A Deep Dive into Centrifugal Blower Solution

Introduction: Navigating the Global Market for centrifugal blower

In today’s global marketplace, sourcing the right centrifugal blower can be a daunting task for international B2B buyers. With a myriad of options available, from high-pressure models for specialized applications to energy-efficient designs suited for general ventilation, navigating these choices requires a strategic approach. This guide serves as a comprehensive resource, addressing the various types of centrifugal blowers, their applications across industries, and essential factors to consider when vetting suppliers.

For businesses operating in diverse regions, including Africa, South America, the Middle East, and Europe—particularly in countries like Germany and Saudi Arabia—understanding the unique market dynamics and regulatory environments is crucial. This guide empowers buyers with actionable insights into cost considerations, performance metrics, and maintenance requirements, ensuring that they make informed purchasing decisions.

By breaking down complex information into digestible segments, we aim to simplify the selection process, helping you identify the most suitable centrifugal blower for your specific needs. Whether your focus is on durability, efficiency, or compliance with local standards, our guide equips you with the knowledge necessary to navigate the global market effectively and confidently.

Understanding centrifugal blower Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Backward Inclined Fans | High efficiency, low noise, and designed for clean air applications | HVAC systems, air pollution control | Pros: Energy-efficient, quiet operation. Cons: Limited pressure capabilities compared to other types. |

| Forward Curved Fans | Compact design, suited for low-pressure applications | Ventilation, cooling systems | Pros: Cost-effective, high airflow. Cons: Lower efficiency at high pressures. |

| Radial Fans | Non-overloading horsepower curve, higher noise levels | Material handling, dust collection | Pros: Robust design, versatile applications. Cons: Noisy operation may require additional soundproofing. |

| Pressure Blowers | High pressure capabilities, belt-driven or direct drive options | Industrial processes, pneumatic conveying | Pros: High performance, durable. Cons: More complex maintenance requirements. |

| Plug Fans | Compact design, high efficiency, and direct drive options | Clean air applications, ventilation | Pros: Space-saving, energy-efficient. Cons: Limited to specific applications. |

What Are Backward Inclined Fans and Their Applications?

Backward inclined fans are characterized by their unique blade design that allows for high efficiency and low noise levels. These fans excel in clean air applications, making them ideal for HVAC systems and air pollution control. When considering a backward inclined fan, businesses should evaluate their airflow needs and noise constraints, as these fans are particularly suited for environments where sound levels must be minimized.

How Do Forward Curved Fans Work and Where Are They Used?

Forward curved fans feature blades that curve in the direction of rotation, allowing for compact design and high airflow at low pressures. They are commonly used in ventilation and cooling systems. B2B buyers should note that while forward curved fans are cost-effective and provide substantial airflow, they may not be suitable for high-pressure applications, which could limit their use in certain industrial settings.

What Are the Key Characteristics of Radial Fans?

Radial fans employ a distinct design that produces a non-overloading horsepower curve, making them suitable for moderate-pressure applications. They are often used in material handling and dust collection systems. Buyers should consider the noise levels associated with radial fans, as their design can lead to higher operational noise, potentially necessitating additional soundproofing measures in sensitive environments.

Why Choose Pressure Blowers for Industrial Applications?

Pressure blowers are designed for high-pressure capabilities and can be either belt-driven or direct drive. They are widely utilized in industrial processes and pneumatic conveying systems. When selecting a pressure blower, companies should assess their specific pressure and airflow requirements, as well as the complexity of maintenance involved, which can be more demanding compared to simpler fan types.

What Benefits Do Plug Fans Offer for Clean Air Applications?

Plug fans are compact, efficient, and often feature direct drive options, making them ideal for clean air applications and ventilation. These fans are particularly advantageous in space-constrained environments. However, buyers should be aware that plug fans may have limited applications, so it’s essential to match their capabilities with specific operational needs to ensure optimal performance.

