A Deep Dive into Cuisinart Defrosting Tray Solution

Introduction: Navigating the Global Market for cuisinart defrosting tray

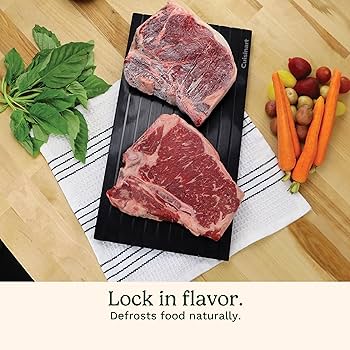

In the fast-paced world of food preparation and safety, sourcing the right tools can be a daunting challenge for B2B buyers, particularly when it comes to products like the Cuisinart defrosting tray. With the increasing demand for efficient kitchen solutions that enhance food safety and streamline operations, understanding the features, benefits, and applications of such tools is crucial. This comprehensive guide will explore the various types of defrosting trays, their practical applications in both commercial and domestic settings, supplier vetting processes, and cost considerations, empowering buyers to make informed purchasing decisions.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe navigate the competitive landscape, the importance of reliable kitchen equipment becomes even more pronounced. The Cuisinart defrosting tray, known for its food-safe aluminum construction and efficiency in reducing defrosting time, exemplifies the kind of innovative solutions that can enhance kitchen operations. By addressing key factors such as supplier reliability, product quality, and compliance with local food safety standards, this guide aims to equip buyers with the necessary insights to confidently select the best products for their unique needs.

Ultimately, understanding the market dynamics surrounding the Cuisinart defrosting tray will not only streamline procurement processes but also ensure that businesses can meet consumer demands effectively and safely.

Understanding cuisinart defrosting tray Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Aluminum Tray | Made of food-safe aluminum; lightweight | Small restaurants, home kitchens | Pros: Affordable, easy to clean. Cons: May not be suitable for large volumes. |

| BBQ Defrosting Tray | Nonstick surface; designed for outdoor cooking | Catering services, outdoor events | Pros: Ideal for grilling; easy to store. Cons: Limited to outdoor use. |

| Large Commercial Tray | Extra-large size; designed for bulk defrosting | Food service operations, large kitchens | Pros: Handles larger quantities; durable. Cons: Higher cost, requires more storage space. |

| Multi-Purpose Defrosting Tray | Versatile design; can also be used for warming foods | Catering, food preparation facilities | Pros: Multi-functional; saves space. Cons: May not perform as well for dedicated tasks. |

| Eco-Friendly Tray | Made from sustainable materials; biodegradable | Eco-conscious businesses, health food stores | Pros: Appeals to green consumers; good for branding. Cons: Typically more expensive. |

What are the Characteristics of the Standard Aluminum Tray?

The standard aluminum Cuisinart defrosting tray is lightweight and made of food-safe materials, making it a popular choice for small restaurants and home kitchens. This type is designed for quick thawing of meats and other frozen foods, promoting efficiency in food preparation. B2B buyers should consider its affordability and ease of cleaning, although it may not accommodate larger volumes of food, limiting its use in high-demand environments.

Why Choose the BBQ Defrosting Tray for Outdoor Events?

The BBQ defrosting tray features a nonstick surface specifically designed for outdoor cooking scenarios. It is ideal for catering services and outdoor events, allowing chefs to quickly prepare frozen meats for grilling. This tray’s compact design makes it easy to store, but potential buyers should note that its functionality is limited to outdoor use, which may not suit all business models.

What Advantages Does the Large Commercial Tray Offer?

The large commercial Cuisinart defrosting tray is designed for bulk defrosting, catering to food service operations and large kitchens. Its extra-large size allows for handling significant quantities of frozen food, enhancing workflow efficiency. While it is durable and effective for high-volume needs, B2B buyers should weigh its higher cost and the requirement for ample storage space against their operational demands.

How Can a Multi-Purpose Defrosting Tray Benefit Your Business?

The multi-purpose defrosting tray is versatile, suitable for defrosting as well as warming foods. This adaptability makes it an excellent choice for catering and food preparation facilities, where space and equipment versatility are crucial. Although it saves space and offers multifunctionality, buyers should consider that it may not perform as effectively for specific tasks compared to dedicated trays.

What Makes the Eco-Friendly Tray a Smart Choice?

Eco-friendly Cuisinart defrosting trays are made from sustainable materials and are biodegradable, appealing to eco-conscious businesses and health food stores. These trays align with the growing consumer demand for environmentally responsible products, enhancing brand reputation. However, potential buyers should be aware that these trays typically come at a higher price point, necessitating a careful cost-benefit analysis for budget-conscious operations.

