A Deep Dive into Comal Electrico Solution

Introduction: Navigating the Global Market for comal electrico

In the competitive landscape of global commerce, sourcing a reliable comal electrico can be a daunting challenge for international buyers. As businesses in regions such as Africa, South America, the Middle East, and Europe seek to enhance their culinary offerings, understanding the nuances of electric griddles becomes critical. This guide aims to demystify the complexities of the comal electrico market, offering insights into various types, applications, and key factors to consider when making a purchase.

From traditional uses in authentic cooking to modern adaptations for commercial kitchens, the versatility of comal electrico makes it a valuable asset in any culinary setting. Buyers will find detailed information on supplier vetting processes, helping them identify trustworthy manufacturers and distributors who meet international standards. Additionally, we will explore the cost implications, ensuring that businesses can make informed financial decisions without compromising on quality.

By equipping B2B buyers with actionable insights and practical knowledge, this comprehensive guide empowers stakeholders to navigate the global market effectively. Whether you’re in Saudi Arabia looking to elevate your restaurant’s menu or in Nigeria seeking efficient cooking solutions for a bustling food service operation, understanding the dynamics of comal electrico procurement is essential for achieving operational success. With this resource, you can streamline your sourcing process and confidently invest in equipment that enhances your culinary capabilities.

Understanding comal electrico Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Electric Comal | Flat surface, typically made of cast iron | Restaurants, catering services | Pros: Durable, even heat distribution. Cons: Heavier, requires more maintenance. |

| Portable Electric Comal | Lightweight, compact design | Food trucks, small vendors | Pros: Easy to transport, quick setup. Cons: Smaller cooking area, may have less power. |

| Commercial Electric Comal | High wattage, larger cooking surface | Large-scale food production | Pros: High efficiency, suitable for bulk cooking. Cons: Higher upfront cost, requires more space. |

| Induction Electric Comal | Uses induction technology for heating | Modern kitchens, upscale restaurants | Pros: Energy-efficient, precise temperature control. Cons: Requires compatible cookware, potentially higher cost. |

| Multi-Function Electric Comal | Versatile, can grill, bake, and steam | Versatile food service operations | Pros: Space-saving, multifunctional. Cons: Complexity may require training, higher price point. |

What are the Characteristics of Traditional Electric Comals?

