hardware cloth 6

5. Coating Type

Some hardware cloth options feature additional coatings, such as PVC, which enhance corrosion resistance and aesthetic appeal. This coating can also provide UV protection, increasing the lifespan of the product in outdoor settings. B2B buyers should consider whether additional coatings are necessary based on their specific application and environment.

6. Life Expectancy

The expected lifespan of hardware cloth is an essential consideration. Many products offer a life expectancy of over 15 years, depending on the material and coating. Understanding the longevity of the product can help buyers justify their investment and plan for future replacements or maintenance.

What Are Common Trade Terms Associated with Hardware Cloth 6?

Understanding trade terminology is vital for effective communication and negotiations in B2B environments. Here are several common terms you should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hardware cloth, OEMs can provide specialized products or modifications based on buyer specifications, which is particularly useful for unique applications.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. This term is crucial for buyers to understand their purchasing limits and to negotiate better terms, especially for bulk orders. Knowing the MOQ can help buyers manage their inventory effectively and assess the feasibility of their projects.

3. RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. When sourcing hardware cloth, issuing an RFQ can help buyers compare prices and terms from multiple suppliers, ensuring they secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help B2B buyers understand shipping responsibilities, insurance, and risk management, which are critical when sourcing materials globally.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. For hardware cloth, understanding lead times is essential for project planning and ensuring that materials arrive on schedule, particularly in time-sensitive projects.

By familiarizing yourself with these technical properties and trade terms, you can make informed purchasing decisions, ensuring that your hardware cloth meets your operational needs and standards.

Navigating Market Dynamics and Sourcing Trends in the hardware cloth 6 Sector

What Are the Key Market Dynamics and Trends Impacting the Hardware Cloth 6 Sector?

The hardware cloth market is experiencing robust growth driven by increasing demand across multiple sectors, including agriculture, construction, and home improvement. The global market is influenced by several key factors, including urbanization, the rise of sustainable farming practices, and a growing focus on home and garden improvements. Emerging economies in Africa and South America, such as Nigeria and Brazil, are witnessing a surge in construction activities, further amplifying the demand for reliable fencing solutions like hardware cloth. Moreover, the Middle East is investing heavily in agricultural technology, leading to a higher requirement for pest control measures, where hardware cloth plays a crucial role.

In terms of sourcing trends, the integration of technology in procurement processes is notable. B2B buyers are increasingly leveraging e-commerce platforms and digital marketplaces to streamline their purchasing processes, ensuring better price competitiveness and access to a wider range of suppliers. Additionally, the use of data analytics for demand forecasting and inventory management is becoming prevalent among international buyers, allowing for optimized supply chains and reduced lead times. Furthermore, manufacturers are innovating by introducing galvanized and PVC-coated options to enhance durability and performance, catering to specific regional requirements.

How Are Sustainability and Ethical Sourcing Influencing the Hardware Cloth 6 Market?

Sustainability is becoming a critical aspect of the hardware cloth sector, as environmental concerns drive demand for greener products. The production of hardware cloth, particularly those made from galvanized steel, can have significant environmental impacts if not managed responsibly. B2B buyers are increasingly prioritizing suppliers that adhere to ethical sourcing practices, including the use of recycled materials and sustainable manufacturing processes. This shift is not just about compliance; it also reflects a growing consumer preference for eco-friendly products, which can enhance brand reputation and customer loyalty.

Moreover, certifications such as ISO 14001 for environmental management systems and the use of eco-friendly coatings are gaining traction. Buyers should look for manufacturers that offer products with these certifications, ensuring that they are sourcing responsibly. In addition to environmental impacts, ethical sourcing extends to labor practices within the supply chain. Buyers are encouraged to engage with suppliers who demonstrate transparency and uphold fair labor practices, contributing to a more sustainable and ethical marketplace.

Illustrative image related to hardware cloth 6

How Has the Hardware Cloth 6 Sector Evolved Over Time?

