A Deep Dive into Diff Pressure Switch Solution

Introduction: Navigating the Global Market for diff pressure switch

In today’s fast-paced industrial landscape, sourcing reliable differential pressure switches is a critical challenge for businesses across the globe. These essential devices monitor the difference in pressure between two points, ensuring operational efficiency and safety in various applications—from HVAC systems to industrial machinery. However, navigating the complexities of the global market can be daunting, especially for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia.

This comprehensive guide aims to empower you with the knowledge needed to make informed purchasing decisions regarding differential pressure switches. It covers a wide array of topics, including different types of switches, their specific applications, and essential considerations for supplier vetting. You’ll also find insights into cost factors, ensuring you can evaluate pricing against quality and reliability effectively.

By equipping yourself with this information, you can streamline your procurement processes, mitigate risks associated with sourcing, and ultimately enhance your operational capabilities. Whether you’re looking to improve system performance, ensure compliance with safety standards, or reduce maintenance costs, this guide serves as your trusted resource in the intricate world of differential pressure switches.

Understanding diff pressure switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Differential Switch | Operates via mechanical components; no external power needed | HVAC systems, industrial automation | Pros: Reliable, cost-effective. Cons: Limited precision compared to electronic types. |

| Electronic Differential Switch | Utilizes electronic sensors for high accuracy | Clean rooms, laboratories, medical equipment | Pros: High precision, adjustable settings. Cons: Higher cost, requires power supply. |

| Adjustable Differential Switch | Field-adjustable setpoints for varied applications | Air filtration, airflow monitoring | Pros: Versatile, customizable. Cons: Complexity may increase installation time. |

| Miniature Pressure Switch | Compact design for tight spaces | OEM applications, HVAC, automotive | Pros: Space-saving, lightweight. Cons: Lower pressure range capabilities. |

| Explosion-Proof Differential Switch | Designed for hazardous environments; weatherproof | Oil & gas, chemical processing | Pros: Safety in volatile conditions, durable. Cons: Higher initial investment. |

What are the Characteristics of Mechanical Differential Switches?

Mechanical differential switches rely on mechanical components to detect pressure changes. These switches are often used in HVAC systems and industrial automation, where they activate systems based on preset thresholds. Their simplicity and reliability make them a cost-effective solution for many applications. However, buyers should consider that these switches may not provide the same level of precision as electronic alternatives, making them less suitable for applications requiring fine control.

Why Choose Electronic Differential Switches?

Electronic differential switches are known for their high accuracy and responsiveness. They utilize advanced sensors to monitor pressure differences, making them ideal for sensitive environments like clean rooms and laboratories. B2B buyers should note that while these switches often come with a higher price tag, their adjustable settings and precision can lead to significant operational efficiencies, especially in medical equipment and research applications.

How Do Adjustable Differential Switches Enhance Versatility?

Adjustable differential switches allow users to modify setpoints in the field, making them highly versatile for various applications, including air filtration and airflow monitoring. This feature is particularly beneficial for businesses that require flexibility in their operations. However, the added complexity of installation and calibration may be a consideration for buyers, as it can lead to longer setup times.

What Advantages Do Miniature Pressure Switches Offer?

Miniature pressure switches are designed for applications where space is at a premium. Their compact size makes them suitable for OEM applications, HVAC systems, and automotive use. While they are lightweight and easy to integrate, buyers should be aware that they typically have lower pressure range capabilities compared to larger switches, which may limit their application in high-pressure environments.

When to Invest in Explosion-Proof Differential Switches?

Explosion-proof differential switches are specifically engineered for hazardous environments, such as oil and gas or chemical processing industries. These switches provide safety and reliability in volatile conditions, making them a critical investment for businesses operating in such sectors. Although the initial investment is higher, the durability and safety features can justify the cost, especially in compliance-heavy industries.

Key Industrial Applications of diff pressure switch

| Industry/Sector | Specific Application of diff pressure switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC | Airflow Monitoring and Control | Ensures optimal airflow, enhances energy efficiency | Look for adjustable setpoints and robust construction |

| Oil & Gas | Pipeline Pressure Monitoring | Prevents leaks and ensures safety in hazardous environments | Seek explosion-proof models and compliance with local regulations |

| Water Treatment | Filter Monitoring and Control | Improves operational efficiency and prolongs equipment life | Consider compatibility with various fluids and easy maintenance |

| Pharmaceutical | Cleanroom Pressure Control | Maintains sterile environments, ensuring product integrity | Focus on precision and reliability, as well as certifications |

| Manufacturing | Equipment Protection in Dusty Environments | Prevents equipment failure, reducing downtime and maintenance costs | Evaluate environmental ratings and durability under harsh conditions |

How is a Differential Pressure Switch Used in HVAC Applications?

In HVAC systems, differential pressure switches are critical for monitoring airflow to ensure systems operate efficiently. They detect pressure drops across filters or ducts, triggering alarms or system adjustments when thresholds are exceeded. This capability not only enhances energy efficiency by maintaining optimal airflow but also extends the lifespan of HVAC equipment. Buyers should prioritize switches that offer adjustable setpoints and robust construction to withstand various environmental conditions, especially in regions with fluctuating climates like Europe and the Middle East.

What Role Does a Differential Pressure Switch Play in Oil & Gas Operations?

In the oil and gas sector, differential pressure switches are essential for monitoring pipeline pressures. They help detect leaks or pressure drops that could indicate equipment failure or safety hazards. By providing early warnings, these switches contribute to safer operational practices and compliance with industry regulations. For international buyers, especially in oil-rich regions like Saudi Arabia, sourcing explosion-proof models that comply with local safety standards is critical to ensure operational integrity.