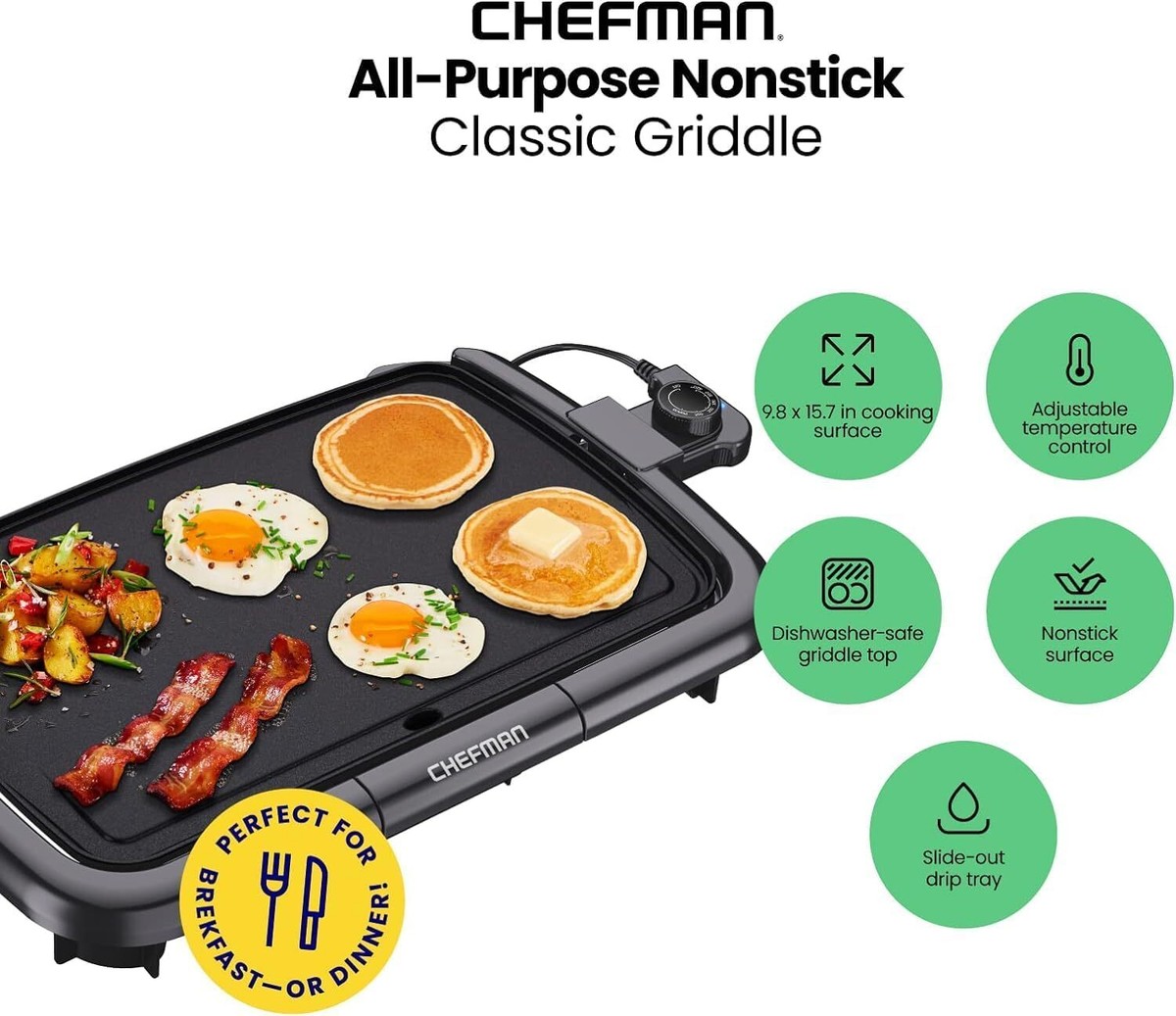

Traditional electric comals are characterized by their flat surfaces, often constructed from durable materials such as cast iron. They provide excellent heat retention and distribution, making them ideal for cooking tortillas, pancakes, and other flatbreads. These comals are commonly used in restaurants and catering services that require consistent cooking results. When purchasing, buyers should consider their weight and maintenance needs, as heavier models can be more challenging to handle but offer longevity and reliability.

How Do Portable Electric Comals Serve Small Vendors?

Portable electric comals are designed for mobility, featuring a lightweight and compact structure that allows for easy transportation. They are particularly suited for food trucks and small vendors who need to set up quickly in various locations. These comals often have a smaller cooking area and may not provide the same power as larger models, but their ease of use and quick setup make them appealing for businesses with limited space. Buyers should assess the power output and cooking capacity to ensure it meets their operational demands.

What Makes Commercial Electric Comals Ideal for Large-Scale Food Production?

Commercial electric comals are built for efficiency and high-volume cooking, featuring larger cooking surfaces and higher wattage. These are the go-to choice for establishments that need to prepare large quantities of food quickly, such as catering companies or banquet facilities. While they offer significant advantages in terms of productivity, buyers must consider the higher initial investment and the need for adequate space in their kitchen setups. The long-term savings from energy efficiency can offset these initial costs.

Why Choose Induction Electric Comals for Modern Kitchens?

Induction electric comals utilize advanced induction heating technology, which allows for precise temperature control and energy efficiency. This type is particularly favored in modern kitchens and upscale restaurants where quality and speed are paramount. Induction models require compatible cookware, which can be an additional cost for buyers. However, their efficiency and quick heating capabilities make them a worthwhile investment for businesses focused on high-quality food preparation.

How Do Multi-Function Electric Comals Enhance Versatility in Food Service?

Multi-function electric comals offer a range of cooking options, including grilling, baking, and steaming, making them a versatile choice for food service operations. Their ability to perform various cooking methods in one unit can save space and reduce equipment costs. However, the complexity of these machines may require additional training for staff, and their higher price point can be a consideration for budget-conscious buyers. Businesses should evaluate their menu offerings to determine if the multifunctionality aligns with their operational needs.

Key Industrial Applications of comal electrico

| Industry/Sector | Specific Application of comal electrico | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Tortilla production | Increased efficiency and consistency in cooking | Energy efficiency, capacity, and ease of cleaning |

| Hospitality | Restaurant kitchen equipment | Enhanced cooking speed and quality for customer satisfaction | Durability, size, and compatibility with existing equipment |

| Retail | Food stalls and kiosks | High-volume cooking for fast service | Portability, power supply requirements, and service support |

| Catering Services | Event catering | Versatile cooking options for diverse menus | Size, weight, and ease of transportation |

| Residential | Home cooking appliances | Convenient meal preparation for families | Safety features, energy consumption, and warranty options |

How is ‘comal electrico’ Used in the Food & Beverage Industry?

In the food and beverage sector, the comal electrico is primarily utilized for tortilla production. This electric griddle offers precise temperature control, enabling manufacturers to achieve consistent cooking results. By automating the cooking process, businesses can significantly increase output while minimizing labor costs. International buyers should consider energy efficiency and the machine’s capacity to meet production demands, as well as ease of maintenance to ensure long-term reliability.

What Role Does ‘comal electrico’ Play in the Hospitality Sector?

In the hospitality industry, particularly within restaurant kitchens, the comal electrico enhances cooking speed and food quality. Chefs can prepare a variety of dishes, from tortillas to grilled meats, quickly and efficiently, which is essential during peak service times. Buyers in this sector should prioritize the durability of the equipment and its compatibility with existing kitchen setups to avoid costly modifications. Additionally, a compact design can be beneficial in optimizing kitchen space.

Illustrative image related to comal electrico

How Do Retail Businesses Utilize ‘comal electrico’?

