A Deep Dive into Exhaust Pipe Tube Bender Solution

Introduction: Navigating the Global Market for exhaust pipe tube bender

In an increasingly competitive global marketplace, sourcing the right exhaust pipe tube bender can be a daunting task for B2B buyers. With various options available, from manual to fully automatic systems, finding the ideal bender that aligns with operational needs and budget constraints is crucial. This guide aims to demystify the complexities of the exhaust pipe tube bender market by providing comprehensive insights into the different types of benders, their applications across various industries, and critical factors to consider when vetting suppliers.

International buyers, particularly those from Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and established economies such as Germany—face unique challenges in sourcing reliable equipment. This guide empowers businesses to make informed purchasing decisions by detailing essential considerations such as product quality, pricing structures, and technological advancements in bender design. Additionally, it offers valuable tips on assessing supplier reliability and after-sales support, ensuring that buyers can establish long-term partnerships with trusted manufacturers.

By equipping B2B buyers with actionable insights and best practices, this guide serves as a vital resource for navigating the global market for exhaust pipe tube benders, ultimately helping businesses enhance their operational efficiency and maintain competitive advantages.

Understanding exhaust pipe tube bender Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Pipe Bender | Operated by hand, allowing for precise control over bends. | Custom fabrication, small workshops | Pros: Cost-effective, simple operation. Cons: Labor-intensive, slower production rates. |

| Automatic Pipe Bender | Digitally controlled with programmable settings for repeatability. | High-volume manufacturing, automotive shops | Pros: Increased efficiency, consistent results. Cons: Higher upfront cost, requires technical knowledge. |

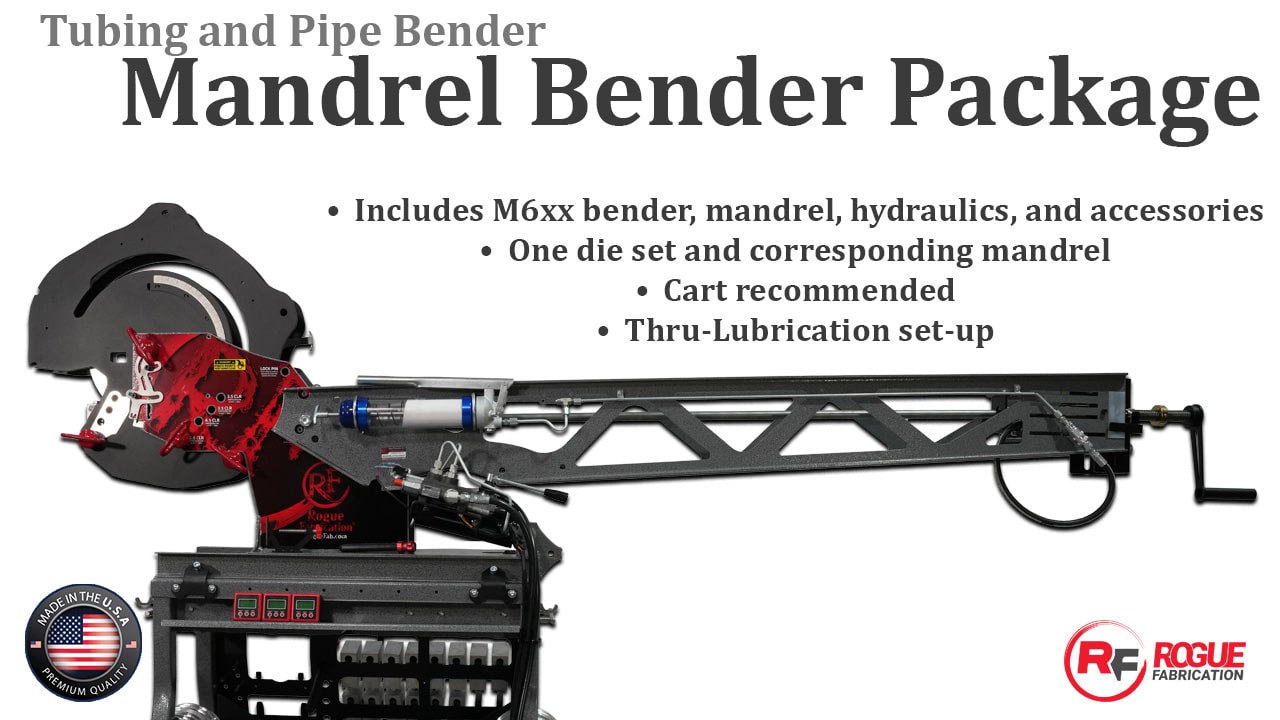

| Mandrel Tube Bender | Uses a mandrel to support the pipe during bending, preventing deformation. | Aerospace, automotive, and custom fabrication | Pros: Capable of bending thicker materials, high-quality bends. Cons: More complex setup, generally higher price point. |

| Hydraulic Pipe Bender | Utilizes hydraulic power for bending, offering strong force with less effort. | Heavy-duty applications, industrial settings | Pros: Greater bending power, suitable for larger pipes. Cons: Requires maintenance, can be bulky. |

| CNC Pipe Bender | Computer Numerical Control for automated and precise bending. | Mass production, specialized industries | Pros: High precision, programmable for complex designs. Cons: Significant investment, requires skilled operators. |

What Are the Characteristics of Manual Pipe Benders?

Manual pipe benders are known for their simplicity and cost-effectiveness. They allow operators to have direct control over the bending process, making them ideal for custom fabrication and small workshops. Buyers should consider the labor intensity of these machines, as they require more physical effort and time to produce bends compared to automated options. They are suitable for businesses that prioritize flexibility and hands-on craftsmanship over high-volume production.

How Do Automatic Pipe Benders Enhance Production Efficiency?

Automatic pipe benders are designed for high-volume manufacturing, particularly in automotive shops. They feature programmable settings that allow for consistent and precise bending, significantly enhancing production efficiency. While the initial investment can be higher, the long-term savings in labor and increased output can justify the cost. B2B buyers should evaluate their production needs to determine if the benefits of automation align with their operational goals.

Why Choose a Mandrel Tube Bender for Complex Projects?

