A Deep Dive into Egg Vending Machine Solution

Introduction: Navigating the Global Market for egg vending machine

In an increasingly competitive landscape, sourcing effective solutions like egg vending machines can be a game-changer for businesses looking to streamline operations and boost revenue. The challenge lies in identifying the right machines that not only meet quality standards but also cater to local market demands across diverse regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide delves into the various types of egg vending machines available, their applications, and the critical factors to consider when selecting a supplier.

From understanding the latest technological advancements, such as cashless payment systems and smart inventory management, to evaluating the cost implications and return on investment, this guide equips international B2B buyers with the insights needed to make informed purchasing decisions. We will also explore customization options that enhance brand visibility and customer engagement, ensuring your vending solution stands out in a crowded market.

By leveraging this resource, businesses can navigate the global market confidently, discovering reliable suppliers that offer high-quality products suited to their specific needs. Whether you’re operating in bustling urban centers or remote agricultural regions, the insights presented here will empower you to capitalize on the growing demand for convenient, fresh food solutions, ultimately driving your business forward.

Understanding egg vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Egg Vending Machine | Simple design, mechanical dispensing, cash-only payment | Farms, local markets, convenience stores | Pros: Low initial investment, easy maintenance. Cons: Limited payment options, not suitable for high-tech environments. |

| Refrigerated Egg Vending Machine | Integrated cooling system, touchscreen interface, cashless payments | Supermarkets, schools, urban areas | Pros: Maintains freshness, user-friendly. Cons: Higher upfront cost, requires electricity. |

| Modular Egg Vending Machine | Customizable tray sizes, adjustable capacity, branding options | Specialty stores, kiosks, farm gates | Pros: Flexible, tailored to specific needs. Cons: Customization may lead to longer lead times. |

| Smart Egg Vending Machine | Remote monitoring, advanced payment systems, inventory management | Large retailers, urban locations | Pros: Efficient management, real-time data access. Cons: More complex, potential for technical issues. |

| Farm Gate Egg Vending Machine | Simple design, placed at farm locations, often cash-only | Direct-to-consumer sales, rural areas | Pros: Supports local farmers, minimal overhead. Cons: Limited reach, dependent on local traffic. |

What are the Characteristics and Suitability of Traditional Egg Vending Machines?

Traditional egg vending machines are characterized by their straightforward mechanical design, which typically involves a cash-only payment system. These machines are well-suited for farm locations or local markets where the target audience is familiar with the concept of vending machines. B2B buyers should consider the low initial investment and ease of maintenance as significant advantages. However, the limitation to cash transactions may hinder sales in areas where digital payments are preferred.

How Do Refrigerated Egg Vending Machines Enhance Freshness?

Refrigerated egg vending machines incorporate integrated cooling systems that ensure the freshness of eggs, making them ideal for supermarkets, schools, and urban areas where consumers expect high-quality products. These machines often feature user-friendly touchscreen interfaces and support cashless payment options, appealing to modern buyers. While the initial investment may be higher, the ability to maintain product quality can lead to increased sales and customer satisfaction.

What Makes Modular Egg Vending Machines a Flexible Option?

Modular egg vending machines are distinguished by their customizable tray sizes and adjustable capacities, allowing businesses to tailor them to specific product offerings. They are particularly beneficial for specialty stores, kiosks, and farm gates where branding can enhance visibility. Buyers should weigh the advantages of flexibility and customization against the potential for longer lead times during the ordering process.

How Do Smart Egg Vending Machines Revolutionize Inventory Management?

Smart egg vending machines utilize advanced technology for remote monitoring and inventory management, making them suitable for large retailers and urban locations. These machines often feature sophisticated payment systems and provide real-time data access, which can streamline operations for businesses. While they offer efficiency and improved management capabilities, the complexity of the technology may pose challenges, especially for those unfamiliar with such systems.

Why are Farm Gate Egg Vending Machines Ideal for Local Farmers?

Farm gate egg vending machines are designed for placement directly at farm locations, allowing farmers to sell their products directly to consumers. With a simple design and often cash-only transactions, these machines are perfect for rural areas where local traffic can drive sales. While they support local farmers and incur minimal overhead costs, their reach may be limited compared to machines located in more urban environments.

Key Industrial Applications of egg vending machine

| Industry/Sector | Specific Application of egg vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Farm Gate Sales at Local Markets | Direct sales increase revenue for farmers without staffing. | Consider machine capacity, payment options, and durability. |

| Retail | Supermarkets and Grocery Stores | Offers 24/7 availability of fresh eggs, enhancing customer convenience. | Assess refrigeration capabilities and branding options. |

| Hospitality | Hotels and Bed & Breakfasts | Provides guests with fresh, local eggs, enhancing their experience. | Evaluate machine size, ease of use, and maintenance support. |

| Education | Schools and Universities | Supplies fresh eggs for cafeterias, promoting healthy eating. | Look for machines with high security and ease of restocking. |

| Food Processing | Egg Processing Facilities | Facilitates quick access to fresh eggs for production needs. | Ensure compatibility with processing requirements and reliability. |

How are Egg Vending Machines Used in Agriculture and What Problems Do They Solve?

