A Deep Dive into Glenn Metalcraft Texas Solution

Introduction: Navigating the Global Market for glenn metalcraft texas

In today’s competitive landscape, sourcing quality metal spinning products from Glenn Metalcraft Texas can present challenges for international B2B buyers. Companies looking to procure precision-engineered metal components often grapple with issues such as supplier reliability, material selection, and compliance with regional standards. This guide serves as a comprehensive resource, addressing these concerns by exploring various types of metal spinning applications, the intricacies of supplier vetting, and cost considerations.

We delve into the specifics of Glenn Metalcraft Texas’s offerings, including their advanced metalworking services that cater to diverse industries—ranging from aerospace to automotive. By highlighting the unique capabilities of Glenn Metalcraft, we empower businesses in Africa, South America, the Middle East, and Europe, including regions like Vietnam and Saudi Arabia, to make informed purchasing decisions.

The insights provided herein will equip you with the knowledge needed to navigate the complexities of sourcing high-quality metal products. From understanding the nuances of material properties to assessing the technological advancements in metal spinning, this guide is designed to streamline your procurement process, ensuring that you find the best solutions tailored to your business needs. With a focus on quality, craftsmanship, and customer satisfaction, Glenn Metalcraft Texas stands as a pivotal partner in your supply chain, ready to meet your unique specifications and drive your projects to success.

Understanding glenn metalcraft texas Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Spinning | Utilizes advanced techniques for shaping metals into cylindrical forms | Aerospace, Automotive, Architecture | Pros: Customization, high precision. Cons: Potentially longer lead times for complex designs. |

| CNC Machining | Computer-controlled machining for high precision and repeatability | Industrial Equipment, Prototyping | Pros: Consistent quality, efficient production. Cons: Higher initial setup costs. |

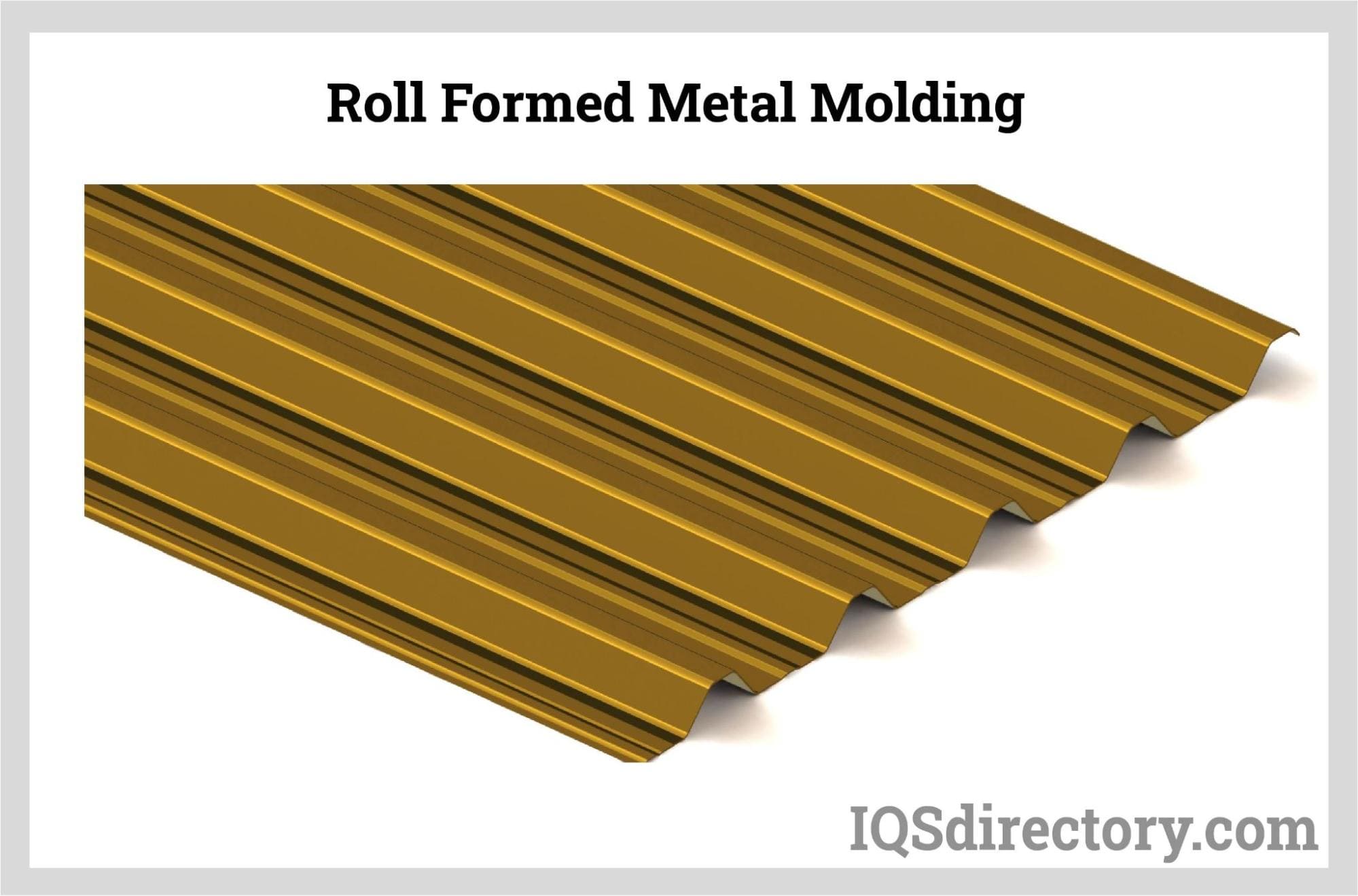

| Metal Fabrication | Involves cutting, bending, and assembling metal materials | Construction, Manufacturing | Pros: Versatile applications, tailored solutions. Cons: Complexity in project management. |

| Welding Services | Joining metals through various welding techniques | Heavy Machinery, Aerospace | Pros: Strong, durable joints. Cons: Requires skilled labor for quality assurance. |

| Finishing Services | Surface treatments like painting and powder coating | Consumer Products, Electronics | Pros: Enhances aesthetics and corrosion resistance. Cons: May add to project timelines. |

What are the Key Characteristics of Metal Spinning in B2B Applications?