Retail establishments, especially food stalls and kiosks, leverage the comal electrico for its ability to handle high-volume cooking. This equipment allows vendors to serve food quickly, catering to the fast-paced demands of street food consumers. For international buyers, considerations should include the portability of the comal electrico, as many retail operations require mobility. Additionally, understanding the power supply requirements in different regions is crucial to ensure seamless operation.

What Advantages Does ‘comal electrico’ Offer Catering Services?

Catering services benefit from the versatility of the comal electrico, which can accommodate diverse menus for events. This equipment allows caterers to prepare large quantities of food efficiently, ensuring that quality is maintained across various dishes. Sourcing considerations for catering operations include the size and weight of the comal electrico, as transportation is a key factor in catering logistics. Ensuring that the equipment can be easily moved and set up at different locations is essential for operational success.

How is ‘comal electrico’ Beneficial for Residential Cooking?

For residential applications, the comal electrico serves as a convenient cooking appliance for families looking to prepare traditional meals at home. Its user-friendly design allows for easy operation, making it ideal for everyday cooking. When sourcing for residential use, buyers should focus on safety features, such as automatic shut-off mechanisms, as well as energy consumption ratings to ensure cost-effective use. Warranty options are also important for peace of mind regarding the investment in this kitchen equipment.

3 Common User Pain Points for ‘comal electrico’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Comal Electrico for Diverse Markets

The Problem: B2B buyers often struggle to find suppliers that provide high-quality ‘comal electrico’ that meets the specific needs of their market. This challenge is amplified in regions like Africa and South America, where local preferences and cooking styles vary significantly. Buyers may encounter issues such as inconsistent product quality, limited availability of sizes and features, or suppliers that do not adhere to international safety standards. This can lead to dissatisfaction among end users and damage the buyer’s reputation.

The Solution: To overcome sourcing challenges, B2B buyers should conduct thorough research to identify reputable manufacturers and suppliers with a proven track record. Utilizing platforms like MercadoLibre or regional trade shows can provide insights into local suppliers that understand market demands. When assessing potential suppliers, prioritize those who offer detailed product specifications, certifications, and customer reviews. Establishing a relationship with suppliers that can provide samples for testing is crucial, allowing buyers to evaluate the quality and performance of the ‘comal electrico’ before committing to larger orders. Furthermore, consider engaging in direct negotiations to customize features that align with local cooking traditions, ensuring a better fit for your market.

Scenario 2: Navigating Compliance and Safety Standards for ‘Comal Electrico’

The Problem: Compliance with local and international safety standards is a significant concern for B2B buyers when sourcing ‘comal electrico.’ Different regions may have varying regulations regarding electrical appliances, leading to confusion and potential legal ramifications if products do not meet these requirements. Buyers may face challenges in ensuring that their products are safe, energy-efficient, and suitable for consumer use, which could result in costly recalls or damage to their brand reputation.

The Solution: B2B buyers should proactively educate themselves about the specific compliance and safety standards relevant to their target markets. This includes understanding certifications such as CE marking in Europe or SABS in South Africa. Collaborating with suppliers who are knowledgeable about these standards can help streamline the process. Requesting documentation that proves compliance before placing orders is essential. Additionally, consider investing in third-party testing and certification services to validate product safety and performance. By prioritizing compliance, buyers can mitigate risks and assure their customers of the quality and safety of their ‘comal electrico.’

Scenario 3: Challenges in Providing After-Sales Support and Maintenance

The Problem: After-sales support can be a daunting task for B2B buyers dealing with ‘comal electrico,’ especially when it comes to maintenance and repair. Buyers may face difficulties in providing adequate training for their customers on the proper use of the equipment or handling warranty claims and repairs. This lack of support can lead to customer dissatisfaction and increased operational costs, as buyers may struggle to address issues that arise post-sale.

The Solution: To enhance after-sales support, B2B buyers should develop a comprehensive customer service strategy that includes training programs and accessible resources. Providing user manuals, maintenance guides, and online tutorials can empower end users to troubleshoot basic issues independently. Additionally, establishing a clear warranty policy and streamlined claims process will enhance customer trust. Consider partnering with local technicians or service centers that can handle repairs and maintenance, ensuring that customers have access to support when needed. By investing in after-sales services, buyers can foster long-term relationships with their customers and improve overall satisfaction with their ‘comal electrico’ products.

Strategic Material Selection Guide for comal electrico

When selecting materials for the production of a comal electrico, it’s crucial to consider their properties, advantages, limitations, and compliance with international standards. This guide will analyze four common materials used in the manufacturing of comales eléctricos: aluminum, stainless steel, cast iron, and carbon steel. Each material has distinct characteristics that can influence performance, durability, and suitability for various applications.

What Are the Key Properties of Aluminum in Comal Electrico Manufacturing?

Aluminum is a lightweight metal known for its excellent thermal conductivity and corrosion resistance. It typically has a temperature rating of up to 600°F (315°C), making it suitable for high-temperature cooking applications. Additionally, aluminum’s resistance to oxidation ensures longevity in humid environments.