In the agricultural sector, egg vending machines are often placed at farm gates or local markets, allowing farmers to sell their produce directly to consumers. This approach eliminates the need for intermediaries, increasing profit margins for farmers. The machines provide a convenient solution for consumers seeking fresh eggs while ensuring that farmers can operate without the overhead costs associated with traditional retail setups. For international buyers, it is essential to consider the machine’s capacity, payment options (including cashless systems), and durability against local environmental conditions.

What Role Do Egg Vending Machines Play in Retail Settings?

In supermarkets and grocery stores, egg vending machines serve as an innovative solution for enhancing customer experience. They enable consumers to purchase fresh eggs at any time, thus increasing foot traffic and sales. This 24/7 availability meets the demand for convenience in modern retail. For B2B buyers in this sector, sourcing machines with robust refrigeration capabilities, customizable branding options, and efficient inventory tracking systems are critical to ensuring freshness and brand visibility.

How Can Hospitality Businesses Benefit from Egg Vending Machines?

Hotels and bed & breakfasts can utilize egg vending machines to provide guests with easy access to fresh, local eggs. This not only enhances the guest experience but also promotes local agriculture, which can be a unique selling point. When sourcing for the hospitality industry, it’s important to evaluate machine size to fit available space, ease of use for guests, and the level of maintenance support offered by the supplier, ensuring smooth operation throughout the year.

Why Are Egg Vending Machines Valuable in Educational Institutions?

Educational institutions, such as schools and universities, can implement egg vending machines in cafeterias to provide students with healthy food options. This not only encourages better eating habits but also supports local farmers by creating a direct sales channel. For buyers in this sector, key considerations include the machine’s security features, ease of restocking, and the ability to accommodate various payment methods to cater to a diverse student body.

How Do Egg Vending Machines Assist Food Processing Facilities?

In food processing, egg vending machines facilitate quick access to fresh eggs necessary for various production processes. This efficiency can significantly streamline operations, ensuring that production schedules are met without delay. For B2B buyers in this sector, it is crucial to ensure that the vending machines are compatible with specific processing requirements and offer reliability to minimize downtime, thereby maximizing productivity.

3 Common User Pain Points for ‘egg vending machine’ & Their Solutions

Scenario 1: Limited Payment Options Leading to Lost Sales

The Problem: Many B2B buyers face a common challenge with egg vending machines: limited payment methods can restrict customer access. In regions where cashless transactions are becoming the norm, machines that only accept cash can lead to lost sales opportunities. This issue is particularly pronounced in urban areas or among younger consumers who prefer digital payments. As a result, businesses may struggle to maximize their revenue potential and reach a wider customer base.

The Solution: To overcome this challenge, buyers should invest in egg vending machines equipped with multi-payment systems that accept various forms of payment, including credit/debit cards, mobile wallets, and even cryptocurrency where applicable. When sourcing these machines, inquire about integrated payment solutions like Nayax or other smart vending systems that allow for seamless transactions. Additionally, ensure that the machines are adaptable to local currencies and payment preferences, which may vary significantly across different regions such as Africa, South America, or Europe. By providing multiple payment options, businesses can enhance customer satisfaction and ultimately increase sales.

Scenario 2: Concerns About Egg Freshness and Quality

The Problem: One significant concern among B2B buyers is ensuring the freshness and quality of eggs sold through vending machines. Without proper refrigeration, eggs can spoil quickly, leading to dissatisfied customers and wasted inventory. This concern is especially relevant in warmer climates or during summer months, where temperature control becomes critical. If customers perceive the eggs as stale or of low quality, it can harm the brand’s reputation and reduce repeat business.

The Solution: To address freshness concerns, buyers should prioritize vending machines that include advanced refrigeration technology, such as those with air-chilled and insulated compartments. Machines that offer temperature control settings allow operators to maintain optimal conditions for egg storage. Additionally, sourcing machines that provide real-time monitoring of temperature can help ensure that any deviations are promptly addressed. Buyers should also consider implementing a tracking system to monitor inventory turnover and freshness, allowing for timely restocking. By ensuring that eggs are stored under the best conditions, businesses can enhance customer trust and loyalty.

Scenario 3: Difficulty in Managing Inventory and Sales Data

The Problem: B2B buyers often struggle with efficiently managing inventory and tracking sales data from egg vending machines. Without a robust management system, operators may find it challenging to keep track of stock levels, leading to either overstocking or stockouts. This inefficiency can lead to lost revenue and wasted resources, particularly if machines are not regularly monitored. For international buyers, especially those operating in remote areas, this can pose an even greater challenge.

The Solution: To streamline inventory management and sales tracking, buyers should select egg vending machines that feature integrated smart vending management systems. These systems allow for remote monitoring of inventory levels, sales data, and machine performance. Buyers should look for machines that send automated alerts when stock is low, enabling timely restocking and reducing the risk of running out of popular products. Additionally, consider systems that provide analytics on sales trends, which can inform purchasing decisions and optimize pricing strategies. By leveraging technology for inventory management, businesses can enhance operational efficiency and ensure that their egg vending machines remain profitable.

