A Deep Dive into Glue For Silicone Solution

Introduction: Navigating the Global Market for glue for silicone

In today’s competitive global market, sourcing the right glue for silicone applications can be a daunting challenge for B2B buyers. With a myriad of options available, selecting the appropriate adhesive not only affects the performance and durability of your products but also influences overall operational efficiency. This guide serves as a comprehensive resource for international buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Vietnam. It covers various types of silicone adhesives, their specific applications, and essential factors for supplier vetting, ensuring that you make informed purchasing decisions.

Understanding the nuances of silicone adhesives is crucial; different applications require specific adhesive properties, such as flexibility, heat resistance, and curing time. This guide delves into the key characteristics of various adhesives, offering insights into their suitability for tasks ranging from construction to automotive and household repairs. Additionally, it provides practical advice on cost considerations and potential suppliers, enabling you to navigate the complexities of the global adhesive market effectively.

By leveraging the information in this guide, B2B buyers can streamline their sourcing processes, enhance product quality, and ultimately achieve better business outcomes. Empower yourself with the knowledge needed to select the best glue for silicone, ensuring your projects are executed with precision and reliability.

Understanding glue for silicone Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Room Temperature Curing Silicone Adhesive | Bonds without primer; fast curing options available | Automotive, Electronics, Medical Devices | Pros: Versatile, easy application. Cons: Limited to specific silicone types. |

| Thermosetting Silicone Adhesive | Short curing time; requires knowledge of silicone type | Manufacturing, Aerospace, Molding | Pros: Strong bonds, customizable joints. Cons: Requires careful selection and testing. |

| Primer + Cyanoacrylate Adhesive | Quick bonding with primer; suitable for small parts | Small-scale repairs, Prototyping | Pros: Fast application, effective for small components. Cons: Brittle, not ideal for larger or flexible joints. |

| Pressure Sensitive Adhesive (PSA) | High initial strength; flexible after curing | Gasket bonding, Large assemblies | Pros: Good for larger parts, flexible joints. Cons: Solvent-based, requires careful handling. |

| Self-Leveling Silicone Sealant | Flows into gaps; weather-resistant | Construction, Plumbing, HVAC | Pros: Effective for sealing and filling gaps. Cons: Not suitable for vertical applications due to sagging. |

What Are the Characteristics of Room Temperature Curing Silicone Adhesives?

Room temperature curing silicone adhesives are designed to bond silicone materials effectively without the need for a primer. They are particularly advantageous in environments where rapid curing is essential, making them ideal for applications in automotive, electronics, and medical devices. B2B buyers should consider the specific silicone types they are working with, as not all formulations are universally compatible. These adhesives are favored for their ease of application and versatility, but their effectiveness can be limited to certain silicone formulations, necessitating careful selection.

How Do Thermosetting Silicone Adhesives Work?

Thermosetting silicone adhesives cure rapidly, allowing for quick assembly and design flexibility. They require knowledge of the silicone type being bonded, whether it is condensation or addition curing, which can complicate their use. These adhesives are commonly employed in manufacturing, aerospace, and molding applications due to their strong bonding capabilities and durability. For B2B buyers, understanding the specific requirements of their silicone materials is crucial to ensure optimal performance, as improper selection can lead to bond failure.

What Are the Benefits of Using Primer + Cyanoacrylate Adhesives?

This adhesive method involves applying a primer to the silicone surface before using cyanoacrylate (quick glue) for bonding. It is particularly effective for small parts and prototypes, offering fast application and strong initial bonding. However, this approach has limitations, as cyanoacrylate is brittle and may not withstand outdoor conditions or larger applications. B2B buyers should assess the scale of their projects and the environmental conditions to determine if this method meets their needs.

What Makes Pressure Sensitive Adhesive (PSA) Ideal for Silicone?

Pressure Sensitive Adhesives (PSA) are contact adhesives that provide high initial strength and flexibility after curing, making them suitable for bonding gaskets and larger assemblies. They are particularly effective for applications requiring a durable bond that can accommodate movement. However, since PSA is solvent-based, it requires careful handling and proper ventilation during application. B2B buyers should weigh the benefits of flexibility and strength against the handling requirements and potential health risks associated with solvent-based adhesives.

Why Choose Self-Leveling Silicone Sealants?

Self-leveling silicone sealants are designed to fill gaps and provide a smooth finish, making them ideal for construction, plumbing, and HVAC applications. They are weather-resistant and can accommodate movement, which is essential in outdoor settings. However, these sealants may sag in vertical applications, limiting their use in certain scenarios. For B2B buyers, the choice of self-leveling sealants should be based on the specific sealing needs and environmental conditions of their projects, ensuring effective performance and durability.

Key Industrial Applications of glue for silicone

| Industry/Sector | Specific Application of glue for silicone | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Bonding silicone gaskets and seals | Enhances durability and weather resistance, reducing maintenance costs | Ensure high-temperature and chemical resistance; consider local climate factors |

| Construction | Sealing joints in glass and window installations | Provides waterproofing and thermal insulation, improving energy efficiency | Look for low VOC options to comply with environmental regulations |

| Electronics | Encapsulation of electronic components | Protects against moisture and dust, extending product lifespan | Seek FDA-approved adhesives for compliance with safety standards |

| Medical Devices | Bonding silicone tubing and components | Ensures biocompatibility and durability, crucial for patient safety | Verify certifications for medical-grade materials and adhesives |

| Consumer Products | Assembly of silicone kitchenware and appliances | Increases product longevity and user satisfaction | Focus on flexibility and heat resistance for diverse applications |

How is Glue for Silicone Used in the Automotive Industry?