Mandrel tube benders are essential for industries requiring high-quality bends without deformation, such as aerospace and automotive sectors. These machines support the pipe during the bending process, allowing for thicker materials to be bent effectively. While they offer superior performance, buyers must consider the complexity of setup and the associated costs. Investing in a mandrel tube bender is ideal for businesses that need precision and quality in their bending operations.

What Advantages Do Hydraulic Pipe Benders Offer?

Hydraulic pipe benders leverage hydraulic power to deliver strong bending forces with less manual effort, making them suitable for heavy-duty applications in industrial settings. These machines are capable of bending larger pipes and handling thicker materials. However, potential buyers should factor in maintenance requirements and the physical space needed for operation. Hydraulic benders are best suited for businesses focused on robust applications and high production volumes.

How Does CNC Technology Transform Pipe Bending?

CNC pipe benders represent the pinnacle of precision in pipe bending technology. They utilize computer numerical control to automate the bending process, allowing for complex designs and high repeatability. This technology is particularly advantageous for mass production in specialized industries. However, the investment is substantial, and operators must possess the necessary skills to program and maintain these machines. Companies looking to scale their operations and improve design capabilities should seriously consider CNC options.

Illustrative image related to exhaust pipe tube bender

Key Industrial Applications of exhaust pipe tube bender

| Industry/Sector | Specific Application of exhaust pipe tube bender | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom exhaust system fabrication | Enhanced vehicle performance and compliance with emissions regulations | Durability, precision, and ease of use; consider local service support and parts availability. |

| Oil and Gas | Pipe bending for exhaust systems in drilling rigs | Improved operational efficiency and reduced maintenance costs | Look for machines capable of handling high-pressure pipes and resistant to corrosion. |

| Aerospace | Exhaust system development for aircraft engines | Weight reduction and enhanced fuel efficiency | Ensure compliance with strict safety standards and material specifications. |

| Construction | Exhaust piping in heavy machinery | Increased equipment lifespan and reliability | Assess the machine’s ability to handle various material thicknesses and types. |

| Marine Engineering | Exhaust systems for ships and marine vessels | Compliance with environmental regulations and improved performance | Seek machines that can handle large diameters and complex bends. |

How is an Exhaust Pipe Tube Bender Used in Automotive Manufacturing?

In the automotive sector, exhaust pipe tube benders are crucial for fabricating custom exhaust systems. These systems must meet stringent emissions standards while enhancing vehicle performance. Benders are used to create precise bends in various materials, allowing for unique designs tailored to specific vehicle models. For international buyers, especially from regions like Africa and South America, sourcing high-quality benders that ensure durability and precision can significantly reduce production costs and increase compliance with local regulations.

What is the Role of Exhaust Pipe Tube Benders in Oil and Gas Applications?

In the oil and gas industry, exhaust pipe tube benders are employed to fabricate piping for drilling rigs and processing facilities. The ability to bend high-pressure pipes accurately is essential to ensure safety and operational efficiency. These benders help in creating exhaust systems that can withstand harsh environments and reduce maintenance costs. Buyers from the Middle East, rich in oil resources, should prioritize machines that offer corrosion resistance and robust performance under extreme conditions.

How Do Exhaust Pipe Tube Benders Benefit Aerospace Applications?

Aerospace applications require exhaust systems that not only perform effectively but also comply with rigorous safety and weight standards. Exhaust pipe tube benders are used to develop lightweight exhaust systems for aircraft engines, contributing to improved fuel efficiency. For international buyers in Europe, where aviation standards are particularly stringent, it’s vital to choose benders that can handle advanced materials and complex geometries while ensuring compliance with industry regulations.

In What Ways are Exhaust Pipe Tube Benders Used in Construction?

In the construction industry, exhaust pipe tube benders are essential for creating exhaust systems in heavy machinery. These systems enhance the machinery’s efficiency and longevity by ensuring optimal exhaust flow. For buyers in developing regions, investing in reliable benders that can handle various material thicknesses is crucial for maintaining equipment performance and reducing downtime.

How Do Marine Engineering Applications Utilize Exhaust Pipe Tube Benders?

Marine engineering relies on exhaust pipe tube benders to produce exhaust systems for ships and marine vessels. These systems must comply with strict environmental regulations while ensuring optimal performance. The ability to create complex bends and handle larger diameters is essential in this sector. International buyers should focus on sourcing machines that offer versatility and durability, especially when operating in challenging marine environments.

3 Common User Pain Points for ‘exhaust pipe tube bender’ & Their Solutions

Scenario 1: Inefficient Production Due to Equipment Limitations

The Problem: A mid-sized automotive parts manufacturer in South America faces challenges with their exhaust pipe tube bender, which is limited in its bending capacity. As a result, the company struggles to meet increasing demand for custom bends in exhaust systems. The existing machine cannot handle the required wall thicknesses or bending angles, leading to production delays and a backlog of orders. This inefficiency not only affects revenue but also damages the company’s reputation for reliability.

The Solution: To overcome this issue, the manufacturer should consider investing in a high-capacity exhaust pipe tube bender that offers a broader range of bending capabilities. It’s crucial to conduct a thorough needs assessment, evaluating current and future production requirements. A model with adjustable dies and hydraulic capabilities can accommodate various materials, including aluminum, stainless steel, and titanium, ensuring versatility in production. Engaging with reputable suppliers who provide detailed specifications and performance reviews will help in selecting a machine that meets the demands of custom exhaust systems. Additionally, implementing a regular maintenance schedule will keep the equipment running efficiently, minimizing downtime and maximizing production output.

Scenario 2: Inconsistent Quality in Bending Processes

The Problem: A fabricator in Europe experiences significant variability in the quality of bends produced by their current exhaust pipe tube bender. Inconsistent results lead to increased rework and scrap rates, driving up costs and causing frustration among the production team. This inconsistency stems from manual operation and the lack of precision in the bending process, affecting the overall quality of the final product.

The Solution: The solution lies in upgrading to a digital automatic pipe bender that features programmable settings for specific bending patterns. This technology ensures repeatability and accuracy, significantly reducing the likelihood of defects. Buyers should look for benders equipped with advanced control systems that allow for easy adjustment of bend angles and radii, as well as the ability to store multiple bending programs. Training operators on the new technology will also be essential to maximize its capabilities. By investing in automation and precision, the fabricator can improve product quality, reduce scrap rates, and enhance overall operational efficiency.

