A Deep Dive into Gas Strut Springs Solution

Introduction: Navigating the Global Market for gas strut springs

In an increasingly competitive global market, sourcing high-quality gas strut springs can pose significant challenges for international B2B buyers. With diverse applications ranging from automotive to industrial machinery, the need for reliable and efficient gas struts is paramount. This comprehensive guide aims to illuminate the complexities of navigating the gas strut springs market, offering insights into various types, applications, and best practices for supplier vetting. From understanding the technical specifications to evaluating pricing structures, this resource equips buyers with the knowledge necessary to make informed purchasing decisions.

As businesses in regions such as Africa, South America, the Middle East, and Europe—particularly in countries like Saudi Arabia and Vietnam—strive for operational efficiency, the role of gas strut springs becomes even more critical. This guide will delve into the nuances of selecting the right gas strut for specific applications, assessing suppliers’ capabilities, and identifying cost-effective solutions without compromising quality. By providing actionable insights and expert recommendations, we empower B2B buyers to streamline their procurement processes, optimize product performance, and ultimately enhance their operational success in a global marketplace. Whether you are a seasoned procurement professional or new to the industry, this guide serves as an invaluable tool for mastering the art of sourcing gas strut springs effectively.

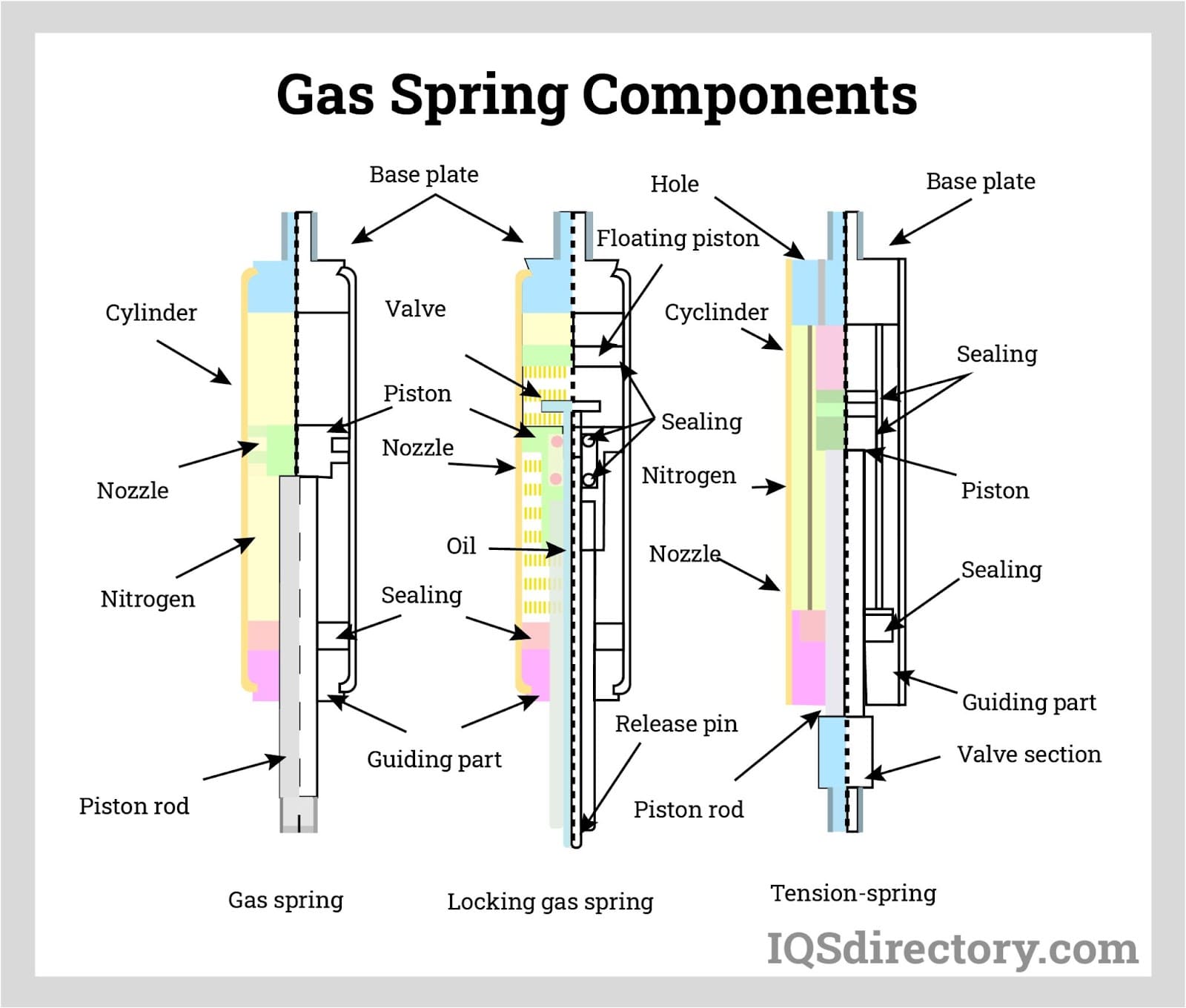

Understanding gas strut springs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Gas Struts | Typically made of steel, with adjustable pressure via a valve. | Automotive, furniture, industrial machinery. | Pros: Versatile, cost-effective. Cons: Limited customization. |

| Stainless Steel Gas Struts | Corrosion-resistant, suitable for harsh environments. | Marine applications, medical equipment, outdoor furniture. | Pros: Durable, long lifespan. Cons: Higher cost compared to standard. |

| Adjustable Gas Struts | Pressure can be manually adjusted for varying loads. | Custom applications, automotive hoods, toolboxes. | Pros: Flexible load handling. Cons: Complexity in adjustment. |

| Twin-Tube Gas Struts | Dual cylinder design for improved performance and stability. | Heavy machinery, commercial vehicles, RVs. | Pros: Enhanced stability, increased load capacity. Cons: Bulkier design. |

| Mini Gas Struts | Compact size for limited space applications. | Small appliances, compact furniture, automotive interiors. | Pros: Space-saving, lightweight. Cons: Limited load capacity. |

What are the Characteristics and Suitability of Standard Gas Struts?