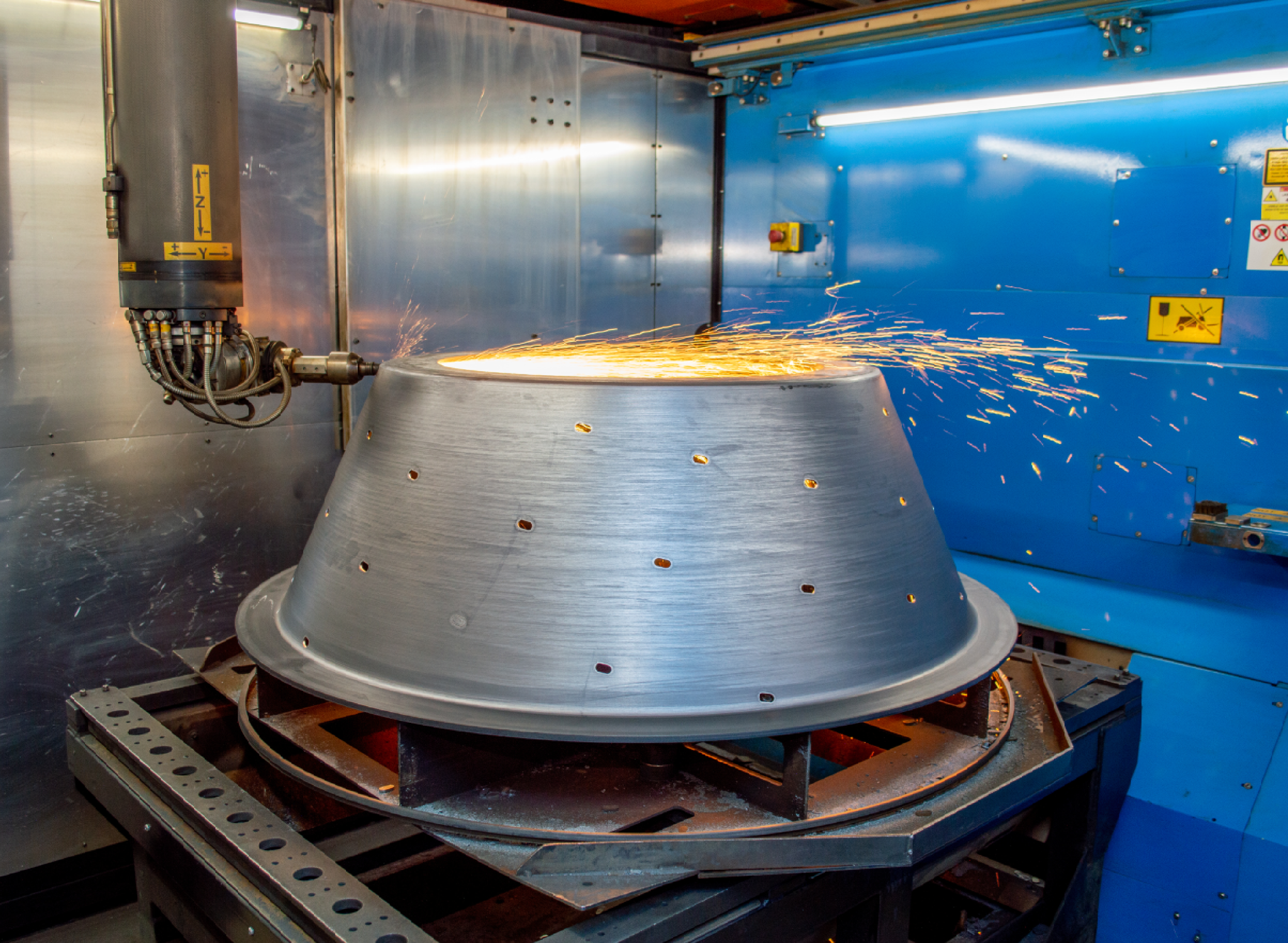

Metal spinning is a unique process that shapes metal into precise cylindrical and conical forms using a lathe. This technique is particularly suited for creating parts with symmetrical designs, making it ideal for industries like aerospace and automotive, where precision is paramount. Buyers should consider factors such as material selection and design complexity, as these can influence production timelines and costs. Customization options allow for tailored solutions, but intricate designs may lead to longer lead times.

How Does CNC Machining Benefit B2B Buyers?

CNC machining employs computer-controlled tools to achieve high precision and repeatability in manufacturing. This method is crucial for producing components that require tight tolerances, making it suitable for industrial equipment and prototyping. B2B buyers benefit from consistent quality and efficient production runs, although the initial setup costs can be higher compared to other methods. It’s essential for buyers to assess their volume needs and budget constraints when considering CNC machining services.

Why is Metal Fabrication a Versatile Choice for Various Industries?

Metal fabrication encompasses a range of processes, including cutting, bending, and assembling metal materials into finished products. Its versatility allows it to cater to diverse sectors such as construction and manufacturing. Buyers should evaluate project complexity and the required lead time, as managing multiple fabrication processes can be challenging. Tailored solutions often result in enhanced project outcomes, but effective communication with the fabricator is key to success.

What Should B2B Buyers Consider About Welding Services?

Welding services are essential for creating strong and durable metal joints, especially in heavy machinery and aerospace applications. Various welding techniques are available, allowing for flexibility based on material types and project requirements. Buyers must consider the skill level of the welding personnel, as quality assurance is critical to prevent structural failures. While welding provides robust solutions, it may also require additional inspections and certifications, adding to project timelines.

How Do Finishing Services Enhance Product Value for Buyers?

