A Deep Dive into Electrical Motor Parts Solution

Introduction: Navigating the Global Market for electrical motor parts

In an increasingly interconnected world, sourcing high-quality electrical motor parts has become a critical challenge for B2B buyers across various industries. From manufacturing to energy production, the reliability of electric motors is essential for operational efficiency, making the procurement of appropriate components a priority. This comprehensive guide delves into the diverse landscape of electrical motor parts, covering essential topics such as types of components, applications across different sectors, effective supplier vetting strategies, and cost considerations.

By addressing these key areas, this guide empowers international B2B buyers—especially those from Africa, South America, the Middle East, and Europe, including Brazil and Vietnam—to make informed purchasing decisions. It provides actionable insights that simplify the complexities of sourcing and procurement, ensuring that you select the right parts for your specific needs. Whether you are looking for OEM replacement parts, understanding the implications of motor failures, or seeking reliable suppliers, this resource equips you with the knowledge necessary to navigate the global market effectively.

With a focus on quality, performance, and strategic sourcing, this guide serves as a vital tool for enhancing your operational resilience and maintaining a competitive edge in today’s dynamic business environment.

Understanding electrical motor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotor | Rotating part of the motor; can be squirrel-cage or wound. | HVAC systems, manufacturing, automotive | Pros: High efficiency; Cons: Can be costly to replace. |

| Stator | Stationary part generating magnetic fields; various designs. | Pumps, compressors, conveyor systems | Pros: Durable; Cons: Limited flexibility in design. |

| Bearings | Support rotating shaft; crucial for smooth operation. | Heavy machinery, electric vehicles, turbines | Pros: Reduces friction; Cons: Requires regular maintenance. |

| Thermal Protectors | Prevents overheating; can be built-in or external. | Industrial motors, home appliances | Pros: Enhances motor lifespan; Cons: May add to complexity. |

| Cooling Fans | Essential for heat dissipation; can be axial or centrifugal. | Electronics, automotive, industrial equipment | Pros: Improves efficiency; Cons: Noise can be an issue. |