Pros: Aluminum is cost-effective and easy to manufacture, allowing for intricate designs and lightweight products. Its rapid heating and cooling properties make it ideal for cooking tortillas and other flatbreads.

Illustrative image related to comal electrico

Cons: While aluminum is durable, it can be prone to warping under extreme heat if not properly treated. It may also react with acidic foods, which could affect flavor and safety.

Impact on Application: Aluminum is particularly compatible with electric heating elements, providing efficient heat distribution. However, international buyers should consider local regulations regarding food safety and material compliance.

How Does Stainless Steel Compare for Comal Electrico Applications?

Stainless steel is renowned for its strength, durability, and resistance to corrosion and staining. It can withstand high temperatures (up to 1,500°F or 815°C) and is often used in commercial kitchens due to its hygienic properties.

Pros: The longevity of stainless steel makes it a preferred choice for B2B buyers looking for a reliable, low-maintenance option. It is also non-reactive, ensuring that the taste of food remains unaffected.

Illustrative image related to comal electrico

Cons: The initial cost of stainless steel is higher than aluminum, and its heavier weight can complicate handling and transport. Additionally, manufacturing processes can be more complex due to the material’s hardness.

Impact on Application: Stainless steel is compatible with various cooking methods, including induction heating, making it versatile for different culinary applications. Buyers from regions with strict food safety standards will find stainless steel compliant with most regulations.

What Are the Advantages of Using Cast Iron in Comal Electrico?

Cast iron is a traditional material known for its excellent heat retention and even cooking. It can withstand high temperatures and has a natural non-stick surface when seasoned properly.

Pros: Cast iron is incredibly durable and can last a lifetime with proper care. It enhances flavor through seasoning and is favored for its ability to retain heat, making it ideal for cooking.

Illustrative image related to comal electrico

Cons: The weight of cast iron can be a disadvantage for mobility and handling. It requires regular maintenance to prevent rust and may be less suitable for electric heating due to its slow heating properties.

Impact on Application: Cast iron is compatible with various cooking surfaces but may not be ideal for electric applications unless designed specifically for that purpose. B2B buyers should consider the maintenance requirements and potential for rust in humid climates.

Why Consider Carbon Steel for Comal Electrico?

Carbon steel combines the benefits of steel and cast iron, offering excellent heat conduction and responsiveness. It is often used in commercial settings for its durability and performance.

Illustrative image related to comal electrico

Pros: Carbon steel is lighter than cast iron and heats up quickly, making it suitable for various cooking techniques. It also develops a natural non-stick surface over time.

Cons: Like cast iron, carbon steel requires seasoning and maintenance to prevent rust. It is also more susceptible to warping if not manufactured correctly.

Impact on Application: Carbon steel is versatile and works well with electric heating elements. Buyers should ensure that the product meets local standards for food safety and material quality.

Summary Table of Material Selection for Comal Electrico

| Material | Typical Use Case for comal electrico | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Home and commercial cooking | Lightweight and excellent heat conduction | Prone to warping and reactivity with acids | Low |

| Stainless Steel | Commercial kitchens and food service | Durable, hygienic, and non-reactive | Higher cost and heavier weight | High |

| Cast Iron | Traditional cooking methods | Excellent heat retention and flavor enhancement | Heavy and requires maintenance | Medium |

| Carbon Steel | Versatile cooking applications | Quick heating and lightweight | Requires seasoning and can warp | Medium |

In conclusion, selecting the right material for a comal electrico involves balancing performance, cost, and compliance with local standards. Understanding the properties and implications of each material will help international B2B buyers make informed decisions that align with their operational needs and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for comal electrico

What Are the Key Stages in the Manufacturing Process of Comal Electrico?

The manufacturing process of a comal electrico involves several critical stages, each designed to ensure the final product meets both functional and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial step involves sourcing high-quality materials, typically metals such as stainless steel or aluminum for durability and heat conductivity. Suppliers often conduct rigorous checks to ensure the raw materials meet industry standards. This may involve reviewing certifications and conducting material tests to confirm properties such as tensile strength and thermal conductivity.

-

Forming: In this stage, the prepared materials are shaped into the desired form. Techniques such as stamping, bending, or machining are commonly used to create the body of the comal. Advanced technologies like CNC (Computer Numerical Control) machining may be employed for precision and efficiency, ensuring each component is manufactured to exact specifications.

-

Assembly: Once the components are formed, they are assembled into the final product. This stage can involve both manual and automated processes. Skilled labor is essential to ensure that electrical connections are made correctly and that the heating elements are positioned accurately. Quality control checkpoints during assembly are crucial to identify any defects early.

-

Finishing: The final stage includes surface treatment and coating to enhance durability and aesthetic appeal. Processes such as polishing, anodizing, or applying non-stick coatings are common. This not only improves the product’s lifespan but also ensures compliance with safety and hygiene standards, particularly for food-grade appliances.

How Is Quality Assurance Implemented in Comal Electrico Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the comal electrico meets international standards and customer expectations. QA encompasses several aspects, including adherence to international standards, quality checkpoints, and testing methods.