How are Differential Pressure Switches Utilized in Water Treatment Facilities?

Water treatment facilities employ differential pressure switches to monitor filter performance and ensure that water quality remains high. These switches detect pressure changes that signal when filters need maintenance or replacement, thus optimizing operational efficiency. For buyers in Africa and South America, it is crucial to consider switches that are compatible with various types of fluids and designed for easy maintenance, given the often remote locations of treatment plants in these regions.

Why are Differential Pressure Switches Important for Cleanroom Environments?

In the pharmaceutical industry, maintaining strict cleanroom conditions is vital for product integrity. Differential pressure switches help control the pressure differentials between cleanrooms and adjacent areas, ensuring contaminants do not enter sensitive environments. Buyers in this sector should focus on switches that offer high precision and reliability, along with necessary certifications to meet stringent industry standards, particularly in Europe where regulations can be more rigorous.

What Benefits Do Differential Pressure Switches Offer in Manufacturing Settings?

Manufacturing environments, particularly those exposed to dust and particulates, utilize differential pressure switches to protect equipment and ensure efficient operation. These switches monitor pressure differentials that indicate filter saturation or equipment blockages, helping prevent costly downtime. Buyers should evaluate models with high durability ratings and protection against environmental factors, especially in regions like South America where manufacturing conditions can be challenging.

3 Common User Pain Points for ‘diff pressure switch’ & Their Solutions

Scenario 1: Inconsistent Performance in Pressure Monitoring Systems

The Problem: B2B buyers often face issues with differential pressure switches that do not provide consistent readings, leading to unreliable system performance. This inconsistency can stem from a variety of factors, such as improper calibration, environmental conditions, or the use of switches not suited for specific applications. In industries where precise pressure control is critical—like HVAC, pharmaceuticals, or food processing—these discrepancies can result in operational inefficiencies, increased costs, and even safety hazards.

The Solution: To address inconsistent performance, it’s essential to select a differential pressure switch that is specifically designed for the intended application. Buyers should prioritize switches with adjustable setpoints and robust construction to withstand environmental factors like temperature and humidity. Regular calibration and maintenance schedules should be established to ensure the switches function optimally over time. Additionally, investing in units with built-in features like pressure snubbers can enhance stability in readings by filtering out pressure spikes. Finally, collaborating with manufacturers that provide comprehensive support and resources can aid in proper installation and ongoing performance monitoring.

Scenario 2: Difficulty in Installation and Integration

The Problem: Another common challenge faced by B2B buyers is the complexity of installing and integrating differential pressure switches into existing systems. Many switches require specific mounting orientations, electrical connections, or compatibility with various media types. This complexity can lead to increased labor costs, installation delays, and potential system downtime, which is particularly detrimental in fast-paced industrial environments.

The Solution: To mitigate installation difficulties, buyers should prioritize differential pressure switches that come with clear installation guidelines and user-friendly designs. It’s beneficial to opt for products with modular designs that allow for easy adjustments and integration into existing systems. Engaging with suppliers who offer technical support can also streamline the installation process. Furthermore, investing in training for maintenance staff on the correct installation procedures can help prevent common mistakes and reduce the time needed for system setup. Choosing switches with multiple mounting options and versatile media compatibility will also ensure a smoother integration process.

Scenario 3: High Replacement Costs Due to Frequent Failures

The Problem: Frequent failures of differential pressure switches can lead to high replacement costs and operational disruptions. Buyers may experience this issue when they select low-quality switches or those not rated for the specific pressure ranges or environmental conditions of their applications. Over time, these failures can result in not only increased expenditure on replacements but also potential losses in productivity and service delivery.

The Solution: To combat high replacement costs, it is crucial to invest in high-quality differential pressure switches that meet or exceed industry standards for durability and performance. Buyers should conduct thorough research on the manufacturer’s reputation and product specifications, focusing on materials used, pressure ratings, and expected lifecycle. Opting for switches with warranties and robust customer service can provide additional assurance of quality. Implementing predictive maintenance practices can also help identify potential failures before they occur, allowing for timely replacements without disrupting operations. Additionally, considering the total cost of ownership—including installation, maintenance, and downtime—can guide buyers to make more informed purchasing decisions.

Strategic Material Selection Guide for diff pressure switch

What Are the Key Materials Used in Differential Pressure Switches?

Differential pressure switches are critical components in various industrial applications, and the choice of materials significantly impacts their performance, durability, and suitability for specific environments. Below, we analyze four common materials used in the construction of differential pressure switches, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Do Stainless Steel Components Enhance Differential Pressure Switch Performance?

Key Properties:

Stainless steel is renowned for its high corrosion resistance, strength, and ability to withstand extreme temperatures and pressures. Common grades like 304 and 316 are often used, with 316 offering superior resistance to chlorides, making it ideal for marine or chemical applications.

Pros & Cons:

The durability of stainless steel translates to a longer lifespan in harsh environments, reducing maintenance costs. However, it is more expensive than other materials and may require complex manufacturing processes, which can increase lead times.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive fluids and gases. This versatility makes it suitable for applications in industries such as oil and gas, pharmaceuticals, and food processing.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN for material quality. The higher initial cost may be justified by the long-term savings on maintenance and replacement.

What Role Does Brass Play in Differential Pressure Switch Design?

Key Properties:

Brass is a copper-zinc alloy known for its good corrosion resistance and excellent machinability. It typically operates well in moderate temperature and pressure conditions.

