A Deep Dive into Chemical Etching Companies Near Me Solution

Introduction: Navigating the Global Market for chemical etching companies near me

Navigating the global market for chemical etching companies near you can be a daunting task, especially when the stakes involve precision engineering and high-quality standards. B2B buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Saudi Arabia and Germany—often face challenges in sourcing reliable suppliers that meet their specific requirements. This guide serves as a comprehensive resource for understanding the nuances of chemical etching services, including the various types of etching processes available, their applications across diverse industries, and essential criteria for vetting potential suppliers.

In this guide, we delve into critical factors that influence purchasing decisions, such as cost structures, lead times, and material compatibilities. You’ll gain insights into the certification standards that ensure quality and compliance, alongside best practices for establishing fruitful partnerships with chemical etching companies. By providing actionable information and expert recommendations, this guide empowers international buyers to make informed decisions that align with their operational needs and market demands. Whether you are looking for precision parts for aerospace applications or intricate designs for medical devices, our resource is designed to streamline your procurement process, ensuring you find the right chemical etching partner to meet your business goals.

Understanding chemical etching companies near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Precision Chemical Etching | High tolerances (up to ±0.0001 in), suitable for complex designs | Aerospace, medical devices, electronics | Pros: High accuracy; Cons: Higher costs due to precision requirements. |

| Laser Etching Services | Utilizes laser technology for detailed etching | Custom furniture, electronic components | Pros: Versatile materials; Cons: May not be suitable for thicker materials. |

| Metal Photochemical Etching | Ideal for thin sheets, produces intricate patterns | Telecommunications, automotive, appliances | Pros: Cost-effective for large volumes; Cons: Limited to thin materials. |

| Custom Finishing Services | Offers a variety of finishing techniques alongside etching | Awards, signage, promotional items | Pros: Customization options; Cons: May lack specialization in etching alone. |

| Contract Manufacturing | Provides full-service manufacturing including etching | Various industries needing prototypes | Pros: Comprehensive service; Cons: Potentially longer lead times. |

What are the Characteristics of Precision Chemical Etching Companies?

Precision chemical etching companies focus on delivering high-tolerance etching services, often required in industries like aerospace and medical devices. These companies utilize advanced technologies to achieve intricate designs with minimal material waste. B2B buyers should consider the company’s certifications, such as AS9100 or NADCAP, which indicate adherence to strict quality standards. While the precision offered is unparalleled, buyers must also be prepared for potentially higher costs associated with these specialized services.

How Do Laser Etching Services Stand Out?

Laser etching services are distinguished by their ability to create highly detailed designs on a wide range of materials, including metals and plastics. This technology allows for both prototyping and production runs, making it suitable for custom furniture and electronic components. B2B buyers should evaluate the company’s equipment and capabilities, particularly for intricate designs. While laser etching offers versatility, it may not be the best choice for thicker materials, which can limit its applications.

What Are the Benefits of Metal Photochemical Etching?

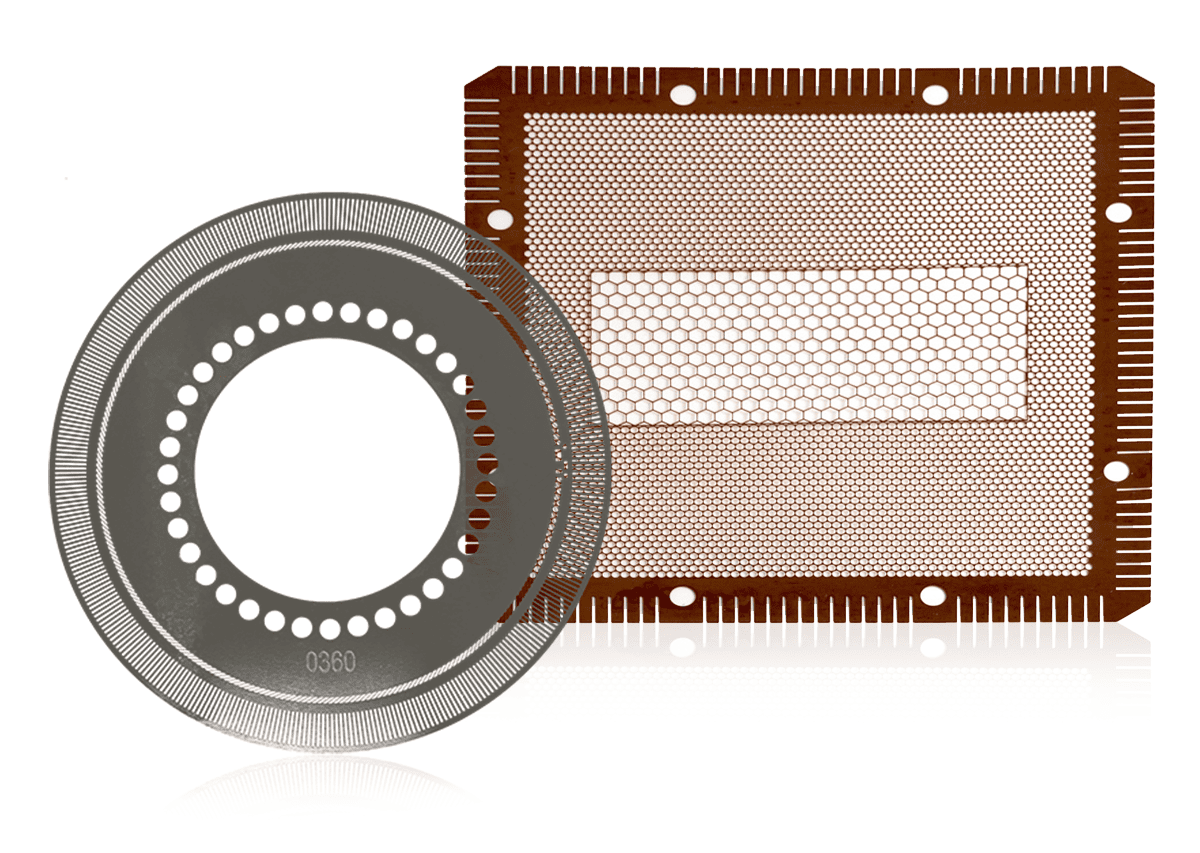

Metal photochemical etching is particularly effective for processing thin sheet metal components, making it ideal for industries such as telecommunications and automotive. This method allows for high-volume production at a lower cost, making it attractive for companies looking to scale. Buyers should ensure that the etching company can handle the specific materials required for their projects. However, the limitation to thinner materials might restrict its use in applications requiring more robust components.