Key Industrial Applications of centrifugal blower

| Industry/Sector | Specific Application of Centrifugal Blower | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Drying and removing excess moisture from products | Enhances product quality and extends shelf life | Efficiency ratings, material compatibility, and energy consumption |

| Chemical Processing | Ventilation and dust removal in production areas | Improves workplace safety and compliance | Noise levels, explosion-proof options, and maintenance requirements |

| HVAC | Air circulation and pressure boosting in large buildings | Increases energy efficiency and comfort levels | Size, airflow capacity, and adaptability to existing systems |

| Pharmaceutical | Drying of packaging and sterilization processes | Ensures product integrity and safety | Hygiene standards, material specifications, and energy efficiency |

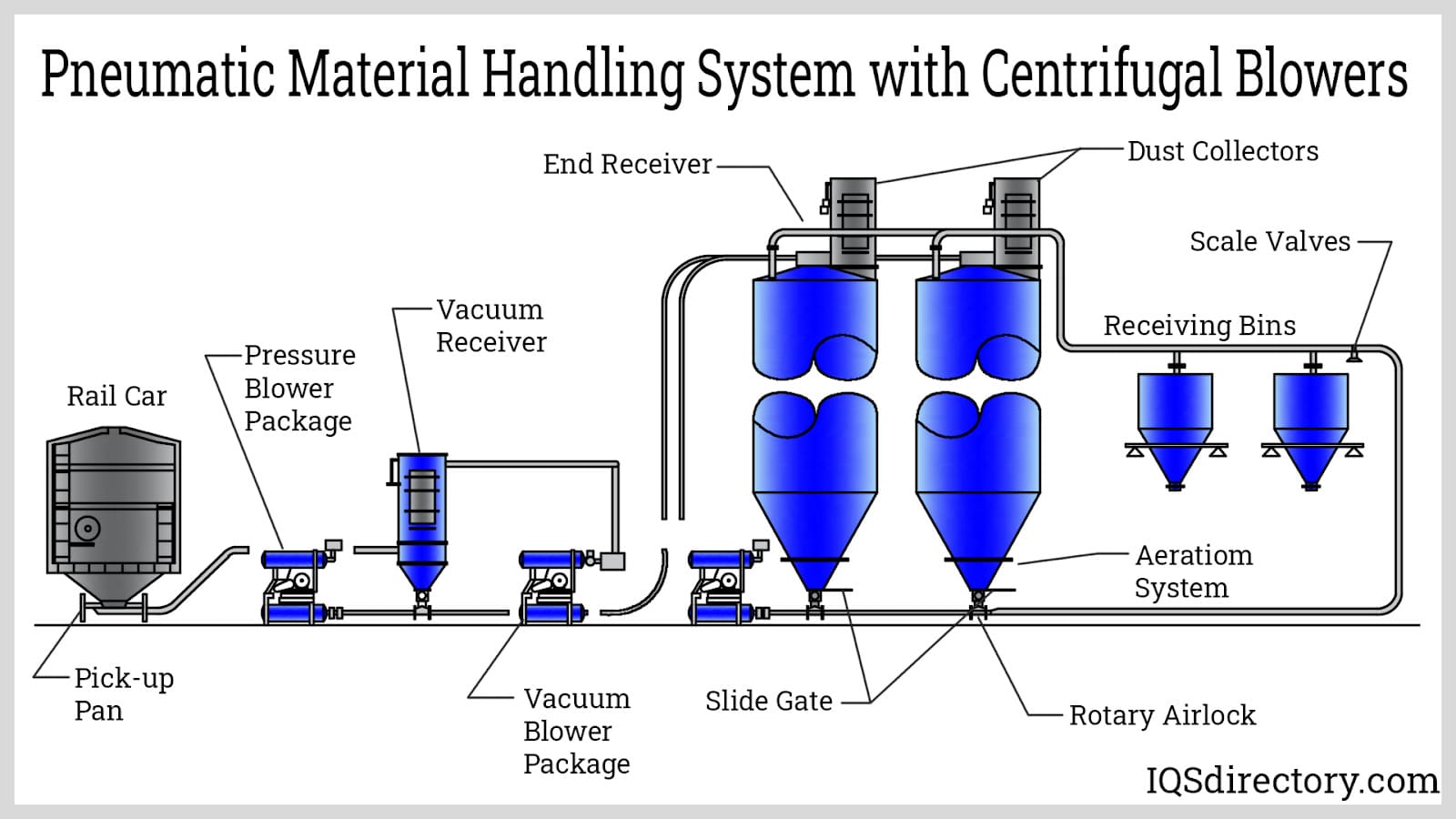

| Waste Management | Airflow management in pneumatic conveying systems | Optimizes material handling and reduces costs | Durability, maintenance ease, and adaptability to various materials |

How Are Centrifugal Blowers Used in Food Processing?