Standard gas struts are the most commonly used type and are characterized by their steel construction and adjustable pressure through an integrated valve. They are ideal for a variety of applications, including automotive, furniture, and industrial machinery. When considering a purchase, B2B buyers should evaluate the specific weight and dimensions they need to support, as standard gas struts offer versatility but may not provide the customization needed for specialized applications.

How Do Stainless Steel Gas Struts Compare in Harsh Environments?

Stainless steel gas struts are designed to withstand corrosive environments, making them suitable for marine applications and medical equipment. Their resistance to rust and wear extends their lifespan, which can justify the higher upfront cost. B2B buyers should consider the operating environment and potential exposure to moisture or chemicals when selecting stainless steel options, as this will enhance the reliability of the equipment they are using.

What Advantages Do Adjustable Gas Struts Offer for Custom Applications?

Adjustable gas struts allow for manual pressure adjustments, making them ideal for custom applications where varying loads are common. They are frequently used in automotive hoods and toolboxes. B2B buyers should weigh the benefits of flexibility against the complexity of adjustments, which may require additional training or expertise to manage effectively.

Why Choose Twin-Tube Gas Struts for Heavy Machinery?

Twin-tube gas struts feature a dual cylinder design that provides improved performance and stability, making them suitable for heavy machinery and commercial vehicles. They can handle increased loads and provide enhanced stability during operation. Buyers in industries that require robust support systems should consider the bulkier design, which may impact installation space, but the benefits in load capacity can outweigh these concerns.

When are Mini Gas Struts the Best Option for B2B Buyers?

Mini gas struts are compact and lightweight, making them perfect for applications where space is limited, such as small appliances and automotive interiors. Their design allows for efficient use of space without compromising functionality. However, B2B buyers must be mindful of the limited load capacity and ensure that the mini struts can adequately support their specific needs.

Key Industrial Applications of gas strut springs

| Industry/Sector | Specific Application of gas strut springs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Liftgate and hood supports for vehicles | Enhances ease of access and safety for vehicle users | Durability, load capacity, and compatibility with vehicle models |

| Marine | Support for hatches and storage compartments on boats | Improves accessibility and safety in marine environments | Corrosion resistance and pressure specifications for marine use |

| Aerospace | Cabin storage compartment doors and equipment access | Facilitates efficient use of space and safety in aircraft | Weight considerations, pressure settings, and regulatory compliance |

| Furniture Manufacturing | Adjustable tables and reclining mechanisms | Adds functionality and user comfort in furniture products | Design compatibility, force adjustments, and aesthetic options |

| Industrial Equipment | Access doors and panels in machinery | Enhances maintenance efficiency and operator safety | Load ratings, environmental resistance, and installation ease |

How Are Gas Strut Springs Utilized in the Automotive Sector?

In the automotive industry, gas strut springs are essential for liftgate and hood supports, allowing for smooth opening and closing mechanisms. They enhance user convenience and safety by ensuring that heavy lids can be easily managed without manual strain. Buyers in this sector should consider the durability of the struts, as well as their load capacity and compatibility with specific vehicle models to ensure optimal performance and safety.

What Role Do Gas Strut Springs Play in Marine Applications?

Gas strut springs are widely used in the marine industry for supporting hatches and storage compartments on boats. These springs improve accessibility to essential equipment and storage areas, which is critical in the often confined spaces of marine vessels. For international buyers, sourcing options must prioritize corrosion resistance and precise pressure specifications to withstand harsh marine environments, ensuring longevity and reliability.

How Are Gas Strut Springs Essential in Aerospace?

In the aerospace sector, gas strut springs are utilized for cabin storage compartment doors and other access points. They facilitate efficient use of space and ensure safety during the boarding process. Buyers must pay close attention to weight considerations, as excessive weight can impact aircraft performance. Additionally, compliance with aviation regulations regarding pressure settings and materials is crucial for sourcing these components.

In What Ways Are Gas Strut Springs Used in Furniture Manufacturing?

Gas strut springs find application in furniture manufacturing, particularly in adjustable tables and reclining mechanisms. They provide added functionality and enhance user comfort, making products more appealing in competitive markets. Sourcing considerations include design compatibility with existing furniture lines, the ability to adjust force for various user weights, and aesthetic options that align with design trends.

What Are the Applications of Gas Strut Springs in Industrial Equipment?

In industrial settings, gas strut springs are commonly used for access doors and panels in machinery. They improve maintenance efficiency by allowing easy access to internal components, thereby enhancing operator safety. When sourcing for this application, businesses should focus on load ratings suitable for heavy machinery, environmental resistance to chemicals or extreme temperatures, and the ease of installation to minimize downtime during maintenance.

3 Common User Pain Points for ‘gas strut springs’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right Gas Strut for Specific Applications

The Problem: Many B2B buyers encounter significant challenges when it comes to selecting the appropriate gas strut for their specific application. With a wide range of options available in terms of force, size, and materials, the risk of choosing an unsuitable strut can lead to product failures, safety issues, and increased costs. Buyers often find themselves overwhelmed by technical specifications, making it difficult to discern which gas strut will effectively meet their requirements. This confusion can be exacerbated by a lack of detailed product information and inadequate support from suppliers.

The Solution: To alleviate this pain point, B2B buyers should leverage gas spring configurators and calculators provided by reputable suppliers. These tools allow users to input specific application details, such as the weight of the object being supported and the required stroke length. By using these resources, buyers can generate tailored recommendations for gas struts that are suitable for their needs. Additionally, engaging with customer support teams can provide valuable insights. A knowledgeable representative can guide buyers through the selection process, ensuring they understand the nuances of gas strut specifications and helping to mitigate the risk of incorrect purchases.