Scenario 3: High Operational Costs Due to Inefficient Processes

The Problem: A manufacturing company in Africa is facing escalating operational costs linked to their outdated exhaust pipe tube bender. The current equipment consumes excessive energy and requires frequent maintenance, leading to high utility bills and lost labor hours. As the company strives to improve its bottom line, these inefficiencies are becoming unsustainable.

The Solution: Transitioning to an energy-efficient exhaust pipe tube bender with modern hydraulic systems can dramatically reduce operational costs. When sourcing new equipment, buyers should prioritize models that boast energy-saving features, such as variable speed controls and optimized hydraulic performance. Additionally, considering benders that offer advanced maintenance monitoring can prevent costly breakdowns and extend the lifespan of the machine. Implementing an energy management system can also help track and analyze energy consumption, providing insights into further cost-saving opportunities. By investing in a more efficient bender, the company can not only cut operational costs but also improve its sustainability profile, which is increasingly important in today’s market.

Strategic Material Selection Guide for exhaust pipe tube bender

What Materials Are Commonly Used in Exhaust Pipe Tube Benders?

When selecting materials for exhaust pipe tube benders, it is essential to consider properties that influence performance, durability, and cost. Here, we analyze four common materials: carbon steel, stainless steel, aluminum, and titanium, focusing on their suitability for various applications.

How Does Carbon Steel Perform in Exhaust Pipe Tube Benders?

Key Properties: Carbon steel is known for its high yield strength and excellent machinability, making it a preferred choice for many industrial applications. It typically has a temperature rating suitable for exhaust systems, and its pressure rating is robust enough to handle standard operational demands.

Pros & Cons: The primary advantage of carbon steel is its durability and cost-effectiveness. However, it is prone to corrosion, particularly in high-humidity environments or when exposed to chemicals. This limitation can lead to increased maintenance costs over time.

Illustrative image related to exhaust pipe tube bender

Impact on Application: Carbon steel is compatible with a wide range of exhaust gases and is suitable for high-pressure applications. However, its susceptibility to rust may limit its use in regions with high moisture or corrosive environments.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local climate conditions when selecting carbon steel. Compliance with ASTM standards is crucial, as many manufacturers may require certification to ensure quality and performance.

What Role Does Stainless Steel Play in Exhaust Pipe Tube Benders?

Key Properties: Stainless steel offers excellent corrosion resistance, high-temperature tolerance, and strength. It is particularly suitable for exhaust applications due to its ability to withstand the harsh conditions of exhaust gases.

Pros & Cons: The main advantage of stainless steel is its longevity and minimal maintenance needs, making it ideal for high-performance applications. However, it is significantly more expensive than carbon steel, which can impact budget considerations for buyers.

Impact on Application: Stainless steel’s corrosion resistance makes it suitable for various exhaust media, including those containing sulfur and other corrosive elements. It is often the material of choice for high-performance and luxury vehicles.

Illustrative image related to exhaust pipe tube bender

Considerations for International Buyers: European buyers, especially in Germany, may prefer stainless steel due to stringent emissions regulations and standards. Compliance with DIN standards is essential for ensuring product quality and performance.

Why Is Aluminum Considered for Exhaust Pipe Tube Benders?

Key Properties: Aluminum is lightweight and has good corrosion resistance, making it an attractive option for exhaust systems where weight reduction is critical. It can handle moderate temperatures but may not be suitable for all high-pressure applications.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can improve overall vehicle efficiency. However, its lower strength compared to steel can be a limiting factor in high-stress applications, and its cost can be higher than carbon steel.

Illustrative image related to exhaust pipe tube bender

Impact on Application: Aluminum is compatible with exhaust gases but may require additional coatings or treatments to enhance durability in harsh environments. Its use is often limited to specific applications where weight savings are prioritized.

Considerations for International Buyers: Buyers in the Middle East may find aluminum appealing for lightweight vehicles, but they should be aware of the need for proper treatment to prevent corrosion. Compliance with JIS standards can also be a consideration for Japanese manufacturers.

How Does Titanium Compare in Exhaust Pipe Tube Benders?

Key Properties: Titanium is known for its exceptional strength-to-weight ratio and outstanding corrosion resistance. It can withstand extreme temperatures and pressures, making it suitable for high-performance exhaust systems.

Pros & Cons: The key advantage of titanium is its durability and lightweight characteristics, which are ideal for racing and high-performance applications. However, it is the most expensive option, which can deter budget-conscious buyers.

Impact on Application: Titanium is compatible with various exhaust media and is particularly beneficial in applications where weight and performance are critical. Its use is often limited to specialized markets due to its high cost.

Considerations for International Buyers: Buyers in Europe and the Middle East may be more inclined to invest in titanium for high-performance applications, but they must consider the associated costs and ensure compliance with relevant industry standards.

Summary Table of Material Selection for Exhaust Pipe Tube Benders

| Material | Typical Use Case for exhaust pipe tube bender | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General industrial applications | Cost-effective and durable | Prone to corrosion | Low |

| Stainless Steel | High-performance and luxury vehicles | Excellent corrosion resistance | Higher cost | High |

| Aluminum | Lightweight vehicles | Lightweight and good corrosion resistance | Lower strength | Medium |

| Titanium | Racing and high-performance applications | Exceptional strength-to-weight ratio | Very high cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for exhaust pipe tube bender

What Are the Main Manufacturing Processes for Exhaust Pipe Tube Benders?

The production of exhaust pipe tube benders involves a series of well-defined stages that ensure quality and precision. The main manufacturing processes can be categorized into four key stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Exhaust Pipe Tube Benders?

Material preparation is crucial as it sets the foundation for the entire manufacturing process. Typically, high-strength steel or aluminum is selected based on the required specifications. This material undergoes several treatments, including cutting to size, surface cleaning, and sometimes heat treatment to enhance mechanical properties. Advanced suppliers often use CNC (Computer Numerical Control) machines for precise cutting, ensuring that the dimensions are accurate and consistent, which is vital for the subsequent stages of manufacturing.

What Techniques Are Used in Forming Exhaust Pipe Tube Benders?

The forming stage is where the raw materials are transformed into functional components. Different techniques are employed, including:

- Hydraulic Bending: This method uses hydraulic pressure to shape the material around a die. It is favored for its ability to create complex shapes without compromising the material’s integrity.