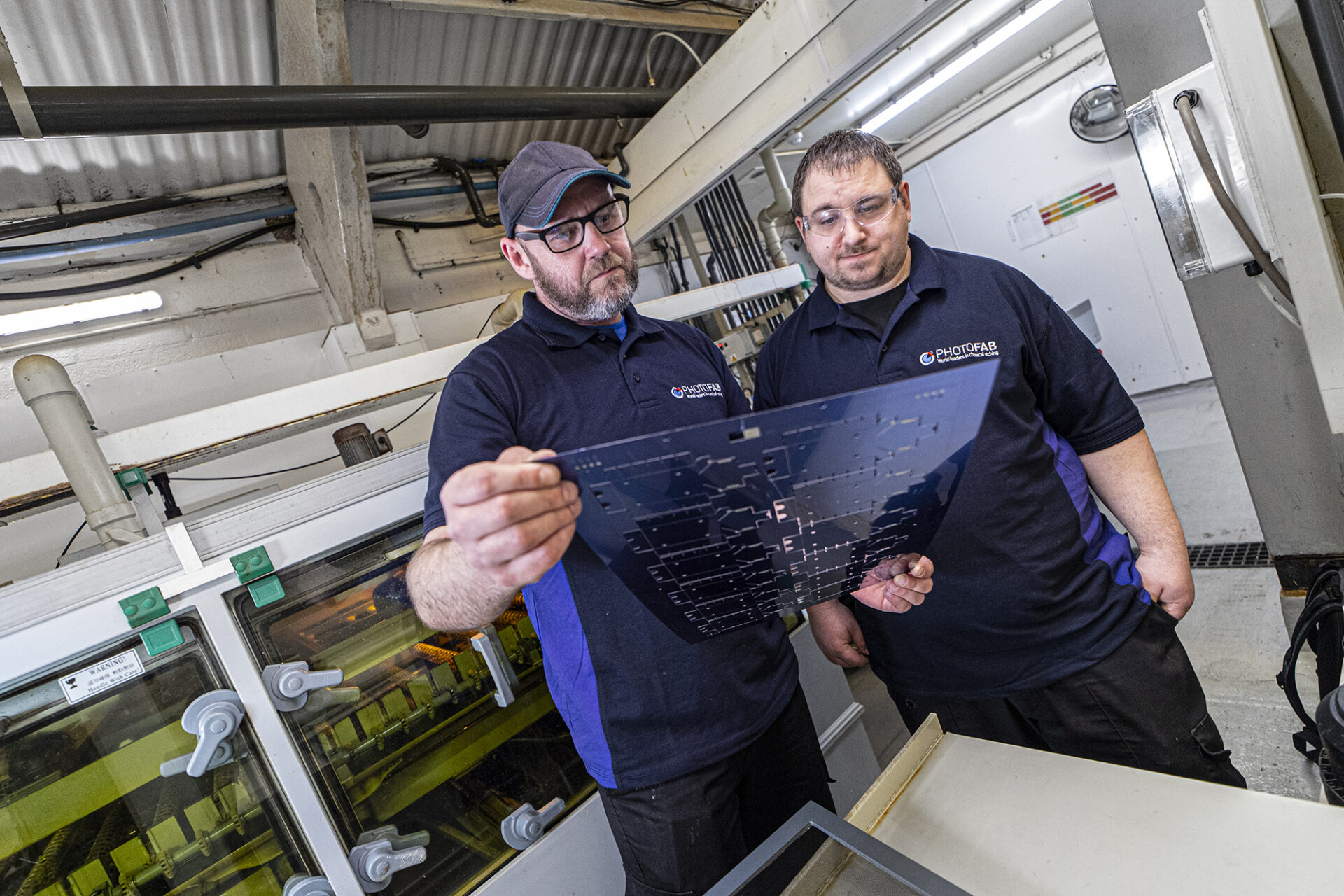

Illustrative image related to chemical etching companies near me

What Should Buyers Know About Custom Finishing Services?

Custom finishing services encompass a wide range of techniques, including etching, engraving, and surface finishing. These companies cater to diverse applications, from awards to signage, providing significant customization options. B2B buyers looking for unique branding or promotional items may find these services particularly beneficial. However, buyers should be cautious as these companies may not specialize solely in etching, which could affect the quality of the etching work.

How Does Contract Manufacturing Integrate Chemical Etching?

Contract manufacturing companies often provide a comprehensive suite of services, including chemical etching, prototyping, and full-scale production. This integration is advantageous for businesses seeking a one-stop solution for their manufacturing needs. B2B buyers should assess the company’s capacity to handle their specific requirements and timelines. While this approach can streamline the procurement process, it may also lead to longer lead times compared to specialized etching firms.

Key Industrial Applications of chemical etching companies near me

| Industry/Sector | Specific Application of chemical etching companies near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components for avionics and aircraft systems | Enhanced performance and safety in critical applications | Certifications (NADCAP, AS9100), material specifications |

| Medical Devices | Custom etching for surgical instruments and implants | Improved product reliability and patient safety | Compliance with medical standards, biocompatibility |

| Electronics | Etching for circuit boards and electronic components | Higher efficiency and miniaturization of devices | Material compatibility, precision tolerances |

| Automotive | Components for fuel systems and automotive electronics | Increased durability and performance in harsh conditions | Resistance to corrosion, adherence to automotive standards |

| Telecommunications | Antennas and EMI shielding components | Enhanced signal quality and device reliability | Customization options, lead times for prototypes |

How Is Chemical Etching Used in Aerospace Applications?

In the aerospace industry, chemical etching is vital for producing precision components used in avionics and aircraft systems. This process allows manufacturers to create intricate designs with tight tolerances, which are essential for ensuring safety and performance in flight. For international buyers, especially from regions like Europe and the Middle East, it is crucial to source from companies with certifications like NADCAP and AS9100, ensuring compliance with stringent aerospace standards.

What Role Does Chemical Etching Play in Medical Device Manufacturing?

Chemical etching is extensively used in the medical device sector for custom etching of surgical instruments and implants. This method allows for the production of complex shapes and fine details that enhance the functionality and reliability of medical devices. Buyers from Africa and South America should prioritize suppliers who adhere to rigorous medical device regulations and can demonstrate biocompatibility, as these factors are critical for patient safety and regulatory compliance.

How Is Chemical Etching Beneficial for Electronics Manufacturing?

In electronics, chemical etching is employed to create circuit boards and electronic components that require high precision and miniaturization. The ability to produce intricate designs helps in improving the efficiency of electronic devices, making them smaller and more powerful. International buyers must consider material compatibility and the precision tolerances offered by suppliers to ensure that the components meet their specific electronic applications.