Scenario 2: Inconsistent Quality and Performance Across Different Suppliers

The Problem: Quality inconsistency is a common concern for B2B buyers sourcing gas strut springs from various suppliers. While some manufacturers may offer high-quality products, others may compromise on materials or manufacturing processes, leading to premature failures. This inconsistency can disrupt operations, resulting in unexpected downtimes and additional costs for replacements. Furthermore, buyers often struggle to evaluate the reliability of new suppliers, particularly when entering unfamiliar markets.

The Solution: To overcome this challenge, B2B buyers should prioritize sourcing gas struts from reputable suppliers with proven track records. This includes checking certifications, customer reviews, and industry reputation before making a purchase. Establishing long-term relationships with trusted suppliers can also enhance reliability, as they are more likely to provide consistent quality and performance. Implementing a quality assurance process—such as testing samples before large orders—can further ensure that the gas struts meet the necessary performance standards. Additionally, buyers should actively seek feedback from their operational teams regarding the performance of gas struts in real-world applications to inform future sourcing decisions.

Scenario 3: Complications in Replacement and Compatibility Issues

The Problem: When it comes time to replace existing gas struts, many buyers face compatibility issues. The original specifications may be difficult to find, especially for older models, leading to uncertainty about which replacement parts will work effectively. This can result in prolonged downtimes, as the search for a suitable replacement can be time-consuming and frustrating. Furthermore, without proper guidance, buyers may inadvertently order struts that do not fit the existing mounting systems, compounding the issue.

The Solution: To streamline the replacement process, B2B buyers should utilize comprehensive databases or catalogs provided by suppliers that include detailed specifications and compatibility information for various gas struts. Many suppliers also offer replacement configurators that allow users to search by the original part number or type, facilitating the identification of suitable alternatives. In cases where specific replacements are not readily available, buyers can work with suppliers to customize gas struts based on their existing requirements. It’s also beneficial to maintain a record of the specifications for all gas struts used in operations, which can serve as a quick reference for future replacements. Engaging in proactive communication with suppliers regarding their replacement policies and support services can further enhance the efficiency of sourcing compatible parts.

Strategic Material Selection Guide for gas strut springs

What Are the Key Materials Used in Gas Strut Springs?

Gas strut springs are integral components in various applications, requiring careful material selection to ensure optimal performance and longevity. Here, we analyze four common materials used in the manufacturing of gas strut springs: steel, stainless steel, aluminum, and composite materials.

How Does Steel Perform in Gas Strut Springs?

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for applications requiring significant load-bearing capacity. It typically has a temperature rating of up to 300°C and can withstand high pressures, which is essential for gas strut functionality.

Pros & Cons: The primary advantage of steel is its strength and cost-effectiveness, making it a popular choice for many applications. However, it is prone to corrosion if not adequately protected, which can limit its lifespan in harsh environments.

Impact on Application: Steel gas struts are compatible with a wide range of media, including oils and gases. However, in humid or corrosive environments, additional coatings or treatments may be necessary to prevent rust.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or DIN. The availability of quality steel can vary, so sourcing from reputable suppliers is crucial.

What Are the Advantages of Stainless Steel for Gas Strut Springs?

Key Properties: Stainless steel offers excellent corrosion resistance, high strength, and good temperature stability. It can perform well in temperatures ranging from -40°C to 300°C, making it suitable for diverse applications.

Pros & Cons: The key advantage of stainless steel is its resistance to rust and corrosion, making it ideal for outdoor or marine applications. However, it is generally more expensive than regular steel, which can impact the overall project budget.

Illustrative image related to gas strut springs

Impact on Application: Stainless steel gas struts are particularly effective in environments where exposure to moisture or chemicals is a concern. They are also compatible with a variety of media, ensuring versatility in application.

Considerations for International Buyers: Buyers in Europe and South America often prefer stainless steel for its durability. It’s essential to verify compliance with international standards, especially for industries like automotive or aerospace.

How Does Aluminum Compare for Gas Strut Springs?

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a temperature rating of up to 150°C. Its lower density makes it suitable for applications where weight reduction is critical.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which can enhance the performance of applications requiring mobility. However, it has lower tensile strength compared to steel, which may limit its use in heavy-load applications.

Impact on Application: Aluminum gas struts are ideal for applications in the aerospace and automotive industries where weight savings are paramount. However, they may not be suitable for high-pressure environments.

Considerations for International Buyers: In regions like Vietnam and Brazil, where weight is a critical factor, aluminum gas struts are increasingly popular. Buyers should ensure that the material meets local manufacturing standards.

Are Composite Materials a Viable Option for Gas Strut Springs?

Key Properties: Composite materials offer a unique combination of lightweight and high strength, with excellent resistance to corrosion and chemicals. They can operate effectively in a wide temperature range, typically from -50°C to 120°C.

Pros & Cons: The key advantage of composites is their high strength-to-weight ratio, making them ideal for specialized applications. However, they can be more expensive and complex to manufacture, which may deter some buyers.

Impact on Application: Composite gas struts are particularly useful in industries like aerospace and automotive, where performance and weight are critical. Their chemical resistance makes them suitable for harsh environments.

Considerations for International Buyers: Buyers from regions with stringent environmental regulations may prefer composites for their durability and low maintenance. Compliance with international standards is essential for ensuring product reliability.

