A Deep Dive into Conveyor Installation Solution

Introduction: Navigating the Global Market for conveyor installation

In today’s fast-paced global market, sourcing reliable conveyor installation services is a significant challenge for businesses aiming to optimize material handling and operational efficiency. Whether you are in manufacturing, warehousing, or logistics, understanding the nuances of conveyor systems is crucial for enhancing productivity and reducing operational costs. This comprehensive guide delves into the intricacies of conveyor installation, covering various types of systems, their applications across different industries, and the key considerations for selecting the right supplier.

Navigating the complexities of international procurement requires a strategic approach, particularly for B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Brazil. This guide equips you with the insights needed to make informed purchasing decisions by exploring essential topics such as cost implications, supplier vetting processes, and the best practices for installation and maintenance.

With expert advice and actionable strategies, you will gain a deeper understanding of how to streamline your conveyor installation process, ensuring that your investment leads to long-term operational success. Empower your organization to tackle the challenges of conveyor systems head-on and unlock new levels of efficiency and productivity in your operations.

Understanding conveyor installation Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Belt Conveyor | Continuous belt system; ideal for bulk materials | Mining, food processing, packaging | Pros: Efficient for long distances; versatile. Cons: Limited to horizontal or slight inclines. |

| Roller Conveyor | Uses rollers for material transport; gravity or powered | Warehousing, distribution centers | Pros: Easy to integrate; low maintenance. Cons: Requires more space; can be less flexible in layout. |

| Modular Conveyor | Flexible design; customizable sections | Manufacturing, assembly lines | Pros: Adaptable to various layouts; quick reconfiguration. Cons: Higher initial cost; potential complexity in assembly. |

| Overhead Conveyor | Suspended system; maximizes floor space | Automotive, textiles, and packaging | Pros: Saves ground space; efficient for moving lightweight items. Cons: Installation can be complex; requires structural support. |

| Chain Conveyor | Uses chains for heavy loads; suitable for harsh environments | Heavy manufacturing, automotive, foundries | Pros: Durable and robust; handles heavy materials. Cons: Higher energy consumption; more expensive to install. |

What are the Key Characteristics of Belt Conveyors for B2B Buyers?

Belt conveyors are characterized by their continuous belt system, which is perfect for transporting bulk materials over long distances. They are commonly used in industries such as mining, food processing, and packaging. B2B buyers should consider the operational efficiency of belt conveyors, especially for applications requiring consistent material flow. However, they are limited to horizontal or slightly inclined paths, which may not suit all facilities.

How Do Roller Conveyors Stand Out in Material Handling?

Roller conveyors utilize a series of rollers to facilitate the movement of materials, either through gravity or powered systems. They are predominantly found in warehousing and distribution centers. For B2B buyers, the key advantage of roller conveyors is their ease of integration into existing systems and low maintenance needs. However, they typically require more physical space and may be less flexible regarding layout changes compared to other conveyor types.

Why Choose Modular Conveyors for Manufacturing Needs?

Modular conveyors are designed with flexible, customizable sections that allow for various configurations. They are well-suited for manufacturing and assembly lines where adaptability is crucial. Buyers should note the benefits of quick reconfiguration and the ability to accommodate changes in production needs. However, the initial investment may be higher, and assembly complexity could pose challenges for some businesses.

Illustrative image related to conveyor installation

What Advantages Do Overhead Conveyors Offer to B2B Buyers?

Overhead conveyors are unique in that they are suspended from the ceiling, maximizing floor space for other activities. This type is particularly effective in industries such as automotive, textiles, and packaging. B2B buyers should appreciate the space-saving benefits and efficiency in moving lightweight items. However, the installation can be complex and requires adequate structural support, which may add to the overall cost.

When Should Businesses Consider Chain Conveyors?

Chain conveyors are ideal for transporting heavy loads and are often used in harsh industrial environments. They find applications in heavy manufacturing, automotive, and foundries. Buyers should consider the durability and robustness of chain conveyors, which can handle significant weight. However, they tend to consume more energy and can be more expensive to install, making them suitable for businesses with specific heavy-load requirements.

Key Industrial Applications of conveyor installation

| Industry/Sector | Specific Application of Conveyor Installation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Automated packaging lines for bottling and canning | Increases efficiency and reduces manual labor costs | Compliance with food safety standards; need for hygienic design |

| Manufacturing | Assembly line conveyors for automotive production | Enhances production speed and reduces bottlenecks | Customization options; integration with existing machinery |

| Warehousing and Logistics | Sortation conveyors for distribution centers | Improves order fulfillment speed and accuracy | Space optimization; scalability for future growth |

| Mining and Minerals | Bulk material handling conveyors | Increases material throughput and reduces manual handling | Durability under harsh conditions; maintenance support and parts availability |

| Pharmaceuticals | Conveyors for cleanroom environments | Ensures contamination control and regulatory compliance | Specialized materials; certifications for cleanroom standards |

How is Conveyor Installation Used in the Food and Beverage Industry?

In the food and beverage sector, conveyor installation is pivotal for automated packaging lines, particularly in bottling and canning processes. These systems enhance operational efficiency by minimizing manual labor and reducing the risk of contamination. Buyers must consider compliance with stringent food safety standards and opt for designs that facilitate easy cleaning and maintenance. Features such as stainless steel components and hygienic design are crucial for ensuring product safety and quality.

What Role Does Conveyor Installation Play in Manufacturing?