Pros & Cons:

Brass is less expensive than stainless steel and easier to manufacture, which can lead to lower overall costs. However, it has lower strength and may not be suitable for high-pressure applications. Additionally, brass can corrode in certain environments, particularly where chlorides are present.

Impact on Application:

Brass is commonly used in applications involving air and non-corrosive gases. It is often found in HVAC systems and general industrial settings.

Considerations for International Buyers:

Buyers should be aware of the specific environmental conditions in their region. For example, in coastal areas of South America or the Middle East, the use of brass may require additional protective coatings to prevent corrosion.

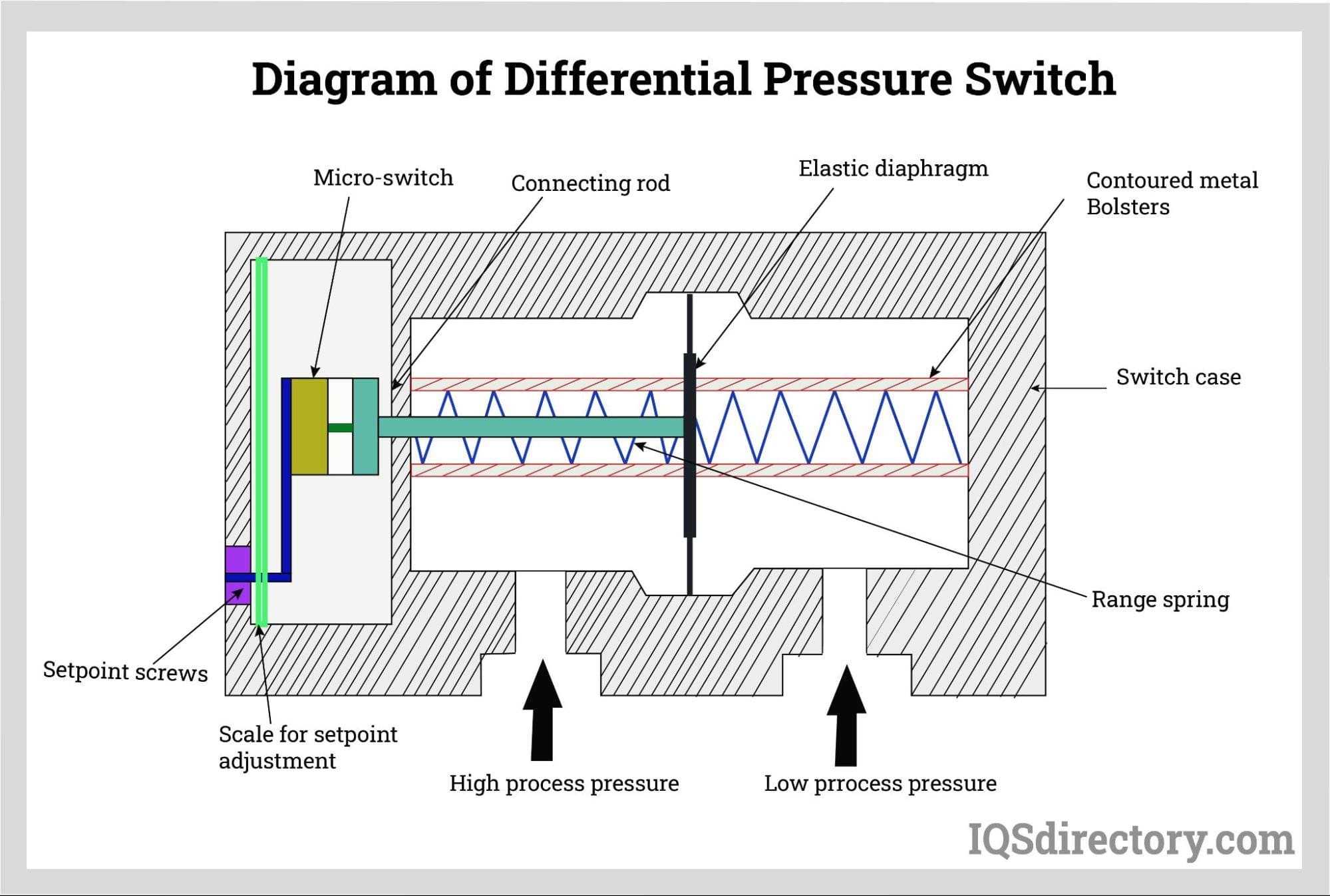

Illustrative image related to diff pressure switch

How Does Plastic Material Influence Differential Pressure Switch Functionality?

Key Properties:

Plastics, such as polycarbonate and PVC, offer lightweight and cost-effective solutions with good chemical resistance. They can operate at lower temperature and pressure thresholds compared to metals.

Pros & Cons:

The primary advantage of plastic is its low cost and ease of manufacturing, which can significantly reduce production times. However, plastics generally have lower durability and may not withstand high-pressure applications or extreme temperatures.

Impact on Application:

Plastic components are suitable for applications involving low-pressure air or non-corrosive liquids. They are often used in consumer products and less demanding industrial environments.

Considerations for International Buyers:

In regions with stringent environmental regulations, such as Germany, buyers should ensure that the selected plastic materials comply with local standards for safety and environmental impact.

What Benefits Does Aluminum Provide in Differential Pressure Switches?

Key Properties:

Aluminum is lightweight, corrosion-resistant, and offers good thermal and electrical conductivity. It can handle moderate temperature and pressure levels effectively.