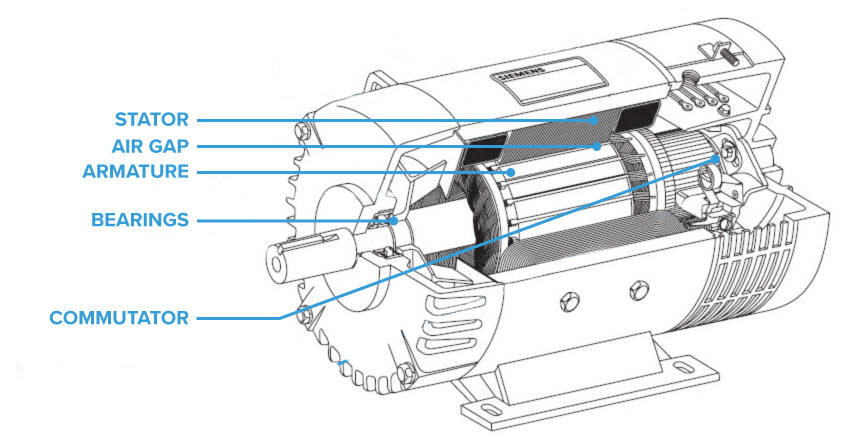

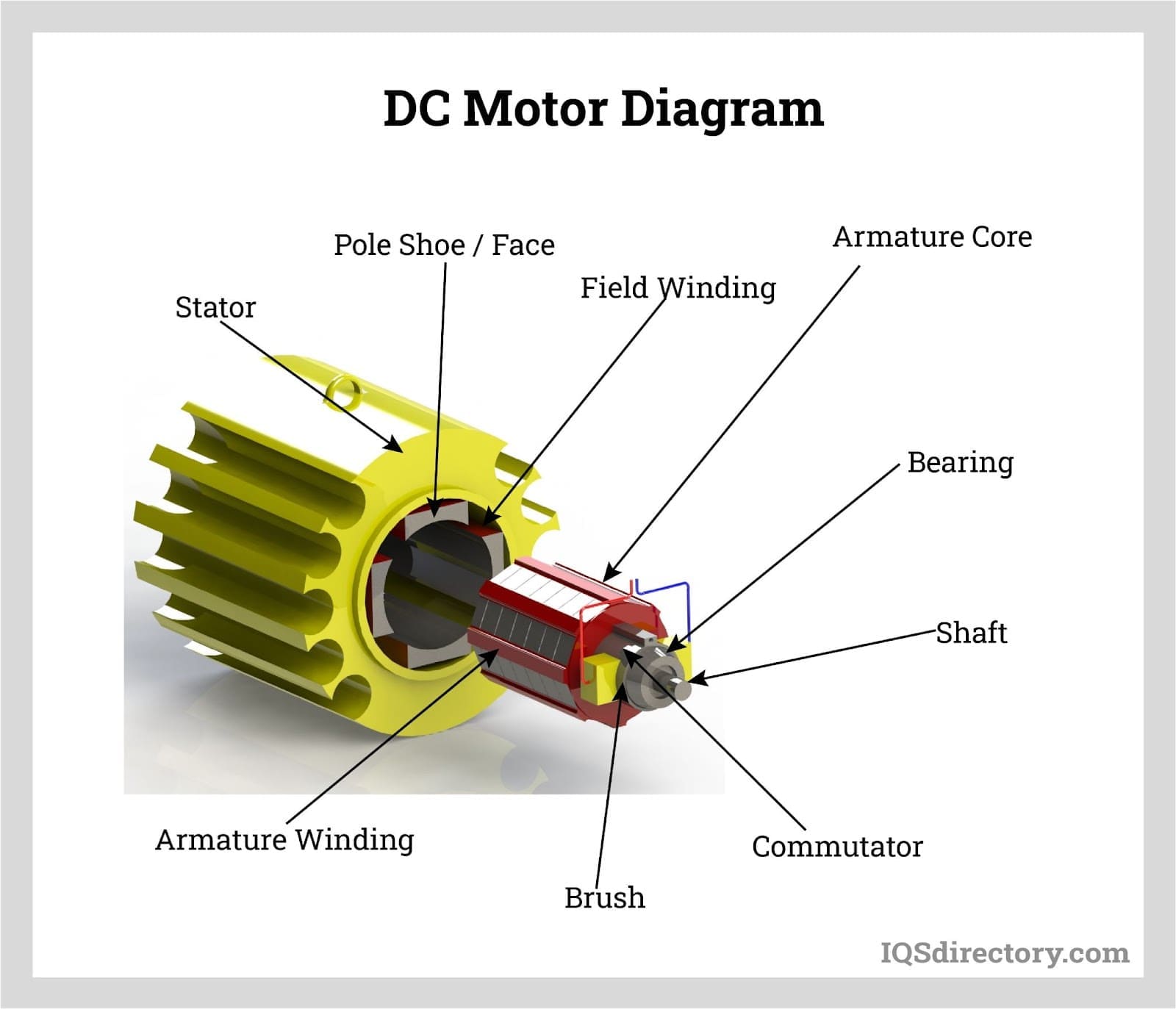

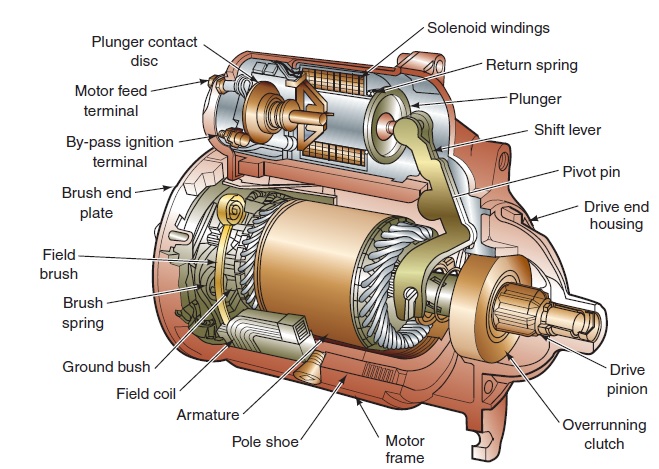

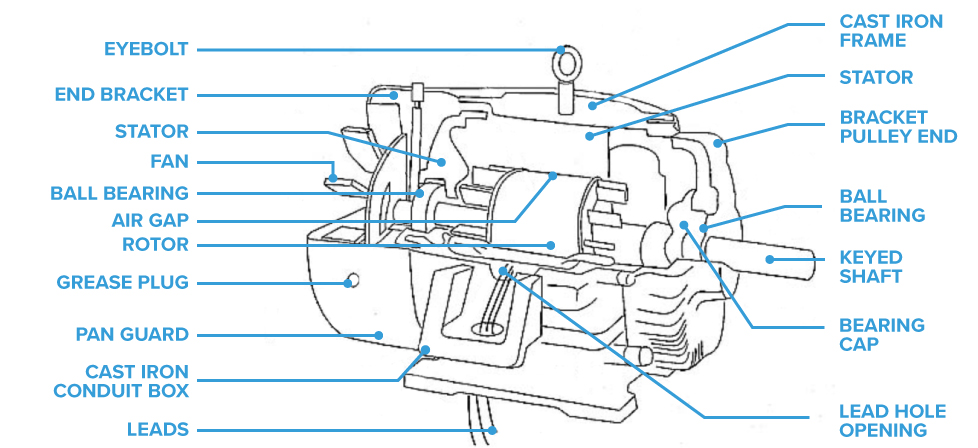

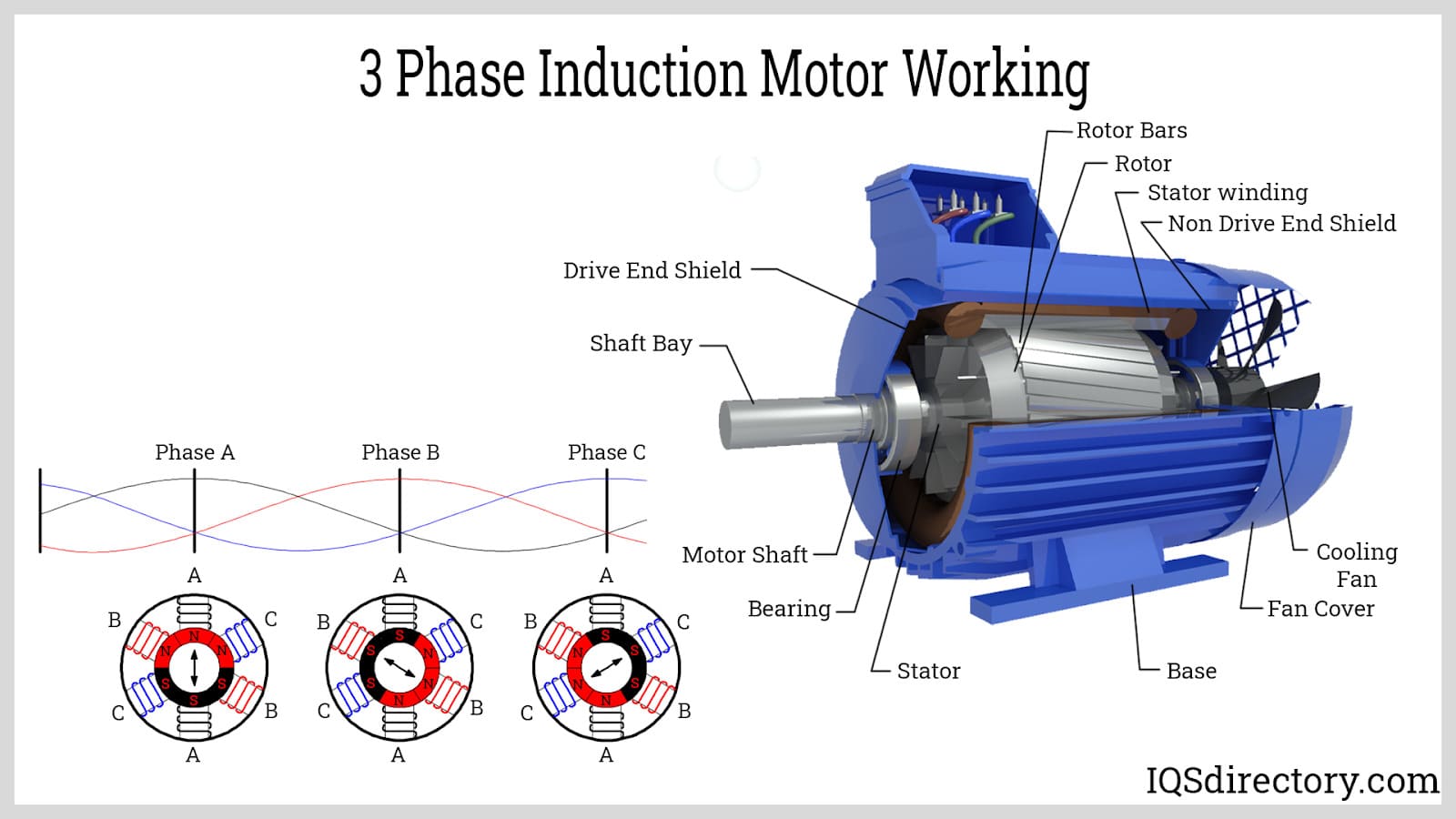

What are the characteristics and suitability of the rotor in electric motors?

The rotor is the critical rotating component of an electric motor, responsible for converting electrical energy into mechanical energy. Two common types of rotors are squirrel-cage and wound rotors. Squirrel-cage rotors are known for their simplicity and robustness, making them ideal for high-efficiency applications like HVAC systems and manufacturing. Wound rotors, while more complex, offer better control and are often used in applications requiring variable speed operations. When purchasing rotors, buyers should consider factors such as efficiency, compatibility with existing systems, and maintenance requirements.

How does the stator contribute to motor performance?

The stator is the stationary part of an electric motor that generates the magnetic field necessary for rotor rotation. It comes in various designs, including distributed and concentrated windings, which affect the motor’s efficiency and performance. The stator is commonly used in applications such as pumps and compressors, where reliability and durability are paramount. Buyers should assess the stator’s design, material quality, and compatibility with the rotor to ensure optimal performance and longevity.

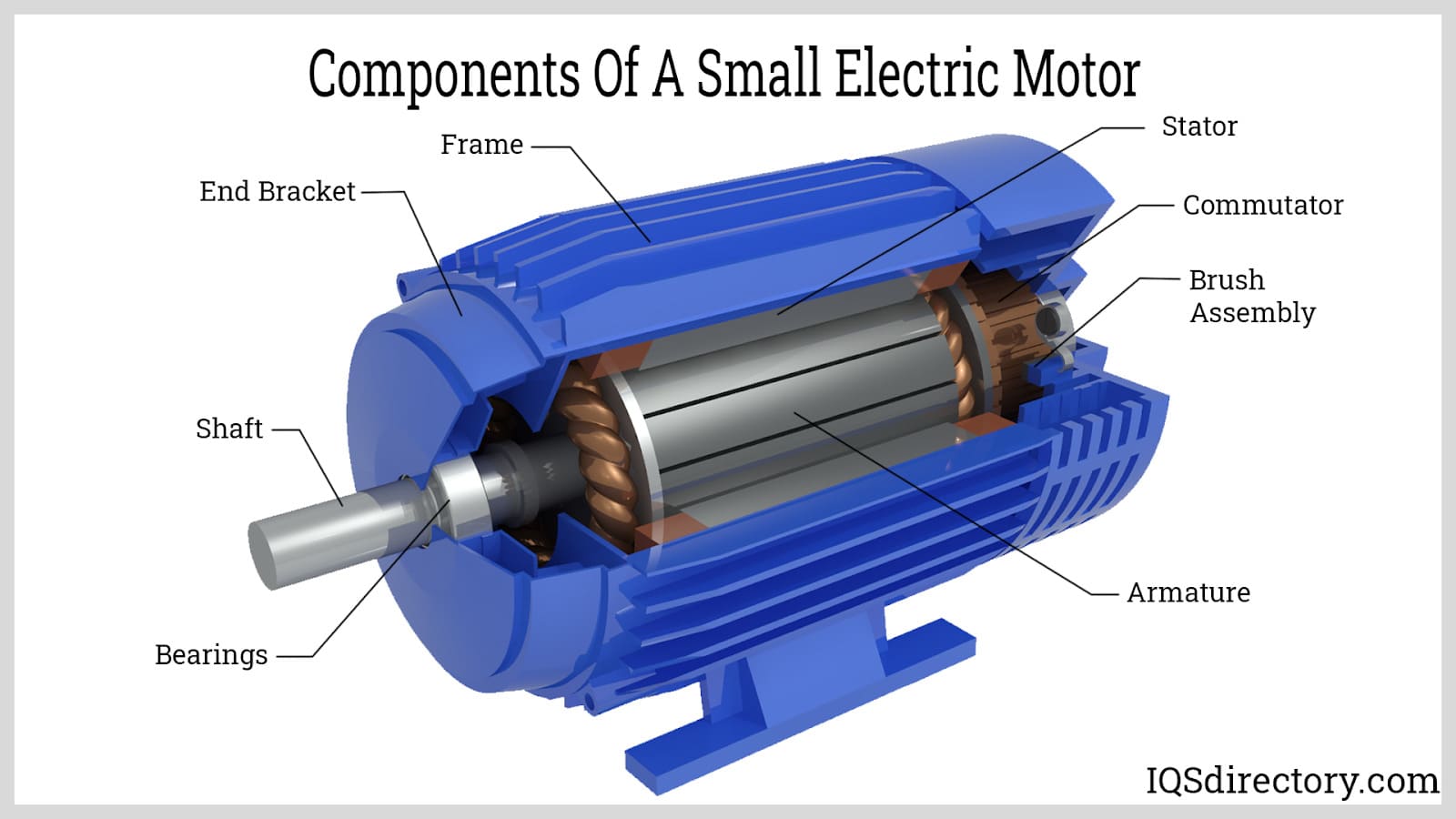

Illustrative image related to electrical motor parts

What role do bearings play in electric motors?