In manufacturing, particularly in automotive production, conveyor systems are integral to assembly lines. They facilitate the smooth movement of components through various stages of assembly, significantly enhancing production speed while reducing bottlenecks. Buyers should focus on customization options that allow for seamless integration with existing machinery and workflows. Additionally, understanding the specific throughput requirements and operational constraints is essential for optimizing the installation process.

How Do Conveyors Improve Efficiency in Warehousing and Logistics?

Conveyor installation in warehousing and logistics focuses on sortation systems that streamline the order fulfillment process. These conveyors automate the sorting and distribution of products, improving speed and accuracy in fulfilling customer orders. For international buyers, key considerations include space optimization to fit within existing layouts and scalability to accommodate future growth. It’s essential to evaluate the system’s adaptability to various product sizes and weights to ensure maximum efficiency.

Why is Conveyor Installation Critical in Mining and Minerals?

In the mining and minerals industry, conveyor systems are essential for bulk material handling, allowing for the efficient transportation of heavy materials over long distances. These systems increase material throughput while minimizing manual handling, which can be hazardous. Buyers should prioritize durability and reliability, as these systems operate in harsh conditions. Maintenance support and the availability of replacement parts are also critical factors to ensure uninterrupted operations.

How Does Conveyor Installation Ensure Compliance in Pharmaceuticals?

In pharmaceuticals, conveyor systems are used in cleanroom environments to transport products while ensuring contamination control. These systems must comply with strict regulatory standards, necessitating the use of specialized materials and designs. Buyers should look for conveyors that meet cleanroom certifications and feature easy-to-clean surfaces. Understanding the specific regulatory requirements in their region, such as those set by the FDA or EMA, is vital for ensuring compliance and maintaining product integrity.

3 Common User Pain Points for ‘conveyor installation’ & Their Solutions

Scenario 1: Navigating Unexpected Installation Delays

The Problem: B2B buyers often face unexpected delays during conveyor installation, which can stem from various factors such as site preparation challenges, equipment delivery issues, or even regulatory compliance hurdles. For instance, a manufacturing facility in Brazil may discover that the site needs additional modifications to accommodate the conveyor system, leading to increased downtime and frustration among stakeholders. Such delays can disrupt production schedules, affect order fulfillment, and ultimately impact the bottom line.

The Solution: To mitigate these delays, it is crucial to invest time in thorough pre-installation planning and communication. Begin by conducting a detailed site assessment that identifies potential challenges early on. Collaborate with your installation partner to create a comprehensive project timeline that includes buffer periods for unforeseen circumstances. Additionally, ensure all necessary permits and approvals are secured before commencing the installation. This proactive approach not only helps in anticipating and addressing issues but also streamlines the installation process, minimizing disruptions.

Illustrative image related to conveyor installation

Scenario 2: Ensuring Proper Conveyor Alignment

The Problem: Misalignment during conveyor installation can lead to significant operational inefficiencies, including increased wear and tear on the system, safety hazards, and higher maintenance costs. For example, a logistics company in Nigeria might find that their newly installed conveyor system is not aligned correctly, causing materials to jam and slowing down their operations. This misalignment can result in costly downtime and a negative impact on productivity.

The Solution: To ensure proper alignment, it’s essential to utilize precision tools and techniques during installation. Work with experienced technicians who understand the nuances of conveyor systems and can perform accurate measurements throughout the installation process. Implement a rigorous alignment verification phase, where the conveyor is tested under load conditions before finalizing the installation. Additionally, consider utilizing advanced alignment technology, such as laser alignment tools, which can significantly enhance the accuracy of the setup. Regular post-installation checks can further help maintain alignment, ensuring long-term efficiency.

Scenario 3: Overcoming Staff Training Challenges

The Problem: A common pain point for businesses is the lack of proper training for staff on the new conveyor system, which can lead to operational inefficiencies and safety risks. For instance, a manufacturing facility in South America may install a sophisticated conveyor system but fail to provide adequate training for employees. As a result, operators may not fully understand how to use the system effectively, leading to mistakes that could jeopardize safety and productivity.

Illustrative image related to conveyor installation

The Solution: To address this issue, develop a structured training program as part of the installation process. Collaborate with your conveyor installation provider to ensure that they offer comprehensive training sessions for all relevant staff members. This training should cover not only the operation of the conveyor system but also maintenance practices and safety protocols. Incorporate hands-on training and simulations to reinforce learning. Additionally, create accessible training materials and resources that employees can refer to as needed. Regular refresher courses and assessments can also help maintain a high level of competence among staff, ensuring the conveyor system operates smoothly and safely.

Strategic Material Selection Guide for conveyor installation

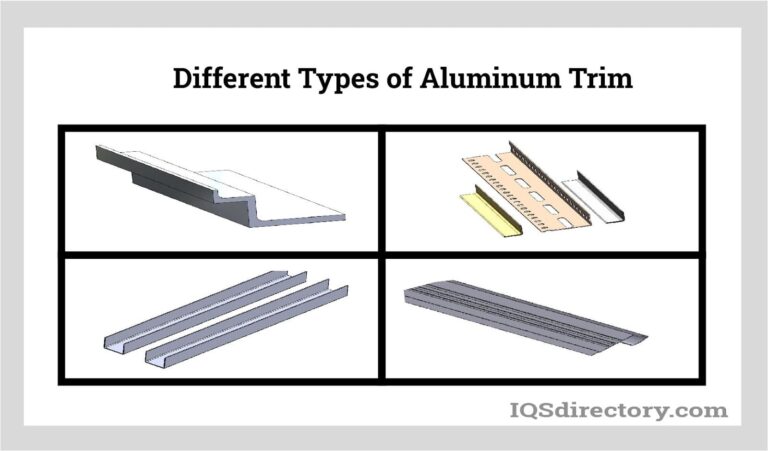

What Are the Key Materials for Conveyor Installation?

