A Deep Dive into Engine Rubber Gasket Solution

Introduction: Navigating the Global Market for engine rubber gasket

In the fast-paced global market, sourcing reliable engine rubber gaskets can pose significant challenges for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With the critical role these components play in sealing engine joints and preventing leaks, the quality of rubber gaskets directly impacts vehicle performance and maintenance costs. This comprehensive guide delves into various types of engine rubber gaskets, their applications across different vehicle models, and best practices for supplier vetting.

Understanding the nuances of engine gaskets—from valve cover to oil pan gaskets—enables businesses to make informed purchasing decisions. This guide also addresses key factors influencing cost, including material quality and manufacturing standards, ensuring buyers can evaluate potential suppliers effectively. Furthermore, the insights provided will aid in identifying reputable manufacturers and distributors, ultimately enhancing supply chain efficiency.

By equipping international B2B buyers with actionable knowledge and strategic recommendations, this resource empowers businesses to navigate the complexities of sourcing engine rubber gaskets. Whether you’re operating in Brazil, Nigeria, or beyond, you will gain valuable insights that facilitate smarter procurement strategies, reduce operational risks, and enhance your competitive edge in the automotive market.

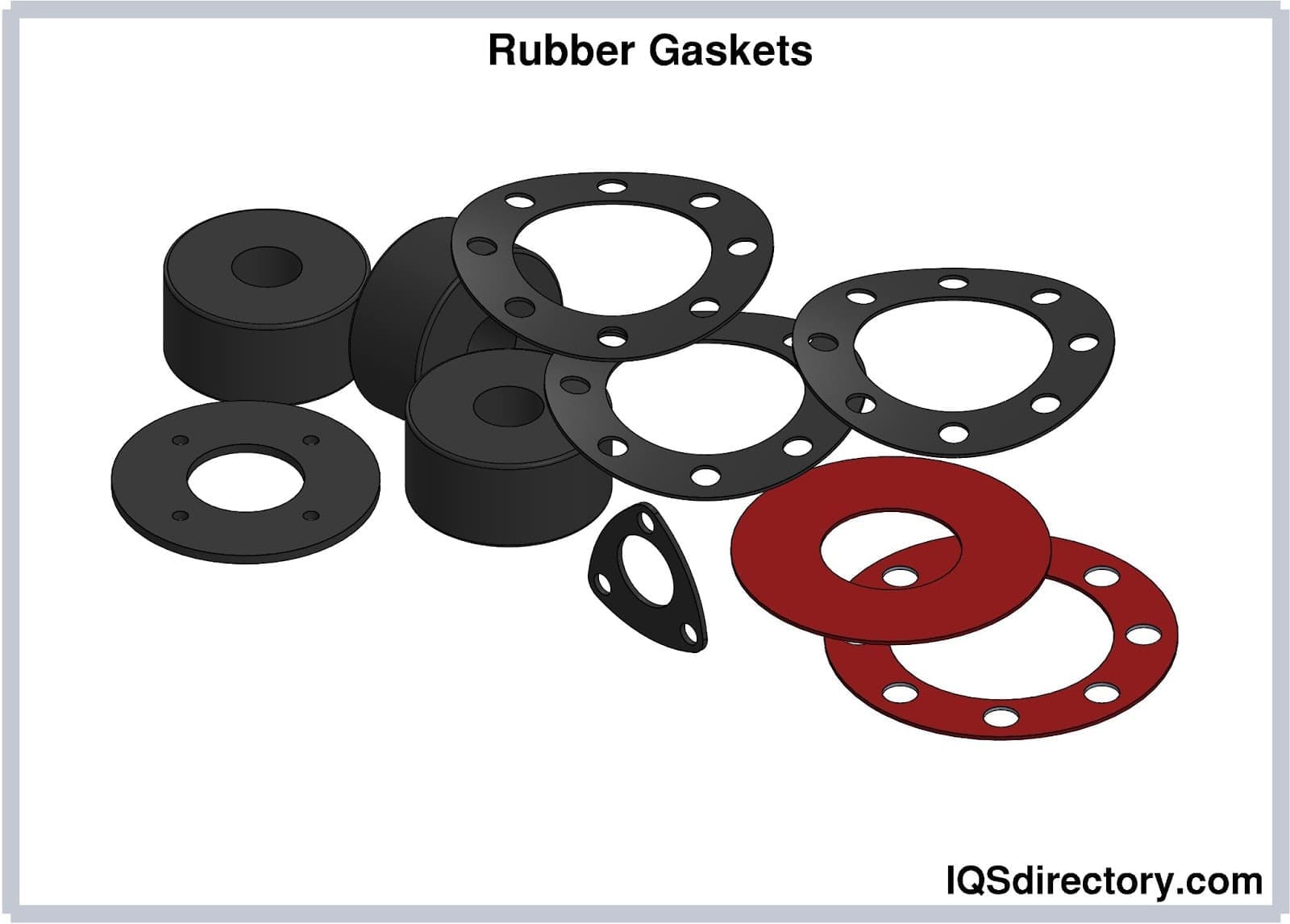

Understanding engine rubber gasket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Valve Cover Gasket | Seals the valve cover to the cylinder head; often made of rubber or silicone. | Automotive repair and maintenance | Pros: Effective sealing, easy to replace. Cons: Prone to wear over time, may require frequent replacement. |

| Oil Pan Gasket | Located at the bottom of the engine, sealing the oil pan to the crankcase; typically made from rubber or cork. | Heavy machinery, automotive engines | Pros: Durable, prevents oil leaks. Cons: Sensitive to temperature changes, can degrade quickly if not maintained. |

| Intake Manifold Gasket | Seals the intake manifold to the engine; made from molded rubber or composite materials. | Automotive manufacturing and aftermarket parts | Pros: Enhances engine performance, reduces risk of vacuum leaks. Cons: Complex installation, can fail due to overheating. |

| Timing Cover Gasket | Seals the timing cover at the front of the engine; often made from rubber or silicone. | Automotive repair shops, engine rebuilds | Pros: Prevents oil and coolant leaks. Cons: Requires careful installation, sensitive to engine conditions. |

| Exhaust Manifold Gasket | Seals the exhaust manifold to the engine; usually made from metal or composite materials. | Automotive aftermarket, performance upgrades | Pros: High-temperature resistance, ensures efficient exhaust flow. Cons: Can crack under extreme conditions, may require special tools for installation. |

What Are the Characteristics of Valve Cover Gaskets?

Valve cover gaskets are crucial components that prevent oil leaks between the valve cover and the cylinder head. Typically made from rubber or silicone, they are designed to withstand high temperatures and pressures within the engine. B2B buyers should consider the compatibility with specific vehicle models and the quality of materials, as higher-grade gaskets can offer better durability and longevity. Regular maintenance and timely replacement are essential to prevent engine damage due to oil leaks.

How Do Oil Pan Gaskets Function in Engine Systems?

Oil pan gaskets provide a seal between the oil pan and the crankcase, preventing oil leaks that could lead to significant engine damage. They are often constructed from rubber or cork, making them flexible yet durable. For B2B buyers, selecting oil pan gaskets involves considering the type of engine and operating conditions, such as temperature extremes. A quality oil pan gasket can enhance engine reliability, but buyers should also be aware of the potential for deterioration over time.