-

International and Industry-Specific Standards: Compliance with international standards such as ISO 9001 is essential for manufacturers aiming to export to global markets. This standard focuses on maintaining an effective quality management system (QMS) that covers all manufacturing processes. Additionally, industry-specific certifications like CE (Conformité Européenne) for Europe and API (American Petroleum Institute) for certain applications may be required, depending on the target market.

-

Quality Control Checkpoints: Manufacturers typically implement several quality control checkpoints throughout the production process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet required specifications.

– In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to detect any deviations from standards.

– Final Quality Control (FQC): Once the comals are assembled, a final inspection is performed to ensure the product is free from defects and meets all safety and performance criteria. -

Common Testing Methods: Various testing methods are employed to assess the performance and safety of comal electrico. These may include thermal efficiency tests, electrical safety tests, and durability assessments. Manufacturers may also conduct user experience trials to ensure that the product performs well under typical usage conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to ensure reliable partnerships. Here are several effective strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. Buyers should assess the supplier’s adherence to international standards and their ability to maintain consistent quality.

-

Requesting Quality Reports: Buyers can request detailed quality assurance reports that document the results of various tests and inspections. These reports should include information on the methodologies used, the frequency of testing, and any corrective actions taken in response to identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an impartial evaluation of the supplier’s quality control processes. These services often include pre-shipment inspections to ensure that products meet specified requirements before they are shipped.

-

Certifications and Compliance Documents: Buyers should review all relevant certifications and compliance documents. This includes checking for ISO certifications, CE markings, and any other industry-specific certifications that may be necessary for their target market.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from various regions face unique challenges and considerations regarding quality control in the manufacturing of comal electrico. Understanding these nuances can help buyers navigate the complexities of international procurement.

-

Regional Standards and Regulations: Different regions may have specific safety and quality standards that must be met. For instance, products intended for the European market must comply with CE marking regulations, while those for the Middle Eastern market may need to adhere to local safety standards. Buyers should familiarize themselves with these requirements to avoid compliance issues.

-

Cultural and Operational Differences: Cultural differences can influence manufacturing practices and quality perceptions. Buyers should consider how local customs and operational practices may impact quality control. Establishing clear communication and expectations with suppliers can mitigate misunderstandings.

-

Logistical Challenges: Shipping and logistics can introduce risks to product quality. B2B buyers should ensure that suppliers have robust logistics processes in place to protect products during transit. This includes proper packaging, handling instructions, and temperature control if necessary.

-

Building Long-Term Relationships: Establishing long-term relationships with reliable suppliers can enhance quality assurance. Buyers should focus on building trust and open communication with their suppliers, enabling them to address quality concerns proactively.

In summary, the manufacturing processes and quality assurance of comal electrico involve a detailed and systematic approach. B2B buyers must be proactive in verifying supplier capabilities and ensuring compliance with international standards to secure high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘comal electrico’

This guide serves as a practical checklist for B2B buyers looking to procure ‘comal electrico’, a vital equipment in various culinary settings. By following these steps, you can ensure that your sourcing process is efficient, cost-effective, and aligned with your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for any procurement process. Determine the size, power output, and material of the comal electrico that suits your needs. Consider factors such as cooking capacity and energy efficiency, which can significantly impact your operational costs and food quality.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing for comal electrico can provide leverage in negotiations. Explore platforms like MercadoLibre and Walmart to gather information on pricing ranges and popular models. Additionally, pay attention to seasonal trends that may affect availability and costs, particularly in different regions.

Step 3: Evaluate Potential Suppliers

Before making any commitments, it’s essential to thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies that showcase their experience and reliability. Check for customer reviews and testimonials, especially from businesses in similar sectors or geographic locations, to gauge supplier performance.

Illustrative image related to comal electrico

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers comply with international quality standards and local regulations. Certifications such as ISO or other relevant industry standards can indicate a commitment to quality and safety. Additionally, inquire about warranties and after-sales support, which can be crucial for long-term operational success.

Step 5: Request Samples or Demonstrations

Before finalizing your order, consider requesting samples or arranging for product demonstrations. This allows you to assess the quality, performance, and usability of the comal electrico firsthand. Evaluate how it fits into your existing kitchen setup and whether it meets your culinary requirements.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, enter into negotiations regarding pricing, payment terms, and delivery schedules. Ensure that you clarify shipping costs and timelines, as these can impact your overall budget and operational planning. A well-structured agreement can prevent misunderstandings later on.

Step 7: Establish a Communication Plan

Effective communication is vital for a successful procurement process. Set clear expectations for updates regarding order status and potential issues. Establishing a reliable point of contact at the supplier’s end can facilitate smoother interactions and help resolve any concerns promptly.

Illustrative image related to comal electrico

By following this checklist, you can streamline your sourcing process for comal electrico, ensuring that you make informed decisions that enhance your business operations.

Comprehensive Cost and Pricing Analysis for comal electrico Sourcing

What Are the Key Cost Components of Comal Electrico Sourcing?