Summary Table of Material Selection for Gas Strut Springs

| Material | Typical Use Case for gas strut springs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General industrial applications | High strength and cost-effective | Prone to corrosion | Low |

| Stainless Steel | Marine and outdoor applications | Excellent corrosion resistance | Higher cost than regular steel | Med |

| Aluminum | Aerospace and automotive applications | Lightweight and good corrosion resistance | Lower tensile strength | Med |

| Composite | Specialized aerospace and automotive | High strength-to-weight ratio | More expensive and complex to manufacture | High |

This analysis provides a comprehensive overview of material options for gas strut springs, highlighting critical factors for B2B buyers in diverse global markets. Understanding these materials’ properties and implications will assist in making informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for gas strut springs

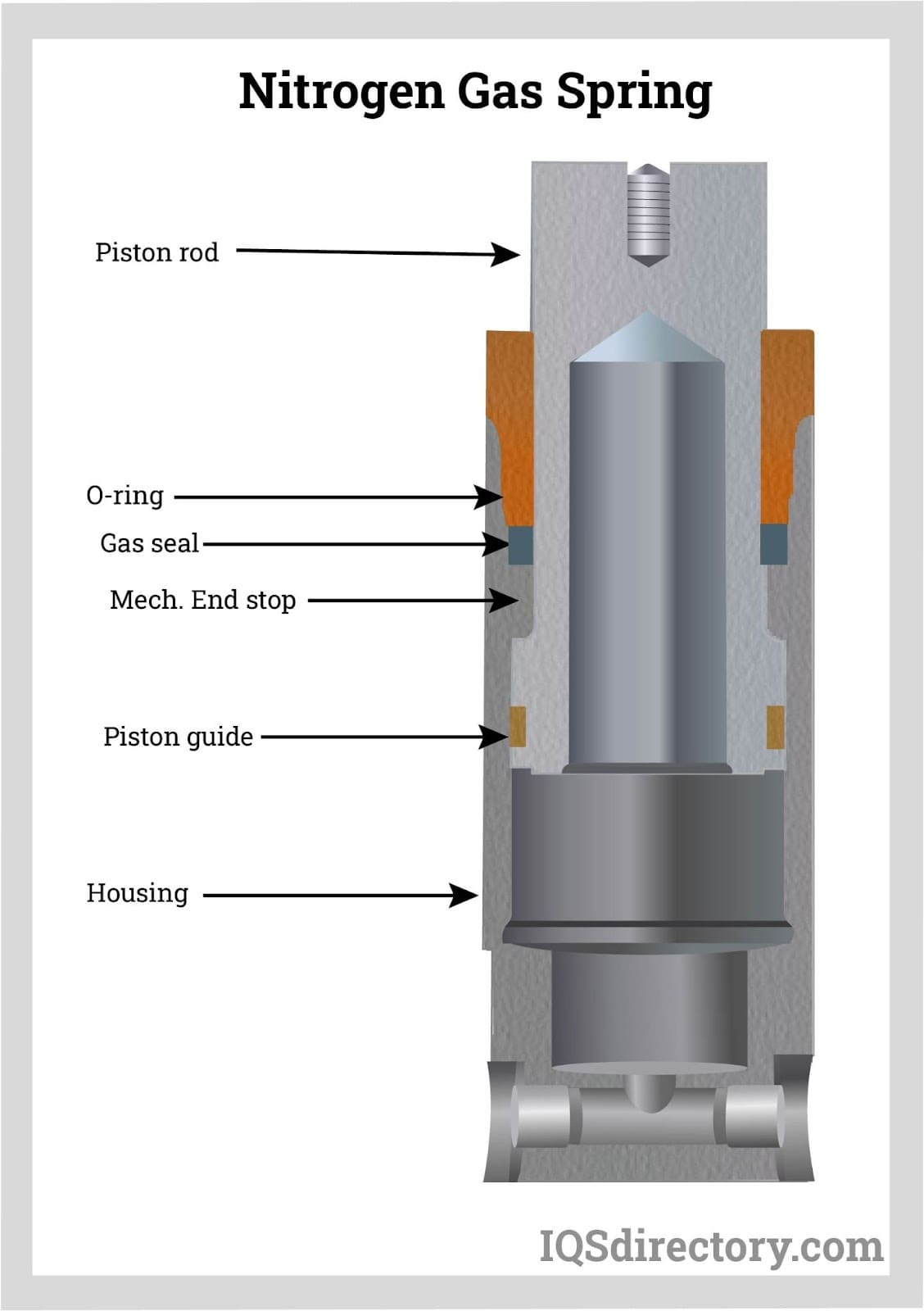

What Are the Key Stages in the Manufacturing Process of Gas Strut Springs?

The manufacturing process of gas strut springs involves several critical stages, each designed to ensure the final product meets the necessary performance standards. Understanding these stages helps B2B buyers make informed decisions when selecting suppliers.

Illustrative image related to gas strut springs

1. Material Preparation

The first step in manufacturing gas strut springs is material preparation. The primary materials used are high-strength steel or stainless steel, which provide the necessary durability and resistance to corrosion. Suppliers typically source these materials from certified vendors, ensuring they meet specific industry standards. The raw materials undergo initial inspections to verify their quality, dimensions, and chemical properties.

2. Forming Techniques for Gas Strut Springs

Once the materials are prepared, they undergo various forming techniques. The most common methods include:

-

Cold Drawing: This process involves pulling the steel through a die to achieve the desired diameter and surface finish. It enhances tensile strength while maintaining ductility.

-

Hot Forging: For larger components, hot forging is employed, where heated metal is shaped under high pressure. This technique allows for complex geometries and better mechanical properties.

-

Coiling: In this stage, the formed metal is coiled to create the spring shape. Precision is critical here, as the coil diameter and pitch directly affect the spring’s performance.

3. Assembly of Gas Strut Components

After forming, the components are assembled. This typically involves:

-

Integrating the Gas Cylinder and Rod: The gas cylinder is filled with nitrogen gas, creating the pressure required for the spring’s functionality. The assembly must ensure airtight seals to prevent gas leakage.

-

Adding Mounting Hardware: Depending on the application, various mounting brackets and fittings are included. These are often customizable to meet specific client requirements.

