A Deep Dive into Concealed Hinge Solution

Introduction: Navigating the Global Market for concealed hinge

In an increasingly interconnected world, sourcing the right concealed hinge can pose significant challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. These hinges, known for their ability to provide a clean aesthetic while maintaining structural integrity, are essential components in a wide range of applications, from residential cabinetry to commercial doors. Navigating the complexities of this market involves understanding the various types, finishes, and specifications available, as well as the nuances of supplier vetting and pricing structures.

This comprehensive guide delves into the multifaceted world of concealed hinges, offering insights into their diverse applications, from luxury residential projects to high-traffic commercial environments. Readers will find detailed sections on the different types of concealed hinges, their installation requirements, and best practices for selecting the right hinge for specific needs. Additionally, the guide provides valuable tips on evaluating potential suppliers, ensuring quality, and understanding cost implications, empowering buyers to make informed purchasing decisions.

By addressing key challenges and providing actionable insights, this guide serves as an indispensable resource for international B2B buyers seeking to optimize their sourcing strategies in the concealed hinge market. Whether you are in Saudi Arabia, Brazil, or beyond, understanding these elements will enhance your procurement process, ultimately leading to better project outcomes and customer satisfaction.

Understanding concealed hinge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Concealed Door Hinges | Hidden installation, suitable for solid and hollow doors | Commercial and residential doors | Pros: Aesthetically pleasing, space-saving; Cons: Installation can be complex. |

| Concealed Cabinet Hinges | Designed for various cabinet overlays, adjustable | Kitchen and bathroom cabinetry | Pros: Soft-close options available; Cons: May require precise measurements for installation. |

| Heavy-Duty Concealed Hinges | Robust construction for high traffic usage | Industrial applications, heavy doors | Pros: Durable, supports heavy loads; Cons: Higher cost compared to standard hinges. |

| Self-Closing Concealed Hinges | Automatically closes doors, often with a soft close feature | Residential and commercial cabinetry | Pros: Increases security, enhances convenience; Cons: Mechanism may wear over time. |

| Three-Way Adjustable Concealed Hinges | Offers multiple adjustment options for alignment | Custom cabinetry and furniture | Pros: Flexibility in installation, easy adjustments; Cons: More complex design may lead to higher costs. |

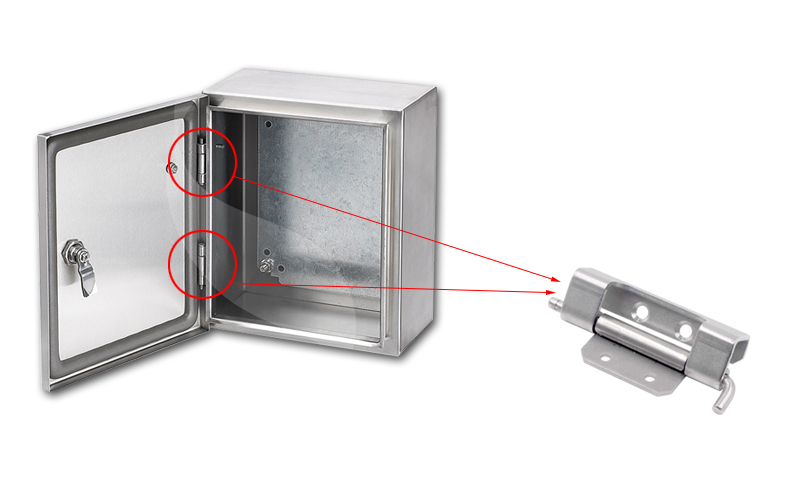

What Are the Characteristics of Concealed Door Hinges?

Concealed door hinges are specifically designed to be hidden from view when the door is closed. This type of hinge is suitable for both solid and hollow core doors, making it versatile for various applications. They are often used in commercial and residential settings where aesthetics are a priority. Buyers should consider the installation complexity, as these hinges may require specialized tools and skills. Additionally, the choice of finish can impact the overall design and functionality.

