A Deep Dive into Chain Bucket Conveyor Solution

Introduction: Navigating the Global Market for chain bucket conveyor

In the fast-evolving landscape of industrial automation, sourcing a reliable chain bucket conveyor can pose significant challenges for businesses aiming to optimize their material handling processes. With diverse applications ranging from transporting cement and gravel to handling delicate food products, the need for robust, efficient, and durable solutions is paramount. This comprehensive guide addresses key elements that international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, must consider when investing in chain bucket conveyors.

We delve into the various types of chain bucket conveyors available, examining their applications across different industries, and highlighting the critical factors for supplier vetting. From understanding the intricacies of chain specifications and materials to evaluating cost considerations, this guide equips buyers with the knowledge needed to make informed purchasing decisions.

Moreover, we provide insights into the latest technological advancements and market trends, ensuring that you stay ahead in a competitive global market. By empowering businesses to select the right chain bucket conveyor systems tailored to their unique operational needs, this guide serves as an essential resource for achieving enhanced efficiency and reliability in material handling processes. Whether you’re a seasoned buyer or new to the industry, our expert insights will help you navigate the complexities of sourcing and implementing chain bucket conveyor solutions effectively.

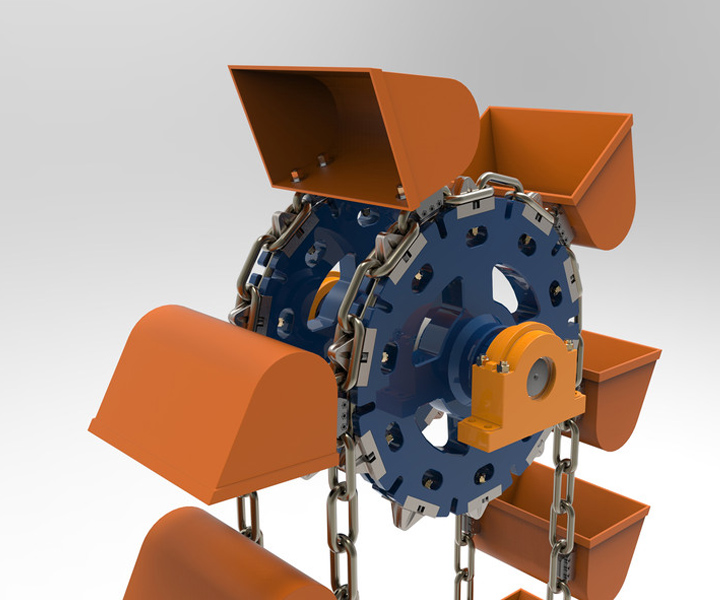

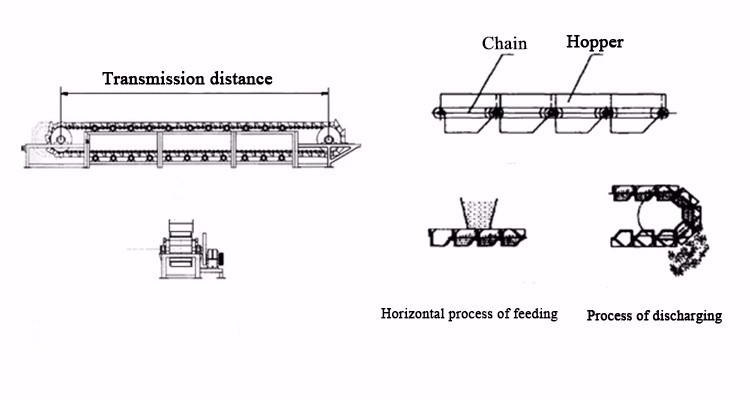

Understanding chain bucket conveyor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Bucket Elevator Chains | Designed for general use; robust construction; various sizes | Cement, gravel, and agricultural products | Pros: Versatile, easy to install. Cons: May require frequent maintenance in harsh conditions. |

| Super Capacity Bucket Chains | Higher load capacity; reinforced materials; larger buckets | Heavy industries; bulk material handling | Pros: Increased efficiency, handles larger volumes. Cons: Higher initial cost, may need specialized installation. |

| Welded Steel Drag Chains | Heavy-duty design; resistant to wear and tear; welded links | Mining, steel production, and recycling | Pros: Extremely durable, ideal for abrasive materials. Cons: Heavier, may require more power to operate. |

| Sealed Joint Chains | Enhanced durability; sealed joints to prevent debris entry | Food processing, pharmaceuticals, and chemicals | Pros: Longer lifespan, reduced maintenance. Cons: Higher cost, potential for limited compatibility with existing systems. |

| Apron Conveyors | Flat or slightly inclined design; robust metal plates | Bulk handling of heavy materials | Pros: Suitable for uneven surfaces, versatile. Cons: Bulkier design, may require more space. |