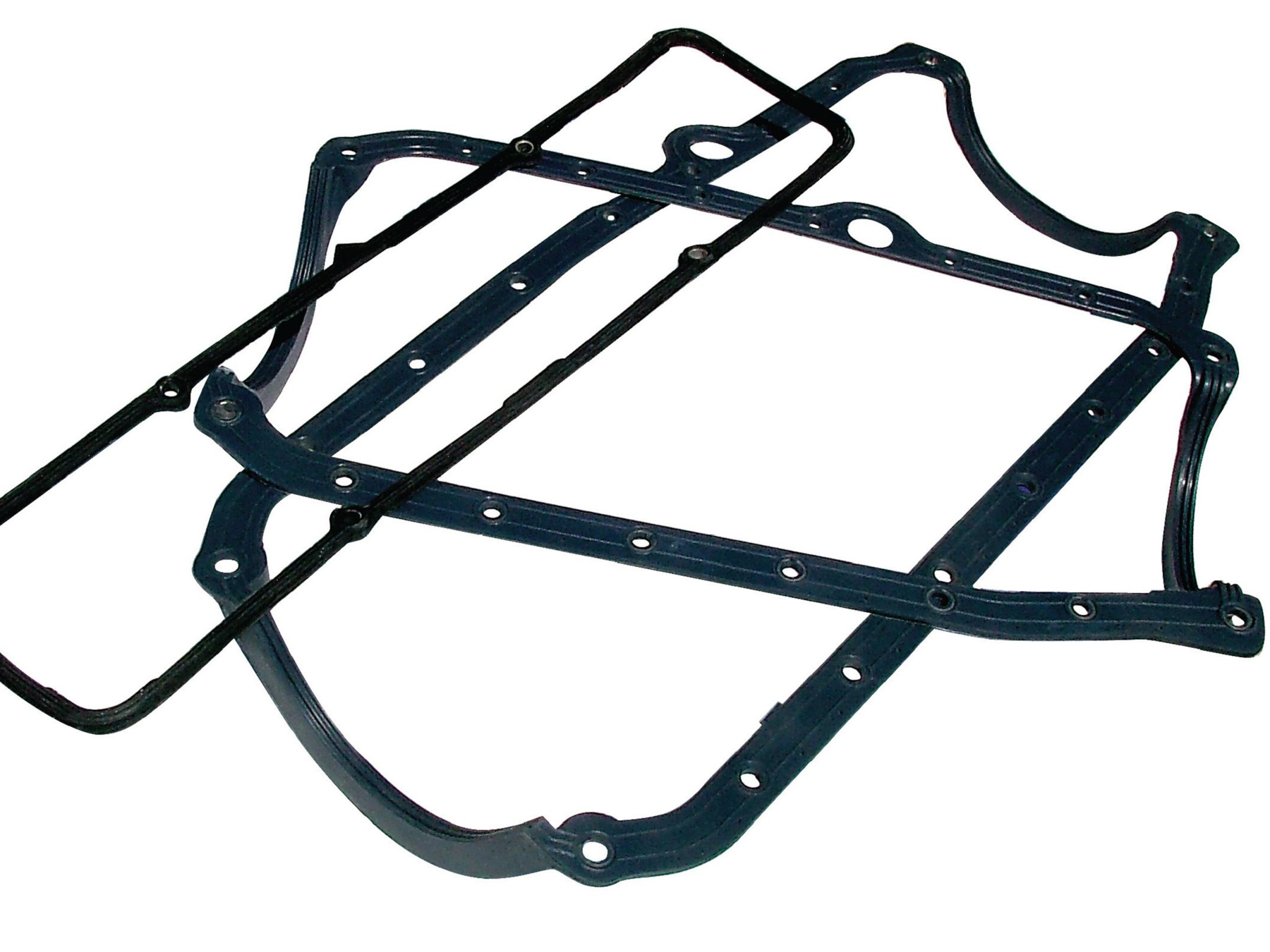

Illustrative image related to engine rubber gasket

Why Are Intake Manifold Gaskets Important for Engine Performance?

Intake manifold gaskets are designed to seal the intake manifold to the engine, and they play a critical role in maintaining engine performance. Made from molded rubber or composite materials, they must resist decay from oils and coolants. B2B purchasers should focus on the gasket’s resistance to high temperatures and its compatibility with various fuel types. A reliable intake manifold gasket enhances fuel efficiency and engine power, making it a valuable investment for automotive manufacturers and repair shops.

What Role Do Timing Cover Gaskets Play in Engine Maintenance?

Timing cover gaskets are essential for sealing the timing cover at the front of the engine. These gaskets are typically made from rubber or silicone and are designed to prevent oil and coolant leaks. For B2B buyers, it is vital to consider the specific engine model and the gasket’s ability to withstand the dynamic conditions of engine operation. Proper installation is critical, as a poorly fitted gasket can lead to leaks and costly repairs.

How Do Exhaust Manifold Gaskets Contribute to Engine Efficiency?

Exhaust manifold gaskets seal the connection between the exhaust manifold and the engine, ensuring that exhaust gases are efficiently expelled from the engine. These gaskets are often made from metal or composite materials to withstand high temperatures. B2B buyers should evaluate the gasket’s thermal resistance and compatibility with different engine types. Quality exhaust manifold gaskets can improve engine performance and reduce emissions, making them essential for automotive applications and performance upgrades.

Key Industrial Applications of engine rubber gasket

| Industry/Sector | Specific Application of engine rubber gasket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine assembly in vehicles | Ensures optimal performance and prevents leaks, enhancing engine longevity. | Compatibility with various makes and models, high-temperature resistance, and durability under pressure. |

| Industrial Machinery | Sealing in heavy machinery engines | Reduces maintenance costs by preventing fluid leaks and improving efficiency. | Material specifications to withstand harsh operating conditions and compliance with industry standards. |

| Marine | Engine sealing in boats and vessels | Protects against water intrusion and engine overheating, ensuring reliable operation at sea. | Resistance to saltwater corrosion, flexibility in extreme temperatures, and custom sizing for specific engine types. |

| Power Generation | Gaskets in generators and turbines | Enhances efficiency and safety by preventing gas and fluid leaks during operation. | Sourcing from certified manufacturers to ensure reliability and adherence to safety regulations. |

| Aerospace | Sealing in aircraft engines | Critical for maintaining pressure and preventing leaks, ensuring safety and performance. | Compliance with strict aerospace standards, lightweight materials, and high-temperature resistance. |

How is Engine Rubber Gasket Used in the Automotive Industry?

In the automotive sector, engine rubber gaskets are integral to the assembly of various vehicle engines. They are specifically designed to create airtight seals between engine components, such as the cylinder head and the engine block, preventing oil and coolant leaks. This functionality not only enhances engine performance but also extends the lifespan of the vehicle by mitigating the risk of overheating and damage due to fluid loss. For international buyers, especially from regions like Africa and South America, sourcing high-quality gaskets that are compatible with different vehicle makes and models is crucial to ensure optimal performance.

What Role Do Engine Rubber Gaskets Play in Industrial Machinery?

In industrial machinery, engine rubber gaskets are employed to seal engine components in heavy machinery, such as excavators and generators. These gaskets are essential for maintaining operational efficiency by preventing leaks of oil and coolant, which can lead to costly downtimes and repairs. Buyers in this sector should prioritize gaskets that meet specific material requirements to withstand extreme conditions, including high pressure and temperature fluctuations, which are common in industrial applications.