Pros & Cons:

Aluminum’s lightweight nature makes it easy to install and transport, while its resistance to corrosion extends the product’s life. However, it is generally less durable than stainless steel and can be more expensive than plastic options.

Impact on Application:

Aluminum is often used in applications where weight is a critical factor, such as in aerospace or portable equipment. It is compatible with a variety of media, including air and non-corrosive liquids.

Considerations for International Buyers:

Buyers in Africa or South America should consider the local availability of aluminum and its cost-effectiveness compared to other materials. Compliance with international standards for manufacturing and safety is also crucial.

Summary Table of Material Selection for Differential Pressure Switches

| Material | Typical Use Case for diff pressure switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas, pharmaceuticals | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | HVAC systems, general industrial | Cost-effective and easy to manufacture | Lower strength and corrosion susceptibility | Medium |

| Plastic | Consumer products, low-pressure applications | Low cost and lightweight | Limited pressure and temperature tolerance | Low |

| Aluminum | Aerospace, portable equipment | Lightweight and corrosion-resistant | Less durable than stainless steel | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in differential pressure switches, enabling informed decision-making tailored to specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for diff pressure switch

What Are the Main Stages of Manufacturing a Differential Pressure Switch?

The manufacturing process of a differential pressure switch typically involves several key stages, each crucial for ensuring the final product meets high-performance standards.

-

Material Preparation: The process begins with sourcing high-quality materials, such as stainless steel or brass for the housing and diaphragm, and specialized polymers for seals. Suppliers must ensure that materials comply with industry standards, such as ASTM and ISO, to guarantee durability and resistance to various environmental conditions.

-

Forming: After material preparation, the forming stage involves machining and shaping the components. Techniques such as CNC machining, stamping, and molding are commonly used. CNC machining allows for precise dimensions, while stamping is efficient for high-volume production. Quality control measures should be integrated into this stage, including dimensional inspections to verify that components meet specifications.

-

Assembly: The assembly stage brings together all the individual components, including diaphragms, contacts, and enclosures. This is often performed in a cleanroom environment to prevent contamination. Automated assembly lines may be used for efficiency, but skilled technicians are essential for critical assembly tasks that require precision. Each assembly should undergo initial quality checks to ensure proper fit and function.

-

Finishing: The final stage involves applying protective coatings and finishes, such as anodizing or powder coating, to enhance corrosion resistance and aesthetic appeal. This step may also include the installation of electrical components, such as connectors and circuit boards. After finishing, the products are typically packaged for shipment, ensuring that they are protected during transport.

How Is Quality Assurance Implemented in the Manufacturing of Differential Pressure Switches?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that differential pressure switches are reliable and safe for use in various applications.

-

International and Industry-Specific Standards: Compliance with international standards such as ISO 9001 for quality management systems is essential. This standard helps manufacturers establish consistent quality in their processes. Additionally, industry-specific certifications such as CE for European markets or API for oil and gas applications may be required, depending on the application of the pressure switch.

-

Quality Control Checkpoints: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint assesses raw materials and components upon arrival. Suppliers must provide documentation proving compliance with relevant standards.

– In-Process Quality Control (IPQC): During manufacturing, periodic inspections ensure that processes are being followed correctly and that components are within specifications. Techniques such as statistical process control (SPC) may be employed to monitor production consistency.

– Final Quality Control (FQC): Once the assembly is complete, a thorough inspection is conducted. This includes functional testing, where the differential pressure switch is subjected to pressure testing to ensure it activates at the correct thresholds. -

Common Testing Methods: Various testing methods are utilized to verify the functionality and reliability of the pressure switches. These include:

– Functional Testing: Verifies that the switch operates correctly under specified conditions.

– Environmental Testing: Assesses how the switch performs under extreme temperatures, humidity, or corrosive environments.

– Electrical Testing: Ensures that electrical components function correctly and safely.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers maintain rigorous quality control processes. Here are several strategies for verification:

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should look for evidence of adherence to international standards and proper documentation practices.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand their quality control performance. These reports should include data on defect rates, inspection results, and compliance with relevant standards.

-

Third-Party Inspection: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. These inspections can cover various aspects, from raw material quality to final product testing.

-

Certifications and Compliance Documents: Buyers should verify that suppliers possess relevant certifications, such as ISO 9001, CE, or API. It is essential to review these documents regularly to ensure they remain valid and reflect the current practices of the supplier.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers operating in diverse markets like Africa, South America, the Middle East, and Europe, understanding the regional nuances in quality control is vital:

-

Regional Standards: Different regions may have specific regulations and standards governing pressure switches. For instance, the CE marking is crucial for products sold in the European Union, while UL certification might be necessary for North American markets. Buyers should familiarize themselves with these requirements to avoid compliance issues.

-

Cultural Considerations: Cultural differences can influence quality expectations and communication styles. Buyers should be aware of these nuances when negotiating with suppliers from different regions, ensuring that they establish clear quality expectations and standards.

-

Logistical Challenges: International shipping can pose challenges in maintaining product quality. Buyers should consider the potential impacts of transportation on product integrity and work with suppliers to implement protective packaging and handling procedures.

-

Building Relationships: Establishing strong relationships with suppliers can foster better communication and transparency regarding quality control practices. Regular interactions and feedback can help ensure that quality standards are consistently met.