When selecting materials for conveyor installation, it’s essential to consider their properties, advantages, and limitations in relation to specific applications. Here, we analyze four common materials: steel, aluminum, plastic, and stainless steel, focusing on their performance characteristics and implications for international B2B buyers.

How Does Steel Perform as a Material for Conveyor Systems?

Steel is a widely used material in conveyor systems due to its strength and durability. It offers excellent temperature and pressure ratings, making it suitable for heavy-duty applications. Steel conveyors can withstand harsh environments, including high-load conditions and abrasive materials.

Pros: Steel is highly durable and can support significant weight, making it ideal for heavy materials. It is also relatively cost-effective compared to other metals, providing good value for money.

Cons: However, steel is prone to corrosion, especially in humid or chemical-laden environments, which can lead to increased maintenance costs. Additionally, its weight can complicate installation and increase transportation costs.

Illustrative image related to conveyor installation

Impact on Application: Steel conveyors are best suited for industries like mining, manufacturing, and logistics, where heavy loads and durability are critical.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local standards (e.g., ASTM or DIN) for safety and performance. Additionally, they should consider the availability of corrosion-resistant coatings to enhance longevity in humid climates.

What Are the Advantages of Using Aluminum in Conveyor Systems?

Aluminum is another popular choice for conveyor systems, particularly in environments where weight is a concern. Its lightweight nature allows for easier installation and flexibility in design.

Pros: Aluminum is resistant to corrosion and can be easily fabricated into various shapes, making it versatile for different applications. It also offers a good strength-to-weight ratio, ensuring efficient operation.

Cons: The primary drawback of aluminum is its lower load-bearing capacity compared to steel, which may limit its use in heavy-duty applications. Additionally, it can be more expensive than steel.

Impact on Application: Aluminum conveyors are ideal for light to medium-duty applications, such as packaging, food processing, and assembly lines.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific alloy grades that meet industry standards. It’s crucial to verify that the aluminum used complies with regulations like JIS for quality assurance.

How Does Plastic Compare in Conveyor Applications?

Plastic materials, particularly engineered plastics, are increasingly being used in conveyor systems due to their lightweight and corrosion-resistant properties. They are particularly beneficial in environments where hygiene is paramount.

Pros: Plastic conveyors are easy to clean and can be designed to resist chemicals, making them suitable for food and pharmaceutical industries. They are also quieter in operation compared to metal conveyors.

Illustrative image related to conveyor installation

Cons: The main limitation of plastic is its lower strength and load capacity, which may not be suitable for heavy materials. Additionally, certain plastics can degrade under UV exposure or extreme temperatures.

Impact on Application: Plastic is ideal for applications in food processing, pharmaceuticals, and packaging, where cleanliness and corrosion resistance are critical.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with food safety regulations, such as FDA standards in the U.S. or similar regulations in Europe and South America.

Why Choose Stainless Steel for Conveyor Systems?

Stainless steel is renowned for its exceptional corrosion resistance and hygiene, making it a top choice in industries that require stringent cleanliness standards.

Illustrative image related to conveyor installation

Pros: Stainless steel conveyors are durable, easy to clean, and resistant to rust and corrosion, making them suitable for a wide range of applications, including food and beverage processing.

Cons: The primary disadvantage is the higher cost compared to other materials, which can impact budget considerations. Additionally, stainless steel can be heavier, complicating installation.

Impact on Application: Stainless steel is ideal for environments where hygiene is critical, such as food processing, pharmaceuticals, and chemical handling.

Illustrative image related to conveyor installation

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM for material quality and consider the specific grades of stainless steel that are suitable for their applications.

Summary Table of Material Selection for Conveyor Installation

| Material | Typical Use Case for Conveyor Installation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications in manufacturing | High durability and load capacity | Prone to corrosion | Medium |

| Aluminum | Light to medium-duty applications | Lightweight and corrosion-resistant | Lower load capacity | High |

| Plastic | Food processing and packaging | Easy to clean and chemical-resistant | Lower strength | Medium |

| Stainless Steel | Food and beverage processing | Exceptional corrosion resistance | Higher cost | High |

In summary, selecting the right material for conveyor installation involves evaluating the specific application requirements, including load capacity, environmental conditions, and compliance with local regulations. By understanding the pros and cons of each material, international buyers can make informed decisions that align with their operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor installation

What Are the Main Stages of the Manufacturing Process for Conveyor Installation?

The manufacturing process for conveyor systems encompasses several critical stages, each designed to ensure that the final product meets the operational requirements and quality standards expected by B2B buyers. Understanding these stages can help buyers make informed decisions when selecting suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage involves sourcing and preparing raw materials, which can include metals, plastics, and rubber. Suppliers typically select high-quality materials that can withstand the operational stresses of a conveyor system.

- Material Selection: This involves assessing the characteristics of the materials, such as durability, resistance to wear, and suitability for specific environments (e.g., corrosive conditions).

- Cutting and Shaping: Raw materials are cut to size using advanced techniques such as laser cutting or water jet cutting, ensuring precision and reducing waste.

These initial steps lay the groundwork for a robust and efficient conveyor system, and buyers should inquire about the sourcing practices and materials used by potential suppliers.