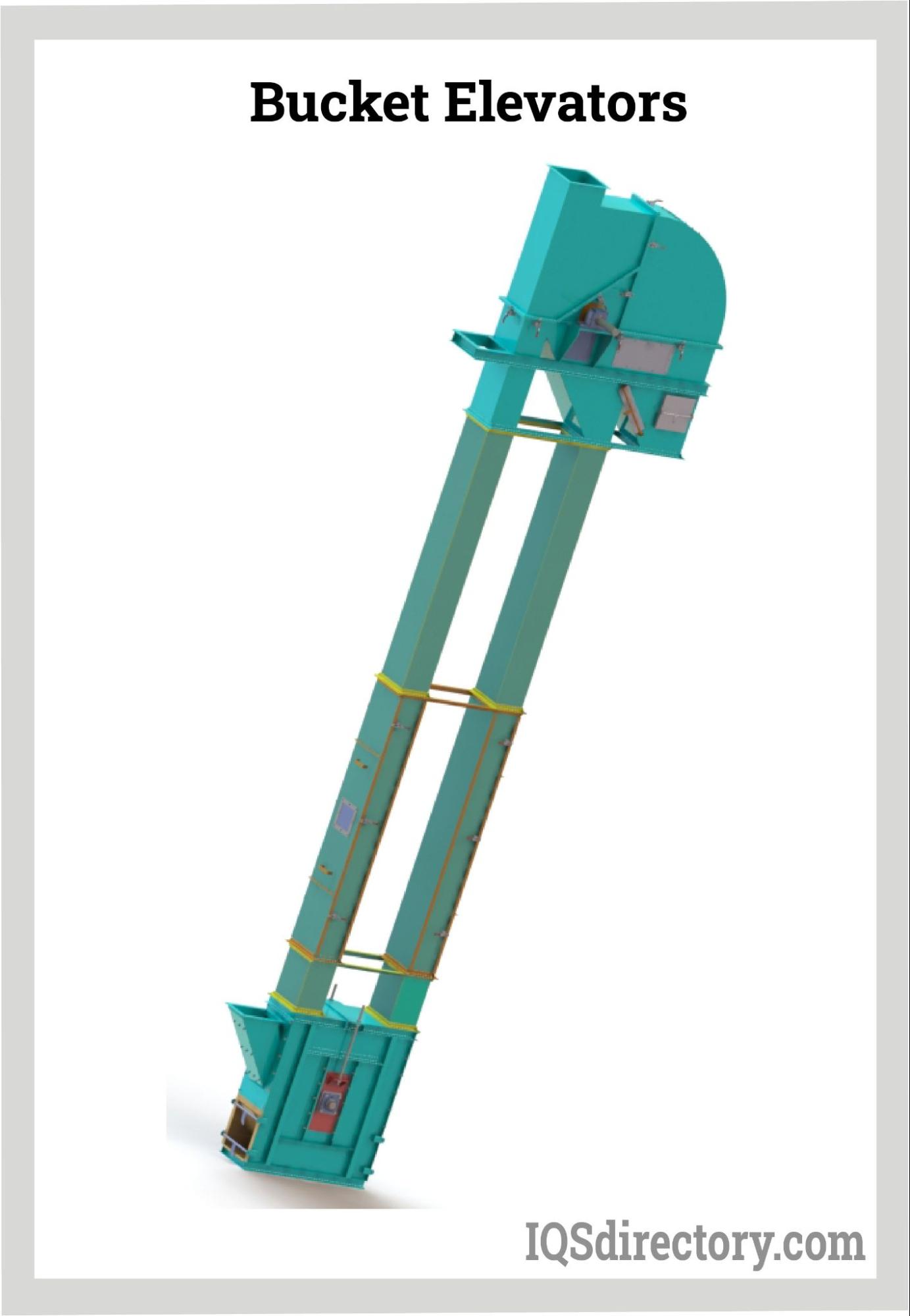

What are Standard Bucket Elevator Chains and Their Key Characteristics?

Standard bucket elevator chains are designed for general material handling applications. They are known for their robust construction, which allows for various sizes and configurations to suit different operational needs. Commonly used in industries such as cement and agriculture, these chains are versatile and easy to install. However, they may require frequent maintenance, especially in harsh environments, which could impact operational efficiency.

How Do Super Capacity Bucket Chains Enhance Material Handling?

Super capacity bucket chains are engineered to handle larger loads than standard options, making them ideal for heavy industries such as mining and bulk material handling. They feature reinforced materials and larger buckets, increasing efficiency and throughput. While they offer significant advantages in terms of capacity, buyers should consider their higher initial costs and the need for specialized installation, which could affect overall project budgets.

What Are the Advantages of Welded Steel Drag Chains?

Welded steel drag chains are designed for heavy-duty applications, particularly in environments that involve abrasive materials like those found in mining and steel production. Their welded links provide exceptional durability, making them resistant to wear and tear. However, their heavier construction may require more power to operate, which is a crucial consideration for businesses looking to optimize energy efficiency.

Illustrative image related to chain bucket conveyor

Why Choose Sealed Joint Chains for Sensitive Industries?

Sealed joint chains are specifically designed to enhance durability by preventing debris entry through sealed joints. This makes them particularly suitable for sensitive industries such as food processing and pharmaceuticals, where hygiene and equipment longevity are paramount. While they offer a longer lifespan and reduced maintenance needs, the higher cost and potential compatibility issues with existing systems should be carefully evaluated by buyers.

What Are the Key Features of Apron Conveyors?

Apron conveyors are characterized by their flat or slightly inclined design and use robust metal plates to transport materials. They are particularly effective for bulk handling of heavy materials and can adapt to uneven surfaces. While their versatility is a significant advantage, buyers should consider the bulkier design, which may require more installation space and impact layout planning in facilities.

Key Industrial Applications of chain bucket conveyor

| Industry/Sector | Specific Application of chain bucket conveyor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Cement Industry | Transporting cement, clinker, and aggregates | Increases efficiency and reduces manual handling costs | Durability against harsh conditions; high strength and reliability |

| Mining and Minerals | Handling bulk materials like gravel, coal, and ores | Enhances operational throughput and minimizes downtime | Resistance to abrasion and corrosion; ability to handle heavy loads |

| Food Processing | Elevating grains, sugar, and other bulk food products | Ensures hygienic transport and minimizes contamination risks | Compliance with food safety standards; material suitability |

| Recycling | Moving recyclable materials such as plastics and metals | Streamlines waste management processes and increases recovery rates | Customization for specific materials; robust design for heavy loads |

| Agriculture | Conveying seeds, fertilizers, and animal feed | Improves efficiency in material handling and reduces waste | Compatibility with various materials; ability to operate in diverse environments |

The cement industry heavily relies on chain bucket conveyors for transporting cement, clinker, and aggregates. These conveyors are designed to endure heavy loads and harsh conditions, ensuring continuous operation. For international buyers, particularly in regions like Africa and South America, sourcing durable and reliable equipment is crucial. Suppliers should provide chains that can withstand shock loadings and offer options for sealed joints to enhance longevity.

In the mining and minerals sector, chain bucket conveyors are essential for handling bulk materials such as gravel, coal, and ores. These systems facilitate efficient material transport, significantly boosting operational throughput while minimizing downtime. Buyers in the Middle East and Europe should prioritize equipment that offers resistance to abrasion and corrosion, ensuring long-lasting performance in challenging environments.

The food processing industry utilizes chain bucket conveyors for elevating grains, sugar, and other bulk food products. These conveyors help maintain hygiene standards and reduce the risk of contamination during material handling. When sourcing for this sector, businesses must ensure compliance with food safety regulations, selecting materials that are not only robust but also suitable for food contact.

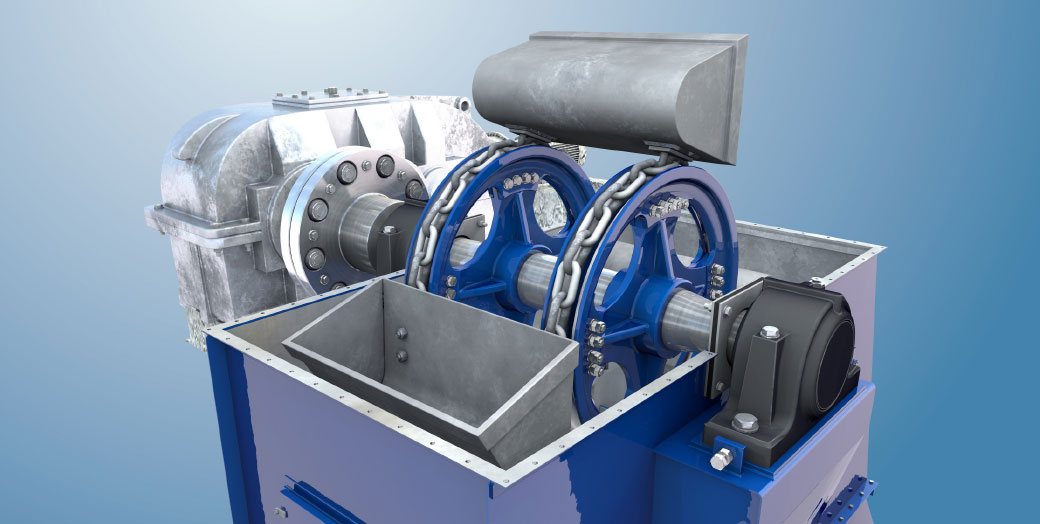

Illustrative image related to chain bucket conveyor

In the recycling industry, chain bucket conveyors streamline the movement of recyclable materials like plastics and metals. They enhance waste management processes and improve recovery rates, making recycling operations more efficient. Buyers should consider suppliers that offer customization options for specific materials and ensure the equipment can handle heavy loads effectively.

For the agriculture sector, chain bucket conveyors are utilized for conveying seeds, fertilizers, and animal feed, improving efficiency in material handling. This reduces waste and enhances productivity. When sourcing equipment, it is vital to ensure compatibility with various materials and confirm that the systems can operate effectively in diverse environmental conditions.