In conclusion, understanding the manufacturing processes and quality assurance measures for differential pressure switches is essential for B2B buyers. By familiarizing themselves with these practices, buyers can make informed decisions and ensure they source reliable, high-quality products for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diff pressure switch’

When sourcing a differential pressure switch (diff pressure switch), it is essential to follow a structured approach to ensure you select the right product that meets your operational needs. This guide provides a comprehensive checklist to assist B2B buyers in navigating the procurement process effectively.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your differential pressure switch. Consider factors such as pressure range, media compatibility, and environmental conditions.

– Pressure Range: Ensure it meets your operational needs, whether measuring low or high pressures.

– Media Compatibility: Confirm that the materials used in the switch can handle the specific gases or liquids involved in your application.

Step 2: Identify Your Application Needs

Different applications may require different types of differential pressure switches. Clearly identify how you intend to use the switch, whether for HVAC systems, industrial processes, or air filter monitoring.

– Common Applications: Look for switches that are designed for your specific use case, such as static pressure proving or airflow monitoring.

– Field Adjustability: Consider models that allow for on-site adjustments, enhancing flexibility for varying operational conditions.

Step 3: Evaluate Potential Suppliers

Before making a purchase, it is crucial to vet potential suppliers thoroughly. Look for suppliers with a solid reputation in the industry and request company profiles, case studies, and references.

– Certifications: Ensure that the suppliers have relevant certifications (e.g., ISO, UL) that validate their quality standards.

– Customer Reviews: Seek feedback from clients in similar regions or industries to gauge the supplier’s reliability and product performance.

Step 4: Check Compliance and Safety Standards

Verify that the differential pressure switches comply with local and international safety standards. This is particularly important in industries like oil and gas or healthcare, where safety is paramount.

– Safety Ratings: Look for switches with explosion-proof or weatherproof ratings if used in hazardous environments.

– Regulatory Compliance: Ensure the products meet regulations specific to your region or industry to avoid legal issues.

Step 5: Request Product Samples

Whenever possible, request samples of the differential pressure switches you are considering. Testing a sample can provide invaluable insights into its performance and suitability for your application.

– Testing Conditions: Evaluate the switch under conditions that mimic your operational environment.

– Performance Metrics: Pay attention to response times, reliability, and ease of installation.

Step 6: Assess Warranty and After-Sales Support

A robust warranty and solid after-sales support can significantly impact the long-term value of your purchase. Confirm the terms of the warranty and the availability of technical support.

– Warranty Duration: Look for warranties that offer sufficient coverage to protect your investment.

– Technical Support: Ensure that the supplier provides accessible technical assistance for installation and troubleshooting.

Step 7: Compare Pricing and Payment Terms

Finally, compare pricing structures and payment terms from different suppliers. While cost is a critical factor, ensure that you are not compromising on quality or service.

– Total Cost of Ownership: Consider factors like installation costs, maintenance, and potential downtime when evaluating price.

– Flexible Payment Options: Look for suppliers who offer favorable payment terms that align with your budget and cash flow needs.

By following this checklist, B2B buyers can navigate the procurement process for differential pressure switches with confidence, ensuring they select the right product for their operational needs while fostering strong supplier relationships.

Illustrative image related to diff pressure switch

Comprehensive Cost and Pricing Analysis for diff pressure switch Sourcing

What Are the Key Cost Components in Differential Pressure Switch Sourcing?

When sourcing differential pressure switches, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of materials used directly influences the price. Components such as brass, stainless steel, and specific polymers for housing can vary significantly in cost. For example, a high-grade stainless steel switch may command a premium due to its durability and corrosion resistance.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, assembly, and testing. This can vary by region, with labor-intensive manufacturing processes likely incurring higher costs in developed countries compared to emerging markets.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses. Efficient manufacturing processes can help keep these costs down, impacting the overall pricing of the switches.

-

Tooling: Custom tooling for specific designs or high-volume production runs can add to initial costs. However, these costs may be amortized over large orders, reducing per-unit costs.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure product reliability, which can influence pricing. Higher QC standards typically lead to increased costs but result in better-performing products.

-

Logistics: Shipping and handling costs are influenced by the size and weight of the switches, as well as the distance to the buyer. International shipping can introduce additional costs, such as tariffs and customs duties.

-

Margin: Suppliers will add a markup to cover their costs and generate profit. This margin can vary based on competition, market demand, and the supplier’s positioning.

How Do Price Influencers Affect Differential Pressure Switch Costs?

Several factors can influence the pricing of differential pressure switches:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to significant discounts. Suppliers are more willing to negotiate prices for larger orders, making it essential for buyers to consider their long-term needs.

-

Specifications/Customization: Custom features or specific certifications (like UL or CE) can increase costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications for safety or environmental standards can elevate costs. Buyers must weigh the benefits of these features against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record and better customer service.

-

Incoterms: The chosen Incoterms can significantly affect total costs. For instance, terms like DDP (Delivered Duty Paid) can simplify logistics for buyers but may come with higher upfront costs.

What Buyer Tips Can Enhance Cost-Efficiency in Differential Pressure Switch Sourcing?

To maximize cost-efficiency, buyers should consider the following strategies:

-

Negotiation: Engage in negotiations to secure better pricing, especially for large orders. Suppliers may offer discounts or favorable payment terms to close deals.

-

Total Cost of Ownership (TCO): Assess the total cost, including installation, maintenance, and potential downtime. A cheaper switch may lead to higher long-term costs due to reliability issues.

-

Understanding Pricing Nuances: International buyers should be aware of exchange rates, shipping costs, and potential tariffs, which can affect the final price. Researching local suppliers may also yield better pricing options.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Consider long-term partnerships to negotiate favorable terms.