When sourcing comal electrico, understanding the cost structure is vital for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly affects the overall cost. High-quality metals and electrical components can increase initial costs but may lead to better durability and efficiency.

-

Labor: Labor costs can vary widely depending on the region of production. For instance, countries with lower labor costs may offer a more affordable option but could compromise on craftsmanship or expertise.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with production. Efficient manufacturing processes can help minimize these costs.

-

Tooling: If custom designs are required, the tooling cost can be substantial. Investing in high-quality tooling can lead to better production efficiency and reduced wastage.

-

Quality Control (QC): Ensuring that products meet quality standards is crucial. However, rigorous QC processes can increase costs, particularly if third-party testing or certifications are involved.

-

Logistics: Shipping and handling costs should not be overlooked. These can vary based on the distance from the manufacturer to the buyer, the mode of transport, and any potential tariffs or taxes.

-

Margin: Suppliers will typically mark up their costs to achieve a profit margin. Understanding the acceptable margin in your industry can help in negotiating better pricing.

How Do Price Influencers Affect Comal Electrico Sourcing?

Several factors influence pricing in the comal electrico market.

-

Volume and Minimum Order Quantity (MOQ): Higher purchase volumes can lead to significant cost savings. Suppliers often offer discounts for bulk orders, which can be particularly advantageous for businesses planning large-scale operations.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should clearly outline their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Products with certifications or higher material standards typically command higher prices. Ensure that these certifications align with your market’s regulations and consumer expectations.

-

Supplier Factors: The reputation and reliability of a supplier can influence pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: Understanding Incoterms is essential for determining shipping responsibilities and costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total price you pay.

What Buyer Tips Can Help Optimize Comal Electrico Costs?

For B2B buyers looking to optimize their sourcing of comal electrico, several strategies can enhance cost-efficiency.

-

Negotiate Effectively: Be prepared to negotiate on price, especially if you can demonstrate a long-term purchasing commitment or larger order volumes. Building a relationship with suppliers can also lead to better terms.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess ongoing costs such as maintenance, energy efficiency, and potential resale value to understand the full financial impact.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe may face unique challenges such as currency fluctuations, import duties, and varying shipping times. It’s crucial to factor these into your overall cost analysis.

-

Stay Informed About Market Trends: Regularly review market trends and competitor pricing to ensure that your sourcing strategy remains competitive.

Disclaimer on Pricing

It is important to note that prices for comal electrico can fluctuate based on market conditions, supplier pricing strategies, and geopolitical factors. Therefore, always consult with multiple suppliers and conduct thorough market research to establish a realistic budget for sourcing.

Alternatives Analysis: Comparing comal electrico With Other Solutions

When evaluating the best cooking solutions for commercial applications, it is essential to consider various alternatives to the comal electrico. This electric griddle offers unique benefits, but other technologies may also serve similar culinary needs. By analyzing these alternatives, B2B buyers can make informed decisions based on performance, cost, and ease of use.

Illustrative image related to comal electrico

| Comparison Aspect | Comal Electrico | Gas Griddle | Induction Cooktop |

|---|---|---|---|

| Performance | Quick heating, even cooking | High temperature, rapid cooking | Fast heating, precise temperature control |

| Cost | Moderate initial cost | Generally lower upfront but higher fuel costs | Higher upfront cost, energy-efficient long-term |

| Ease of Implementation | Simple plug-and-play design | Requires gas line installation | Needs compatible cookware, limited to specific pots |

| Maintenance | Low maintenance, easy to clean | Requires regular cleaning and checks for gas leaks | Minimal maintenance, easy surface cleaning |

| Best Use Case | Ideal for high-volume cooking in restaurants | Suitable for outdoor grilling and high-heat cooking | Perfect for precision cooking and small-scale operations |

What Are the Key Benefits and Drawbacks of Using a Gas Griddle?

The gas griddle is a traditional alternative to the comal electrico, favored for its high-temperature capabilities and rapid cooking times. It excels in outdoor settings and is often used in food trucks and commercial kitchens. However, the need for a gas line can complicate setup, and ongoing fuel costs may add up over time. Furthermore, safety concerns related to gas leaks necessitate regular maintenance checks.

How Does Induction Cooktop Technology Compare to Comal Electrico?

The induction cooktop stands out for its precision in temperature control and energy efficiency. It heats cookware directly, leading to faster cooking times and lower energy usage. However, the initial investment can be steep, and it requires specific types of cookware to function effectively. While it may not be the best fit for high-volume cooking, it is ideal for establishments focusing on precision and smaller batch sizes.

What Factors Should B2B Buyers Consider When Choosing Between These Cooking Solutions?

In choosing the right cooking solution, B2B buyers should evaluate their specific operational needs. The comal electrico is excellent for businesses that prioritize speed and ease of use, particularly in high-volume environments. Gas griddles are suitable for those seeking robust outdoor cooking capabilities, while induction cooktops cater to those who value precision and energy efficiency.