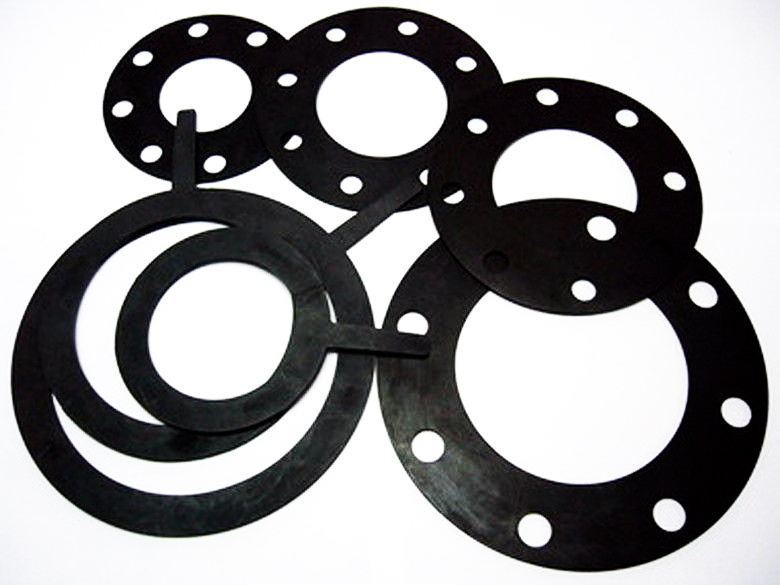

Illustrative image related to engine rubber gasket

Why Are Engine Rubber Gaskets Critical in Marine Applications?

Marine engines utilize engine rubber gaskets to create reliable seals that prevent water intrusion and overheating, which are critical for safe operation at sea. The exposure to saltwater and varying temperatures necessitates gaskets that are resistant to corrosion and can maintain flexibility under extreme conditions. International buyers in the marine industry must ensure that the gaskets they source are tailored for specific engine types and comply with maritime safety standards.

How Do Engine Rubber Gaskets Enhance Power Generation Systems?

In power generation, engine rubber gaskets are used in generators and turbines to maintain gas and fluid integrity, preventing leaks that could compromise efficiency and safety. These gaskets play a vital role in the overall performance of power generation systems, as any leaks can lead to significant operational disruptions. Buyers should consider sourcing gaskets from certified manufacturers to guarantee reliability and compliance with safety regulations in energy production.

What is the Importance of Engine Rubber Gaskets in Aerospace?

In the aerospace sector, engine rubber gaskets are critical components that ensure the integrity of aircraft engines by maintaining pressure and preventing fuel leaks. The safety of air travel heavily relies on the performance of these gaskets, which must meet stringent aerospace standards. Buyers in this field should focus on sourcing lightweight, high-temperature resistant gaskets that comply with rigorous industry regulations to ensure both safety and efficiency in aircraft operations.

3 Common User Pain Points for ‘engine rubber gasket’ & Their Solutions

Scenario 1: Frequent Engine Overheating Due to Gasket Failures

The Problem: B2B buyers often face the challenge of engine overheating in their fleets, which can be traced back to failing engine rubber gaskets. These gaskets are critical for sealing coolant passages and preventing leaks. Over time, exposure to heat, pressure, and coolant can cause gaskets to become brittle and crack, leading to leaks. This not only affects engine performance but can also result in costly repairs and downtime for vehicles that are essential for business operations.

The Solution: To mitigate the risk of engine overheating, it’s vital to regularly inspect and replace engine rubber gaskets before they fail. Buyers should source high-quality gaskets that are designed to withstand the specific temperature and pressure conditions of their engines. Opt for gaskets made from advanced materials such as silicone or fluorocarbon rubber, which offer better thermal resistance and longevity. When purchasing, ensure to check compatibility with the specific engine models in use and consider working with a trusted supplier that can provide detailed specifications and testing data for their products. Additionally, implementing a proactive maintenance schedule that includes regular inspections of engine gaskets can help identify wear before it leads to severe issues.

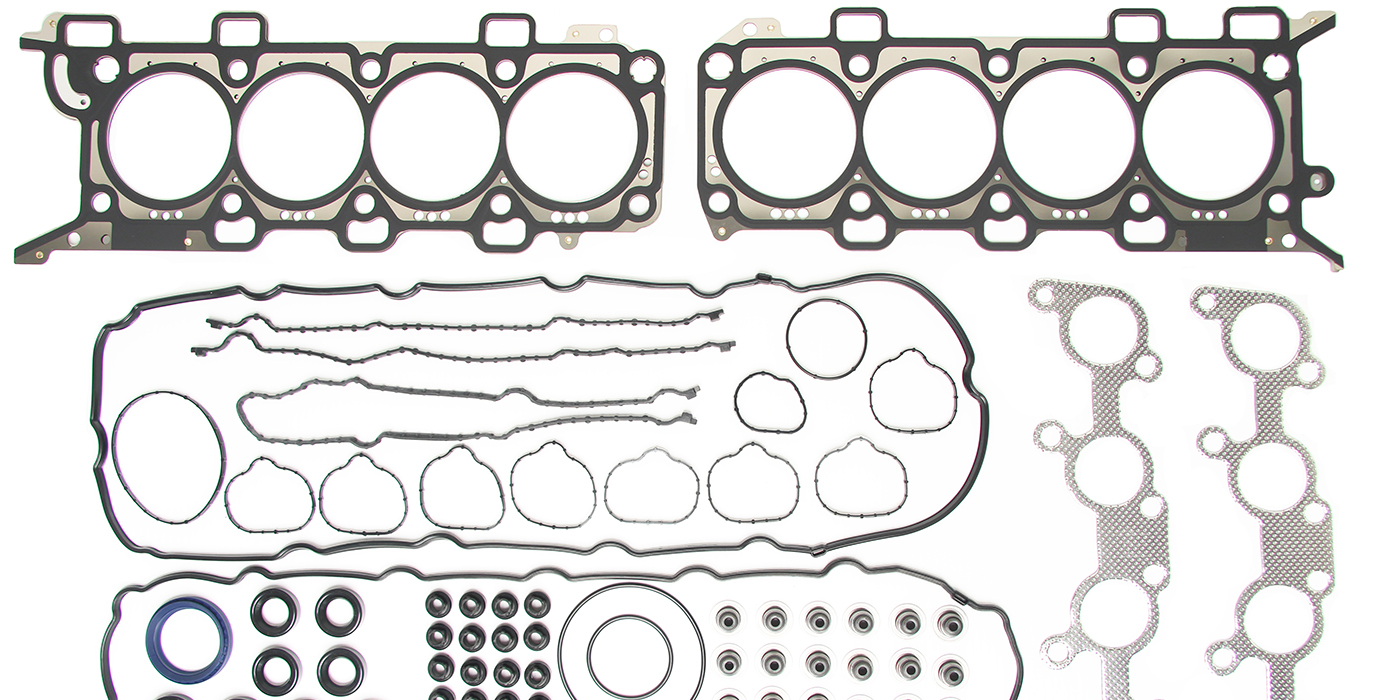

Illustrative image related to engine rubber gasket

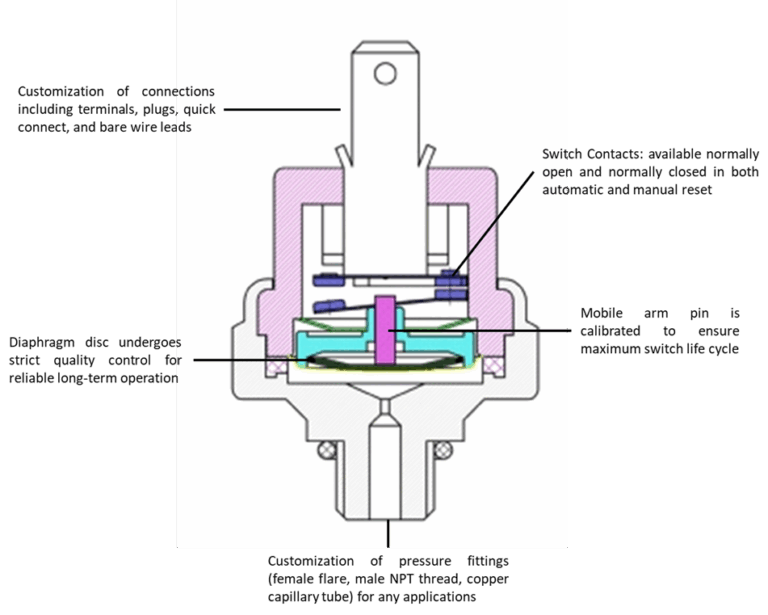

Scenario 2: Difficulty in Sourcing Custom Gaskets for Diverse Engine Models

The Problem: Many international B2B buyers struggle with sourcing engine rubber gaskets that fit a wide variety of engine models, especially in regions with diverse vehicle fleets. This can lead to delays in repairs and increased inventory costs as businesses stock multiple gasket types to meet varied needs. Without a streamlined sourcing process, these challenges can impact service delivery and customer satisfaction.

