A Deep Dive into Conveyor Belt Drive Design Solution

Introduction: Navigating the Global Market for conveyor belt drive design

Navigating the complexities of conveyor belt drive design can be a daunting task for international B2B buyers, especially when sourcing reliable solutions tailored to diverse operational needs. With various types of conveyor systems available—ranging from flat and roller conveyors to advanced pneumatic and screw systems—understanding the right fit for your specific application is crucial. This guide provides an in-depth exploration of conveyor belt drive design, covering essential aspects such as types, applications, supplier vetting, and cost considerations.

For businesses in regions like Africa, South America, the Middle East, and Europe, including emerging markets like Saudi Arabia and Brazil, making informed purchasing decisions is vital to optimize efficiency and reduce operational costs. The insights offered here will empower you to navigate the global market with confidence, ensuring you select the most suitable conveyor systems that align with your production requirements.

By understanding the key components, including drive systems, belting materials, and maintenance needs, this guide equips you with the knowledge to enhance productivity and streamline material handling processes. Whether you’re looking to improve your supply chain logistics or upgrade your existing systems, this comprehensive resource serves as a strategic tool to drive your business forward in today’s competitive landscape.

Understanding conveyor belt drive design Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Belt Conveyor | Simple design, versatile for horizontal transport | Warehousing, food processing | Pros: Cost-effective, easy maintenance. Cons: Limited incline capability. |

| Roller Conveyor | Utilizes powered or non-powered rollers for easy movement | Construction, bulk material handling | Pros: Handles heavy loads, low friction. Cons: Requires more space for installation. |

| Cleated Conveyor | Features raised cleats to prevent slippage on inclines | Mining, agricultural transport | Pros: Effective for steep inclines. Cons: More complex design increases cost. |

| Bucket Elevator | Vertical transport using buckets attached to a belt | Grain handling, mining | Pros: Efficient for bulk materials, space-saving. Cons: Limited to specific materials. |

| Magnetic Conveyor | Incorporates magnets to hold ferrous materials | Recycling, automotive parts handling | Pros: Ideal for metal objects, reduces slippage. Cons: Limited to magnetic materials. |

What Are the Key Characteristics of Flat Belt Conveyors?