Key Industrial Applications of cuisinart defrosting tray

| Industry/Sector | Specific Application of cuisinart defrosting tray | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Rapid defrosting of proteins for restaurants and catering events | Decreases wait time, improves service efficiency | Ensure food-safe materials, evaluate size for batch processing |

| Grocery Retail | In-store defrosting demonstrations for frozen food sections | Enhances customer experience, promotes product sales | Look for durable designs, assess ease of cleaning and storage |

| Hospitality | Quick defrosting for banquet and event preparation | Streamlines kitchen operations, supports meal quality | Consider compliance with health regulations, evaluate portability |

| Meal Kit Delivery Services | Efficient thawing of ingredients for meal preparation | Reduces preparation time, ensures ingredient freshness | Assess compatibility with diverse meal types, focus on size and weight |

| Food Processing Facilities | Thawing of bulk meat for processing and packaging | Improves workflow efficiency, minimizes spoilage risk | Evaluate volume capacity, prioritize easy cleaning features |

How is the Cuisinart Defrosting Tray Used in Food Service?

In the food service industry, the Cuisinart defrosting tray is employed to quickly thaw proteins such as meats and seafood, which is crucial during peak hours or for catering events. By significantly reducing defrosting time by 30-40%, it enhances service efficiency and allows chefs to maintain a continuous workflow. International buyers should consider the tray’s size and food-safe materials to ensure compliance with local health regulations and ease of use in high-volume settings.

What Role Does the Cuisinart Defrosting Tray Play in Grocery Retail?

Grocery retailers utilize the Cuisinart defrosting tray to conduct in-store demonstrations, showcasing the convenience of defrosting frozen products. This application not only improves customer engagement but also promotes sales of frozen items by highlighting their ease of use. For sourcing, retailers should prioritize durable designs that can withstand frequent use and easy cleaning, ensuring they can maintain hygiene standards while providing a positive shopping experience.

How Can the Cuisinart Defrosting Tray Benefit the Hospitality Sector?

In the hospitality sector, the Cuisinart defrosting tray is essential for quickly thawing ingredients needed for banquets and large events. It streamlines kitchen operations by allowing staff to prepare meals efficiently without compromising on quality. Buyers in this sector must ensure that the tray complies with food safety regulations and is portable enough to be moved around different kitchen stations, enhancing its utility in various settings.

How Does the Cuisinart Defrosting Tray Assist Meal Kit Delivery Services?

Meal kit delivery services benefit from the Cuisinart defrosting tray by using it to efficiently thaw ingredients before assembly. This application is vital for ensuring that ingredients remain fresh and are ready for packaging and delivery. When sourcing, companies should focus on the tray’s compatibility with a variety of meal types and consider its size and weight to optimize storage and transportation logistics.

Why is the Cuisinart Defrosting Tray Useful in Food Processing Facilities?

Food processing facilities use the Cuisinart defrosting tray to thaw bulk meat products before processing and packaging. This application enhances workflow efficiency and minimizes spoilage risk, which is critical in maintaining product quality. Buyers should evaluate the tray’s volume capacity and prioritize features that facilitate easy cleaning, as hygiene is paramount in food processing environments.

3 Common User Pain Points for ‘cuisinart defrosting tray’ & Their Solutions

Scenario 1: Ensuring Food Safety During Defrosting

The Problem: One of the primary concerns for B2B buyers, especially those in the food service and hospitality industries, is food safety. The Cuisinart defrosting tray can expedite the defrosting process, but if not used correctly, it can create a hazardous environment for food. Bacteria can proliferate if proteins are left in the temperature danger zone (40°F to 140°F) for too long, leading to potential health risks and liability issues for businesses.

The Solution: To ensure food safety while using the Cuisinart defrosting tray, it is essential to implement strict monitoring protocols. Buyers should invest in digital thermometers to regularly check the internal temperature of the food being defrosted. It is advisable to limit the defrosting time to no more than four hours and to prioritize defrosting smaller cuts of meat that will thaw more evenly. Additionally, businesses should educate their staff on proper usage guidelines, emphasizing the importance of avoiding prolonged exposure to the danger zone. Proper training on defrosting practices not only enhances food safety but also protects the reputation of the business.

Scenario 2: Managing Storage and Space Constraints

The Problem: Many commercial kitchens operate with limited space, making it challenging to store additional kitchen gadgets like the Cuisinart defrosting tray. Without a designated storage area, these trays can become a nuisance, cluttering countertops and leading to inefficiencies in the kitchen workflow. This is especially true for businesses that need to maximize their operational footprint.

The Solution: The Cuisinart defrosting tray is designed with a slim profile that allows for convenient storage, but it is vital to plan its placement strategically. Buyers should consider dedicated, easily accessible storage solutions that integrate well into existing kitchen layouts, such as under-counter shelving or wall-mounted racks. Furthermore, implementing a designated area in the kitchen for tools that require quick access can streamline operations. This way, the defrosting tray can be utilized effectively without compromising space efficiency, allowing staff to focus on food preparation without distraction.