Strategic Material Selection Guide for egg vending machine

What are the Common Materials Used in Egg Vending Machines?

When selecting materials for egg vending machines, it is essential to consider properties that affect performance, durability, and compliance with international standards. Here, we analyze four common materials: stainless steel, aluminum, high-density polyethylene (HDPE), and tempered glass.

How Does Stainless Steel Perform in Egg Vending Machines?

Key Properties: Stainless steel is known for its high corrosion resistance, strength, and ability to withstand varying temperatures. It can maintain structural integrity under pressure and is relatively easy to clean, making it ideal for food-related applications.

Pros & Cons: The durability of stainless steel is one of its primary advantages, ensuring a long lifespan even in challenging environments. However, it is more expensive than other materials, which can increase the initial investment for businesses. Manufacturing complexity is moderate, as stainless steel requires specialized equipment for cutting and welding.

Impact on Application: Stainless steel is compatible with various media, including water and cleaning agents, which are essential for maintaining hygiene in egg vending machines. Its robustness makes it suitable for outdoor installations in diverse climates.

Considerations for International Buyers: Compliance with food safety regulations, such as those set by the FDA or EU standards, is crucial. Buyers from regions like Africa and South America should also consider local availability and cost implications.

What Role Does Aluminum Play in Egg Vending Machines?

Key Properties: Aluminum is lightweight and has good corrosion resistance, making it suitable for applications where weight is a concern. It can be anodized to enhance its durability and aesthetic appeal.

Pros & Cons: The primary advantage of aluminum is its lower cost compared to stainless steel, making it an attractive option for budget-conscious buyers. However, it is not as strong as stainless steel, which may limit its use in high-traffic areas. Manufacturing processes are simpler, allowing for quicker production times.

Impact on Application: Aluminum is generally compatible with food products but may require coatings to enhance its safety and longevity. It is suitable for indoor vending machines but may not perform well in extreme outdoor conditions without additional treatment.

Considerations for International Buyers: Buyers should ensure that aluminum meets local standards for food safety and durability. In regions like Europe, adherence to DIN standards is essential, while in the Middle East, buyers may need to consider local climate impacts on material choice.

How Does High-Density Polyethylene (HDPE) Benefit Egg Vending Machines?

Key Properties: HDPE is a thermoplastic known for its high strength-to-density ratio and excellent resistance to impact and chemicals. It is also lightweight and can be easily molded into various shapes.

Pros & Cons: The cost-effectiveness of HDPE makes it an appealing choice for manufacturers. However, its lower temperature resistance compared to metals may limit its application in environments with extreme heat or cold. The manufacturing process is straightforward, allowing for rapid production.

Impact on Application: HDPE is suitable for internal components of vending machines, such as trays and storage bins, but may not be ideal for external structures exposed to harsh weather. It is compatible with a wide range of food products, including eggs.

Considerations for International Buyers: Buyers should check for compliance with local food safety regulations, especially in regions with strict guidelines like Europe. The material’s recyclability may also appeal to environmentally conscious markets.

What Advantages Does Tempered Glass Offer in Egg Vending Machines?

Key Properties: Tempered glass is known for its high strength and thermal resistance. It can withstand significant pressure and temperature fluctuations, making it ideal for display cases in vending machines.

Pros & Cons: The aesthetic appeal of tempered glass can enhance the visibility of products, attracting more customers. However, it is more fragile than metals and can shatter under extreme impact. The manufacturing process is complex, requiring specialized techniques.

Impact on Application: Tempered glass is suitable for transparent panels in vending machines, allowing customers to view products without compromising safety. It is compatible with various cleaning agents, ensuring hygiene.

Considerations for International Buyers: Buyers should ensure that tempered glass meets safety standards, particularly in regions with stringent regulations like Germany. The cost may be higher, but the potential for increased sales through better product visibility can justify the investment.

Summary Table of Material Selection for Egg Vending Machines

| Material | Typical Use Case for Egg Vending Machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External casing and structural support | High durability and corrosion resistance | Higher initial cost | High |

| Aluminum | Internal components and frames | Lightweight and cost-effective | Lower strength than stainless steel | Medium |

| High-Density Polyethylene (HDPE) | Trays and internal storage | Cost-effective and resistant to chemicals | Limited temperature resistance | Low |

| Tempered Glass | Display panels | Aesthetic appeal and visibility | Fragile and complex manufacturing | Medium |

This strategic material selection guide provides B2B buyers with actionable insights into the advantages and limitations of various materials used in egg vending machines, helping them make informed purchasing decisions based on their specific market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for egg vending machine

What Are the Key Manufacturing Processes for Egg Vending Machines?

The production of egg vending machines involves several critical stages that ensure the final product meets both functional and aesthetic standards. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

What Are the Main Stages of Manufacturing an Egg Vending Machine?