4. Finishing Processes for Quality Enhancement

Finishing processes are crucial for enhancing the aesthetic and functional properties of gas strut springs. Common finishing techniques include:

-

Surface Treatment: Processes such as zinc plating or powder coating provide corrosion resistance and improve the appearance of the springs.

-

Heat Treatment: This step can improve the mechanical properties of the springs, ensuring they can withstand the loads and stresses they will encounter in use.

How Is Quality Assurance Implemented in Gas Strut Spring Manufacturing?

Quality assurance (QA) is vital in ensuring that gas strut springs meet international standards and customer specifications. Here are some key components of QA in the manufacturing process.

Relevant International Standards for Gas Strut Springs

For B2B buyers, it is essential to ensure that suppliers adhere to recognized international standards. Some of the key certifications include:

-

ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers aiming to enhance customer satisfaction through effective process management.

-

CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Certification: For applications in the oil and gas industry, API certification ensures that products meet specific industry standards for quality and safety.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure each component meets the required specifications:

-

Incoming Quality Control (IQC): This initial checkpoint inspects raw materials for compliance with specifications before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken to ensure that processes are being followed and that the products are meeting quality standards.

-

Final Quality Control (FQC): After the assembly and finishing processes, final inspections are conducted to ensure the products meet all specifications, including functional tests for pressure and load.

What Testing Methods Are Commonly Used for Gas Strut Springs?

Testing is a critical aspect of quality assurance. Here are some common testing methods employed in the industry:

-

Pressure Testing: This test checks for gas leakage and ensures that the gas strut can withstand the specified pressure.

-

Load Testing: Gas strut springs are subjected to load tests to verify that they can support the intended weight and operate within design parameters.

-

Fatigue Testing: This method assesses the durability and lifespan of the springs under repeated loading conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should be proactive in verifying the quality control processes of their suppliers. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, quality control processes, and compliance with international standards firsthand.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation that outlines their quality control processes, including any certifications and test results.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance practices and product quality.

What Are the QC and Certification Nuances for International Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is essential:

-

Regional Standards Compliance: Ensure that suppliers are compliant with local and international standards relevant to your region. This is particularly important for markets with stringent safety and environmental regulations.

-

Documentation for Customs Clearance: Proper documentation is necessary for customs clearance. Buyers should ensure that the supplier provides all necessary certificates and compliance documents.

-

Cultural Considerations in Quality Expectations: Different regions may have varying expectations regarding quality. Understanding these cultural nuances can aid in better communication with suppliers and ensure that expectations are aligned.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for gas strut springs is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, alongside robust quality control measures, buyers can ensure they select reliable suppliers who meet their specific needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gas strut springs’

In the competitive landscape of B2B sourcing, procuring the right gas strut springs is crucial for ensuring product reliability and performance. This guide provides a step-by-step checklist to help international buyers make informed decisions when sourcing gas strut springs, particularly for applications in diverse industries such as automotive, marine, and industrial sectors.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of your application is the first step in sourcing gas strut springs. This includes identifying factors such as the weight they need to support, the required stroke length, and the force rating. Be specific about dimensions, materials (steel vs. stainless steel), and mounting options to ensure compatibility with your design.

- Weight and Dimensions: Clearly state the weight that the gas strut will support and the dimensions of the installation space.

- Force Rating: Determine the necessary force exerted by the strut to ensure proper functionality.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in gas strut springs. Look for companies with a proven track record in your industry and strong customer testimonials. Supplier reliability is essential for maintaining your production timelines and quality standards.

Illustrative image related to gas strut springs

- Supplier Reputation: Check online reviews and ratings, focusing on feedback from clients in similar sectors.

- Industry Experience: Choose suppliers with extensive experience in manufacturing gas struts tailored to specific applications.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that demonstrate their compliance with industry standards. Certifications such as ISO 9001 or specific automotive standards can indicate a commitment to quality and reliability.

- Quality Assurance: Look for suppliers who have quality control processes in place.

- Regulatory Compliance: Ensure that the products meet regional safety and environmental regulations, especially if sourcing from international suppliers.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples to evaluate the quality and performance of the gas strut springs. Testing samples in your application can help you identify potential issues and ensure the product meets your specifications.

- Performance Testing: Assess the samples under actual operating conditions to verify their functionality.

- Material Inspection: Examine the build quality and material integrity to ensure long-lasting performance.

Step 5: Negotiate Pricing and Terms

Once you have shortlisted suppliers, engage in negotiations to secure favorable pricing and terms. Discuss bulk order discounts, shipping costs, and payment terms to find a mutually beneficial agreement.

- Cost Comparison: Analyze the pricing structures of different suppliers to ensure you are getting the best value for your investment.

- Delivery Timelines: Confirm lead times and delivery schedules to avoid disruptions in your supply chain.

Step 6: Confirm After-Sales Support

Ensure that the supplier offers reliable after-sales support, including warranty options and customer service. This is essential for addressing any issues that may arise post-purchase and ensuring that your operations run smoothly.

- Warranty Details: Review warranty terms to understand coverage in case of product failure.

- Customer Support: Evaluate the supplier’s responsiveness and willingness to assist with any inquiries or issues.

Step 7: Finalize the Order and Monitor Delivery

After finalizing the supplier and terms, place your order and closely monitor the delivery process. Stay in communication with the supplier to track the shipment and ensure it arrives on time and in good condition.

- Shipping Confirmation: Obtain tracking information to stay updated on the delivery status.

- Quality Check Upon Arrival: Inspect the gas strut springs immediately upon receipt to confirm that they meet your specifications.

By following this checklist, B2B buyers can streamline the sourcing process for gas strut springs, ensuring they select the right products from reliable suppliers to meet their operational needs.

Comprehensive Cost and Pricing Analysis for gas strut springs Sourcing

What Are the Key Cost Components in Sourcing Gas Strut Springs?