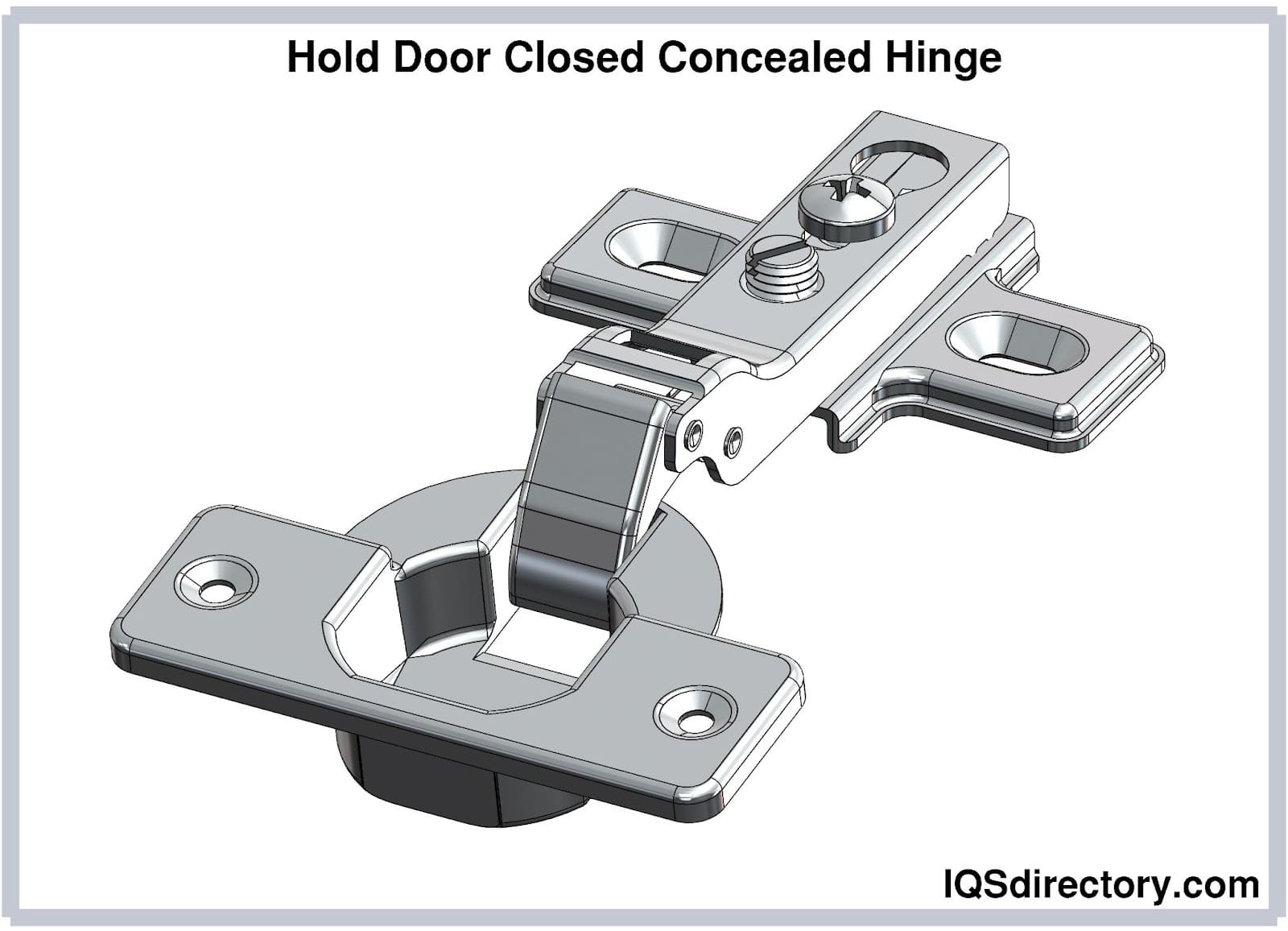

How Do Concealed Cabinet Hinges Work?

Concealed cabinet hinges are tailored for cabinetry, allowing for a clean look by hiding the hinge when the cabinet doors are closed. They come in various overlay configurations, making them suitable for different cabinet styles. Adjustable options are also available to ensure proper alignment. When purchasing, it’s crucial for B2B buyers to measure accurately and consider the overlay type to ensure compatibility with existing cabinetry. The availability of soft-close features can enhance user experience and longevity.

Why Choose Heavy-Duty Concealed Hinges?

Heavy-duty concealed hinges are built for demanding environments, offering robust construction that can withstand frequent use and heavy loads. They are ideal for industrial applications or large commercial doors where strength and durability are critical. Buyers should evaluate the weight capacity and material quality when selecting these hinges, as investing in higher-grade options can lead to long-term savings and reduced maintenance costs. While the initial investment may be higher, the longevity and reliability often justify the expense.

What Are the Benefits of Self-Closing Concealed Hinges?

Self-closing concealed hinges provide the added benefit of automatically closing doors, which enhances security and convenience in both residential and commercial settings. Many models feature a soft-close mechanism that prevents slamming, thereby extending the lifespan of the doors and hinges. When considering these hinges, buyers should assess the durability of the closing mechanism and its compatibility with existing door structures. Although they may require periodic maintenance, the ease of use can greatly improve user satisfaction.

How Do Three-Way Adjustable Concealed Hinges Enhance Installation Flexibility?

Three-way adjustable concealed hinges allow for multiple adjustments in alignment, making them ideal for custom cabinetry and furniture applications. This flexibility is particularly beneficial when dealing with uneven surfaces or when precise alignment is crucial for aesthetic purposes. Buyers should look for models that offer easy adjustment mechanisms to facilitate installation. While they may come at a higher price point due to their complexity, the ability to fine-tune the fit can significantly enhance the final product’s quality.

Key Industrial Applications of concealed hinge

| Industry/Sector | Specific Application of Concealed Hinge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Hidden hinges for cabinets and drawers | Enhances aesthetics and functionality of furniture | Durability, load capacity, and ease of installation |

| Commercial Construction | Doors in high-end offices and hotels | Provides a sleek, modern look while ensuring security | Compliance with local building codes and regulations |

| Automotive | Interior paneling and doors | Optimizes space and enhances interior design | Weight, corrosion resistance, and compatibility with materials |

| Residential Architecture | Interior doors and cabinetry | Improves space utilization and design flexibility | Finish options, weight capacity, and maintenance needs |

| Kitchen Design | Concealed hinges for cabinetry and appliances | Maximizes storage space and aesthetic appeal | Customization options, load-bearing specifications |

How is Concealed Hinge Used in Furniture Manufacturing?

In the furniture manufacturing sector, concealed hinges are commonly utilized in cabinets and drawers to create a seamless appearance. These hinges allow doors to close flush against the cabinet body, enhancing the overall design while providing functional benefits. For international B2B buyers, especially in regions like Africa and South America, sourcing hinges that are durable and can withstand varying humidity levels is crucial. Manufacturers should consider the load capacity and ease of installation to ensure long-lasting performance.

What Role Do Concealed Hinges Play in Commercial Construction?

In commercial construction, concealed hinges are often used for doors in high-end offices and hotels. They provide a sleek, modern look that aligns with contemporary architectural designs while ensuring security and durability. Buyers in the Middle East and Europe should prioritize hinges that comply with local building codes and regulations. Additionally, the ability to customize finishes to match interior design themes can significantly enhance the property’s aesthetic appeal.

How Are Concealed Hinges Beneficial in the Automotive Industry?

The automotive sector employs concealed hinges in interior paneling and doors to optimize space and enhance design. These hinges contribute to a cleaner, more streamlined look, which is essential in modern vehicle design. For B2B buyers in this industry, key considerations include weight, corrosion resistance, and compatibility with various interior materials. Sourcing hinges that can withstand the rigors of automotive environments is essential for maintaining vehicle integrity and longevity.

Why Are Concealed Hinges Important in Residential Architecture?

In residential architecture, concealed hinges are favored for interior doors and cabinetry, improving both aesthetics and space utilization. They allow for a clean look without visible hardware, which is particularly appealing in modern home designs. Buyers from Europe and the Middle East should focus on hinge finishes that match the home’s interior decor and consider the weight capacity to accommodate different door types. Furthermore, understanding maintenance needs is vital for ensuring longevity.