-

Material Preparation: The first step involves sourcing high-quality materials such as stainless steel for durability, tempered glass for visibility, and various electronic components for operational efficiency. Suppliers should prioritize materials that comply with food safety standards and are resistant to corrosion and wear.

-

Forming: This stage includes cutting, bending, and shaping the materials into the necessary components. Advanced techniques such as laser cutting and CNC machining are often employed to ensure precision. This stage is crucial as it determines the structural integrity of the vending machines.

-

Assembly: Once the individual parts are formed, they are assembled into a complete unit. This process may involve both manual labor and automated systems, depending on the scale of production. Key components such as refrigeration units, payment systems, and user interfaces are integrated during this phase.

-

Finishing: The final stage includes painting, coating, and quality checks. This not only enhances the machine’s appearance but also adds protective layers to extend its lifespan. Custom branding can also be applied at this stage, allowing businesses to showcase their identity.

How Is Quality Assurance Managed in Egg Vending Machine Production?

Quality assurance (QA) is an essential aspect of manufacturing egg vending machines, ensuring that the final product meets international standards and customer expectations.

What International Standards Should B2B Buyers Be Aware Of?

-

ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers to demonstrate their commitment to quality. Compliance with ISO 9001 can instill confidence in B2B buyers regarding the supplier’s operational consistency.

-

CE Marking: In Europe, CE marking indicates that the product meets health, safety, and environmental protection standards. This is vital for machines intended for public use, such as vending machines.

-

API Standards: For machines incorporating advanced technology, adherence to API (American Petroleum Institute) standards may be relevant, particularly if the machine uses sophisticated payment systems or cooling technologies.

What Are the Key Quality Control Checkpoints in Egg Vending Machine Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that each stage meets specific standards.

-

Incoming Quality Control (IQC): Before production begins, raw materials undergo inspection to verify their quality. This includes checking for compliance with safety standards and ensuring that materials are free from defects.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to catch any issues early in the process. This may involve testing the functionality of electronic components and verifying the integrity of welded or joined parts.

-

Final Quality Control (FQC): After assembly, the finished machines undergo rigorous testing to ensure they function correctly and meet all specifications. This may include stress tests, safety evaluations, and performance assessments.

What Common Testing Methods Are Used in Egg Vending Machine Quality Assurance?

Testing methods play a crucial role in ensuring that vending machines operate reliably and safely.

-

Functional Testing: Each machine is tested to ensure that all components, including payment systems and refrigeration units, work correctly. This helps identify any operational issues before the machines are deployed.

-

Safety Testing: Compliance with safety standards is crucial, particularly regarding electrical components. Testing for short circuits, overheating, and electrical leakage is essential to ensure user safety.

-

Durability Testing: Machines are subjected to wear-and-tear tests to simulate long-term usage. This includes testing for resistance to environmental factors such as temperature fluctuations and humidity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying the quality control practices of potential suppliers is essential to mitigate risks associated with product quality.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and QC practices firsthand. This can provide insights into the supplier’s commitment to quality.

-

Reviewing Quality Reports: Suppliers should provide detailed quality reports that outline testing methods, results, and compliance with relevant standards. These documents can be essential for assessing the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer unbiased assessments of the supplier’s quality control systems. This is particularly beneficial for buyers unfamiliar with local manufacturing standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

-

Regulatory Compliance: Different regions have varying regulations regarding food safety and machinery standards. Buyers must ensure that the machines comply with local regulations to avoid legal issues.

-

Cultural Expectations: Understanding the cultural context of the target market can influence design features and functionalities. For instance, some regions may prioritize eco-friendly designs or specific payment methods.

-

Logistical Considerations: Quality control doesn’t end with manufacturing. International buyers should consider the logistics of transporting machines, including the need for packaging that protects against damage during shipping.

Conclusion

For B2B buyers in the egg vending machine market, a comprehensive understanding of the manufacturing processes and quality assurance practices is crucial. By focusing on the stages of production, quality standards, testing methods, and verification processes, buyers can make informed decisions that align with their operational needs and market expectations. Investing time in evaluating suppliers can lead to successful partnerships that enhance product offerings and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘egg vending machine’

To assist international B2B buyers in procuring egg vending machines, this guide outlines essential steps to ensure a smooth sourcing process. By following these steps, buyers can make informed decisions and secure high-quality machines that meet their business needs.

Step 1: Define Your Technical Specifications

Before approaching suppliers, clearly outline your technical requirements. Consider factors such as capacity, payment options (cash, card, mobile payments), and whether you need a refrigerated unit to maintain egg freshness. This clarity will help streamline your discussions with potential suppliers and ensure that the machines you consider align with your business model.

Step 2: Research Market Trends and Regulations

Understanding local market trends and regulations is crucial, especially in diverse regions like Africa, South America, and Europe. Research consumer preferences for fresh produce and check any specific regulations regarding vending machines in your target market. This knowledge will not only inform your purchasing decision but also aid in marketing your vending solutions effectively.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they have a proven track record. Request company profiles, client testimonials, and case studies from similar markets or industries. Additionally, inquire about their production capabilities and whether they can meet your volume requirements consistently.