When sourcing gas strut springs, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. Gas struts are often made from steel or stainless steel, with stainless steel generally commanding a higher price due to its durability and resistance to corrosion. Buyers should also consider the costs associated with additional features, such as valves for pressure adjustment.

-

Labor: Labor costs can vary widely based on geographic location and the complexity of the manufacturing process. Regions with lower labor costs, such as parts of South America and Africa, may offer more competitive pricing, but the quality of workmanship should not be overlooked.

-

Manufacturing Overhead: This encompasses the indirect costs of production, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help minimize these costs, which is vital for maintaining competitive pricing.

-

Tooling: Custom tooling for unique gas strut designs or specifications can represent a significant upfront investment. For bulk orders, these costs can be amortized over a larger volume, making it more cost-effective for the buyer.

-

Quality Control (QC): The implementation of rigorous QC processes ensures product reliability and safety. However, enhanced QC measures can add to the overall production cost. Buyers should weigh the importance of certifications and quality assurance against the potential price increases.

-

Logistics: Transportation and warehousing costs must be factored into the total cost of ownership. Shipping methods, distances, and import duties can significantly affect the final price, especially for international transactions.

-

Margin: Suppliers will typically add a margin to cover their costs and generate profit. This margin can vary based on market conditions, demand, and the supplier’s pricing strategy.

How Do Price Influencers Impact Gas Strut Springs Pricing?

Several factors influence the pricing of gas strut springs:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced unit prices. Buyers should negotiate MOQs to achieve better pricing, particularly when sourcing from manufacturers that offer scale advantages.

-

Specifications and Customization: Custom designs or specific performance specifications can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected charges during the procurement process.

-

Material Selection: The choice between standard and premium materials can influence price. While premium materials may have higher upfront costs, they often result in lower maintenance and replacement costs over time.

-

Quality and Certifications: Compliance with international standards and certifications can add to costs but is crucial for applications in regulated industries. Buyers should assess whether the added expense aligns with their quality requirements.

-

Supplier Factors: Supplier reputation, experience, and location can all impact pricing. Established suppliers may charge more due to their reliability and service levels, while newer suppliers may offer lower prices to build their market presence.

-

Incoterms: Understanding shipping terms is essential for international transactions. Different Incoterms (e.g., FOB, CIF) can affect the total landed cost, including shipping, insurance, and tariffs.

What Are Effective Buyer Tips for Sourcing Gas Strut Springs?

B2B buyers should consider the following strategies to optimize their sourcing process:

-

Negotiation: Engage suppliers in discussions about pricing and terms. Leverage volume commitments to negotiate better prices and payment terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as durability, maintenance, and lifecycle costs when making purchasing decisions.

-

Understand Pricing Nuances for International Transactions: Buyers from regions like Africa, South America, and the Middle East should account for currency fluctuations, import duties, and shipping costs when evaluating supplier quotes. It’s essential to clarify all terms and conditions upfront to avoid unexpected expenses.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide insight into market pricing and help identify the best value. Ensure that all quotes include comparable specifications and terms for an accurate assessment.

Disclaimer on Indicative Prices

Prices for gas strut springs can vary significantly based on the factors outlined above. The figures mentioned in this analysis are indicative and may not reflect the actual costs experienced in real-world transactions. Buyers are encouraged to conduct thorough market research and supplier evaluations to determine the most accurate pricing for their specific needs.

Alternatives Analysis: Comparing gas strut springs With Other Solutions

Introduction: Exploring Alternatives to Gas Strut Springs

When considering solutions for lifting, supporting, or dampening applications, gas strut springs are a popular choice due to their reliability and efficiency. However, several alternative technologies exist that may serve similar functions, each with distinct advantages and disadvantages. Understanding these alternatives can help international B2B buyers make informed decisions based on their specific needs and constraints.

Comparison Table

| Comparison Aspect | Gas Strut Springs | Pneumatic Cylinders | Mechanical Springs |

|---|---|---|---|

| Performance | High, adjustable force | Very high, with rapid response | Moderate, limited adjustment |

| Cost | Moderate to high | High initial investment | Low to moderate |

| Ease of Implementation | Simple installation with mounting parts | Requires more complex setup | Straightforward installation |

| Maintenance | Low; periodic checks needed | Moderate; may require seals replacement | Low; occasional inspection needed |

| Best Use Case | Automotive, furniture, machinery | Industrial machinery, automation | General applications, toys, light machinery |

Detailed Breakdown of Alternatives

Pneumatic Cylinders

Pneumatic cylinders utilize compressed air to create motion and are often employed in industrial applications requiring high force and speed. The key advantage of pneumatic systems is their rapid response time, making them ideal for automation processes where speed is critical. However, they require more complex setup and maintenance, including regular checks on air supply and seals. The initial investment can be significant, especially when considering the necessary air compressor equipment. This makes pneumatic cylinders less suitable for smaller businesses or applications with lower budgets.

Mechanical Springs

Mechanical springs are a traditional alternative to gas strut springs and are widely used across various applications. They are cost-effective and easy to install, with minimal maintenance requirements. Mechanical springs can handle a range of loads, though they typically offer less adjustability compared to gas strut springs. This limitation can restrict their application in scenarios requiring precise force control or constant adjustment. While suitable for general use, mechanical springs may not provide the same level of performance and reliability in more demanding environments.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate solution for lifting and support applications is crucial for optimizing efficiency and performance. Gas strut springs offer a balance of adjustability, low maintenance, and robust performance, making them ideal for various industries. However, alternatives like pneumatic cylinders may be better suited for high-speed, high-force applications, while mechanical springs can serve as a cost-effective option for general use. B2B buyers should carefully evaluate their specific requirements, including performance needs, budget constraints, and ease of implementation, to make the best choice for their operational demands.

Essential Technical Properties and Trade Terminology for gas strut springs

What Are the Key Technical Properties of Gas Strut Springs?