The Solution: To tackle this issue, buyers should consider partnering with manufacturers or suppliers that offer customizable gasket solutions. When selecting a supplier, prioritize those who can provide a comprehensive catalog that includes both standard and custom options, along with detailed specifications for each gasket type. Establishing a strong relationship with a manufacturer that specializes in gaskets allows for better communication regarding specific needs and leads to quicker turnaround times on custom orders. Additionally, utilizing advanced inventory management systems can help track gasket usage across different engine models, allowing businesses to maintain optimal stock levels without overcommitting to inventory that may not be used.

Scenario 3: Gasket Installation Errors Leading to Leaks

The Problem: Installation errors are a common pain point for B2B buyers when it comes to engine rubber gaskets. Incorrect installation can lead to leaks, reduced engine efficiency, and increased wear on engine components. This not only results in additional repair costs but also leads to potential safety hazards, particularly if leaks involve oil or coolant.

The Solution: To reduce the risk of installation errors, comprehensive training for technicians is crucial. Buyers should invest in training programs that cover best practices for gasket installation, including the importance of cleaning mating surfaces, applying the correct torque specifications, and using appropriate sealants where necessary. Additionally, providing technicians with access to detailed installation guides and videos can reinforce proper techniques. It’s also beneficial to implement a quality control process that includes checks after installation to ensure that gaskets are properly seated and functioning. By prioritizing education and quality control, businesses can enhance the reliability of their installations and minimize the likelihood of costly leaks.

Strategic Material Selection Guide for engine rubber gasket

When selecting materials for engine rubber gaskets, it is essential to consider their properties, advantages, and limitations, especially in the context of international B2B markets. Here, we analyze four common materials used for engine rubber gaskets, focusing on their performance characteristics and implications for buyers in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Nitrile Rubber (NBR) for Engine Gaskets?

Nitrile rubber, also known as Buna-N, is widely used in engine gaskets due to its excellent resistance to oil, fuel, and other automotive fluids. It typically operates effectively within a temperature range of -40°F to 250°F (-40°C to 121°C) and can withstand moderate pressures.

Pros and Cons of Nitrile Rubber:

NBR is durable and cost-effective, making it a popular choice for various automotive applications. However, it has limitations in high-temperature environments and can degrade when exposed to ozone or sunlight over extended periods.

Impact on Application:

NBR is suitable for oil and fuel applications, but its compatibility with certain coolants may be limited. Buyers should ensure that the specific media used in their engines aligns with NBR’s chemical resistance.

Considerations for International Buyers:

Buyers from regions like Brazil and Nigeria should verify compliance with local automotive standards, such as ASTM D2000, which outlines the classification of rubber materials.

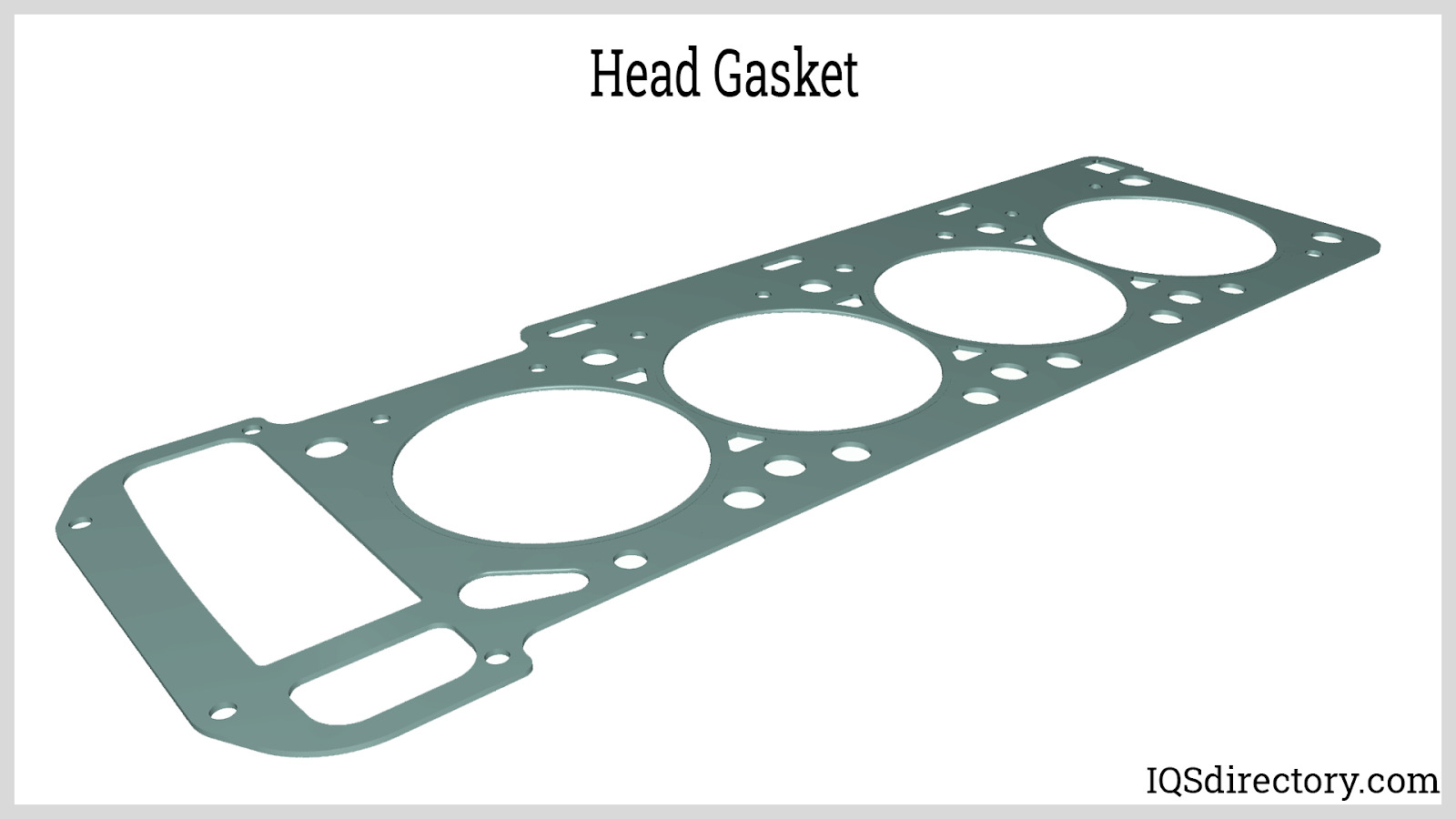

Illustrative image related to engine rubber gasket

Why Choose Silicone Rubber for Engine Gaskets?