In the food processing industry, centrifugal blowers play a vital role in drying and removing excess moisture from products like baked goods and packaged foods. By ensuring that moisture is effectively removed, these blowers enhance product quality and extend shelf life, which is crucial for market competitiveness. For international buyers, it is essential to consider efficiency ratings, material compatibility with food-grade standards, and energy consumption to optimize operational costs.

What Role Do Centrifugal Blowers Play in Chemical Processing?

Centrifugal blowers are critical in chemical processing for ventilation and dust removal in production areas. They help maintain a safe working environment by managing airborne particulates and ensuring compliance with safety regulations. Buyers in this sector should focus on features such as noise levels, the availability of explosion-proof options, and the ease of maintenance to ensure long-term operational reliability and compliance with industry standards.

How Do Centrifugal Blowers Improve HVAC Systems?

In HVAC applications, centrifugal blowers are utilized for air circulation and pressure boosting in large buildings. They contribute to increased energy efficiency and enhanced comfort levels for occupants. For B2B buyers, key considerations include the size of the blower, airflow capacity, and its adaptability to existing HVAC systems. Selecting the right blower can significantly impact energy consumption and overall system performance.

Why Are Centrifugal Blowers Important in the Pharmaceutical Industry?

Centrifugal blowers are essential in the pharmaceutical sector for drying packaging and sterilization processes. They ensure product integrity and safety by providing a controlled environment free from moisture. Buyers should prioritize hygiene standards, material specifications that meet regulatory requirements, and energy efficiency to maintain compliance and reduce operational costs.

How Do Centrifugal Blowers Optimize Waste Management?

In waste management, centrifugal blowers are used for airflow management in pneumatic conveying systems. They optimize material handling processes by ensuring efficient transport of waste materials, which can lead to significant cost reductions. When sourcing blowers for this application, durability, ease of maintenance, and adaptability to various materials are critical factors to ensure reliability and efficiency in operations.

3 Common User Pain Points for ‘centrifugal blower’ & Their Solutions

Scenario 1: Inefficient Airflow Leading to Production Delays

The Problem: A manufacturer in the food processing industry experiences significant production delays due to insufficient airflow from their existing centrifugal blowers. The equipment is failing to maintain the necessary air pressure levels, causing bottlenecks in their drying processes. This not only hampers productivity but also threatens compliance with stringent quality control standards, leading to potential financial losses and reputational damage.

The Solution: To resolve this issue, the buyer should conduct a thorough assessment of their current centrifugal blower system. This includes evaluating the specifications of the existing equipment against the required airflow and pressure parameters for their specific application. Upgrading to a high-capacity centrifugal blower designed for high-pressure applications—such as those with backward inclined wheels—can significantly improve airflow efficiency. Additionally, sourcing models with variable frequency drives allows for adjustable speed settings, optimizing performance based on real-time demands. Collaboration with experienced suppliers can provide tailored recommendations and ensure the selected blower meets both operational and regulatory requirements.