In the automotive sector, glue for silicone is essential for bonding gaskets and seals that withstand extreme temperatures and environmental conditions. This application enhances the durability of components like engine covers and weatherstrips, ultimately reducing maintenance costs. International buyers should prioritize adhesives that offer high-temperature resistance and chemical stability, especially in regions with varying climates, such as the Middle East and South America.

What Role Does Silicone Glue Play in Construction Projects?

In construction, silicone adhesives are utilized for sealing joints in glass installations and window frames. These adhesives provide superior waterproofing and thermal insulation, contributing to energy efficiency in buildings. Buyers must consider low VOC options to adhere to stringent environmental regulations, particularly in Europe. Additionally, understanding local building codes can guide the selection of appropriate adhesives for specific applications.

Why is Silicone Adhesive Important in Electronics Manufacturing?

For the electronics industry, silicone glue is crucial for encapsulating electronic components to protect them from moisture and dust. This application significantly extends the lifespan of products, ensuring reliability in various environments. B2B buyers should look for adhesives that are FDA-approved, particularly when manufacturing devices intended for sensitive applications or healthcare settings. Compliance with international safety standards is paramount.

How is Glue for Silicone Used in Medical Devices?

In the medical device sector, silicone adhesives are used to bond tubing and other silicone components. Ensuring biocompatibility is critical, as these devices often come into direct contact with patients. Buyers should verify that the adhesives meet necessary certifications for medical-grade materials, especially when sourcing from international suppliers. Understanding the specific requirements for sterilization and durability is vital for compliance and safety.

What Applications Exist for Silicone Glue in Consumer Products?

Silicone adhesives play a significant role in assembling kitchenware and appliances, where flexibility and heat resistance are essential. These adhesives enhance product longevity and user satisfaction, making them critical in a competitive market. When sourcing, businesses should focus on adhesives that can withstand high temperatures and provide excellent bonding strength, particularly for products designed for high-use environments.

3 Common User Pain Points for ‘glue for silicone’ & Their Solutions

Scenario 1: Difficulty in Achieving Strong Bonds with Silicone Materials

The Problem:

Many B2B buyers encounter significant challenges when trying to bond silicone materials effectively. The inherent low surface tension of silicone makes it notoriously difficult for adhesives to adhere properly. This can lead to failures in product applications, such as gaskets or seals, where a reliable bond is critical. For companies in sectors like automotive, construction, or manufacturing, these failures can result in costly rework, delays, and decreased customer satisfaction.

The Solution:

To address this issue, B2B buyers should consider using specialized silicone adhesives that are formulated to bond silicone rubber effectively. Products like room temperature curing silicone adhesives, such as TSE397C or RTV108, have been proven to achieve strong bonds without requiring a primer. It is crucial to ensure that the silicone surface is free from contaminants, such as release agents, which can inhibit adhesion. Cleaning the surfaces before applying the adhesive enhances the bond’s effectiveness. For larger parts or applications requiring flexibility, utilizing thermosetting silicone adhesives can provide a durable, elastic joint with a quick curing time. By selecting the right adhesive and preparing the surfaces properly, businesses can significantly improve their bonding results and reduce the incidence of failures.

Scenario 2: Incompatibility with Environmental Conditions

The Problem:

Another common challenge faced by B2B buyers is the need for adhesives that can withstand harsh environmental conditions. Silicone materials may be used in applications exposed to extreme temperatures, moisture, or UV radiation. Many standard adhesives fail under these conditions, leading to degradation, loss of bond strength, and ultimately, product failure. This is particularly problematic in industries such as construction and automotive, where components must perform reliably over time.

The Solution:

To combat this issue, it is essential to select adhesives specifically designed for high-performance applications. Buyers should look for silicone adhesives that are labeled as weather-resistant, heat-resistant, or low-VOC (volatile organic compounds). Products like ASI 600 High Temperature Red Gasket Maker Silicone or 3M CP 25WB+ Red Fire Barrier Sealant are excellent choices for applications requiring durability against extreme conditions. Additionally, conducting environmental testing during the adhesive selection process can help ensure compatibility with specific application conditions. By investing in high-quality, specialized adhesives, businesses can enhance product longevity and reliability, ultimately leading to improved customer trust and satisfaction.

Illustrative image related to glue for silicone

Scenario 3: Uncertainty in Adhesive Selection Process

The Problem:

B2B buyers often face confusion when navigating the myriad of adhesive options available for silicone bonding. With various types of adhesives, such as cyanoacrylate, room temperature curing, and thermosetting adhesives, determining the best solution for specific applications can be overwhelming. This uncertainty can lead to poor decision-making, resulting in increased costs and project delays.

The Solution:

To simplify the adhesive selection process, buyers should start by clearly defining their application requirements, including the materials involved, environmental conditions, and desired bond characteristics. Consulting with adhesive manufacturers or suppliers who can provide expert guidance tailored to specific needs is invaluable. Utilizing resources such as technical datasheets, application guides, and customer support can help streamline the decision-making process. Additionally, conducting small-scale trials with different adhesives can provide practical insights into performance, allowing buyers to make informed choices. By taking a systematic approach to adhesive selection, businesses can mitigate risks, reduce costs, and ensure successful bonding outcomes in their projects.

Strategic Material Selection Guide for glue for silicone

When selecting adhesive materials for bonding silicone, B2B buyers must consider various factors that impact performance, application suitability, and compliance with international standards. Here, we analyze four common adhesive materials used for gluing silicone, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Cyanoacrylate Adhesives for Silicone?