3 Common User Pain Points for ‘chain bucket conveyor’ & Their Solutions

Scenario 1: Overcoming Frequent Chain Breakage Issues in High-Volume Operations

The Problem: B2B buyers often encounter the frustration of frequent chain breakage in their chain bucket conveyor systems, especially in high-volume production environments. This issue can lead to costly downtime, affecting overall productivity and operational efficiency. The challenge is compounded by the need to maintain consistent performance while handling abrasive materials such as cement, gravel, or slag, which can wear down the chain faster than expected. Buyers may struggle to find a durable solution that meets their specific operational demands, particularly in harsh conditions.

The Solution: To mitigate chain breakage, it is crucial to invest in high-strength bucket elevator chains specifically designed for heavy-duty applications. Buyers should look for chains made from superior steel alloys and those that have undergone rigorous heat treatment processes, such as through-hardening or induction hardening. When sourcing chains, detailed specifications should be reviewed, including ultimate strength ratings and working load limits. Engaging with suppliers who offer tailored solutions and can provide expert guidance on the right chain for specific materials and conditions is essential. Additionally, implementing regular maintenance schedules and monitoring wear can help identify potential issues before they lead to failures, ensuring continuous operation.

Illustrative image related to chain bucket conveyor

Scenario 2: Managing Material Contamination Risks

The Problem: In industries like food processing or pharmaceuticals, material contamination is a critical concern. Buyers of chain bucket conveyors must ensure that the materials being transported do not come into contact with contaminants that can jeopardize product quality and compliance with safety regulations. This is particularly challenging when using chains that are not designed for easy cleaning or maintenance, leading to the risk of cross-contamination between different materials.

The Solution: To address contamination risks, buyers should prioritize sourcing chain bucket conveyors that feature easy-to-clean designs and materials. Look for chains with sealed joints and special coatings that prevent material build-up and facilitate regular cleaning. It’s also advisable to choose systems that allow for quick disassembly, making it easier to maintain hygiene standards. Buyers should collaborate with manufacturers who understand industry-specific regulations and can recommend appropriate materials and designs. Additionally, investing in training for staff on proper cleaning protocols and routine inspections can help maintain the integrity of the product being transported.

Scenario 3: Balancing Cost with Performance in Diverse Applications

The Problem: B2B buyers often face the challenge of balancing cost with performance when selecting chain bucket conveyors for diverse applications. Many buyers are tempted to opt for lower-cost options to reduce initial expenditures, but this can lead to higher long-term costs due to frequent repairs, replacements, or inefficient operations. This dilemma is particularly evident in regions where budget constraints are prevalent, yet the need for reliable and efficient systems remains critical.

Illustrative image related to chain bucket conveyor

The Solution: To achieve a balance between cost and performance, buyers should take a strategic approach by conducting a thorough analysis of their operational needs and the specific demands of the materials being handled. Investing in quality chains that offer longer life cycles and lower maintenance costs can be more economical in the long run. When evaluating suppliers, it’s vital to consider not only the price but also the total cost of ownership, which includes factors such as durability, efficiency, and warranty support. Engaging with manufacturers who provide comprehensive service packages, including installation, maintenance training, and technical support, can also enhance value. Lastly, participating in industry forums and peer discussions can provide insights into successful strategies and recommendations from similar businesses facing comparable challenges.

Strategic Material Selection Guide for chain bucket conveyor

What Are the Key Properties of Common Materials Used in Chain Bucket Conveyors?

When selecting materials for chain bucket conveyors, several factors must be considered to ensure optimal performance and longevity. Here, we analyze four common materials: carbon steel, stainless steel, plastic composites, and alloy steel. Each material has distinct properties that can significantly impact the performance of the conveyor system.

Carbon Steel: The Cost-Effective Workhorse

Key Properties: Carbon steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It typically has a temperature rating up to 400°F (204°C) and can withstand high loads.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-conscious projects. However, it has limited corrosion resistance, which can lead to rust and degradation in humid or corrosive environments. Manufacturing processes are relatively straightforward, but additional coatings may be required for enhanced protection.

Illustrative image related to chain bucket conveyor

Impact on Application: Carbon steel is ideal for transporting bulk materials like grains, cement, and aggregates. However, its susceptibility to corrosion makes it less suitable for applications involving wet or corrosive materials.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards (e.g., ASTM) for material quality. In markets like Germany, where environmental regulations are stringent, carbon steel may require protective coatings to meet compliance.

Stainless Steel: The Corrosion-Resistant Champion

Key Properties: Stainless steel offers excellent corrosion resistance and can handle temperatures up to 800°F (427°C). It is also resistant to oxidation, making it suitable for food-grade applications.

Pros & Cons: The key advantage of stainless steel is its durability and long lifespan, particularly in harsh environments. However, it comes at a higher cost compared to carbon steel. The manufacturing process can be more complex, requiring specialized equipment and techniques.

Illustrative image related to chain bucket conveyor

Impact on Application: Stainless steel is ideal for applications involving food, pharmaceuticals, and chemicals, where hygiene and corrosion resistance are paramount. It is also suitable for high-temperature environments.

Considerations for International Buyers: Buyers in the Middle East and Europe often prefer stainless steel for its compliance with hygiene standards. Understanding the specific grades (e.g., 304, 316) and their respective applications is crucial for meeting local regulations.

Plastic Composites: The Lightweight Alternative

Key Properties: Plastic composites are lightweight and can resist corrosion and chemicals. They typically operate effectively at temperatures up to 200°F (93°C).

Pros & Cons: The main advantage of plastic composites is their lightweight nature, which reduces energy consumption during operation. They are also resistant to corrosion and do not require additional coatings. However, their lower strength compared to metals limits their use in heavy-duty applications.

Illustrative image related to chain bucket conveyor

Impact on Application: Plastic composites are suitable for transporting lightweight materials and are often used in food processing and packaging industries. They are not ideal for heavy bulk materials like cement or gravel.

Considerations for International Buyers: Buyers in regions with high humidity or corrosive environments may find plastic composites advantageous. However, they should verify compliance with food safety regulations in their respective markets.

Alloy Steel: The High-Performance Option

Key Properties: Alloy steel combines carbon steel with other elements to enhance its properties, offering high tensile strength and improved wear resistance. It can withstand temperatures up to 600°F (316°C).

Illustrative image related to chain bucket conveyor

Pros & Cons: The key advantage of alloy steel is its superior strength and durability, making it suitable for demanding applications. However, it is more expensive than carbon steel and may require more complex manufacturing processes.

Impact on Application: Alloy steel is ideal for heavy-duty applications where high strength and resistance to wear are essential, such as in mining and heavy construction.

Considerations for International Buyers: Buyers from Europe and the Middle East should ensure that alloy steel components meet international standards for quality and performance, as these markets often have stringent requirements.