Silicone rubber is renowned for its temperature resistance, typically performing well in a range from -100°F to 500°F (-73°C to 260°C). It is also resistant to UV light and ozone, making it ideal for applications exposed to harsh environmental conditions.

Pros and Cons of Silicone Rubber:

The primary advantage of silicone rubber is its exceptional thermal stability and flexibility. However, it tends to be more expensive than other materials and may not be suitable for certain oil applications due to potential swelling.

Impact on Application:

Silicone gaskets are ideal for high-temperature applications, such as valve covers and exhaust systems. Buyers should assess the specific fluid compatibility to avoid performance issues.

Considerations for International Buyers:

In Europe, compliance with REACH regulations is crucial for silicone materials. Buyers should ensure that their suppliers can provide certifications to meet these standards.

How Does EPDM Rubber Perform in Engine Gaskets?

Ethylene Propylene Diene Monomer (EPDM) rubber is another popular choice for engine gaskets, particularly for applications requiring excellent weather and ozone resistance. EPDM gaskets can typically handle temperatures from -40°F to 300°F (-40°C to 149°C).

Pros and Cons of EPDM Rubber:

EPDM is highly durable and resistant to aging, making it suitable for long-term applications. However, it has limited oil resistance, which may restrict its use in certain engine components.

Impact on Application:

EPDM is ideal for coolant and water applications but should be avoided in oil-based environments. Buyers must consider the specific media to ensure compatibility.

Considerations for International Buyers:

In South America, adherence to local automotive standards and certifications is essential, especially for EPDM products used in cooling systems.

What Are the Benefits of Fluoroelastomer (FKM) for Engine Gaskets?

Fluoroelastomers, commonly referred to as FKM, are engineered for high-performance applications, boasting excellent chemical resistance and temperature stability from -15°F to 400°F (-26°C to 204°C).

Pros and Cons of Fluoroelastomer:

The primary advantage of FKM is its superior resistance to fuels, oils, and harsh chemicals. However, it is one of the most expensive materials, which may deter budget-conscious buyers.

Impact on Application:

FKM gaskets are particularly suitable for high-performance engines and applications requiring robust chemical resistance. Buyers should assess the cost-benefit ratio when considering FKM for less demanding applications.

Considerations for International Buyers:

Compliance with international standards such as DIN and JIS is vital for FKM materials, especially in competitive markets like Europe and the Middle East.

Summary Table of Material Selection for Engine Rubber Gaskets

| Material | Typical Use Case for engine rubber gasket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nitrile Rubber (NBR) | Oil and fuel applications | Excellent oil and fuel resistance | Limited high-temperature performance | Low |

| Silicone Rubber | High-temperature applications | Exceptional thermal stability | Higher cost, limited oil compatibility | High |

| EPDM Rubber | Coolant and water applications | Excellent weather and ozone resistance | Limited oil resistance | Medium |

| Fluoroelastomer (FKM) | High-performance engine applications | Superior chemical resistance | High cost | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties and implications of various materials used in engine rubber gaskets, enabling informed decision-making tailored to specific applications and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for engine rubber gasket

What Are the Main Stages of Manufacturing Engine Rubber Gaskets?

The manufacturing process of engine rubber gaskets involves several critical stages that ensure the final product meets industry standards for performance and durability. Understanding these stages can help B2B buyers make informed decisions when sourcing gaskets.

How Is Material Prepared for Engine Rubber Gaskets?

The first step in the manufacturing process is material preparation. Engine gaskets are typically made from various rubber compounds, including nitrile, silicone, or fluorocarbon rubber, each chosen based on the specific application and environmental conditions they will face.

-

Material Selection: The right rubber formulation is selected based on factors such as temperature resistance, chemical compatibility, and durability. Suppliers often provide technical data sheets to guide buyers in choosing the appropriate material.

-

Compounding: Once the material is selected, it undergoes a compounding process where additives such as fillers, curing agents, and colorants are mixed in. This step is crucial as it influences the mechanical properties and performance of the gasket.

-

Quality Control: Before moving forward, raw materials are subjected to Incoming Quality Control (IQC) checks to ensure they meet predefined specifications. This helps in identifying any potential issues early in the manufacturing process.

What Forming Techniques Are Used for Engine Rubber Gaskets?

The next stage involves forming the prepared rubber into the desired gasket shape. Several techniques can be employed, depending on the complexity and volume of production.

-

Compression Molding: This traditional method involves placing the rubber compound into a heated mold, where it is compressed under heat and pressure. This technique is ideal for producing simple shapes in high volumes.

-

Transfer Molding: Similar to compression molding, transfer molding allows for more intricate designs. The rubber is transferred from a chamber into a mold cavity, enabling more precise control over the material flow.

-

Injection Molding: This technique is increasingly popular for producing gaskets with complex geometries. Rubber is heated until it becomes pliable and then injected into a mold. This method provides high precision and consistency, making it suitable for large-scale production.

-

Die Cutting: For gaskets requiring flat shapes or specific profiles, die cutting is utilized. This process involves cutting the rubber sheet into the required shape using a die, ensuring efficiency and minimal waste.

How Is the Assembly Process Managed for Engine Rubber Gaskets?

In many cases, engine gaskets may consist of multiple layers or components. The assembly process ensures that these components are correctly aligned and bonded.

-

Layering: If the gasket design requires multiple layers, these are carefully stacked and aligned. The use of adhesives or bonding agents may be necessary to ensure proper adhesion between layers.

-

Final Inspection: After assembly, the gaskets undergo a final inspection to ensure they meet design specifications. This step is crucial for identifying any defects that could lead to failure in application.

What Finishing Processes Are Essential for Engine Rubber Gaskets?

Finishing touches are vital to ensure that the gaskets are ready for use. This stage may include several processes:

Illustrative image related to engine rubber gasket

-

Trimming: Excess material is trimmed away to achieve the final dimensions. This ensures that the gasket fits perfectly into the engine assembly.

-

Surface Treatment: Depending on the application, surface treatments may be applied to enhance properties such as resistance to oil, heat, and environmental factors.

-

Packaging: Finally, gaskets are packaged to prevent contamination and damage during transportation. Proper packaging is essential for maintaining the integrity of the product until it reaches the end user.

How Is Quality Assurance Implemented in Engine Rubber Gasket Manufacturing?

Quality assurance is critical in ensuring that engine rubber gaskets perform effectively in their applications. B2B buyers should be familiar with the quality control measures and standards that manufacturers adhere to.

What International Standards Govern Engine Rubber Gasket Quality?

Manufacturers often comply with various international quality standards to ensure their products are reliable and safe.

-

ISO 9001: This standard outlines the requirements for a quality management system. It ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

-

CE Marking: In Europe, the CE marking indicates that a product meets European safety standards. Gaskets intended for use in specific applications may require CE certification to be legally sold in EU countries.

-

API Standards: For gaskets used in the oil and gas industry, adherence to API (American Petroleum Institute) standards is crucial. These standards ensure that gaskets can withstand the demanding conditions found in these applications.

What Are the Key Quality Control Checkpoints in Gasket Manufacturing?

Quality control checkpoints are established throughout the manufacturing process to ensure compliance with the required specifications.

Illustrative image related to engine rubber gasket

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify they meet quality standards.

-

In-Process Quality Control (IPQC): During manufacturing, various parameters are monitored, including temperature, pressure, and material flow. This ensures that any deviations from the standard can be addressed immediately.