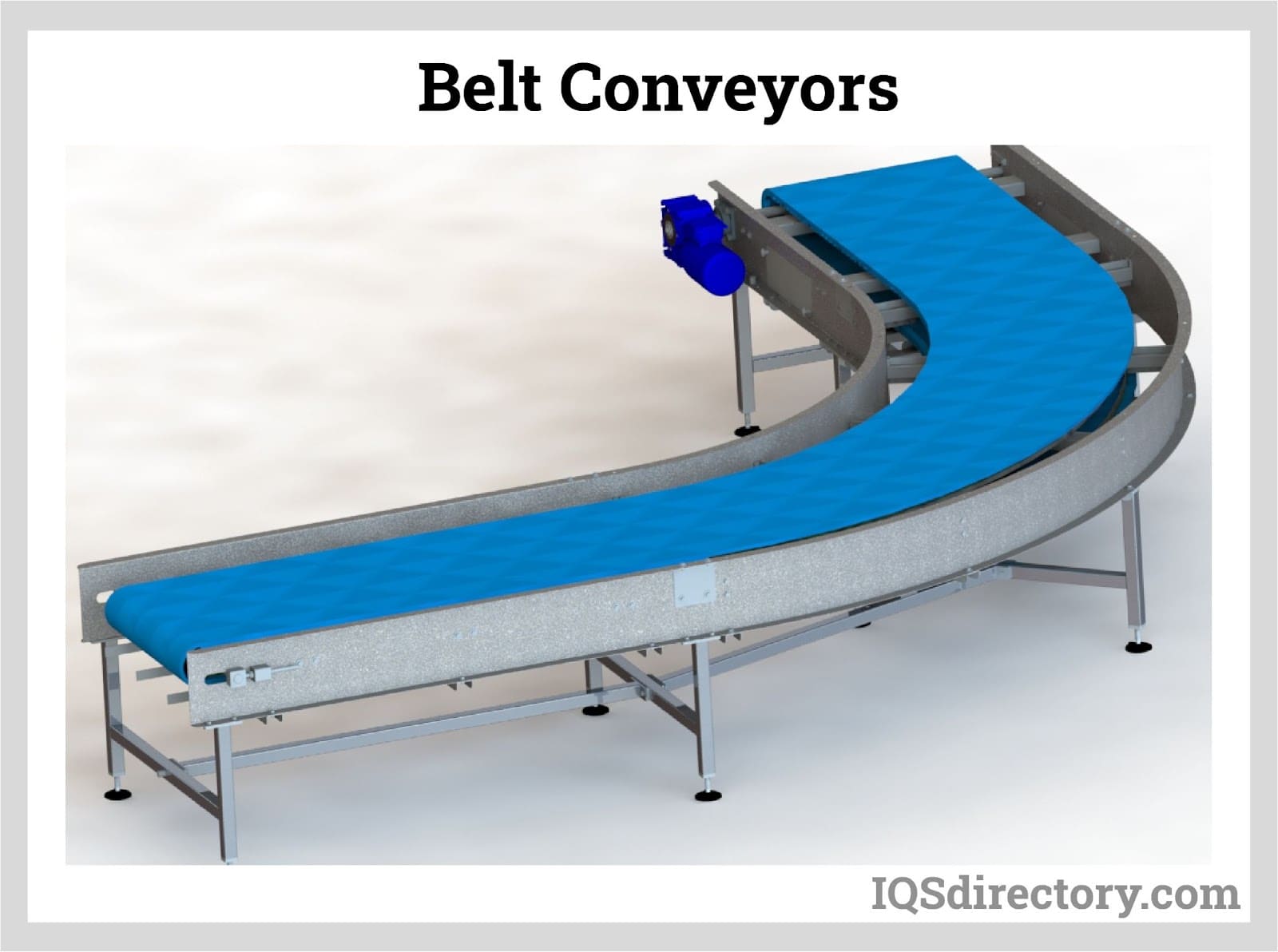

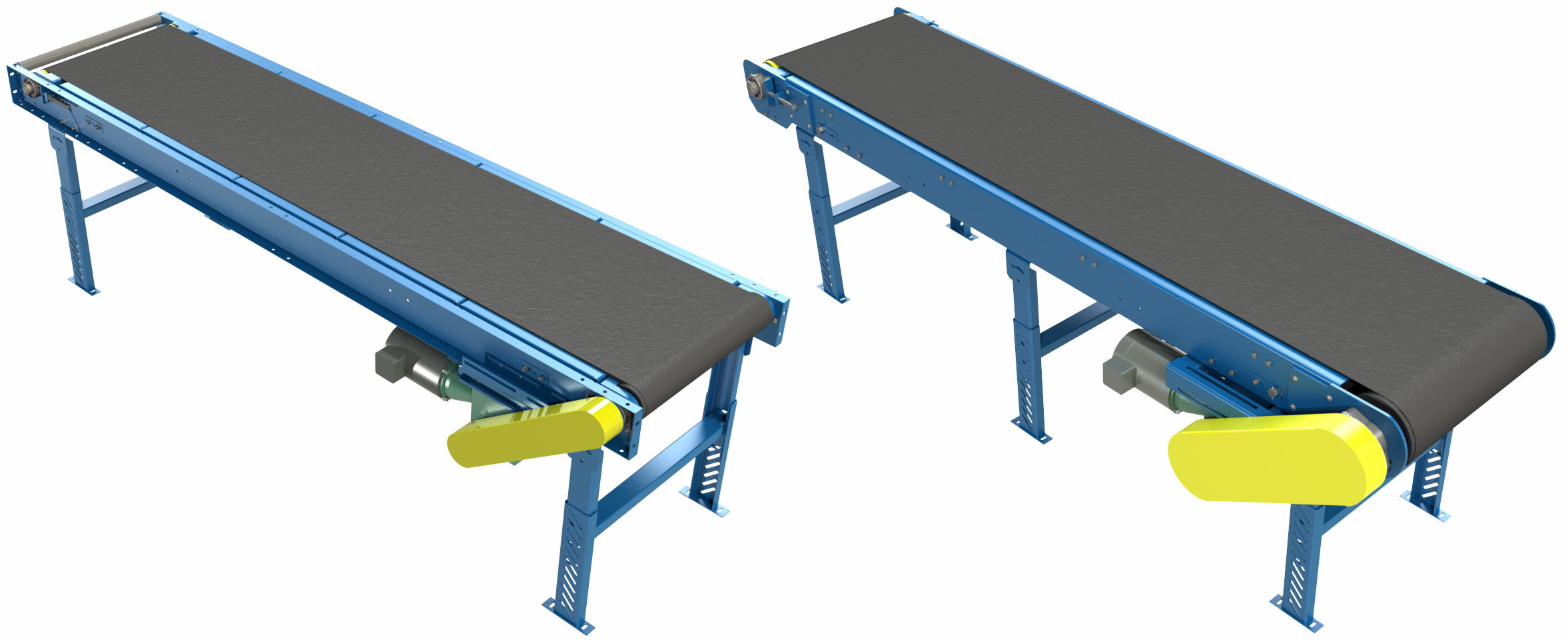

Flat belt conveyors are characterized by their simple, continuous design that allows for the horizontal or slight incline movement of materials. They are highly versatile and can handle various products, making them a staple in industries like warehousing and food processing. When considering a flat belt conveyor, B2B buyers should evaluate the material characteristics, as well as the required speed and load capacity, to ensure compatibility with their specific applications.

How Do Roller Conveyors Stand Out in Material Handling?

Roller conveyors utilize a series of rollers to facilitate the movement of heavy or irregularly shaped items. They are particularly effective in construction and bulk material handling applications, where heavy loads need to be transported efficiently. Buyers should consider the space available for installation and the need for powered versus non-powered rollers, as these factors can significantly influence operational efficiency and cost.

Why Are Cleated Conveyors Essential for Certain Industries?

Cleated conveyors are designed with raised elements or cleats on the belt surface, making them ideal for transporting materials on inclines or declines. Commonly used in mining and agricultural transport, they prevent slippage and ensure the safe movement of bulk materials. When purchasing, buyers should assess the incline angles required and the specific materials being transported to maximize efficiency and minimize wear on the conveyor system.

What Advantages Do Bucket Elevators Provide for Bulk Handling?

Bucket elevators are engineered for vertical transport, utilizing buckets attached to a belt to move bulk materials like grains and minerals. Their design is particularly beneficial in industries where space is limited, as they can move materials upward without requiring extensive floor space. Buyers should consider the type of material being handled, as well as the elevator’s capacity and height requirements, to ensure it meets operational needs.

How Do Magnetic Conveyors Enhance Material Handling Processes?

Magnetic conveyors are specialized systems that utilize magnets to secure ferrous materials during transport. They are widely used in recycling and automotive parts handling industries, where maintaining the integrity of metal components is crucial. Buyers should evaluate the types of materials being processed and the specific magnetic requirements to ensure optimal performance and minimize operational disruptions.

Key Industrial Applications of conveyor belt drive design

| Industry/Sector | Specific Application of conveyor belt drive design | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Transporting raw ingredients and finished products | Enhances efficiency, reduces manual labor, ensures hygiene | Compliance with food safety standards, ease of cleaning, durability |

| Mining | Moving bulk materials such as ore and coal | Increases operational efficiency, minimizes downtime | Material strength, resistance to wear and tear, capacity requirements |

| Automotive Manufacturing | Assembling vehicles and transporting parts | Streamlines production processes, reduces lead times | Customization options, integration with existing systems, maintenance needs |

| Construction | Handling heavy materials like concrete and steel | Improves site productivity, reduces labor costs | Load capacity, mobility, and adaptability to site conditions |

| Packaging | Automating the packaging process for various products | Increases throughput, reduces errors in packaging | Compatibility with packaging machinery, speed control, material handling capabilities |

How is Conveyor Belt Drive Design Applied in Food Processing?

In the food processing industry, conveyor belt drive design is crucial for transporting raw ingredients and finished products through various stages of production. These systems help maintain hygiene standards by minimizing manual handling and are designed for easy cleaning. For international buyers, especially in regions with strict food safety regulations, sourcing conveyor systems that comply with these standards while offering durability and efficiency is essential. The ability to integrate variable speed drives also allows for adjustments based on production demands, optimizing workflow.

What Role Does Conveyor Belt Drive Design Play in Mining Operations?

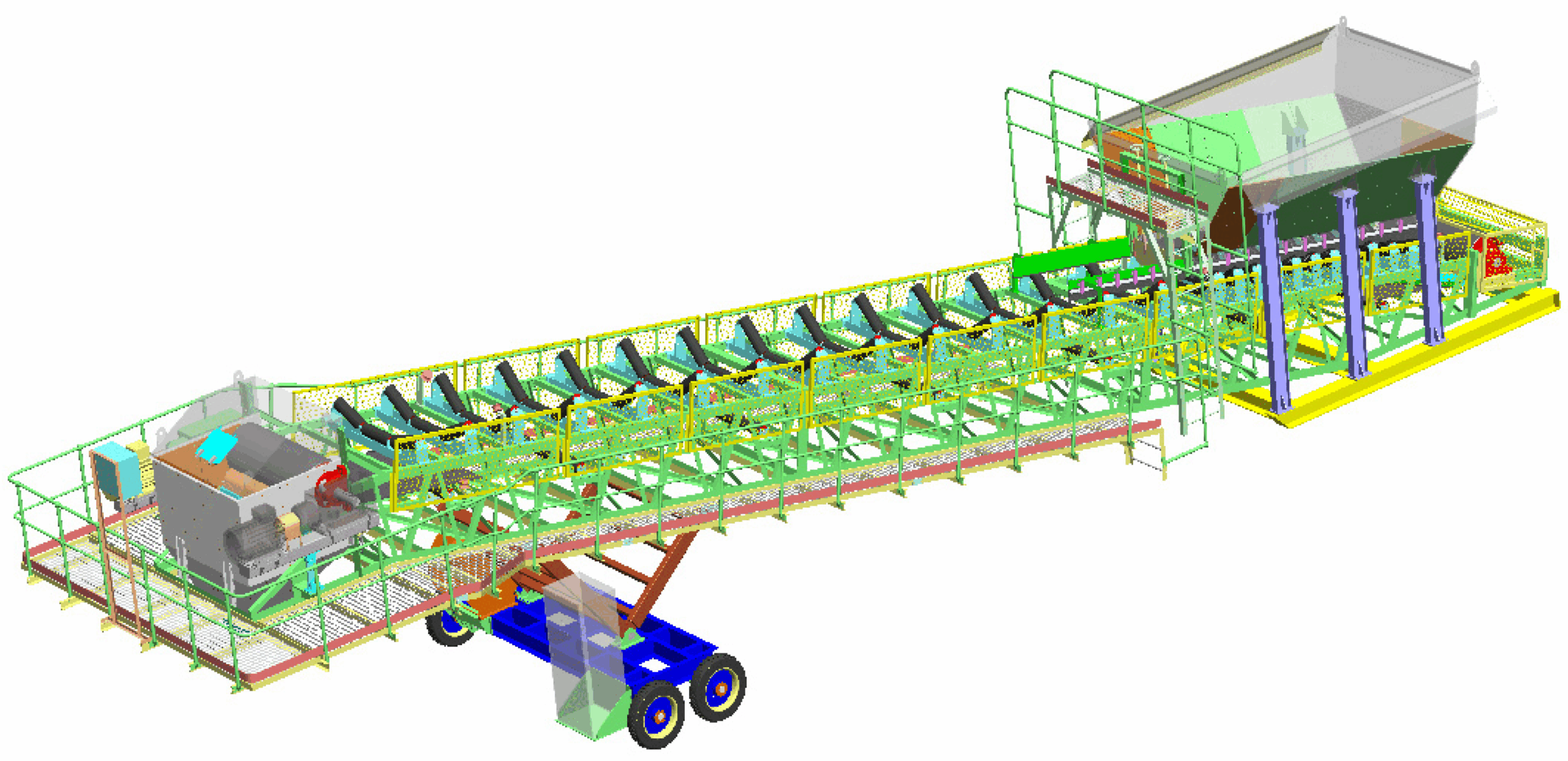

Mining operations rely heavily on conveyor belt drive design to move bulk materials, such as ore and coal, efficiently from extraction points to processing facilities. These systems are engineered to withstand harsh conditions and heavy loads, significantly increasing operational efficiency and reducing downtime. Buyers in Africa and South America, where mining is a key industry, should prioritize sourcing conveyors with high resistance to wear and tear and ensure that they meet the specific capacity requirements of their operations.