How Do Concealed Hinges Enhance Kitchen Design?

In kitchen design, concealed hinges are essential for cabinetry and appliance doors, maximizing storage space while maintaining a sleek appearance. These hinges allow for full access to cabinet interiors, making them practical for everyday use. For B2B buyers, customization options and load-bearing specifications are critical when selecting hinges that align with specific kitchen designs. Ensuring that the hinges can withstand the kitchen’s humid environment is also a key sourcing consideration.

3 Common User Pain Points for ‘concealed hinge’ & Their Solutions

Scenario 1: Misalignment Issues with Concealed Hinges

The Problem: One common challenge that B2B buyers face when using concealed hinges is the misalignment of doors and cabinets during installation. This issue can lead to doors that do not close properly, resulting in gaps or uneven openings. Misalignment often arises from improper measurements or installation techniques, which can compromise the aesthetic appeal and functionality of the cabinetry or doors. For businesses, this can mean costly delays and increased labor expenses as adjustments are made.

The Solution: To overcome misalignment issues, it is crucial to invest in high-quality concealed hinges that offer adjustability features. When sourcing hinges, look for models with three-way adjustment capabilities, which allow for vertical, horizontal, and depth adjustments. This flexibility enables installers to fine-tune the door alignment even after the hinges have been mounted. Additionally, before installation, ensure that all measurements are double-checked, and consider using a router template to create precise cutouts for the hinges. This preparation minimizes the risk of misalignment and streamlines the installation process, leading to better outcomes and reduced rework.

Scenario 2: Choosing the Right Finish for Concealed Hinges

The Problem: Another pain point for B2B buyers is selecting the appropriate finish for concealed hinges that matches the overall design and functionality of their projects. With various finishes available, such as satin nickel, oil-rubbed bronze, and polished chrome, the choice can become overwhelming. An incorrect selection can not only clash with the design aesthetics but also lead to premature wear and corrosion, especially in humid or harsh environments.

The Solution: To make an informed decision regarding hinge finishes, buyers should consider both the aesthetic and practical aspects of their projects. Start by evaluating the environment where the hinges will be installed; for instance, areas prone to moisture may benefit from finishes like stainless steel or coated options that provide additional corrosion resistance. Additionally, it’s advisable to request samples from suppliers to see how different finishes complement the overall design. Collaborating with manufacturers who offer custom finishes can also provide tailored solutions, ensuring that the selected hinges meet both aesthetic and durability requirements.

Scenario 3: Difficulty in Finding Replacement Parts

The Problem: B2B buyers often encounter difficulties in sourcing replacement concealed hinges for ongoing maintenance or repair projects. As different manufacturers may use unique specifications and designs, finding an exact match can be challenging and time-consuming. This situation can lead to extended downtimes for businesses and potential loss of revenue if doors or cabinets cannot be used effectively.

The Solution: To alleviate the challenges of sourcing replacement concealed hinges, buyers should establish strong relationships with reliable suppliers who maintain comprehensive inventories. It is beneficial to keep a detailed record of hinge specifications, including brand, model, and finish, to ensure accurate replacements can be ordered swiftly. Implementing a preventive maintenance program that includes regular inspections of hinges can also help identify wear and tear before it necessitates replacement, allowing for proactive ordering of parts. Additionally, consider partnering with suppliers who offer a wide range of hinge options and accessories, making it easier to find replacements without extensive delays.

Strategic Material Selection Guide for concealed hinge

What Are the Key Materials Used for Concealed Hinges?

When selecting concealed hinges for various applications, the choice of material plays a crucial role in performance, durability, and overall suitability. Below are analyses of four common materials used in the manufacturing of concealed hinges, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Stainless Steel Perform in Concealed Hinges?

Stainless steel is a popular choice for concealed hinges due to its excellent corrosion resistance and strength. This material can withstand harsh environmental conditions, making it ideal for applications in regions with high humidity or exposure to chemicals. Stainless steel hinges typically have a temperature rating that allows them to function effectively in both high and low-temperature environments.

Pros: The durability of stainless steel ensures a long lifespan, reducing replacement costs. It is also aesthetically pleasing, often available in various finishes to match design requirements.

Cons: The primary drawback is the higher cost compared to other materials. Manufacturing complexity can also be an issue, as stainless steel may require specialized tools for cutting and shaping.

Impact on Application: Stainless steel hinges are suitable for heavy-duty applications, including commercial doors and high-traffic areas. Their corrosion resistance makes them compatible with environments where moisture or chemicals are present.

Considerations for International Buyers: Compliance with standards such as ASTM A240 or DIN 1.4301 is essential. Buyers should also consider local preferences for finishes and the availability of stainless steel grades.

What Are the Benefits of Zinc Alloy for Concealed Hinges?

Zinc alloy is another common material used for concealed hinges, known for its good strength-to-weight ratio and excellent corrosion resistance. It is often used in applications where weight is a concern, such as in lightweight cabinetry or doors.

Pros: Zinc alloy is generally more affordable than stainless steel, making it an attractive option for budget-conscious projects. It is also relatively easy to manufacture, allowing for intricate designs.

Cons: While zinc alloy offers decent strength, it may not be suitable for heavy-duty applications. Over time, it can be susceptible to wear and tear, especially in high-friction environments.

Impact on Application: Zinc alloy hinges are ideal for residential applications and light commercial use, particularly in environments with moderate humidity.

Considerations for International Buyers: Compliance with standards like ASTM B69 and JIS H 8601 is important. Buyers should evaluate the local market for availability and preferences regarding finishes.

How Does Plastic Compare for Concealed Hinges?

Plastic hinges, often made from high-density polyethylene (HDPE) or polyamide, are lightweight and resistant to corrosion. They are particularly useful in applications where weight reduction is a priority.