Cyanoacrylate adhesives, often referred to as “super glue,” are known for their rapid curing capabilities. They typically exhibit high tensile strength and can bond quickly at room temperature. However, their performance can be limited by environmental conditions, as they are not well-suited for outdoor applications due to brittleness and low resistance to moisture.

Pros:

– Fast curing time, ideal for quick repairs.

– Strong bond on small parts.

Cons:

– Brittle joints that may not withstand flexing.

– Limited outdoor durability due to moisture sensitivity.

Impact on Application:

Cyanoacrylate adhesives are suitable for small-scale applications where quick bonding is essential, but they may not hold up in environments with varying temperatures or humidity levels.

Considerations for International Buyers:

Buyers should ensure that the selected cyanoacrylate meets local compliance standards (e.g., ASTM, DIN) and consider the availability of primers to enhance bonding efficacy.

How Do Room Temperature Curing Silicone Adhesives Perform?

Room temperature curing silicone adhesives are designed specifically for bonding silicone materials. They provide excellent adhesion without the need for a primer, making them user-friendly. These adhesives typically offer good flexibility and can withstand temperature fluctuations.

Pros:

– Excellent adhesion to various silicone types.

– Flexible joints that accommodate movement.

Cons:

– Longer curing times compared to cyanoacrylates.

– May require surface preparation to remove contaminants.

Impact on Application:

These adhesives are ideal for applications where flexibility is essential, such as in automotive or construction sectors, where materials may expand and contract.

Considerations for International Buyers:

It is crucial to verify that the adhesive complies with health and safety regulations and is suitable for the specific environmental conditions of the target market.

What Are the Advantages of Thermosetting Silicone Adhesives?

Thermosetting silicone adhesives cure through a heat process, providing a robust bond with excellent chemical resistance. They are particularly advantageous for applications requiring high durability and temperature resistance.

Pros:

– High tensile strength and durability.

– Excellent resistance to chemicals and extreme temperatures.

Cons:

– More complex manufacturing processes.

– Higher costs associated with heat curing.

Impact on Application:

These adhesives are well-suited for industrial applications where exposure to harsh chemicals or extreme temperatures is common.

Illustrative image related to glue for silicone

Considerations for International Buyers:

Buyers should assess the compatibility of thermosetting adhesives with local silicone materials and ensure compliance with international manufacturing standards.

How Do Pressure Sensitive Adhesives (PSA) Work with Silicone?

Pressure sensitive adhesives (PSA) are designed to bond upon contact, providing immediate adhesion. They are particularly effective for large silicone parts and applications requiring a flexible bond.

Pros:

– Quick and easy application without curing time.

– High initial bond strength.

Cons:

– Solvent-based, requiring careful handling.

– Potential for degradation over time in extreme conditions.

Impact on Application:

PSAs are ideal for applications where immediate adhesion is necessary, such as in the manufacturing of gaskets or seals.

Illustrative image related to glue for silicone

Considerations for International Buyers:

Buyers should consider local regulations regarding solvent-based adhesives and ensure that the PSA used meets the necessary environmental standards.

Summary Table of Adhesive Materials for Silicone

| Material | Typical Use Case for glue for silicone | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cyanoacrylate Adhesives | Small part repairs | Fast curing time | Brittle joints, limited outdoor durability | Low |

| Room Temperature Curing Adhesives | Automotive and construction applications | Excellent adhesion without primer | Longer curing times, may require surface prep | Medium |

| Thermosetting Silicone Adhesives | Industrial applications | High durability and chemical resistance | Complex manufacturing, higher costs | High |

| Pressure Sensitive Adhesives | Gasket and seal manufacturing | Quick application, high initial bond strength | Solvent-based, potential degradation over time | Medium |

This strategic guide aims to equip B2B buyers with the necessary insights to make informed decisions regarding adhesive materials for silicone applications, ensuring compliance and suitability for their specific needs across various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for glue for silicone

What Are the Main Stages of Manufacturing Glue for Silicone?

The manufacturing process for silicone adhesives involves several critical stages, each contributing to the final product’s performance and quality. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Illustrative image related to glue for silicone

Material Preparation: What Raw Materials Are Used in Silicone Glue Production?

The initial phase is material preparation, where raw materials such as silicone polymers, fillers, curing agents, and additives are sourced and tested for quality. High-quality silicone polymers are essential for achieving the desired flexibility and temperature resistance. Suppliers often utilize materials from reputable manufacturers to ensure consistency and reliability.

During this stage, companies may perform tests on the raw materials to confirm that they meet specific industry standards. For instance, silicone polymers might undergo viscosity testing, while fillers are assessed for particle size distribution. This initial quality control sets the stage for subsequent manufacturing stages.

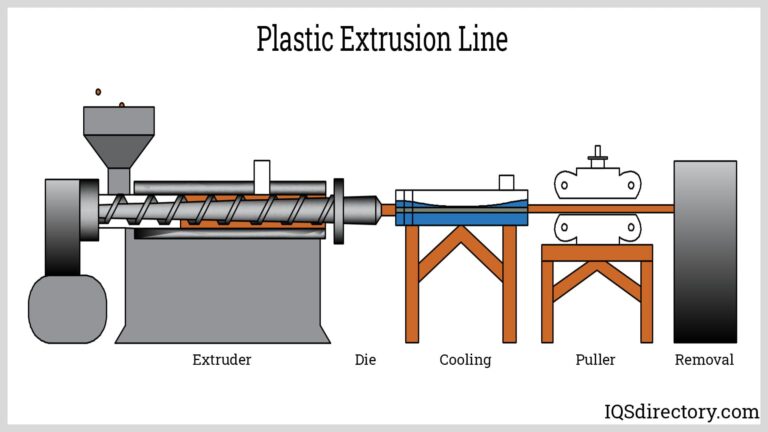

Forming: How Is Silicone Glue Molded or Processed?