-

Market Research: Stay informed about market trends and pricing fluctuations. This knowledge can empower buyers to make timely purchases and avoid overpaying.

Disclaimer

The prices referenced in this analysis are indicative and can vary based on numerous factors, including market conditions, supplier negotiations, and specific project requirements. Buyers should conduct thorough research and request quotes tailored to their needs for accurate pricing.

Alternatives Analysis: Comparing diff pressure switch With Other Solutions

Exploring Alternatives to Differential Pressure Switches: What Are Your Options?

In the realm of pressure monitoring and control, differential pressure switches (DPS) are widely utilized for their reliability and precision. However, there are alternative solutions that can also meet the needs of industrial applications. Understanding these alternatives can help B2B buyers make informed decisions based on specific operational requirements and budget constraints.

Comparison Table of Differential Pressure Switch and Alternatives

| Comparison Aspect | Diff Pressure Switch | Pressure Transmitter | Pressure Sensor Module |

|---|---|---|---|

| Performance | High accuracy, reliable over a wide range of pressures | Very high accuracy, continuous monitoring | Good accuracy, suitable for less critical applications |

| Cost | Moderate ($84 – $98) | Higher ($200 – $500+) | Lower ($50 – $150) |

| Ease of Implementation | Generally easy, requires basic installation skills | More complex, may need calibration and programming | Easy, often plug-and-play |

| Maintenance | Low, periodic checks recommended | Moderate, requires calibration | Low, minimal intervention needed |

| Best Use Case | HVAC, industrial systems, air filtration | Process control, critical systems requiring constant monitoring | General applications, non-critical systems |

In-Depth Analysis of Alternatives

Pressure Transmitter

Pressure transmitters are advanced devices that provide continuous pressure readings and can convert physical pressure measurements into standardized electrical signals. Their high accuracy makes them suitable for critical applications, such as in process control and automation. However, they typically come at a higher price point and may require more complex installation and calibration processes. While they offer greater versatility in terms of output signals and integration with control systems, their complexity can be a drawback for smaller operations or those with less technical expertise.

Pressure Sensor Module

Pressure sensor modules are compact devices that measure pressure and are often used in a variety of applications, including automotive and HVAC systems. They are generally more affordable than differential pressure switches and transmitters, making them an attractive option for budget-conscious buyers. However, they may not provide the same level of accuracy or reliability in high-stakes environments. These modules are typically easy to install and require minimal maintenance, making them a practical choice for non-critical applications where high precision is not paramount.

Making the Right Choice for Your Business Needs

When evaluating the best solution for pressure monitoring, B2B buyers should consider their specific application requirements, budget constraints, and the level of expertise available for installation and maintenance. Differential pressure switches offer a reliable and moderately priced option for HVAC and industrial applications, while pressure transmitters excel in high-accuracy environments but come at a higher cost. Pressure sensor modules provide an economical choice for less critical applications but may lack the precision needed in more demanding settings.

Ultimately, the right choice will depend on balancing performance needs with financial considerations and operational complexity. By carefully assessing these factors, buyers can select the most suitable pressure monitoring solution for their unique business environment.

Essential Technical Properties and Trade Terminology for diff pressure switch

What Are the Key Technical Properties of Differential Pressure Switches?

Understanding the essential technical properties of differential pressure switches is crucial for B2B buyers, especially in industries like HVAC, oil and gas, and process control. Here are several key specifications that should be considered:

-

Measurement Range

This indicates the minimum and maximum differential pressure the switch can accurately measure, typically expressed in units such as inches of water column (inWC) or pascals (Pa). A broader measurement range allows for versatility across various applications, making it essential for buyers to match the switch to their specific operational requirements. -

Switch Rating

The switch rating defines the maximum electrical load the switch can handle. This is often specified in amperes (A) and voltage (V). Understanding the switch rating is critical to ensure the switch can safely operate within the electrical parameters of the system, preventing failures or hazards. -

Deadband

Deadband refers to the range of pressure change that must occur before the switch activates or deactivates. A smaller deadband allows for more precise control, which is vital in applications requiring fine-tuning. Buyers should evaluate the deadband according to the sensitivity needed in their operations. -

Operating Temperature

This specification outlines the maximum and minimum temperatures in which the pressure switch can function effectively. Operating temperature is vital for ensuring reliability, especially in extreme environments common in industries like petrochemicals or manufacturing. -

Materials of Construction

The materials used in the wetted components of the switch—those that come into contact with the media—are crucial for compatibility and durability. Common materials include brass, stainless steel, and various plastics. Buyers should consider material compatibility with the media being monitored to avoid corrosion and ensure longevity. -

Compliance and Certifications

Regulatory compliance (e.g., UL, CE, or ATEX certifications) indicates that the product meets specific safety and quality standards. Compliance is particularly important for international buyers, as it may impact market access and legal liability.

What Common Trade Terms Should B2B Buyers Know for Differential Pressure Switches?

Navigating the procurement process for differential pressure switches involves understanding various industry terms. Here are some common jargon and trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, understanding OEM relationships can impact sourcing decisions, especially regarding quality and warranty. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is crucial for buyers to consider, as it affects inventory costs and the ability to scale orders based on demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specified products. This process helps buyers compare pricing and terms across different vendors, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers for shipping and delivery. Understanding Incoterms is essential for international transactions to clarify who is responsible for costs and risks at various stages of transport. -

NEMA Ratings

NEMA ratings classify the environmental protection of electrical enclosures. For differential pressure switches, appropriate NEMA ratings ensure that the device is suited for the intended environment, whether it’s exposed to dust, moisture, or corrosive substances. -

Field Adjustable Setpoint

This term indicates that the user can easily adjust the pressure threshold at which the switch activates or deactivates. Field-adjustable setpoints are particularly advantageous for applications that require flexibility and quick reconfiguration without needing specialized tools.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing differential pressure switches, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the diff pressure switch Sector

What are the Key Market Dynamics and Trends Affecting Differential Pressure Switch Sourcing?