Bearings are essential components that support the rotating shaft of the rotor, ensuring smooth operation and reducing friction. They are critical in applications involving heavy machinery, electric vehicles, and turbines, where operational efficiency is crucial. When selecting bearings, buyers should consider load capacity, lubrication type, and maintenance needs, as these factors significantly impact the motor’s reliability and operational costs.

Why are thermal protectors important in electric motors?

Thermal protectors are devices that prevent electric motors from overheating, which can lead to failure and costly downtime. These can be built into the motor or installed externally. They are particularly beneficial in industrial motors and home appliances, where overheating can cause significant damage. Buyers should evaluate the type of thermal protection needed based on the application, as well as the ease of integration into existing systems.

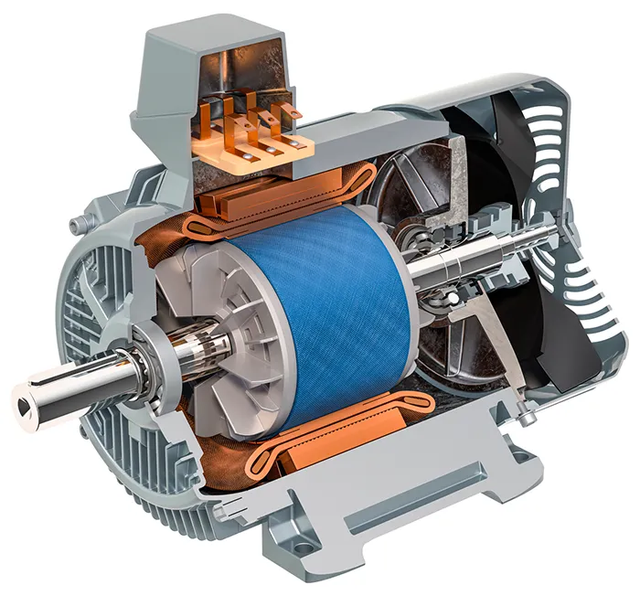

How do cooling fans enhance electric motor efficiency?

Cooling fans are vital for dissipating heat generated during motor operation, thereby improving efficiency and extending the motor’s lifespan. They can be axial or centrifugal, each suited for different applications, such as electronics and industrial equipment. When sourcing cooling fans, buyers should consider airflow requirements, noise levels, and compatibility with the motor design to ensure effective cooling and optimal performance.

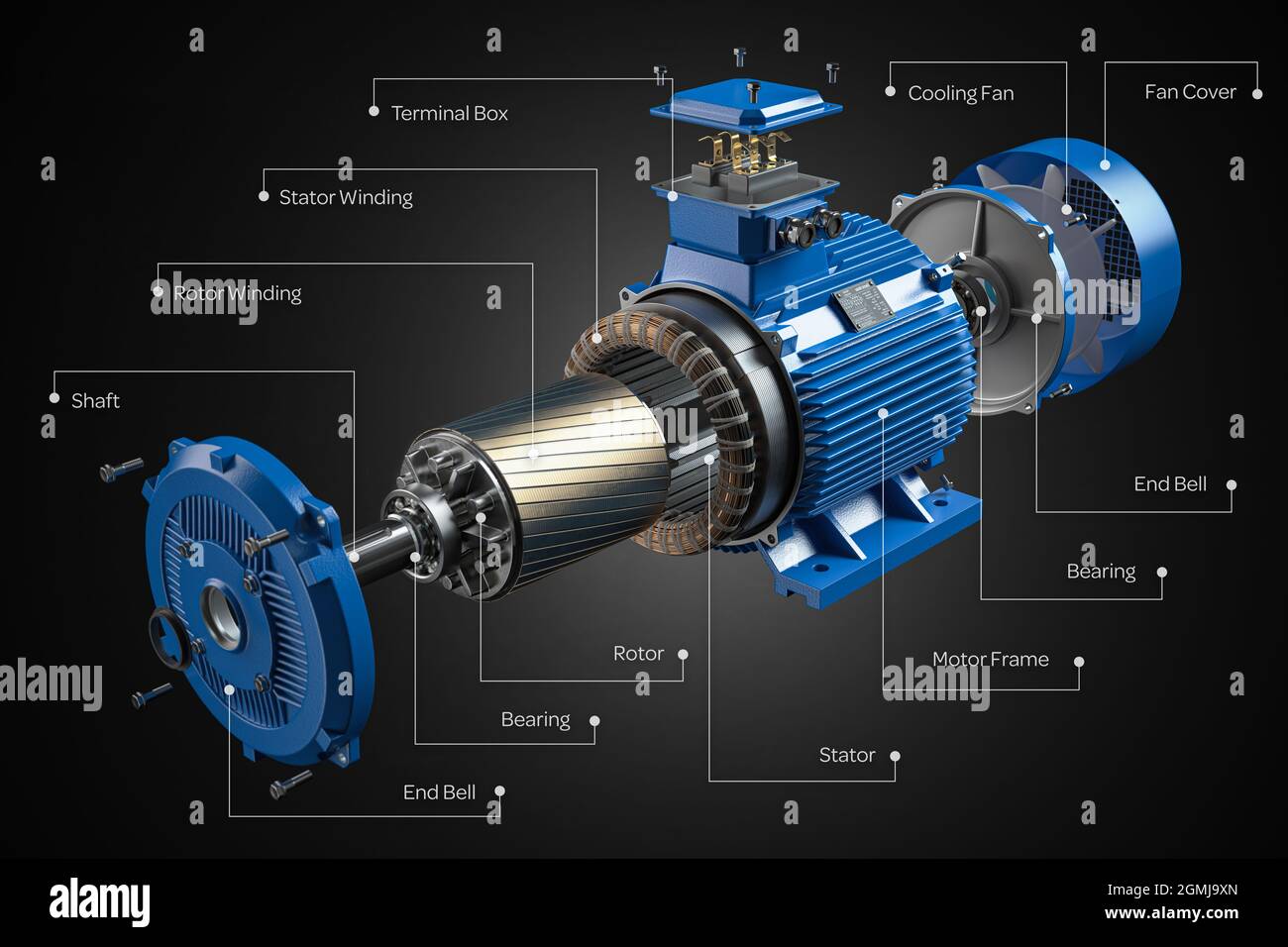

Illustrative image related to electrical motor parts

Key Industrial Applications of electrical motor parts

| Industry/Sector | Specific Application of Electrical Motor Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Electric Motor Replacement in Production Lines | Minimizes downtime, ensuring continuous operation | Quality assurance, compatibility with existing systems, lead time |

| Oil & Gas | Motors for Pumping and Drilling Equipment | Enhances operational efficiency and reliability | OEM specifications, resistance to harsh environments, service support |

| Agriculture | Motors in Irrigation Systems | Increases crop yield through efficient water management | Energy efficiency, maintenance requirements, adaptability to local conditions |

| Transportation | Electric Motors in Rail and Transit Systems | Reduces operational costs and emissions | Compliance with international standards, reliability, and availability |

| Mining | Motors for Conveyor Systems and Crushers | Increases productivity and reduces operational risks | Durability, performance under heavy loads, and local support services |

How Are Electrical Motor Parts Used in Manufacturing?

In manufacturing, electrical motor parts are critical for maintaining the efficiency of production lines. Motors are used in conveyor systems, mixers, and assembly machines. When motors fail, production can halt, leading to significant financial losses. Buyers need to source high-quality replacement parts that are compatible with their existing equipment to minimize downtime. Considerations include the specifications of the motor, the availability of parts, and the supplier’s ability to provide quick delivery to avoid interruptions.

What Role Do Electrical Motor Parts Play in the Oil & Gas Sector?

In the oil and gas industry, electrical motors are essential for powering pumps and drilling equipment. These motors must operate reliably in harsh environments, often exposed to extreme temperatures and corrosive substances. Effective sourcing of motor parts requires adherence to OEM specifications to ensure compatibility and durability. Additionally, buyers should prioritize suppliers who offer robust support services, including maintenance and rapid replacement options, to mitigate risks associated with equipment failure.

How Are Electrical Motor Parts Beneficial for Agriculture?

Agricultural operations utilize electrical motors in irrigation systems, enabling efficient water distribution critical for crop growth. Motors must be energy-efficient to reduce operational costs and environmentally friendly to comply with regulations. Buyers in this sector should consider sourcing motors that can withstand varying weather conditions and require minimal maintenance. Local sourcing options are also advantageous to ensure timely support and service, which is crucial during peak agricultural seasons.