Once the materials are prepared, the next step involves forming the silicone glue. This can be accomplished through various techniques, including:

-

Mixing: The raw materials are mixed in precise ratios to create a homogeneous blend. Advanced mixing technologies, such as high-shear mixers, ensure uniform dispersion of components.

-

Extrusion: For certain applications, the mixed adhesive can be extruded into specific shapes or forms. This is particularly useful for creating adhesive strips or specialized packaging.

-

Dispensing: In some cases, manufacturers use automated dispensing systems to apply the adhesive in precise amounts, reducing waste and ensuring consistency.

Each of these methods requires careful calibration and monitoring to maintain product integrity.

Assembly: What Role Does Assembly Play in Silicone Adhesive Production?

While silicone adhesives are often supplied as standalone products, assembly can be crucial for specific applications. For example, adhesive bonding of components may involve the integration of silicone with substrates such as metal, glass, or plastics. Manufacturers often employ pre-treatment processes, such as corona treatment, to enhance adhesion by increasing the surface tension of the silicone.

In assembly, the timing of the application is critical, as the adhesive must be applied within a specific timeframe to ensure optimal bonding. This requires close coordination between different stages of production.

Finishing: How Is Quality Ensured in the Final Product?

The finishing stage involves packaging and labeling the adhesive products. This step is essential not only for branding but also for providing users with critical information, such as application instructions and safety warnings. Quality checks during the finishing process may include visual inspections for defects, ensuring that each product meets the specified standards.

What Are the Key Quality Control Measures for Silicone Adhesives?

Quality assurance is paramount in the manufacturing of silicone adhesives, especially for B2B buyers who require consistent performance and reliability. Several international and industry-specific standards guide these quality control measures.

Which International Standards Should B2B Buyers Be Aware Of?

One of the most recognized quality standards is ISO 9001, which sets out the criteria for a quality management system. Compliance with ISO 9001 signifies that a manufacturer has demonstrated the ability to consistently provide products that meet customer and regulatory requirements.

Additionally, certifications like CE (Conformité Européenne) mark and API (American Petroleum Institute) standards may apply depending on the product’s intended use. For example, adhesives used in automotive or aerospace applications may require adherence to specific safety and performance standards.

What Are the QC Checkpoints Throughout the Manufacturing Process?

Quality control in the production of silicone adhesives typically involves several checkpoints:

-

Incoming Quality Control (IQC): Raw materials are assessed upon arrival at the manufacturing facility. This includes testing for purity, viscosity, and compatibility with existing formulations.

-

In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to ensure that the process remains within defined parameters. This may involve checking the mixing consistency and monitoring curing times.

-

Final Quality Control (FQC): Once the product is finished, it undergoes final testing to confirm that it meets all specified performance criteria. This may include tensile strength testing, flexibility assessments, and environmental resistance evaluations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must be diligent in verifying the quality control processes of their suppliers. Here are some actionable steps:

-

Conduct Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers can evaluate adherence to international standards and assess the effectiveness of QC measures.

-

Request Documentation: Suppliers should provide quality control documentation, including testing reports and certifications. This transparency builds trust and confidence in the supplier’s capabilities.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. This is particularly beneficial for buyers in regions where they may not have the capacity to conduct thorough inspections themselves.

What Are the Quality Assurance Nuances for International Buyers?

International buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate various quality assurance nuances. These may include:

-

Regulatory Differences: Different regions may have specific regulations governing adhesive products. Buyers should ensure that their suppliers comply with local regulations to avoid legal complications.

-

Cultural Considerations: Understanding cultural differences in business practices can enhance communication and collaboration with suppliers. This is especially important in regions with distinct business customs.

-

Logistical Challenges: International shipping can introduce risks related to product integrity and compliance. Buyers should work closely with suppliers to establish reliable logistics and handling practices.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions, fostering successful partnerships with suppliers of silicone adhesives. This diligence not only ensures product quality but also enhances operational efficiency and customer satisfaction in their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glue for silicone’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of glue for silicone applications. Given the unique challenges of bonding silicone materials, understanding the nuances of adhesive selection is crucial. This checklist will help streamline your sourcing process and ensure you make informed decisions tailored to your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as the types of silicone you will be bonding, the required flexibility of the adhesive, and environmental conditions (e.g., temperature, moisture exposure). These specifications will guide your search and help filter out unsuitable products.

- Types of silicone: Identify whether you are working with silicone rubber, silicone gel, or silicone sealants.

- Application requirements: Determine if the adhesive needs to withstand extreme temperatures or be waterproof.

Step 2: Research Different Adhesive Types

Understanding the various adhesive formulations available for silicone bonding is essential for making an informed choice. Familiarize yourself with options such as room temperature curing silicones, thermosetting adhesives, and pressure-sensitive adhesives (PSAs). Each type has its advantages and limitations based on the application.

Illustrative image related to glue for silicone

- Room temperature curing silicones: These are versatile and often require no primer, suitable for a wide range of applications.

- Thermosetting adhesives: Ideal for applications requiring quick curing times but may need careful selection based on the silicone type.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly evaluate potential suppliers to ensure they meet your business standards. Request detailed company profiles, product data sheets, and case studies that demonstrate their expertise in silicone adhesives. This step minimizes risks associated with quality and reliability.