The differential pressure switch market is experiencing significant growth driven by various global factors, including industrial automation, increasing demand for HVAC systems, and the need for precise monitoring and control in various applications. As international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, navigate this landscape, understanding the emerging trends is critical.

One key trend is the shift towards smart technology integration. Companies are increasingly adopting Internet of Things (IoT) solutions that enable remote monitoring and control of differential pressure switches. This move not only enhances operational efficiency but also provides real-time data analytics, allowing for predictive maintenance and reduced downtime. Furthermore, the demand for customizable solutions is on the rise, as companies seek products that can be tailored to specific applications, from HVAC to industrial processes.

Another dynamic influencing the market is the growing focus on regulatory compliance and safety standards. Countries in Europe and the Middle East are implementing stringent regulations regarding environmental impact and safety, driving the demand for reliable and certified pressure switch solutions. Buyers must ensure that the products they source meet these regulatory requirements to avoid disruptions in their operations.

How is Sustainability and Ethical Sourcing Impacting the Differential Pressure Switch Industry?

Sustainability is becoming a cornerstone of B2B sourcing strategies in the differential pressure switch sector. Companies are increasingly aware of the environmental impact of their supply chains and are seeking suppliers who prioritize eco-friendly practices. This includes the use of recyclable materials, energy-efficient manufacturing processes, and adherence to environmental certifications.

Ethical sourcing is equally important, with buyers looking for suppliers that uphold fair labor practices and transparency in their operations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are gaining traction among B2B buyers. These standards not only enhance a company’s reputation but also align with the growing consumer preference for sustainable and ethically produced products.

In the context of differential pressure switches, sourcing from manufacturers that utilize green materials and processes can significantly reduce a company’s carbon footprint. Furthermore, integrating sustainable practices into the supply chain can lead to cost savings and improved operational efficiency, making it a strategic advantage for B2B buyers.

Illustrative image related to diff pressure switch

What is the Historical Evolution of Differential Pressure Switch Technology?

The differential pressure switch has evolved significantly since its inception in the early 20th century. Initially designed for simple pressure monitoring, these devices have transformed into sophisticated instruments capable of providing precise measurements and automation capabilities. The early mechanical designs relied on basic diaphragm technology, which has since advanced to incorporate electronic sensors and IoT connectivity.

As industries have developed, the applications of differential pressure switches have expanded across various sectors, including HVAC, automotive, and medical devices. The introduction of digital technology has further enhanced their functionality, allowing for greater accuracy, reliability, and ease of integration into modern systems. This evolution reflects the broader trends in industrial automation and the increasing demand for smart, efficient solutions in today’s competitive marketplace.

Understanding these trends and historical developments is crucial for B2B buyers looking to make informed sourcing decisions in the differential pressure switch sector. By aligning with innovative suppliers who embrace technology and sustainability, companies can enhance their operational capabilities while meeting regulatory and consumer demands.

Frequently Asked Questions (FAQs) for B2B Buyers of diff pressure switch

-

How do I choose the right differential pressure switch for my application?

Choosing the right differential pressure switch involves understanding your specific application requirements, including the pressure range, media compatibility, and environmental conditions. Consider factors such as the maximum and minimum pressure limits, whether the switch needs to handle gases or liquids, and if it requires explosion-proof or weatherproof features. Additionally, assess the mounting orientation and electrical connection types to ensure compatibility with your existing systems. Consulting product datasheets and seeking expert advice can further guide your selection process. -

What is the best differential pressure switch for HVAC applications?

For HVAC applications, look for differential pressure switches that offer precise pressure monitoring and adjustable setpoints. Models such as the BAPI Differential Pressure Switch or the Dwyer Series 1950 provide excellent performance, featuring built-in pressure snubbers for stable readings and robust enclosures for durability. Ensure that the switch can handle the specific pressure range required for your HVAC system, typically between 0.1” to 40” WC. Always verify that the switch is compliant with local regulations and standards. -

What are the typical lead times for ordering differential pressure switches internationally?

Lead times for international orders of differential pressure switches can vary significantly depending on the supplier’s location, production capacity, and shipping logistics. Typically, you can expect lead times ranging from two to eight weeks. It’s advisable to confirm these details with the supplier prior to placing an order. Additionally, factors such as customs clearance and local regulations may impact delivery times, so plan accordingly to avoid project delays. -

What customization options are available for differential pressure switches?

Many manufacturers offer customization options for differential pressure switches to meet specific application needs. Common customizations include adjusting the pressure range, modifying electrical connections, or adding features like alarms and visual indicators. Some suppliers may also provide bespoke enclosures or materials to suit harsh environments. It’s essential to discuss your requirements with the supplier early in the process to ensure that any modifications can be accommodated. -

What are the minimum order quantities (MOQ) for differential pressure switches?

Minimum order quantities for differential pressure switches can differ between manufacturers and product lines. Generally, MOQs can range from 10 to 100 units, depending on the complexity of the switch and the supplier’s production capabilities. For bulk orders, some suppliers might offer more favorable terms or discounts. Always inquire about MOQs upfront to align your purchasing strategy with your operational needs. -

How can I ensure the quality of differential pressure switches before purchasing?