Scenario 3: Overcoming Misconceptions About Defrosting Methods

The Problem: There is often confusion surrounding the best methods for defrosting food, with some staff members believing that using a tray like the Cuisinart defrosting tray is the only or best option. This misconception can lead to improper defrosting practices that may not align with food safety standards and best practices in the culinary industry.

The Solution: To combat this misunderstanding, B2B buyers should prioritize comprehensive training programs for their staff. This training should cover various defrosting methods, including safe practices such as refrigeration and cold running water. Emphasizing the strengths of the Cuisinart defrosting tray as a convenient tool for specific scenarios, rather than a one-size-fits-all solution, can help staff make informed decisions in the kitchen. Moreover, providing clear guidelines on when to use the tray (e.g., for small cuts of meat) versus other methods can enhance efficiency and safety. Regular refresher courses can further instill best practices and ensure that all team members are aligned on food safety protocols.

By addressing these common pain points with targeted solutions, B2B buyers can enhance their operational efficiency, ensure food safety, and optimize the use of the Cuisinart defrosting tray in their kitchens.

Strategic Material Selection Guide for cuisinart defrosting tray

What Are the Key Materials Used in Cuisinart Defrosting Trays?

When evaluating the materials used in Cuisinart defrosting trays, several options stand out, primarily aluminum, stainless steel, silicone, and plastic. Each material presents unique properties, advantages, and disadvantages that can significantly impact product performance and suitability for various markets.

How Does Aluminum Perform in Cuisinart Defrosting Trays?

Aluminum is a popular choice for defrosting trays due to its excellent thermal conductivity. This property allows for rapid heat transfer, enabling food to defrost quickly. Aluminum trays are typically lightweight, making them easy to handle and store. However, they can be prone to corrosion if not properly coated or treated, particularly in humid environments.

Pros:

– High thermal conductivity for quick defrosting.

– Lightweight and easy to handle.

– Generally cost-effective.

Cons:

– Susceptible to corrosion without proper treatment.

– May not be suitable for acidic foods which can react with the metal.

For international buyers, especially in regions like Africa and South America, it’s essential to ensure that the aluminum used meets local food safety standards, such as those outlined by the FDA or EFSA. Compliance with standards like ASTM for material quality can also be crucial.

What Advantages Does Stainless Steel Offer for Defrosting Trays?

Stainless steel is another common material for defrosting trays, known for its durability and resistance to corrosion and staining. This material is particularly advantageous in commercial kitchens where longevity and hygiene are paramount. Stainless steel trays can withstand high temperatures and are dishwasher safe, making them easy to clean.

Pros:

– Highly durable and resistant to corrosion.

– Non-reactive, suitable for all food types.

– Easy to clean and maintain.

Cons:

– Heavier than aluminum, which may affect handling.

– Generally more expensive than aluminum.

For B2B buyers in Europe, such as those in Germany, adherence to DIN standards for stainless steel quality is vital. Buyers should also consider the environmental impact of stainless steel production and whether the supplier practices sustainable sourcing.

How Does Silicone Enhance the Functionality of Defrosting Trays?

Silicone is a flexible material that offers unique advantages for defrosting trays. It is non-stick, making it easy to remove food without sticking, and it can withstand a wide range of temperatures. Silicone trays are also lightweight and easy to store, but they may not conduct heat as efficiently as metal options.

Pros:

– Non-stick surface for easy food release.

– Flexible and lightweight for easy storage.

– Temperature resistant, suitable for various uses.

Cons:

– Lower thermal conductivity compared to metal.

– May not provide the same level of durability as aluminum or stainless steel.

International buyers should verify that the silicone used is food-grade and compliant with relevant safety standards, such as FDA regulations. Understanding local preferences for materials can also guide purchasing decisions, especially in markets that value eco-friendly products.

What Role Does Plastic Play in Cuisinart Defrosting Trays?

Plastic is often used in lower-cost defrosting trays, offering a lightweight and versatile option. While plastic trays are easy to manufacture and can be made in various colors and designs, they may not provide the same level of durability or heat conductivity as metal options. Additionally, some plastics can warp under high temperatures.

Pros:

– Cost-effective and lightweight.

– Available in various designs and colors.

Cons:

– Less durable than metal options.

– Potential for warping at high temperatures.

For buyers in the Middle East or Africa, it’s crucial to ensure that any plastic used is BPA-free and meets local safety regulations. Compliance with standards like JIS for plastic quality can also be a deciding factor.

Summary Table of Material Properties

| Material | Typical Use Case for Cuisinart Defrosting Tray | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Home and commercial kitchens for quick defrosting | High thermal conductivity for rapid defrosting | Susceptible to corrosion without treatment | Medium |

| Stainless Steel | Professional kitchens requiring durability | Highly durable and non-reactive | Heavier and generally more expensive | High |

| Silicone | Home kitchens for easy food release | Non-stick and flexible for easy storage | Lower thermal conductivity compared to metals | Medium |

| Plastic | Budget-friendly options for casual use | Lightweight and cost-effective | Less durable and may warp under heat | Low |

This analysis provides a comprehensive overview of the materials used in Cuisinart defrosting trays, enabling B2B buyers to make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cuisinart defrosting tray

What Are the Main Stages in the Manufacturing Process of a Cuisinart Defrosting Tray?