- Mandrel Bending: This technique utilizes a mandrel to support the pipe during bending, preventing kinks and ensuring smooth curves. This is particularly important for exhaust systems where flow efficiency is critical.

- Roll Bending: For larger diameters, roll bending might be employed, where the material is passed through a series of rollers to achieve the desired curvature.

Each technique is chosen based on the specific requirements of the exhaust pipe bender being produced, including factors like wall thickness and bend radius.

What Does the Assembly Process Involve for Exhaust Pipe Tube Benders?

Assembly is a critical phase where individual components are brought together. Skilled technicians ensure that all parts fit correctly and function as intended. This stage may involve:

- Joining Techniques: Methods such as welding, bolting, or riveting are used to secure parts. Each method is selected based on the strength requirements and design of the bender.

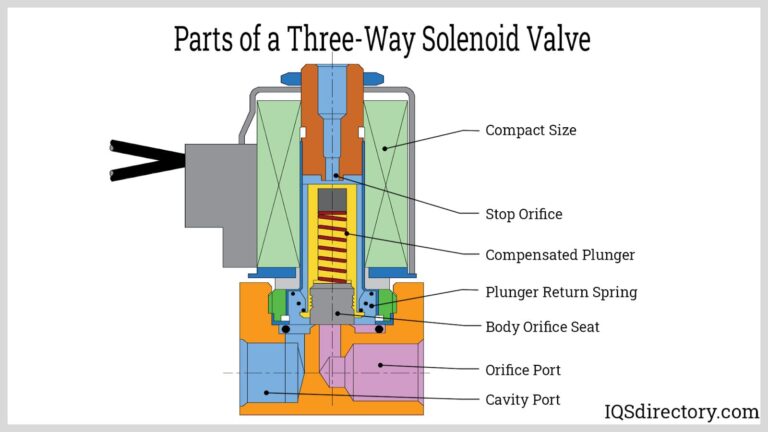

- Integration of Hydraulic Systems: For automatic or semi-automatic benders, the hydraulic system is integrated during assembly. This includes installing hydraulic cylinders, hoses, and control systems, which require precise alignment to ensure optimal performance.

- Installation of Control Systems: Advanced benders often feature digital displays and programmable controls. During assembly, these systems must be calibrated to guarantee accurate bending patterns.

How Is Quality Assurance Implemented in Exhaust Pipe Tube Bender Manufacturing?

Quality assurance (QA) is essential to ensure that exhaust pipe tube benders meet both international standards and customer expectations. The QA process typically involves several checkpoints and testing methodologies.

What International Standards Are Relevant for Exhaust Pipe Tube Bender Quality Assurance?

Manufacturers aiming for a competitive edge often adhere to recognized international standards such as:

- ISO 9001: This standard focuses on quality management systems and is applicable to all organizations. Compliance demonstrates a commitment to quality and customer satisfaction.

- CE Marking: For products marketed in Europe, CE marking indicates compliance with safety, health, and environmental protection standards.

- API Standards: For benders used in the oil and gas sector, compliance with American Petroleum Institute (API) standards ensures reliability and safety.

Adhering to these standards not only enhances product credibility but also facilitates market access in various regions, including Africa, South America, the Middle East, and Europe.

Illustrative image related to exhaust pipe tube bender

What Are the Key Quality Control Checkpoints in Manufacturing Exhaust Pipe Tube Benders?

Quality control (QC) involves systematic checks throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards. This may include checks for material composition, dimensions, and surface quality.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, ongoing inspections are conducted to catch any deviations early. This may involve measuring critical dimensions and verifying the functionality of hydraulic components during assembly.

- Final Quality Control (FQC): Once the bender is assembled, it undergoes final testing to ensure it operates correctly. This includes checking the bending accuracy, hydraulic function, and overall performance under load conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s QC practices is crucial for ensuring product reliability. Here are actionable steps to take:

What Should Buyers Look for in Supplier Audits and Reports?

- Supplier Audits: Requesting an audit report from suppliers can provide insight into their manufacturing processes and adherence to quality standards. A well-documented audit should cover compliance with ISO 9001 and other relevant certifications.

- Quality Control Reports: Regular QC reports should be made available, detailing inspection outcomes, test results, and corrective actions taken for any non-conformities.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality control measures in place. This can be especially valuable for buyers unfamiliar with local manufacturing practices in regions like Africa, South America, or the Middle East.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing exhaust pipe tube benders from different regions, buyers should be aware of potential quality control nuances:

- Regulatory Compliance: Different countries may have varying regulations regarding manufacturing standards. Understanding these can prevent complications during customs clearance and ensure compliance with local laws.

- Cultural Differences in Quality Standards: Some regions may prioritize cost over quality, leading to variations in manufacturing practices. Buyers should ensure that the supplier aligns with their quality expectations and industry standards.

- After-Sales Support and Warranty: Evaluating the after-sales support and warranty policies can provide additional assurance of product quality and supplier reliability. This is particularly important in regions where access to spare parts and service may be limited.

By understanding the manufacturing processes and quality assurance practices for exhaust pipe tube benders, B2B buyers can make informed decisions, ensuring they invest in equipment that meets their operational needs and quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘exhaust pipe tube bender’

Introduction

This guide serves as a practical sourcing checklist for B2B buyers looking to procure exhaust pipe tube benders. With a multitude of options available on the market, it is crucial to follow a structured approach to ensure that you select the right equipment that meets your operational needs and quality standards.

Step 1: Define Your Technical Specifications

Before starting your search for a tube bender, clearly outline your technical requirements. This includes the types of materials you will be bending (e.g., aluminum, stainless steel, titanium) and the wall thicknesses you’ll be working with. Understanding your specific needs helps in narrowing down suitable models and features.

Illustrative image related to exhaust pipe tube bender

- Consider bend radius and angles: Determine the specific angles and radius of bends you require for your projects.

- Evaluate production capacity: Assess how many bends per hour you need to achieve to meet your production targets.

Step 2: Research Available Models

Explore various models and types of exhaust pipe tube benders on the market. Different benders offer unique features, such as manual vs. automatic operation, and varying capacities for different materials.

- Compare features: Look for features like digital controls, built-in lubrication systems, and ease of use.