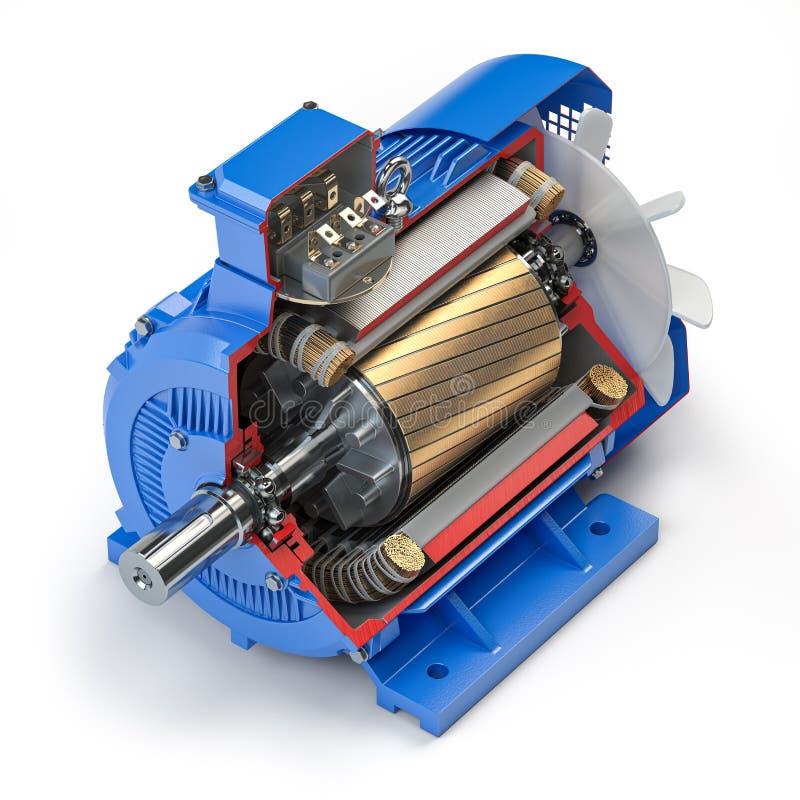

Illustrative image related to electrical motor parts

What Is the Importance of Electrical Motor Parts in Transportation?

Electric motors are increasingly used in rail and public transit systems, where they drive trains and trams. These motors contribute to reducing operational costs and emissions compared to traditional combustion engines. For international buyers, compliance with safety and environmental standards is paramount when sourcing these parts. Additionally, reliability and the ability to provide ongoing support are key considerations, as any motor failure can disrupt service and impact ridership.

How Do Electrical Motor Parts Enhance Mining Operations?

In the mining industry, electrical motors drive conveyor systems and crushers, playing a vital role in the extraction and processing of minerals. The durability of these motors is critical, as they operate under heavy loads and in challenging conditions. Buyers should focus on sourcing high-performance motors that can handle significant stress while maintaining operational efficiency. Local support services and parts availability are essential to minimize downtime and ensure continuous operation.

3 Common User Pain Points for ‘electrical motor parts’ & Their Solutions

Scenario 1: Delayed Production Due to Outdated Motor Parts

The Problem: B2B buyers in industries such as manufacturing and processing often face significant challenges when their production lines are interrupted by outdated or failing electric motor parts. This can lead to extensive downtime, resulting in lost revenue and delayed deliveries to clients. For instance, a steel mill relying on electric motors for its conveyor systems may experience a halt in operations if a critical component like a rotor or stator fails. The urgency of replacing these parts is heightened by the need to maintain operational efficiency, but sourcing the right parts quickly can be a daunting task.

The Solution: To mitigate such risks, B2B buyers should establish relationships with reliable suppliers who can provide OEM (Original Equipment Manufacturer) parts and ensure timely deliveries. It’s crucial to keep an inventory of essential spare parts that are frequently used in operations. Regular audits of motor parts and predictive maintenance practices can help identify potential failures before they occur. Additionally, investing in digital inventory management systems allows for real-time tracking of parts usage, making it easier to reorder items proactively. Establishing a partnership with suppliers that offer expedited shipping options can also significantly reduce downtime when an emergency replacement is needed.

Scenario 2: Compatibility Issues with Replacement Parts

The Problem: Another common issue faced by B2B buyers is the compatibility of replacement electric motor parts with existing equipment. Many companies may attempt to save costs by opting for generic parts, only to discover later that these components do not fit or operate correctly, leading to further complications. For instance, a manufacturing facility may purchase a universal motor starter only to find that it does not integrate seamlessly with their specific motor model, resulting in operational inefficiencies and additional costs.

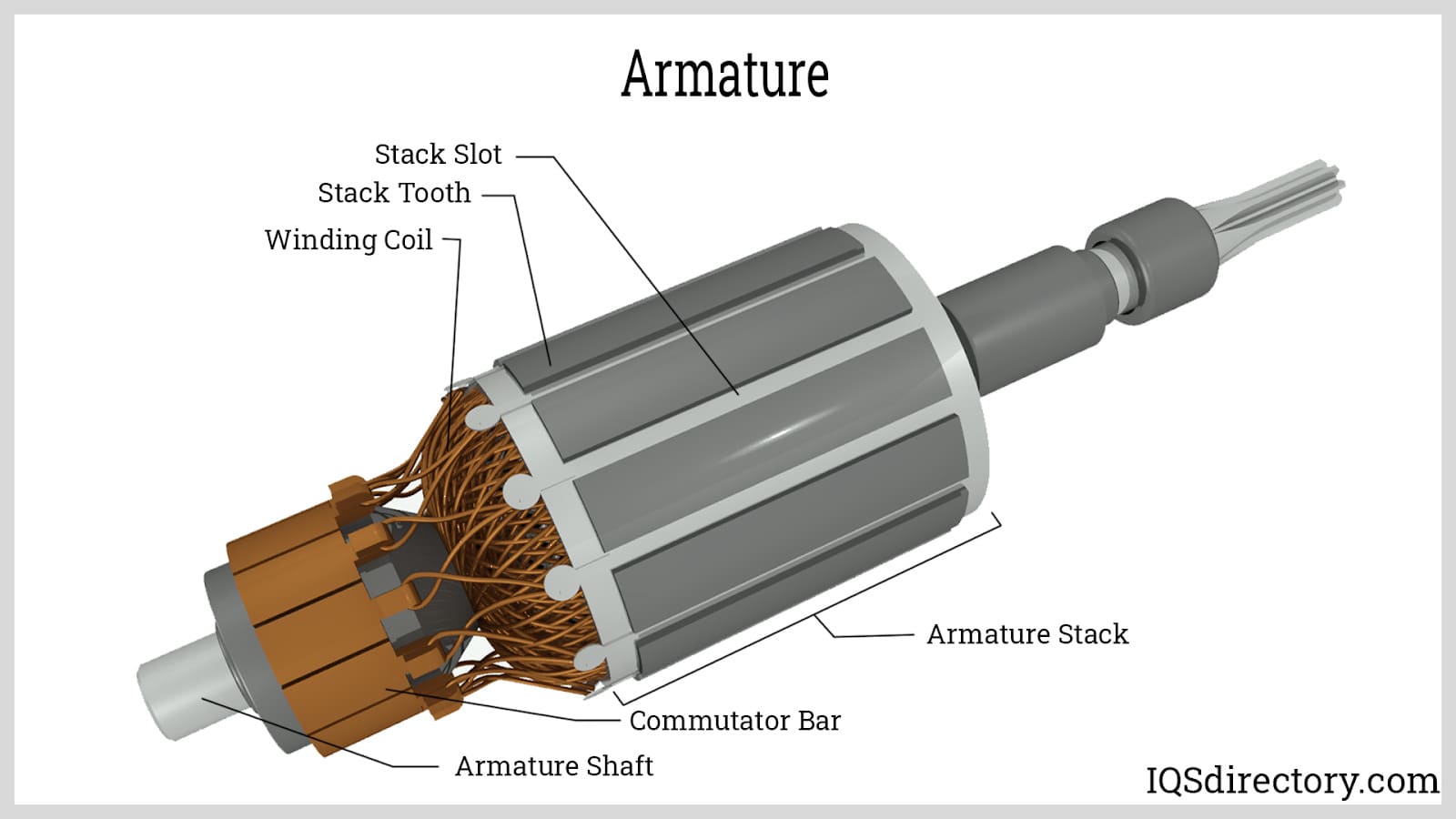

Illustrative image related to electrical motor parts

The Solution: To avoid compatibility issues, buyers should conduct thorough research on the specifications of their current electric motors before purchasing replacement parts. This includes understanding the model numbers, dimensions, and operational requirements of both the motor and the parts. Working closely with a knowledgeable supplier who can provide guidance on compatible parts is essential. Furthermore, utilizing parts that come with manufacturer certifications can ensure that they meet quality and compatibility standards. In cases where custom parts are necessary, engaging in discussions with manufacturers about bespoke solutions can lead to better outcomes and prevent costly mistakes.

Scenario 3: Inefficient Energy Use Leading to Increased Costs

The Problem: As energy prices fluctuate, B2B buyers are increasingly concerned about the efficiency of their electric motors and the parts that comprise them. Old or poorly maintained motor parts can lead to inefficient energy use, resulting in higher operational costs. For example, if bearings are worn out, the motor has to work harder, consuming more electricity and increasing the overall energy bill. This not only affects the bottom line but can also lead to sustainability concerns for companies aiming to reduce their carbon footprint.