Summary Table of Material Selection for Chain Bucket Conveyors

| Material | Typical Use Case for chain bucket conveyor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Bulk materials like grains and cement | Cost-effective | Limited corrosion resistance | Low |

| Stainless Steel | Food and pharmaceutical applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic Composites | Lightweight materials in food processing | Lightweight and corrosion-resistant | Lower strength limits applications | Medium |

| Alloy Steel | Heavy-duty applications in mining | Superior strength and durability | Higher cost and manufacturing complexity | High |

This guide provides a comprehensive overview of material options for chain bucket conveyors, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for chain bucket conveyor

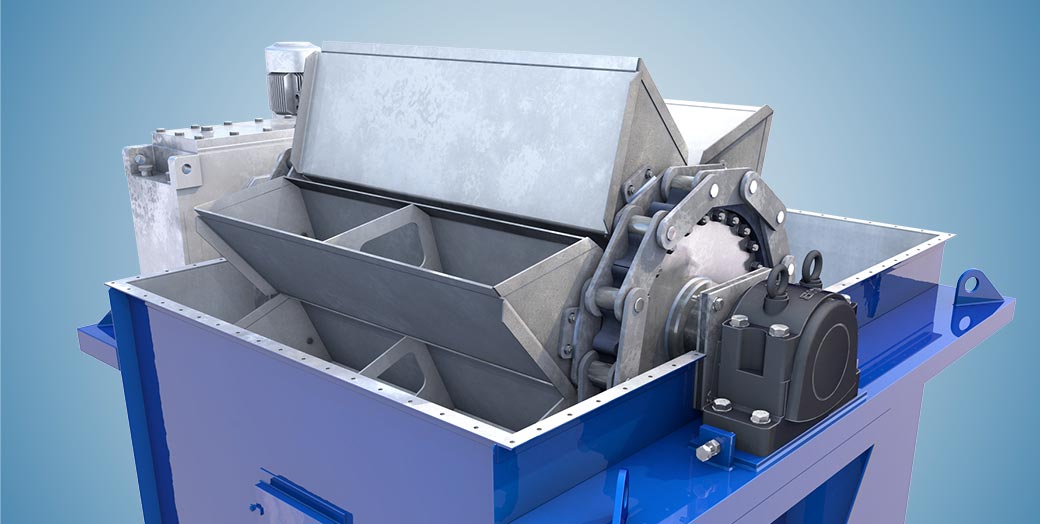

What Are the Key Manufacturing Processes for Chain Bucket Conveyors?

The manufacturing of chain bucket conveyors involves several intricate stages that ensure durability and efficiency. These processes typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Chain Bucket Conveyor Production?

Material preparation is the first crucial step in the manufacturing process. High-strength steel alloys are often selected for their ability to withstand heavy loads and harsh conditions. Suppliers should ensure that the raw materials meet specific mechanical properties required for various applications, such as cement or mining.

The materials undergo processes such as heat treatment to enhance their strength and durability. Techniques like through-hardening and induction hardening are commonly employed to improve the mechanical properties of the chains. Each batch of raw material should be tested for tensile strength, ductility, and hardness to ensure compliance with industry standards.

What Techniques Are Used in Forming Chain Bucket Conveyor Components?

The forming stage involves shaping the prepared materials into the various components of the chain bucket conveyor. This typically includes cutting, bending, and welding processes. Advanced CNC (Computer Numerical Control) machines are often used to ensure precision in the cutting and shaping of parts.

Illustrative image related to chain bucket conveyor

For example, side plates and pins are formed to specific dimensions that allow for seamless assembly and functionality. The use of robotics in welding can enhance consistency and reduce human error. Additionally, forming techniques should consider the specific requirements of the application, such as high-temperature resistance in cement transport or corrosion resistance in mining.

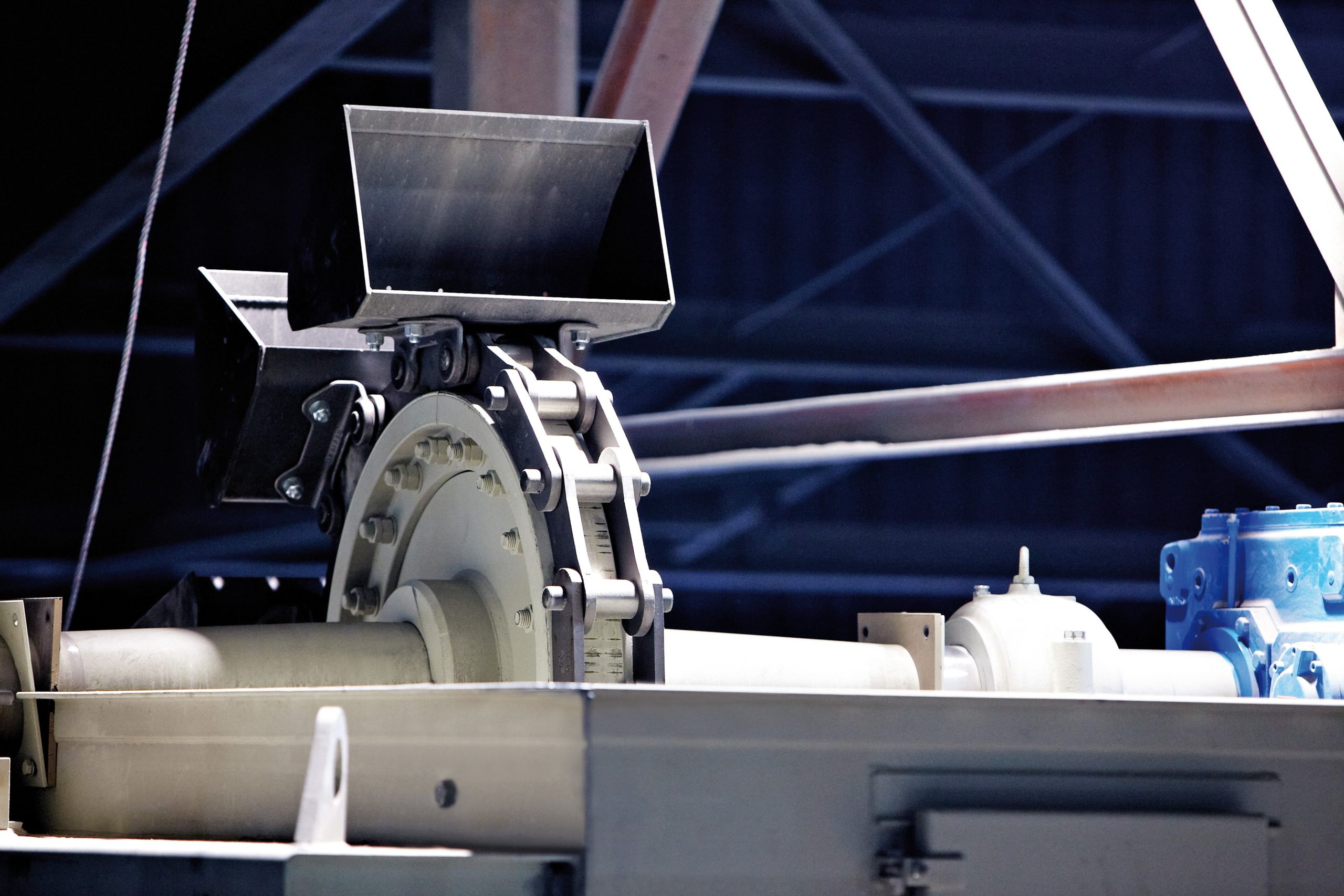

How Is the Assembly of Chain Bucket Conveyors Conducted?

Assembly is where individual components come together to create the final product. This stage requires meticulous attention to detail to ensure that all parts fit together correctly and function efficiently.

During assembly, components such as buckets, chains, sprockets, and frames are connected using bolts or welding, depending on the design specifications. It’s essential to follow a defined assembly process to minimize the risk of defects. Each assembly line should be equipped with tools and fixtures that guarantee the correct alignment and secure fitting of all components.