- Check for International Certifications: Look for suppliers with certifications that guarantee quality and safety standards, which can enhance your brand’s credibility.

Step 4: Assess Customization Options

Customization can be a significant advantage in differentiating your product in the market. Inquire about branding opportunities, such as incorporating your logo and specific designs on the vending machines. Furthermore, assess whether the machines can be tailored to accommodate various products beyond eggs, which could broaden your business scope.

Step 5: Examine After-Sales Support and Warranty

Before finalizing your supplier choice, ensure they offer robust after-sales support and warranty terms. A one-year warranty with free spare parts and lifetime remote technical support can save you significant costs and downtime in the future. Understand the process for addressing issues like machine malfunctions or inventory management.

Step 6: Request a Demonstration or Trial Period

If possible, request a demonstration of the vending machine or a trial period. This allows you to evaluate the machine’s functionality, user interface, and maintenance requirements firsthand. Ensure that the machine operates smoothly in different conditions and meets your expectations regarding ease of use for customers.

Step 7: Negotiate Pricing and Payment Terms

Finally, engage in negotiations regarding pricing and payment terms. Consider all costs, including shipping and installation, and evaluate the total cost of ownership. A transparent agreement on payment schedules and terms can help maintain a healthy cash flow as you scale your vending operations.

By following these steps, B2B buyers can effectively navigate the sourcing process for egg vending machines, ensuring they select the right equipment to meet their business objectives.

Comprehensive Cost and Pricing Analysis for egg vending machine Sourcing

What Are the Key Cost Components for Egg Vending Machines?

When analyzing the cost structure for egg vending machines, several core components must be considered:

-

Materials: The primary materials include high-quality stainless steel for durability and insulation, electronic components for payment systems, and refrigeration units for maintaining freshness. The choice of materials significantly impacts both cost and longevity.

-

Labor: Labor costs encompass the wages for skilled technicians involved in manufacturing, assembly, and quality control. Regions with lower labor costs may offer competitive pricing, but this should be balanced against quality.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and indirect labor. Efficient production processes can minimize these overheads, leading to lower overall costs.

-

Tooling: Customization often requires specialized tooling, which can add to initial costs. However, investing in quality tooling can enhance the machine’s performance and longevity.

-

Quality Control (QC): Ensuring that every unit meets quality standards is crucial. QC processes may add costs but can prevent future expenses related to defects and repairs.

-

Logistics: Shipping costs vary widely depending on the supplier’s location and the destination. International buyers should consider freight costs, insurance, and customs duties when calculating total expenses.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding typical margins in the vending machine industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Egg Vending Machine Costs?

Several factors can influence the pricing of egg vending machines:

-

Volume/MOQ: Purchasing in larger quantities often leads to bulk pricing discounts. Minimum Order Quantities (MOQs) set by suppliers can also dictate total upfront investment.

-

Specifications and Customization: Custom features, such as branding or specific technological integrations, can significantly increase costs. Buyers should clearly outline their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Machines built with higher-grade materials or those that comply with specific quality certifications may command higher prices. International buyers should verify compliance with local regulations.

-

Supplier Factors: The supplier’s reputation, experience, and geographical location can affect pricing. Established suppliers may charge a premium but often provide better reliability and support.

-

Incoterms: Understanding the delivery terms (e.g., FOB, CIF) can affect pricing. Incoterms define the responsibilities of buyers and sellers in terms of shipping costs and risks, impacting overall cost assessments.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

To maximize value, buyers should consider the following strategies:

-

Negotiate Terms: Always negotiate pricing, payment terms, and warranties. Suppliers may have flexibility, especially for larger orders.

-

Assess Total Cost of Ownership (TCO): Beyond initial purchase costs, consider maintenance, energy consumption, and potential repair costs. A lower upfront price may lead to higher TCO if the machine is less efficient.

-

Leverage Local Knowledge: Buyers in regions like Africa or South America should leverage local contacts and market knowledge to identify suppliers with competitive pricing and reliable service.

-

Evaluate Multiple Suppliers: Obtaining quotes from multiple suppliers can provide leverage in negotiations. This also allows buyers to compare features and services comprehensively.

-

Consider Long-term Relationships: Building a long-term relationship with a supplier can lead to better pricing and support in the future. Loyalty often results in preferential pricing for repeat customers.

Conclusion: Understanding Costs and Pricing Nuances for International Buyers

International buyers should approach the sourcing of egg vending machines with a clear understanding of both cost components and pricing influencers. While indicative prices can provide a starting point, the final costs will depend on various factors, including customization, specifications, and supplier negotiations. Buyers are encouraged to conduct thorough research and leverage local insights to achieve the best value for their investment.

Alternatives Analysis: Comparing egg vending machine With Other Solutions

Exploring Alternatives to Egg Vending Machines: What Are Your Options?