The manufacturing process for a Cuisinart defrosting tray involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring that the final product meets quality and safety standards.

-

Material Preparation: The primary material used for the Cuisinart defrosting tray is food-safe aluminum. This metal is selected for its excellent thermal conductivity, which facilitates efficient defrosting. In this stage, aluminum sheets are procured, and any necessary pre-treatment processes, such as cleaning and surface preparation, are conducted to ensure optimal adhesion and performance.

-

Forming: The forming process typically involves techniques such as die-cutting or stamping to shape the aluminum into the desired tray configuration. Precision is paramount in this stage to create trays with uniform dimensions and surface characteristics, which directly affect their thermal performance and usability.

-

Assembly: For the Cuisinart defrosting tray, assembly may include integrating non-stick coatings to enhance usability and facilitate easy cleaning. This process often involves applying a non-toxic, food-safe coating to the tray’s surface, followed by curing at controlled temperatures to ensure durability.

-

Finishing: The finishing stage involves polishing and inspection. The trays undergo a thorough quality check to identify any defects in surface finish or structural integrity. This stage ensures that the final product not only looks appealing but also meets the functional requirements of consumers.

Which Quality Control Standards Are Relevant for Cuisinart Defrosting Trays?

Quality assurance is crucial in the manufacturing of kitchen products, especially those that come into direct contact with food. Cuisinart defrosting trays adhere to several international and industry-specific quality control standards.

-

ISO 9001 Certification: This international standard focuses on quality management systems and is essential for manufacturers aiming to ensure consistent quality in their products. Compliance with ISO 9001 indicates that the manufacturer has established effective processes for production and quality assurance.

-

CE Marking: For products sold in Europe, CE marking signifies compliance with European safety, health, and environmental protection standards. This certification is vital for gaining access to European markets and assures buyers that the product meets all regulatory requirements.

-

FDA Compliance: In the United States, kitchenware that comes into contact with food must comply with FDA regulations, ensuring that materials used are safe and non-toxic. This compliance is crucial for global B2B buyers, particularly those importing goods into North America.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is embedded at multiple checkpoints throughout the manufacturing process of Cuisinart defrosting trays. These checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Ensuring that the aluminum and any other materials meet specified quality standards is essential to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During the forming and assembly stages, IPQC measures monitor various parameters, such as temperature, humidity, and adherence to design specifications. Regular checks help to catch any deviations early, minimizing waste and ensuring that production runs smoothly.

-

Final Quality Control (FQC): Once the trays are fully assembled and finished, they undergo FQC, which includes visual inspections, dimensional checks, and functional tests. This stage ensures that each tray meets the required specifications and is free of defects before packaging and shipping.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control practices of suppliers is essential to ensure product integrity and compliance with local regulations. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide invaluable insights into their manufacturing processes and quality control measures. This firsthand evaluation allows buyers to assess the adherence to international standards and the overall operational capabilities of the supplier.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the outcomes of various quality checks performed throughout the manufacturing process. These reports should include information about defect rates, compliance with standards, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an objective evaluation of the supplier’s quality control practices. These inspections can be scheduled at different stages of production to ensure that the trays meet the specified standards before shipment.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

For B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is critical. Here are some considerations:

-

Regional Compliance Requirements: Different regions may have varying compliance requirements. For example, while CE marking is essential for European markets, buyers in the Middle East may need to consider GCC standards. Understanding these regional differences helps buyers ensure compliance and avoid potential penalties.

-

Cultural Sensitivity in Quality Expectations: Cultural perceptions of quality can vary significantly between regions. Buyers from Europe may prioritize rigorous testing and certification, while those in emerging markets may focus more on cost-effectiveness. Understanding these nuances can aid in selecting suppliers that align with specific market expectations.

-

Documentation and Traceability: Ensuring that suppliers provide adequate documentation for all quality control measures is crucial for traceability and accountability. B2B buyers should insist on clear records of all inspections, test results, and certifications to facilitate smooth import processes and adherence to local regulations.

By understanding the manufacturing processes and quality assurance measures associated with Cuisinart defrosting trays, B2B buyers can make informed decisions and ensure that they source high-quality products that meet their operational needs and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cuisinart defrosting tray’

The following guide serves as a practical checklist for B2B buyers interested in procuring the Cuisinart defrosting tray. This step-by-step approach will help you navigate the sourcing process effectively, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to meet your operational requirements. Consider factors such as size, material (food-safe aluminum is ideal), and non-stick properties, which facilitate easy cleaning. Knowing your specifications will help you communicate effectively with suppliers and streamline the selection process.