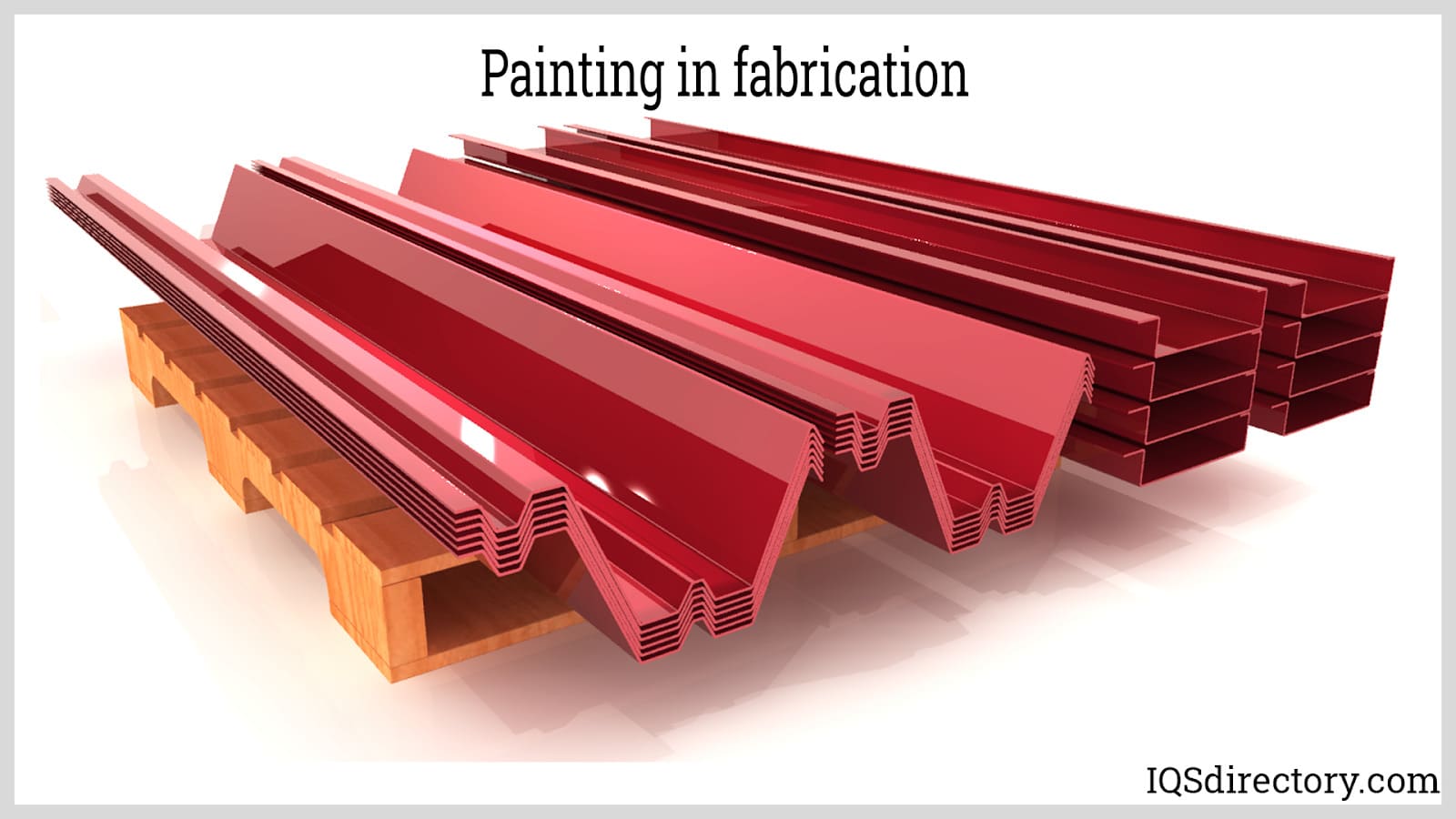

Finishing services, including painting and powder coating, play a vital role in enhancing the aesthetics and durability of metal products. These treatments are particularly important in consumer products and electronics, where appearance and corrosion resistance are critical. Buyers should weigh the benefits of improved product value against the potential for increased project timelines. Understanding the specific finishing requirements and their impact on overall project delivery is crucial for effective procurement.

Key Industrial Applications of glenn metalcraft texas

| Industry/Sector | Specific Application of Glenn Metalcraft Texas | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Custom components for aircraft interiors and exteriors | Enhanced performance and aesthetics in aircraft design | Need for precision, compliance with aerospace standards, and material certification |

| Automotive | Metal spun parts for vehicle manufacturing | Lightweight and durable components improving fuel efficiency | Demand for high-volume production, custom designs, and quick turnaround times |

| Architectural | Decorative metal elements for buildings and structures | Unique design possibilities that enhance visual appeal | Focus on design flexibility, material choices, and installation support |

| Industrial Equipment | Specialized parts for machinery and equipment | Increased operational efficiency and reduced downtime | Importance of durability, custom specifications, and integration with existing systems |

| Renewable Energy | Components for wind turbines and solar panels | Contribution to sustainable energy solutions | Need for high-quality materials, compliance with industry regulations, and reliability under extreme conditions |

How Does Glenn Metalcraft Texas Serve the Aerospace Industry?

In the aerospace sector, Glenn Metalcraft Texas specializes in producing custom components that meet stringent safety and performance standards. Their expertise in metal spinning allows for the creation of lightweight yet strong parts essential for aircraft interiors and exteriors. International buyers, particularly from regions like the Middle East and Europe, must consider compliance with aerospace regulations and certification of materials. The focus on precision ensures that these components enhance both the aesthetics and functionality of aircraft, providing a competitive edge in a highly regulated industry.

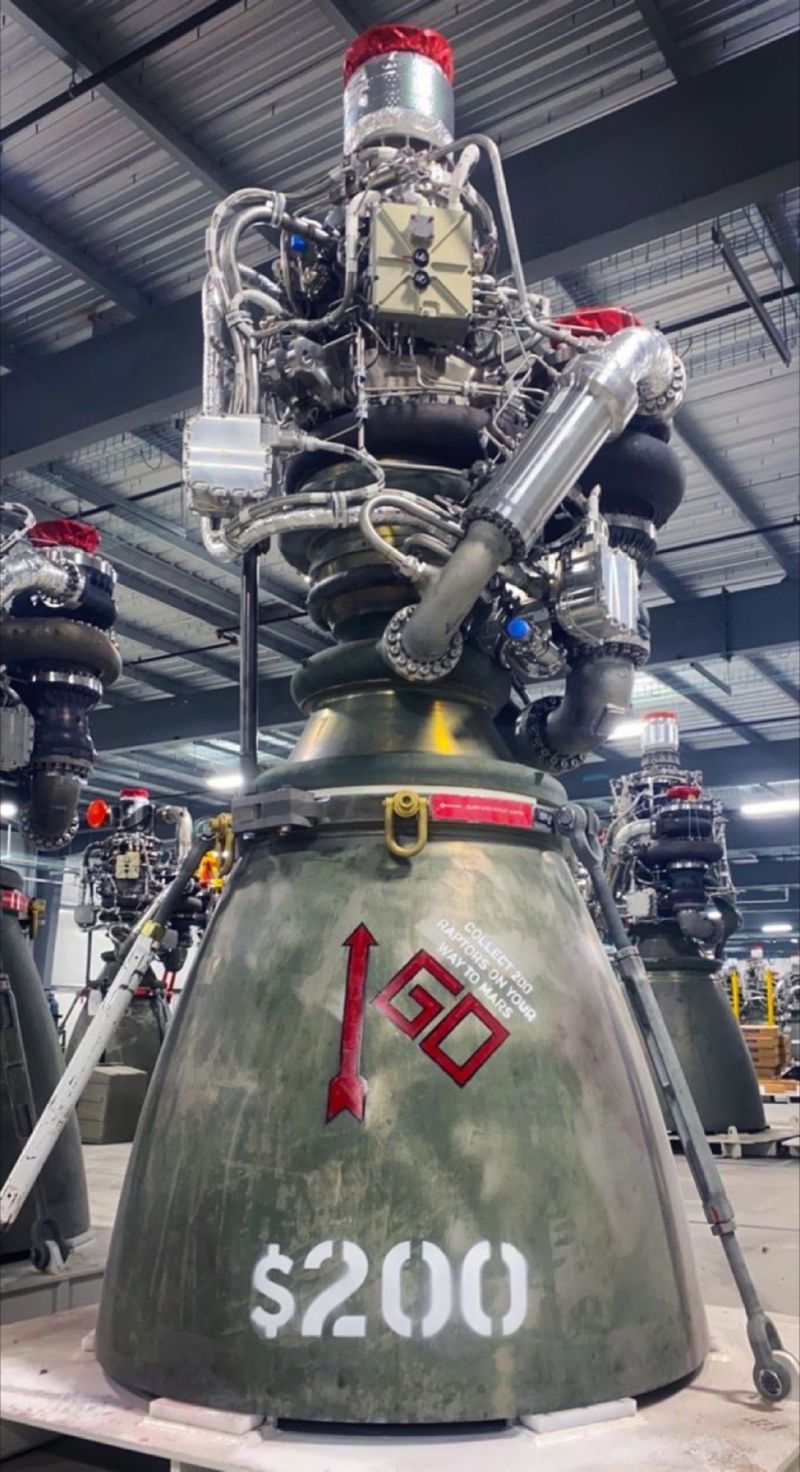

Illustrative image related to glenn metalcraft texas

What Are the Applications in the Automotive Industry?

Glenn Metalcraft Texas plays a pivotal role in the automotive industry by providing metal spun parts that contribute to vehicle manufacturing. These components are designed to be lightweight, which is crucial for improving fuel efficiency and overall vehicle performance. B2B buyers from South America and Africa should prioritize suppliers that can handle high-volume production while ensuring quick turnaround times. Custom designs tailored to specific vehicle models are essential, as they help automotive manufacturers differentiate their products in a crowded market.