What Techniques Are Used in the Forming Stage of Conveyor Manufacturing?

The forming stage is where raw materials are transformed into parts that will be assembled into the conveyor system.

- Bending and Forming: Techniques such as press braking and roll forming are commonly employed to shape metal components into desired profiles. For plastic components, injection molding may be used to create complex shapes.

- Welding and Joining: Various welding techniques, including MIG and TIG welding, are used to join metal parts securely. This ensures structural integrity and longevity of the conveyor system.

Buyers should look for suppliers who utilize advanced forming techniques, as this can greatly influence the quality and performance of the final product.

Illustrative image related to conveyor installation

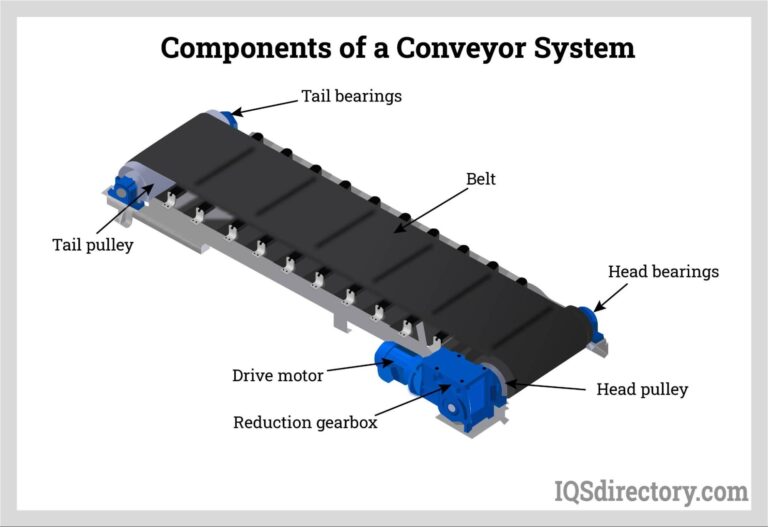

How Is the Assembly Process Conducted for Conveyor Systems?

The assembly stage is where individual components come together to form a complete conveyor system.

- Component Assembly: Skilled technicians assemble the conveyor system according to detailed engineering specifications. This includes attaching belts, rollers, motors, and control systems.

- Alignment and Calibration: During assembly, precise alignment is crucial to prevent operational issues. Technicians employ tools and technology to ensure components are correctly positioned.

The expertise of the assembly team can significantly impact the efficiency and reliability of the conveyor system, making it essential for buyers to assess the qualifications and training of assembly personnel.

What Finishing Techniques Are Commonly Used in Conveyor Manufacturing?

The finishing stage involves applying treatments and coatings to enhance the durability and aesthetic appeal of the conveyor system.

- Surface Treatments: Processes such as powder coating, galvanizing, or anodizing are employed to protect components from corrosion and wear.

- Quality Checks: Finishing also includes quality control checks to ensure that components meet specified standards before proceeding to the next stage.

B2B buyers should inquire about the finishing techniques used by suppliers, as these can affect the longevity and maintenance requirements of the conveyor systems.

What Quality Assurance Practices Are Essential in Conveyor Installation?

Quality assurance (QA) is vital in ensuring that conveyor systems meet both international standards and specific industry requirements.

Which International Standards Should Buyers Consider for Conveyor Quality Assurance?

International standards such as ISO 9001 are critical for ensuring quality management systems are in place. This standard outlines requirements for a quality management system that can enhance customer satisfaction through consistent product quality.

Illustrative image related to conveyor installation

- ISO 9001: Emphasizes a process approach to managing quality, which can lead to improved efficiency and reduced waste.

- CE Marking: For machinery sold in Europe, compliance with CE marking is necessary. This signifies that the product meets EU safety, health, and environmental protection standards.

Buyers from regions like Africa and South America should ensure that suppliers can demonstrate compliance with these standards, as it often influences regulatory acceptance and market entry.

What Are the Key QC Checkpoints During Conveyor Manufacturing?

Quality control checkpoints play a crucial role in maintaining product integrity throughout the manufacturing process.

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Regular checks during manufacturing help catch defects early in the production process, reducing rework and waste.

- Final Quality Control (FQC): Comprehensive testing of the finished product ensures it meets all design specifications and performance criteria before delivery.

B2B buyers should ask suppliers about their QC processes, including the frequency and methods of testing at each checkpoint.

How Can B2B Buyers Verify Supplier Quality Control Measures?

Verifying a supplier’s quality control measures is essential for ensuring that products will meet operational standards.

Illustrative image related to conveyor installation

- Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality assurance practices.

- Quality Reports: Requesting detailed quality reports can help buyers assess the consistency of the supplier’s performance over time.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the supplier’s quality control measures.

For international buyers, particularly in regions like the Middle East and Europe, understanding the nuances of local regulations and standards can further aid in making informed decisions.

What Are the Common Testing Methods Used in Conveyor Quality Assurance?

Testing methods are integral to ensuring the functionality and reliability of conveyor systems.

- Load Testing: This involves running the conveyor under its maximum load capacity to ensure it operates smoothly without failure.

- Performance Testing: Assessing the speed, efficiency, and accuracy of material handling during various operational scenarios.

- Safety Testing: Verifying that safety features, such as emergency stops and guards, function correctly.

Understanding these testing methods can help B2B buyers gauge the robustness of the conveyor systems they are considering.