The evolution of hardware cloth can be traced back to its origins as a simple barrier against pests and small animals in agricultural settings. Initially made from basic wire materials, advancements in technology have led to the development of more durable and versatile products. The introduction of galvanized steel improved corrosion resistance, while PVC coatings added a layer of protection and aesthetic appeal. Over time, the applications for hardware cloth expanded beyond agricultural uses to include construction, home improvement, and even creative DIY projects.

Today, the market is characterized by a diverse range of options, including various mesh sizes and materials designed to meet specific needs. The shift towards sustainable practices has also influenced product development, with many manufacturers now prioritizing eco-friendly materials and processes. This evolution reflects broader trends in consumer behavior and industry standards, positioning hardware cloth as a key player in both practical applications and the growing demand for sustainable solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of hardware cloth 6

-

How do I solve supply chain disruptions when sourcing hardware cloth 6?

Supply chain disruptions can significantly affect the availability of hardware cloth. To mitigate this, establish relationships with multiple suppliers across different regions. Regularly communicate with your suppliers to get updates on inventory and lead times. Consider diversifying your sourcing strategy by looking for local suppliers in your target markets, such as Africa or South America, which may reduce shipping times and costs. Additionally, having a contingency plan in place, such as maintaining safety stock, can help you navigate unexpected shortages. -

What is the best type of hardware cloth for agricultural use?

For agricultural applications, galvanized steel hardware cloth is often the best choice due to its durability and resistance to corrosion. A mesh size of 1/2 inch is ideal for protecting crops from small animals while allowing adequate airflow and sunlight. Additionally, consider options with PVC coating for added longevity and aesthetic appeal. When sourcing, ensure that the gauge (preferably 19 or 23) meets the specific needs of your project, balancing strength and flexibility. -

How can I vet suppliers for hardware cloth 6 internationally?

Vetting suppliers is crucial to ensure quality and reliability. Start by checking their credentials, such as certifications and years in business. Request samples of the hardware cloth to assess quality firsthand. Look for reviews or testimonials from previous clients, particularly those in your region. Additionally, consider visiting the supplier’s facility if feasible or using third-party inspection services to verify their operations. Establishing clear communication about quality standards and expectations is also essential. -

What are the common minimum order quantities (MOQs) for hardware cloth?

Minimum order quantities (MOQs) for hardware cloth can vary widely depending on the supplier and the product specifications. Typically, MOQs range from 100 to 1,000 square feet. For larger B2B buyers, negotiating lower MOQs may be possible, especially if you’re willing to commit to a long-term partnership. Always inquire about bulk pricing options as well, which can lead to significant savings. Understanding the supplier’s production capabilities can also help tailor your order to meet your needs. -

What payment terms should I expect when sourcing hardware cloth internationally?

Payment terms can vary significantly between suppliers and regions. Common terms include upfront payments, letter of credit, or net 30/60 days after delivery. For new suppliers, it’s often safer to opt for partial payments upfront and the balance upon delivery. Discussing payment terms early in negotiations is essential to avoid misunderstandings later. Ensure that you understand the currency exchange implications and any additional fees that may apply, especially when dealing with international transactions. -

How can I ensure quality assurance (QA) for hardware cloth products?

Implementing a robust quality assurance process is vital when sourcing hardware cloth. Start by establishing clear specifications and standards that the product must meet. Request that suppliers provide quality certifications, such as ISO or similar. Conduct regular inspections during production and upon delivery. Consider third-party quality assurance services to perform inspections and testing, especially for large orders. Creating a feedback loop with your supplier can also help address any quality issues promptly. -

What logistics considerations should I keep in mind when importing hardware cloth?

When importing hardware cloth, consider both shipping and customs logistics. Choose a reliable freight forwarder experienced in handling construction materials. Understand the shipping costs, including duties and taxes, which can vary by destination. Ensure that all documentation, including invoices and certificates of origin, is prepared accurately to avoid customs delays. Additionally, consider the mode of transport (air vs. sea) based on your timeline and budget constraints. -

Are there customization options available for hardware cloth products?