How Is Glenn Metalcraft Texas Used in Architectural Projects?

In architecture, Glenn Metalcraft Texas offers decorative metal elements that significantly enhance the visual appeal of buildings and structures. Their ability to spin metals into intricate shapes allows architects to explore unique design possibilities. Buyers from Europe looking for custom architectural components should consider the flexibility in design and the variety of materials available. Additionally, the company provides installation support, ensuring that the decorative elements are not only visually striking but also structurally sound.

What Role Does Glenn Metalcraft Texas Play in Industrial Equipment?

Glenn Metalcraft Texas supplies specialized parts for industrial machinery and equipment, focusing on enhancing operational efficiency. These components are crafted to withstand rigorous use, reducing the likelihood of equipment downtime. Buyers in Africa and South America need to emphasize the durability and reliability of these parts, as well as their compatibility with existing machinery. Custom specifications are often required to meet the diverse needs of different industrial applications, making Glenn Metalcraft a valuable partner in the manufacturing process.

Illustrative image related to glenn metalcraft texas

How Is Glenn Metalcraft Texas Contributing to Renewable Energy Solutions?

In the renewable energy sector, Glenn Metalcraft Texas manufactures components for wind turbines and solar panels, supporting the transition to sustainable energy sources. The focus on high-quality materials ensures that these parts can withstand harsh environmental conditions while maintaining performance. International buyers should prioritize sourcing from manufacturers that comply with industry regulations and provide reliable components. Glenn Metalcraft’s commitment to quality and innovation positions it as a leader in supplying critical components for the renewable energy industry, contributing to global sustainability efforts.

3 Common User Pain Points for ‘glenn metalcraft texas’ & Their Solutions

Scenario 1: Navigating Complex Customization Needs

The Problem: B2B buyers often require highly customized metal components that fit specific project specifications. However, they can struggle to communicate their needs effectively, leading to misunderstandings, delays, and additional costs. This is particularly challenging for international buyers who may face language barriers or cultural differences in technical communication.

The Solution: To mitigate these challenges, buyers should engage in a thorough preliminary consultation with Glenn Metalcraft Texas. Begin by preparing a detailed project brief that outlines the specific requirements, including dimensions, material specifications, and intended applications. Utilize visual aids such as sketches or CAD drawings to enhance understanding. Furthermore, leveraging Glenn Metalcraft’s expertise in design assistance can lead to more accurate specifications and potentially uncover cost-saving adjustments. Establishing a direct line of communication with their design team can ensure clarity and foster collaboration, ultimately streamlining the customization process.

Scenario 2: Overcoming Supply Chain Disruptions

The Problem: International buyers often face disruptions in their supply chains due to geopolitical factors, shipping delays, or regulatory hurdles. This unpredictability can lead to project delays and increased costs, especially for businesses relying on timely delivery of metal components for manufacturing or construction projects.

The Solution: To address these issues, buyers should work closely with Glenn Metalcraft Texas to develop a proactive supply chain strategy. This includes discussing lead times upfront and understanding their production schedules. Consider placing bulk orders or establishing long-term contracts to secure a consistent supply of essential components. Furthermore, inquire about Glenn Metalcraft’s capabilities for expedited production or alternative materials that can be sourced more readily. By fostering a transparent relationship and maintaining regular communication, buyers can better anticipate potential disruptions and adapt their plans accordingly.

Illustrative image related to glenn metalcraft texas

Scenario 3: Ensuring Quality Control Across Borders

The Problem: Quality control is a significant concern for B2B buyers, particularly when sourcing products from overseas manufacturers. There may be apprehensions regarding whether the products meet the required industry standards, which can lead to costly reworks or product failures in the field.

The Solution: To ensure high-quality outcomes, buyers should leverage Glenn Metalcraft Texas’s robust quality assurance protocols. Prior to placing an order, request detailed information about their quality control processes, including inspection methods and certifications. It’s beneficial to establish clear quality benchmarks and communicate these expectations during the design and production phases. Buyers can also arrange for periodic updates or even on-site inspections if feasible. By actively involving themselves in the quality assurance process and utilizing Glenn Metalcraft’s commitment to craftsmanship, buyers can significantly reduce the risk of quality-related issues and enhance their overall satisfaction with the products received.

Strategic Material Selection Guide for glenn metalcraft texas

What Are the Key Properties of Aluminum for Metal Spinning Applications?

Aluminum is a popular choice for metal spinning due to its lightweight nature and excellent corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for a variety of applications, including aerospace and automotive components. The material’s malleability allows for intricate designs and shapes, which can enhance the aesthetic appeal of products. Additionally, aluminum is recyclable, aligning with sustainability goals that many international buyers prioritize.

What Are the Advantages and Disadvantages of Using Stainless Steel?

Stainless steel is renowned for its strength and durability, with high resistance to corrosion, making it ideal for applications in harsh environments. It can handle elevated temperatures and pressures, ensuring longevity in demanding applications. However, the cost of stainless steel is generally higher compared to other materials, and its manufacturing process can be more complex due to its toughness. This complexity may lead to longer lead times, which is a critical consideration for international buyers who need timely delivery.

How Does Brass Perform in Metal Spinning Applications?

Brass is another viable material for metal spinning, known for its excellent machinability and aesthetic qualities. It offers good corrosion resistance and is often used in decorative applications as well as in plumbing and electrical components. However, brass can be more expensive than aluminum and may not perform as well under extreme conditions. For international buyers, understanding the specific grades of brass and their compliance with local standards is essential, as preferences can vary significantly across regions.

What Should International Buyers Consider When Selecting Copper?

Copper is widely recognized for its superior electrical and thermal conductivity, making it an excellent choice for electrical components and heat exchangers. It has good corrosion resistance, especially in non-oxidizing environments. However, copper is heavier and more expensive than aluminum and brass, which may limit its use in certain applications. For international buyers, compliance with industry standards such as ASTM or JIS is crucial, as is the understanding of local market preferences regarding copper’s use in various applications.

Summary Table of Material Selection for Glenn Metalcraft Texas

| Material | Typical Use Case for glenn metalcraft texas | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, decorative elements | Lightweight and corrosion-resistant | Limited strength compared to steel | Medium |

| Stainless Steel | Industrial parts, automotive components | High strength and durability | Higher cost and manufacturing complexity | High |

| Brass | Plumbing fixtures, decorative applications | Excellent machinability and aesthetics | More expensive and less durable | Medium |

| Copper | Electrical components, heat exchangers | Superior conductivity | Heavy and higher cost | High |

This guide provides a comprehensive overview of material selection considerations for international B2B buyers engaging with Glenn Metalcraft Texas. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their specific project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for glenn metalcraft texas

What Are the Key Stages of Manufacturing at Glenn Metalcraft Texas?