- Review brand reputation: Investigate brands that are well-regarded in the industry for quality and performance, such as BendPak and Rogue Fabrication.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and service standards. Request detailed company profiles, customer testimonials, and case studies from businesses in similar industries.

- Ask for certifications: Verify that suppliers have relevant certifications (e.g., ISO) that reflect their commitment to quality.

- Consider after-sales support: Inquire about warranty terms, maintenance services, and technical support availability.

Step 4: Request Quotes and Compare Pricing

Once you have shortlisted suppliers, request detailed quotes that outline the total costs, including shipping and any additional fees. Comparing prices helps you understand the market rate and identify any potential deals.

Illustrative image related to exhaust pipe tube bender

- Look for financing options: Some suppliers may offer financing plans, which can ease cash flow concerns.

- Factor in long-term costs: Consider not just the purchase price but also the potential costs for maintenance and repairs over the equipment’s lifespan.

Step 5: Inspect Equipment Before Purchase

If possible, arrange for a demonstration or inspection of the tube bender before finalizing your purchase. This allows you to assess the machine’s functionality and ease of use firsthand.

- Check for build quality: Inspect the materials and construction of the bender to ensure it meets your durability standards.

- Test operational features: Ensure that all controls and features are intuitive and function as advertised.

Step 6: Review Shipping and Delivery Terms

Understand the shipping and delivery terms associated with your order. Confirm lead times, shipping costs, and whether the equipment will be fully assembled upon arrival.

- Clarify installation support: Some suppliers may offer installation services or guidance, which can be beneficial for complex machinery.

- Account for customs and import duties: If sourcing internationally, be aware of any additional costs related to customs that may affect your budget.

Step 7: Finalize the Purchase Agreement

Once all the details are confirmed and you are satisfied with the supplier and equipment, finalize the purchase agreement. Ensure that all terms discussed are documented clearly.

- Review the payment terms: Understand payment schedules and conditions before signing.

- Confirm warranty and return policy: Make sure you have a clear understanding of the warranty and what to do in case of defects or dissatisfaction.

By following these steps, you will be well-equipped to make an informed decision when sourcing an exhaust pipe tube bender that aligns with your business needs.

Comprehensive Cost and Pricing Analysis for exhaust pipe tube bender Sourcing

Understanding the cost structure and pricing dynamics of exhaust pipe tube benders is crucial for international B2B buyers seeking to optimize their sourcing strategies. This analysis delves into the various components that influence pricing, as well as actionable insights tailored for buyers from regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to exhaust pipe tube bender

What Are the Key Cost Components for Exhaust Pipe Tube Benders?

Materials: The primary materials used in manufacturing exhaust pipe tube benders include high-grade steel and hydraulic components. The quality of these materials significantly impacts the durability and performance of the bender. As such, sourcing from reputable suppliers that offer certified materials can help ensure long-term reliability.

Labor: Labor costs vary by region and manufacturing practices. In regions with lower labor costs, such as parts of South America and Africa, suppliers may offer competitive pricing. However, this can also come with trade-offs in terms of quality control and craftsmanship.

Manufacturing Overhead: Overhead costs encompass expenses related to factory operations, equipment maintenance, and utilities. Manufacturers with efficient production processes can often provide more competitive pricing, while those with higher overhead may pass these costs onto buyers.

Tooling: Custom tooling is often required for specific bending needs. The cost of tooling can vary based on the complexity of the dies and mandrels needed for the job. Buyers should inquire about tooling costs upfront, as they can significantly affect the overall price.

Illustrative image related to exhaust pipe tube bender

Quality Control (QC): A robust QC process ensures that each bender meets specified performance standards. Suppliers that invest in comprehensive testing and certification processes may charge higher prices but provide better assurance of product quality.

Logistics: Shipping and handling costs can vary widely depending on the origin of the bender and the destination. Buyers should consider shipping terms and potential import duties, as these can significantly impact the total cost.

Margin: Supplier margins can vary based on market positioning and competition. Understanding the typical margins in different regions can help buyers negotiate better deals.

Illustrative image related to exhaust pipe tube bender

How Do Price Influencers Affect Sourcing Decisions?

Volume/MOQ: Bulk purchases often lead to discounted pricing. Buyers should assess their needs carefully and consider negotiating Minimum Order Quantities (MOQ) to leverage better pricing.

Specifications and Customization: Customized benders that meet specific operational requirements typically incur higher costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

Materials and Quality Certifications: The choice of materials and associated certifications (such as ISO or CE) can influence pricing. High-quality, certified products may come at a premium but can reduce long-term operational costs.

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers with a track record of quality may charge more but offer better post-sale support and warranty options.

Incoterms: Understanding Incoterms is essential for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect overall costs and risk exposure in the shipping process.

What Are Some Effective Buyer Tips for Cost-Efficiency?

Negotiation: Engage in open discussions with suppliers about pricing structures. Inquire about discounts for bulk orders and any flexibility in customization costs.

Total Cost of Ownership (TCO): Consider the TCO rather than just the initial purchase price. Factors such as maintenance, durability, and operational efficiency should influence sourcing decisions.

Pricing Nuances for International Buyers: Buyers from different regions should be aware of currency fluctuations, import tariffs, and local market conditions that can affect pricing. Establishing relationships with local distributors can sometimes yield better deals and smoother logistics.

Disclaimer for Indicative Prices: While the prices of exhaust pipe tube benders can range significantly based on specifications and supplier, it is essential to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

In conclusion, a comprehensive understanding of the cost components and price influencers associated with exhaust pipe tube benders can empower international B2B buyers to make informed sourcing decisions, enhancing their operational efficiency and profitability.

Illustrative image related to exhaust pipe tube bender

Alternatives Analysis: Comparing exhaust pipe tube bender With Other Solutions

Exploring Alternatives to Exhaust Pipe Tube Benders: What Are Your Options?

When it comes to bending exhaust pipes, businesses have a variety of solutions at their disposal. While exhaust pipe tube benders are specifically designed for this task, other methods and technologies can also achieve similar outcomes. Understanding these alternatives can help businesses make informed decisions based on performance, cost, and operational efficiency.