How is Conveyor Belt Drive Design Used in Automotive Manufacturing?

In automotive manufacturing, conveyor belt drive design facilitates the seamless assembly of vehicles by transporting parts along the production line. This design minimizes lead times and enhances production efficiency, allowing manufacturers to meet high demand. Key considerations for international buyers include the need for customization to fit existing assembly lines, as well as the reliability of the drive systems to minimize maintenance disruptions. Choosing a supplier that offers robust support and integration services is critical in this fast-paced industry.

Why is Conveyor Belt Drive Design Important in Construction?

The construction sector utilizes conveyor belt drive design to handle heavy materials, such as concrete and steel, efficiently on job sites. This reduces labor costs and improves overall site productivity by automating the transportation of materials. When sourcing conveyor systems, buyers must consider the load capacity and adaptability of the design to various site conditions, especially in regions with challenging terrains. Mobile conveyor systems that can be easily relocated are particularly advantageous in dynamic construction environments.

How Does Conveyor Belt Drive Design Enhance Packaging Processes?

In packaging applications, conveyor belt drive design automates the movement of products through various packaging stages, significantly increasing throughput and reducing human error. This efficiency is vital for maintaining competitive advantage in fast-moving consumer goods markets. International buyers should look for conveyor systems that are compatible with existing packaging machinery and offer features like speed control to adapt to different product types. Additionally, sourcing from suppliers who provide robust after-sales support can enhance operational reliability in packaging processes.

3 Common User Pain Points for ‘conveyor belt drive design’ & Their Solutions

Scenario 1: Inefficient Material Handling Leading to Downtime

The Problem: A manufacturing plant in Brazil faces frequent production delays due to the inefficiency of its conveyor belt drive system. The existing design struggles to handle heavy loads, causing the belt to slip and misalign. This misalignment not only disrupts the flow of materials but also leads to excessive wear on components, resulting in costly downtime for repairs. The team is frustrated as they cannot meet production targets, and the financial impact of halted operations is significant.

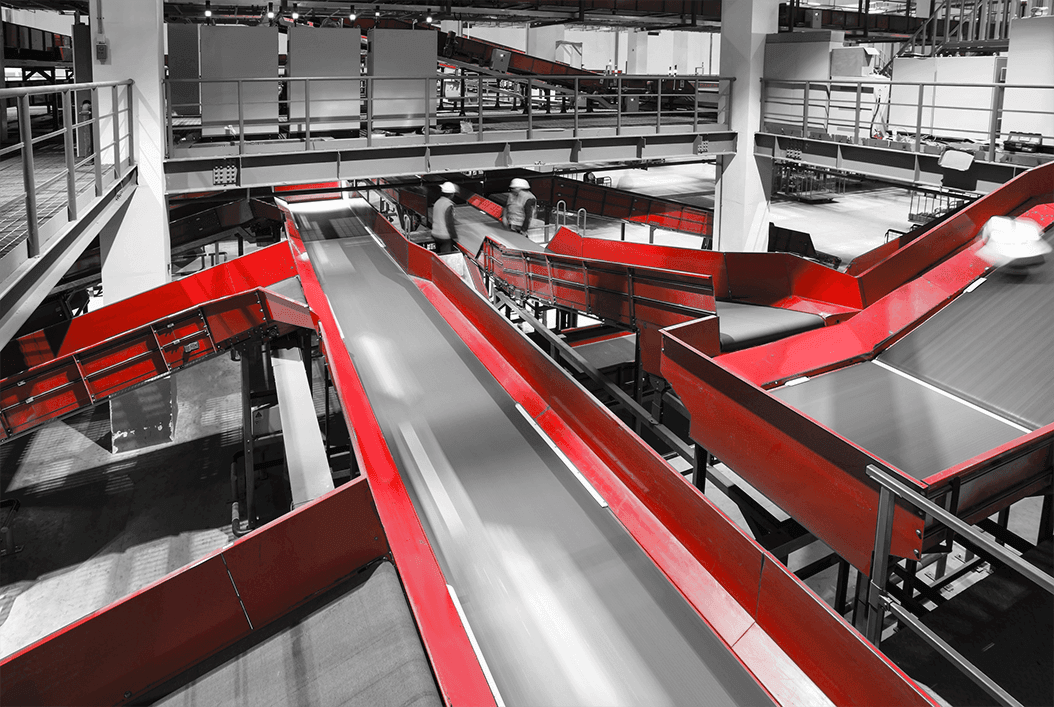

Illustrative image related to conveyor belt drive design

The Solution: To address this issue, it is essential to reassess the conveyor belt drive design with a focus on load capacity and alignment features. B2B buyers should source heavy-duty conveyor belts specifically engineered for high-capacity applications. Opting for a drive system that includes adjustable pulleys and a robust take-up mechanism will help maintain proper tension and alignment, reducing slippage. Additionally, integrating variable speed drives can optimize the belt speed according to load variations, enhancing overall efficiency. Regular maintenance schedules should also be established to monitor wear and ensure timely adjustments, preventing future downtimes.

Scenario 2: Inadequate Material Compatibility Causing Damage

The Problem: A company in Saudi Arabia specializing in food processing is experiencing significant challenges with its conveyor belt system. The existing belt is made of a material that does not withstand the high temperatures and chemical exposure from the products being processed. As a result, the belt degrades quickly, leading to material contamination and increased operational costs due to frequent replacements and cleaning protocols.

The Solution: To resolve this compatibility issue, buyers should conduct a thorough analysis of the materials being conveyed and the environmental conditions they will face. It is crucial to select a conveyor belt made from heat-resistant and chemically inert materials, such as specialized rubber or metal belting. Consulting with manufacturers who provide customized conveyor solutions can lead to the development of a tailored drive design that incorporates the necessary features for food-grade applications. Implementing a training program for staff on proper handling and maintenance can also mitigate damage and prolong the lifespan of the conveyor system.

Scenario 3: Complex Integration with Existing Systems

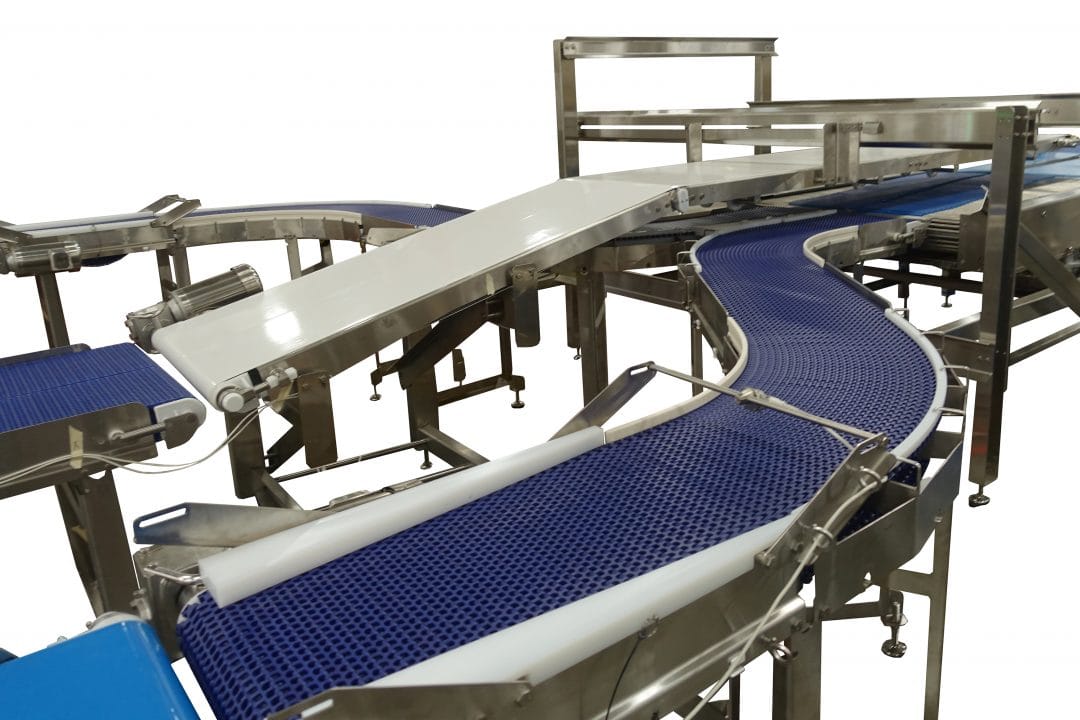

The Problem: An electronics manufacturing firm in Europe is struggling to integrate its new conveyor belt system with existing machinery. The challenge lies in the lack of compatibility between the conveyor drive’s control systems and the current inventory management software. This disconnection results in bottlenecks in production, as operators must manually synchronize the flow of materials, leading to inefficiencies and increased labor costs.