Ultimately, the decision will hinge on factors such as the type of cuisine, the scale of operations, and long-term cost considerations. By carefully weighing these aspects, businesses can select the most appropriate cooking solution that aligns with their culinary goals and operational efficiency.

Essential Technical Properties and Trade Terminology for comal electrico

What Are the Key Technical Properties of a Comal Electrico?

When sourcing a comal electrico, understanding its technical properties is crucial for ensuring that the equipment meets operational needs and performance expectations. Here are some essential specifications to consider:

-

Material Composition

The material used in the construction of a comal electrico significantly influences its durability and heat retention capabilities. Common materials include cast iron, stainless steel, and aluminum. Cast iron offers excellent heat retention, while stainless steel provides corrosion resistance, making it ideal for high-humidity environments. For buyers, selecting the right material can impact the lifespan and maintenance needs of the equipment. -

Heating Element Type

The heating element in a comal electrico can be either resistive or induction-based. Resistive heating is traditional and generally less expensive, whereas induction heating provides faster cooking times and greater energy efficiency. Understanding the heating method is vital, as it affects both operational costs and cooking performance, which are crucial for high-volume food service businesses. -

Power Rating

The power rating, usually measured in watts, indicates the energy consumption and cooking efficiency of the comal electrico. Higher wattage generally translates to quicker heating times but may also result in higher energy costs. For B2B buyers, aligning the power rating with kitchen capacity and expected usage patterns can optimize performance and cost-effectiveness. -

Temperature Range

The temperature range indicates the versatility of the comal electrico in preparing different types of food. A broader temperature range allows for various cooking methods, from searing to simmering. Buyers should evaluate their menu requirements to ensure the chosen equipment can handle all necessary cooking tasks. -

Size and Dimensions

The physical dimensions of the comal electrico are critical for fitting into existing kitchen spaces. It’s essential to assess both the cooking surface area and the overall footprint to ensure it meets operational needs without overcrowding the kitchen. Additionally, space considerations can affect workflow efficiency in busy food service environments. -

Safety Features

Safety features such as automatic shut-off, temperature control, and overheat protection are essential for preventing accidents in commercial kitchens. Understanding these safety protocols can help in meeting regulatory compliance and enhancing employee safety, which is a significant concern for B2B buyers.

What Are Common Trade Terms Related to Comal Electrico?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another company. For buyers, engaging with OEMs can ensure access to high-quality components tailored for specific needs, thereby enhancing the reliability of the comal electrico. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. Understanding MOQs is crucial for B2B buyers to manage inventory costs and ensure that they are meeting suppliers’ terms while aligning with their own purchasing strategies. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of products. This process allows buyers to compare options and negotiate better deals, making it an essential step in procurement. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international shipping and freight. Familiarity with these terms helps buyers understand their responsibilities and risks during transportation, thereby facilitating smoother transactions. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is vital for planning inventory and ensuring that equipment is available when needed, particularly in fast-paced culinary environments. -

Warranty and Service Agreements

These terms outline the conditions under which a product is guaranteed and the support provided post-purchase. Buyers should carefully evaluate warranty terms to safeguard their investment and ensure ongoing operational support.

By comprehensively understanding both the technical properties and the trade terminology related to comal electrico, B2B buyers can make informed decisions that align with their operational needs and market expectations.

Navigating Market Dynamics and Sourcing Trends in the comal electrico Sector

What Are the Current Market Dynamics and Key Trends Influencing the Comal Electrico Sector?

The global market for comal electrico is experiencing dynamic changes driven by increasing consumer demand for energy-efficient cooking solutions and a growing emphasis on modern culinary techniques. As urbanization continues across regions such as Africa, South America, the Middle East, and Europe, the demand for versatile kitchen appliances like the comal electrico is on the rise. These markets are increasingly influenced by technological advancements, with smart appliances integrating IoT capabilities to enhance user experience and energy management.

Illustrative image related to comal electrico

Emerging trends also reflect a shift toward customization and local production, allowing suppliers to cater to specific regional tastes and preferences. For instance, in Nigeria and Saudi Arabia, there is a growing inclination towards locally sourced materials, which can reduce lead times and logistics costs for international buyers. Additionally, e-commerce platforms such as MercadoLibre and Walmart have become essential channels for sourcing, providing buyers with access to a broad range of suppliers and competitive pricing. The rise of digital marketplaces facilitates not only product discovery but also price comparison, enabling B2B buyers to make informed decisions.

How Does Sustainability Impact the Comal Electrico Supply Chain?

Sustainability has become a cornerstone of modern B2B procurement strategies, particularly in the comal electrico sector. As environmental concerns escalate, buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing materials that are renewable, recyclable, and produced with minimal environmental impact. Certifications such as Energy Star and various eco-labels are becoming vital in helping buyers identify products that align with their sustainability goals.

Moreover, ethical sourcing is gaining traction, particularly in markets sensitive to labor practices and environmental regulations. International buyers must ensure that their supply chains are transparent and that they partner with manufacturers who uphold fair labor standards and environmental stewardship. By investing in sustainable and ethically sourced comal electrico products, businesses not only contribute to environmental conservation but also enhance their brand reputation, appealing to a growing base of eco-conscious consumers.