What Finishing Processes Are Important for Chain Bucket Conveyors?

Finishing processes are crucial for enhancing the durability and aesthetic appeal of chain bucket conveyors. Common finishing techniques include surface treatment, painting, and coating.

Surface treatments such as shot blasting or sandblasting can remove any surface imperfections and prepare the metal for painting or coating. Protective coatings, such as powder coating or galvanization, are applied to prevent corrosion and extend the lifespan of the conveyor system.

Moreover, proper finishing not only improves the conveyor’s performance in harsh environments but also enhances its visual appeal, which can be essential for client presentations.

What Quality Assurance Processes Are Integral to Chain Bucket Conveyor Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that the final products meet international standards and customer expectations.

Which International Standards Should Chain Bucket Conveyor Manufacturers Adhere To?

Manufacturers of chain bucket conveyors must comply with several international standards, such as ISO 9001 for quality management systems. Compliance with these standards demonstrates a commitment to quality and reliability.

Additionally, industry-specific certifications like CE marking for safety and API (American Petroleum Institute) standards for equipment used in oil and gas can enhance credibility in the global market. For B2B buyers, verifying these certifications ensures that they are sourcing products that meet rigorous safety and performance criteria.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints should be integrated throughout the manufacturing process to identify and rectify issues early.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Each batch should be tested for compliance with specifications, including material properties and dimensions.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, periodic inspections should be conducted. These checks focus on the adherence to manufacturing procedures, including dimensions and assembly quality.

-

Final Quality Control (FQC): Before dispatch, the finished product undergoes a comprehensive inspection. This includes functional testing, dimensional checks, and visual inspections to ensure the conveyor meets all specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers.

-

Audits: Conducting on-site audits allows buyers to review the manufacturing processes, quality control systems, and compliance with international standards firsthand.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes, including test results and compliance with industry standards.

-

Third-Party Inspection: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s products and quality assurance practices. These inspections can be particularly valuable for international buyers who may face language barriers or unfamiliarity with local manufacturing standards.

What Nuances Should International B2B Buyers Consider in Quality Control?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding regional compliance and quality nuances is essential.

-

Local Standards and Regulations: Each region may have specific regulations that govern manufacturing processes. Buyers should be aware of these regulations to ensure compliance and avoid potential legal issues.

-

Cultural Considerations: Understanding the cultural context of suppliers can enhance communication and foster better relationships. This is particularly important in regions where business practices may differ significantly from the buyer’s home country.

-

Supply Chain Logistics: International buyers should also consider logistics and transportation challenges, which can impact delivery times and product integrity. Ensuring that suppliers have robust logistics management systems in place is crucial for maintaining quality throughout the supply chain.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing chain bucket conveyors, ensuring they receive high-quality products that meet their operational needs.

Illustrative image related to chain bucket conveyor

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chain bucket conveyor’

This guide serves as a comprehensive checklist for B2B buyers in search of reliable and efficient chain bucket conveyors. Whether you are operating in Africa, South America, the Middle East, or Europe, following these steps will ensure you make an informed purchasing decision that aligns with your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing a chain bucket conveyor. Consider factors such as the type of material to be transported (e.g., cement, gravel, or food products), required lifting height, and throughput capacity. Detailed specifications will help you communicate your needs effectively to potential suppliers and ensure compatibility with your existing systems.

Step 2: Assess Environmental Conditions

Understanding the operational environment where the conveyor will be installed is crucial. Factors like humidity, temperature extremes, and exposure to dust or corrosive materials can affect the performance and durability of the conveyor system. Choose materials and coatings that are appropriate for these conditions, such as sealed joint chains for harsh environments, to extend the life of your equipment.

Step 3: Evaluate Potential Suppliers

Before committing, it’s essential to conduct thorough evaluations of potential suppliers. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with proven track records, especially those who have experience in your specific application area, to ensure they can meet your needs.

- Check for Certifications: Ensure the supplier has relevant industry certifications, which can indicate adherence to quality and safety standards.

- Review Customer Feedback: Analyze reviews and testimonials to gauge customer satisfaction and the supplier’s responsiveness to issues.

Step 4: Inquire About Product Quality and Testing

Quality assurance is paramount in sourcing chain bucket conveyors. Inquire about the materials used and the manufacturing processes, such as heat treatments or coatings, that enhance performance. Suppliers should provide documentation on testing procedures to verify the strength and reliability of their products.

Illustrative image related to chain bucket conveyor

- Ask for Sample Products: If possible, request samples to assess the quality firsthand before making a bulk purchase.

Step 5: Compare Pricing Structures

Once you have a shortlist of potential suppliers, compare their pricing structures. Consider not just the initial costs, but also the total cost of ownership, which includes maintenance, replacement parts, and operational efficiency. A lower initial price might not always be the best value if the product requires frequent repairs or replacements.

- Negotiate Terms: Engage in discussions about payment terms, warranties, and after-sales support to ensure you receive the best possible deal.

Step 6: Review Delivery and Installation Support

Confirm the supplier’s ability to deliver and install the conveyor system within your timeline. Efficient logistics are essential, especially if you operate in remote areas. Evaluate their installation support services, including training for your staff on operation and maintenance.

Step 7: Plan for Long-term Partnerships

Consider suppliers who are open to building long-term relationships. A reliable supplier can provide ongoing support, maintenance services, and upgrades as your operational needs evolve. Establish clear communication channels to facilitate a collaborative partnership that benefits both parties over time.

By following this checklist, you can streamline the sourcing process for chain bucket conveyors, ensuring you choose a solution that meets your operational demands and enhances productivity.

Comprehensive Cost and Pricing Analysis for chain bucket conveyor Sourcing

What Are the Key Cost Components in Sourcing Chain Bucket Conveyors?

Understanding the cost structure of chain bucket conveyors is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly affects the price. High-strength alloys and specialized coatings for durability can increase initial costs but enhance longevity and performance, offering better value over time.

-

Labor: Labor costs vary by region and can impact the overall price. Countries with higher labor costs may have higher manufacturing prices, while regions with lower labor costs might offer competitive pricing.

-

Manufacturing Overhead: This includes costs related to facilities, equipment, and utilities. Buyers should inquire about production capabilities and whether the supplier can scale production to meet demand.

-

Tooling: Custom tooling can add to the cost, especially for unique specifications. Standardized tooling may reduce costs, making it essential to balance customization needs with budget constraints.

-

Quality Control: Rigorous QC processes ensure that the product meets industry standards. While this can increase costs, it reduces the likelihood of failures, ultimately saving money on replacements and maintenance.

-

Logistics: Transportation costs are a significant component of the total price. Factors such as distance, shipping method, and Incoterms can greatly influence logistics expenses.

-

Margin: Suppliers typically include a profit margin that varies based on their market position and competition. Understanding a supplier’s margin can aid in negotiations.

How Do Price Influencers Affect Chain Bucket Conveyor Costs?

Several factors influence the pricing of chain bucket conveyors, and understanding these can help buyers make informed decisions.

-

Volume/MOQ: Bulk purchases often lead to discounts. Suppliers may offer lower prices for larger orders, which can be beneficial for companies planning to scale operations.

-

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized materials or manufacturing processes. It’s essential to balance the need for customization with cost considerations.

-

Material Quality and Certifications: Higher quality materials often come with certifications that ensure durability and compliance with international standards. While these materials may be pricier, they can reduce maintenance costs and downtime.