The Solution: To streamline operations, it is vital to choose a conveyor belt drive design that supports compatibility with existing systems. B2B buyers should prioritize conveyor solutions that offer advanced control systems with communication protocols such as Ethernet/IP or Modbus. These systems can seamlessly integrate with existing inventory management software, enabling real-time data exchange and automated control of the conveyor speed and operation. Additionally, working closely with a systems integrator during the design phase can ensure that the new conveyor system is tailored to fit within the existing operational framework, ultimately enhancing productivity and reducing manual intervention.

Strategic Material Selection Guide for conveyor belt drive design

What Are the Key Properties of Rubber in Conveyor Belt Drive Design?

Rubber is one of the most common materials used in conveyor belt drive design due to its excellent flexibility and grip. It typically operates effectively at temperatures ranging from -30°C to 80°C, making it suitable for a variety of environments. Rubber’s inherent elasticity allows it to absorb shock and reduce wear on both the belt and the components it interacts with. However, it is not inherently resistant to chemicals or UV light, which can lead to degradation over time.

Illustrative image related to conveyor belt drive design

Pros and Cons of Rubber

The primary advantage of rubber is its durability and ability to handle abrasive materials, making it ideal for heavy-duty applications. Its lower cost compared to other materials also makes it a popular choice among manufacturers. However, rubber can be prone to wear and tear, particularly in harsh environments, and may require more frequent replacements, leading to higher long-term costs.

Impact on Application

Rubber’s compatibility with various media types, including bulk materials in mining and agriculture, makes it a versatile choice. However, its limitations in extreme temperatures or chemical exposure must be considered when selecting rubber for specific applications.

How Does PVC Compare as a Material for Conveyor Belt Drive Design?

Polyvinyl chloride (PVC) is another widely used material in conveyor belt systems, known for its excellent resistance to chemicals, oils, and fats. PVC belts can typically withstand temperatures from -10°C to 60°C, making them suitable for food processing and packaging applications. Their lightweight nature contributes to lower energy consumption during operation.

Pros and Cons of PVC

PVC’s key advantage lies in its chemical resistance and ease of cleaning, which is crucial in industries such as food and pharmaceuticals. Its lower manufacturing complexity also allows for cost-effective production. However, PVC is less durable than rubber and may not perform well under heavy loads or extreme temperatures, limiting its use in heavy-duty applications.

Illustrative image related to conveyor belt drive design

Impact on Application

PVC’s compatibility with food-grade standards makes it a preferred choice in the food industry, particularly for transporting raw ingredients or packaged goods. However, buyers must ensure compliance with local regulations regarding food safety.

What Are the Benefits of Metal in Conveyor Belt Drive Design?

Metal conveyor belts, often made from stainless steel or other alloys, are known for their strength and durability. They can handle high temperatures (up to 1200°C in some cases) and are highly resistant to corrosion, making them suitable for applications in high-temperature environments like foundries and bakeries.

Pros and Cons of Metal

The main advantage of metal belts is their longevity and ability to carry heavy loads without deformation. They are also easy to clean, making them suitable for hygienic applications. However, the cost of metal belts is generally higher than rubber or PVC, and their manufacturing complexity can lead to longer lead times.

Impact on Application

Metal belts are ideal for industries requiring high durability and temperature resistance. However, buyers must consider the additional weight and potential for increased energy consumption when integrating metal belts into their systems.

What Role Does Fabric Play in Conveyor Belt Drive Design?

Fabric belts, often made from polyester or nylon, are lightweight and flexible, making them suitable for a variety of applications. They typically operate effectively at temperatures ranging from -20°C to 70°C. Fabric belts can be coated with various materials to enhance their performance characteristics, such as improving grip or chemical resistance.

Illustrative image related to conveyor belt drive design

Pros and Cons of Fabric

The primary advantage of fabric belts is their lightweight nature, which allows for easier handling and lower energy consumption. They are also customizable, allowing manufacturers to tailor them to specific applications. However, they may not offer the same level of durability as rubber or metal belts, leading to shorter lifespans in heavy-duty applications.

Impact on Application

Fabric belts are ideal for light to medium-duty applications, such as packaging and assembly lines. However, buyers should assess the specific load and environmental conditions to ensure fabric belts will meet their operational needs.

Summary of Material Selection for Conveyor Belt Drive Design

| Material | Typical Use Case for conveyor belt drive design | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Heavy-duty applications in mining and agriculture | Excellent durability and flexibility | Prone to wear in harsh conditions | Medium |

| PVC | Food processing and packaging | Chemical resistance and ease of cleaning | Less durable under heavy loads | Low |

| Metal | High-temperature environments in foundries | High strength and longevity | Higher cost and manufacturing complexity | High |

| Fabric | Light to medium-duty applications like packaging | Lightweight and customizable | Shorter lifespan in heavy-duty use | Medium |

This strategic material selection guide provides essential insights for international B2B buyers in Africa, South America, the Middle East, and Europe, ensuring they can make informed choices tailored to their specific operational needs and compliance requirements.

Illustrative image related to conveyor belt drive design

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor belt drive design

What Are the Main Stages in the Manufacturing Process of Conveyor Belt Drive Design?

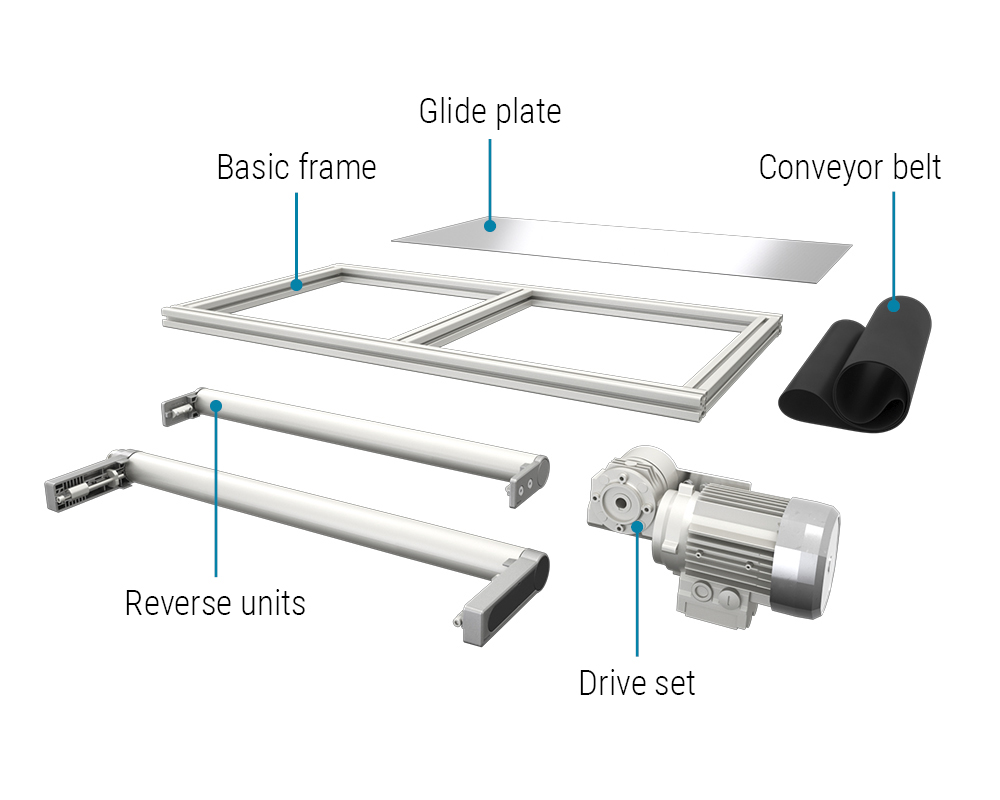

The manufacturing process for conveyor belt drive systems involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product meets the high standards required for effective and efficient material handling.