Comparison Table

| Comparison Aspect | Exhaust Pipe Tube Bender | Mandrel Tube Bender | Manual Pipe Bender |

|---|---|---|---|

| Performance | High precision and speed for complex bends | Excellent for thick-walled materials; versatile | Adequate for simple bends; slower process |

| Cost | $12,195 – $13,795 | $2,579.50 – $4,000 | $300 – $2,000 |

| Ease of Implementation | Requires training; setup can be complex | Moderate; some assembly needed | Simple, minimal training required |

| Maintenance | Regular checks; hydraulic systems need monitoring | Moderate; lubrication systems require attention | Low; manual tools need less upkeep |

| Best Use Case | High-volume production of exhaust systems | Custom applications with varying material types | Low-budget projects or simple fabrications |

Detailed Breakdown of Alternatives

1. Mandrel Tube Bender

Mandrel tube benders provide an alternative for businesses looking to bend thicker materials or require more versatility in their bending operations. They are designed to accommodate a broad range of wall thicknesses and are ideal for applications involving aluminum, stainless steel, and titanium. One of the standout features of mandrel benders is their unique lubrication system, which enhances bending performance, especially for complex shapes. However, these machines can be more expensive than traditional manual benders, and they may require a certain level of technical knowledge for setup and operation.

2. Manual Pipe Bender

For companies on a tight budget or those that do not require high-volume production, manual pipe benders can be an effective solution. These devices are generally more affordable and require less training to operate. While they excel in simplicity and ease of use, they may not provide the precision and speed of automated solutions. Manual benders are best suited for small-scale operations or projects where complex bends are not necessary. However, the time taken for bending and the potential for human error can be drawbacks in high-demand environments.

How to Choose the Right Solution for Your Needs

When selecting the best solution for bending exhaust pipes, B2B buyers should assess their specific operational requirements, including the materials they typically work with, the complexity of bends needed, and their budget constraints. For high-volume production with intricate designs, an exhaust pipe tube bender or mandrel tube bender would be the best fit. In contrast, businesses with simpler needs or limited budgets may find that a manual pipe bender meets their needs effectively. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for exhaust pipe tube bender

What Are the Essential Technical Properties of Exhaust Pipe Tube Benders?

When evaluating exhaust pipe tube benders, several critical specifications can significantly influence performance and suitability for specific applications. Understanding these properties helps B2B buyers make informed decisions.

1. Material Grade

The material grade of the bender’s construction, typically high-strength steel or aluminum, impacts durability and weight. Higher-grade materials provide better resistance to wear and deformation, ensuring longevity and reducing maintenance costs. For buyers in industries that demand high-performance benders, selecting a model with superior material quality is crucial.

2. Bending Radius

Bending radius refers to the minimum radius that a tube can be bent without compromising its structural integrity. A smaller bending radius allows for more intricate designs, which is essential for custom exhaust systems. Buyers should consider their specific needs for radius capabilities to ensure compatibility with their projects.

3. Wall Thickness Capacity

This specification indicates the range of wall thicknesses that the bender can handle. A broader capacity allows for versatility in working with different materials, including stainless steel, aluminum, and even titanium. Understanding this property is vital for businesses that require flexibility in their bending operations.

4. Hydraulic Pressure Rating

The hydraulic pressure rating denotes the maximum pressure that the bender can exert during operation. Higher pressure ratings translate to the ability to bend tougher materials and achieve precise angles. For B2B buyers, this means the potential for more complex and demanding projects without compromising quality.

5. Tolerance Levels

Tolerance levels indicate the precision of the bends produced by the machine. Tight tolerances are crucial for applications where exact specifications are necessary, such as in automotive exhaust systems. Buyers focused on precision engineering should prioritize benders with superior tolerance capabilities.

6. Control Mechanism

Benders can be manual, semi-automatic, or fully automatic. The control mechanism affects ease of use, speed, and repeatability of bends. Automatic models can significantly enhance productivity by reducing operator fatigue and minimizing errors, making them ideal for high-volume production environments.

Which Industry Terms Are Important to Understand When Purchasing an Exhaust Pipe Tube Bender?

Familiarizing oneself with industry jargon is essential for effective communication and negotiation in the B2B landscape. Below are some key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications helps buyers identify compatible parts and ensures that they are sourcing from reputable manufacturers.

Illustrative image related to exhaust pipe tube bender

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, as it can impact the overall cost of procurement.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other information for specific products. It is a critical step in the procurement process, enabling buyers to compare offers and negotiate terms effectively.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Understanding these terms is vital for managing logistics and minimizing risks associated with international transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Knowing the lead time is crucial for project planning and ensuring that production schedules remain on track.

6. Warranty and Support

Warranty terms and after-sales support can vary significantly between manufacturers. Understanding these aspects is essential for assessing the long-term value of a purchase and ensuring that adequate support is available in case of issues.

By grasping these technical properties and industry terms, B2B buyers can navigate the complexities of selecting an exhaust pipe tube bender more effectively, ensuring they choose the right equipment for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the exhaust pipe tube bender Sector

What Are the Key Trends and Dynamics Influencing the Exhaust Pipe Tube Bender Market?

The global exhaust pipe tube bender market is witnessing significant growth driven by various factors, including the increasing demand for automotive customization, advancements in manufacturing technologies, and the need for high-precision bending solutions. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focusing on automation and digitalization in their operations. The shift towards automated and semi-automated benders, such as those offered by BendPak and Rogue Fabrication, is particularly notable. These machines not only enhance productivity but also ensure consistent quality, which is crucial for businesses looking to meet stringent international standards.

Emerging technologies, such as smart manufacturing and Industry 4.0, are reshaping sourcing strategies. Buyers are now looking for suppliers who can provide advanced features like programmable bending patterns and real-time monitoring capabilities. Additionally, sustainability is becoming a key consideration, with buyers favoring suppliers that offer eco-friendly practices and materials. The rise of e-commerce and online procurement platforms has also changed how businesses source equipment, enabling them to access a broader range of suppliers and compare products easily.

Illustrative image related to exhaust pipe tube bender

How Can Sustainability and Ethical Sourcing Influence B2B Relationships in the Exhaust Pipe Tube Bender Sector?

Sustainability and ethical sourcing are becoming essential criteria for B2B buyers in the exhaust pipe tube bender sector. The environmental impact of manufacturing processes, particularly in metalworking, has come under scrutiny. Businesses are increasingly aware of their carbon footprint and are seeking suppliers who demonstrate a commitment to reducing environmental harm. This includes using materials that are recyclable or sourced from sustainable practices, such as certified steel that meets international standards.