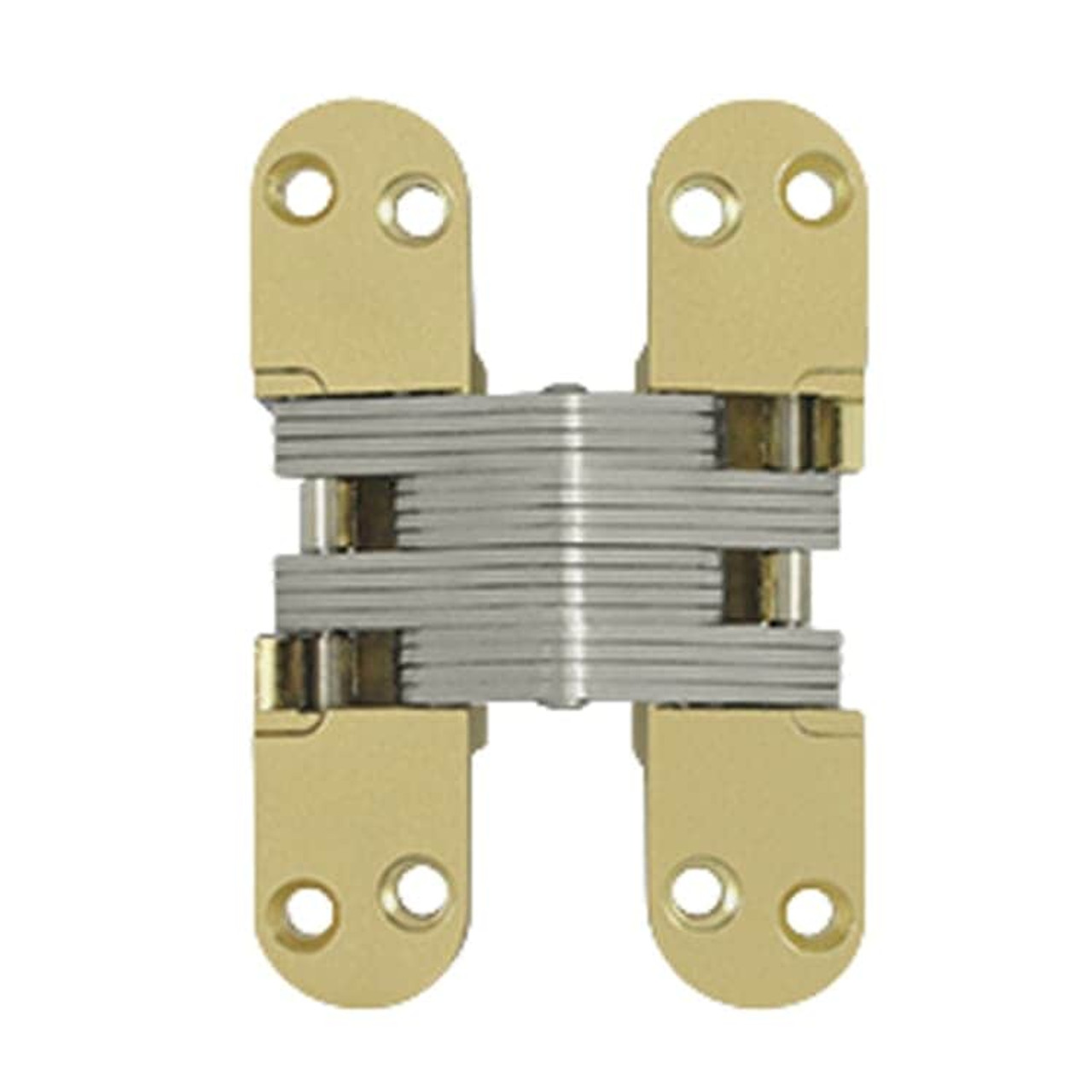

与concealed hinge相关的说明性图片

Pros: The low cost and ease of manufacturing make plastic hinges an economical choice. They also have good resistance to moisture and chemicals, making them suitable for various environments.

Cons: Plastic hinges may not provide the same strength and durability as metal options, which limits their use in heavy-duty applications. They can also be affected by temperature extremes, leading to potential warping.

Impact on Application: Ideal for lightweight doors and cabinetry, plastic hinges are often used in residential and light commercial applications.

Considerations for International Buyers: Compliance with specific standards such as ASTM D638 for tensile properties is crucial. Buyers should also ensure that the chosen plastic can withstand local environmental conditions.

What Role Does Brass Play in Concealed Hinges?

Brass is a traditional material for concealed hinges, known for its aesthetic appeal and moderate corrosion resistance. It is often used in high-end residential applications where appearance is a key factor.

Pros: Brass provides a classic look and is easy to machine, allowing for detailed designs. Its antimicrobial properties can be beneficial in certain environments.

与concealed hinge相关的说明性图片

Cons: Brass is generally less durable than stainless steel and can tarnish over time, requiring regular maintenance. It is also more expensive than zinc alloy and plastic.

Impact on Application: Brass hinges are suitable for decorative applications, such as in luxury cabinetry or historical restorations.

Considerations for International Buyers: Compliance with standards such as ASTM B36 is essential. Buyers should also consider local preferences for finishes and the potential need for maintenance in various climates.

Summary Table of Material Selection for Concealed Hinges

| Material | Typical Use Case for Concealed Hinge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty commercial doors | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Zinc Alloy | Residential and light commercial use | Affordable and easy to manufacture | Less suitable for heavy-duty applications | Medium |

| Plastic | Lightweight doors and cabinetry | Low cost and moisture resistant | Limited strength and durability | Low |

| Brass | Decorative high-end applications | Aesthetic appeal and easy machining | Tarnishes and requires maintenance | Medium to High |

This strategic material selection guide provides valuable insights into the various materials used in concealed hinges, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

与concealed hinge相关的说明性图片

In-depth Look: Manufacturing Processes and Quality Assurance for concealed hinge

What Are the Key Manufacturing Processes for Concealed Hinges?

The manufacturing of concealed hinges involves several critical stages, each essential for producing high-quality products that meet the demands of international buyers. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Concealed Hinges?

The first step in the manufacturing process is material preparation. High-quality metals, such as stainless steel or brass, are often selected for their durability and corrosion resistance. The chosen material undergoes thorough inspection and testing to ensure it meets specifications. This may include checking for defects, thickness, and material properties. Suppliers may also source materials from certified vendors to ensure consistency and quality.

What Techniques Are Used for Forming Concealed Hinges?