-

Supplier Factors: Reputation, reliability, and service levels of suppliers can affect pricing. Established suppliers may charge more but offer better service and product guarantees.

-

Incoterms: The choice of Incoterms can significantly impact the total cost of ownership (TCO). Buyers should understand the responsibilities for shipping, insurance, and duties to avoid unexpected expenses.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, strategic approaches can enhance cost efficiency.

Illustrative image related to chain bucket conveyor

-

Negotiation: Engage suppliers in discussions about pricing and terms. Understanding the cost structure can empower buyers to negotiate better deals, especially for bulk orders.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and operational costs over the equipment’s lifespan. Selecting higher-quality components may incur higher upfront costs but result in lower TCO.

-

Pricing Nuances for International Transactions: Be aware of currency fluctuations, tariffs, and local taxes that can affect pricing. Establishing long-term relationships with suppliers may also lead to better pricing and terms.

-

Research and Compare: Evaluate multiple suppliers to understand market rates and quality offerings. This can help identify the best value for money while ensuring compliance with local regulations and standards.

Disclaimer

The prices discussed are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with multiple suppliers to gain a comprehensive understanding of current pricing trends and options.

Alternatives Analysis: Comparing chain bucket conveyor With Other Solutions

In the realm of material handling, selecting the right conveyor technology is crucial for optimizing production efficiency and operational costs. While chain bucket conveyors are a popular choice for vertical lifting of bulk materials, various alternatives may also serve specific needs effectively. This analysis compares chain bucket conveyors with two viable alternatives: screw conveyors and pneumatic conveyors, to help B2B buyers make informed decisions.

| Comparison Aspect | Chain Bucket Conveyor | Screw Conveyor | Pneumatic Conveyor |

|---|---|---|---|

| Performance | High capacity; ideal for heavy loads | Moderate capacity; effective for bulk materials | High-speed transport; suitable for powders and granules |

| Cost | Moderate initial cost; lower operating costs | Low initial cost; moderate maintenance costs | High initial cost; higher operational costs |

| Ease of Implementation | Moderate; requires structural support | Easy to install; flexible layout options | Complex; requires careful design and installation |

| Maintenance | Low maintenance; robust design | Moderate maintenance; wear on screws | High maintenance; potential for clogging |

| Best Use Case | Ideal for heavy, abrasive materials | Best for granular materials; less abrasive | Suitable for powders and lightweight materials |

What Are the Advantages and Disadvantages of Screw Conveyors?

Screw conveyors are a cost-effective alternative known for their simple design and versatility. They excel in transporting granular materials like grains and cement. The initial investment is lower than that of chain bucket conveyors, and they require less structural support. However, their capacity is limited compared to chain bucket conveyors, and they may not handle abrasive materials as effectively, leading to potential wear and tear on the screws.

How Do Pneumatic Conveyors Compare?

Pneumatic conveyors offer a unique method of transporting materials using air pressure. They are particularly advantageous for moving fine powders and lightweight materials quickly and efficiently. Pneumatic systems can be designed to fit into tight spaces and have a high speed of operation. However, the complexity of the system leads to a higher initial investment and ongoing operational costs. Maintenance can also be more demanding due to the potential for clogging and the need for regular checks on air pressure and seals.

Conclusion: How to Choose the Right Conveyor Solution?

Selecting the right conveyor solution hinges on understanding the specific requirements of your operation. If you are dealing with heavy, abrasive materials and require high capacity, a chain bucket conveyor is likely the best choice. Conversely, for projects focusing on granular materials or those that require flexibility in layout, screw conveyors may be more appropriate. If speed and space-saving are critical, consider pneumatic conveyors, keeping in mind their higher costs and maintenance needs. A thorough assessment of your material type, budget, and operational demands will guide you to the most suitable solution for your business.

Illustrative image related to chain bucket conveyor

Essential Technical Properties and Trade Terminology for chain bucket conveyor

What Are the Critical Technical Properties of Chain Bucket Conveyors?

Understanding the technical properties of chain bucket conveyors is essential for making informed purchasing decisions. Here are some key specifications to consider:

Material Grade

The material grade of chains and buckets is crucial for their durability and performance. High-strength steel alloys are often used to enhance resistance against wear and tear, especially in harsh environments. This property is vital for ensuring longevity and reducing maintenance costs, making it a key consideration for B2B buyers in industries like mining and cement.

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. For chain bucket conveyors, maintaining strict tolerances ensures proper fit and function, reducing the risk of mechanical failure. This is particularly important in high-capacity applications where even minor deviations can lead to significant operational issues, ultimately affecting productivity.

Pitch

Pitch is the distance between the centers of two consecutive chain links. It is a critical dimension that affects the compatibility of the chain with sprockets and other components. Understanding the pitch is essential for B2B buyers to ensure seamless integration with existing systems or when designing new conveyors.

Illustrative image related to chain bucket conveyor

Ultimate Strength

Ultimate strength indicates the maximum stress a material can withstand before failing. For chain bucket conveyors, this property is essential in determining load capacity and overall performance. Buyers should evaluate ultimate strength ratings to ensure that the conveyor will meet their operational demands without compromising safety.

Working Load Limit (WLL)

The working load limit is the maximum load that a conveyor can safely handle during operation. This specification is particularly important for B2B buyers as it directly impacts the efficiency and reliability of material handling processes. Choosing a conveyor with an appropriate WLL helps prevent overload scenarios that could lead to equipment failure.

What Are Common Trade Terms Used in the Chain Bucket Conveyor Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms to know:

Illustrative image related to chain bucket conveyor

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of chain bucket conveyors, buyers often work directly with OEMs to ensure they receive high-quality, compatible components tailored to their specific needs.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for B2B buyers as it can affect inventory management and cost efficiency. Buyers should negotiate MOQs that align with their operational requirements to avoid excess inventory or stock shortages.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers inviting them to bid on providing specific goods or services. In the chain bucket conveyor sector, submitting an RFQ allows businesses to gather pricing and service options from multiple suppliers, helping them make informed purchasing decisions.

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify aspects like shipping costs, risk, and delivery responsibilities. For B2B buyers in different regions, understanding Incoterms is crucial for managing logistics and ensuring smooth cross-border transactions.

Lead Time

Lead time is the period between the initiation of an order and its fulfillment. In the context of chain bucket conveyors, shorter lead times can enhance operational efficiency and responsiveness to market demands. Buyers should assess lead times when planning projects to avoid potential delays in production or delivery.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the complexities of chain bucket conveyor procurement more effectively, ensuring they select the right equipment to meet their operational needs.

Illustrative image related to chain bucket conveyor

Navigating Market Dynamics and Sourcing Trends in the chain bucket conveyor Sector

What Are the Current Market Dynamics and Key Trends in the Chain Bucket Conveyor Sector?

The global chain bucket conveyor market is currently experiencing significant growth, driven by the increasing demand for efficient material handling solutions across various industries, including cement, mining, and agriculture. International B2B buyers are particularly focused on sourcing robust and high-performance bucket elevator chains that can withstand harsh operating conditions. Emerging technologies, such as predictive maintenance and IoT integration, are enhancing the operational efficiency of chain bucket conveyors. These advancements not only improve productivity but also minimize downtime, which is critical for companies in fast-paced markets in regions like Africa, South America, the Middle East, and Europe.