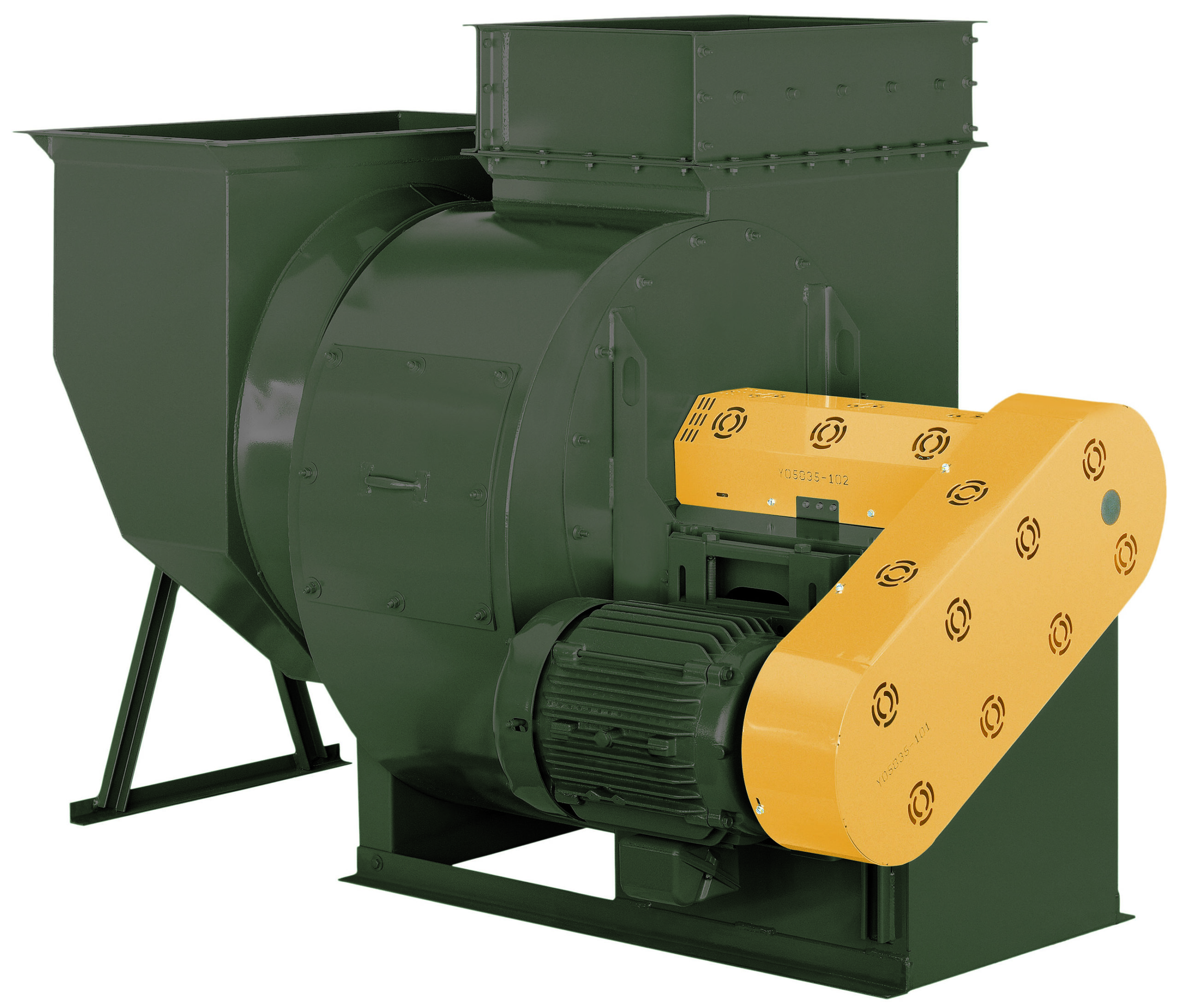

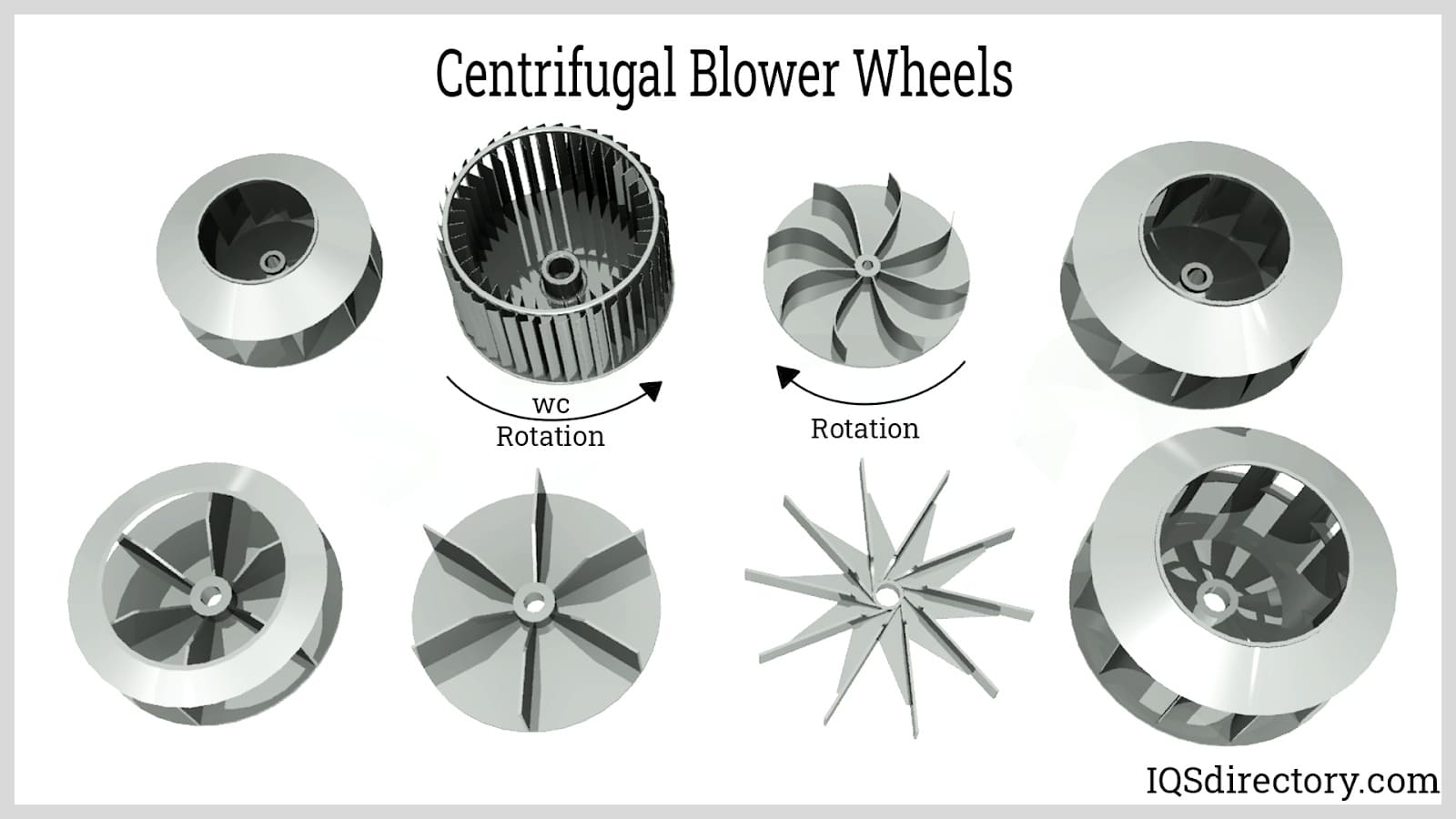

Illustrative image related to centrifugal blower

Scenario 2: Frequent Maintenance Interruptions and High Operational Costs

The Problem: A chemical processing company faces frequent maintenance interruptions due to their aging centrifugal blowers, which require regular servicing and part replacements. The downtime not only leads to increased operational costs but also impacts overall productivity and efficiency. Moreover, the cost of spare parts and maintenance labor is eating into their profit margins, creating a pressing need for a more reliable solution.

The Solution: Buyers in this situation should consider investing in modern centrifugal blowers that feature advanced materials and engineering designs aimed at reducing maintenance needs. Options like the RBX-Series centrifugal blowers, which utilize ceramic hybrid bearings and have a longer lifespan, can be particularly beneficial. These blowers are designed for high-duty applications, minimizing wear and tear while maximizing efficiency. Additionally, establishing a partnership with a supplier that offers comprehensive service contracts can help ensure regular maintenance checks and quick access to replacement parts, thereby reducing unplanned downtime and lowering overall operational costs.

Scenario 3: Incompatibility with Existing Systems Leading to Installation Challenges

The Problem: An industrial facility in South America is expanding its operations and requires new centrifugal blowers. However, the existing ventilation and material handling systems are outdated, creating compatibility issues with new equipment. The buyer is concerned about the potential complexity and costs associated with retrofitting or modifying their current setup to accommodate new blowers.