Once the materials are ready, the forming process begins. This involves techniques such as stamping, machining, or casting to shape the hinge components. Advanced CNC (Computer Numerical Control) machines are commonly used to achieve precise dimensions and intricate designs. Techniques like laser cutting may also be employed for complex geometries. The forming process is crucial as it affects the hinge’s functionality, longevity, and compatibility with various door types.

与concealed hinge相关的说明性图片

How Are Concealed Hinges Assembled?

After forming, the individual components of the concealed hinge are assembled. This stage may involve welding, riveting, or using screws to join parts together. Quality control checkpoints are established at this stage to ensure that components fit together seamlessly. Automated assembly lines can enhance efficiency, but manual assembly may still be used for more complex or customized hinges.

What Finishing Processes Are Applied to Concealed Hinges?

The finishing stage is where the concealed hinges receive their final treatment. This may include polishing, plating, or coating to enhance aesthetics and protect against wear and corrosion. Common finishes include satin nickel, oil-rubbed bronze, and matte black, which not only improve the hinge’s appearance but also its durability. Environmental considerations are increasingly important in this stage, with manufacturers adhering to regulations concerning chemical use and waste management.

How Is Quality Assurance Implemented in Concealed Hinge Production?

Quality assurance (QA) is a vital aspect of the manufacturing process for concealed hinges, ensuring that products meet international standards and customer expectations.

What International Standards Are Relevant for Concealed Hinges?

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines criteria for an effective quality management system. Compliance with these standards demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications, such as CE marking for products sold in the European market or API standards for certain applications, may be relevant.

与concealed hinge相关的说明性图片

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control is integrated throughout the manufacturing process, with several key checkpoints:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring takes place during the manufacturing stages to catch defects early. This may include dimensional checks and functional tests of components.

- Final Quality Control (FQC): Finished hinges undergo rigorous testing for functionality, aesthetics, and durability. This may include load testing, corrosion resistance tests, and cycle tests to simulate long-term usage.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is crucial. Here are some effective ways to ensure quality:

What Are Effective Audit Strategies for Supplier Verification?

Conducting audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers can request access to audit reports and certifications that demonstrate compliance with international standards. On-site audits can also provide insights into manufacturing capabilities and quality assurance practices.

How Can Buyers Use Reports and 3rd-Party Inspections?

Buyers should ask suppliers for detailed quality reports, which may include results from inspections and tests performed at various stages of production. Third-party inspections can provide an unbiased assessment of the supplier’s quality management system. This is particularly valuable in regions where buyers may have limited access to reliable suppliers.

What Are the QC and Certification Nuances for International Buyers?

Understanding the nuances of quality control and certification is essential for international buyers. Different regions may have varying standards and regulations, which can impact product acceptance. For instance, while CE marking is necessary for products entering the European market, other regions may have their own compliance requirements.

Furthermore, buyers should be aware of the language and cultural differences that may affect communication with suppliers. Clear agreements outlining quality expectations and compliance with international standards can help mitigate misunderstandings and ensure product quality.

Conclusion

The manufacturing processes and quality assurance for concealed hinges are complex yet vital for ensuring that products meet the high standards expected by international buyers. By understanding these processes and implementing robust verification strategies, B2B buyers can make informed decisions and establish long-lasting partnerships with reliable suppliers. As the global market continues to evolve, prioritizing quality assurance will be key to maintaining competitiveness and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘concealed hinge’

Introduction

This practical sourcing guide is designed to help B2B buyers effectively procure concealed hinges. Whether you are sourcing for commercial projects or manufacturing needs, following this checklist will ensure that you select the right hinges that meet your specifications, quality standards, and project requirements.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your concealed hinges. Consider factors such as load capacity, door thickness, and material type. This step is crucial as it ensures that the hinges you select will function correctly and meet the durability needs of your application.

- Load capacity: Determine the weight each hinge needs to support.

- Material: Decide if you need stainless steel, brass, or other materials based on environmental factors.

Step 2: Research Different Types of Concealed Hinges

Familiarize yourself with various concealed hinge types, as they are designed for specific applications. Understanding the differences will help you choose the right hinge for your project, whether it’s for cabinetry, doors, or specialty applications.

- Types: Look into self-closing, soft-close, and pivot hinges.

- Applications: Identify where each type is best utilized to optimize functionality.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, product catalogs, and case studies that illustrate their experience in your industry. A solid supplier should have a proven track record of reliability and quality.

与concealed hinge相关的说明性图片

- References: Ask for testimonials from other clients in similar markets.

- Certifications: Check for industry certifications that validate quality standards.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the concealed hinges. Testing samples in real-world conditions will allow you to assess their performance, durability, and ease of installation.

- Installation: Ensure samples are easy to install and fit your specifications.

- Performance: Observe how the hinges operate under load and over time.

Step 5: Verify Compliance with International Standards

Ensure that the concealed hinges you are considering comply with relevant international standards. This is particularly important for projects in different regions, as compliance can affect safety and performance.

- Standards: Familiarize yourself with standards such as ISO or ANSI that may apply.

- Documentation: Request compliance certificates from your suppliers.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate favorable terms and conditions. This includes pricing, payment terms, delivery timelines, and warranties. Clear agreements can prevent misunderstandings and ensure smooth transactions.

- Pricing: Discuss bulk order discounts and payment options.

- Warranties: Understand the warranty terms to safeguard your investment.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics of your order. Ensure that the supplier can meet your delivery deadlines and that you have a plan for receiving and inspecting the hinges upon arrival.

- Shipping options: Discuss shipping methods and costs.

- Inspection: Plan for a quality inspection upon delivery to ensure all items meet your specifications.

By following this comprehensive checklist, you can confidently navigate the sourcing process for concealed hinges and ensure that you make informed decisions that align with your project needs.

Comprehensive Cost and Pricing Analysis for concealed hinge Sourcing

What Are the Key Cost Components in Sourcing Concealed Hinges?

When sourcing concealed hinges, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost of concealed hinges. Common materials such as stainless steel, brass, or high-grade plastic have varying costs, with stainless steel typically being the most durable and expensive option.