The Solution: To address energy inefficiency, businesses should prioritize regular maintenance schedules that include inspecting and replacing worn motor parts like bearings, seals, and cooling fans. Implementing a predictive maintenance strategy using IoT (Internet of Things) technology can provide valuable insights into the motor’s performance, helping to identify inefficiencies before they escalate. Additionally, investing in high-efficiency motor parts can significantly reduce energy consumption. Buyers should look for components that are designed to meet or exceed energy efficiency standards, which can lead to long-term cost savings and improved operational sustainability.

Strategic Material Selection Guide for electrical motor parts

What Are the Key Materials Used in Electrical Motor Parts?

When selecting materials for electrical motor parts, it’s essential to consider their properties, advantages, and limitations. Here, we analyze four common materials used in the manufacturing of electrical motor components, focusing on their performance characteristics and implications for international B2B buyers.

Illustrative image related to electrical motor parts

How Does Copper Perform in Electrical Motor Applications?

Copper is widely regarded as the primary conductor in electrical motors due to its excellent electrical conductivity and thermal properties. It can withstand high temperatures, making it ideal for windings and rotor components. Copper also exhibits good corrosion resistance, which is crucial for longevity in various environments.

Pros: Copper’s high conductivity ensures efficient energy transfer, reducing energy losses. Its durability makes it suitable for high-performance applications.

Cons: The primary drawback of copper is its cost, which can be significantly higher than alternatives like aluminum. Additionally, copper is heavier, which may impact the overall weight of the motor.

Impact on Application: Copper is compatible with high-temperature and high-load applications, making it suitable for industrial motors in sectors like manufacturing and energy.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of the fluctuating copper prices and ensure compliance with international standards such as ASTM for material quality.

What Role Does Aluminum Play in Electrical Motor Parts?

Aluminum is increasingly used in electric motors, particularly for components such as housings and some windings. It is lighter than copper, which can lead to overall weight savings in motor design.

Pros: The lower cost and lighter weight of aluminum make it an attractive alternative for many applications. Its corrosion resistance is beneficial in humid or harsh environments.

Cons: While aluminum has good conductivity, it is not as efficient as copper, which can lead to higher energy losses. Additionally, aluminum may require more complex manufacturing processes to ensure structural integrity.

Impact on Application: Aluminum is suitable for applications where weight reduction is critical, such as in automotive and aerospace industries.

Considerations for International Buyers: Buyers should ensure that aluminum components meet local and international standards for safety and performance, such as DIN or JIS, particularly in regions with stringent regulations.

Why Is Steel a Common Choice for Structural Components in Motors?

Steel, particularly silicon steel, is commonly used for the stator and rotor cores in electric motors due to its magnetic properties. It provides a strong magnetic circuit, essential for efficient motor operation.

Pros: Steel’s strength and durability make it ideal for structural components. Its magnetic properties enhance the efficiency of the motor.

Cons: Steel can be susceptible to corrosion if not properly treated, which may lead to premature failure in certain environments. Additionally, it is heavier than other materials, which may not be suitable for all applications.

Impact on Application: Steel is well-suited for heavy-duty applications in industries such as mining and manufacturing, where robustness is essential.

Illustrative image related to electrical motor parts

Considerations for International Buyers: Buyers should verify that the steel used complies with international standards to ensure quality and performance, especially in regions like the Middle East where environmental conditions can be harsh.

How Do Insulating Materials Affect Electrical Motor Performance?

Insulating materials, such as rubber, glass fiber, and high-temperature polymers, are critical for preventing electrical shorts and ensuring safe operation. These materials must withstand high temperatures and mechanical stress.

Pros: High-quality insulation enhances safety and performance, extending the lifespan of electrical components.

Cons: The cost of advanced insulating materials can be high, and they may require specific manufacturing processes that complicate production.

Illustrative image related to electrical motor parts

Impact on Application: Insulating materials are crucial in applications involving high voltages and temperatures, such as in power generation and industrial machinery.

Considerations for International Buyers: Compliance with local and international insulation standards is vital for safety and reliability, particularly in diverse markets like Europe and Africa.

Summary Table of Material Selection for Electrical Motor Parts

| Material | Typical Use Case for electrical motor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings, rotor components | Excellent conductivity and durability | High cost and weight | High |

| Aluminum | Motor housings, some windings | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Steel | Stator and rotor cores | Strong magnetic properties and durability | Susceptible to corrosion | Medium |

| Insulating Materials | Electrical insulation components | Enhances safety and performance | High cost and complex manufacturing | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on performance, cost, and compliance considerations in various global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for electrical motor parts

What Are the Main Stages of Manufacturing Electrical Motor Parts?

The manufacturing of electrical motor parts involves several critical stages that ensure each component meets industry standards and functions efficiently. Understanding these stages can help B2B buyers make informed decisions when sourcing parts.

Material Preparation: What Materials Are Used in Electrical Motor Parts?

The first step in the manufacturing process is material preparation. Common materials for electric motor parts include:

- Copper and Aluminum: Used for windings and conductors due to their excellent electrical conductivity.

- Silicon Steel: This material is essential for the stator and rotor cores, as it enhances magnetic properties.

- Insulating Materials: High-polymer compounds, enamel, and glass fiber are used to insulate wires and components, preventing electrical shorts.

Materials undergo rigorous quality checks upon arrival to ensure they meet specifications before moving to the next stage.

Forming: How Are Electric Motor Parts Shaped?

In the forming stage, raw materials are transformed into specific shapes required for various motor components. Key techniques include:

- Stamping: Used to create flat components like end plates and brackets from sheets of metal.

- Winding: Copper or aluminum wire is wound into coils, forming the motor’s electromagnetic field.

- Machining: Processes such as turning and milling shape components with high precision, particularly for shafts and housings.

Quality control at this stage often involves measuring dimensions and material properties to confirm compliance with design specifications.