The Solution: To navigate this challenge, it is crucial for the buyer to engage with suppliers who offer customizable centrifugal blowers. These suppliers can work collaboratively to design systems that fit seamlessly into existing infrastructures. Conducting a comprehensive site assessment prior to purchasing can identify specific integration needs, ensuring that the selected blowers are tailored to the facility’s operational requirements. Additionally, investing in blowers with adjustable mounting options and modular designs can facilitate easier installation and reduce the need for extensive modifications. By prioritizing compatibility and seeking expert consultation, the buyer can achieve a smoother installation process while ensuring that the new blowers meet performance expectations.

Strategic Material Selection Guide for centrifugal blower

What Are the Key Materials Used in Centrifugal Blowers?

Selecting the right material for centrifugal blowers is crucial for optimizing performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the manufacturing of centrifugal blowers, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Cast Aluminum Perform in Centrifugal Blowers?

Key Properties: Cast aluminum is lightweight yet strong, with excellent thermal conductivity and a temperature rating of up to 600°F. It is resistant to corrosion, making it suitable for various environments.

Pros & Cons: The primary advantage of cast aluminum is its low weight, which facilitates easier installation and maintenance. It also offers good resistance to oxidation. However, it can be more expensive than other materials, and its strength may not match that of steel in high-pressure applications.

Impact on Application: Cast aluminum is ideal for applications requiring lightweight components, such as HVAC systems and clean air applications. Its corrosion resistance makes it suitable for environments with moisture or chemicals.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN. Cast aluminum’s recyclability may appeal to environmentally conscious buyers.

Why Choose Stainless Steel for Centrifugal Blowers?

Key Properties: Stainless steel offers high strength and excellent corrosion resistance, with temperature ratings often exceeding 1,200°F. It withstands high-pressure environments and is durable against wear and tear.

Pros & Cons: The key advantage of stainless steel is its longevity and ability to handle harsh conditions, making it suitable for industrial applications. However, it is typically more expensive than aluminum and may require specialized manufacturing processes, increasing lead times.

Impact on Application: Stainless steel is particularly effective in chemical processing and food industries, where hygiene and corrosion resistance are critical.

Considerations for International Buyers: Compliance with food safety standards (e.g., FDA, EU regulations) is essential for buyers in the food and beverage sector. The higher cost may be justified by the material’s longevity and reduced maintenance needs.

What Role Does Carbon Steel Play in Centrifugal Blower Manufacturing?

Key Properties: Carbon steel is known for its high strength and durability, with a temperature rating of up to 1,000°F. It is less resistant to corrosion compared to aluminum and stainless steel.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-conscious projects. However, its susceptibility to rust and corrosion limits its use in humid or corrosive environments unless properly treated.

Impact on Application: Carbon steel is suitable for applications where cost is a major concern, such as in general industrial processes. It is often used in environments where the blower is not exposed to moisture.

Illustrative image related to centrifugal blower

Considerations for International Buyers: Buyers should consider the need for protective coatings to enhance corrosion resistance, especially in humid regions like parts of Africa and South America. Compliance with local manufacturing standards is also critical.

How Effective Are Composite Materials in Centrifugal Blowers?

Key Properties: Composite materials are lightweight and can be engineered for specific applications, with excellent corrosion resistance and temperature ratings that vary widely based on the resin used.

Pros & Cons: The main advantage of composites is their versatility and the ability to tailor properties for specific applications. They are often lighter than metals, which can reduce energy costs. However, they can be more expensive and may require specialized manufacturing techniques.

Impact on Application: Composites are ideal for corrosive environments, such as chemical processing, where metal components may fail. They are also used in applications requiring lightweight solutions.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant international standards and consider the availability of skilled labor for installation and maintenance in their regions.

Summary Table of Material Selection for Centrifugal Blowers

| Material | Typical Use Case for centrifugal blower | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Aluminum | HVAC systems, clean air applications | Lightweight and corrosion-resistant | Higher cost than some alternatives | Medium |

| Stainless Steel | Chemical processing, food industries | High strength and durability | More expensive and complex to manufacture | High |

| Carbon Steel | General industrial processes | Cost-effective | Susceptible to corrosion | Low |

| Composite Materials | Chemical processing, corrosive environments | Tailored properties and lightweight | Higher cost and manufacturing complexity | High |

This strategic material selection guide equips international B2B buyers with essential insights to make informed decisions when sourcing centrifugal blowers, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for centrifugal blower

What Are the Main Stages of Manufacturing Centrifugal Blowers?