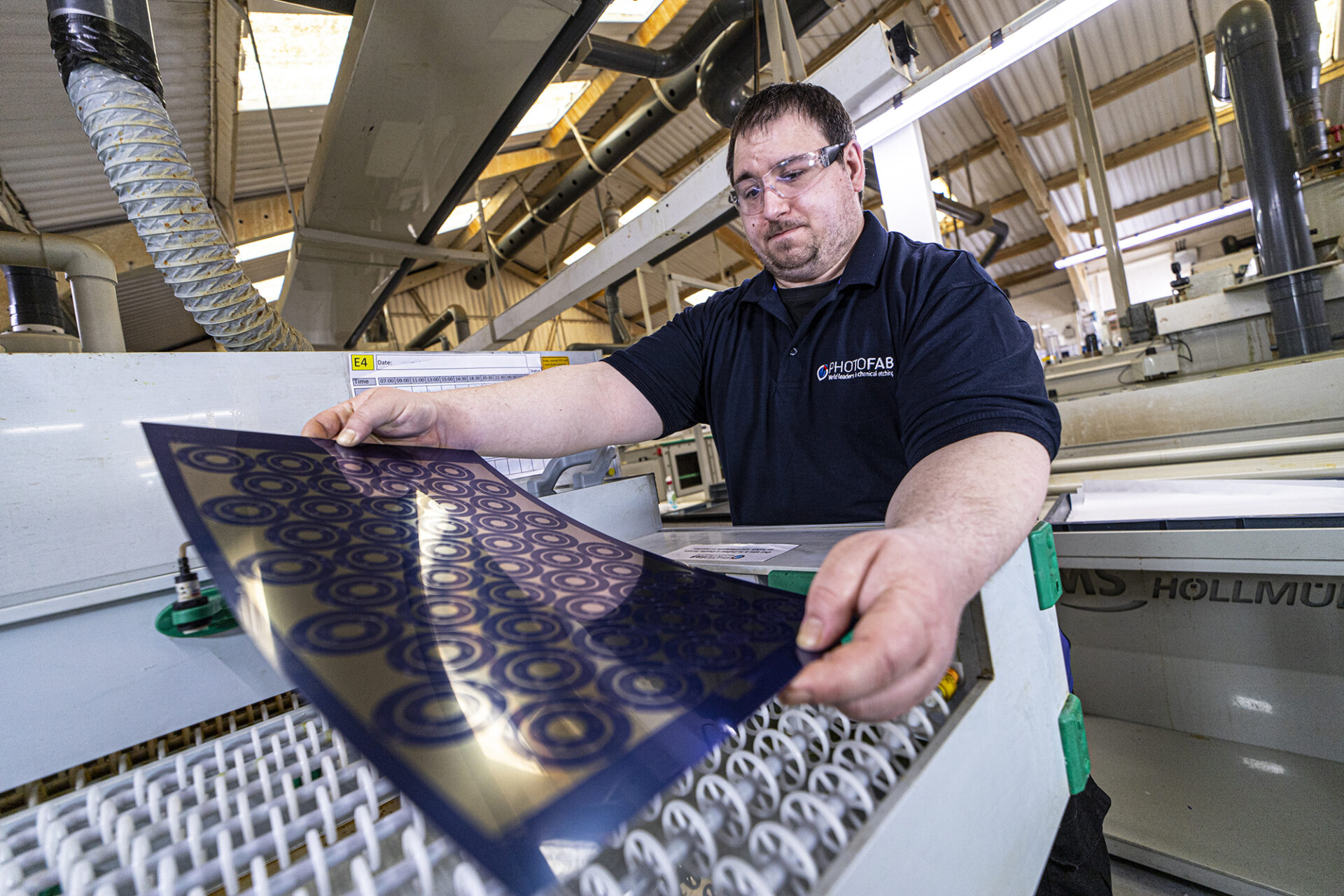

Illustrative image related to chemical etching companies near me

Why Is Chemical Etching Important for Automotive Components?

The automotive industry utilizes chemical etching for creating components in fuel systems and automotive electronics. This process enhances the durability and performance of parts, especially in harsh environments. Buyers should focus on sourcing etching services that provide materials resistant to corrosion and comply with automotive industry standards, ensuring longevity and reliability in their applications.

How Does Chemical Etching Enhance Telecommunications Equipment?

In telecommunications, chemical etching is used to manufacture antennas and EMI shielding components. These etched parts are crucial for enhancing signal quality and reliability in communication devices. When sourcing from chemical etching companies, international buyers should evaluate customization options and lead times for prototypes, as these factors can significantly impact the development timeline of telecommunications projects.

3 Common User Pain Points for ‘chemical etching companies near me’ & Their Solutions

Scenario 1: Delays in Production Due to Inadequate Supplier Communication

The Problem:

B2B buyers often face significant delays in their production schedules due to poor communication with chemical etching companies. This can stem from unclear specifications, lack of timely updates on order status, or difficulty in reaching the supplier for urgent queries. For instance, a company in the aerospace sector may require precision-etched parts for a new aircraft model but finds that their supplier is unresponsive or does not provide clarity on lead times. Such delays can result in missed deadlines, increased costs, and potential damage to business relationships.

The Solution:

To mitigate communication issues, B2B buyers should prioritize establishing clear lines of communication from the outset. This involves setting expectations regarding response times and preferred communication channels (email, phone, or project management software). Additionally, buyers should consider developing a comprehensive specification document that outlines all technical requirements, timelines, and quality standards. This document can serve as a reference point for both parties, reducing misunderstandings. Scheduling regular check-ins during the production process can also facilitate updates and address any concerns proactively. By fostering a collaborative relationship, buyers can ensure that their projects stay on track.

Illustrative image related to chemical etching companies near me

Scenario 2: Variability in Quality Standards Across Suppliers

The Problem:

Quality inconsistency is a major concern for B2B buyers when sourcing from multiple chemical etching companies. A buyer may find that parts received from different suppliers do not meet the same quality standards, leading to rework, increased scrap rates, and ultimately higher costs. This is particularly critical in industries such as medical devices or aerospace, where precision is paramount. For example, a buyer may receive parts that are not etched to the required tolerances, causing delays in assembly and potential safety risks.

The Solution:

To address quality variability, buyers should conduct thorough due diligence before selecting a chemical etching supplier. This includes verifying certifications such as ISO 9001 or NADCAP, which demonstrate a commitment to quality management systems. Requesting samples or conducting pilot runs can provide insight into a supplier’s capabilities and consistency. Establishing a clear set of quality expectations and metrics upfront can also help ensure alignment. Implementing a robust quality control process that includes regular audits and feedback loops can further maintain standards across multiple suppliers, ensuring that all parts meet the required specifications.

Scenario 3: Difficulty in Finding Specialized Services for Unique Applications

The Problem:

B2B buyers often struggle to find chemical etching companies that can handle specialized applications or unique materials. For instance, a company in the electronics sector may need etching services for a specific alloy or require intricate designs that are not offered by general etching suppliers. The lack of available expertise can lead to suboptimal outcomes, including the use of inferior materials or processes that do not meet the necessary industry standards.

The Solution:

To overcome this challenge, buyers should invest time in researching suppliers that specialize in their specific industry needs. This can involve using industry directories, trade shows, and professional networks to identify companies with a proven track record in specialized applications. Engaging in initial consultations with potential suppliers can help clarify their capabilities and whether they can meet unique requirements. Buyers should also consider forming partnerships with suppliers that offer design and engineering support, ensuring that the etching process is optimized for their specific applications. By taking a proactive approach in supplier selection, buyers can enhance the quality and performance of their products while reducing the risk of sourcing errors.

Strategic Material Selection Guide for chemical etching companies near me

What Are the Key Materials Used in Chemical Etching and Their Properties?

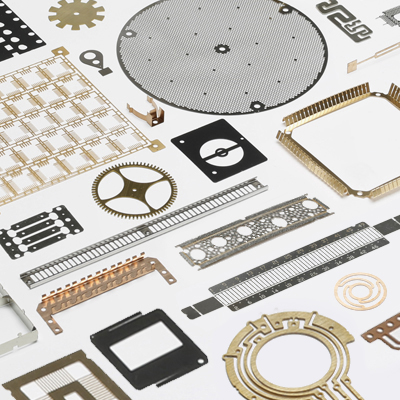

Chemical etching is a precise manufacturing process that relies heavily on the selection of appropriate materials. Here, we analyze four common materials used in chemical etching, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to chemical etching companies near me

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating up to 800°C and can handle a range of pressures, making it suitable for various applications.

Pros & Cons:

The durability of stainless steel is a significant advantage, as it can withstand harsh environments without degrading. However, its higher cost compared to other metals can be a drawback for budget-sensitive projects. Manufacturing complexity is moderate, requiring specialized equipment for etching.

Impact on Application:

Stainless steel is ideal for applications in the medical and aerospace industries, where hygiene and durability are paramount. Its compatibility with various media makes it a versatile choice.

International Buyer Considerations:

Buyers from regions like Europe and the Middle East should ensure compliance with ASTM and DIN standards, which are commonly referenced in specifications for stainless steel components.

2. Aluminum

Key Properties:

Aluminum is lightweight and has excellent corrosion resistance, particularly when anodized. It can withstand temperatures up to 600°C, making it suitable for a variety of applications.

Pros & Cons:

The primary advantage of aluminum is its low weight, which reduces shipping costs and makes it easier to handle. However, it is less durable than stainless steel and can be more prone to scratching and denting. The manufacturing process is generally straightforward, but care must be taken to avoid oxidation during etching.