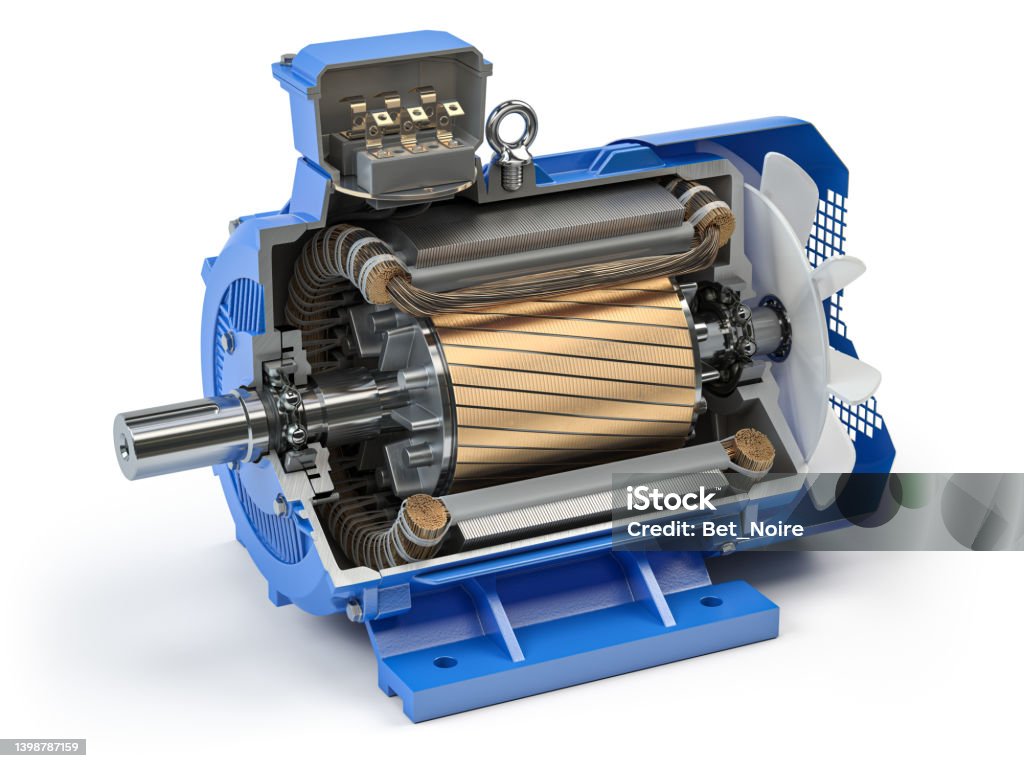

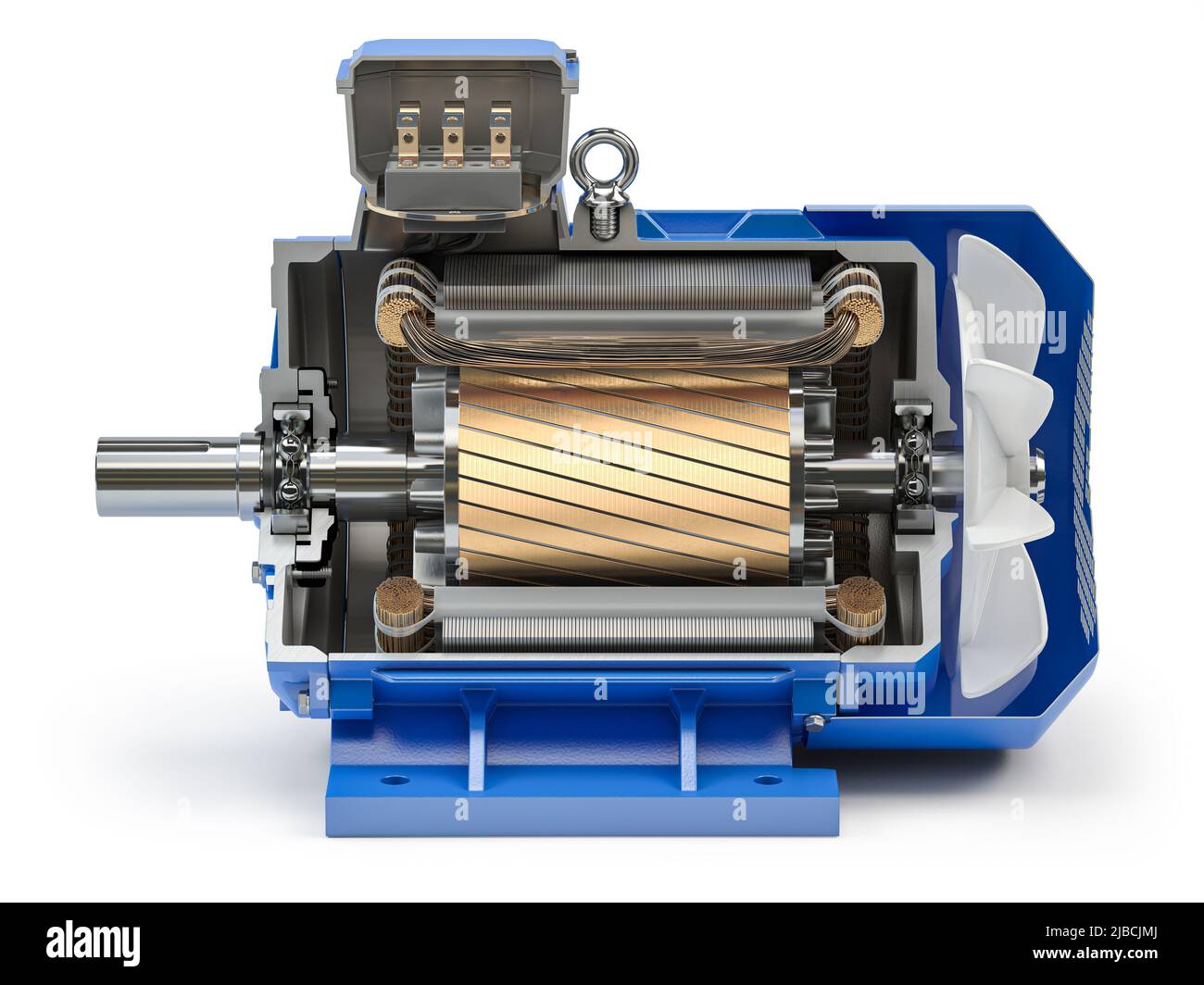

Assembly: What Processes Are Involved in Assembling Electric Motors?

The assembly stage involves putting together the various components into a complete motor. This includes:

- Component Integration: Parts such as the rotor, stator, bearings, and brackets are assembled, often in a clean room to prevent contamination.

- Wiring Connections: Lead wires are connected to power supplies, ensuring proper electrical flow.

- Testing Assemblies: Initial tests are conducted to ensure components function correctly before moving to the final assembly.

Effective assembly requires skilled labor and adherence to strict protocols to minimize defects.

Finishing: How Are Electrical Motor Parts Finished?

The finishing stage enhances the durability and performance of motor parts. Key processes include:

- Coating and Painting: Protective coatings or paints are applied to prevent corrosion and wear.

- Final Inspection: A thorough inspection is performed to identify any defects or inconsistencies in appearance or functionality.

Finishing processes not only improve aesthetics but also extend the lifespan of the components.

What Quality Assurance Measures Are Essential for Electrical Motor Parts?

Quality assurance (QA) is critical in the manufacturing of electrical motor parts, ensuring reliability and performance. B2B buyers should be aware of the following QA measures and standards.

Which International Standards Are Relevant for Electrical Motor Parts?

Compliance with international standards is essential for ensuring quality. Relevant standards include:

- ISO 9001: This standard focuses on quality management systems, ensuring consistent quality in products and services.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Certification: For motors used in the oil and gas industry, the American Petroleum Institute (API) standards ensure reliability in harsh environments.

Understanding these standards helps B2B buyers evaluate the credibility of suppliers.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to catch defects early. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During production, components are monitored for defects, and adjustments are made as necessary.

- Final Quality Control (FQC): The completed product undergoes a final inspection and testing to verify performance and safety.

These checkpoints help ensure that any potential issues are addressed before products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Consider the following approaches:

Illustrative image related to electrical motor parts

What Methods Can Be Used to Audit and Evaluate Suppliers?

- Supplier Audits: Conducting regular audits allows buyers to assess the supplier’s manufacturing processes and quality assurance measures directly.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their compliance with international standards and internal benchmarks.

- Third-Party Inspections: Engaging independent third-party inspectors can help validate the quality of products before they are shipped.

These methods provide buyers with the confidence that they are sourcing high-quality components.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control. Some nuances to consider include:

- Cultural Differences in Standards: Understanding regional variations in quality standards is essential for effective communication with suppliers.

- Logistics and Supply Chain Considerations: Delays in shipping can impact the quality of components, making it vital for buyers to verify that suppliers have robust logistics in place.

- Regulatory Compliance: Buyers must ensure that suppliers comply with local regulations and standards specific to their regions.

By being aware of these nuances, buyers can navigate the complexities of international sourcing more effectively.

Conclusion

Understanding the manufacturing processes and quality assurance measures for electrical motor parts is essential for B2B buyers looking to make informed purchasing decisions. By focusing on material preparation, forming, assembly, finishing, and the relevant quality standards, buyers can better assess suppliers and ensure they receive high-quality components that meet their operational needs.

Illustrative image related to electrical motor parts

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electrical motor parts’

Introduction

Sourcing electrical motor parts requires a strategic approach to ensure you procure high-quality components that meet your operational needs. This guide offers a practical checklist for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, to streamline the purchasing process and make informed decisions.

1. Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the electrical motor parts you need. This includes specifications such as dimensions, material types, and performance ratings. Understanding these details helps in identifying the right components and avoiding costly mistakes later in the process.

- Identify essential components: Consider parts such as rotors, stators, bearings, and thermal protectors.

- Understand compatibility: Ensure that the parts align with your existing motor models to prevent compatibility issues.

2. Research Reputable Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the industry. Look for companies that specialize in electrical motor parts and have a proven track record of reliability and quality.

Illustrative image related to electrical motor parts

- Check online reviews and ratings: Utilize platforms like Trustpilot or industry forums to gauge customer satisfaction.

- Request supplier profiles: This should include company history, product range, and client testimonials.

3. Evaluate Potential Suppliers

Before committing to a supplier, perform a comprehensive evaluation. This is crucial to ensure that they can meet your quality and delivery expectations.

- Request certifications: Look for ISO or other relevant certifications that demonstrate adherence to industry standards.

- Ask for case studies: Review examples of past projects or partnerships that highlight their experience with similar products.

4. Inquire About Product Availability

Confirm that the supplier has the electrical motor parts readily available or can manufacture them in a timely manner. Delays in sourcing can significantly impact your operations.

- Discuss lead times: Ask about average shipping times and stock levels for the specific parts you require.

- Understand minimum order quantities: Ensure the supplier can accommodate your needs without imposing excessive order limits.

5. Assess Warranty and Return Policies

Understanding the warranty and return policies is essential to safeguard your investment. A clear policy can provide peace of mind and protect against potential defects.

- Review warranty terms: Look for warranties that cover defects in materials and workmanship for a reasonable period.

- Clarify return procedures: Know the steps to take if parts do not meet your specifications or are defective.

6. Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations to secure the best pricing and terms. This can lead to significant savings and more favorable payment conditions.

- Compare quotes: Gather quotes from multiple suppliers to understand the market rate for the parts you need.

- Discuss payment options: Explore different payment terms, such as net 30 or discounts for early payment.

7. Finalize the Order and Confirm Delivery Details

After agreeing on terms, finalize the order and ensure that all details are confirmed in writing. This includes specifications, pricing, delivery timelines, and payment methods.

- Create a purchase order: This formalizes the agreement and provides a reference for both parties.

- Confirm shipping details: Ensure you have tracking information and delivery dates to manage your inventory effectively.

By following this checklist, B2B buyers can navigate the complexities of sourcing electrical motor parts with confidence, ensuring they make informed decisions that support their business needs.

Comprehensive Cost and Pricing Analysis for electrical motor parts Sourcing

When sourcing electrical motor parts, understanding the cost structure and pricing dynamics is crucial for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. This section delves into the key cost components and price influencers that shape the sourcing landscape, along with actionable tips for buyers.

What Are the Key Cost Components in Electrical Motor Parts Sourcing?