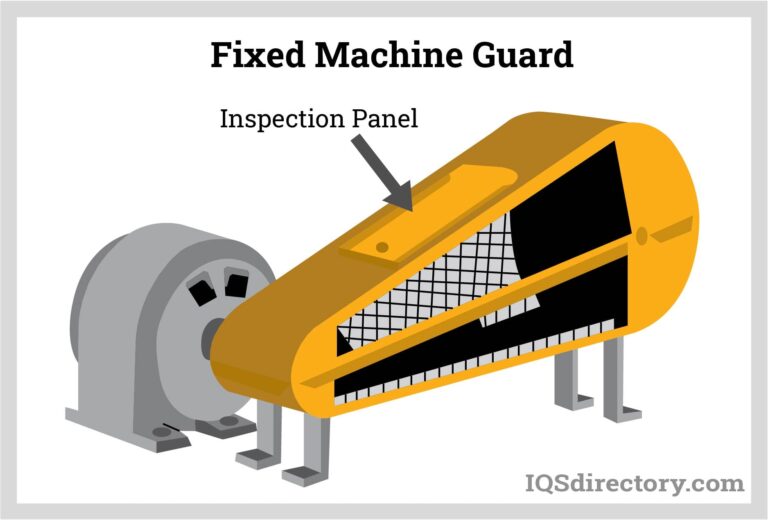

Glenn Metalcraft Texas employs a systematic approach to manufacturing that ensures precision and quality in metal spinning and metalworking services. The main stages of their manufacturing process include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting the appropriate metal type, such as aluminum, stainless steel, brass, or copper, based on the specific requirements of the project. The materials are then cut to size and prepped for the spinning process. This preparation is crucial, as the quality of raw materials directly impacts the final product.

-

Forming: Utilizing advanced metal spinning techniques, Glenn Metalcraft transforms the prepared metal sheets into cylindrical and conical shapes. This process involves applying lateral forces to the metal while it is rotated, allowing for precise shaping without compromising the material’s integrity. The company employs state-of-the-art CNC spin forming technology, which enhances accuracy and reduces production time.

-

Assembly: After the forming stage, the various components may require assembly, especially for complex projects that involve multiple parts. The assembly process is carefully managed to ensure that all parts fit together seamlessly, meeting the design specifications and performance requirements.

-

Finishing: The final stage includes surface treatments and finishing processes such as welding, machining, painting, or coating. These processes not only enhance the aesthetics of the products but also improve their durability and resistance to environmental factors.

How Does Glenn Metalcraft Texas Ensure Quality Control?

Quality assurance is integral to Glenn Metalcraft’s operations, ensuring that every product meets both industry standards and customer expectations. The company adheres to several international quality standards, including ISO 9001, which outlines the criteria for an effective quality management system.

-

Quality Control Checkpoints: Quality control is embedded at various stages of the manufacturing process:

– Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon receipt to ensure they meet specified standards and are free from defects.

– In-Process Quality Control (IPQC): During the manufacturing process, various inspections are conducted to monitor and maintain quality. This includes checking dimensions and tolerances at critical stages.

– Final Quality Control (FQC): Before products are dispatched, they undergo a comprehensive final inspection to verify that they meet all specifications and quality standards. -

Testing Methods: Glenn Metalcraft employs various testing methods to ensure product integrity, including dimensional inspections, material property tests, and visual inspections. These tests help identify any potential issues early in the process, allowing for timely corrections.

How Can B2B Buyers Verify the Quality Control Processes of Glenn Metalcraft Texas?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding and verifying a supplier’s quality control processes is essential. Here are several strategies to ensure that Glenn Metalcraft meets your quality expectations:

Illustrative image related to glenn metalcraft texas

-

Supplier Audits: Conducting a thorough audit of Glenn Metalcraft’s facilities can provide insights into their manufacturing processes and quality control measures. This includes examining their equipment, staff qualifications, and adherence to quality standards.

-

Quality Control Reports: Requesting detailed quality control reports can help buyers understand the outcomes of the various inspections and tests conducted throughout the manufacturing process. These reports should outline any non-conformities and the actions taken to address them.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing and quality assurance processes at Glenn Metalcraft. These inspections can be particularly beneficial for buyers who may not have the resources to conduct in-house evaluations.

-

Certifications and Compliance: Buyers should look for certifications that demonstrate compliance with international standards, such as CE marking for European markets or API specifications for the oil and gas industry. These certifications indicate that Glenn Metalcraft adheres to recognized quality and safety standards.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must navigate various nuances when it comes to quality control, especially when dealing with suppliers in different countries. Here are some considerations specific to B2B transactions with Glenn Metalcraft:

-

Understanding Regional Standards: Different regions may have specific quality standards and regulations that must be adhered to. Buyers should familiarize themselves with these standards to ensure compliance and avoid potential issues during importation.

-

Cultural Differences in Quality Expectations: Different cultures may have varying expectations regarding quality and service. Clear communication of quality standards and expectations is crucial to ensure alignment between Glenn Metalcraft and its international clients.

-

Logistical Challenges: Shipping products internationally can introduce risks such as damage during transit. Buyers should discuss packaging and shipping methods with Glenn Metalcraft to ensure that products arrive in optimal condition.

-

Long-Term Relationships: Establishing a long-term relationship with Glenn Metalcraft can facilitate better communication and understanding regarding quality expectations. Regular feedback and collaboration can enhance product quality and service delivery.

Conclusion

Glenn Metalcraft Texas exemplifies a comprehensive approach to manufacturing and quality assurance in the metal spinning industry. By understanding their manufacturing processes and quality control measures, international B2B buyers can make informed decisions and foster successful partnerships. Whether you are looking for custom solutions for aerospace, automotive, or architectural applications, Glenn Metalcraft’s commitment to quality and innovation positions them as a reliable partner in your supply chain.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glenn metalcraft texas’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring metal spinning products and services from Glenn Metalcraft Texas. By following these steps, you can ensure a seamless purchasing experience, minimize risks, and secure high-quality solutions tailored to your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for successful procurement. This includes identifying the type of metal, dimensions, tolerances, and surface finishes required for your project. By providing precise specifications, you enable Glenn Metalcraft Texas to deliver products that meet your expectations and avoid costly revisions later.

Illustrative image related to glenn metalcraft texas

- Key Details to Include:

- Material type (e.g., aluminum, stainless steel)

- Required dimensions and tolerances

- Surface treatment specifications

Step 2: Research Glenn Metalcraft Texas Capabilities

Understanding the capabilities of Glenn Metalcraft Texas is crucial. Review their portfolio to see examples of their metal spinning projects, including the industries they serve such as aerospace, automotive, and architectural applications. This knowledge will help you assess whether they can meet your specific project needs.

- Things to Look For:

- Range of metalworking services offered (e.g., welding, machining)

- Past projects and case studies

- Customer testimonials and feedback

Step 3: Evaluate Supplier Certifications

Before proceeding, verify the certifications and quality control measures implemented by Glenn Metalcraft Texas. Certifications such as ISO 9001 indicate a commitment to quality management systems, which can significantly impact the reliability and performance of the products you receive.

- Important Certifications:

- ISO 9001 for quality management

- Industry-specific standards relevant to your sector

Step 4: Request Detailed Quotes

Once you have defined your specifications and evaluated the supplier, request a detailed quote. A comprehensive quote should include pricing, lead times, and any additional costs for tooling or modifications. This transparency will help you gauge the overall value of the offering and make informed decisions.