Impact on Application:

Aluminum is often used in the automotive and electronics industries due to its lightweight nature and good electrical conductivity.

International Buyer Considerations:

B2B buyers from Africa and South America should consider local regulations regarding aluminum recycling and environmental impact, as these can influence procurement decisions.

3. Brass

Key Properties:

Brass is a copper-zinc alloy known for its excellent machinability and moderate corrosion resistance. It typically performs well in temperatures up to 300°C.

Pros & Cons:

Brass offers good aesthetic qualities, making it suitable for decorative applications. However, it is less durable than stainless steel and can tarnish over time. The etching process for brass can be more complex due to its softer nature.

Impact on Application:

Brass is commonly used in plumbing fittings and electrical components, where its conductivity and aesthetic appeal are beneficial.

International Buyer Considerations:

Buyers from Europe should be aware of REACH regulations concerning brass materials, as compliance is essential for market entry.

4. Copper

Key Properties:

Copper is renowned for its excellent electrical and thermal conductivity. It can withstand temperatures up to 300°C and is highly resistant to corrosion in non-oxidizing environments.

Pros & Cons:

The key advantage of copper is its superior conductivity, making it ideal for electrical applications. However, it is relatively soft and can be easily scratched or dented, which limits its use in high-wear applications. The etching process can be straightforward but requires careful handling to avoid oxidation.

Impact on Application:

Copper is widely used in electrical connectors and circuit boards, where its conductivity is crucial.

International Buyer Considerations:

B2B buyers from the Middle East should consider the availability of copper and the potential for price fluctuations due to global demand.

Summary Table of Material Selection for Chemical Etching

| Material | Typical Use Case for chemical etching companies near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Aerospace and medical components | Excellent corrosion resistance | Higher cost | High |

| Aluminum | Automotive and electronics | Lightweight | Less durable | Medium |

| Brass | Plumbing fittings and electrical components | Good machinability and aesthetics | Tarnishes over time | Medium |

| Copper | Electrical connectors and circuit boards | Superior conductivity | Soft and prone to damage | Medium |

This strategic material selection guide provides a comprehensive understanding of the materials commonly used in chemical etching, along with insights that are particularly relevant for international B2B buyers in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for chemical etching companies near me

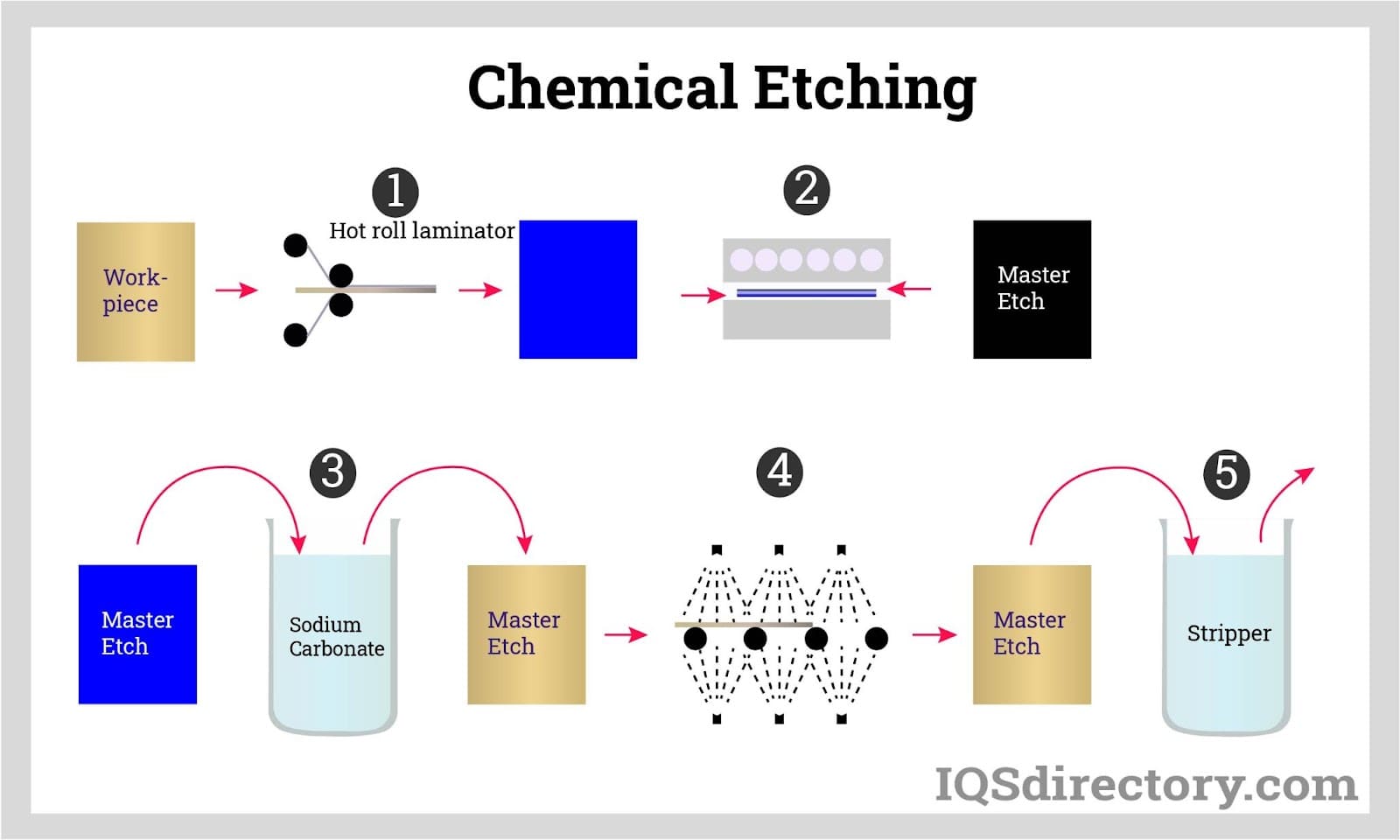

What Are the Key Stages in the Manufacturing Process of Chemical Etching?