In addition to technological advancements, supply chain resilience is a key focus. The disruptions experienced during the COVID-19 pandemic highlighted the importance of diversified sourcing strategies. Buyers are increasingly seeking suppliers who can provide not only quality products but also reliable delivery times and support. This trend is particularly relevant for international buyers in Nigeria and Germany, where local suppliers are becoming more competitive by offering customized solutions that meet specific regional needs.

Furthermore, sustainability is gaining traction as a market driver. Companies are increasingly prioritizing suppliers who demonstrate a commitment to environmentally friendly practices, from sourcing raw materials to manufacturing processes. As a result, the chain bucket conveyor sector is evolving, with a growing emphasis on innovative materials and sustainable manufacturing practices.

Illustrative image related to chain bucket conveyor

How Is Sustainability and Ethical Sourcing Impacting the Chain Bucket Conveyor Market?

Sustainability and ethical sourcing are becoming integral to supply chain strategies for international B2B buyers in the chain bucket conveyor sector. As environmental regulations tighten globally, companies are under pressure to reduce their carbon footprints. This has led to a shift towards sourcing materials that are not only durable but also produced with minimal environmental impact. Buyers are increasingly interested in suppliers that offer ‘green’ certifications, such as ISO 14001, which indicates adherence to environmental management standards.

Additionally, the use of recycled materials in the production of chain bucket conveyors is gaining popularity. Suppliers who utilize sustainable practices, such as energy-efficient manufacturing processes and eco-friendly materials, are likely to attract more business from environmentally conscious buyers. For regions like South America and Africa, where sustainability initiatives are being actively promoted, this trend is particularly pertinent.

Furthermore, ethical sourcing practices are critical to building trust and long-term relationships between buyers and suppliers. Companies that prioritize transparency in their supply chains and ensure fair labor practices are more likely to succeed in today’s competitive landscape. By aligning with suppliers who share these values, international buyers can enhance their brand reputation and meet the growing consumer demand for sustainable products.

What Is the Historical Context of Chain Bucket Conveyors in B2B Sourcing?

The chain bucket conveyor has evolved significantly since its inception in the early 20th century. Initially designed for simple material handling tasks, advancements in engineering and materials science have transformed these systems into robust and efficient solutions for heavy-duty applications. The introduction of high-strength steel alloys and advanced manufacturing techniques has increased the durability and performance of bucket elevator chains, allowing them to operate in more demanding environments.

Over the decades, the application of chain bucket conveyors has expanded beyond agriculture to include critical industries such as cement, mining, and food processing. This diversification has led to the development of specialized chains designed to handle various materials, from granular substances to heavy aggregates. As global supply chains have become more interconnected, the importance of reliable and efficient material handling solutions has only grown, making the chain bucket conveyor a vital component in modern industrial operations.

In conclusion, understanding the market dynamics, sustainability considerations, and historical context of chain bucket conveyors is essential for international B2B buyers. These insights can guide sourcing decisions and help businesses align with current trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of chain bucket conveyor

-

How do I solve common issues with chain bucket conveyors?

To address common issues with chain bucket conveyors, such as material blockages or inconsistent lifting, start by ensuring that the conveyor is correctly aligned and that all components are properly lubricated. Regular maintenance checks are crucial; inspect the chains, buckets, and drive systems for wear and tear. Additionally, consider the material’s characteristics—if it’s prone to clumping, you may need to adjust the bucket design or spacing. Consulting with your supplier for tailored solutions based on your specific application can also enhance performance. -

What is the best type of chain bucket conveyor for heavy-duty applications?

For heavy-duty applications, look for chain bucket conveyors that utilize high-strength, through-hardened steel chains. These chains should be designed to withstand significant shock loads and harsh operating conditions, such as those found in mining or cement production. Additionally, ensure that the buckets are made from durable materials that can handle abrasive or high-temperature materials. Collaborating with suppliers that offer customizable options can help you tailor the conveyor to meet your unique operational demands. -

What should I consider when vetting suppliers for chain bucket conveyors?

When vetting suppliers, prioritize those with a proven track record in your industry. Look for certifications that indicate compliance with international quality standards, such as ISO. Request references and case studies to evaluate their experience with similar projects. Additionally, assess their engineering capabilities to ensure they can provide custom solutions. Finally, consider their customer support and after-sales service, as ongoing support is critical for maintaining operational efficiency. -

What are the typical minimum order quantities (MOQ) for chain bucket conveyors?

Minimum order quantities for chain bucket conveyors can vary widely depending on the supplier and the specific components required. Generally, suppliers may set an MOQ to offset production costs and ensure profitability. It’s advisable to discuss your needs directly with potential suppliers; many may be willing to accommodate smaller orders, especially for custom or specialized components. Engaging in negotiations can often lead to more favorable terms, especially if you foresee ongoing procurement. -

What payment terms are commonly offered by suppliers of chain bucket conveyors?

Payment terms can vary significantly by supplier and region. Common arrangements include advance payments, net 30, or net 60 days, depending on the buyer’s creditworthiness and relationship with the supplier. Some suppliers may offer discounts for early payments or larger orders. When negotiating, consider discussing flexible payment options, especially if you are a new customer. Establishing a clear understanding of payment terms upfront can help avoid disputes later. -

How can I ensure quality assurance (QA) for my chain bucket conveyor?

To ensure quality assurance, work with suppliers who have robust QA processes in place. Request documentation regarding their testing procedures and quality control measures, including material certifications and performance testing results. Additionally, consider visiting the manufacturing facility if possible or requesting third-party inspections for large orders. Establishing clear specifications and performance expectations in your contracts can also help ensure that the delivered products meet your standards. -

What are the logistics considerations for importing chain bucket conveyors?

Logistics for importing chain bucket conveyors involve several key considerations, including shipping methods, customs regulations, and delivery timelines. Engage with suppliers who can assist with logistics planning, including arranging transportation and handling customs paperwork. Be aware of import tariffs and duties that may apply based on the destination country. Additionally, consider the lead times for production and shipping when planning your inventory needs to avoid disruptions in your operations. -

Can chain bucket conveyors be customized for specific applications?

Yes, many suppliers offer customization options for chain bucket conveyors to meet the specific needs of different applications. Customization can include adjustments to the size and design of buckets, chain materials, and even the conveyor layout itself. Discussing your unique operational requirements with suppliers can lead to tailored solutions that enhance efficiency and performance. Be sure to provide detailed information about the materials being handled and any environmental factors that may affect the conveyor’s operation.

Top 5 Chain Bucket Conveyor Manufacturers & Suppliers List

1. Renold Jeffrey – Bucket Elevator Conveyor Chain

Domain: renoldjeffrey.com

Registered: 2002 (23 years)

Introduction: Bucket Elevator Conveyor Chain by Renold Jeffrey is designed for the cement industry to withstand shock loadings. Key features include:

– Through-hardened sideplates and pins (induction hardened for maximum performance)

– Full round design on knuckles (bushings) and pins

– Sealed joint chains and special coatings for harsh conditions

– Additional products include apron conveyors, hard face dra…

2. Gough Econ – Elecon™ Bucket Conveyor

Domain: goughecon.com

Registered: 1997 (28 years)

Introduction: Gough Econ offers a range of bucket elevators and conveyors designed for various applications. Key products include:

1. **Elecon™**: The world’s only bucket conveyor that can move materials in any direction, featuring a patented chain design and wedge-shaped buckets. Benefits include increased efficiency, improved safety, reduced maintenance, gentle material handling, and minimized footprint.