- Key Elements to Include in Your Request:

- Breakdown of costs

- Estimated delivery times

- Terms of payment and warranty information

Step 5: Assess Communication and Support

Effective communication is vital in any B2B relationship. Reach out to Glenn Metalcraft Texas to evaluate their responsiveness and willingness to assist. Strong customer support can make a significant difference, especially during project development and troubleshooting.

- Questions to Ask:

- How quickly do they respond to inquiries?

- What support is available during and after the project?

Step 6: Review Shipping and Logistics Options

Consider the logistics involved in shipping your products from Glenn Metalcraft Texas to your location. Discuss shipping methods, costs, and delivery timelines to ensure they align with your project schedule. Understanding these factors can help you avoid delays and additional expenses.

Illustrative image related to glenn metalcraft texas

- Logistical Considerations:

- Shipping methods available (e.g., air, sea)

- Estimated shipping costs

- Customs and import regulations for your region

Step 7: Establish a Trial Order

Before committing to a large order, consider placing a trial order. This allows you to evaluate the quality of the products and the efficiency of the supplier without significant risk. A trial order can serve as a benchmark for future collaborations.

- Benefits of a Trial Order:

- Assess product quality firsthand

- Evaluate the overall service experience

- Identify any potential issues early in the relationship

By following this checklist, you can confidently navigate the procurement process with Glenn Metalcraft Texas, ensuring that you secure the best possible metal spinning solutions for your business needs.

Comprehensive Cost and Pricing Analysis for glenn metalcraft texas Sourcing

Understanding the cost structure and pricing strategy of Glenn Metalcraft Texas is crucial for international B2B buyers looking to source metal spinning products and related services. Here, we break down the key components of their pricing model, the factors that influence these prices, and provide actionable insights for effective negotiation.

What Are the Key Cost Components in Glenn Metalcraft Texas Pricing?

-

Materials: The choice of materials significantly impacts costs. Glenn Metalcraft Texas works with various metals, including aluminum, stainless steel, brass, and copper. Prices can fluctuate based on market demand, availability, and the specific characteristics required for the project.

-

Labor: Skilled labor is essential in the metal spinning process. The expertise of technicians and artisans contributes to labor costs. Companies must account for the labor intensity of custom projects, which may require more intricate workmanship.

-

Manufacturing Overhead: Overhead costs encompass utilities, equipment maintenance, and facility expenses. Glenn Metalcraft Texas invests in advanced technologies, such as CNC spin forming, which may increase initial overhead but can enhance efficiency and reduce long-term costs.

-

Tooling: The cost of tooling is a critical factor, especially for custom orders. Initial tooling investments can be significant, but they are amortized over large production runs. Buyers may face higher costs for low-volume orders due to the necessity of creating custom tools.

-

Quality Control (QC): Stringent QC measures ensure that products meet industry standards and client specifications. This process incurs additional costs but is vital for maintaining product integrity and reducing defects, which can lead to costly reworks.

-

Logistics: Shipping costs can vary significantly based on location and the chosen Incoterms. For international buyers, understanding logistics is crucial, as duties, taxes, and shipping rates can impact the overall cost.

-

Margin: Glenn Metalcraft Texas, like any manufacturer, incorporates a profit margin into its pricing. The margin can vary based on market conditions, competition, and the specific nature of the projects.

Which Factors Influence Pricing for International Buyers?

-

Volume and Minimum Order Quantity (MOQ): Pricing is often tiered based on order volume. Larger orders typically benefit from reduced per-unit costs, while smaller orders may incur higher prices due to increased setup and tooling costs.

-

Specifications and Customization: Custom projects may entail additional costs related to design and engineering. Buyers seeking unique specifications should be prepared for potential price increases.

-

Material Choices: The selection of materials not only affects the base price but also influences durability and suitability for specific applications. Buyers should consider the long-term value of their material choices.

-

Quality and Certifications: Products with higher quality standards or specific certifications (e.g., ISO, ASTM) may come at a premium. Buyers should evaluate the importance of these certifications based on their industry requirements.

-

Supplier Factors: The reputation and reliability of Glenn Metalcraft Texas play a role in pricing. Established suppliers with a strong track record may command higher prices due to perceived value.

-

Incoterms: Understanding the agreed Incoterms can impact the overall cost. Different terms can affect who is responsible for shipping, insurance, and tariffs, thereby influencing the final price.

What Tips Can Help Buyers Negotiate Better Prices?

-

Leverage Volume Discounts: If possible, consolidate orders to meet higher volume thresholds to benefit from reduced pricing.

-

Discuss Specifications Upfront: Clearly outline project specifications early in the discussion to avoid unexpected costs related to customizations.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also the durability and maintenance costs of products over their lifecycle. Sometimes, investing in higher-quality products can lead to long-term savings.

-

Research Market Conditions: Stay informed about fluctuations in metal prices and labor costs, as these can influence negotiations.

-

Utilize Local Knowledge: For international buyers, engaging local representatives or consultants familiar with the U.S. market can provide valuable insights and enhance negotiating power.

Disclaimer on Indicative Prices

Prices may vary based on market conditions, material availability, and project specifics. It is advisable for buyers to request detailed quotes that reflect their unique requirements and circumstances.

Alternatives Analysis: Comparing glenn metalcraft texas With Other Solutions

Understanding Alternatives in Metal Spinning and Fabrication

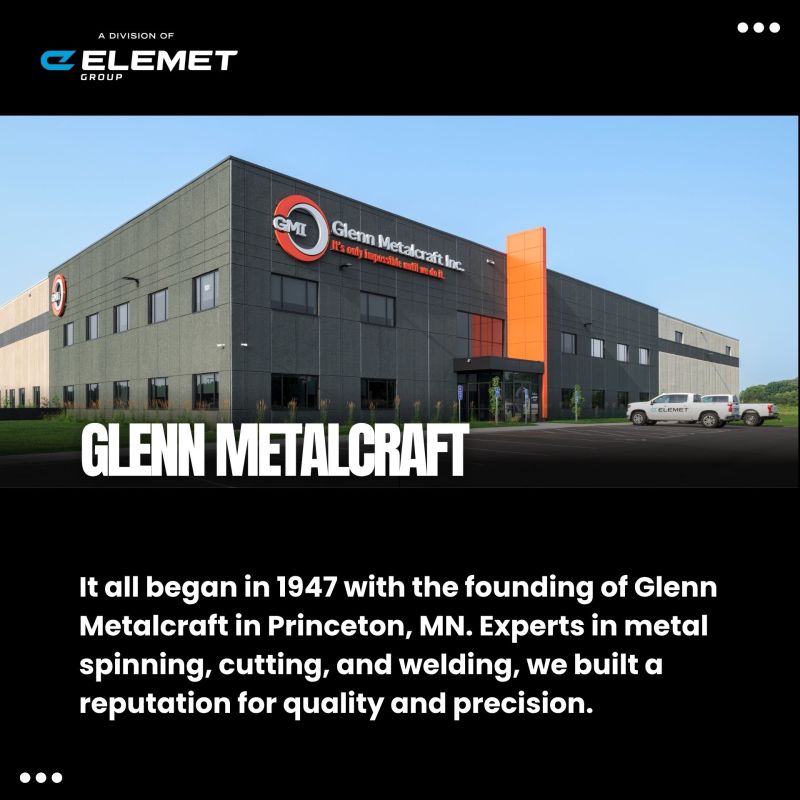

In the competitive landscape of metal spinning and fabrication, businesses often seek alternatives that can provide similar or enhanced capabilities compared to established players like Glenn Metalcraft Texas. Evaluating alternatives is crucial for B2B buyers to ensure they are making informed decisions that align with their operational needs and budget constraints. This section presents a comparative analysis of Glenn Metalcraft Texas against two viable alternatives: Elemet Group and US Metal Spinning Inc.