Moreover, buyers are looking for manufacturers who hold ‘green’ certifications, which indicate adherence to environmental regulations and commitment to sustainable practices. This not only enhances the brand image but also attracts environmentally conscious customers. Ethical supply chains are also gaining importance; buyers are interested in knowing the sourcing practices of their suppliers, ensuring they do not contribute to labor exploitation or environmental degradation. Thus, companies that prioritize sustainability and ethical sourcing are likely to gain a competitive edge in the market.

What Is the Historical Context of the Exhaust Pipe Tube Bender Industry?

The exhaust pipe tube bender industry has evolved significantly over the decades, reflecting advancements in technology and shifts in market demand. Initially, manual benders dominated the market, requiring skilled labor for operation. However, as automotive manufacturing grew and customization became more popular, the need for precision and efficiency led to the development of hydraulic and electric benders.

In recent years, the introduction of computer-controlled benders has revolutionized the industry, allowing for intricate designs and mass production without compromising quality. This evolution has not only improved production speed but has also expanded the application of tube benders beyond automotive uses to industries such as aerospace and construction. As the market continues to evolve, international B2B buyers are advised to stay updated on technological advancements and emerging trends to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of exhaust pipe tube bender

-

1. How do I ensure the quality of an exhaust pipe tube bender before purchase?

To verify the quality of an exhaust pipe tube bender, request detailed specifications, including material composition and manufacturing standards. Look for certifications such as ISO or CE that indicate adherence to international quality standards. It’s advisable to ask for product samples or arrange a factory visit to inspect the bender firsthand. Additionally, seek references or reviews from other buyers who have previously purchased from the supplier. A robust warranty and after-sales service can also be indicators of a manufacturer’s commitment to quality. -

2. What is the best exhaust pipe tube bender for small to medium-scale operations?

For small to medium-scale operations, a manual or semi-automatic pipe bender may be the best option. Models like the BendPak Blue-Bullet series are renowned for their reliability and ease of use, making them ideal for fabricators who prefer hands-on work. Additionally, consider benders with features that allow for customization, such as interchangeable die packages, to accommodate various bending needs. The Rogue Fab M600 also offers versatility and affordability, making it suitable for diverse applications while maintaining high-quality performance. -

3. How do I vet suppliers for exhaust pipe tube benders in international markets?

Begin by researching potential suppliers through online marketplaces, trade shows, and industry directories. Verify their business credentials and reputation through reviews and ratings from previous customers. Request references and case studies to understand their experience in your specific region. It’s also essential to assess their production capabilities, lead times, and compliance with international trade regulations. Engage in direct communication to gauge their responsiveness and willingness to meet your requirements, including customization options. -

4. What are typical minimum order quantities (MOQs) for exhaust pipe tube benders?

Minimum order quantities for exhaust pipe tube benders can vary significantly based on the supplier and the type of bender. Generally, established manufacturers might have MOQs ranging from 1 to 10 units for standard models, while custom or specialized benders may require larger orders. Discuss your needs with suppliers to understand their flexibility on MOQs, especially if you are looking to start with a smaller investment. Some suppliers may offer trial orders or pilot programs to help you evaluate the product before committing to larger quantities. -

5. What payment terms should I expect when purchasing exhaust pipe tube benders internationally?

Payment terms for international purchases typically vary by supplier and can include options like upfront payment, partial payment upon order confirmation, and the balance upon delivery. Common payment methods include wire transfers, letters of credit, and PayPal. It’s crucial to clarify these terms before finalizing your order to avoid any misunderstandings. Additionally, consider negotiating terms that provide some level of buyer protection, such as escrow services, to ensure that you receive the equipment as agreed. -

6. How can I customize an exhaust pipe tube bender to fit my specific needs?

Customization options for exhaust pipe tube benders can include modifications to bending angles, die sizes, and hydraulic capacities. When approaching suppliers, clearly outline your specific requirements and any unique applications you intend to use the bender for. Many manufacturers are willing to work with clients on custom solutions, so be prepared to discuss your operational needs in detail. Additionally, inquire about lead times and any additional costs associated with custom features. -

7. What logistics considerations should I keep in mind when importing exhaust pipe tube benders?

When importing exhaust pipe tube benders, consider shipping options, lead times, and customs regulations in your country. Ensure you have a clear understanding of the total landed cost, which includes shipping, tariffs, and any additional fees. It’s beneficial to work with a logistics partner experienced in international shipping to navigate these complexities. Additionally, confirm that the supplier can provide all necessary documentation, such as invoices, packing lists, and certificates of origin, to facilitate a smooth customs clearance process. -

8. What warranties and after-sales support should I expect for exhaust pipe tube benders?

Reputable manufacturers typically offer warranties ranging from one to three years, covering defects in materials and workmanship. It’s essential to inquire about the specifics of the warranty, including what it covers and the process for claims. Additionally, assess the availability of after-sales support, including technical assistance, spare parts, and maintenance services. A supplier that provides comprehensive after-sales support can significantly enhance your operational efficiency and minimize downtime in case of equipment issues.

Top 8 Exhaust Pipe Tube Bender Manufacturers & Suppliers List

1. BendPak – BB-2 Blue-Bullet Pipe Bender

Domain: bendpak.com

Registered: 1997 (28 years)

Introduction: BendPak offers a range of pipe benders, including:

1. BB-2 Blue-Bullet Pipe Bender with B-1 Die Package – Heavy-duty exhaust pipe bender, includes die package and dual-function end-finishing unit. Price: $12,195.00.