- Check references: Ask for testimonials or references from other businesses in your industry or region.

- Assess certifications: Ensure suppliers comply with relevant industry standards, such as ISO certifications.

Step 4: Request Samples for Testing

Obtaining product samples is a critical step in the evaluation process. Testing samples in real-world applications allows you to assess performance, adhesion quality, and suitability for your specific needs. This hands-on approach helps to mitigate any potential issues before making a larger investment.

- Conduct adhesion tests: Evaluate how well the adhesive bonds to your specific silicone materials.

- Consider environmental tests: Check performance under varying temperature and humidity conditions.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier and tested their products, engage in negotiations to secure favorable pricing and terms. Consider factors such as bulk order discounts, payment terms, and shipping options. Establishing a good relationship with your supplier can lead to better deals and support in the future.

- Explore bulk discounts: Discuss pricing tiers based on order volumes.

- Clarify lead times: Ensure you understand the delivery timelines to avoid production delays.

Step 6: Plan for Long-Term Supply Needs

Lastly, consider your long-term adhesive requirements. Establishing a reliable supply chain is vital for ongoing projects and production. Discuss potential future needs with your supplier to ensure they can meet your scaling demands.

- Discuss stock levels: Ensure the supplier can maintain adequate inventory to support your production schedule.

- Plan for new product development: Collaborate with suppliers on upcoming adhesive technologies that may enhance your applications.

By following these steps, B2B buyers can navigate the complexities of sourcing glue for silicone, ensuring they make well-informed decisions that align with their operational needs and quality standards.

Illustrative image related to glue for silicone

Comprehensive Cost and Pricing Analysis for glue for silicone Sourcing

What Are the Key Cost Components in Sourcing Glue for Silicone?

When sourcing glue for silicone, understanding the cost structure is essential. The main components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of adhesive plays a crucial role in pricing. Silicone adhesives vary significantly based on their chemical composition, curing time, and specific use cases (e.g., high-temperature applications). Premium formulations, such as those with enhanced elasticity or resistance to chemicals, will incur higher costs.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process. For instance, producing high-quality silicone adhesives that require precise formulations may necessitate skilled labor, thus raising costs.

-

Manufacturing Overhead: This includes expenses related to plant operation, utilities, and equipment maintenance. Manufacturers with advanced technology and automation may have lower overhead in the long run, affecting pricing competitiveness.

-

Tooling: Initial investments in specialized machinery for producing silicone adhesives can be substantial. This is especially true for manufacturers focusing on custom formulations or packaging, which can also influence the final price.

-

Quality Control (QC): Rigorous testing and certification processes add to production costs. Buyers should prioritize suppliers with strong QC protocols to ensure product reliability, as this can mitigate risks associated with defective adhesives.

-

Logistics: Transportation and warehousing costs should not be overlooked. International shipping, especially to regions like Africa or South America, can add significant overhead due to tariffs and longer transit times.

-

Margin: Lastly, the profit margin varies by supplier and market dynamics. Established brands may charge a premium due to their reputation and reliability, while emerging suppliers might offer lower prices to gain market share.

How Do Price Influencers Affect the Cost of Glue for Silicone?

Several factors can influence the final price of silicone adhesives:

-

Volume/MOQ: Bulk purchases typically lead to lower per-unit costs. Buyers should inquire about minimum order quantities (MOQs) and volume discounts to optimize their procurement budget.

-

Specifications and Customization: Custom formulations tailored to specific applications may incur additional costs. Suppliers often charge for R&D and development time, which can be significant for specialized needs.

-

Materials: The quality and source of raw materials directly impact pricing. Using high-purity silicone or eco-friendly materials can lead to increased costs but may offer long-term benefits in terms of performance and safety.

-

Quality and Certifications: Products with certifications (e.g., FDA, ISO) may be priced higher due to the costs associated with achieving and maintaining these standards. Buyers should weigh the importance of these certifications against potential cost savings.

-

Supplier Factors: Established suppliers with a robust track record may command higher prices. In contrast, newer suppliers may offer lower prices to penetrate the market. It’s vital for buyers to assess supplier reliability and product quality before making a decision.

-

Incoterms: The chosen Incoterms can significantly affect the total cost. Terms like CIF (Cost, Insurance, and Freight) may lead to higher prices, as they include shipping and insurance costs, while FOB (Free on Board) may offer more control over logistics expenses.

What Tips Can Help Buyers Negotiate Better Prices for Glue for Silicone?

International B2B buyers should consider the following strategies to enhance cost-efficiency:

-

Negotiate Terms: Engage in discussions about pricing, payment terms, and delivery schedules. Suppliers may offer flexible terms that could lead to cost savings.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes shipping, storage, and potential wastage. A slightly higher upfront cost may lead to lower overall expenses if the adhesive performs better.

-

Understand Pricing Nuances: Be aware of regional pricing variations. Suppliers may adjust prices based on local market conditions, currency fluctuations, or demand. In regions like the Middle East or Europe, understanding these nuances can aid in negotiating better deals.

-

Build Relationships: Establishing long-term partnerships with suppliers can lead to better pricing and service. Loyal customers may receive preferential treatment, including discounts or access to exclusive products.

-

Conduct Market Research: Keep abreast of market trends, competitor pricing, and new product developments. This knowledge empowers buyers during negotiations and helps in making informed purchasing decisions.

Disclaimer

The prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific customer requirements. Always consult with multiple suppliers to obtain accurate quotes tailored to your needs.