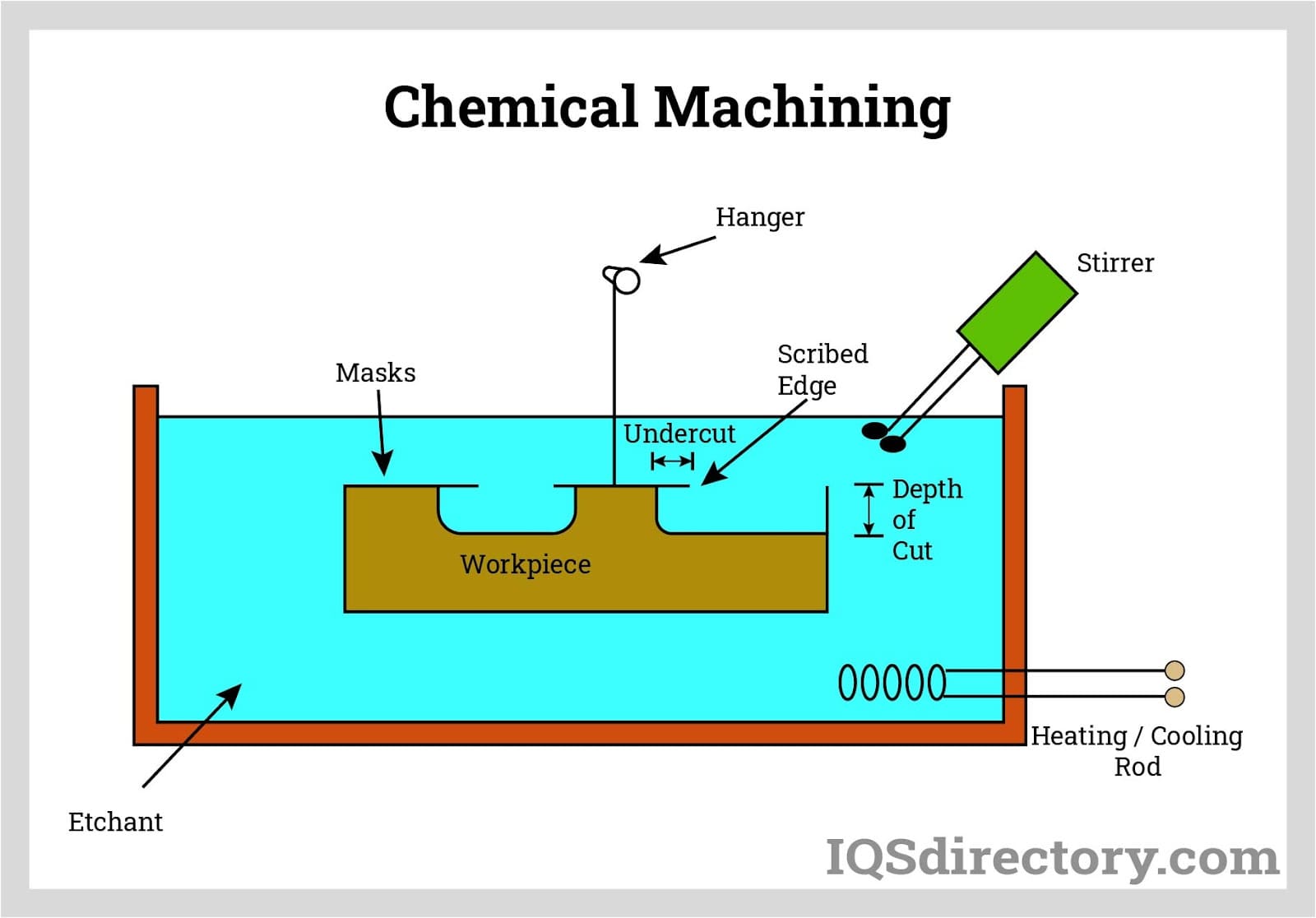

The manufacturing process of chemical etching is intricate and involves several critical stages, ensuring precision and quality in the final product. The main stages include material preparation, etching, rinsing, drying, and finishing.

-

Material Preparation: This initial stage involves selecting the appropriate substrate materials, such as metals or plastics. The materials are cleaned to remove any contaminants, ensuring optimal adhesion and etching quality. Surface treatments may also be applied to enhance the etching process.

-

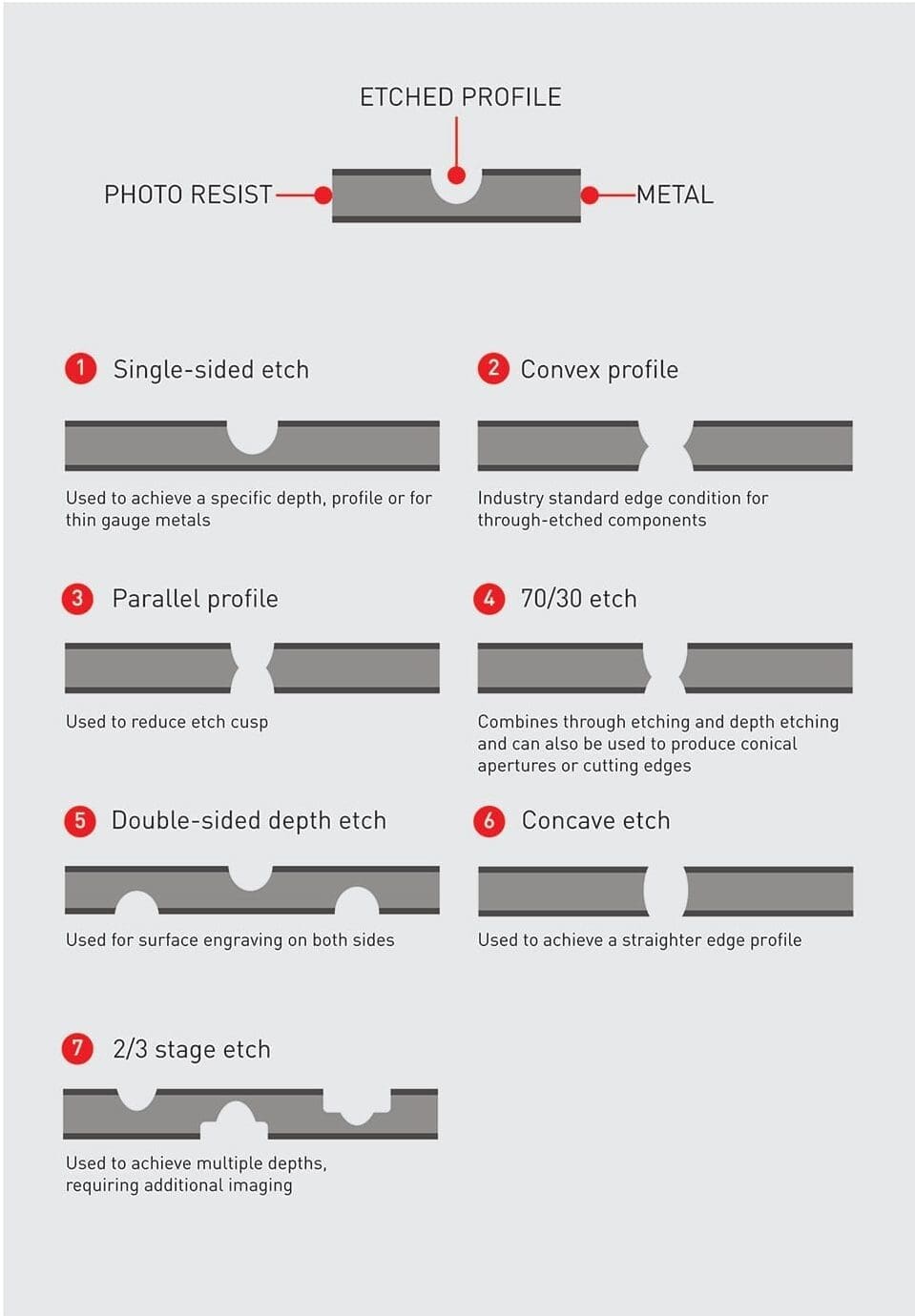

Etching: The core of the chemical etching process utilizes photoresist techniques. A layer of photoresist is applied to the substrate, which is then exposed to ultraviolet light through a patterned mask. This step creates a precise pattern on the material. After exposure, the unexposed photoresist is removed, allowing the underlying material to be etched using a chemical solution. The choice of etching solution varies based on the substrate, with common chemicals including ferric chloride for copper and sodium hydroxide for aluminum.

-

Rinsing and Drying: Once etching is complete, the parts undergo rinsing to remove residual chemicals. This step is crucial to prevent any post-etching corrosion or contamination. After rinsing, the parts are dried using air blowers or heat, ensuring they are ready for the next steps.

-

Finishing: The finishing stage may involve additional processes such as deburring, polishing, or applying protective coatings. These steps enhance the aesthetic quality and durability of the etched components. For industries requiring stringent standards, such as aerospace or medical devices, this stage is particularly critical.

What Techniques Are Commonly Used in Chemical Etching?

Chemical etching companies employ various techniques to achieve different results, tailored to specific applications. The most common methods include:

-

Photochemical Etching: This technique involves using light-sensitive materials and is ideal for producing intricate patterns with high precision. It is widely used in electronics for creating circuit boards.