2….

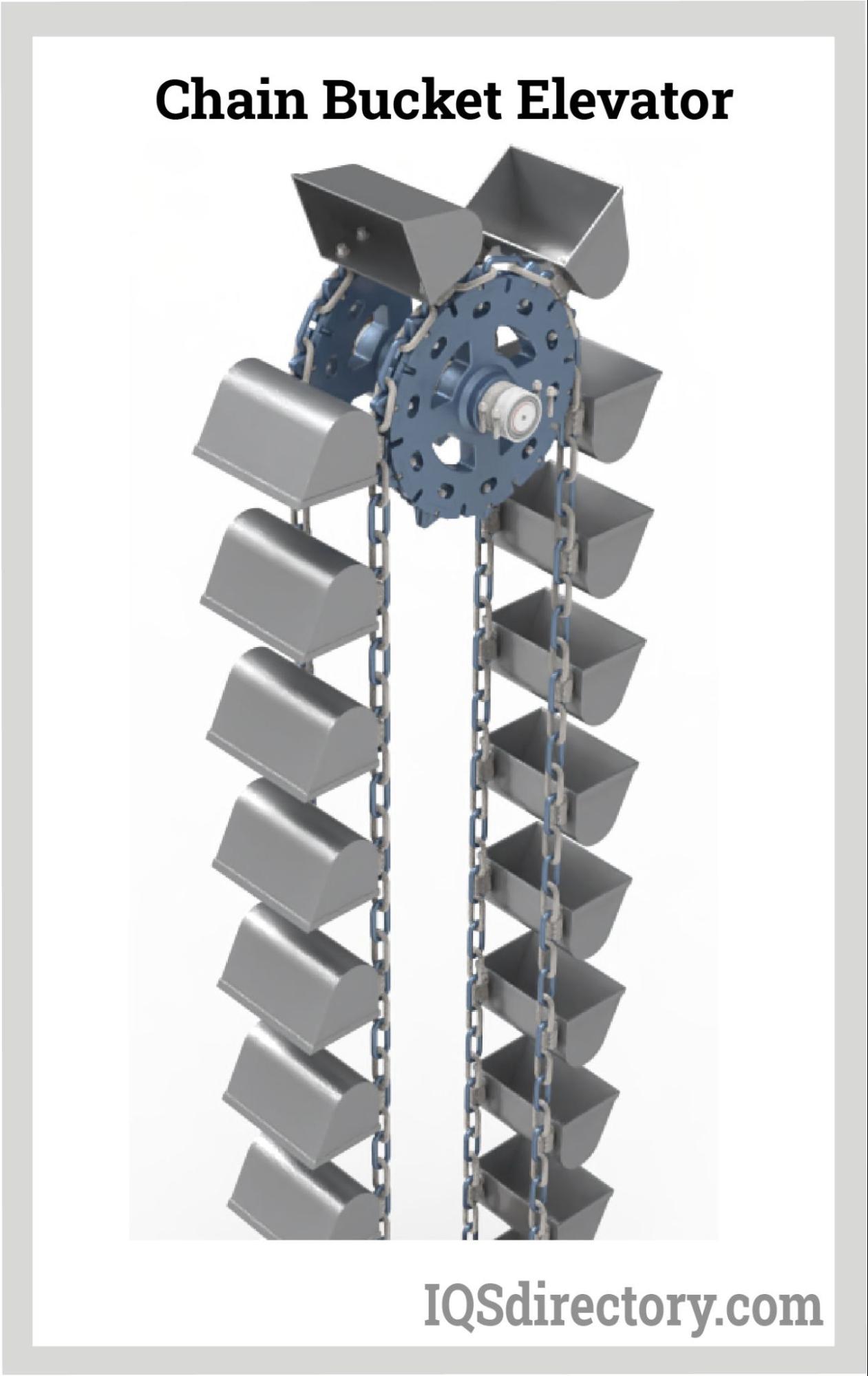

3. IQS Directory – Bucket Elevators and Conveyors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Bucket Elevators and Conveyors are designed for transporting bulk materials efficiently, primarily used in commercial agriculture and mining. Bucket elevators, also known as grain legs, facilitate vertical lifting of goods using a series of buckets propelled by centrifugal force. Bucket conveyors, equipped with dual-strand roller chains, transport materials both horizontally and at an incline, mai…

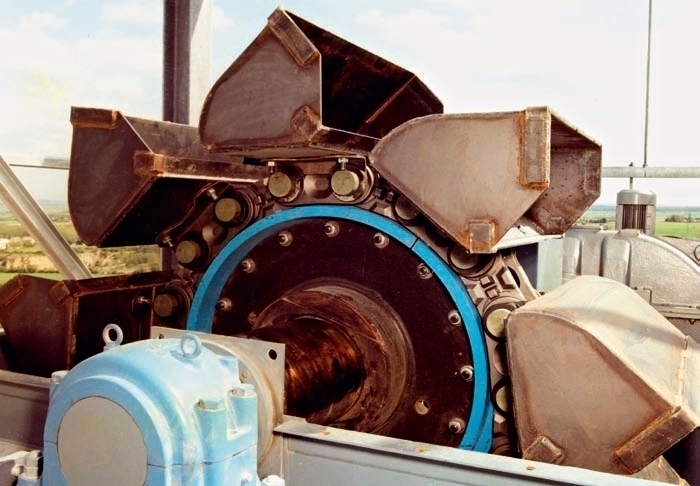

4. Beumer Group – Central Chain Bucket Elevators

Domain: beumergroup.com

Registered: 2011 (14 years)

Introduction: Central chain bucket elevators developed for maximum conveyor performance. Conveying capacity up to 1,900 m³/h depending on bucket width. Designed for reliable vertical transport of hot, abrasive, or granular bulk materials, particularly in cement milling operations. Capable of conveying heights up to 70 m and handling materials with grain sizes up to 100 mm. Various chain sizes available with bre…

5. NERAK – Pendulum Bucket Conveyors

Domain: nerak-systems.com

Registered: 1998 (27 years)

Introduction: Pendulum Bucket Conveyors by NERAK are designed for conveying powder and bulk materials both vertically and horizontally to multiple discharge points without intermediate transfers. They are available in various configurations including “Z”, “C”, and “O” for recirculation in packaging systems. Conveying capacities can reach up to 45 ft³/min (80 m³/hr). Suitable for a wide range of products such as…

Strategic Sourcing Conclusion and Outlook for chain bucket conveyor

In conclusion, strategic sourcing of chain bucket conveyors is crucial for enhancing operational efficiency and ensuring reliable material handling across various industries. By investing in high-quality bucket elevator chains, businesses can significantly reduce downtime and maintenance costs, especially when operating under harsh conditions. The emphasis on robust materials, innovative engineering, and tailored solutions will empower companies to meet increasing production demands while maintaining safety and performance standards.

Illustrative image related to chain bucket conveyor

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of chain specifications, load capacities, and environmental adaptability is essential for making informed procurement decisions. Collaborating with established suppliers who offer comprehensive support—from design to implementation—can further streamline operations and elevate productivity.

As we look ahead, the demand for advanced chain bucket conveyor systems will continue to grow. Buyers are encouraged to leverage strategic partnerships that prioritize quality and innovation to stay competitive in the global marketplace. Investing in these systems not only enhances operational capabilities but also positions businesses to thrive in an ever-evolving industrial landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.