Alternatives Analysis: Comparing glue for silicone With Other Solutions

In the quest for effective bonding solutions, particularly when working with silicone materials, various alternatives exist beyond traditional silicone adhesives. Understanding these alternatives can help B2B buyers make informed decisions based on their specific application needs and operational constraints. Below is a detailed comparison of “Glue for Silicone” against two viable alternatives: cyanoacrylate (super glue) with a primer and pressure-sensitive adhesives (PSA).

| Comparison Aspect | Glue For Silicone | Cyanoacrylate with Primer | Pressure-Sensitive Adhesive (PSA) |

|---|---|---|---|

| Performance | Excellent flexibility and durability, ideal for dynamic applications | Good for small parts but can be brittle and less flexible | High initial bond strength, suitable for larger surfaces |

| Cost | Moderate to high, depending on formulation | Generally low cost | Moderate, varies with type and application |

| Ease of Implementation | Requires surface preparation, but user-friendly | Simple application with primer | Easy to apply; requires pressure to bond |

| Maintenance | Low maintenance; long-lasting | Limited lifespan, brittle over time | Requires careful handling; can be affected by temperature |

| Best Use Case | Ideal for gaskets, o-rings, and repairs on silicone molds | Small, non-flexible parts in controlled environments | Bonding larger surfaces or gaskets requiring flexibility |

What are the Pros and Cons of Using Cyanoacrylate with Primer as an Alternative?

Cyanoacrylate, commonly known as super glue, when combined with a primer, can effectively bond silicone materials, especially for small components. The primer enhances adhesion by increasing the surface tension of silicone, allowing the cyanoacrylate to wet the surface adequately. However, the primary drawback of this method is the brittleness of the bond, which is not suitable for applications requiring flexibility. Additionally, cyanoacrylate bonds may not perform well in outdoor environments where temperature fluctuations occur, making them less ideal for long-term applications.

How Does Pressure-Sensitive Adhesive (PSA) Work as an Alternative to Silicone Glue?

Pressure-sensitive adhesives (PSA) are another alternative that can bond silicone materials effectively. They offer the advantage of high initial bond strength and can be applied easily without the need for extensive surface preparation. PSAs are particularly useful for larger surfaces and applications where flexibility is essential, as they maintain their elastic properties after curing. However, they can be sensitive to environmental conditions, such as temperature and humidity, which may affect their performance over time. Furthermore, handling and application require some care to ensure optimal bonding.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right adhesive for silicone applications, B2B buyers should consider several factors, including the intended application, environmental conditions, and the specific materials involved. For projects that demand high flexibility and durability, silicone adhesives are often the best choice. Conversely, for smaller components or less demanding applications, cyanoacrylate with a primer may suffice. For larger surfaces or when ease of application is a priority, pressure-sensitive adhesives can be advantageous. Ultimately, understanding the pros and cons of each option, alongside the specific requirements of the project, will enable buyers to make informed decisions that ensure optimal performance and longevity of their bonding solutions.

Essential Technical Properties and Trade Terminology for glue for silicone

What Are the Key Technical Properties of Glue for Silicone?

When sourcing glue for silicone applications, understanding the critical technical properties is essential for ensuring performance and compatibility. Here are some key specifications that B2B buyers should consider:

1. Curing Type

Curing refers to the process by which the adhesive transitions from a liquid to a solid state. Silicone adhesives can be categorized into several types, including room temperature curing, thermosetting, and moisture-curing. The choice of curing type affects application speed and the adhesive’s final properties. For instance, room temperature curing adhesives are advantageous for quick repairs, while thermosetting adhesives offer enhanced durability.

2. Tensile Strength

Tensile strength measures the maximum amount of tensile (pulling) stress that an adhesive can withstand before failing. This property is crucial for applications where the bond will experience stress. A higher tensile strength (e.g., 7.5 MPa for some specialized adhesives) indicates a stronger bond that can endure mechanical forces, making it essential for high-performance applications in automotive or industrial settings.

3. Viscosity

Viscosity indicates the flow characteristics of the adhesive, impacting how easily it can be applied and its ability to fill gaps. Low-viscosity adhesives flow easily and are ideal for intricate applications, while high-viscosity options provide better gap-filling capabilities. Choosing the right viscosity ensures optimal bonding performance, especially in environments with varying temperatures.

4. Flexibility

Flexibility is a critical property for adhesives used in applications where movement or vibration occurs. Silicone adhesives are known for their elastic properties, allowing them to maintain a strong bond even when subjected to dynamic stress. This characteristic is particularly important in industries such as construction and automotive, where materials expand and contract with temperature changes.

Illustrative image related to glue for silicone

5. Resistance Properties

Silicone adhesives often exhibit excellent resistance to environmental factors such as UV radiation, moisture, and extreme temperatures. These resistance properties enhance the longevity of the bond in outdoor or harsh environments. B2B buyers should ensure that the adhesive selected meets the specific environmental challenges of their application.

What Are Common Trade Terms Related to Glue for Silicone?

Understanding trade terminology is vital for effective communication and negotiation in B2B transactions. Here are several common terms relevant to sourcing glue for silicone:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of silicone adhesives, buyers often source products from OEMs to ensure compatibility with their specific applications. Understanding OEM relationships can provide insights into product quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Suppliers may set MOQs based on production costs, and understanding this can help buyers negotiate better terms based on their needs.

3. RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to solicit price quotes from suppliers. This document typically outlines specific requirements, quantities, and delivery timelines. Submitting an RFQ is essential for obtaining competitive pricing and ensuring that all parties understand the scope of the project.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost of procurement. Familiarity with Incoterms helps B2B buyers navigate international shipping logistics effectively.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. This term is vital for planning and inventory management, especially in industries where timely delivery is critical. Buyers should inquire about lead times to ensure they can meet their production schedules.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing glue for silicone applications, ensuring optimal performance and successful partnerships.