-

Laser Etching: Utilizing high-powered lasers, this method offers flexibility in design and can be applied to a wide range of materials. It is suitable for low to medium production runs and allows for quick adjustments in design.

-

Electrochemical Etching: This technique uses electrical current to remove material, which can be beneficial for certain types of metals and applications requiring deeper etches.

How Is Quality Assurance Implemented in Chemical Etching Processes?

Quality assurance (QA) is critical in the chemical etching industry to ensure that products meet international standards and customer specifications. Key elements of QA include adherence to relevant international standards, systematic checkpoints throughout the manufacturing process, and rigorous testing methodologies.

-

International Standards and Certifications: Many chemical etching companies pursue certifications such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications like AS9100 for aerospace applications or API for oil and gas further ensure compliance with safety and quality standards.

-

Quality Control Checkpoints: Implementing quality control (QC) at various stages of the manufacturing process is essential. Common checkpoints include:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the etching process helps identify any deviations from standards early on.

– Final Quality Control (FQC): Completed products undergo thorough inspections to verify they meet all specifications before shipment. -

Testing Methods: Various testing methods are employed to assess the quality of etched products. Common techniques include:

– Dimensional Inspection: Using tools like calipers and micrometers to ensure parts meet precise measurements.

– Surface Finish Evaluation: Assessing the quality of the finish through visual inspections or using surface roughness testers.

– Adhesion Tests: Ensuring that coatings or finishes adhere properly to the substrate.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control measures of chemical etching suppliers is paramount. Here are actionable steps to ensure due diligence:

Illustrative image related to chemical etching companies near me

-

Conduct Audits: Regular audits can provide insights into the supplier’s operations, adherence to quality standards, and overall manufacturing practices. Buyers should consider conducting on-site audits or requesting third-party audit reports.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection reports, testing results, and certifications. This information can help buyers assess the reliability of the supplier.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can offer an unbiased assessment of the supplier’s quality control measures. These inspectors can evaluate products before shipment, ensuring they meet the required standards.

-

Understand Certification Nuances: Different regions may have specific certification requirements. For example, suppliers catering to the European market may need CE certification, while those in the aerospace sector may require NADCAP certification. Buyers should familiarize themselves with these nuances to ensure compliance.

What Are the Challenges for International B2B Buyers in Ensuring Quality?

International B2B buyers often face challenges in verifying quality due to geographical distances, language barriers, and differing regulatory standards. To navigate these challenges effectively:

-

Establish Clear Communication: Maintain open lines of communication with suppliers to clarify expectations and requirements. Utilizing translation services may help overcome language barriers.

-

Leverage Technology: Utilize digital tools for real-time monitoring and communication, allowing buyers to stay informed about production processes and quality assurance measures.

-

Build Relationships: Developing strong relationships with suppliers can foster trust and transparency, making it easier to address any quality concerns that may arise.

By understanding the manufacturing processes and quality assurance practices of chemical etching companies, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chemical etching companies near me’

When sourcing chemical etching companies, it’s essential to follow a structured approach to ensure that you find a partner that meets your specific needs. This guide outlines key steps to help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Clearly outline the requirements for your project, including the materials, dimensions, tolerances, and volume of parts needed. This is crucial as different etching companies specialize in various materials and processes. For instance, if you require etching on high-precision components, ensure the supplier has the necessary capabilities to meet your specifications.

Illustrative image related to chemical etching companies near me

Step 2: Research Local and International Suppliers

Conduct thorough research to identify potential suppliers both locally and internationally. Utilize platforms like Thomasnet, industry directories, and trade shows to compile a list of companies. Pay attention to their geographic location, as proximity can influence lead times and shipping costs.

Step 3: Verify Supplier Certifications

Before proceeding, ensure that the suppliers hold relevant certifications, such as ISO 9001, NADCAP, or AS 9100. These certifications indicate adherence to quality management and industry standards, which is particularly important in sectors like aerospace and medical. Request copies of these certifications to confirm their validity.

Step 4: Evaluate Potential Suppliers

Thoroughly vet the shortlisted suppliers by reviewing their company profiles, case studies, and customer testimonials. Look for experience in your specific industry and examples of similar projects they’ve completed. This step will help you assess their reliability and expertise.

- Request References: Ask for references from clients in similar sectors to gauge their satisfaction with the supplier’s services.

- Review Case Studies: Analyze how the supplier has successfully handled challenges in past projects.

Step 5: Request and Compare Quotes

Once you have a shortlist of potential suppliers, request detailed quotes that outline pricing, lead times, and payment terms. Comparing multiple quotes will give you a clearer picture of the market rates and help you identify which suppliers offer the best value for your requirements.

Step 6: Assess Customer Support and Communication

Evaluate the responsiveness and clarity of communication from each supplier. Effective communication is essential for a smooth procurement process and successful project execution. Consider how quickly they respond to inquiries and their willingness to provide additional information.

Step 7: Conduct a Facility Visit (if feasible)

If possible, arrange a visit to the supplier’s facility to observe their processes and capabilities firsthand. This step can provide valuable insights into their operations, quality control measures, and overall professionalism. It also offers an opportunity to discuss your project in detail and build a stronger relationship.

By following these steps, you can make informed decisions when sourcing chemical etching companies, ensuring that you partner with a reliable supplier that meets your business needs.

Comprehensive Cost and Pricing Analysis for chemical etching companies near me Sourcing

What Are the Key Cost Components in Chemical Etching Services?

Understanding the cost structure of chemical etching services is essential for B2B buyers seeking to optimize their sourcing strategies. The primary cost components typically include:

Illustrative image related to chemical etching companies near me

-

Materials: The type of materials used significantly impacts the cost. Common materials such as aluminum, brass, copper, and specialized alloys like Hastelloy® and Inconel® can vary widely in price. Higher-grade materials tend to be more expensive but may offer better performance and durability.

-

Labor: Skilled labor is necessary for precision etching, which involves meticulous handling and quality control. Labor costs can fluctuate based on regional wage standards, the complexity of the design, and the expertise required for the project.

-

Manufacturing Overhead: This includes costs related to facility maintenance, equipment depreciation, and utilities. Companies with advanced technology or certifications (like NADCAP or AS9100) may have higher overhead costs but can provide superior quality and reliability.

-

Tooling: Custom tooling for specific projects can add to the initial cost. However, investing in high-quality tooling can improve efficiency and reduce long-term costs by minimizing defects and rework.

-

Quality Control (QC): Rigorous QC processes are crucial in industries such as aerospace and medical, where precision is non-negotiable. The costs associated with QC can vary based on the required certifications and testing methods.

-

Logistics: Shipping and handling costs depend on the supplier’s location and the buyer’s destination. International shipping can introduce additional complexities, including customs duties and tariffs.

-

Margin: Suppliers typically add a profit margin to cover their costs and achieve profitability. This margin can vary based on competition, market demand, and the supplier’s positioning in the market.

How Do Price Influencers Affect Chemical Etching Costs?

Several factors can influence the pricing of chemical etching services:

-

Volume/MOQ: Larger orders often benefit from lower per-unit costs due to economies of scale. Understanding the minimum order quantities (MOQs) is crucial for negotiating better pricing.

-

Specifications and Customization: Customized etching services tailored to specific design requirements can lead to higher costs. Buyers should assess whether the added customization justifies the price increase.

-

Materials: As mentioned earlier, material choices significantly affect pricing. It’s advisable to request multiple quotes based on different materials to find the most cost-effective solution.