Conclusion

In conclusion, the manufacturing processes and quality assurance practices involved in conveyor installation are critical factors for B2B buyers. By understanding the stages of manufacturing—from material preparation to finishing—and the importance of quality control measures, businesses can make informed decisions when selecting suppliers. This knowledge is particularly valuable for international buyers looking to ensure compliance with relevant standards and achieve operational excellence in their material handling solutions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor installation’

Introduction

This practical sourcing guide provides a step-by-step checklist for B2B buyers seeking to procure conveyor installation services. The installation of conveyor systems is a significant investment that can greatly enhance operational efficiency. By following this checklist, buyers can ensure they make informed decisions throughout the procurement process, leading to successful installations that meet their specific needs.

Illustrative image related to conveyor installation

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is essential for guiding the procurement process. This includes understanding the types of materials to be transported, the required throughput, and any unique features that your operation might demand. A well-defined specification ensures that suppliers can provide solutions that truly fit your operational requirements.

- Considerations:

- Material types (e.g., heavy, fragile, hazardous)

- Required load capacity and speed

- Environmental factors (e.g., temperature, humidity)

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation in conveyor installation. Focus on companies that have experience within your industry and region, as they are likely to understand your specific challenges and requirements.

- Key Actions:

- Utilize industry directories and trade shows to find suppliers.

- Look for online reviews and testimonials from previous clients.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet your shortlisted suppliers. Request company profiles, case studies, and references from clients in similar industries or regions. This step helps to validate their capabilities and ensures they can meet your installation needs.

Illustrative image related to conveyor installation

- Important Factors:

- Check for relevant certifications and compliance with safety standards.

- Assess their experience with similar projects and their ability to deliver on time.

Step 4: Request Detailed Proposals

Once you have identified potential suppliers, request detailed proposals that outline their approach to your project. A comprehensive proposal should include timelines, cost estimates, installation methodologies, and post-installation support options.

- What to Look For:

- Clarity in pricing and any hidden costs.

- A well-defined project timeline with milestones.

Step 5: Verify Supplier Certifications and Compliance

Ensure that the suppliers you are considering have the necessary certifications and compliance with local regulations. This is crucial not only for legal compliance but also for ensuring the safety and reliability of the installed conveyor systems.

- Specific Certifications to Check:

- ISO certifications relevant to manufacturing and installation.

- Compliance with local health and safety regulations.

Step 6: Assess Post-Installation Support and Maintenance Services

Inquire about the post-installation support and maintenance services offered by the supplier. A reliable supplier should provide ongoing support to ensure the longevity and efficiency of the conveyor system.

- Key Considerations:

- Availability of training for your staff.

- Schedule for routine maintenance and emergency support options.

Step 7: Finalize Contract and Payment Terms

Once you have selected a supplier, finalize the contract detailing the scope of work, payment terms, and warranties. Clear contracts protect both parties and set expectations for the project.

- Key Elements to Include:

- Payment schedules linked to project milestones.

- Clauses covering delays and penalties for non-compliance.

By following these steps, B2B buyers can effectively navigate the procurement of conveyor installation services, ensuring that they choose the right supplier for their operational needs.

Illustrative image related to conveyor installation

Comprehensive Cost and Pricing Analysis for conveyor installation Sourcing

What Are the Key Cost Components for Conveyor Installation?

When considering conveyor installation, it’s essential to understand the various cost components that contribute to the overall pricing structure. The primary cost elements include:

-

Materials: The type and quality of materials used for the conveyor system significantly impact costs. Common materials include steel, aluminum, and specialized plastics. The choice of material affects not only the initial cost but also the longevity and maintenance requirements of the system.

-

Labor: Labor costs can vary widely based on the complexity of the installation and regional labor rates. Skilled technicians are required for installation, which can include assembly, alignment, and testing of the conveyor system.

-

Manufacturing Overhead: This encompasses the indirect costs associated with producing the conveyor systems, including utilities, rent, and administrative expenses. Understanding these overheads is crucial for buyers to gauge the pricing accurately.

-

Tooling: Specific tools and equipment may be necessary for the installation process. The costs associated with these tools, whether purchased or rented, should be factored into the overall project budget.

-

Quality Control (QC): Implementing QC processes ensures that the conveyor system meets operational standards and specifications. This can add to the cost but is essential for ensuring reliability and safety.

-

Logistics: The cost of transporting materials and equipment to the installation site can be significant, especially for international shipments. Factors such as distance, shipping methods, and tariffs influence these costs.

-

Margin: Suppliers typically add a profit margin to the base costs, which can vary based on market conditions, competition, and the supplier’s positioning.

How Do Price Influencers Affect Conveyor Installation Costs?

Several factors influence the pricing of conveyor installations, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often benefit from bulk pricing discounts, which can significantly reduce per-unit costs.

-

Specifications and Customization: Tailored solutions that meet specific operational needs may incur higher costs due to the additional design and engineering work required.

-

Materials and Quality Certifications: Higher-quality materials or those with specific certifications (such as ISO) may command premium prices but can lead to lower long-term costs through increased durability and reduced maintenance.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more for their expertise and reliability.

-

Incoterms: The chosen Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions, impacting shipping costs, insurance, and risk management.

What Are Effective Buyer Tips for Negotiating Conveyor Installation Costs?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of conveyor installation pricing can lead to significant cost savings. Here are some actionable tips:

-

Negotiate with Multiple Suppliers: Obtaining quotes from several suppliers can provide leverage in negotiations. Understanding the range of pricing helps identify fair market value.