The cost structure for electrical motor parts typically comprises several essential components:

-

Materials: The choice of materials significantly impacts costs. Common materials include copper for windings, silicon steel for cores, and various plastics and rubbers for insulation. High-quality materials may increase upfront costs but can enhance longevity and performance, reducing Total Cost of Ownership (TCO).

-

Labor: Labor costs vary by region and supplier. Skilled labor for assembly and quality control can be a significant expense, especially in countries with higher wage standards. Understanding local labor markets can help buyers anticipate these costs.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative expenses. Efficient production processes can minimize overhead, but buyers should be wary of suppliers who skimp on quality to cut costs.

-

Tooling: Custom tooling for specific motor parts can be a substantial initial investment. This cost is often amortized over production runs, making it critical to evaluate the expected volume of orders.

-

Quality Control (QC): Investing in robust QC processes ensures product reliability and compliance with international standards. While this adds to the cost, it can prevent costly failures and recalls, especially in critical applications.

-

Logistics: Shipping costs, customs duties, and insurance are vital components of the total cost. These can fluctuate based on geopolitical factors, making it essential for buyers to factor in logistics from the outset.

-

Margin: Suppliers will typically include a profit margin in their pricing. This varies based on market conditions, competitive landscape, and the supplier’s positioning.

How Do Price Influencers Affect Electrical Motor Parts Pricing?

Several factors can significantly influence the pricing of electrical motor parts:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for discounts, while low-volume purchases may incur higher unit costs. Buyers should assess their needs to leverage volume pricing effectively.

-

Specifications and Customization: Custom parts typically cost more due to the additional engineering and tooling required. Understanding the balance between standard and custom specifications can aid in cost management.

-

Material Quality and Certifications: Parts that meet specific certifications (like ISO or CE) may be priced higher due to the assurance of quality. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can alter costs significantly. For instance, opting for FOB (Free on Board) may reduce upfront shipping costs but can shift risk and additional charges to the buyer.

What Tips Can Help Buyers Negotiate Better Prices for Electrical Motor Parts?

-

Negotiate Terms: Always discuss payment terms, delivery schedules, and warranty conditions. Flexibility in these areas can lead to better pricing.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and potential downtime costs. A lower-priced part may not always be the most economical choice.

-

Research Market Trends: Keeping an eye on market trends and material costs can provide leverage during negotiations. Being informed about fluctuations can help buyers time their purchases for optimal pricing.

-

Utilize Local Suppliers: For buyers in Africa, South America, and the Middle East, engaging local suppliers can reduce logistics costs and lead times while supporting regional economies.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local taxes that can affect the final price.

By comprehensively understanding these cost structures and pricing influencers, B2B buyers can make informed sourcing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing electrical motor parts With Other Solutions

Introduction: Exploring Alternatives to Electrical Motor Parts

In the rapidly evolving industrial landscape, B2B buyers must consider various solutions to enhance operational efficiency and cost-effectiveness. While electrical motor parts are essential for numerous applications, alternative technologies and methods may offer comparable or superior benefits. This section delves into viable alternatives, comparing them against traditional electrical motor components to help international buyers make informed decisions.

Comparison Table

| Comparison Aspect | Electrical Motor Parts | Pneumatic Systems | Hydraulic Systems |

|---|---|---|---|

| Performance | High efficiency; suitable for various industrial applications | Excellent for high-speed operations; limited by air pressure | High torque and power density; effective for heavy lifting |

| Cost | Moderate initial investment; lower operating costs | Lower initial cost; ongoing costs for air compressor | Higher initial investment; higher maintenance costs |

| Ease of Implementation | Generally straightforward; requires electrical infrastructure | Easy to install; needs compressed air supply | More complex setup; requires hydraulic pumps and reservoirs |

| Maintenance | Requires regular checks; parts can be easily replaced | Low maintenance; requires periodic checks of air quality | Regular maintenance is critical; potential leaks can be costly |

| Best Use Case | Ideal for applications requiring precise control and energy efficiency | Best for applications needing rapid movement and flexibility | Suited for heavy-duty applications like construction and manufacturing |

Detailed Breakdown of Alternatives

Pneumatic Systems

Pneumatic systems utilize compressed air to perform work, making them an attractive alternative to electrical motors in various applications. They are known for their speed and flexibility, particularly in assembly lines and packaging processes. The initial cost of pneumatic systems is often lower than that of electrical motors; however, ongoing costs related to air compressors and energy consumption can accumulate. Maintenance is generally minimal, but ensuring air quality and preventing leaks is essential for optimal performance.

Hydraulic Systems

Hydraulic systems harness the power of pressurized fluids to generate force, making them particularly effective for heavy-duty applications such as construction and manufacturing. They excel in delivering high torque and power density, which is beneficial for tasks like lifting heavy loads. However, the initial investment in hydraulic systems can be significant, and maintenance is crucial due to the risk of leaks and system failures. While they provide robust performance, the complexity of installation and operation can be a drawback for some industries.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating alternatives to electrical motor parts, B2B buyers must consider the specific requirements of their applications, including performance, cost, and maintenance needs. Pneumatic systems may be ideal for operations requiring speed and flexibility, while hydraulic systems are better suited for heavy-duty tasks. Ultimately, the choice will depend on the unique operational demands, budget constraints, and long-term maintenance capabilities of the organization. By carefully assessing these factors, businesses can select the most suitable solution to enhance efficiency and drive growth.

Essential Technical Properties and Trade Terminology for electrical motor parts

What Are the Key Technical Properties of Electrical Motor Parts?

When procuring electrical motor parts, several critical specifications must be understood to ensure optimal performance and compatibility. Below are key properties that buyers should consider:

-

Material Grade

The material grade of motor components, such as copper or aluminum for windings, significantly affects conductivity and durability. For instance, copper is preferred for its superior electrical conductivity, while aluminum is lighter and often more cost-effective. B2B buyers should evaluate the material grade based on the intended application and environment, as these factors can influence long-term performance and maintenance costs. -

Tolerance Levels

Tolerance refers to the allowable variation in the dimensions of a part. Precise tolerances are crucial for ensuring proper fit and function within the motor assembly. For example, if the rotor and stator do not meet specified tolerances, it can lead to inefficiencies or even mechanical failure. Understanding tolerance levels helps buyers ensure that parts will integrate seamlessly, reducing the risk of costly downtime. -

Operating Temperature Range

Each motor part has a specified operating temperature range, which indicates the temperatures it can withstand without degradation. Components like thermal protectors and insulation materials must be chosen based on their ability to operate within the motor’s temperature limits. Buyers should consider the operational environment and peak load conditions to avoid premature failure. -

Power Rating

The power rating of an electric motor part indicates its capacity to handle electrical load, typically measured in watts or horsepower. This specification is vital for ensuring that the selected components can support the motor’s intended application, whether in industrial machinery or household appliances. Choosing parts with appropriate power ratings is crucial for efficiency and longevity. -

Efficiency Class

Efficiency classes, such as IE2, IE3, and IE4, categorize motors based on their energy consumption relative to output. Higher efficiency classes often lead to lower operational costs and reduced environmental impact. B2B buyers should prioritize high-efficiency components to align with sustainability goals and optimize energy use. -

Insulation Class

Insulation class defines the temperature rating of the insulation material used in electrical windings. Common classes include A, B, F, and H, with class H being the most heat-resistant. Selecting the appropriate insulation class is essential for ensuring safety and reliability in various operational environments.

What Are Common Trade Terms in the Electrical Motor Parts Industry?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of another company’s products. In the context of electrical motors, OEM parts are typically of higher quality and designed to meet specific performance criteria. Buyers should consider OEM parts for reliability and compatibility. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs and ensure they meet supplier requirements. This term is particularly relevant in international trade, where shipping costs can make smaller orders economically unfeasible. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit price quotes for specific products or services. It typically includes detailed specifications and quantities. B2B buyers should prepare RFQs carefully to ensure they receive accurate and competitive pricing from suppliers. -

Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms helps buyers assess total costs and manage risks associated with international procurement. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. This is a critical consideration for inventory management, as longer lead times can affect production schedules. Buyers should communicate their lead time expectations to suppliers to avoid operational disruptions. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace it if necessary. Understanding warranty terms is essential for B2B buyers, as it provides assurance of product quality and support in case of defects or failures.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance operational efficiency and ensure successful procurement of electrical motor parts.

Navigating Market Dynamics and Sourcing Trends in the electrical motor parts Sector

What are the Key Market Dynamics and Trends in Electrical Motor Parts?

The electrical motor parts market is experiencing significant growth driven by industrial automation, advancements in technology, and a surge in renewable energy applications. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate a landscape where demand for high-efficiency motors and components is rising. This is especially true in sectors such as manufacturing, oil and gas, and transportation, where electric motors are critical to operational efficiency and sustainability.

Emerging technologies, such as IoT-enabled motors and predictive maintenance solutions, are reshaping sourcing strategies. Buyers are increasingly looking for suppliers that offer not only quality parts but also integrated technology solutions that can enhance operational performance. The trend towards digital procurement platforms is also gaining traction, allowing businesses to streamline their supply chains and access a wider range of parts and services. Additionally, the growing focus on electric vehicles (EVs) is driving demand for specialized motor components, further diversifying the market.