To ensure quality, request detailed product specifications, certifications, and quality assurance processes from potential suppliers. Look for switches that comply with international standards such as ISO, CE, or UL. Additionally, consider asking for product samples or conducting site visits to assess manufacturing processes. Reviews and testimonials from other B2B buyers can also provide valuable insights into the reliability and performance of the switches. -

What payment terms should I expect when sourcing differential pressure switches internationally?

Payment terms for international purchases of differential pressure switches can vary widely among suppliers. Common terms include upfront payment, partial payment upon order confirmation, and balance before shipment. Some suppliers may also offer credit terms based on established relationships. It’s crucial to negotiate terms that align with your budget and cash flow needs while ensuring that you maintain a secure transaction process. -

What logistics considerations should I keep in mind when importing differential pressure switches?

When importing differential pressure switches, consider factors such as shipping methods, customs duties, and local regulations. Evaluate whether air or sea freight is more cost-effective based on your urgency and budget. Additionally, ensure that the supplier provides all necessary documentation, including invoices, packing lists, and certificates of origin, to facilitate smooth customs clearance. Partnering with a reliable logistics provider can help navigate these complexities and ensure timely delivery.

Top 6 Diff Pressure Switch Manufacturers & Suppliers List

1. BAPI – Differential Pressure Switch

Domain: bapihvac.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Differential Pressure Switch”, “Price Range”: “$84.00 – $98.00”, “Pressure Range Options”: [“0.1” to 0.8” WC (20 to 200 Pa)”, “0.5” to 1.2” WC (120 to 300 Pa)”, “0.7” to 2.2” WC (180 to 550 Pa)”, “3.2” to 10.4” WC (800 to 2600 Pa)”, “8.8” to 24” WC (2200 to 6000 Pa)”, “12” to 40” WC (3000 to 10000 Pa)”], “Setpoint Adjustment”: “Field adjustable from 0.1” to 40” WC (20 to 10,000 P…

2. Alps Controls – Differential Pressure Switches

Domain: alpscontrols.com

Registered: 2000 (25 years)

Introduction: Differential Pressure Switches from Alps Controls include various specifications such as setpoint ranges (e.g., 0.00..0.05 w.c. to 50.00..500.00 psi), connection types (e.g., 0.125 IN. FEMALE NPT, 0.50 IN. FEMALE NPT), switch types (e.g., DPDT, SPDT, SPST), and reset types (e.g., automatic, manual). The products cater to multiple mediums including air, gas, and liquid, and are available from vario…

3. Carrier – Differential Pressure Switches NSA-DIFFER

Domain: carrier.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Differential Pressure Switches NSA-DIFFER”, “Part Numbers”: [“NSA-AFS-222”, “NSA-AFS-262”, “NSA-AFS-460”], “Applications”: [“Monitoring Filter Blockage”, “Proof of Flow”, “Prove Excessive or Insufficient Flow”, “Alarms and Control”], “Specifications”: {“Input Pressure Range”: {“NSA-AFS-222”: “0.05 +/- 0.02\” to 12\” wc”, “NSA-AFS-262”: “0.05 +/- 0.02\” to 2.0\” wc”, “NSA-AFS-460″…

4. McMaster – Differential Pressure Solutions

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Differential Pressure Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Neodyn – 152P8 Hazardous Rated Differential Pressure Switch

Domain: neodyn.com

Registered: 1997 (28 years)

Introduction: Industrial Differential Switches:

1. **152P8 Hazardous Rated Differential Pressure Switch**

– Type: Ultra low adjustable hazardous rated differential pressure switch

– Features: Unique construction using Nega-Rate® Belleville disc spring for stable set points and high proof pressure

– Applications: Suitable for applications that formerly required diaphragm seals

2. **152P NEMA 4…

6. Wika – DPS40 Differential Pressure Switch

Domain: wika.com

Registered: 1996 (29 years)

Introduction: Model: DPS40 Differential pressure switch DELTA-switch. Applications: Monitoring and control of filters, compressors, and pumps for boilers and pressure vessels, drinking and cooling-water treatment plants, pressure-boosting and pumping stations, heating technology, fire-extinguishing systems. Features: One or two adjustable micro switches, shatterproof window, robust aluminium or stainless steel …

Strategic Sourcing Conclusion and Outlook for diff pressure switch

What Are the Key Insights for Strategic Sourcing of Differential Pressure Switches?

In the evolving landscape of industrial automation and HVAC applications, differential pressure switches have emerged as critical components for ensuring operational efficiency and safety. By strategically sourcing these devices, international buyers can not only optimize their supply chains but also enhance the reliability of their systems. Key considerations include understanding the specific application requirements, such as pressure ranges, media compatibility, and compliance with regional standards, particularly in diverse markets across Africa, South America, the Middle East, and Europe.

The value of strategic sourcing lies in leveraging supplier relationships to access high-quality products that offer durability and precision. Buyers should prioritize suppliers that provide customizable options and robust support services, ensuring that the selected pressure switches can adapt to varying operational conditions.

Illustrative image related to diff pressure switch

As we look to the future, it’s imperative for businesses to remain proactive in their sourcing strategies. By staying informed about technological advancements and market trends, B2B buyers can secure a competitive edge. Engage with trusted suppliers to explore innovative solutions and elevate your operational capabilities. The right differential pressure switch is not just a component; it’s an investment in your business’s efficiency and safety.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.