-

Focus on Total Cost of Ownership (TCO): Instead of just considering the upfront costs, evaluate the long-term costs associated with maintenance, energy consumption, and potential downtime. A higher initial investment in quality might yield lower TCO.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to labor costs, material availability, and economic conditions. Familiarizing yourself with these factors can enhance negotiation strategies.

-

Consider Local Suppliers: Engaging with local suppliers can reduce logistics costs and lead to faster service and support. They may also have a better understanding of regional regulations and compliance requirements.

-

Plan for Currency Fluctuations: For international transactions, currency exchange rates can impact final costs. Locking in prices early or negotiating in a stable currency can mitigate risks.

Disclaimer for Indicative Prices

While this analysis provides a framework for understanding costs and pricing for conveyor installations, it is important to note that actual prices can vary significantly based on specific project requirements, regional factors, and market conditions. Buyers should conduct thorough research and seek multiple quotations to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing conveyor installation With Other Solutions

Understanding Alternatives to Conveyor Installation

In the realm of material handling and logistics, conveyor installation is a widely adopted solution for transporting goods efficiently. However, businesses often explore various alternatives that may better suit their specific operational needs, budget constraints, or facility layouts. This analysis compares conveyor installation with two viable alternatives: Automated Guided Vehicles (AGVs) and Forklift Systems. Each option presents unique advantages and challenges that can significantly impact the decision-making process for B2B buyers.

Comparison of Conveyor Installation and Alternatives

| Comparison Aspect | Conveyor Installation | Automated Guided Vehicles (AGVs) | Forklift Systems |

|---|---|---|---|

| Performance | High throughput, continuous operation | Flexible routing, variable loads | High load capacity, versatile use |

| Cost | Moderate to high initial investment | Variable costs based on complexity | High operational costs (labor, fuel) |

| Ease of Implementation | Requires significant planning and design | Quick to deploy in open environments | Easy to implement but requires training |

| Maintenance | Regular inspections and preventive care | Minimal maintenance, software updates | High maintenance, skilled operators needed |

| Best Use Case | Large-scale, fixed operations | Dynamic environments, varied tasks | Warehousing, short-distance transport |

In-Depth Look at Each Alternative

Automated Guided Vehicles (AGVs)

AGVs are mobile robots that follow predefined paths to transport materials within a facility. They are particularly advantageous in environments where flexibility and adaptability are crucial. AGVs can navigate around obstacles and adjust their routes as needed, which makes them ideal for facilities with changing layouts or variable product flows. However, the initial investment can vary significantly based on the sophistication of the technology, and while they require less ongoing labor, they do necessitate regular software updates and occasional maintenance.

Forklift Systems

Forklift systems are a traditional solution for material handling, offering high load capacities and versatility in various environments. They can efficiently transport goods across short distances and are capable of lifting heavy items. However, they require skilled operators and can incur high operational costs due to fuel consumption and maintenance needs. Additionally, safety concerns arise with forklift operation, as they pose risks in crowded or confined spaces. While they are effective for certain applications, their reliance on human operators can lead to variability in performance.

How to Choose the Right Solution for Your Business Needs

Selecting the appropriate material handling solution hinges on several factors including operational requirements, facility layout, and budget constraints. Conveyor installation is often the best choice for businesses that require a fixed, high-capacity solution for consistent throughput. In contrast, AGVs may be better suited for dynamic environments where flexibility is essential, while forklift systems can be advantageous for facilities that prioritize load versatility and manual handling. By carefully evaluating these aspects, B2B buyers can make informed decisions that align with their operational goals and enhance overall productivity.

Illustrative image related to conveyor installation

Essential Technical Properties and Trade Terminology for conveyor installation

What Are the Critical Technical Properties of Conveyor Installation?

When considering conveyor installation, understanding the essential technical properties is vital for ensuring optimal performance and longevity of the system. Here are some key specifications to keep in mind:

1. Material Grade

The material grade of conveyor components, such as belts, rollers, and frames, is crucial. Common materials include steel, stainless steel, and various polymers. Each material offers different strengths, resistances, and costs. Selecting the appropriate material grade can significantly impact durability, maintenance needs, and overall system efficiency, making it an essential consideration for B2B buyers.

2. Load Capacity

Load capacity refers to the maximum weight that the conveyor system can transport at any given time. This specification is critical for ensuring the conveyor meets operational demands without risking failure or damage. Understanding load capacity helps businesses prevent overloading, which can lead to increased wear and tear, safety hazards, and costly downtimes.

3. Tolerance

Tolerance indicates the permissible limits of variation in the dimensions of conveyor components. Precise tolerances are essential for ensuring proper alignment and operation. In B2B contexts, a focus on tolerance can enhance system efficiency and minimize maintenance needs, reducing operational disruptions.

Illustrative image related to conveyor installation

4. Speed

The operational speed of a conveyor system determines how quickly materials can be transported. Speed is essential for maximizing throughput and improving operational efficiency. Understanding the required speed for specific applications allows businesses to tailor their conveyor systems to meet production goals, ensuring that they remain competitive in their markets.

5. Drive Type

The drive type—whether it’s direct drive, belt-driven, or chain-driven—affects the system’s efficiency and maintenance requirements. Different applications may require different drive types based on factors such as load size, speed, and operational environment. Choosing the right drive type can optimize energy consumption and enhance overall system performance.

What Are Common Trade Terms in Conveyor Installation?