In the quest for efficient distribution of fresh eggs, businesses often consider various solutions beyond traditional methods. The egg vending machine has gained traction for its convenience and efficiency, but it’s essential to evaluate other viable alternatives. This analysis aims to compare egg vending machines with alternative solutions, providing insights for B2B buyers in diverse regions.

| Comparison Aspect | Egg Vending Machine | Mobile Egg Delivery Service | Farm Stand or Market Stall |

|---|---|---|---|

| Performance | 24/7 availability; minimal labor needed | Dependent on delivery schedules; labor-intensive | Limited hours; relies on foot traffic |

| Cost | High initial investment; low ongoing costs | Moderate startup costs; variable operational costs | Low startup costs; variable income based on location |

| Ease of Implementation | Requires installation and setup; location-dependent | Requires logistics planning; can be set up relatively quickly | Simple setup; requires location and market research |

| Maintenance | Regular stocking and occasional repairs; tech support available | Requires ongoing vehicle maintenance and staffing | Minimal upkeep; depends on seasonal demand |

| Best Use Case | High foot traffic areas; urban settings | Rural areas with demand for fresh eggs | Local communities; farmers’ markets |

What Are the Advantages and Disadvantages of a Mobile Egg Delivery Service?

Mobile egg delivery services provide a flexible solution to distribute fresh eggs directly to consumers. The primary advantage is convenience, as customers receive their orders without needing to travel. However, this model requires a reliable logistics setup and may incur higher operational costs due to vehicle maintenance and staffing needs. Moreover, delivery schedules can limit availability, making it less appealing for spontaneous purchases.

How Does a Farm Stand or Market Stall Compare?

Farm stands or market stalls offer a traditional method for selling eggs directly to consumers. They typically have low startup costs and can be set up quickly, making them accessible for small-scale farmers. However, their performance is heavily reliant on foot traffic and may not generate sales year-round, particularly in less populated areas. Additionally, they require manual labor for setup and operation, which may not be sustainable for all businesses.

Conclusion: How Should B2B Buyers Choose the Right Egg Distribution Solution?

Selecting the right solution for egg distribution hinges on various factors, including location, target market, and budget. For businesses in high-traffic urban areas, egg vending machines may offer the best balance of convenience and efficiency. Conversely, rural enterprises might benefit more from mobile delivery services that cater directly to consumer demand. Farm stands are ideal for localized markets where personal interaction and fresh produce appeal to customers. Ultimately, B2B buyers should assess their unique needs and operational capabilities to determine the most suitable approach for their specific context.

Essential Technical Properties and Trade Terminology for egg vending machine

What Are the Key Technical Properties of Egg Vending Machines?

In the competitive landscape of vending solutions, understanding the technical specifications of egg vending machines is crucial for B2B buyers. Here are several key properties that can significantly impact operational efficiency and product quality:

-

Cooling System Efficiency

Egg vending machines often incorporate advanced refrigeration units to maintain optimal temperatures for preserving freshness. The efficiency of these cooling systems is measured in energy consumption (Watts) and temperature range (typically between 0°C to 7°C). For B2B buyers, investing in machines with high cooling efficiency can reduce operational costs and enhance product quality, leading to higher customer satisfaction. -

Capacity and Size Specifications

The dimensions of the machine, including the number of trays and the size of each tray, dictate how many eggs or products can be offered at a time. For instance, a machine holding 28 egg trays can accommodate varying tray sizes, allowing businesses to customize their offerings. Understanding capacity helps businesses gauge potential revenue and inventory management, especially in high-demand areas. -

Payment System Versatility

Modern egg vending machines support multiple payment options, including cash, cards, and mobile wallets. This versatility is essential for catering to diverse customer preferences and improving sales. B2B buyers should prioritize machines that offer comprehensive payment solutions, especially in regions with varying payment habits. -

Durability and Material Grade

The materials used in manufacturing the vending machine, such as stainless steel or high-grade plastic, affect durability and resistance to environmental factors. Machines designed for outdoor use should be robust enough to withstand weather conditions. Investing in durable machines minimizes maintenance costs and prolongs the lifespan, crucial for businesses operating in remote or harsh environments. -

Smart Technology Integration

Advanced vending machines now include smart technology features, such as remote inventory management and data analytics capabilities. These systems enable operators to monitor sales in real-time and automate stock replenishment, reducing downtime and maximizing profitability. B2B buyers should consider machines with these features to streamline operations and enhance decision-making processes. -

Energy Efficiency Ratings

Many vending machines come with energy efficiency ratings that indicate their power consumption relative to their performance. Machines with higher efficiency ratings help businesses reduce electricity costs, an important factor for profitability. Understanding these ratings can guide buyers toward sustainable choices that align with eco-friendly initiatives.

Which Trade Terminology Is Essential for Egg Vending Machine Transactions?