-

Final Quality Control (FQC): After manufacturing, gaskets undergo final inspections and testing to confirm that they meet all specified requirements before shipment.

What Common Testing Methods Are Used to Ensure Gasket Performance?

Testing methods are employed to verify that the gaskets will perform as expected in real-world conditions.

-

Leak Testing: Gaskets are subjected to pressure tests to ensure they do not leak under operational conditions. This is critical for maintaining engine integrity.

-

Durability Testing: Samples may undergo accelerated aging tests to evaluate how well they withstand heat, pressure, and chemical exposure over time.

-

Dimensional Inspection: Gaskets are measured to ensure they meet specified dimensions and tolerances. This step is vital for ensuring a proper fit in engine applications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should conduct due diligence when selecting suppliers to ensure they adhere to high-quality standards.

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality control measures in place. This also allows buyers to assess the supplier’s adherence to international standards.

-

Quality Reports: Requesting quality reports and certificates can provide assurance that the supplier meets required standards. These documents should detail testing methods and results.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. This is especially important for buyers in regions where local standards may vary.

-

Understanding Certification Nuances: Buyers should be aware that certification requirements may differ by region. For instance, certifications recognized in Europe may not hold the same weight in Africa or South America. Thus, understanding local regulations and standards is essential for effective sourcing.

By comprehensively understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing engine rubber gaskets, ensuring they select suppliers that meet their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘engine rubber gasket’

In the competitive landscape of automotive components, sourcing high-quality engine rubber gaskets is crucial for maintaining the integrity of engine performance. This guide provides a practical checklist for B2B buyers seeking to procure these essential components effectively. Each step is designed to streamline the sourcing process and ensure that you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline the technical specifications for the engine rubber gaskets you require. Consider factors such as material type, size, thickness, and temperature resistance. Understanding these specifications will help you communicate your needs effectively and ensure compatibility with your machinery.

Illustrative image related to engine rubber gasket

Step 2: Research Reliable Suppliers

Conduct thorough research to identify suppliers that specialize in engine rubber gaskets. Look for companies with a proven track record in the automotive sector, as well as positive reviews from other B2B buyers. Utilize online directories, trade shows, and industry publications to compile a list of potential suppliers.

Step 3: Evaluate Supplier Certifications

It’s vital to verify that your potential suppliers hold relevant certifications that ensure product quality and safety standards. Look for certifications such as ISO 9001 or IATF 16949, which indicate a commitment to quality management systems. These certifications can provide assurance that the gaskets will meet industry standards.

Step 4: Request Samples for Quality Assessment

Before placing a large order, request samples of the engine rubber gaskets to assess their quality firsthand. Evaluate the samples for durability, flexibility, and resistance to wear and tear. This step is crucial to ensure that the gaskets will perform optimally under the conditions they will face in your engines.

Step 5: Inquire About Customization Options

Depending on your unique needs, inquire whether the supplier offers customization options for their engine rubber gaskets. Customization can include specific dimensions, materials, or special coatings that enhance performance. This flexibility can be particularly beneficial for specialized machinery or unique engine designs.

Step 6: Assess Pricing and Payment Terms

Once you have narrowed down your options, compare pricing among different suppliers. Ensure that the quotes you receive include all relevant costs, such as shipping and taxes. Additionally, discuss payment terms to understand the financial implications of your purchase, including any discounts for bulk orders.

Step 7: Establish a Long-Term Relationship

Building a long-term relationship with a reliable supplier can lead to better pricing, priority service, and tailored support. Discuss potential partnerships that may include regular orders or exclusive agreements. A strong supplier relationship can enhance your operational efficiency and ensure a consistent supply of high-quality engine rubber gaskets.

By following these steps, B2B buyers can navigate the sourcing process for engine rubber gaskets with confidence, ensuring they select suppliers that align with their technical requirements and operational goals.

Comprehensive Cost and Pricing Analysis for engine rubber gasket Sourcing

Analyzing the costs and pricing for sourcing engine rubber gaskets involves a comprehensive understanding of various cost components, price influencers, and negotiation strategies that are particularly relevant to B2B buyers in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Engine Rubber Gaskets?

Materials: The primary cost driver for engine rubber gaskets is the raw materials used in their production. Common materials include rubber compounds, which can vary in cost based on quality and specific performance requirements. High-performance gaskets may use specialized compounds that resist heat and chemical degradation, increasing material costs.

Illustrative image related to engine rubber gasket

Labor: Labor costs are influenced by the complexity of gasket manufacturing. Automated processes can reduce labor costs, but skilled labor is required for quality control and assembly. Labor costs may vary significantly by region, with lower costs in developing markets compared to established manufacturing hubs.

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and general administrative expenses. Efficient production processes can lower overhead costs, but investments in advanced technology may initially increase these expenses.

Tooling: The costs associated with creating molds and dies for gasket production can be substantial, particularly for custom or specialized gaskets. Initial tooling investments are amortized over production runs, so larger orders can significantly reduce per-unit tooling costs.

Quality Control (QC): Ensuring that gaskets meet stringent quality standards incurs additional costs. This includes testing materials, inspecting finished products, and maintaining certification processes that can enhance product credibility in international markets.

Logistics: Transportation and storage costs are critical, especially for international shipments. Factors such as shipping method, distance, and local tariffs can affect overall logistics costs. Incoterms will also play a role in defining responsibilities and cost allocation between buyers and sellers.

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s market position, competition, and the perceived value of their products.

How Do Price Influencers Impact the Sourcing of Engine Rubber Gaskets?

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Larger orders typically reduce the per-unit cost due to economies of scale, while smaller orders may incur higher costs.

Specifications and Customization: Customized gaskets designed for specific engine models or performance criteria often carry a premium. Buyers should clearly define their specifications to avoid unexpected costs.

Material Quality and Certifications: Gaskets that meet specific industry standards or certifications may cost more. Buyers should weigh the benefits of higher quality against the potential for increased failure rates and associated costs of cheap alternatives.

Illustrative image related to engine rubber gasket

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and service, while less-known suppliers might provide lower prices but at higher risk.

Incoterms: Understanding and negotiating Incoterms is crucial for international buyers. These terms dictate who is responsible for shipping costs, insurance, and risk, which can significantly impact the total cost of ownership.

What Tips Can Help Buyers Negotiate Better Prices for Engine Rubber Gaskets?

Negotiation Strategies: Engage suppliers in discussions about pricing structures, focusing on long-term partnerships that could yield better rates. Leverage volume commitments to negotiate lower prices per unit.

Illustrative image related to engine rubber gasket

Cost-Efficiency Considerations: Evaluate the Total Cost of Ownership (TCO), not just the initial purchase price. Consider factors such as durability, potential downtime from failures, and warranty terms when assessing the value of gaskets.

Pricing Nuances for International Buyers: Be aware of currency fluctuations and potential tariffs that can impact prices. Establish relationships with local distributors or suppliers who understand the regional market dynamics and can provide insights into pricing strategies.