Step 2: Research Market Trends and Demand

Understanding current market trends can provide insights into the demand for the Cuisinart defrosting tray in your target regions. Analyze sales data, consumer preferences, and competitor offerings to identify opportunities. This step is vital for positioning your product effectively and forecasting inventory needs.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request detailed company profiles, product catalogs, and references from other businesses in your industry. Pay attention to their production capabilities and lead times, as these can significantly impact your supply chain efficiency.

Step 4: Verify Supplier Certifications

Confirm that suppliers hold relevant certifications that demonstrate compliance with food safety standards and quality assurance. Certifications such as ISO 9001 or local food safety regulations ensure that the products meet necessary safety and quality benchmarks. This verification helps mitigate risks associated with product recalls or safety incidents.

Step 5: Request Samples for Testing

Before finalizing your purchase, request samples of the Cuisinart defrosting tray for testing. Evaluate the product’s performance, durability, and safety features to ensure it aligns with your quality standards. This hands-on assessment can prevent costly mistakes and dissatisfaction post-purchase.

Step 6: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that the terms align with your budget and cash flow requirements. Don’t hesitate to discuss volume discounts or promotional offers, especially if you plan to order in bulk.

Step 7: Establish a Long-Term Partnership

After the initial procurement, focus on building a long-term relationship with your supplier. Regular communication and feedback can enhance collaboration and ensure consistent quality. Consider establishing a performance review process to evaluate the supplier’s service and product quality periodically.

By following this checklist, B2B buyers can streamline their sourcing process for the Cuisinart defrosting tray, ensuring they make informed decisions that contribute to their operational success.

Comprehensive Cost and Pricing Analysis for cuisinart defrosting tray Sourcing

What Are the Key Cost Components for Sourcing Cuisinart Defrosting Trays?

When analyzing the cost structure for sourcing Cuisinart defrosting trays, several key components come into play:

-

Materials: The primary material used for Cuisinart defrosting trays is food-safe aluminum, which offers both durability and an eco-friendly profile. The cost of aluminum fluctuates based on market demand and global supply chain conditions. Buyers should also consider any surface treatments or coatings that may enhance non-stick properties, which could add to material costs.

-

Labor: Labor costs will vary depending on the country of manufacture. In regions with lower labor costs, such as parts of Asia or South America, the overall production cost may be reduced. However, it is essential to ensure that labor practices meet international labor standards to avoid potential reputational risks.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and factory management. Manufacturers with higher overhead costs might pass these onto buyers, making it crucial to assess the production facilities of potential suppliers.

-

Tooling: Custom tooling may be required if any modifications or specific designs are requested. This upfront investment can significantly affect the cost structure, especially for smaller order volumes.

-

Quality Control (QC): Implementing a robust QC process ensures product safety and compliance with food safety standards. This may involve additional costs but is critical for maintaining product integrity, especially when entering markets with stringent regulations.

-

Logistics: Transportation costs can vary widely based on shipping methods, distances, and current fuel prices. Additionally, customs duties and tariffs should be factored in for international shipments, particularly for buyers in Africa, South America, the Middle East, and Europe.

-

Margin: Supplier margins can vary significantly based on brand reputation, exclusivity, and market positioning. Buyers should be aware of potential markups associated with branded products like Cuisinart, which can impact the final pricing.

How Do Price Influencers Affect Cuisinart Defrosting Tray Costs?

Several factors influence the pricing of Cuisinart defrosting trays beyond the basic cost components:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders typically lead to better per-unit pricing, allowing buyers to negotiate more favorable terms.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should consider whether standard options meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials or certifications (such as food safety certifications) can drive up costs but may be necessary for compliance in certain markets. Buyers should weigh the importance of certifications against potential cost increases.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their products, but they often provide better support and quality assurance.

-

Incoterms: Understanding the Incoterms used in international shipping is critical. They define the responsibilities of buyers and sellers in the shipping process and can affect total costs significantly.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing Cuisinart Defrosting Trays?

-

Negotiation: Always approach suppliers with a clear understanding of your requirements and market pricing. This knowledge empowers buyers to negotiate better terms, especially for larger orders.

-

Cost-Efficiency: Evaluate the total cost of ownership, not just the purchase price. Consider factors such as durability, maintenance, and potential replacement costs when assessing the overall value.

-

Pricing Nuances for International Buyers: International buyers should be aware of potential fluctuations in shipping costs, tariffs, and exchange rates. Establishing relationships with local distributors can also reduce costs and simplify logistics.

-

Market Research: Conduct thorough market research to understand pricing trends and competitor offerings. This can provide leverage in negotiations and ensure you secure the best possible deal.

-

Quality Assurance: Prioritize suppliers with strong quality assurance processes. Investing in quality may incur higher upfront costs but can prevent losses related to product returns or customer dissatisfaction.