Understanding the technical specifications of gas strut springs is essential for B2B buyers to ensure the right fit for their applications. Here are several critical properties:

1. Material Grade

Gas strut springs are typically made from steel or stainless steel. The choice of material affects durability, corrosion resistance, and overall strength. For example, stainless steel gas springs are ideal for marine applications where exposure to moisture is frequent. Selecting the right material grade is crucial for ensuring longevity and performance, which can reduce maintenance costs and improve reliability.

2. Force Rating

The force rating, measured in pounds or newtons, indicates how much load the gas strut can support. This specification is vital for applications ranging from automotive hoods to industrial machinery. Ensuring that the force rating matches the weight of the lid or component being supported is critical for safety and functionality. An incorrect force rating can lead to failure or inefficiency in operation.

3. Stroke Length

The stroke length refers to the distance the gas spring can extend and compress. This measurement is essential for applications where space is limited, as it determines how far a lid or door can open. Understanding stroke length helps in selecting a gas strut that fits the specific dimensions of your project, ensuring optimal functionality.

4. End Fittings

End fittings are the attachment points of the gas strut and come in various styles, such as ball joints or clevis ends. The right end fitting is crucial for compatibility with existing components and can affect the ease of installation. Selecting appropriate end fittings can enhance the performance and durability of the gas strut in its intended application.

5. Temperature Range

Gas strut springs operate effectively within specific temperature ranges. Knowing the operating environment’s temperature is essential to ensure the gas spring performs optimally without losing pressure or structural integrity. This property is particularly important in extreme climates, such as those found in the Middle East or South America, where temperature fluctuations can be significant.

What Are Common Trade Terms Related to Gas Strut Springs?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several key terms:

Illustrative image related to gas strut springs

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. When dealing with gas strut springs, understanding whether a supplier is an OEM can influence the quality and compatibility of the parts you purchase.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers to understand, especially when sourcing gas strut springs in bulk for manufacturing or large-scale projects. Knowing the MOQ can help in budgeting and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products, such as gas strut springs. This process helps buyers compare offers and select suppliers that meet their needs in terms of cost, quality, and delivery timelines.

Illustrative image related to gas strut springs

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. For gas strut springs, knowing the applicable Incoterms can clarify who is responsible for shipping costs, insurance, and risk during transit, ensuring smoother transactions.

5. Lead Time

Lead time is the duration from placing an order to receiving the goods. For gas strut springs, understanding lead times is crucial for project planning and inventory management. Longer lead times can affect production schedules, making it essential to account for this in procurement strategies.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they select the appropriate gas strut springs for their applications while navigating the procurement process with confidence.

Illustrative image related to gas strut springs

Navigating Market Dynamics and Sourcing Trends in the gas strut springs Sector

What Are the Key Trends Shaping the Gas Strut Springs Market?

The gas strut springs market is experiencing robust growth, driven by increasing demand across various sectors, including automotive, aerospace, and furniture. As industries worldwide strive for enhanced efficiency and safety, gas struts are becoming essential components in applications that require controlled movement and support. Key trends influencing the market include the rise of automation and smart technology, which demand more sophisticated gas strut solutions. International B2B buyers from Africa, South America, the Middle East, and Europe are particularly keen on suppliers that offer advanced customization options, allowing for tailored solutions that meet specific application needs.

Additionally, there is a noticeable shift towards online sourcing platforms that simplify the procurement process. These platforms often feature configurators and calculators that enable buyers to identify and order the appropriate gas strut springs with precision. This trend is particularly beneficial for buyers in emerging markets, where access to specialized technical support may be limited. Furthermore, sustainable practices are gaining traction, with manufacturers focusing on eco-friendly materials and production processes, appealing to the growing segment of environmentally-conscious buyers.

How Is Sustainability Influencing Sourcing Decisions for Gas Strut Springs?

Sustainability has become a pivotal factor in sourcing decisions for gas strut springs. The environmental impact of manufacturing processes is under scrutiny, prompting businesses to seek suppliers that prioritize ethical practices and eco-friendly materials. Buyers are increasingly looking for gas strut springs that come with certifications such as ISO 14001, which indicates adherence to environmental management standards.

Moreover, the use of recyclable materials and sustainable manufacturing processes is becoming a competitive advantage. Suppliers who can demonstrate their commitment to reducing carbon footprints and utilizing ‘green’ materials often find favor among international buyers. This trend is not only beneficial for the environment but also enhances brand reputation, making it a crucial aspect of procurement strategies. For companies operating in regions like Africa and South America, where regulatory frameworks around sustainability are evolving, aligning with suppliers that emphasize ethical sourcing can also mitigate risks related to compliance and market access.

What Is the Historical Context of Gas Strut Springs in B2B Markets?

The evolution of gas strut springs dates back to their inception in the late 20th century, where they were primarily used in automotive applications. Initially designed for simple lifting mechanisms, advancements in technology have transformed gas struts into highly specialized components utilized across diverse sectors. Today, they are integral to applications ranging from industrial machinery to consumer products.

Illustrative image related to gas strut springs

Over the years, the focus has shifted from basic functionality to performance optimization, with manufacturers investing in research and development to enhance durability and efficiency. This evolution has led to a wider variety of gas strut configurations, allowing for more specific applications. The historical growth of gas strut springs reflects broader trends in engineering and manufacturing, highlighting the importance of innovation in meeting evolving B2B needs. As companies continue to prioritize efficiency and sustainability, the gas strut springs market is poised for further advancements and opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of gas strut springs

-

How do I choose the right gas strut spring for my application?

To select the appropriate gas strut spring, consider several factors: the weight of the object it will support, the required stroke length, and the mounting options. Utilize online configurators provided by suppliers to input specifications such as weight, dimensions, and required force. Additionally, reviewing CAD files can help visualize how the gas strut will fit within your application. If you’re uncertain, consult with supplier experts who can guide you through the selection process based on your specific needs. -

What is the best gas strut spring for automotive applications?