| Comparison Aspect | Glenn Metalcraft Texas | Elemet Group | US Metal Spinning Inc. |

|---|---|---|---|

| Performance | High precision and quality control | Comprehensive range of services | Reliable but slightly lower precision |

| Cost | Competitive pricing for quality | Moderate pricing, value in bundling | Generally lower cost, variable quality |

| Ease of Implementation | Streamlined processes, customer-focused | Integrated services simplify projects | Direct approach, less customization |

| Maintenance | Strong support and quality assurance | Extensive customer support | Standard support, less proactive |

| Best Use Case | Custom solutions for diverse industries | Large-scale projects needing multiple services | Smaller projects with budget constraints |

What Are the Pros and Cons of Each Alternative?

Elemet Group: A Comprehensive Metal Fabrication Solution

Elemet Group emerges as a strong contender, particularly for businesses looking for a one-stop-shop solution. With a wide array of services that include CNC machining, welding, and finishing alongside metal spinning, Elemet Group is well-positioned to handle complex projects that require coordination across multiple stages. However, while the breadth of services can simplify project management, it may lead to higher costs and longer lead times compared to specialized providers like Glenn Metalcraft Texas. Their emphasis on customer support enhances the overall experience but may not cater to projects needing highly customized solutions.

US Metal Spinning Inc.: Cost-Effective for Smaller Projects

US Metal Spinning Inc. offers a more budget-friendly option for companies, especially those with smaller projects or simpler requirements. Their straightforward approach allows for quicker turnaround times, making them an attractive choice for clients needing fast solutions. However, the trade-off may be in the precision and quality of the products, which might not meet the same stringent standards as Glenn Metalcraft Texas. While cost-effective, this option may require buyers to compromise on quality and customization, which could affect the final project’s performance.

How to Choose the Right Metal Spinning Solution for Your Business

When considering alternatives to Glenn Metalcraft Texas, B2B buyers should assess their specific needs, including project scale, budget, and the required level of customization. Understanding the strengths and weaknesses of each option is essential in making an informed decision. For businesses focused on high-quality, custom solutions, Glenn Metalcraft Texas remains a strong choice. However, for projects that prioritize cost-effectiveness or require a broader range of services, Elemet Group or US Metal Spinning Inc. could serve as viable alternatives. Ultimately, aligning the chosen solution with your operational goals will lead to the best outcomes for your projects.

Essential Technical Properties and Trade Terminology for glenn metalcraft texas

What Are the Key Technical Properties of Glenn Metalcraft Texas Products?

1. Material Grade

Material grade is crucial in determining the strength, durability, and corrosion resistance of the products manufactured by Glenn Metalcraft Texas. Common materials used include aluminum, stainless steel, brass, and copper. Each material grade has specific characteristics that make it suitable for various applications, such as aerospace or automotive components. Understanding material grades helps B2B buyers select the right material for their specific project requirements.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measured value of a product. In metal spinning and fabrication, achieving tight tolerances is essential for ensuring that parts fit together correctly and function as intended. Glenn Metalcraft Texas employs advanced techniques and equipment to maintain precise tolerances, which is critical for industries that require high levels of accuracy, such as aerospace or medical devices.

3. Finish

The finish of a metal product can significantly impact both aesthetics and functionality. Common finishes include polished, anodized, and powder-coated surfaces. A proper finish can enhance corrosion resistance, improve appearance, and facilitate easier cleaning. B2B buyers should consider the required finish for their applications to ensure that the final product meets operational standards and visual expectations.

4. Weight

Weight specifications are particularly important in industries where material weight can affect performance, such as aerospace and automotive. Lighter materials can improve fuel efficiency and reduce costs, while heavier materials may be necessary for structural integrity. Understanding the weight of the components being sourced is crucial for B2B buyers to optimize performance and cost-effectiveness.

5. Heat Treatment

Heat treatment involves controlled heating and cooling processes to alter the physical and sometimes chemical properties of a material. This can enhance strength, ductility, and hardness. For applications in extreme environments, such as aerospace or industrial machinery, heat treatment can be a critical factor in the longevity and reliability of components. Buyers should inquire about heat treatment options to ensure that products meet their operational demands.

6. Customization Capabilities

Customization refers to the ability to tailor products to meet specific customer requirements. Glenn Metalcraft Texas offers extensive customization options, allowing clients to specify dimensions, materials, and finishes. This flexibility is vital for B2B buyers who require unique solutions that align with their project specifications, ensuring that the final product integrates seamlessly into their applications.

What Are Common Trade Terms Relevant to Glenn Metalcraft Texas?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Glenn Metalcraft Texas, they provide OEM services to create custom metal components that are integrated into larger systems or products. Understanding OEM relationships helps buyers assess the reliability and quality of parts sourced for their operations.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest amount of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory planning. Glenn Metalcraft Texas may have specific MOQs based on production capabilities, which can influence purchasing decisions.

3. RFQ (Request for Quotation)

An RFQ is a formal process for soliciting price quotes from suppliers for specific products or services. B2B buyers should issue RFQs to Glenn Metalcraft Texas to receive detailed pricing and terms for their metal spinning and fabrication needs. This process enables buyers to compare costs and services among various suppliers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify shipping, insurance, and tariffs, which are crucial for global B2B buyers sourcing from Glenn Metalcraft Texas. Familiarity with Incoterms helps ensure smooth transactions and reduces the risk of misunderstandings in logistics.

5. Lead Time

Lead time refers to the period between the initiation of an order and its completion. Understanding lead times is critical for B2B buyers to plan their projects effectively. Glenn Metalcraft Texas communicates lead times based on order complexity and production schedules, helping clients manage their timelines and expectations.

6. Quality Assurance (QA)

QA encompasses the processes and measures taken to ensure that products meet specified requirements and standards. At Glenn Metalcraft Texas, stringent QA protocols are in place to guarantee product reliability and performance. Buyers should prioritize suppliers with robust QA practices to ensure they receive high-quality components that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the glenn metalcraft texas Sector

What Are the Key Market Dynamics and Trends Affecting Glenn Metalcraft Texas?

The market landscape for metalworking and metal spinning services is witnessing significant transformation driven by globalization, technological advancements, and evolving customer demands. International buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking high-quality, customized metal solutions that can be delivered with speed and efficiency. Key trends include the rise of automation and digitalization in manufacturing processes, which enhance precision and reduce lead times. The adoption of Industry 4.0 principles is enabling companies like Glenn Metalcraft Texas to streamline operations through real-time data analytics and predictive maintenance, thus improving overall productivity.