Disclaimer on Indicative Prices: Prices for engine rubber gaskets can vary widely based on the factors discussed. It is essential for buyers to conduct thorough market research and consult multiple suppliers to obtain accurate and competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing engine rubber gasket With Other Solutions

Introduction: Exploring Alternatives to Engine Rubber Gaskets

In the automotive industry, engine rubber gaskets play a crucial role in sealing engine components to prevent leaks and maintain optimal performance. However, as technology advances and manufacturing techniques evolve, several alternative solutions have emerged. This section will compare engine rubber gaskets with alternative sealing solutions, allowing B2B buyers to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Engine Rubber Gasket | Metal Gasket | Silicone Gasket |

|---|---|---|---|

| Performance | Excellent sealing under varying temperatures and pressures; prone to wear over time. | High resistance to extreme conditions; durable but may require precise fitting. | Good flexibility and resistance to chemicals; suitable for lower pressure applications. |

| Cost | Generally affordable; prices vary by type and application. | Typically higher initial cost due to material and manufacturing complexity. | Moderate cost; often more affordable than metal gaskets but pricier than rubber. |

| Ease of Implementation | Easy to install; often comes pre-cut for specific applications. | Installation can be complex and may require specialized tools. | Simple installation; often available in various shapes and sizes. |

| Maintenance | Requires regular inspection; can deteriorate with age and heat. | Low maintenance; lasts longer but can be challenging to replace. | Minimal maintenance; remains functional unless damaged. |

| Best Use Case | Ideal for standard automotive applications and general use. | Best for high-performance engines and extreme environments. | Suitable for applications where flexibility and chemical resistance are prioritized. |

Detailed Breakdown of Alternatives

Metal Gaskets

Metal gaskets are often utilized in high-performance and industrial applications due to their durability and ability to withstand extreme temperatures and pressures. They provide excellent sealing capabilities, making them suitable for critical engine components. However, their installation can be more complex, requiring precise fitting and sometimes specialized tools. The initial cost of metal gaskets tends to be higher compared to rubber options, which may deter some buyers looking for budget-friendly solutions.

Silicone Gaskets

Silicone gaskets offer an excellent alternative, particularly in applications requiring flexibility and resistance to chemicals. They maintain their sealing properties under a range of temperatures and pressures, making them a reliable choice for various automotive applications. Silicone gaskets are generally easy to install and often come in various shapes, which can simplify the replacement process. However, they may not withstand extreme conditions as effectively as metal gaskets, making them less suitable for high-performance engines.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate sealing solution for engine components requires careful consideration of several factors, including performance requirements, budget, and installation complexity. Engine rubber gaskets remain a popular choice for many standard automotive applications due to their affordability and ease of use. However, alternatives like metal and silicone gaskets may provide better performance in specific scenarios, particularly in high-stress environments. B2B buyers should assess their unique operational needs and consider long-term maintenance implications when deciding on the best gasket solution for their applications. By doing so, they can ensure optimal engine performance and longevity.

Essential Technical Properties and Trade Terminology for engine rubber gasket

What Are the Key Technical Properties of Engine Rubber Gaskets?

When sourcing engine rubber gaskets, understanding their technical specifications is crucial for ensuring compatibility and performance. Here are some essential properties to consider:

1. Material Grade

Engine rubber gaskets are typically made from materials like nitrile rubber, silicone, or fluorocarbon rubber. Each material has distinct properties, such as temperature resistance and chemical compatibility. For example, nitrile rubber is excellent for oil resistance, while silicone can withstand higher temperatures. Selecting the right material grade is vital to prevent premature failure and maintain engine efficiency.

2. Compression Set

Compression set refers to the gasket’s ability to return to its original shape after being compressed. A low compression set indicates that the gasket will maintain its sealing properties over time, reducing the risk of leaks. This property is particularly important in high-performance applications where engine vibrations and thermal cycles are prevalent.

3. Tolerance Levels

Tolerance specifies the allowable deviation in the gasket’s dimensions. Precise tolerances are critical for ensuring a proper fit between engine components. Poor tolerance can lead to misalignment, resulting in leaks or even engine damage. Understanding tolerance levels helps buyers ensure that gaskets will fit their specific engine models without modification.

4. Temperature Resistance

Gaskets must endure significant temperature fluctuations. Understanding the maximum and minimum temperature limits of a gasket material is essential for preventing degradation. For instance, a gasket used in high-performance engines may require materials that can withstand temperatures above 200°C (392°F) without losing integrity.

5. Chemical Resistance

Gaskets are often exposed to various fluids, including oil, coolant, and fuel. Assessing chemical resistance ensures that the gasket will not degrade when in contact with these substances. For example, a gasket with poor chemical resistance may swell or crack, leading to leaks that compromise engine performance.

6. Hardness (Shore A)

The hardness of rubber gaskets is measured on the Shore A scale, which indicates the material’s stiffness. Softer gaskets may provide better sealing but can wear out more quickly, while harder gaskets are more durable but may not seal as effectively. Finding the right balance based on the engine’s requirements is essential for optimal performance.

What Are Common Trade Terms Related to Engine Rubber Gaskets?

Understanding industry terminology can enhance communication and facilitate smoother transactions. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the manufacturer of the original vehicle components. For buyers, choosing OEM gaskets ensures compatibility and reliability, as they are designed to meet the same specifications as the original parts.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory effectively and avoid over-purchasing, especially in regions with varying demand like Africa and South America.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. This term is crucial for B2B transactions, as it allows buyers to compare prices and terms from multiple suppliers before making a decision.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and rights, facilitating smoother logistics and reducing potential disputes.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving it. Understanding lead times is vital for planning and ensuring that production schedules are not disrupted, especially in industries where timely maintenance is critical.

6. Aftermarket

The aftermarket refers to parts and accessories sold after the original sale of the vehicle. For buyers, aftermarket gaskets can offer cost-effective alternatives to OEM parts, but it’s essential to ensure that they meet required specifications for performance and durability.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing engine rubber gaskets, ensuring they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the engine rubber gasket Sector

What Are the Key Market Dynamics and Trends Impacting the Engine Rubber Gasket Sector?

The engine rubber gasket market is witnessing significant growth driven by several global factors. The automotive industry’s shift towards electric vehicles (EVs) and hybrid models is reshaping demand for gaskets, as these vehicles require innovative sealing solutions for battery compartments and thermal management systems. Additionally, the increasing focus on vehicle maintenance and repair, particularly in emerging markets such as Brazil and Nigeria, is leading to a rise in the aftermarket parts segment, including engine rubber gaskets.

International B2B buyers should pay attention to the growing integration of technology in sourcing processes. Digital platforms and supply chain management systems are enhancing efficiency and transparency in procurement. For instance, B2B marketplaces are facilitating direct connections between manufacturers and buyers, which helps in reducing lead times and costs. Furthermore, automation in manufacturing is leading to improved quality and consistency in gasket production, catering to the exact specifications of various engine types.

Another noteworthy trend is the increasing collaboration between manufacturers and automotive OEMs (Original Equipment Manufacturers) to develop specialized gaskets that meet stringent performance standards. This is particularly relevant for regions such as the Middle East and Europe, where regulatory compliance and quality assurance are critical. Buyers are encouraged to leverage these trends by exploring partnerships with innovative suppliers that offer advanced gasket solutions tailored to specific market needs.

Illustrative image related to engine rubber gasket

How Are Sustainability and Ethical Sourcing Impacting the Engine Rubber Gasket Industry?

Sustainability is becoming a crucial consideration in the engine rubber gasket sector, as both manufacturers and buyers are increasingly aware of their environmental footprint. The production of rubber gaskets can have significant environmental impacts, including resource depletion and waste generation. Consequently, there is a growing emphasis on sourcing from suppliers that prioritize eco-friendly materials and manufacturing processes.

Ethical sourcing is also gaining traction, with buyers seeking suppliers who can demonstrate responsible labor practices and sustainable supply chain management. Certifications such as ISO 14001 for environmental management and certifications for recycled materials are becoming essential for companies aiming to enhance their brand reputation and meet the demands of environmentally conscious consumers.