What Is the Historical Context of the Comal Electrico?

The comal electrico has evolved significantly from its traditional counterparts, which were typically made from clay or metal and used over open flames. Historically rooted in Latin American cuisine, the comal has adapted to modern cooking needs with the introduction of electric models that offer enhanced efficiency and versatility. This evolution reflects broader trends in culinary technology, where traditional cooking methods meet contemporary demands for convenience and energy efficiency. As international markets continue to embrace these innovations, the comal electrico stands as a testament to the blending of culture and modern technology, fostering new culinary experiences across diverse regions.

By understanding these market dynamics, sustainability considerations, and the historical context, international B2B buyers can make informed sourcing decisions that align with both their operational goals and the growing consumer demand for responsible and innovative cooking solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of comal electrico

-

How do I choose the right comal electrico for my business needs?

Selecting the appropriate comal electrico involves assessing your specific cooking requirements, such as the type of dishes you plan to prepare and the volume of production. Consider factors like the size, power rating, and material quality of the comal, as these elements will impact cooking efficiency and durability. Additionally, review supplier specifications and customer reviews to ensure the product meets industry standards and aligns with your operational needs. -

What are the key features to look for in a comal electrico?

When sourcing a comal electrico, prioritize features such as adjustable temperature controls for precise cooking, non-stick surfaces for easy cleaning, and energy efficiency to reduce operational costs. Durability is also crucial; opt for models made from robust materials that can withstand high heat. Furthermore, consider safety features like automatic shut-off mechanisms, which can enhance user safety in busy kitchen environments. -

What are the typical minimum order quantities (MOQs) for comal electrico?

MOQs for comal electrico can vary significantly depending on the supplier and the manufacturing location. Generally, manufacturers may set MOQs ranging from 10 to 100 units. It’s essential to discuss your needs directly with suppliers, as some may offer flexibility, especially for first-time orders or long-term partnerships. Understanding the MOQ can help you gauge your initial investment and plan your inventory effectively. -

How can I ensure the quality of comal electrico when sourcing internationally?

To ensure quality, conduct thorough research on potential suppliers, including their manufacturing processes and quality assurance protocols. Request product samples to evaluate their performance firsthand. Additionally, consider third-party quality inspections before shipment, especially if sourcing from regions with varying quality standards. Certifications such as ISO or CE can also indicate adherence to international quality norms. -

What payment terms should I expect when sourcing comal electrico?

Payment terms can vary widely among suppliers, but common arrangements include a deposit of 30-50% upfront with the balance due upon shipment or delivery. Some suppliers may offer letter of credit options for added security. Always clarify payment terms before finalizing any agreements and consider negotiating terms that align with your cash flow needs to ensure a smooth procurement process. -

What are the logistics considerations for importing comal electrico?

When importing comal electrico, consider shipping methods, customs regulations, and potential tariffs in your destination country. Sea freight is often more economical for bulk orders, while air freight is faster but costlier. Work with logistics partners familiar with international shipping to navigate customs clearance and ensure compliance with local regulations. Additionally, factor in lead times for production and shipping to avoid delays in your operations. -

How can I customize comal electrico to fit my brand?

Many manufacturers offer customization options, such as branding with your logo, specific color schemes, or unique design features. To initiate the customization process, discuss your requirements with potential suppliers and request their design capabilities. Be prepared to provide detailed specifications and possibly pay additional costs for custom features. Customization can enhance your brand identity and differentiate your products in the market. -

What are the common challenges faced when sourcing comal electrico internationally?

Challenges may include language barriers, cultural differences in business practices, and variations in product quality standards. Additionally, navigating the complexities of international shipping and customs can present hurdles. To mitigate these issues, establish clear communication with suppliers, utilize professional translation services if necessary, and consider working with local agents who understand the market dynamics. Building strong relationships with suppliers can also facilitate smoother transactions and resolution of any issues that arise.

A Look at Comal Electrico Manufacturers & Suppliers

Could not verify enough suppliers for comal electrico to create a list at this time.

Strategic Sourcing Conclusion and Outlook for comal electrico

In the rapidly evolving landscape of global commerce, strategic sourcing for comal electrico emerges as a vital component for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The insights gleaned from market trends highlight the necessity for businesses to prioritize quality, supplier reliability, and cost-effectiveness. Establishing strong relationships with manufacturers and distributors ensures not only competitive pricing but also access to the latest innovations in electric griddle technology.

Investing in strategic sourcing can significantly enhance operational efficiencies and product offerings. By diversifying supply chains and leveraging local market insights, companies can mitigate risks associated with global sourcing challenges. This approach fosters resilience and adaptability, which are crucial in today’s dynamic marketplace.

Looking ahead, B2B buyers are encouraged to engage proactively with suppliers, exploring new partnerships and technologies that enhance product quality and sustainability. As the demand for comal electrico continues to grow, now is the time to align sourcing strategies with emerging market needs. Embrace this opportunity to elevate your business’s competitive edge and drive success in the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.