Navigating Market Dynamics and Sourcing Trends in the glue for silicone Sector

What Are the Current Market Dynamics and Key Trends in the Glue for Silicone Sector?

The global market for silicone adhesives and sealants is witnessing robust growth, driven by the increasing demand across various industries such as construction, automotive, electronics, and healthcare. Particularly in regions like Africa, South America, the Middle East, and Europe, there is a growing emphasis on high-performance adhesives that can withstand extreme environmental conditions. Emerging technologies, such as the development of room temperature curing silicone adhesives, are gaining traction, allowing for faster application and curing times, which is crucial for B2B operations focused on efficiency.

International B2B buyers are increasingly looking for suppliers who can provide not just the product, but also comprehensive technical support and customization options. The rise of e-commerce platforms has further simplified the sourcing process, enabling buyers to access a wider range of products and suppliers. Additionally, the demand for low-VOC and environmentally friendly adhesives is steering manufacturers towards innovations that align with global sustainability goals. This shift not only enhances product appeal but also meets regulatory requirements, making it essential for buyers to stay informed about the latest advancements in adhesive technologies.

How Is Sustainability and Ethical Sourcing Impacting the Glue for Silicone Sector?

Sustainability has become a central theme in the glue for silicone sector, influencing purchasing decisions and supplier relationships. The environmental impact of adhesives is under scrutiny, particularly regarding their chemical composition and disposal methods. As a result, many manufacturers are investing in developing ‘green’ adhesives that utilize renewable resources and minimize harmful emissions. For B2B buyers, sourcing adhesives with eco-friendly certifications—such as Green Seal or EcoLabel—can enhance their corporate social responsibility (CSR) profile and meet the growing consumer demand for sustainable products.

Moreover, ethical supply chains are critical for ensuring that raw materials are sourced responsibly. Buyers should prioritize suppliers who demonstrate transparency in their sourcing processes and adhere to ethical labor practices. Establishing partnerships with manufacturers committed to sustainability not only mitigates risks associated with regulatory compliance but also fosters trust and loyalty among stakeholders. As markets continue to evolve, buyers who align their procurement strategies with sustainability goals will likely benefit from competitive advantages in their respective industries.

What Is the Evolution of Glue for Silicone and Its Importance in B2B Context?

The evolution of glue for silicone can be traced back to the early 20th century when silicone compounds were first synthesized. Initially, these materials were primarily used for industrial applications due to their unique properties, such as flexibility, durability, and resistance to temperature extremes. Over the decades, advancements in chemical formulations have led to the development of specialized adhesives that cater to diverse applications, from automotive assembly to household repairs.

Today, silicone adhesives are integral to various B2B sectors, providing solutions that enhance product performance and durability. The continuous innovation in adhesive technologies—such as the introduction of hybrid formulations and pressure-sensitive adhesives—demonstrates the industry’s commitment to meeting the evolving needs of global buyers. For B2B stakeholders, understanding this evolution is crucial, as it informs purchasing decisions and highlights the importance of selecting the right adhesive for specific applications. As the market grows, staying updated on these trends will empower buyers to make informed choices that drive their businesses forward.

Frequently Asked Questions (FAQs) for B2B Buyers of glue for silicone

-

How do I solve adhesion issues with silicone materials?

Adhesion challenges with silicone are common due to its low surface energy. To improve bonding, consider using a primer designed for silicone, such as Loxeal Primer 7, followed by a suitable adhesive like cyanoacrylate for small parts. For larger applications, opt for room temperature curing silicone adhesives that can bond without primers, provided the surface is clean. Additionally, thermosetting silicone adhesives may offer quicker curing times and better performance. Always ensure the silicone surface is free of contaminants for optimal adhesion. -

What is the best adhesive for bonding silicone rubber?

The best adhesive for bonding silicone rubber varies based on the application. Room temperature curing silicone adhesives, such as TSE397C or IS5628E, are highly effective and provide strong, elastic joints without needing a primer. For quick repairs or smaller parts, cyanoacrylate adhesives can be used, but they may not withstand outdoor conditions or provide elasticity. Understanding the specific silicone type and application requirements will guide you to the most suitable adhesive solution. -

What factors should I consider when selecting a silicone adhesive supplier?

When selecting a supplier for silicone adhesives, consider their product range, quality certifications, and compliance with international standards. Evaluate their expertise in silicone bonding applications, including technical support and guidance. Additionally, review customer testimonials and case studies to gauge their reliability. Ensure they offer flexible payment terms and have a robust logistics framework to facilitate timely deliveries, especially for international transactions. -

What are the minimum order quantities (MOQs) for silicone adhesives?

Minimum order quantities (MOQs) for silicone adhesives can vary significantly by supplier and product type. Many suppliers set MOQs to ensure cost-effectiveness in production and shipping. As a B2B buyer, inquire about MOQs for specific products, as some may offer lower quantities for first-time orders or samples. Understanding the MOQ can help in planning your inventory and ensuring you meet production demands without excessive stock. -

How can I ensure the quality of silicone adhesives before purchasing?

To ensure the quality of silicone adhesives, request product samples for testing before making a bulk purchase. Evaluate their performance in real-world applications relevant to your needs. Additionally, review the supplier’s quality assurance processes, including certifications like ISO or other relevant industry standards. Regular audits and feedback loops can also be established to maintain quality over time, ensuring the adhesives meet your specifications consistently. -

What payment terms should I negotiate with silicone adhesive suppliers?