-

Labor: Labor costs are influenced by the complexity of manufacturing processes. Automated production methods can lower labor costs, while intricate designs requiring skilled craftsmanship may drive prices up.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment depreciation, and factory maintenance. Efficient production facilities can help minimize these costs.

-

Tooling: Investment in specialized tooling for hinge production can be substantial. These costs are often amortized over the production volume, meaning higher volume orders can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring that hinges meet quality standards necessitates investment in QC processes. Compliance with industry standards can affect overall costs but is essential for ensuring product reliability and customer satisfaction.

-

Logistics: Transportation costs are a significant consideration, especially for international shipping. Factors like distance, mode of transport, and import tariffs can all impact the final cost.

-

Margin: Suppliers typically add a markup to cover their costs and profit. This margin can vary based on market conditions, supplier reputation, and the overall demand for concealed hinges.

How Do Pricing Influencers Affect Concealed Hinge Costs?

Several factors influence the pricing of concealed hinges, which buyers should consider when sourcing:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to bulk pricing discounts. Understanding a supplier’s MOQ can help buyers negotiate better rates.

-

Specifications and Customization: Custom designs or specific finishes can increase costs. Buyers should weigh the need for customization against potential price increases.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or CE) can raise costs but may be necessary for specific applications. Buyers should evaluate the importance of these factors relative to their projects.

-

Supplier Factors: Supplier reputation, reliability, and location can influence pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) can impact overall costs. Buyers should clarify responsibilities for shipping, insurance, and tariffs to avoid unexpected expenses.

What Are the Best Practices for Negotiating Concealed Hinge Prices?

International B2B buyers should consider several strategies to enhance cost-efficiency in their purchasing process:

与concealed hinge相关的说明性图片

-

Negotiate Wisely: Engage suppliers in discussions about pricing, especially if purchasing in bulk. Highlighting long-term relationships can also lead to more favorable terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, and potential replacement costs. A lower initial price might result in higher TCO if quality is compromised.

-

Understand Pricing Nuances for Different Markets: Buyers from regions such as Africa, South America, the Middle East, and Europe may encounter varying price structures due to local market conditions and demand. Familiarizing oneself with these nuances can lead to more informed negotiations.

-

Seek Multiple Quotes: Obtaining quotes from multiple suppliers can provide a clearer picture of the market rate and help identify the best value.

-

Build Relationships: Developing strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming trends that may affect pricing.

Conclusion

While the costs associated with sourcing concealed hinges can vary significantly based on numerous factors, a thorough understanding of the cost structure and pricing influencers can empower B2B buyers to make strategic purchasing decisions. By leveraging negotiation tactics and considering the Total Cost of Ownership, businesses can optimize their hinge sourcing and ultimately enhance their operational efficiency.

Disclaimer: Prices for concealed hinges can fluctuate based on market conditions and specific supplier agreements. This analysis provides indicative pricing and should be used as a guideline rather than a definitive price list.

Alternatives Analysis: Comparing concealed hinge With Other Solutions

In the realm of hardware solutions for doors and cabinetry, concealed hinges stand out for their aesthetic appeal and functional advantages. However, several alternative solutions exist that may better suit specific applications or budget constraints. This section analyzes how concealed hinges compare to other common hinge types, allowing B2B buyers to make informed decisions based on their unique requirements.

| Comparison Aspect | Concealed Hinge | Butt Hinge | Piano Hinge |

|---|---|---|---|

| Performance | Excellent for seamless operation and high durability | Good for standard applications, provides strong support | Versatile, offers continuous support across long spans |

| Cost | Moderate to high, depending on finish and brand | Generally low to moderate | Moderate, varies with length and material |

| Ease of Implementation | Requires precise installation and routing | Simple installation with basic tools | Requires careful alignment, but easy to install |

| Maintenance | Low, minimal upkeep needed | Low, but may require tightening | Low, but can be affected by wear over time |

| Best Use Case | High-end cabinetry, custom doors | Interior doors, lightweight cabinets | Long doors, foldable applications |

What Are the Pros and Cons of Using Butt Hinges as an Alternative?

Butt hinges are a traditional choice widely used in residential and commercial settings. Their main advantage lies in their simplicity and cost-effectiveness, making them a suitable option for standard interior doors and lightweight cabinetry. However, they are visible when the door is closed, which can detract from the clean lines of modern design. Additionally, butt hinges may not provide the same level of durability and seamless operation as concealed hinges, especially in high-traffic areas.

How Do Piano Hinges Compare to Concealed Hinges?

Piano hinges, or continuous hinges, are ideal for applications requiring stability over long spans, such as in piano lids or large doors. Their design allows for even weight distribution, which can enhance longevity and strength. While they are versatile and easy to install, they may not offer the aesthetic appeal of concealed hinges, as they are fully visible. Moreover, piano hinges can be less suitable for standard cabinetry, where a more discreet solution is preferred.

Conclusion: How Should B2B Buyers Choose the Right Hinge Solution?

When selecting the right hinge solution, B2B buyers should consider the specific requirements of their projects, including design aesthetics, functional needs, and budget. Concealed hinges are an excellent choice for high-end applications that demand a sleek look and durability. In contrast, butt hinges may suffice for standard doors where cost is a primary concern, while piano hinges are best for applications requiring continuous support. By evaluating these factors, buyers can choose the most effective hinge solution that aligns with their operational and design goals.

Essential Technical Properties and Trade Terminology for concealed hinge

What Are the Key Technical Properties of Concealed Hinges?