-

Quality and Certifications: Higher quality and compliance with industry certifications often demand a premium price. Buyers should evaluate if the added costs align with their quality requirements.

-

Supplier Factors: The reputation and location of the supplier can also influence pricing. Established suppliers with a track record of reliability may charge more but could ultimately save costs through reduced risk.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects shipping costs and responsibilities, impacting the overall price. Understanding these terms can help buyers manage logistics costs effectively.

What Are Effective Buyer Tips for Negotiating Chemical Etching Prices?

-

Negotiate Wisely: Leverage the information gathered about cost components and price influencers during negotiations. Discussing specific project requirements can lead to tailored pricing options.

-

Focus on Cost Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, maintenance, and potential rework costs. Evaluating the TCO helps in making informed purchasing decisions.

-

Understand Pricing Nuances: International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations, import tariffs, and shipping delays that can impact overall costs.

-

Request Sample Runs: Before committing to larger orders, request samples to assess quality and ensure the supplier can meet your specifications. This reduces the risk of costly mistakes.

-

Build Long-term Relationships: Establishing a long-term relationship with a supplier can lead to better pricing and priority service. Regular communication and feedback can foster trust and collaboration.

Disclaimer on Pricing Information

Prices for chemical etching services can vary widely based on numerous factors. The figures and considerations outlined here are indicative and should be validated through direct discussions with suppliers to ensure accuracy for your specific needs.

Alternatives Analysis: Comparing chemical etching companies near me With Other Solutions

In today’s competitive manufacturing landscape, businesses often seek effective methods for metal processing and part fabrication. While chemical etching is a popular solution, it’s essential to evaluate other viable alternatives that may suit specific project requirements. This analysis compares chemical etching companies with laser cutting and traditional machining, providing insights for B2B buyers aiming to optimize their production processes.

| Comparison Aspect | Chemical Etching Companies Near Me | Laser Cutting | Traditional Machining |

|---|---|---|---|

| Performance | High precision with intricate designs; excellent for thin materials | Offers fast cutting speeds and clean edges; suitable for various thicknesses | Versatile; capable of working with a wide range of materials; good for complex shapes |

| Cost | Moderate to high; depends on material and complexity | Generally lower for bulk orders; costs can increase with thickness | Can be cost-effective for high-volume production but may require more time |

| Ease of Implementation | Requires setup and expertise; best with established suppliers | Relatively easy to implement with modern machines; minimal setup time | May require skilled operators and longer setup times, depending on the project |

| Maintenance | Low maintenance; mostly dependent on supplier capabilities | Moderate; requires regular calibration and maintenance of laser equipment | High; involves regular maintenance of tools and machines, especially for complex setups |

| Best Use Case | Ideal for high-precision applications in aerospace, medical, and electronics | Best for sheet metal fabrication, signage, and quick prototypes | Suitable for heavy machining, large components, and high-volume production |

What Are the Pros and Cons of Laser Cutting as an Alternative to Chemical Etching?

Laser cutting is a method that uses focused laser beams to cut through materials, offering high-speed operations and excellent precision. One of its significant advantages is its ability to handle various material thicknesses and types, making it versatile for different industries. However, it may not achieve the same intricate detailing that chemical etching offers, particularly on thin substrates. Additionally, while initial costs can be lower for bulk orders, the pricing can escalate with increased material thickness.

How Does Traditional Machining Compare to Chemical Etching?

Traditional machining encompasses various processes such as turning, milling, and drilling to shape materials. This method is highly versatile and can produce complex geometries that chemical etching may not achieve. However, traditional machining often requires skilled operators and can be time-intensive, leading to higher labor costs. While it may be more cost-effective for high-volume production runs, the setup time and maintenance can become significant drawbacks compared to the more streamlined processes of chemical etching.

Illustrative image related to chemical etching companies near me

How Can B2B Buyers Choose the Right Solution for Their Needs?

When deciding between chemical etching and its alternatives, B2B buyers should consider several factors, including the specific requirements of their projects, budget constraints, and the desired precision. For high-precision applications in sensitive industries, chemical etching may be the best choice. Conversely, if speed and flexibility are paramount, laser cutting could be more advantageous. Traditional machining remains a solid option for larger, more complex components but requires careful evaluation of operational costs and time. Ultimately, understanding the strengths and weaknesses of each method will enable buyers to make informed decisions that align with their manufacturing goals.

Essential Technical Properties and Trade Terminology for chemical etching companies near me

What Are the Key Technical Properties Relevant to Chemical Etching?

When considering partnerships with chemical etching companies, understanding the essential technical properties is crucial for making informed decisions. Here are some of the critical specifications to look for:

-

Material Grade

Material grade indicates the quality and composition of the metals used in the etching process. Common materials include aluminum, brass, stainless steel, and various alloys. Knowing the material grade helps in assessing its suitability for specific applications, such as aerospace, medical devices, or electronics. High-grade materials ensure durability and performance in demanding environments. -

Tolerance

Tolerance refers to the allowable deviation from a specified dimension in the finished product. For chemical etching, tolerances can be as tight as ±0.0001 inches. This precision is vital for industries like aerospace or electronics, where even minor discrepancies can lead to failure. A company’s ability to meet strict tolerances can be a significant factor in your selection process. -

Thickness Range

The thickness range of materials that a chemical etching company can process is another important property. Most companies can handle materials ranging from 0.0005 to 0.1250 inches. Knowing the thickness capabilities allows buyers to determine if a supplier can accommodate their specific project requirements, ensuring the integrity and functionality of the final product. -

Surface Finish

Surface finish pertains to the texture and quality of the surface post-etching. Different finishes can affect both aesthetic and functional properties, such as corrosion resistance and adhesion for coatings. Understanding the surface finish options available helps buyers choose the right provider for their application needs. -

Production Capacity

This property indicates the volume of work a chemical etching company can handle, from prototypes to large-scale production runs. Companies that offer flexibility in production capacity can better meet fluctuating demand, making them more appealing partners for businesses with variable project scopes.

What Are Common Trade Terms Used in Chemical Etching?

Understanding industry terminology is equally important when dealing with chemical etching companies. Here are several key terms that are commonly used:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of chemical etching, an OEM may require specific etching services to create components for their products, emphasizing the need for precision and compliance with specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is critical for businesses to manage costs and inventory effectively. A lower MOQ can be advantageous for startups or projects that require limited quantities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing on specific services or products. In the chemical etching industry, submitting an RFQ allows businesses to compare costs and services from different suppliers, helping to identify the best value for their needs. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for companies engaging with suppliers across borders, as they clarify shipping, insurance, and tariff responsibilities. -

NADCAP Certification

The National Aerospace and Defense Contractors Accreditation Program (NADCAP) certification indicates that a company meets stringent industry standards for quality and performance in aerospace and defense manufacturing. This certification can be a deciding factor for buyers in highly regulated industries.

By familiarizing yourself with these technical properties and trade terms, you can engage more effectively with chemical etching companies and make informed decisions that align with your business objectives.

Navigating Market Dynamics and Sourcing Trends in the chemical etching companies near me Sector

What Are the Key Market Dynamics and Trends Impacting Chemical Etching Companies?

The chemical etching market is experiencing a dynamic shift, driven by several global factors. One of the primary drivers is the increasing demand for precision-engineered components across various industries, including aerospace, electronics, and medical devices. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek high-quality, cost-effective solutions, the demand for chemical etching services is expected to rise. Emerging technologies, such as automation and advanced materials, are reshaping sourcing strategies, allowing companies to enhance efficiency and reduce production costs.