Many suppliers offer customization options for hardware cloth, such as specific mesh sizes, gauge thickness, and coatings. When discussing your needs, provide detailed specifications, including dimensions and intended use. Custom products may have longer lead times and higher costs, so plan accordingly. If your project requires unique features, such as color or treatment, inquire about the supplier’s capabilities and any minimum order requirements for customized items.

Top 6 Hardware Cloth 6 Manufacturers & Suppliers List

1. Deer Busters – 6′ x 50′ Galvanized Steel Hardware Cloth

Domain: deerbusters.com

Registered: 1995 (30 years)

Introduction: 6′ x 50′ 19 Gauge Galvanized Steel Black PVC Coated Hardware Cloth 0.5″ x 0.5″ Mesh

2. Critterfence® – 6×50 Metal Fence

Domain: critterfence.com

Registered: 2007 (18 years)

Introduction: Critterfence® 6×50 Metal Fence (Black – Welded Wire – ¼ x ¼ Inch)\n- Size: 6 feet x 50 feet roll\n- Material: Hot dip galvanized steel, black PVC coated\n- Opening Size: 1/4 inch\n- Gauge: 17ga after coating, 20ga before coating\n- Weight: 89.00 lbs\n- SKU: 680332612357\n- MSRP: $399.95, Now: $349.95 (You save)\n- Typically used to exclude snakes, moles, voles, and other small animals.

3. McNICHOLS® – Metal Wire Mesh

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: This company, McNICHOLS® – Metal Wire Mesh, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Reddit – Hardware Cloth Fencing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Hardware cloth is used for fencing to keep rabbits and deer out. The user needs to create a fence that is buried a foot in the ground and 6-7 feet tall, requiring 50 feet in length. The cost is estimated to be a couple hundred dollars. Alternatives mentioned include chicken wire, which is cheaper but may not be as effective against certain pests. The user also considered using 2×4 welded wire catt…

5. FlyBye – 6 x 100′ Galv. Hardware Cloth

Domain: flybye.com

Registered: 1999 (26 years)

Introduction: {“product_name”:”6\” x 100′ Galv. Hardware Cloth”,”dimensions”:”6\” x 100′”,”material”:”Galvanized Steel”,”mesh_size”:”1/4\””,”gauge”:”23GA”,”usage”:”Used to exclude birds and rodents”,”price”:”$79.95″,”product_code”:”DS3000″}

6. Rural King – Galvanized Hardware Cloth

Domain: ruralking.com

Registered: 1996 (29 years)

Introduction: This company, Rural King – Galvanized Hardware Cloth, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for hardware cloth 6

In the evolving landscape of hardware cloth sourcing, international buyers must prioritize strategic partnerships and quality assurance to leverage the full potential of this versatile product. Hardware cloth, particularly the 6-foot variant, offers robust solutions for protecting gardens, livestock, and various agricultural applications, making it an essential component in diverse projects. By understanding the specifications, including mesh size, gauge, and material coatings, buyers can make informed decisions that align with their operational needs and local conditions.

Illustrative image related to hardware cloth 6

Moreover, the emphasis on durability and corrosion resistance in hardware cloth products—such as galvanized and PVC-coated options—underscores the importance of sourcing high-quality materials that can withstand environmental challenges. For businesses in Africa, South America, the Middle East, and Europe, establishing reliable supply chains can lead to significant cost savings and enhanced project outcomes.

As we look to the future, it is crucial for B2B buyers to actively engage with suppliers who prioritize innovation and sustainability. By adopting a forward-thinking approach, companies can not only secure their supply of hardware cloth but also contribute to the overall growth and resilience of their industries. Embrace this opportunity to enhance your procurement strategies and elevate your projects today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to hardware cloth 6

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.