How is Sustainability and Ethical Sourcing Affecting the Electrical Motor Parts Sector?

Sustainability has become a paramount consideration for B2B buyers in the electrical motor parts sector. The environmental impact of manufacturing processes, particularly concerning energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, including the use of recycled materials and energy-efficient manufacturing techniques.

Ethical sourcing is equally important, as companies seek to ensure that their supply chains are free from exploitation and environmental degradation. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for suppliers to prove their commitment to sustainable practices. Furthermore, the adoption of ‘green’ materials—such as low-VOC paints and lubricants—can enhance product appeal and compliance with stringent environmental regulations.

What is the Evolution of the Electrical Motor Parts Market?

The electrical motor parts sector has evolved significantly over the past few decades, driven by technological advancements and increasing industrial demands. Initially, the focus was primarily on basic functionality and reliability. However, with the rise of automation and the growing emphasis on energy efficiency, the market has shifted toward high-performance components that offer enhanced durability and efficiency.

In recent years, the integration of digital technologies has revolutionized the industry. Smart motors equipped with sensors for monitoring performance and predictive analytics have emerged, allowing for real-time data collection and enhanced maintenance strategies. This evolution not only improves operational efficiency but also aligns with global sustainability goals, making the electrical motor parts market a dynamic and rapidly changing landscape for international B2B buyers.

By staying informed about these trends and prioritizing sustainability, B2B buyers can make strategic sourcing decisions that align with both their operational goals and corporate responsibility commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of electrical motor parts

-

How do I solve common issues with electric motor parts?

To address common electric motor issues, first identify the symptoms. For example, if the motor overheats, check the cooling fan and ensure proper ventilation. If it fails to start, examine the power supply and wiring connections. Regular maintenance, including lubrication of bearings and cleaning of components, can prevent many issues. For complex problems, consult with a qualified technician or supplier for diagnostic services and repair options. Keeping a detailed log of maintenance and issues can also aid in troubleshooting. -

What is the best type of electric motor for industrial applications?

The best electric motor for industrial applications often depends on specific requirements such as torque, speed, and operational environment. Common types include AC motors for consistent speed and efficiency, and DC motors for variable speed control. For heavy-duty applications, consider high-efficiency motors that comply with international standards. Discuss your needs with suppliers to find motors that offer reliable performance and suitable features for your particular industry, whether it be manufacturing, mining, or agriculture. -

What factors should I consider when vetting suppliers of electric motor parts?

When vetting suppliers, consider their industry experience, certifications, and product range. Look for suppliers that provide OEM parts and have a reputation for quality and reliability. Assess their logistical capabilities, including shipping times and costs, especially if sourcing internationally. Customer reviews and case studies can provide insights into their service level. It’s also beneficial to establish clear communication channels to address any concerns promptly. -

What are the typical minimum order quantities (MOQs) for electric motor parts?

Minimum order quantities can vary significantly between suppliers and types of parts. Generally, MOQs for standard components may range from 10 to 100 units, while specialized or custom parts could require larger orders. Always inquire about MOQs before placing an order, as some suppliers may be flexible or offer lower MOQs for initial orders to build a business relationship. Understanding these requirements can help in budget planning and inventory management. -

What payment terms are commonly offered by international suppliers?

Payment terms can differ widely, but common options include upfront payment, partial payment upon order confirmation, and balance upon delivery. Letter of Credit (LC) and open account terms may also be available for established relationships. Always clarify payment terms before finalizing a deal to avoid misunderstandings. Consider factors like currency fluctuations and transaction fees when dealing with international suppliers, as these can affect total costs. -

How can I ensure quality assurance (QA) for electric motor parts?

To ensure quality assurance, work with suppliers that provide detailed product specifications and certifications. Request samples before bulk orders to verify quality and compatibility. Many reputable suppliers offer warranties and return policies, which can be an indicator of their commitment to quality. Additionally, consider conducting third-party inspections or audits, especially for high-value or critical components, to validate the supplier’s quality control processes. -

What logistics considerations should I keep in mind when importing electric motor parts?

When importing electric motor parts, consider shipping methods (air vs. sea), lead times, and customs regulations in your country. Ensure that suppliers provide accurate documentation to facilitate smooth customs clearance. Evaluate the total landed cost, including shipping, duties, and taxes, to understand the full financial impact. Establish a reliable logistics partner who can handle the complexities of international shipping, especially if you are operating in regions with unique logistical challenges. -

Can I customize electric motor parts for specific applications?

Yes, many suppliers offer customization options for electric motor parts to meet specific application needs. This can include modifications to dimensions, materials, or performance specifications. Discuss your requirements with potential suppliers early in the procurement process to explore available customization options. Be prepared to provide detailed specifications and possibly prototypes to ensure that the final product meets your expectations. Customization can enhance performance and efficiency, making it a worthwhile investment.

Top 6 Electrical Motor Parts Manufacturers & Suppliers List

1. Electric Motor Wholesale – OEM Motor Parts

Domain: electricmotorwholesale.com

Registered: 2005 (20 years)

Introduction: This company, Electric Motor Wholesale – OEM Motor Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Electric Motor Parts – OEM Quality Replacement Parts

Domain: electricmotorparts.net

Registered: 2013 (12 years)

Introduction: Brush Holders, Carbon Brushes, Insulators & Yokes, Mill Motor Parts, Rubber Grommets, GE Mill Motor Parts, WH Mill Motor Parts, OEM Parts, OEM Quality Replacement Parts, ABB Electric, AEG Electric, Baldor Electric, Bull Electric, Delco/GM Electric, Dover Elevator, Electric Machinery, Electro Motive, General Dynamics, General Electric, General Machinery, Harnischfeger, Hitachi, Louis Allis, Maratho…

3. Electric Motor Repair – Key Components

Domain: electricmotorrepairsales.com

Registered: 2013 (12 years)

Introduction: Key components of an electric motor include: 1. Rotor – The main moving part that turns a shaft to direct power. 2. Stator – Generates the magnetic field necessary for propulsion, typically made with metal linings. 3. Air Gap – Located between the stator and rotor, ensuring efficient magnetic field interaction. 4. Commutator – Reverses the current’s direction in some models. 5. Windings – Connecte…

4. eBay – Electric Motor Parts & Accessories

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Electric Motor Parts & Accessories for sale on eBay include a variety of products such as:

– Dayton 2MDU2 Motor Start Capacitor (460-552 MFD Round) priced at $8.59

– 213t Frame Electric Motor Base Mount Adjustable Slide Plate Universal Mounting priced at $78.95

– HYDAC Pilot Poppet Valve (24vdc Solenoid) with block priced at $232.21

– Goodman Furnace Blower Motor (0131M01003S) priced at $350.0…

5. DB Electrical – DC Motors Replacement Parts

Domain: dbelectrical.com

Registered: 2000 (25 years)

Introduction: DC Motors Replacement Parts | DB Electrical

– Free Same Day Shipping over $50* USA/48 only.

– Various DC Motors available:

1. Item #: 430-22044, Was: $157.13, Pump Motor, Replaces Hino X2772302, Bosch 0-204-788-062, Prestolite HYL5006.

2. Item #: 430-20094, Was: $153.18, P56SX401 12V,1/2HP Scott DC Reel Motor for Hannay Reels, Various CCW Rotation.

3. Item #: SCO-P56SX401, Was: $369.07, 24 V…

6. US Motors – Gearmotors

Domain: usmotor.com

Registered: 1997 (28 years)

Introduction: World’s Largest US Motor Parts Stocking Distributor; Products include: Gearmotors, Horizontals (US, WWE, Louis Allis), Verticals (US, WWE), Parts (Fans, Fan Covers, DC Motor Parts, Brake Parts, Varidrive Parts, Gearboxes), HVAC Motors, VFD/Inverters, Motor Modules; Brands: US Motors, Worldwide Electric, Varidrive, Syncrogear, Browning, CBN Gearboxes, Grove Gear, Shur Stop, Stearns; Services: Same-…

Strategic Sourcing Conclusion and Outlook for electrical motor parts

How Can Effective Strategic Sourcing Transform Your Supply Chain for Electrical Motor Parts?

In the ever-evolving landscape of electrical motor parts, strategic sourcing emerges as a pivotal strategy for international B2B buyers. By prioritizing the procurement of high-quality replacement components such as rotors, stators, and thermal protectors, businesses can significantly enhance operational efficiency and minimize downtime. Understanding the diverse applications of these parts across industries—from manufacturing to energy—allows buyers to make informed decisions that align with their specific needs.

Furthermore, leveraging relationships with reliable suppliers not only ensures access to OEM quality components but also fosters innovation and responsiveness in a competitive market. As global supply chains continue to face challenges, including fluctuating demand and logistical complexities, a proactive sourcing strategy is essential for maintaining a robust supply chain.

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe must embrace a forward-thinking approach to sourcing electrical motor parts. By investing in strategic partnerships and staying informed about market trends, businesses can position themselves for success in an increasingly interconnected world. Take the next step in optimizing your supply chain—explore new sourcing opportunities today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to electrical motor parts

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.