The manufacturing process of centrifugal blowers involves several critical stages that ensure high performance and reliability. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Centrifugal Blowers?

Material preparation begins with selecting high-quality raw materials, such as steel, aluminum, or composite materials, that meet specific performance standards. The chosen materials are then subjected to rigorous quality checks to ensure they conform to industry specifications. This step may include verifying material certifications and conducting initial tests for durability and strength.

Once the materials are approved, they are cut to size using advanced machining techniques, such as laser cutting or water jet cutting. This precision ensures that each component, including the impeller, housing, and other critical parts, meets exact specifications required for optimal airflow and pressure performance.

What Techniques Are Used in Forming Components?

The forming stage is crucial for shaping the blower components. Techniques such as stamping, forging, and casting are commonly employed, depending on the material and the desired properties of the final product. For instance, steel parts may be forged to enhance strength, while aluminum components could be cast for lightweight and corrosion resistance.

Centrifugal impellers, a vital component of blowers, are often manufactured using precision machining processes. This includes CNC (Computer Numerical Control) machining, which allows for intricate designs and high tolerances essential for efficient airflow dynamics.

How Are Centrifugal Blowers Assembled?

The assembly process involves fitting together various components, including the impeller, motor, and housing. This stage is typically performed in a clean, controlled environment to minimize contamination and ensure that all parts fit perfectly.

Quality control checks are integrated throughout the assembly process, where technicians inspect the alignment and integrity of each component. This may involve torque testing on bolts and seals, as well as vibration analysis to ensure that the assembled blower operates smoothly.

What Finishing Techniques Are Applied to Centrifugal Blowers?

Finishing processes enhance the durability and aesthetics of centrifugal blowers. Common techniques include painting, powder coating, or anodizing to protect against corrosion and wear. Each finishing method is chosen based on the application environment and customer requirements.

Illustrative image related to centrifugal blower

In addition to protective coatings, final inspection is a crucial part of the finishing stage. This includes checking for any surface defects, ensuring that all components are securely fastened, and validating that the blower meets specified performance metrics.

What Are the Key Quality Assurance Standards for Centrifugal Blowers?

Quality assurance is paramount in the manufacturing of centrifugal blowers, particularly for B2B buyers looking for reliability and performance. Various international and industry-specific standards govern the manufacturing process.

How Does ISO 9001 Influence Quality Control?

ISO 9001 is one of the most recognized quality management standards globally. Manufacturers of centrifugal blowers often implement ISO 9001 protocols to ensure consistent quality throughout the production process. This includes maintaining detailed documentation of procedures, conducting regular audits, and fostering a culture of continuous improvement.

What Industry-Specific Standards Should B2B Buyers Be Aware Of?

In addition to ISO 9001, centrifugal blowers may also need to comply with specific industry standards such as CE marking for European markets and API (American Petroleum Institute) standards for applications in oil and gas. Compliance with these standards not only ensures safety and performance but also facilitates smoother entry into regulated markets.

Illustrative image related to centrifugal blower

What Are the Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integral to the manufacturing process of centrifugal blowers. These checkpoints help identify defects early and ensure that the final product meets all specifications.

What Are the Stages of Quality Control in Manufacturing?

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components as they arrive at the facility. Materials are tested for compliance with specifications, and any non-conforming items are flagged for further action.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC monitors the production process. This includes regular checks on machining tolerances, alignment during assembly, and operational performance under simulated conditions.

-

Final Quality Control (FQC): After assembly, the final inspection ensures that the blower meets all performance criteria. This may involve testing airflow rates, pressure outputs, and noise levels. Any discrepancies are addressed before the product is shipped.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of suppliers is crucial to ensure they receive reliable products. Here are some strategies to consider:

What Steps Can Buyers Take to Audit Suppliers?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities and quality control processes firsthand. This includes reviewing documentation, observing manufacturing practices, and checking compliance with standards.

-

Quality Reports and Certifications: Requesting quality reports and certifications from suppliers provides insight into their adherence to international standards like ISO 9001 or CE marking. These documents should outline the quality management system in place and any recent audit results.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. These inspections can verify compliance with specified standards and help identify any potential risks before placing large orders.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances in quality control:

-

Regulatory Compliance: Different regions may have specific regulations governing product safety and environmental impact. Buyers must ensure that suppliers comply with these regulations to avoid legal issues.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary significantly across cultures. Understanding the specific expectations of the target market is essential for establishing clear quality criteria with suppliers.