Navigating the B2B landscape involves familiarity with specific trade terminologies. Here are some common terms relevant to egg vending machine procurement:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of egg vending machines, buyers should identify OEMs for reliable sourcing of components, ensuring quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and negotiate better terms, especially when entering new markets. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers. This document outlines specific requirements, enabling suppliers to provide accurate quotations. This is vital for B2B buyers to ensure they receive competitive pricing and transparent terms. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for buyers to comprehend shipping responsibilities, risk management, and cost allocation during the procurement process. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. For businesses reliant on timely inventory replenishment, understanding lead times is critical for planning and maintaining sales continuity. -

Warranty and After-Sales Support

This terminology encompasses the terms regarding the service and support provided after the purchase. A solid warranty can protect B2B buyers from unexpected costs associated with repairs or replacements, making it a key consideration in decision-making.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when investing in egg vending machines, ensuring they choose solutions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the egg vending machine Sector

What Are the Key Market Dynamics and Trends Influencing the Egg Vending Machine Sector?

The egg vending machine market is witnessing significant transformation driven by several global factors. The increasing demand for convenience and fresh produce is reshaping consumer purchasing behavior, leading to a rise in automated retail solutions. In regions like Africa and South America, where access to fresh food can be limited, egg vending machines provide a reliable source of high-quality eggs directly from producers. Meanwhile, in Europe, particularly in countries like Germany, there is a growing trend towards organic and locally sourced products, which can be effectively marketed through vending solutions.

Technological advancements also play a pivotal role in shaping the market. Innovations such as cashless payment systems and smart inventory management tools have made vending machines more user-friendly and efficient. For instance, systems that allow remote monitoring of stock levels and sales data enable operators to optimize inventory and reduce waste. B2B buyers should look for machines that incorporate these technologies, as they not only enhance operational efficiency but also improve customer satisfaction by ensuring product availability.

Another emerging trend is the customization of vending machines to suit specific market needs. Manufacturers are increasingly offering machines that can accommodate various products beyond eggs, such as organic fruits or dairy, allowing businesses to diversify their offerings. This flexibility can be a game-changer for B2B buyers looking to maximize their investment and appeal to a broader customer base.

How Can Sustainability and Ethical Sourcing Be Integrated into Egg Vending Machine Operations?

Sustainability is becoming a crucial consideration for B2B buyers in the egg vending machine sector. The environmental impact of food sourcing and packaging is under scrutiny, and businesses are expected to adopt practices that minimize their carbon footprint. Buyers should prioritize suppliers that use eco-friendly materials and energy-efficient technologies in their machines. For instance, vending machines with refrigeration units that meet high energy efficiency standards can significantly reduce energy consumption.

Moreover, ethical sourcing has gained prominence, particularly in Europe and North America, where consumers are increasingly concerned about animal welfare and the environmental practices of food producers. B2B buyers should ensure that the eggs sold in vending machines come from certified farms that adhere to humane treatment standards and sustainable farming practices. Certifications such as organic or free-range can enhance the brand’s credibility and appeal to a conscientious consumer base.

Establishing a green supply chain is not just about compliance but can also serve as a competitive advantage. By showcasing a commitment to sustainability and ethical sourcing, businesses can attract customers who prioritize these values, thereby driving sales and enhancing brand loyalty.

What is the Historical Context of Egg Vending Machines and Their Evolution?

The concept of vending machines dates back to the early 1880s, with the first machines dispensing items like postcards and chewing gum. However, the introduction of egg vending machines is a more recent development, emerging in response to the demand for fresh, locally sourced food. Initially popularized in rural areas, these machines have evolved to incorporate advanced technologies such as refrigeration, cashless payment systems, and user-friendly interfaces.

Today, egg vending machines are seen not only as a means of convenience but also as a viable business model that supports local farmers and promotes sustainable food practices. As the market continues to expand, it is essential for B2B buyers to stay informed about technological advancements and market trends to leverage opportunities in this growing sector.

Frequently Asked Questions (FAQs) for B2B Buyers of egg vending machine

-

How do I ensure the egg vending machine meets local regulations?

To ensure compliance with local regulations, research the specific food safety and vending machine laws in your region. This includes checking standards for refrigeration, hygiene, and product labeling. Engaging with local health authorities can provide insights into regulations that must be met. Additionally, choose suppliers who are familiar with these regulations and can offer machines that comply with local guidelines, ensuring a smoother operational process. -

What is the best type of egg vending machine for my business model?

The best type of egg vending machine depends on your target market and location. For high-traffic areas like urban centers, a larger machine with multiple product options may be ideal. In contrast, smaller farms might benefit from a compact unit that emphasizes local produce. Consider factors such as capacity, refrigeration features, and payment options (cashless, mobile payments) that align with your customer preferences and operational capabilities. -

How can I customize the vending machine to reflect my brand?

Most suppliers offer customization options, allowing you to brand your vending machine with your logo, colors, and product information. You can request custom stickers or digital displays on touch-screen models to enhance brand visibility. Discuss your branding needs with potential suppliers to ensure they can accommodate your requirements, from machine design to marketing materials that highlight the freshness and quality of your eggs. -

What are the minimum order quantities (MOQs) for egg vending machines?

Minimum order quantities vary by supplier and can depend on the type of machine and customization options. Typically, manufacturers may have MOQs ranging from one unit to several machines for bulk orders. It’s advisable to inquire directly with suppliers about their specific MOQs, as they may offer flexibility based on your business needs, especially if you are looking for a trial run or a pilot program. -

What payment options should I expect for egg vending machines?