When negotiating payment terms with silicone adhesive suppliers, consider factors such as order size, payment method, and your business’s cash flow needs. Common terms may include net 30, net 60, or upfront payments for first orders. Explore options for discounts on early payments or bulk orders. Establishing clear terms can help mitigate risks in international transactions, ensuring both parties are aligned on payment expectations and timelines. -

How do logistics and shipping impact the sourcing of silicone adhesives internationally?

Logistics and shipping play a critical role in the international sourcing of silicone adhesives. Assess the supplier’s ability to manage shipping logistics effectively, including customs clearance and delivery timelines. Consider factors such as shipping costs, lead times, and potential delays due to regulatory requirements in your region. Choosing a supplier with established logistics capabilities can minimize disruptions and ensure timely access to essential materials. -

What customization options are available for silicone adhesives?

Customization options for silicone adhesives can include variations in color, viscosity, curing time, and packaging size. Many suppliers are willing to work with clients to develop tailored solutions that meet specific application needs. Discuss your requirements openly with potential suppliers to explore available options. Custom formulations can enhance performance for particular uses, enabling you to achieve the desired results in your projects.

Top 7 Glue For Silicone Manufacturers & Suppliers List

1. Loctite – 401 Adhesive

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Common adhesives mentioned for bonding silicone to plastic include: Loctite 401 with 777 adhesive promoter, Sil-Poxy, and differential pressure sensitive adhesives like 3M 9699 or Nitto 5302A. Other methods discussed include flame treatment to prepare silicone surfaces, co-molding, and VHB tape.

2. Gluegun – ASI 335 Neutral Cure RTV Silicone

Domain: gluegun.com

Registered: 1997 (28 years)

Introduction: Best Silicone Adhesive and Sealant – All Surfaces

Key Products:

1. ASI 335 Neutral Cure RTV Silicone – All Colors – Sale price $186.00

2. American Sealants ASI 5900 Fast Grab Adhesive – Sale price $110.00

3. American Sealants ASI 502 100% RTV Silicone – Standard Colors – Sale price from $65.00

4. ASI 55 Hybrid Sealant and Adhesive – Sale price $115.00

5. ASI 388 Electronic Grade Silicone Adhesive…

3. Bambu Lab – Key Application Technique

Domain: forum.bambulab.com

Registered: 2019 (6 years)

Introduction: This company, Bambu Lab – Key Application Technique, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Super Glue Corp – Silicone Sealer

Domain: supergluecorp.com

Registered: 2001 (24 years)

Introduction: This company, Super Glue Corp – Silicone Sealer, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Tribotec – Loxeal and Silicone Adhesives

Domain: tribotec.se

Registered: 1996 (29 years)

Introduction: 1. Loxeal Primer 7 and Loxeal 34 quick glue: Used with primer for bonding small silicone parts. 2. TSE397C and RTV108: Room temperature curing silicone adhesives suitable for bonding silicone rubber, often without primer. TSE397C is fast curing; RTV108 is FDA classified. 3. IS5628E: Strong, viscous, room temperature curing adhesive specifically for silicone rubber with a tensile strength of 7.5 MP…

6. Hopson – H230 Cyanoacrylate Super Glue

Domain: hopsonglue.com

Registered: 2021 (4 years)

Introduction: Product Name: Hopson® H230 Cyanoacrylate Super Glue

Type: Cyanoacrylate Super Glue

Key Features:

– Strong and quick bonding in seconds

– Flexible durability that moves with silicone

– Effective on tough surfaces, specifically designed for silicone

– No primer required for bonding

– Fully cured in 24 hours

– Heat-resistant and waterproof (temperature range: -40°F to 250°F / -40°C to 120°C)

Applicat…

7. GE – Silicone 2® Glue

Domain: gesealants.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “GE Silicone 2® Glue”, “size”: “2.8 oz”, “type”: “General-purpose adhesive”, “features”: [“Permanently waterproof”, “Flexible”, “Strong adhesion”, “Shrink and crack-proof”, “Easy to apply”, “Clear and low odor”, “Tack-free in 30 minutes”, “Fully dries in 24 to 48 hours”, “30-minute water-ready”], “guarantee”: “Limited lifetime guarantee”, “applications”: [“Household”, “Craft appli…

Strategic Sourcing Conclusion and Outlook for glue for silicone

Why is Strategic Sourcing Crucial for Glue for Silicone in B2B Markets?

In conclusion, strategic sourcing of silicone adhesives and sealants is essential for international B2B buyers aiming to optimize their supply chain and product quality. The diverse range of silicone adhesives available—including room temperature curing options, thermosetting adhesives, and pressure-sensitive adhesives—offers unique advantages tailored to various applications. Understanding these options allows businesses to select the most effective products for their specific needs, enhancing operational efficiency and product durability.

Moreover, the importance of sourcing from reputable manufacturers cannot be overstated. Reliable suppliers not only guarantee product quality but also ensure compliance with international standards, which is particularly crucial in regions such as Africa, South America, the Middle East, and Europe. As market demands evolve, so too should your sourcing strategies, embracing innovation and sustainability.

Illustrative image related to glue for silicone

Looking ahead, the demand for high-performance silicone adhesives is set to grow. Businesses should proactively explore partnerships with leading suppliers to stay ahead of industry trends. By investing in strategic sourcing now, you position your company for success in the dynamic global market. Engage with trusted manufacturers today to secure a competitive edge in your adhesive solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.