Navigating the conveyor installation process involves familiarizing oneself with industry jargon. Here are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of conveyor systems, working with OEMs ensures that the components meet specific standards and compatibility requirements. Understanding OEM relationships can help businesses ensure quality and reliability in their installations.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it can impact budgeting and inventory management. Knowing the MOQ can help businesses plan their purchases effectively, ensuring they meet operational needs without overcommitting capital.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price proposals from suppliers for specific goods or services. In the conveyor installation context, sending an RFQ to multiple vendors allows businesses to compare costs and services, facilitating informed decision-making. Understanding how to craft an effective RFQ can lead to better pricing and service agreements.

4. Incoterms

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international transactions. They clarify issues such as shipping costs, insurance, and delivery points. Familiarity with Incoterms is essential for B2B buyers operating across borders, as it helps mitigate risks related to international shipping and compliance.

5. Lead Time

Lead time is the period between the initiation of an order and its completion. In conveyor installation, understanding lead times is essential for planning and scheduling projects effectively. This knowledge enables businesses to align their operational timelines with supplier capabilities, ensuring a smoother installation process.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding conveyor installation, ultimately enhancing their operational efficiency and ensuring successful project outcomes.

Illustrative image related to conveyor installation

Navigating Market Dynamics and Sourcing Trends in the conveyor installation Sector

What Are the Current Market Dynamics and Key Trends in Conveyor Installation?

The conveyor installation sector is witnessing transformative changes driven by global economic shifts and technological advancements. A primary factor influencing this market is the increasing demand for automation across industries such as manufacturing, logistics, and e-commerce. As companies strive to enhance operational efficiency, the integration of advanced conveyor systems becomes essential. Emerging technologies like AI and IoT are reshaping how conveyor systems are designed, monitored, and maintained, providing real-time data analytics that optimize performance and reduce downtime.

Internationally, B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers that offer customizable and scalable conveyor solutions. This trend is especially pronounced in markets like Nigeria and Brazil, where rapid industrialization and urbanization are driving the need for efficient material handling systems. Additionally, the rise of e-commerce has intensified the focus on efficient supply chain logistics, making conveyor installation a pivotal aspect of operational strategy for businesses looking to remain competitive.

The sourcing landscape is evolving with a heightened emphasis on partnerships and collaboration. Buyers are seeking suppliers who can provide not just equipment but also integrated solutions that encompass design, installation, and ongoing maintenance. This shift is prompting suppliers to enhance their service offerings and develop innovative financing models, such as pay-per-use arrangements, to accommodate varying buyer capabilities.

Illustrative image related to conveyor installation

How Are Sustainability and Ethical Sourcing Shaping Conveyor Installation?

Sustainability has become a critical consideration in the conveyor installation sector, driven by increasing regulatory pressures and consumer demand for environmentally responsible practices. The environmental impact of conveyor systems, particularly concerning energy consumption and material waste, is prompting businesses to adopt greener technologies. Buyers are increasingly interested in suppliers that utilize energy-efficient motors, recyclable materials, and sustainable manufacturing processes.

Ethical sourcing is also gaining traction, with B2B buyers emphasizing the importance of transparent supply chains. Companies are looking to partner with suppliers who adhere to ethical labor practices and demonstrate a commitment to social responsibility. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming benchmarks for assessing supplier credibility in the conveyor installation space.

Moreover, the use of ‘green’ materials, such as recycled metals and eco-friendly lubricants, is becoming a standard expectation among buyers. This shift not only addresses environmental concerns but also enhances brand reputation and customer loyalty. By prioritizing sustainability and ethical sourcing, companies can differentiate themselves in a competitive market and align their operations with global sustainability goals.

What Is the Historical Evolution of Conveyor Installation?

The conveyor installation sector has evolved significantly since its inception in the late 19th century. Initially developed for industries like mining and agriculture, conveyor systems were simple, mechanical designs that facilitated the transport of bulk materials. The introduction of electric motors in the early 20th century revolutionized conveyor technology, allowing for longer distances and greater efficiency.

In the latter half of the 20th century, advancements in materials science and engineering led to the development of versatile conveyor systems, including belt and roller conveyors, which became staples in manufacturing and distribution centers. The rise of automation in the 21st century further accelerated the evolution of conveyor installation, with smart technologies enabling real-time monitoring and predictive maintenance.

Today, the conveyor installation sector is at the forefront of industrial innovation, integrating cutting-edge technologies that enhance efficiency, sustainability, and adaptability. As industries continue to evolve, so too will the conveyor systems that support them, driving ongoing investment and development in this critical area of material handling.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor installation

-

How do I evaluate the right conveyor system for my business needs?

To evaluate the right conveyor system, begin by analyzing your operational requirements, including the types of materials to be transported, the volume of throughput needed, and the facility layout. Collaborate with suppliers to conduct a thorough assessment, which may involve site visits and discussions about specific challenges and goals. Consider factors like conveyor type, length, speed, and the environment in which it will operate, as these will significantly influence performance and efficiency. -

What are the most common challenges in conveyor installation?

Common challenges in conveyor installation include site preparation, alignment issues, and compliance with safety regulations. Misalignment can lead to operational inefficiencies, while inadequate site preparation may delay the project. To mitigate these risks, ensure thorough planning and communication with all stakeholders, and engage experienced professionals who can navigate potential pitfalls and ensure adherence to industry standards and best practices. -

How can I ensure compliance with local regulations during conveyor installation?