Modern egg vending machines often support multiple payment methods, including cash, credit/debit cards, and mobile wallets. This flexibility is crucial for catering to diverse customer preferences. When sourcing your machine, confirm with suppliers about the payment systems they offer and ensure that they are compatible with currencies in your target market. Look for machines equipped with contactless payment options to enhance convenience and speed of transactions. -

What logistics considerations should I keep in mind when importing machines?

When importing egg vending machines, consider shipping costs, customs duties, and delivery timelines. Research the logistics providers that specialize in international shipping to ensure safe and timely delivery. Also, verify the supplier’s ability to handle shipping logistics, including packing and documentation, to facilitate a smooth import process. Understanding local import regulations in your country is crucial to avoid delays and additional costs. -

How do I evaluate the quality assurance (QA) standards of a supplier?

To evaluate a supplier’s quality assurance standards, request documentation related to their manufacturing processes, certifications, and quality control measures. Look for suppliers with ISO certifications or other recognized quality standards. Additionally, inquire about warranty policies, after-sales support, and customer feedback from other clients. Conducting due diligence through online reviews and industry referrals can also help assess the reliability and quality of potential suppliers. -

Can I receive after-sales support and maintenance services for the vending machines?

Most reputable suppliers provide after-sales support, including maintenance services and technical assistance. Clarify the specifics of what is covered under warranty, including the duration and types of repairs or replacements available. It’s beneficial to choose suppliers who offer remote monitoring capabilities, allowing you to check machine performance and troubleshoot issues without needing on-site visits, thus reducing downtime and ensuring continuous operation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Egg Vending Machine Manufacturers & Suppliers List

1. Eggspress – Egg Vending Machines

Domain: eggspress.ie

Registered: 2021 (4 years)

Introduction: Egg Vending Machines designed and produced by an experienced egg farmer. Direct sales to customers, cutting costs and eliminating middlemen. Locations include Muckian Eggs in Dundalk with a double unit for two products, Donnelly’s Strawberries in Ratoath suitable for organic products, and Nith Valley Eggs in Scotland with cashless payment options.

2. Reids Equipment – Egg Vending Machines

Domain: reidsequipment.co.uk

Registered: 2010 (15 years)

Introduction: Reids Equipment provides egg vending machines designed for a simple solution for selling fresh/organic foods. Key features include:

– Capacity: Holds 28 Keyes egg trays in individual drawers.

– Payment: Nayax contactless payment available.

– Operation: Functions 24/7, sending text notifications when stock is low.

– Dimensions: Machine dimensions are 1840H x 1060W x 583D mm; standard tray dimension…

3. Facebook – Egg Vending Machine

4. Reddit – 24/7 Egg Vending Machine

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: A local farm sells eggs at a 24/7 vending machine located on their driveway.

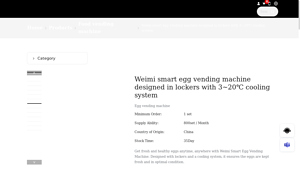

5. Weimi – Smart Egg Vending Machine

Domain: weimivending.com

Registered: 2023 (2 years)

Introduction: Weimi Smart Egg Vending Machine with cooling lockers for sale. Designed with lockers and a cooling system (3~20℃) to keep eggs fresh. Minimum order: 1 set. Supply ability: 800 sets/month. Country of origin: China. Stock time: 35 days. Price range: US $2302.00 – US $3162.00 per set. Features include multiple compartments for high-quality eggs, cashless payments, remote inventory management, and cus…

6. Egg Vending Machines – Fresh Organic Eggs

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Egg vending machines provide a direct way for farmers to sell fresh, organic eggs to consumers. They are becoming popular as grocery stores face shortages. The concept includes various designs, such as custom vending machines that can dispense different farm-fresh products. Locations like California and Japan feature unique egg vending machines, contributing to the trend of innovative vending solu…

Strategic Sourcing Conclusion and Outlook for egg vending machine

In the evolving landscape of food distribution, egg vending machines present a unique opportunity for B2B buyers to tap into the growing demand for fresh, locally sourced products. By strategically sourcing these machines, businesses can benefit from a streamlined supply chain that enhances accessibility and convenience for consumers. Key takeaways include the importance of selecting machines that offer robust payment options, such as contactless systems, to cater to a diverse clientele. Additionally, the ability to monitor inventory and sales data remotely enables operators to optimize stock management and reduce operational costs.

Investing in customizable vending solutions allows businesses to align their brand identity with consumer preferences, enhancing market appeal. Furthermore, egg vending machines can operate independently, providing a continuous revenue stream with minimal staffing requirements.

As the global market continues to embrace automation and innovative retail solutions, now is the time for international B2B buyers from regions like Africa, South America, the Middle East, and Europe to consider integrating egg vending machines into their business models. Embrace this forward-thinking approach to meet consumer needs and capitalize on the fresh produce market.