International buyers should consider suppliers that offer ‘green’ materials, such as bio-based rubbers or recycled rubber compounds, which not only minimize environmental impact but can also improve the overall performance and lifespan of the gaskets. By prioritizing sustainability and ethical sourcing, companies can differentiate themselves in a competitive market and contribute positively to global environmental goals.

Illustrative image related to engine rubber gasket

What Is the Historical Evolution of Engine Rubber Gaskets in the Automotive Sector?

The evolution of engine rubber gaskets is intertwined with advancements in automotive technology. Historically, gaskets were made from simple materials like cork and paper, which provided basic sealing capabilities. As engines became more sophisticated, with higher operating temperatures and pressures, the demand for more durable and resilient materials grew.

In the late 20th century, synthetic rubber compounds began to dominate the market, offering improved resistance to heat, oil, and chemicals. This shift not only enhanced the performance of engine gaskets but also expanded their applications across various engine types, including those in heavy-duty vehicles and industrial machinery.

Today, the focus has shifted towards developing high-performance gaskets that can withstand extreme conditions while minimizing environmental impact. Innovations in material science and manufacturing processes continue to drive the industry forward, ensuring that engine rubber gaskets remain a critical component in the automotive supply chain. International B2B buyers should stay informed about these historical trends as they inform current product offerings and future developments in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of engine rubber gasket

-

How do I solve issues with engine rubber gaskets leaking?

To address leaks in engine rubber gaskets, first identify the source of the leak by inspecting the gasket area for visible damage, cracks, or wear. Ensure the engine is cool before examination to avoid burns. If a leak is detected, replacing the damaged gasket is essential; consider using high-quality materials that can withstand varying temperature and pressure conditions. Regular maintenance, including checking for oil and coolant levels, can prevent future leaks. If unsure, consult with a professional technician to diagnose and remedy the issue effectively. -

What is the best material for engine rubber gaskets?

The best material for engine rubber gaskets typically includes silicone, neoprene, or rubber compounds that are resistant to oil, heat, and chemicals. Silicone gaskets are particularly favored for their flexibility and durability, making them suitable for high-performance engines. Neoprene gaskets offer good resistance to oil and can withstand varying temperatures, making them ideal for various applications. Evaluate the engine’s specific requirements and operating conditions to select the most appropriate gasket material that ensures a reliable seal and longevity. -

What should I consider when sourcing engine rubber gaskets internationally?

When sourcing engine rubber gaskets internationally, consider the supplier’s reputation, quality certifications, and manufacturing standards. Ensure they comply with international regulations and have a solid track record in the automotive industry. Additionally, assess their capacity for customization, lead times, and minimum order quantities (MOQs). It’s crucial to establish clear communication regarding product specifications and expectations. Request samples to evaluate quality before placing larger orders, and review logistics options to ensure timely delivery to your location. -

How can I vet suppliers for engine rubber gaskets?

To effectively vet suppliers for engine rubber gaskets, start by checking their business credentials and industry experience. Look for certifications such as ISO or other relevant quality standards. Request references from previous clients to gauge their reliability and product quality. Conduct online research for reviews and feedback on platforms specific to B2B transactions. Consider visiting their manufacturing facilities, if feasible, to assess their production processes and quality control measures directly. Building a relationship with suppliers can also lead to better negotiation and service terms. -

What are the typical payment terms for B2B transactions in gasket sourcing?

Payment terms for B2B transactions in gasket sourcing can vary widely but typically include options like advance payment, net 30/60/90 days, or letters of credit. Many suppliers may require a deposit upfront, with the balance paid upon shipment or delivery. It’s essential to negotiate terms that align with your cash flow and risk management strategies. Consider using secure payment methods to protect your investment and establish clear agreements on payment timelines and consequences for late payments. -

What is the Minimum Order Quantity (MOQ) for engine rubber gaskets?

Minimum Order Quantities (MOQs) for engine rubber gaskets can vary significantly based on the supplier and the specific type of gasket. Common MOQs may range from 100 to 1,000 units. Some suppliers may offer flexibility for first-time buyers or custom orders. It’s advisable to discuss your needs with potential suppliers to negotiate MOQs that suit your business requirements. Keep in mind that larger orders may result in better pricing, so consider your inventory management capabilities when determining order sizes. -

How do I ensure quality assurance for engine rubber gaskets?

To ensure quality assurance for engine rubber gaskets, collaborate with suppliers who have established quality control processes, including regular testing and inspection protocols. Request detailed documentation of the materials used, manufacturing processes, and any relevant certifications. Implement your own quality checks upon receipt of goods, such as visual inspections and performance testing. Establish clear return policies for defective products and maintain open communication with suppliers to address any quality concerns promptly. -

What logistics considerations should I keep in mind when importing gaskets?

When importing engine rubber gaskets, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Evaluate the reliability of shipping partners and their ability to handle international freight efficiently. Ensure compliance with local import regulations and documentation requirements to avoid delays. It’s wise to plan for potential disruptions in the supply chain and consider insurance options for high-value shipments. Establish a clear timeline for delivery to align with your inventory needs and production schedules.

Top 3 Engine Rubber Gasket Manufacturers & Suppliers List

1. Fel-Pro – Engine Gaskets

Domain: felpro.com

Registered: 1998 (27 years)

Introduction: Fel-Pro offers a variety of engine gaskets including:

1. Valve Cover Gasket – Seals between the valve cover and cylinder head, susceptible to leaks due to temperature changes and engine wear.

2. Oil Pan Gasket – Located below the engine block, seals the crankcase and oil pan, can fail due to thermal cycling.

3. Intake Manifold Gasket – Seals the intake manifold to the cylinder head, made from var…

2. Rubber Gasket Kit – Engine Gasket Sets

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Rubber Gasket Kit Car & Truck Engine Gasket Kits for sale on eBay. Related searches include Gasket, Rubber Gasket Kit, Gasket Kits, Rubber Gasket Sheet, Engine Gasket Material, Engine Gasket Set, Gasket Material, Rubber Auto Gaskets, Auto Parts, Gaskets, Rubber Sealing Gasket, Gasket Set, Gasket Maker Kit. Categories include Gaskets, Seals & Hardware, with specific products like OEM Original for H…

3. Steele Rubber Products – Automotive Restoration Parts

Domain: steelerubber.com

Registered: 1995 (30 years)

Introduction: Steele Rubber Products offers a wide range of engine and other automotive restoration parts, including engine mounts, harmonic balancers, and various seals for fire and rescue vehicles. The product line includes parts for different vehicle types such as street rods, RVs, and marine service vehicles. Categories of products include bumpers, door seals, electrical parts, fuel system components, weath…

Strategic Sourcing Conclusion and Outlook for engine rubber gasket

In the competitive landscape of engine rubber gaskets, strategic sourcing emerges as a vital approach for international B2B buyers. By prioritizing high-quality materials and reliable suppliers, companies can mitigate risks associated with gasket failure, which can lead to costly repairs and operational downtime. Understanding the specific requirements of different vehicle makes and models allows buyers to make informed purchasing decisions that enhance performance and longevity.

Investing in high-quality gaskets not only ensures optimal engine function but also promotes sustainability by reducing waste from frequent replacements. As global supply chains continue to evolve, leveraging partnerships with reputable manufacturers can provide access to innovative gasket solutions tailored to diverse market needs, particularly in emerging economies across Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for advanced engine rubber gaskets will likely increase as industries shift towards more efficient and environmentally friendly technologies. Buyers are encouraged to explore collaborations with trusted suppliers who can meet stringent quality standards while offering competitive pricing. Embrace the opportunity to elevate your sourcing strategy today, ensuring your operations remain resilient and future-ready.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.