Understanding the technical properties of concealed hinges is essential for B2B buyers to ensure product compatibility and performance in various applications. Here are several critical specifications:

-

Material Grade

The material grade of a concealed hinge significantly affects its durability and performance. Common materials include stainless steel, brass, and zinc alloy. Stainless steel, for example, is favored for its corrosion resistance, making it suitable for humid environments or applications requiring longevity. Selecting the right material is vital for meeting the specific environmental demands of your application. -

Load Capacity

Load capacity refers to the maximum weight a hinge can support without compromising its function. This property is crucial when designing cabinetry or doors, as it determines the number of hinges needed and their placement. For B2B buyers, understanding load capacity ensures safety and functionality, preventing potential failures in high-traffic or heavy-use scenarios. -

Degree of Opening

The degree of opening indicates how far a door or panel can swing open when mounted with a concealed hinge. Typical ranges are from 90° to 180°. This specification is important for space planning and user accessibility, especially in commercial settings where ease of access is crucial. Buyers must consider the degree of opening to ensure compliance with accessibility standards and operational efficiency. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions in hinge manufacturing. Precise tolerances are essential for ensuring a proper fit and smooth operation. In B2B contexts, understanding tolerances can prevent costly reworks or delays during installation, making it a critical factor for project timelines and budgets. -

Finish Options

The finish of a concealed hinge affects both aesthetics and functionality. Common finishes include satin nickel, polished chrome, and oil-rubbed bronze. These finishes not only contribute to the visual appeal but also provide additional protection against wear and corrosion. Buyers should choose finishes that align with their design goals while considering the environmental conditions of the installation site. -

Self-Closing Mechanism

Some concealed hinges come with a self-closing feature that automatically pulls the door closed after being opened. This is particularly advantageous in commercial applications where security and energy efficiency are priorities. Understanding this feature can help buyers select hinges that enhance operational efficiency and user convenience.

What Are the Common Trade Terms Related to Concealed Hinges?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Below are several common terms associated with concealed hinges:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of concealed hinges, understanding OEM relationships can help buyers identify quality suppliers and ensure compatibility with existing products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is critical for budgeting and inventory management. It can impact procurement strategies, especially for smaller companies or those with fluctuating demand. -

RFQ (Request for Quotation)

An RFQ is a formal process through which buyers request pricing and terms from suppliers for specific products. Understanding how to prepare and respond to RFQs can facilitate better negotiations and ensure competitive pricing for concealed hinges. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms helps B2B buyers understand cost allocation, risk management, and delivery responsibilities, which are crucial when importing concealed hinges from different regions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. In the context of concealed hinges, understanding lead times is essential for project planning and ensuring timely installation, particularly in industries with tight schedules. -

Certification

Certification indicates that a product meets specific industry standards or regulations. For concealed hinges, certifications can include quality assurance and compliance with safety standards. Buyers should prioritize certified products to ensure reliability and adherence to local regulations.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed purchasing decisions, fostering successful partnerships and ensuring project success.

Navigating Market Dynamics and Sourcing Trends in the concealed hinge Sector

What Are the Key Market Trends Impacting the Concealed Hinge Sector?

The concealed hinge market is witnessing significant growth driven by several global factors. The increasing demand for aesthetically pleasing and modern designs in both residential and commercial spaces has propelled the use of concealed hinges, which offer a sleek, minimalist appearance. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (including Saudi Arabia and Brazil) seek innovative solutions, the emphasis on high-quality materials and durability becomes paramount.

Technological advancements in manufacturing processes, including precision engineering and automated production, have also emerged as critical trends. This enables suppliers to meet the growing demand for customized solutions while maintaining cost-effectiveness. Additionally, the rise of e-commerce platforms has transformed sourcing dynamics, allowing buyers to access a broader range of products and suppliers globally, thus facilitating competitive pricing and better procurement strategies.

Emerging trends such as smart technology integration in door systems are also reshaping the market landscape. The convergence of smart homes with concealed hinges presents opportunities for manufacturers to innovate and expand their product lines. B2B buyers are increasingly looking for suppliers who can provide products that align with the latest technological advancements while ensuring compliance with regional building codes and standards.

How Is Sustainability Influencing Sourcing Decisions in the Concealed Hinge Market?

Sustainability has become a critical consideration for B2B buyers in the concealed hinge sector. The environmental impact of manufacturing processes and the materials used is under scrutiny, making ethical sourcing and sustainability a priority. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to reducing their carbon footprint through sustainable practices and eco-friendly materials.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly seeking suppliers who can provide transparency regarding their sourcing practices, from raw material extraction to production and distribution. Certifications such as FSC (Forest Stewardship Council) for wood-based materials, and adherence to ISO standards for environmental management, are becoming essential criteria for sourcing decisions.

与concealed hinge相关的说明性图片

Furthermore, the demand for ‘green’ certifications and materials is on the rise. Buyers are looking for concealed hinges made from recyclable or sustainably sourced materials, such as stainless steel and recycled composites, which align with their corporate sustainability goals. This trend not only enhances brand reputation but also meets the growing consumer demand for environmentally responsible products.

What Is the Historical Context of Concealed Hinges in the B2B Market?

The evolution of concealed hinges can be traced back to the early 20th century when the need for seamless door operation and aesthetic appeal began to gain prominence. Initially used primarily in high-end residential applications, their adoption expanded into commercial sectors as architects and designers sought to create more visually appealing spaces.

Over the decades, advancements in materials and manufacturing technologies have significantly improved the performance and versatility of concealed hinges. The introduction of various finishes and designs has allowed for greater customization, catering to a wide range of architectural styles and applications. As a result, concealed hinges have transitioned from a niche product to a standard offering in both residential and commercial projects, making them a staple in modern construction and design. This historical context underscores the importance of understanding market dynamics and sourcing trends for informed B2B decisions today.

Frequently Asked Questions (FAQs) for B2B Buyers of concealed hinge

-

How do I solve issues with concealed hinge installation?

To address installation issues with concealed hinges, first, ensure you have the correct tools and templates for precise cutting and mounting. Carefully follow the manufacturer’s instructions, paying attention to the hinge type and door specifications. If misalignment occurs, adjust the hinges slightly before fully securing them. For complex installations, consider hiring a skilled technician who is familiar with concealed hinges to avoid potential damage to the door or frame. -

What is the best concealed hinge for commercial applications?

The best concealed hinge for commercial applications typically features heavy-duty construction and durability. Look for hinges made from high-quality materials like stainless steel to withstand frequent use. Self-closing and soft-close options are also advantageous, as they enhance functionality and user experience. Brands like Sugatsune and SOSS offer reliable products that have been successfully used in various commercial settings, ensuring longevity and performance. -

How can I customize concealed hinges for my specific needs?