Material Preparation: What Materials Are Used in Conveyor Belt Drive Design?

Material preparation is the foundational step in conveyor belt drive design. It involves selecting the appropriate materials based on the intended application. Common materials include high-strength steel for frames, various polymers for belts, and specialized alloys for pulleys and drive systems.

Before production, materials undergo thorough inspections to verify their quality and specifications. This may involve checking tensile strength, elasticity, and resistance to wear and environmental factors. Proper material selection not only affects performance but also impacts the longevity and reliability of the conveyor system.

How Is Conveyor Belt Drive Design Formed?

Forming encompasses the techniques used to shape and prepare the materials for assembly. Techniques such as cutting, welding, and machining are employed. For instance, frames are often cut from steel sheets and then welded together to create robust structures capable of supporting heavy loads.

In the case of belts, various forming techniques, including extrusion and molding, are utilized to create the desired shape and surface characteristics. Advanced manufacturing technologies, like CNC machining, ensure precision in components, leading to higher efficiency and reduced operational issues.

What Are the Key Steps in the Assembly of Conveyor Belt Drive Systems?

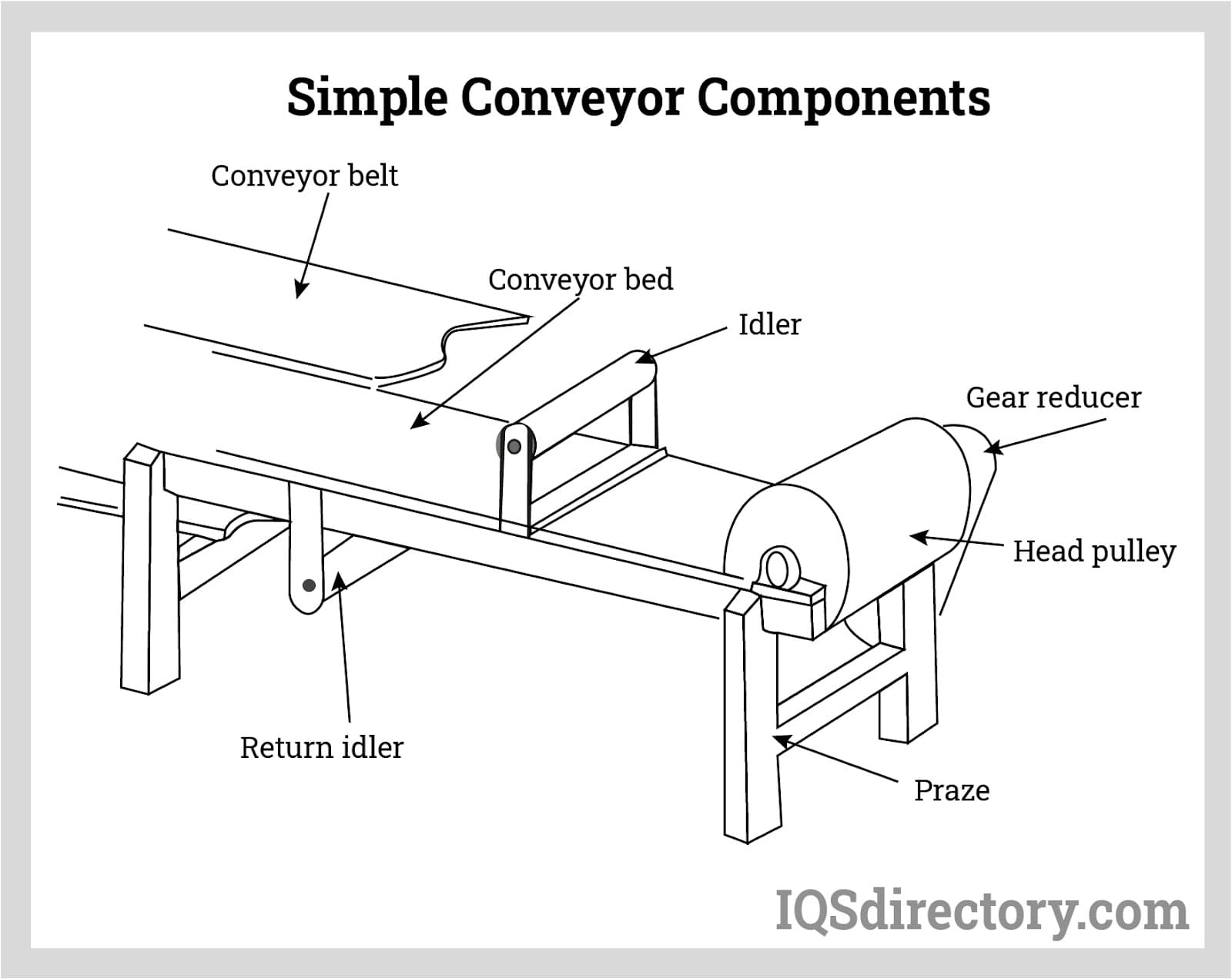

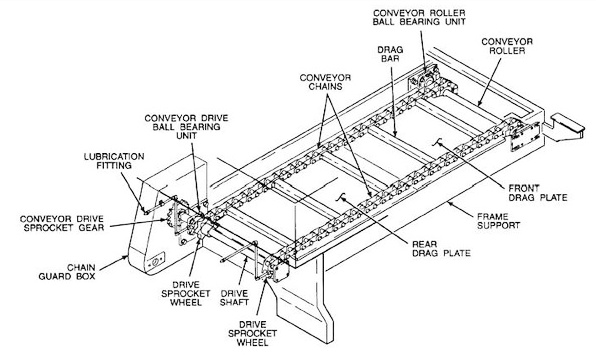

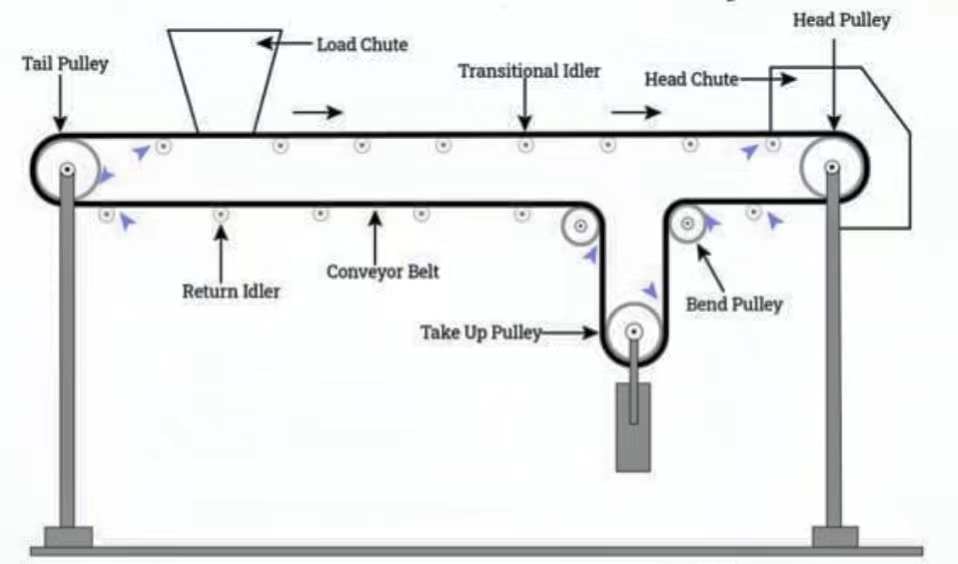

Assembly is where the individual components come together to form the complete conveyor belt drive system. This stage typically includes the integration of the motor, drive pulley, idler rollers, and the belt itself.