To ensure compliance with local regulations, start by familiarizing yourself with the relevant laws and safety standards in your region, particularly if you are operating in Africa, South America, the Middle East, or Europe. Engage with local regulatory bodies and consult with experienced installation partners who understand the legal landscape. Securing necessary permits and conducting regular safety audits during the installation process will help you avoid legal complications and ensure a smooth operation. -

What customization options are available for conveyor systems?

Customization options for conveyor systems can vary widely based on your specific needs. You can request modifications in terms of belt type, speed, length, and the inclusion of additional features such as sensors, controls, or integration with existing systems. Discuss your unique requirements with potential suppliers to explore tailored solutions that enhance efficiency and meet your operational objectives, while also considering future scalability. -

What are the minimum order quantities (MOQs) for conveyor systems?

Minimum order quantities (MOQs) for conveyor systems can differ among suppliers and depend on factors like the complexity of the system and the components required. Some manufacturers may have flexible MOQs for standard systems, while custom solutions often require larger orders. It’s crucial to clarify MOQs with potential suppliers early in the negotiation process to align your purchasing strategy with their production capabilities. -

What payment terms should I expect when sourcing conveyor systems internationally?

When sourcing conveyor systems internationally, payment terms can vary based on supplier policies and the nature of the transaction. Common arrangements include partial upfront payments with the balance due upon delivery or installation completion. Some suppliers may offer financing options or letter of credit arrangements to facilitate smoother transactions. Ensure you discuss and agree upon payment terms in advance to avoid misunderstandings and ensure financial security. -

How do I vet suppliers for conveyor installation projects?

Vetting suppliers for conveyor installation involves assessing their experience, reputation, and expertise in your specific industry. Research their track record by examining case studies, client testimonials, and certifications. Additionally, consider requesting references and conducting site visits to previous installations. It’s also beneficial to engage suppliers in detailed discussions about their installation processes, maintenance support, and compliance with safety standards to ensure they align with your operational goals. -

What logistics considerations should I keep in mind for conveyor system installation?

Logistics considerations are crucial for a successful conveyor system installation. Assess factors like shipping methods, lead times, and customs regulations, especially for international shipments. Coordinate closely with suppliers to ensure timely delivery of components, and plan for on-site storage solutions to handle materials before installation. Effective communication with logistics partners can help minimize delays and ensure that the installation process runs smoothly, maintaining operational continuity.

Top 4 Conveyor Installation Manufacturers & Suppliers List

1. RPM Installation – Conveyor System Solutions

Domain: rpm-installation.com

Registered: 2012 (13 years)

Introduction: RPM Installation provides state of the art conveyor system installation services from Whitehouse, Texas. They offer a comprehensive range of conveyor technologies and techniques tailored to meet specific project needs. Their services are suitable for various applications including manufacturing companies, distribution facilities, warehouses, and airports. RPM Installation emphasizes the importance…

2. Haas – Hennig CDF Conveyor Installation Kits

Domain: haascnc.com

Registered: 1996 (29 years)

Introduction: Hennig CDF Conveyor installation procedure for the following machines: UMC-500, UMC-750, UMC-1000, UMC-1250, UMC-1500-DUO, EC-400, EC-500, EC-630. Installation kits include: 93-1000661 (UMC-500), 93-1000655 (UMC-750), 93-1000656 (UMC-1000), 93-1000657 (UMC-1250), 93-1000658 (UMC-1500 DUO), 93-1000659 (EC-400), 93-1000660 (EC-500), 93-1000950 (EC-630). Prerequisites include ordering the I/O door as…

3. Dorner – Conveyor System Installation Services

Domain: dornerconveyors.com

Registered: 2007 (18 years)

Introduction: Installation services for Dorner conveyor systems include professional on-site installation by qualified engineers, ensuring efficient and trouble-free startup. Services offered are complete turn-key installation, including delivery, staging, set-up, debugging, and maintenance training. Dorner provides supervision for installations using customer or third-party staff, with a focus on safety and ef…

4. JH Foster – Conveyor Systems

Domain: jhfoster.com

Registered: 1998 (27 years)

Introduction: Conveyor systems are essential for moving and sorting products in factories and industrial operations. The most popular type is the belt conveyor, known for its affordability and ability to move various materials over long distances. Installation costs are generally estimated at about $1,500 per linear foot, which includes wire rope, supports, power source, and miscellaneous hardware. Additional a…

Strategic Sourcing Conclusion and Outlook for conveyor installation

What Are the Key Takeaways for B2B Buyers in Conveyor Installation?

In conclusion, strategic sourcing plays a pivotal role in ensuring a successful conveyor installation process. By prioritizing thorough planning, meticulous design, and expert execution, businesses can significantly enhance operational efficiency and reduce potential downtime. Engaging with experienced professionals can help navigate the complexities of installation while adhering to safety and compliance standards, ultimately leading to cost savings and improved productivity.

How Can International Buyers Leverage Strategic Sourcing for Conveyor Systems?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, the importance of sourcing quality conveyor systems cannot be overstated. Investing in reliable, well-designed conveyor solutions not only streamlines material handling but also supports scalability and adaptability in a rapidly changing market landscape.

What Is the Future Outlook for Conveyor Installation in Your Region?

As industries continue to evolve, the demand for innovative conveyor solutions will only grow. Now is the time to partner with trusted suppliers and leverage strategic sourcing to future-proof your operations. Engage with professionals who understand the unique challenges of your region and can provide tailored solutions that meet your specific needs. Don’t wait—take the first step towards optimizing your material handling systems today.

Illustrative image related to conveyor installation

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.