Disclaimer: Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and other influencing factors. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing cuisinart defrosting tray With Other Solutions

When considering the Cuisinart Defrosting Tray, it is essential for B2B buyers to evaluate alternative methods and technologies that can achieve similar defrosting results. Different solutions vary in performance, cost, ease of implementation, and maintenance requirements, which can significantly influence purchasing decisions in a commercial context. Below is a comparative analysis of the Cuisinart Defrosting Tray against two alternative solutions: the traditional refrigerator defrosting method and microwave defrosting.

| Comparison Aspect | Cuisinart Defrosting Tray | Traditional Refrigerator Defrosting | Microwave Defrosting |

|---|---|---|---|

| Performance | Reduces defrosting time by 30-40% | Slow; depends on size and type of meat | Fast but uneven results |

| Cost | Approximately $22-26 | No additional cost | Varies by microwave model |

| Ease of Implementation | Simple; requires no setup | Requires planning ahead | Requires monitoring |

| Maintenance | Easy to clean; nonstick surface | No maintenance required | Requires regular cleaning |

| Best Use Case | Quick defrosting for small to medium cuts | Ideal for large cuts; safe and controlled | Quick defrost for small portions |

What Are the Advantages and Disadvantages of Using a Traditional Refrigerator for Defrosting?

The traditional refrigerator method is widely recognized as the safest and most effective way to defrost food. It keeps food out of the temperature danger zone, minimizing the risk of bacterial growth. However, this method requires advanced planning, as defrosting can take several hours to a day, especially for larger proteins. For businesses that operate on a tight schedule, this delay may be impractical.

How Does Microwave Defrosting Compare to the Cuisinart Defrosting Tray?

Microwave defrosting is a rapid option that can save time, particularly for smaller cuts of meat. However, it often leads to uneven thawing, where parts of the meat may begin cooking while others remain frozen. This can compromise food quality and safety if not monitored carefully. Additionally, some microwaves have specific settings for defrosting, which may not always yield optimal results. In contrast, the Cuisinart Defrosting Tray offers a more consistent performance without the risks associated with microwaving.

Conclusion: Which Defrosting Method Should B2B Buyers Choose?

Choosing the right defrosting solution depends on the specific needs of the business. For operations requiring speed and convenience, the Cuisinart Defrosting Tray stands out as an effective tool, particularly for smaller cuts of meat. However, for larger proteins or when food safety is a primary concern, the traditional refrigerator method remains the best practice. On the other hand, microwave defrosting can serve as a practical option for quick, small portions but may compromise quality. B2B buyers should carefully assess their operational workflow, food safety standards, and cost considerations to determine which defrosting method aligns best with their culinary processes.

Essential Technical Properties and Trade Terminology for cuisinart defrosting tray

What Are the Key Technical Properties of the Cuisinart Defrosting Tray?

-

Material Composition: The Cuisinart defrosting tray is primarily made from food-safe aluminum. This material is critical as it ensures the tray is safe for direct contact with food items. Aluminum is known for its excellent thermal conductivity, which allows the tray to absorb heat from the surrounding environment and transfer it to the food, effectively speeding up the defrosting process. For B2B buyers, selecting products made from safe, high-quality materials is essential for ensuring consumer safety and compliance with health regulations.

-

Nonstick Surface: The tray features a nonstick coating, which simplifies the cleaning process and reduces food residue. This property is particularly important for businesses that prioritize efficiency and hygiene in food preparation. A nonstick surface minimizes the risk of cross-contamination, making it easier to maintain food safety standards in commercial kitchens.

-

Dimensions and Design: The slim design of the Cuisinart defrosting tray allows for easy storage in limited kitchen spaces. Its dimensions are optimized for both functionality and convenience, accommodating various sizes of food items, from smaller cuts of meat to larger poultry. For B2B purchasers, understanding the spatial requirements of kitchen equipment is crucial for effective inventory management and operational efficiency.

-

Thermal Efficiency: The tray’s design is engineered to enhance thermal efficiency, reportedly cutting defrosting time by 30% to 40%. This feature is vital for businesses aiming to optimize food preparation times, which can lead to improved customer satisfaction and reduced operational costs. B2B buyers should consider how product efficiency can impact overall productivity and service delivery in their establishments.

-

Eco-Friendly Attributes: The tray’s manufacturing process and materials are designed with environmental considerations in mind, appealing to businesses that are committed to sustainability. Choosing eco-friendly products can enhance a company’s brand reputation and align with consumer preferences for environmentally responsible products.

What Common Trade Terms Should B2B Buyers Know When Purchasing a Cuisinart Defrosting Tray?

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers seeking quality assurance and brand reliability in kitchen equipment like the Cuisinart defrosting tray.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps businesses plan their purchases to optimize inventory and ensure they meet demand without overstocking.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of goods. B2B buyers should use RFQs to gather competitive pricing for the Cuisinart defrosting tray, enabling them to make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is critical for B2B buyers engaged in international transactions to mitigate risks associated with shipping and delivery.