During assembly, technicians must ensure that components are aligned correctly and securely fastened. This is crucial for preventing slippage and ensuring smooth operation. Assembly may also involve the installation of a take-up system, which is essential for maintaining belt tension.

What Finishing Processes Are Commonly Applied in Conveyor Belt Drive Design?

Finishing processes are the final steps that enhance durability and aesthetics. This can include surface treatments like painting, galvanizing, or applying protective coatings to prevent corrosion.

Quality finishing not only improves the visual appeal of the conveyor system but also extends its lifespan, particularly in harsh industrial environments. Proper finishing techniques ensure that the conveyor belt drive system can withstand the rigors of daily operation without significant wear.

How Is Quality Assurance Implemented in Conveyor Belt Drive Design?

Quality assurance (QA) is integral to the manufacturing of conveyor belt drive systems. Adhering to international and industry-specific standards is crucial for ensuring product reliability and customer satisfaction.

Which International Standards Are Relevant for Conveyor Belt Drive Design Quality Assurance?

ISO 9001 is a widely recognized international standard that outlines the requirements for a quality management system. Companies involved in conveyor belt drive design often pursue this certification to demonstrate their commitment to quality.

Additionally, industry-specific certifications such as CE marking for products sold in Europe and API standards for applications in oil and gas are also essential. These certifications provide assurance that the products meet safety and performance criteria.

Illustrative image related to conveyor belt drive design

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure compliance with specifications. Key checkpoints include:

-

Incoming Quality Control (IQC): Materials are inspected upon arrival to verify they meet predetermined standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards before they escalate into larger issues.

-

Final Quality Control (FQC): The completed conveyor belt drive system undergoes rigorous testing to ensure it performs as expected under operational conditions.

What Common Testing Methods Are Used to Ensure Quality in Conveyor Belt Drive Design?

Testing methods for conveyor belt drive systems can include:

-

Performance Testing: Assessing the system under operational conditions to evaluate efficiency and load capacity.

-

Durability Testing: Subjecting components to stress tests to determine their longevity and resistance to wear.

-

Safety Testing: Ensuring compliance with safety standards, particularly in environments where human interaction occurs.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence to verify the quality control practices of suppliers. This can involve:

-

Audits: Regular audits of supplier facilities can provide insights into their manufacturing processes and QC practices.

-

Reports: Requesting detailed quality assurance reports and certifications can help buyers assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspectors can further validate the quality of the products being supplied.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Factors such as regional regulations, import/export compliance, and specific market demands can influence quality expectations.

Additionally, buyers should be aware of cultural differences in business practices and communication styles that may affect supplier relationships. Establishing clear expectations and maintaining open lines of communication can lead to more successful partnerships.

Conclusion: Why Is Quality Assurance Critical in Conveyor Belt Drive Design?

Quality assurance in conveyor belt drive design is not just a regulatory requirement; it is essential for ensuring operational efficiency and reliability. For B2B buyers, understanding the manufacturing processes and quality control measures can lead to more informed purchasing decisions, ultimately resulting in enhanced productivity and reduced operational costs. By prioritizing quality, businesses can ensure that their conveyor systems operate smoothly and effectively in demanding environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor belt drive design’

In today’s competitive market, selecting the right conveyor belt drive design is crucial for optimizing material handling processes. This checklist serves as a practical guide for B2B buyers to ensure they make informed decisions while sourcing conveyor belt systems tailored to their operational needs.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s essential to clearly outline your technical requirements. Consider factors such as the type of materials you will be transporting, weight capacity, and operational environment. This clarity will help you communicate effectively with potential suppliers and ensure they can meet your specific needs.

- Material Characteristics: Assess the size, shape, and weight of the materials to be conveyed.

- Operating Environment: Consider temperature, humidity, and potential exposure to chemicals.

Step 2: Research Different Conveyor Belt Types

Understand the various types of conveyor belts available and their respective applications. Each type, whether flat, roller, or cleated, has distinct advantages based on the materials being handled and the layout of your facility.

- Flat Belts: Ideal for horizontal transport of packaged goods.

- Cleated Belts: Perfect for inclined transport, preventing materials from slipping.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Request detailed company profiles, client testimonials, and case studies relevant to your industry. This step helps ensure that the supplier has a proven track record and can deliver quality products.

- References: Ask for references from clients in similar industries or regions.

- Certifications: Verify that suppliers hold relevant industry certifications for quality assurance.

Step 4: Assess Material Quality and Durability

Quality of materials used in conveyor belt construction directly impacts performance and lifespan. Inquire about the specifications of the belting materials, such as rubber, PVC, or metal, and ensure they are suitable for your application.

- Abrasion Resistance: For heavy-duty applications, opt for belts with high abrasion resistance.

- Temperature Tolerance: Ensure materials can withstand your operating temperatures.

Step 5: Consider Customization Options

Many suppliers offer customization to meet specific operational needs. Discuss the possibility of tailored designs that can enhance functionality or efficiency in your particular environment.

Illustrative image related to conveyor belt drive design

- Size Adjustments: Ensure the supplier can accommodate the dimensions required for your setup.

- Special Features: Inquire about features like variable speed drives or specialized surface treatments.

Step 6: Review Maintenance and Support Services

A well-designed conveyor system should facilitate easy maintenance to minimize downtime. Ask about the accessibility of components and the availability of maintenance services.

- Access Points: Ensure that critical parts are easily accessible for repairs.

- After-Sales Support: Confirm the supplier provides comprehensive after-sales support and training.

Step 7: Compare Pricing and Total Cost of Ownership

While initial pricing is important, consider the total cost of ownership, which includes installation, maintenance, and operational efficiency. Request detailed quotes from multiple suppliers and compare them against the long-term benefits they offer.

- Installation Costs: Factor in the expenses related to installation and setup.

- Energy Efficiency: Evaluate the energy consumption of different systems to gauge long-term savings.

By following this checklist, B2B buyers can make informed decisions regarding conveyor belt drive design that align with their operational needs and budget, ensuring a successful procurement process.

Illustrative image related to conveyor belt drive design

Comprehensive Cost and Pricing Analysis for conveyor belt drive design Sourcing

What Are the Key Cost Components in Conveyor Belt Drive Design?

When sourcing conveyor belt drive systems, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. For example, rubber belts may be less expensive than metal belts but might not suit high-temperature applications. Materials also vary in durability and lifespan, influencing long-term costs.

-

Labor: Labor costs encompass both manufacturing and assembly. Skilled labor is often required for precision assembly and installation, particularly for complex systems. Buyers should consider the labor market dynamics in the supplier’s region, as this can affect pricing.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. Understanding the supplier’s overhead can provide insights into their pricing strategy.

-

Tooling: Special tools and dies used in manufacturing can add to upfront costs. If custom designs are required, this can further increase expenses.

-

Quality Control (QC): Implementing stringent QC measures ensures reliability and compliance with industry standards. While this may raise initial costs, it can lead to savings in the long run by reducing failures and downtime.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, shipping method, and customs duties can significantly affect the total price.

-

Margin: Supplier profit margins vary widely. Understanding the typical margins in the conveyor belt industry can aid buyers in negotiating better terms.

How Do Price Influencers Affect Conveyor Belt Drive Design Costs?

Several factors can influence the pricing of conveyor belt drive designs:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically reduce the per-unit cost. Establishing a good relationship with suppliers can lead to better pricing for bulk purchases.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. Ensure that specifications are clear to avoid unexpected price hikes.

-

Materials: As previously mentioned, the choice of materials can drastically alter pricing. Buyers should balance cost with the performance characteristics necessary for their applications.

-

Quality and Certifications: Higher-quality products with relevant certifications (ISO, CE) may come with a premium price. However, investing in certified products can enhance reliability and reduce long-term costs.