2. 1302BAS 3-Button Control / Automatic Pipe Bender – Automatic exhaust pipe bender designed for efficiency, includes side-loading swager and dual-function end-finishing unit. Price: $…

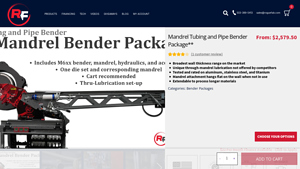

2. Rogue Fab – M600 Mandrel Tubing and Pipe Bender

Domain: roguefab.com

Registered: 2012 (13 years)

Introduction: M600 Mandrel Tubing and Pipe Bender from Rogue Fab

– Price: From $2,579.50

– Rating: 4.00 out of 5 (based on 1 customer review)

– Broadest wall thickness range on the market

– Unique through-mandrel lubrication system

– Tested on aluminum, stainless steel, and titanium

– Mandrel attachment hangs flat on the wall when not in use

– Customizable options for bender capacity, package, die, and mandrel …

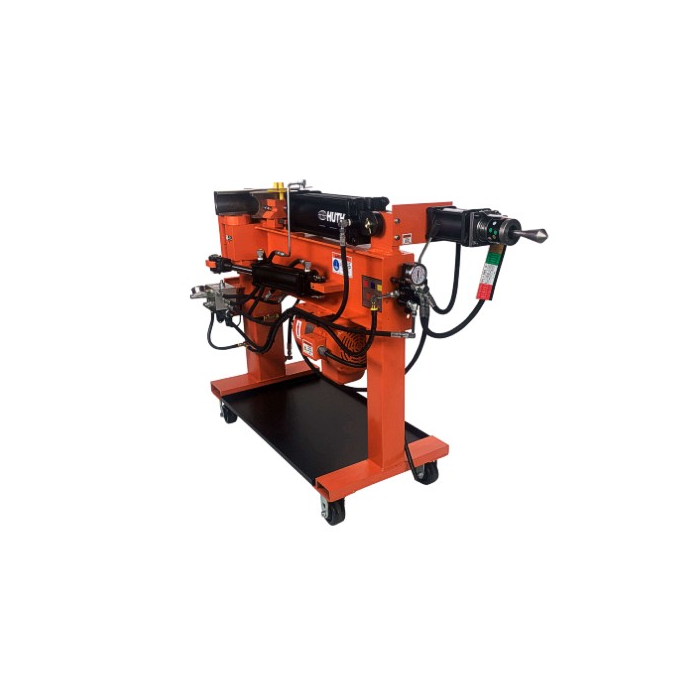

3. Huth – HMRB6017 Manual Rod Bender

Domain: bestbuyautoequipment.com

Registered: 2007 (18 years)

Introduction: Exhaust Pipe Benders & Expanders from Best Buy Auto Equipment include a variety of models from trusted brands such as Huth, BendPak, and Ben Pearson. Key products include:

1. Huth HMRB6017 Manual Rod Bender – List Price: $112.50, Our Price: $101.26

2. Huth Ready Rak II – List Price: $159.50, Our Price: $143.56

3. Huth 986 Muffler Stand – List Price: $251.50, Our Price: $226.36

4. Huth 985 Rod …

4. Trick Tools – Exhaust Benders & Fabrication Tools

Domain: trick-tools.com

Registered: 2001 (24 years)

Introduction: Exhaust Benders for automotive exhaust pipes and headers, including manual benders, powered benders, roll benders, tube bender dies, hydraulic components, and exhaust fabrication tools.

5. Ben Pearson – MC59 Pipe Bender

Domain: ben-pearson.com

Registered: 1998 (27 years)

Introduction: Ben Pearson started designing and manufacturing pipe benders in 1973, with the first bender shipped in 1975. The MC59 pipe bender became a popular choice among exhaust repair shops and is recognized as one of the best in the industry. Ben Pearson benders are used by major US exhaust muffler chains including Meineke, Monro Muffler & Brake, and others. In 2008, Ben Pearson Tubemaster was acquired by…

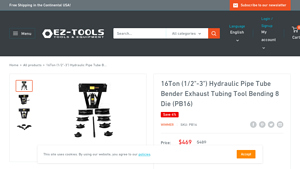

6. EZ Tools – PB16 Hydraulic Pipe Bender

Domain: ez-tools.us

Registered: 2016 (9 years)

Introduction: {“Model”:”PB16″,”Capacity”:”16 Tons”,”Max stroke”:”11.5 inches”,”Pipe diameter range”:”1/2 inch – 3 inch”,”Weight”:”110 lbs”,”Bending formers”:”8 Die”}

7. Garage Journal – Essential Pipe Benders for DIYers

Domain: garagejournal.com

Registered: 2006 (19 years)

Introduction: 1. Harbor Freight 16 Ton Hydraulic Pipe Bender – Considered for DIY exhaust bending, but concerns about collapsing the tube. 2. Baileigh MB-350 Mandrel Tube Bender – Mentioned as a specialized tool for tubing, priced at $42,000. 3. JD2 Tube/Pipe Benders – Suggested as an affordable option for DIYers, but requires additional die sets. 4. Mandrel Bends – Recommended as a better alternative for exhau…

8. BendPak – Large 3 Die Package for Tube Benders

Domain: asedeals.com

Registered: 2001 (24 years)

Introduction: BendPak 300-1 Large 3″ Die Package for Tube Benders – Price: $1,650.00 (Regular Price: $1,739.00) – Extends bending capabilities of BendPak Pipe Bender. BendPak BB-2-DLX-601 Blue Bullet Pipe Bender – Price: $12,195.00 (Regular Price: $12,809.00) – Heavy-duty exhaust pipe bender. BendPak 1302BAS Semi-Automatic Tube Bender – Price: $13,095.00 (Regular Price: $13,749.00) – 3-Button Control with 302 D…

Strategic Sourcing Conclusion and Outlook for exhaust pipe tube bender

In the competitive landscape of exhaust pipe tube benders, strategic sourcing plays a pivotal role in ensuring quality, efficiency, and cost-effectiveness. By partnering with reputable manufacturers like BendPak and Rogue Fabrication, international buyers can access advanced technology that enhances production capabilities. These companies offer a range of bender models tailored to various needs, from manual to fully automated systems, ensuring that businesses can meet diverse client demands while optimizing their operations.

Investing in high-quality equipment not only improves product reliability but also reduces long-term maintenance costs. Buyers should prioritize suppliers that provide comprehensive support, including training and financing options, to facilitate a smooth integration of new machinery into their existing workflows.

As the market continues to evolve, particularly in emerging regions such as Africa and South America, the demand for innovative exhaust solutions is set to rise. Now is the time for businesses to reassess their sourcing strategies and explore partnerships that can bolster their competitive edge. Embrace the future of pipe bending—invest in quality, leverage technology, and position your business for sustained growth in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.