Additionally, there is a noticeable shift toward sourcing from suppliers who can provide integrated solutions. Buyers are looking for one-stop-shop capabilities that encompass design, material selection, and manufacturing services, reducing the complexity of managing multiple vendors. This trend is particularly relevant for industries such as aerospace and automotive, where precision and quality are paramount. Furthermore, the ongoing emphasis on sustainability is reshaping sourcing decisions, with more buyers prioritizing suppliers who demonstrate a commitment to environmentally responsible practices.

How Important Is Sustainability and Ethical Sourcing in B2B Transactions?

Sustainability and ethical sourcing have emerged as critical factors in B2B transactions, particularly in the metalworking sector. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to seek partners who minimize waste and energy consumption. Glenn Metalcraft Texas is well-positioned to meet this demand by integrating sustainable practices into its operations. This includes using eco-friendly materials and employing energy-efficient manufacturing techniques that reduce the carbon footprint of their products.

Illustrative image related to glenn metalcraft texas

Moreover, ethical supply chains are gaining traction, with a focus on transparency and fair labor practices. Buyers are increasingly inclined to collaborate with suppliers that have robust ethical standards and certifications. For Glenn Metalcraft Texas, acquiring green certifications and utilizing recycled materials can enhance its appeal to international clients who prioritize sustainability. By aligning with these values, Glenn Metalcraft Texas not only strengthens its market position but also fosters long-term relationships built on trust and shared goals.

What Is the Historical Context of Glenn Metalcraft Texas in the B2B Landscape?

Established in Fort Worth, Texas, Glenn Metalcraft has a rich history dating back to 1947, positioning itself as a pioneer in the metal spinning industry. Over the decades, the company has evolved from traditional metalworking practices to embracing advanced technologies, such as CNC spin forming. This evolution has enabled Glenn Metalcraft to enhance its product offerings and respond effectively to the diverse needs of its B2B clientele across various sectors, including aerospace, automotive, and industrial applications.

The company’s longstanding commitment to quality and customer satisfaction has fostered a reputation for excellence, making it a trusted partner for businesses seeking high-quality metal solutions. As Glenn Metalcraft continues to innovate and expand its capabilities, it remains focused on building strong, collaborative relationships with its clients, ensuring that they receive tailored solutions that drive their success in an increasingly competitive global market.

Illustrative image related to glenn metalcraft texas

Frequently Asked Questions (FAQs) for B2B Buyers of glenn metalcraft texas

-

How can I ensure the quality of products from Glenn Metalcraft Texas?

To guarantee product quality, Glenn Metalcraft Texas adheres to rigorous quality control measures throughout the manufacturing process. This includes meticulous inspections and testing to meet or exceed industry standards. As a B2B buyer, you can request documentation of quality certifications and previous project examples. Additionally, consider scheduling a factory visit to observe their processes firsthand and discuss your specific quality requirements with their team. -

What customization options are available for metal spinning products?

Glenn Metalcraft Texas offers extensive customization options to cater to diverse industry needs. You can specify dimensions, materials, and finishes for your metal spinning products. Their experienced team collaborates with clients to understand unique requirements and provide tailored solutions. When discussing your project, be clear about your specifications and desired outcomes to ensure the final product aligns with your vision. -

What are the minimum order quantities (MOQs) for international buyers?

Minimum order quantities at Glenn Metalcraft Texas may vary depending on the complexity and type of product required. Generally, they are flexible and can accommodate both small and large orders, but discussing your needs directly with their sales team is advisable. This way, you can find a solution that works within your budget and timeline, especially for international shipments. -

What payment terms does Glenn Metalcraft Texas offer for international orders?

Glenn Metalcraft Texas typically provides various payment options to accommodate international buyers, including wire transfers and letters of credit. Payment terms may vary based on the size of the order and your business relationship with them. It’s recommended to discuss specific payment terms early in the negotiation process to ensure mutual understanding and agreement. -

How does Glenn Metalcraft Texas handle logistics for international shipping?

Logistics for international orders are managed with a focus on efficiency and reliability. Glenn Metalcraft Texas collaborates with experienced freight forwarders to handle shipping and customs clearance, ensuring timely delivery of products. As a buyer, you should communicate your preferred shipping method and destination to help streamline the logistics process. -

What industries does Glenn Metalcraft Texas serve with their metal spinning services?

Glenn Metalcraft Texas serves a diverse range of industries, including aerospace, automotive, architectural, and industrial sectors. Their ability to produce high-quality, customized solutions makes them a versatile supplier for various applications. Understanding your specific industry requirements can help facilitate a more productive discussion regarding potential projects and solutions. -

How can I assess the reliability of Glenn Metalcraft Texas as a supplier?

To evaluate the reliability of Glenn Metalcraft Texas, consider researching their industry reputation, customer testimonials, and case studies. Engaging in direct conversations with their sales representatives can also provide insights into their responsiveness and customer service approach. Additionally, asking for references from other international buyers may help gauge their reliability and service quality. -

What support does Glenn Metalcraft Texas provide for design assistance?

Glenn Metalcraft Texas offers comprehensive design assistance to help clients develop effective and efficient metal spinning solutions. Their team can provide guidance on material selection, tooling solutions, and prototyping. Engaging their design experts early in your project can enhance the final product’s functionality and aesthetic appeal, ensuring it meets your specific requirements.

Top 2 Glenn Metalcraft Texas Manufacturers & Suppliers List

1. Elemet Group – Precision Manufacturing Solutions

Domain: elemetgroup.com

Registered: 2016 (9 years)

Introduction: Heavy Metal Spinning: High-quality parts created within tight tolerances.

Powder Coating: Production volume capacity with an integrated automatic powder coat line.

Large Part Machining: Industry leader in large work envelope CNC machining services.

Fabrication: Advanced technology in CNC, press brake, fiber optic lasers, robotic and manual welding.

Capabilities: ISO 9001:2015 Certified, 5-…

2. Prima Power – Laser Next 2141

Domain: primapower.com

Registered: 2004 (21 years)

Introduction: The Laser Next 2141 is a 3D fiber laser machine from Prima Power, featuring a working volume of 4,140 x 2,100 x 1,020 mm, which is the largest in the industry. It is designed for processing both large and small parts, providing flexibility for various industrial sectors including job shops, press shops, aerospace, agriculture, construction, and automotive. The machine can switch between cutting an…

Strategic Sourcing Conclusion and Outlook for glenn metalcraft texas

In conclusion, Glenn Metalcraft Texas stands out as a premier partner for international B2B buyers seeking high-quality metal spinning and comprehensive metalworking services. With a deep commitment to customer satisfaction, advanced manufacturing techniques, and stringent quality control, Glenn Metalcraft provides tailored solutions that meet the diverse needs of various industries, from aerospace to architecture. The company’s ability to deliver innovative, custom-made products while maintaining operational excellence is a testament to its strategic sourcing capabilities.

For buyers in Africa, South America, the Middle East, and Europe, leveraging Glenn Metalcraft’s expertise can significantly streamline supply chains and enhance project outcomes. The emphasis on collaboration and personalized service ensures that each client receives not just a product, but a partnership aimed at mutual success.

As the global market continues to evolve, the demand for quality and precision in manufacturing will only grow. Engaging with Glenn Metalcraft Texas today can position your business for future success, enabling you to tackle complex projects with confidence and innovation. Reach out now to explore how Glenn Metalcraft can be an integral part of your sourcing strategy.

Illustrative image related to glenn metalcraft texas

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.