-

Lead Time: This term refers to the amount of time from when an order is placed until it is received. Understanding lead times is crucial for inventory management and ensuring that businesses can meet customer demands without delays.

-

Warranty and Return Policy: These terms outline the manufacturer’s guarantee regarding product defects and the conditions under which a product can be returned. Knowledge of warranty and return policies is vital for buyers to protect their investments and ensure long-term satisfaction with their purchases.

In summary, understanding both the technical properties and the relevant trade terminology for the Cuisinart defrosting tray equips B2B buyers with the knowledge necessary to make informed purchasing decisions that align with their operational needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the cuisinart defrosting tray Sector

What Are the Current Market Dynamics and Key Trends Affecting Cuisinart Defrosting Tray Sales?

The global kitchenware market is experiencing significant growth, driven by evolving consumer preferences and the increasing popularity of convenience-oriented cooking solutions. In particular, the Cuisinart defrosting tray is gaining traction as a time-saving tool for both home and professional kitchens. One of the major drivers of this trend is the rising demand for products that streamline meal preparation, particularly among busy professionals and families in regions such as Africa, South America, the Middle East, and Europe. As e-commerce continues to expand, international B2B buyers are increasingly sourcing these products online, enhancing their procurement strategies and improving access to a broader range of kitchen tools.

Technological advancements are also shaping the market. Smart kitchen devices are becoming more prevalent, with features that enhance food safety and efficiency. This trend presents opportunities for suppliers to innovate, integrating temperature monitoring capabilities into defrosting solutions. Additionally, the growing interest in culinary arts, spurred by social media and cooking shows, is further fueling the demand for specialized kitchen tools like the Cuisinart defrosting tray. For international buyers, understanding these dynamics is essential for making informed sourcing decisions and aligning with market trends.

How Is Sustainability and Ethical Sourcing Reshaping the Cuisinart Defrosting Tray Market?

Sustainability has emerged as a crucial consideration for B2B buyers in the kitchenware sector. The environmental impact of products, including the Cuisinart defrosting tray, is under scrutiny, making it essential for suppliers to prioritize eco-friendly materials and practices. The use of food-safe aluminum in the Cuisinart tray is a positive step towards sustainability, as aluminum is recyclable and has a lower environmental footprint compared to other materials.

Ethical sourcing is also gaining importance, particularly among buyers from regions that emphasize corporate social responsibility. Suppliers who can demonstrate transparency in their supply chains and adherence to ethical labor practices are likely to stand out in the competitive landscape. Certifications such as ISO 14001 for environmental management and Fair Trade certification can enhance the credibility of suppliers, making their products more appealing to conscientious buyers.

As B2B buyers prioritize sustainable options, it is crucial for them to engage with suppliers that are committed to minimizing their environmental impact. By choosing products that align with these values, businesses can not only contribute to a healthier planet but also appeal to a growing segment of eco-conscious consumers.

What Is the Brief Evolution of the Cuisinart Defrosting Tray and Its Relevance for B2B Buyers?

The Cuisinart defrosting tray has evolved significantly since its inception, reflecting changes in consumer needs and kitchen technology. Initially designed as a simple tool for defrosting meat and other food items, the tray has gained recognition for its efficiency and convenience. Over the years, the introduction of food-safe materials and ergonomic designs has enhanced its appeal, making it a staple in modern kitchens.

For B2B buyers, understanding the evolution of the Cuisinart defrosting tray is essential for recognizing the product’s potential in various markets. The shift towards convenience and efficiency in food preparation aligns with broader culinary trends, making this product relevant for both retail and commercial sectors. As culinary professionals and home cooks seek innovative solutions to streamline their cooking processes, the Cuisinart defrosting tray stands out as a practical and effective tool, providing ample opportunities for B2B buyers to capitalize on this growing demand.

Frequently Asked Questions (FAQs) for B2B Buyers of cuisinart defrosting tray

-

How do I ensure the quality of Cuisinart defrosting trays from suppliers?

To ensure the quality of Cuisinart defrosting trays, it’s crucial to vet suppliers thoroughly. Start by checking for certifications such as ISO or equivalent quality management standards. Request samples to assess product quality firsthand, focusing on materials used and manufacturing processes. Additionally, review customer feedback and ratings from other B2B buyers. Establish clear quality assurance protocols, including regular inspections and testing upon receipt, to maintain high standards in your supply chain. -

What is the best way to negotiate payment terms for Cuisinart defrosting trays?

Negotiating favorable payment terms is essential for maintaining cash flow. Aim for terms that align with your business cycle, such as Net 30 or Net 60 days. Consider offering a deposit upfront to secure better pricing, especially for bulk orders. It may also be beneficial to discuss discounts for early payments or long-term contracts. Always ensure that payment terms are documented in the purchase agreement to avoid misunderstandings later. -

What are the minimum order quantities (MOQs) for Cuisinart defrosting trays?