Furthermore, there is a growing trend toward customization and rapid prototyping, which aligns with the needs of industries that require bespoke solutions. For instance, companies are now investing in technologies that facilitate low to medium production runs, enabling them to respond quickly to market changes. This flexibility is particularly important for buyers in regions like Saudi Arabia and Germany, where the pace of innovation is accelerating. Additionally, digital transformation is becoming increasingly relevant, with B2B buyers leveraging online platforms to identify and engage with potential suppliers, streamlining the sourcing process.

How Is Sustainability Influencing Sourcing Decisions in Chemical Etching?

Sustainability is a crucial consideration for modern B2B buyers, particularly in the chemical etching sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and environmental stewardship. This includes the use of eco-friendly materials and processes, which can significantly reduce the carbon footprint associated with chemical etching.

Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for suppliers aiming to attract international buyers. Additionally, the use of ‘green’ chemicals in etching processes is gaining traction, as companies seek to minimize hazardous waste and emissions. By prioritizing sustainability, chemical etching companies not only comply with regulatory demands but also appeal to a growing segment of eco-conscious buyers. This trend is particularly relevant for B2B buyers from regions like Europe, where strict environmental regulations are in place.

How Has the Chemical Etching Industry Evolved Over Time?

The evolution of the chemical etching industry can be traced back to its origins in the mid-20th century, when it emerged as a specialized technique for producing intricate designs on metal surfaces. Initially utilized primarily in the jewelry and art sectors, chemical etching quickly gained traction in industrial applications due to its ability to create precise and repeatable patterns without the need for complex tooling. As industries such as aerospace and electronics expanded, the demand for high-precision components surged, driving innovation in etching technologies.

Illustrative image related to chemical etching companies near me

Over the decades, advancements in chemical formulations and etching techniques have significantly improved the quality and efficiency of the process. The introduction of photochemical etching further refined the capabilities of manufacturers, enabling them to work with a wider variety of materials and thicknesses. Today, the industry continues to innovate, incorporating digital technologies and automation to enhance production capabilities and meet the evolving needs of global B2B buyers. This historical context underscores the resilience and adaptability of the chemical etching sector, positioning it as a vital player in the manufacturing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of chemical etching companies near me

-

How can I find reliable chemical etching companies near me?

To find trustworthy chemical etching companies, start by conducting an online search with specific keywords such as “chemical etching services near me” and include your region. Utilize platforms like Thomasnet or industry-specific directories that list certified suppliers. It’s crucial to check for certifications (like NADCAP or ISO) and read reviews from other B2B clients. Networking through industry events or local business associations can also provide referrals to reputable companies. -

What factors should I consider when choosing a chemical etching supplier?

When selecting a chemical etching supplier, consider their industry certifications, experience, and specialization in the materials relevant to your needs. Evaluate their production capabilities, including minimum order quantities (MOQs), lead times, and customization options. Additionally, assess their quality assurance processes, customer service responsiveness, and logistical capabilities for international shipping, especially if you are sourcing from regions like Africa or South America. -

What is the typical lead time for chemical etching projects?

Lead times for chemical etching projects can vary significantly based on the complexity of the design, the volume of the order, and the supplier’s current workload. Generally, expect lead times ranging from a few days for simple prototypes to several weeks for larger production runs. Always discuss timelines upfront with potential suppliers to ensure they can meet your project deadlines, especially for international orders. -

Can I customize my chemical etching design?

Yes, many chemical etching companies offer customization options to meet specific design requirements. This can include variations in material, size, shape, and complexity of the etching. When discussing your project, provide detailed specifications and artwork files, and inquire about their capabilities in producing custom designs. Some suppliers may also offer design assistance to optimize your project for manufacturing. -

What are the payment terms typically offered by chemical etching suppliers?

Payment terms for chemical etching services can vary widely. Many suppliers require a deposit upfront, with the balance due upon completion or prior to shipping. Some may offer net terms (e.g., net 30 or net 60) for established clients. It’s essential to clarify payment options and any associated fees before proceeding with an order, especially if you are an international buyer dealing with currency conversions and cross-border transactions. -

How do chemical etching companies ensure quality assurance?

Quality assurance in chemical etching companies is typically maintained through rigorous testing and adherence to industry standards. Look for suppliers that implement processes such as regular inspections, material traceability, and third-party audits. Certifications like ISO 9001 or NADCAP indicate a commitment to quality management systems. Request information on their QA procedures and any certifications they hold to ensure they meet your quality expectations. -

What logistics considerations should I keep in mind when sourcing internationally?

When sourcing chemical etching services internationally, consider logistics factors such as shipping costs, customs duties, and import regulations specific to your country. It’s advisable to work with suppliers who have experience in international shipping and can provide guidance on documentation and compliance. Additionally, evaluate their ability to offer reliable shipping options that align with your timelines and budget. -

Are there specific industries that commonly use chemical etching services?

Chemical etching services are utilized across various industries, including aerospace, medical devices, electronics, and automotive. Each sector may have unique requirements regarding material specifications and tolerances. When sourcing a supplier, ensure they have experience serving your specific industry, as this can impact their understanding of quality standards, regulatory compliance, and technical capabilities needed for your projects.

Top 3 Chemical Etching Companies Near Me Manufacturers & Suppliers List

1. MISTRAS – Chemical Etching Services

Domain: mistrasgroup.com

Registered: 2002 (23 years)

Introduction: Chemical etching services from MISTRAS are utilized to inspect titanium, nickel alloys, and steel alloys components to ensure they meet quality standards. The services include: Nital Etching, Macro Etching, and Pre-Penetrant Testing. Nital Etching reveals damage by coloring defected areas a darker color, ideal for components undergoing intense heat stress. Macro Etching identifies potential grain …

2. Thin Metal Parts – Chemical Etching Solutions

Domain: thinmetalparts.com

Registered: 2002 (23 years)

Introduction: Chemical etching, also known as chem etch or chemical milling, is a quick, cost-effective, and adaptable metal fabrication process for creating precision metal parts. It retains the structural integrity of the metal, producing custom pieces with the same hardness, ductility, and grain structure as the original material. Key features include:

– Thru-hole features as small as 0.005″

– Custom parts s…

3. Metal Etching – Precision Photo Etching Solutions

Domain: metaletching.com

Registered: 1999 (26 years)

Introduction: Photo etching is a precision manufacturing process for thin metal parts with simple or complex designs. It is also known as chemical etching, photo chemical etching, acid etching, photochemical machining, and chemical milling. The process involves using photo-sensitive material to transfer part images onto metal sheets, followed by a chemical etchant that dissolves unwanted sections. Key advantage…

Strategic Sourcing Conclusion and Outlook for chemical etching companies near me

In conclusion, the strategic sourcing of chemical etching services presents a significant opportunity for international B2B buyers, particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe. By leveraging local suppliers, companies can access tailored solutions that meet specific industry needs, whether in aerospace, medical, or telecommunications sectors. The diversity of materials and capabilities offered by these companies, from NADCAP and AS9100 certified services to custom manufacturing, underscores the importance of selecting a partner that aligns with your operational requirements and quality standards.

Establishing strong relationships with chemical etching providers not only enhances product quality but also optimizes supply chain efficiency, allowing businesses to remain competitive in their respective markets. As demand for precision and customization continues to grow, sourcing from specialized local suppliers can facilitate faster turnaround times and reduce logistical challenges.

Looking ahead, international buyers should actively engage with chemical etching companies to explore innovative solutions and foster collaboration. By prioritizing strategic sourcing, companies can position themselves for success in an increasingly complex global landscape. Take the next step—connect with a local chemical etching provider today to discover how they can help elevate your business operations.

Illustrative image related to chemical etching companies near me

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.