-

Supplier Factors: Supplier reputation, location, and reliability play a role in pricing. Established suppliers may charge more but often provide better service and product quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly impacting overall costs.

What Negotiation and Cost-Efficiency Tips Should Buyers Consider?

To maximize value when sourcing conveyor belt drive designs, consider the following tips:

-

Negotiate Based on Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, evaluate the TCO, which includes installation, maintenance, and operational costs over the product’s lifespan.

-

Leverage Volume Discounts: If feasible, consolidate orders or collaborate with other businesses to reach higher purchase volumes, securing better pricing.

-

Evaluate Different Suppliers: Don’t settle for the first quote. Compare multiple suppliers to identify the best combination of price, quality, and service.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, local suppliers may offer lower shipping costs and faster delivery times, which can influence overall pricing.

-

Be Aware of Currency Fluctuations: For international transactions, currency exchange rates can impact costs. Consider locking in rates when favorable.

Conclusion: Why Is It Important to Stay Informed About Pricing Nuances?

Understanding the complexities of cost and pricing in conveyor belt drive design sourcing is vital for international B2B buyers. This knowledge empowers businesses to make informed decisions, negotiate effectively, and ultimately choose solutions that align with their operational needs and budget constraints. Always remember that indicative prices can vary, so regular market analysis and supplier engagement are key to successful procurement strategies.

Alternatives Analysis: Comparing conveyor belt drive design With Other Solutions

Exploring Alternatives to Conveyor Belt Drive Design

In the realm of material handling, conveyor belt drive systems are widely recognized for their efficiency and versatility. However, there are several alternative technologies that also facilitate the movement of goods and materials. Understanding the strengths and weaknesses of these alternatives can empower B2B buyers to make informed decisions tailored to their specific operational requirements.

Illustrative image related to conveyor belt drive design

Comparison Table

| Comparison Aspect | Conveyor Belt Drive Design | Bucket Elevators | Roller Conveyors |

|---|---|---|---|

| Performance | High throughput for bulk materials; suitable for long distances | Ideal for vertical lifting; efficient for bulk materials | Excellent for irregular shapes; allows gravity-assisted movement |

| Cost | Moderate initial investment; variable ongoing maintenance costs | Higher upfront costs; low maintenance | Lower initial investment; moderate maintenance |

| Ease of Implementation | Requires careful planning and space allocation | Space-intensive; more complex installation | Simple setup; adaptable to existing layouts |

| Maintenance | Regular inspections needed; accessible components | Minimal, but requires specialized parts | Easy access; low frequency of issues |

| Best Use Case | Transporting large volumes over flat or inclined surfaces | Elevating bulk materials in agricultural or mining settings | Handling diverse items in warehouses or production lines |

Detailed Breakdown of Alternatives

Bucket Elevators

Bucket elevators are designed for vertical lifting of bulk materials, making them an excellent choice for applications in agriculture and mining. The primary advantage of bucket elevators is their ability to transport large volumes of materials upward, thus saving floor space. However, they come with higher initial costs and require careful planning for installation, as they are space-intensive. Additionally, while they have low ongoing maintenance needs, any repairs may necessitate specialized knowledge and parts, which can lead to downtime.

Roller Conveyors

Roller conveyors utilize a series of rollers to facilitate the movement of goods, making them particularly effective for irregularly shaped items. They allow for gravity-assisted transport, which can reduce energy costs and increase efficiency. Roller conveyors are often simpler to implement and can be easily integrated into existing setups, providing flexibility for various layouts. However, they may not be as effective for bulk material transport as conveyor belts, and their performance can be limited by the weight and shape of the items being handled.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between conveyor belt drive design and its alternatives, B2B buyers should carefully consider their specific operational needs, including the types of materials being transported, the layout of their facilities, and budget constraints. Each option has distinct advantages and potential drawbacks. By evaluating performance, cost, ease of implementation, maintenance requirements, and best use cases, businesses can select the most effective solution that aligns with their operational goals. Whether you prioritize vertical lifting capabilities, flexibility in handling diverse items, or the efficiency of bulk material transport, making an informed choice will ultimately enhance productivity and streamline operations.

Essential Technical Properties and Trade Terminology for conveyor belt drive design

Understanding the key specifications and terminology associated with conveyor belt drive design is crucial for B2B buyers looking to optimize their material handling systems. This knowledge enables informed decision-making, ensuring the right equipment is selected for specific applications.

What Are the Essential Technical Properties of Conveyor Belt Drive Design?

-

Material Grade

The material grade of the conveyor belt is a critical specification that affects durability, flexibility, and resistance to wear and tear. Common materials include rubber, PVC, and metal, each offering unique advantages based on the application. For instance, rubber belts are ideal for abrasive materials, while metal belts can withstand extreme temperatures. Understanding material grades helps buyers select a conveyor that meets their operational needs and minimizes downtime. -

Belt Thickness

Belt thickness directly influences the load capacity and longevity of the conveyor system. Thicker belts can handle heavier loads and are less prone to damage from sharp objects. Conversely, thinner belts may be more suitable for lighter applications where flexibility is essential. Buyers should evaluate their load requirements and choose a thickness that balances performance and cost-effectiveness. -

Tension Rating

The tension rating indicates the maximum load that a conveyor belt can handle without failure. This specification is vital for ensuring the belt operates within safe limits, preventing slippage or breakage during heavy use. A proper tension rating helps maintain operational efficiency and extends the lifespan of both the belt and the entire conveyor system. -

Belt Width

The width of the conveyor belt impacts its load-bearing capacity and the type of materials it can transport. Wider belts are necessary for bulk materials, while narrower belts might suffice for smaller items. Buyers should assess their specific handling requirements to determine the appropriate belt width, ensuring optimal performance and efficiency. -

Belt Speed

Belt speed is a critical performance metric that influences the throughput of materials. Adjusting the speed can enhance productivity in manufacturing processes, but it must align with the characteristics of the materials being transported. A well-defined belt speed ensures smooth operations, reducing the risk of bottlenecks and improving overall workflow efficiency. -

Take-Up System

The take-up system is essential for maintaining proper belt tension, which prevents slippage and ensures smooth movement. An effective take-up mechanism allows for easy adjustments, accommodating wear and tear over time. Understanding the importance of a reliable take-up system is vital for maintaining operational efficiency and reducing maintenance costs.

What Are Common Trade Terms in Conveyor Belt Drive Design?

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are then sold under another company’s brand name. In the context of conveyor systems, purchasing from an OEM ensures that the buyer receives equipment specifically designed for their needs, often leading to better performance and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it affects inventory management and cost efficiency. Buyers should negotiate MOQs that align with their operational needs to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. This process allows buyers to compare options and negotiate better deals. Crafting a comprehensive RFQ can lead to favorable pricing and terms, enhancing procurement efficiency. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers navigate international trade more effectively, ensuring clarity in contractual obligations and reducing potential disputes. -

Lead Time

Lead time refers to the time it takes from placing an order until its delivery. Understanding lead times is crucial for planning and inventory management, especially in industries with tight production schedules. Buyers should factor in lead times when placing orders to ensure they meet operational demands. -

Service Level Agreement (SLA)

An SLA is a contract that outlines the expected level of service between a supplier and a buyer. It typically includes performance metrics, response times, and quality standards. Establishing an SLA helps ensure accountability and aligns expectations, fostering a smoother working relationship.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions that enhance their conveyor belt drive design and overall operational efficiency.

Illustrative image related to conveyor belt drive design

Navigating Market Dynamics and Sourcing Trends in the conveyor belt drive design Sector

What Are the Current Market Dynamics and Key Trends in Conveyor Belt Drive Design?

The conveyor belt drive design sector is currently experiencing significant transformation driven by global industrial demands and technological advancements. Key trends include the integration of automation and IoT technologies, which enhance operational efficiency and allow for real-time monitoring of conveyor systems. As industries in Africa, South America, the Middle East, and Europe continue to modernize, there is a growing need for flexible and adaptive conveyor solutions. This trend is particularly pronounced in sectors like mining, agriculture, and manufacturing, where efficient material handling is critical.