MOQs for Cuisinart defrosting trays can vary by supplier and region. Typically, manufacturers may set MOQs based on production costs and logistics considerations. For international buyers, it is advisable to discuss MOQs during the initial negotiations to gauge flexibility. If your order volume is lower than the MOQ, consider pooling orders with other businesses or exploring suppliers willing to accommodate smaller quantities. -

How can I customize Cuisinart defrosting trays for my brand?

Customization options for Cuisinart defrosting trays usually include branding, packaging, and design modifications. Contact your supplier to discuss the possibilities, as some manufacturers may offer private labeling or custom designs for bulk orders. Be prepared to provide your branding materials and any specific requirements. Keep in mind that customization may require minimum order quantities and additional lead time, so factor this into your planning. -

What logistics considerations should I keep in mind when importing Cuisinart defrosting trays?

When importing Cuisinart defrosting trays, consider logistics factors such as shipping costs, customs duties, and lead times. Choose a reliable freight forwarder experienced in handling kitchenware to streamline the process. Understand the import regulations specific to your country, including any safety or compliance standards for food-related products. It’s also wise to have a clear communication plan with your supplier regarding shipping timelines to ensure timely delivery. -

What are the common certifications required for kitchenware like Cuisinart defrosting trays?

Common certifications for kitchenware, including Cuisinart defrosting trays, include FDA approval for food safety, CE marking for compliance with European standards, and LFGB certification in Germany. These certifications ensure that the products meet specific safety and quality standards. When sourcing, ask suppliers to provide documentation of these certifications to ensure compliance with regulations in your target market. -

How do I handle potential product recalls or safety issues with Cuisinart defrosting trays?

Handling product recalls or safety issues requires a proactive approach. Establish a clear communication channel with your supplier for immediate reporting of any concerns. Create a comprehensive risk management plan that outlines procedures for identifying, assessing, and responding to safety issues. Additionally, ensure you have a traceability system in place to track product batches. This will facilitate swift action in the event of a recall, protecting both your business and customers. -

What are the advantages of sourcing Cuisinart defrosting trays from specific regions?

Sourcing Cuisinart defrosting trays from specific regions can offer several advantages. For instance, suppliers in Europe may provide higher quality standards and faster shipping times due to proximity. In contrast, sourcing from regions with lower production costs, such as parts of Asia, may result in better pricing. Consider the balance between cost, quality, and delivery times when selecting a supplier, and assess how each region aligns with your business goals and customer expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Cuisinart Defrosting Tray Manufacturers & Suppliers List

1. Cuisinart – Defrosting Tray

Domain: foodandwine.com

Registered: 1998 (27 years)

Introduction: Cuisinart Defrosting Tray; Price: $22; Material: Food-safe aluminum; Claims to reduce defrosting time by 30% to 40%; Recommended by some users as a must-have kitchen tool; Chef Richard LaMarita warns about potential hazards of defrosting proteins at room temperature; Suggested safe defrosting methods include refrigeration, cold running water, or cooking process; Best for larger proteins to defrost…

2. Instagram – Scraping Services Inquiry

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact for scraping Instagram services, inquire about the number of pages to scrape per month.

3. Cuisinart Grill – Aluminum Meat Defrosting Tray

Domain: efireplacestore.com

Registered: 2007 (18 years)

Introduction: {“Product Name”: “Cuisinart Grill Aluminum Meat Defrosting Tray”, “Price”: “$301.41”, “Original Price”: “$369.99”, “Discount”: “19% Off”, “Shipping”: “Free Shipping on orders over $99”, “Availability”: “In Stock, Ships same business day”, “Manufacturer”: “Cuisinart Grill”, “Part Number”: “CDT-010”, “Item Number”: “CUG-CDT-010”, “UPC”: “817096016835”, “Dimensions”: “13 4/5′ W x 52/100′ H x 7 72/100…

Strategic Sourcing Conclusion and Outlook for cuisinart defrosting tray

As the global demand for efficient kitchen solutions continues to rise, the Cuisinart Defrosting Tray presents a compelling opportunity for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. Its food-safe aluminum design and nonstick surface not only enhance user convenience but also align with growing consumer preferences for eco-friendly products. Strategic sourcing of this innovative kitchen tool can help businesses tap into the increasing trend of home cooking, particularly in regions where culinary practices are evolving.

International buyers should consider the Cuisinart Defrosting Tray not only for its practicality in speeding up meal preparation but also as a means to elevate their product offerings. By integrating high-quality kitchen tools like this into their inventory, businesses can meet the demands of modern consumers seeking efficiency without compromising safety.

Looking ahead, it is essential for B2B buyers to stay informed about market trends and consumer preferences. Embracing strategic sourcing initiatives can lead to enhanced supply chain resilience and profitability. Now is the time to act—explore partnerships with suppliers of the Cuisinart Defrosting Tray to capitalize on this growing market segment and drive your business forward.