Customization of concealed hinges can often be achieved through discussions with suppliers regarding size, finish, and specific functionalities. Many manufacturers offer options for different materials, finishes, and hinge types, allowing you to tailor the product to your project requirements. Be sure to provide detailed specifications and any unique design elements to your supplier to ensure the hinges meet your exact needs. -

What are the minimum order quantities (MOQ) for concealed hinges?

Minimum order quantities for concealed hinges vary by supplier and can depend on the type of hinge and customization options. Typically, MOQs can range from 50 to 500 units for standard products. For custom orders, suppliers may set higher MOQs due to production costs. Always inquire about MOQs when sourcing to ensure they align with your project scale and budget. -

What payment terms should I expect when sourcing concealed hinges internationally?

Payment terms for international orders can differ significantly based on the supplier and the buyer’s relationship. Common terms include a 30% deposit with the balance due before shipment, or net 30 days after delivery. It’s essential to negotiate terms that provide security for both parties. Consider using secure payment methods such as letters of credit or escrow services, especially for larger orders, to mitigate risks. -

How do I vet suppliers for concealed hinges effectively?

To vet suppliers, start by checking their business credentials, including registration and certifications relevant to the hinge industry. Look for reviews and testimonials from previous customers to gauge reliability and product quality. Additionally, assess their production capacity and lead times. Engaging in direct communication and requesting samples can also provide insights into their service quality and product standards. -

What quality assurance processes should I look for in concealed hinge suppliers?

When sourcing concealed hinges, inquire about the supplier’s quality assurance processes, such as ISO certification, testing methods, and quality control measures. A reputable supplier should conduct regular inspections and tests on materials and finished products to ensure they meet industry standards. Request documentation of quality checks and compliance certifications to verify their commitment to quality. -

What logistics considerations should I keep in mind when importing concealed hinges?

When importing concealed hinges, consider shipping methods, customs regulations, and potential tariffs that may affect costs and delivery timelines. Choose a reliable freight forwarder experienced in handling hardware imports to navigate customs efficiently. Additionally, ensure that the supplier provides necessary documentation, such as certificates of origin and compliance, to facilitate smooth customs clearance. Always plan for potential delays and factor them into your project timelines.

Top 6 Concealed Hinge Manufacturers & Suppliers List

1. Sugatsune – HES Concealed Hinge Line

Domain: sugatsune.com

Registered: 1996 (29 years)

Introduction: HES Concealed Hinge Line features innovative and versatile concealed hinges designed for residential and commercial projects. Key products include: 1. HES3D Door Hinges: – 3-way adjustable for vertical, horizontal, and depth adjustments. – Lift-off design for easy installation. – Available sizes: HES3D-W190, HES3D-E190, HES3D-E160, HES3D-120, HES3D-90, HES3D-70. – 3-hour UL rated and passed 300,00…

2. Tectus – Concealed Hinge System

Domain: tectushinges.com

Registered: 2009 (16 years)

Introduction: Tectus Hinges are a comprehensive concealed hinge system made in Germany, designed for premium flush doors. They are adjustable in 3 dimensions, allowing for precise alignment and installation of large and heavy doors. The hinges are engineered with maintenance-free bearings, eliminating the need for scheduled greasing, and have been tested to withstand 1,000,000 cycles under full load. Tectus Hin…

3. McKinney – Hidden Hinges

Domain: mckinneyhinge.com

Registered: 1997 (28 years)

Introduction: Hidden Hinges by McKinney are designed for seamless integration into doors, providing a clean aesthetic while maintaining functionality. They are suitable for various applications, including commercial and residential settings. The hinges are made from durable materials to ensure longevity and reliability. Key features include adjustable settings for precise alignment, a variety of sizes and finis…

4. IQS Directory – Concealed Hinges

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Concealed hinges, also known as hidden or European hinges, are designed to sit flush on the inside of cabinet doors, providing a sleek exterior appearance. They support door weights ranging from 50 lbs to 90 lbs and are available in various styles with features like soft-close functions, adjustable arms, and quick-detach options. Common materials include steel, zinc, stainless steel, and aluminum,…

5. Tectus – TE 340 3D for 1-3/4 Thick Doors

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Invisible Door Hinges available from various brands including Tectus, Weider, Sugatsune, and SOSS. Key products include:

– Tectus TE 340 3D for 1-3/4″ Thick Doors – From $137.00

– Tectus TE 240 3D for 1-3/8″ Thick Doors – From $119.00

– Tectus TE 540 3D for 1-3/4″ Thick Doors – From $227.00

– Tectus TE 640 3D A8 Cladding Hinge – From $321.00

– Weider Free Swinging 3D Adjustable Concealed Hing…

6. RocYork® – Concealed Hinges

Domain: ezconcept.com

Registered: 2004 (21 years)

Introduction: RocYork® Concealed Hinges are designed to provide a clean, minimalistic look around internal doors. Key features include: no visible barrel or pin, maintenance-free bearing mechanism, aesthetically pleasing hinge covers, compatibility with right or left handing doors, and three-axis adjustability for perfect alignment. They are designed to withstand heavy traffic flow and come in various sizes and…

Strategic Sourcing Conclusion and Outlook for concealed hinge

As the demand for concealed hinges continues to grow across various industries, strategic sourcing has become essential for international B2B buyers looking to enhance product quality and operational efficiency. By prioritizing high-quality materials and innovative designs, companies can ensure that their concealed hinges meet the rigorous standards required in both residential and commercial applications. This commitment not only improves the functionality of doors and cabinetry but also elevates the aesthetic appeal of their products.

Furthermore, understanding regional preferences and compliance standards in markets such as Africa, South America, the Middle East, and Europe can significantly influence sourcing decisions. Buyers should leverage relationships with trusted manufacturers to negotiate favorable terms and secure reliable supply chains.

Looking ahead, the concealed hinge market is poised for continued innovation, particularly with advancements in technology and sustainable materials. International B2B buyers are encouraged to stay informed about emerging trends and to actively engage with suppliers to explore new opportunities. By doing so, they can ensure their offerings remain competitive and aligned with evolving customer demands. Embrace the future of concealed hinges by making informed sourcing decisions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

与concealed hinge相关的说明性图片

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.