Another notable trend is the shift towards variable speed drives, which enable precise control over conveyor operations. This capability allows businesses to tailor their material handling processes based on the specific characteristics of the products being transported. Additionally, the demand for customized solutions is on the rise as companies seek to optimize their production lines. International B2B buyers are increasingly looking for manufacturers that can provide tailored conveyor belt systems, ensuring that their unique operational needs are met.

Moreover, sustainability is becoming an essential consideration in sourcing decisions. Buyers are seeking suppliers who prioritize eco-friendly materials and practices in their conveyor belt designs. This shift reflects a broader market movement towards sustainable manufacturing processes, driven by both regulatory requirements and consumer expectations. Companies that can demonstrate a commitment to sustainability will likely have a competitive edge in the evolving marketplace.

How Are Sustainability and Ethical Sourcing Influencing Conveyor Belt Drive Design?

The environmental impact of conveyor belt systems is a growing concern for international B2B buyers. As industries grapple with climate change and resource depletion, there is an increasing demand for sustainable and ethically sourced materials in conveyor belt drive design. The use of recycled and eco-friendly materials, such as biodegradable polymers or sustainably sourced metals, is becoming more prevalent. Buyers are encouraged to seek suppliers who are certified for their environmental practices, such as ISO 14001 certification, which signifies effective environmental management systems.

Illustrative image related to conveyor belt drive design

Ethical sourcing extends beyond materials to encompass the entire supply chain. Buyers should evaluate suppliers based on their labor practices, environmental stewardship, and community engagement. This holistic approach not only enhances brand reputation but also ensures compliance with emerging regulations that prioritize corporate social responsibility.

The emphasis on sustainability also drives innovation in the sector. Manufacturers are exploring new technologies, such as energy-efficient motors and low-friction belt designs, which reduce energy consumption and operational costs. By prioritizing sustainable practices and ethical sourcing, B2B buyers can contribute to a more resilient supply chain while also meeting the growing consumer demand for responsible business practices.

What Is the Evolution of Conveyor Belt Drive Design and Its Relevance Today?

The conveyor belt drive design has evolved significantly since its inception in the late 18th century. Initially developed for simple material handling tasks, the technology has transformed into a sophisticated system integral to modern industrial operations. The advent of electricity and advanced materials in the 20th century allowed for the creation of more efficient and versatile conveyor systems. Today, conveyor belt designs are not only focused on functionality but also on integration with automation technologies and smart manufacturing principles.

As global supply chains become more complex, the evolution of conveyor belt systems highlights the importance of adaptability and innovation in meeting contemporary demands. B2B buyers must remain informed about these historical advancements to better appreciate the capabilities of modern conveyor systems and make informed sourcing decisions. Understanding the evolution of these systems provides valuable context for evaluating current and future trends in conveyor belt drive design.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor belt drive design

-

How do I choose the right drive system for my conveyor belt?

Choosing the right drive system depends on several factors including the type of materials being transported, the required speed, and the distance the materials need to travel. A direct drive system is ideal for applications requiring high torque, while a belt-driven system may be more suitable for lighter loads. Considerations such as energy efficiency and maintenance requirements are also crucial. Consulting with a supplier who can analyze your specific needs will ensure you select a drive system that optimizes performance and minimizes downtime. -

What is the best conveyor belt material for heavy-duty applications?

For heavy-duty applications, steel-reinforced rubber or metal conveyor belts are typically the best options. These materials offer exceptional strength and durability, making them ideal for transporting heavy or abrasive materials. Metal belts can withstand extreme temperatures, while rubber belts provide good traction and flexibility. It’s essential to evaluate the specific characteristics of the materials you’ll be moving, such as weight and temperature, to ensure you choose the most appropriate belt material for your application. -

What are the key factors to consider when customizing a conveyor belt design?

When customizing a conveyor belt design, consider the material characteristics, the layout of your facility, and the specific requirements of the products being transported. Key factors include belt width, length, load capacity, incline angles, and environmental conditions (e.g., temperature, humidity). Additionally, ensure the design incorporates accessibility for maintenance and complies with safety regulations. Collaborating with experienced suppliers can help refine your design to meet both operational and regulatory standards effectively. -

What is the typical minimum order quantity (MOQ) for conveyor belt systems?

The minimum order quantity (MOQ) for conveyor belt systems varies widely among manufacturers and depends on the complexity of the design and materials used. Generally, MOQs can range from a few units for standard designs to larger quantities for custom systems. It’s advisable to discuss your specific needs with potential suppliers to understand their MOQ and whether they offer flexibility for smaller orders, especially if you are a smaller business or exploring new product lines. -

What payment terms should I expect when sourcing conveyor belt systems internationally?

Payment terms when sourcing conveyor belt systems internationally can vary significantly based on the supplier and your negotiation. Common terms include partial upfront payment (30-50%) with the balance due upon delivery or after installation. It’s essential to clarify terms such as currency, payment methods (e.g., wire transfer, letter of credit), and any contingencies for delays. Establishing clear payment terms upfront can prevent misunderstandings and ensure a smoother transaction process. -

How can I ensure quality assurance (QA) in my conveyor belt purchase?

To ensure quality assurance in your conveyor belt purchase, request certifications and compliance documentation from your supplier, such as ISO 9001. Conducting factory audits or requesting samples before finalizing your order can also help assess the manufacturing process and material quality. Additionally, establish clear quality criteria and performance metrics in your contract to hold the supplier accountable. Regular communication and updates during the production phase will further enhance quality assurance. -

What logistics considerations should I keep in mind for international shipments of conveyor belts?

When planning logistics for international shipments of conveyor belts, consider factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with handling industrial equipment to navigate these complexities. Additionally, factor in lead times for production and shipping, as well as the need for insurance coverage for high-value items. Proper documentation, including invoices and packing lists, will streamline customs clearance and ensure timely delivery. -

How can I vet suppliers for conveyor belt drive design?

Vetting suppliers for conveyor belt drive design involves several steps. Start by researching their industry reputation through reviews and testimonials from previous clients. Request references and case studies that demonstrate their experience in your specific application. Evaluate their manufacturing capabilities, certifications, and compliance with industry standards. Visiting their facilities, if possible, can provide insights into their operations and quality control processes. Establish clear communication channels to assess their responsiveness and willingness to collaborate on your project.

Top 2 Conveyor Belt Drive Design Manufacturers & Suppliers List

1. Gila Herald – Conveyor Belt Systems

Domain: gilaherald.com

Registered: 2018 (7 years)

Introduction: Conveyor belt systems are essential for material handling, featuring a continuous loop made of various belting materials (rubber, PVC, fabric, metal) supported by idler rollers. Key components include a drive system for movement control, a take-up system for maintaining belt tension, and user-friendly controls for operation. Types of conveyor systems include flat belt conveyors for versatile trans…

2. Elastic Belt – Roller Design Essentials

Domain: elasticbelt.industries

Introduction: Roller design for conveyor belts includes key features such as:

– Pulleys: At least one crowned pulley is necessary to prevent belt slipping, typically crowned to ISO 22. The design usually consists of three equal parts (conical/cylindrical/conical).

– Pulley Width: Recommended to be 1.05-1.1 times the width of the belt, with half being cylindrical and conical.

– Roller Surface: A clean, smooth…

Strategic Sourcing Conclusion and Outlook for conveyor belt drive design

In summary, effective conveyor belt drive design is pivotal for optimizing material handling processes across various industries. Key takeaways include the importance of selecting the appropriate belting material and drive systems tailored to specific operational needs, as well as understanding the role of idler rollers and frames in ensuring smooth operations. Strategic sourcing can significantly enhance your supply chain efficiency by facilitating access to high-quality components while minimizing costs and downtime.

As international B2B buyers from Africa, South America, the Middle East, and Europe consider their conveyor belt needs, it’s essential to prioritize reliable suppliers who can provide innovative solutions that meet local demands. Investing in advanced conveyor technologies will not only improve productivity but also position your business for future growth in an increasingly competitive market.

Looking ahead, the landscape of conveyor belt systems will continue to evolve with advancements in automation and smart technology. Embrace these innovations to stay ahead of the curve. Take action now by evaluating your current conveyor systems and engaging with suppliers who can guide you in making informed decisions for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.