For automotive applications, look for gas strut springs designed specifically for vehicle lift supports, trunk lifts, and hood props. Stainless steel options are preferable due to their durability and resistance to corrosion. Ensure the gas strut can handle the weight of the component it supports, typically measured in pounds of force. Consult with manufacturers for recommendations based on your vehicle’s make and model to ensure compatibility and performance. -

What are the minimum order quantities (MOQ) for gas strut springs?

Minimum order quantities for gas strut springs can vary significantly between suppliers. Many manufacturers have a MOQ ranging from 50 to 500 units, especially for custom or specialized products. For stock items, some suppliers may allow smaller orders. When negotiating with suppliers, clarify MOQs and explore potential flexibility, particularly if you are a new buyer or require a trial order to assess product quality. -

How do I ensure the quality of gas strut springs from international suppliers?

To ensure quality, request certifications and quality assurance documents, such as ISO certifications, from potential suppliers. Consider suppliers who offer samples for testing before placing larger orders. Additionally, utilize third-party quality inspection services to verify the products meet your specifications. Establishing a strong communication line with the supplier can also help address any quality concerns and facilitate prompt resolutions. -

What payment terms should I expect when sourcing gas strut springs internationally?

Payment terms can vary widely among suppliers and regions. Common practices include advance payments, payment upon delivery, or net payment terms (e.g., net 30 days). International transactions may involve letters of credit or escrow services for larger orders. Always clarify payment methods upfront and ensure they align with your financial processes. It’s advisable to negotiate favorable terms that provide both security and flexibility for your business. -

What logistics considerations should I be aware of when importing gas strut springs?

Logistics considerations include shipping methods, lead times, customs duties, and potential import restrictions. Choose reliable freight forwarders familiar with your destination country’s regulations. Understand the total landed cost, including shipping, taxes, and tariffs. Plan for potential delays by allowing ample lead time and maintain clear communication with your supplier regarding shipment tracking and delivery schedules. -

Can I customize gas strut springs for my specific needs?

Yes, many manufacturers offer customization options for gas strut springs. You can typically specify dimensions, force ratings, and mounting types to meet your application requirements. When discussing customization, provide detailed information about your application and performance expectations. Be prepared for potential minimum order quantities and longer lead times for custom products, and ensure to get samples before finalizing your order. -

What should I look for in a supplier of gas strut springs?

When evaluating suppliers, consider their experience and reputation in the industry, customer reviews, and their ability to meet your specific needs. Look for suppliers who provide comprehensive technical support, including assistance with product selection and customization. Ensure they have robust quality control processes and offer competitive pricing without compromising quality. Establishing a strong relationship with your supplier can also lead to better service and support for your ongoing needs.

Top 3 Gas Strut Springs Manufacturers & Suppliers List

1. Gas Springs Shop – Gas Springs

Domain: gasspringsshop.com

Registered: 2014 (11 years)

Introduction: Gas Springs: Steel (Up to 200N, M3.5 thread; Up to 450N, M5 thread; Up to 800N, M8 thread; Up to 1250N, M8 thread; Up to 2500N, M10 thread; Up to 5000N, M14 thread), Stainless Steel – 304 (Up to 450N, M5 thread; Up to 800N, M8 thread; Up to 1250N, M8 thread; Up to 2500N, M10 thread), Gas Tension Springs (Up to 350N, M5 thread; Up to 1200N, M8 thread), Mounting Parts (Steel M3.5, M5, M8, M10, M14; …

2. Industrial Springs – M-Struts

Domain: industrial-springs.com

Registered: 2005 (20 years)

Introduction: {‘product_name’: ‘M-Struts – Mechanical Gas Spring’, ‘description’: ‘A mechanical gas spring similar to a conventional compression gas spring, but with an ordinary wire compression spring inside, making it suitable for dirty environments and capable of withstanding greater loads and impacts.’, ‘material’: ‘Black painted steel’, ‘piston_rod_diameter_mm’: [6, 8], ‘tube_diameter_mm’: [15, 18], ‘strok…

3. Stabilus – LIFT-O-MAT Gas Springs

Domain: stabilus.com

Registered: 1996 (29 years)

Introduction: Stabilus LIFT-O-MAT gas springs provide controlled lifting and lowering of loads, offering force assistance for optimal counterbalancing. They feature exceptional damping characteristics for safe and user-friendly operation, and are designed for easy installation with compact dimensions. Key features include:

– Broad selection of sizes, strengths, and end fittings

– Compact design with small space…

Strategic Sourcing Conclusion and Outlook for gas strut springs

What Are the Key Benefits of Strategic Sourcing for Gas Strut Springs?

In conclusion, strategic sourcing for gas strut springs offers significant advantages for international B2B buyers across diverse industries. By leveraging tools such as configurators and calculators, businesses can ensure the selection of the right gas springs tailored to specific applications, enhancing operational efficiency and performance. The ability to customize specifications—such as length, force, and mounting options—further empowers companies to meet unique project demands, ultimately leading to cost savings and improved product reliability.

How Can International Buyers Navigate the Global Market for Gas Strut Springs?

As the demand for gas strut springs continues to rise in regions like Africa, South America, the Middle East, and Europe, establishing strong supplier relationships and understanding regional market dynamics will be vital. Buyers should prioritize suppliers who offer robust support services, transparent communication, and efficient delivery processes to mitigate risks associated with international procurement.

What’s Next for Your Gas Strut Spring Procurement Strategy?

Looking ahead, it is crucial for businesses to adopt a proactive approach in sourcing gas strut springs. Engage with suppliers who not only provide quality products but also demonstrate a commitment to innovation and customer support. By doing so, companies can position themselves for success in an increasingly competitive landscape. Take the next step in optimizing your sourcing strategy—explore partnerships with reputable suppliers and harness the full potential of gas strut springs in your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.