-

Logistics and Supply Chain Considerations: Shipping and logistics can impact product quality. Buyers should consider how products are packaged and transported to minimize damage during transit.

By understanding the manufacturing processes and quality assurance measures for centrifugal blowers, B2B buyers can make informed decisions and ensure they partner with reliable suppliers who meet their performance and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘centrifugal blower’

In the competitive landscape of industrial equipment procurement, securing the right centrifugal blower is crucial for optimizing operational efficiency and ensuring reliability. This guide offers a structured approach for B2B buyers to navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider factors such as airflow requirements (CFM), pressure ratings (in wg), and material compatibility. This step ensures that the selected blower meets your operational needs and integrates seamlessly into existing systems.

Step 2: Identify Your Application Needs

Different applications require specific types of centrifugal blowers. Determine whether your application involves clean air, material handling, HVAC systems, or dust collection. This understanding will help you narrow down your options to models best suited for your specific operational demands.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in delivering quality centrifugal blowers and robust customer support.

- Check for Industry Experience: Suppliers with extensive experience in your industry are more likely to understand your unique requirements.

- Assess Support Services: Reliable suppliers should offer technical support, maintenance services, and warranty options.

Step 4: Compare Product Features and Performance

Different models may vary significantly in design and performance. Compare features such as motor type (direct drive vs. belt drive), material construction (steel, stainless steel, aluminum), and efficiency ratings. Understanding these differences helps you choose a blower that aligns with your operational goals.

- Consider Energy Efficiency: High-efficiency models can lead to significant energy savings over time.

- Look for Customization Options: Some suppliers offer customizable features that can enhance performance for specific applications.

Step 5: Verify Compliance and Certifications

Ensure that the centrifugal blowers you are considering comply with international standards and industry regulations. Certifications such as ISO, CE, or UL can provide assurance of quality and safety.

- Request Documentation: Ask for certification documents to confirm compliance.

- Understand Regional Standards: Familiarize yourself with any local regulations that may affect your purchase.

Step 6: Request Quotes and Negotiate Terms

Once you have shortlisted potential suppliers and products, request detailed quotes. Evaluate the total cost of ownership, which includes purchase price, installation, maintenance, and operational costs. Use this information to negotiate favorable terms.

- Consider Long-Term Partnerships: Look for suppliers willing to establish long-term relationships, which can lead to better pricing and support.

- Discuss Payment Terms: Clear payment structures can help manage cash flow effectively.

Step 7: Conduct a Risk Assessment

Assess potential risks associated with your purchase. This includes evaluating the reliability of the supplier, the availability of replacement parts, and the blower’s performance under varying operational conditions.

- Prepare Contingency Plans: Develop strategies to mitigate risks, such as having backup suppliers or maintenance plans in place.

- Monitor Performance Post-Purchase: Regularly assess the blower’s performance to ensure it meets expectations and address any issues promptly.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing centrifugal blowers, ensuring they select the best products for their operational needs while minimizing risks and maximizing value.

Illustrative image related to centrifugal blower

Comprehensive Cost and Pricing Analysis for centrifugal blower Sourcing

What Are the Key Cost Components in Centrifugal Blower Manufacturing?

When considering the sourcing of centrifugal blowers, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The selection of materials significantly impacts the overall cost. Common materials include aluminum, steel, and stainless steel, with stainless steel typically commanding a higher price due to its corrosion resistance and durability. Advanced composites or specialty alloys may further increase costs but can offer enhanced performance for specific applications.

-

Labor: Labor costs vary depending on the region and the skill level required for manufacturing. In countries with a higher cost of living, such as Germany, labor costs may represent a larger portion of the total manufacturing expenses compared to regions in Africa or South America, where labor may be cheaper.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, equipment maintenance, and administrative expenses. Efficient production processes and automation can help reduce overhead costs.

-

Tooling: The initial investment in tooling and equipment can be substantial, especially for custom designs. However, these costs can be amortized over larger production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Ensuring that products meet industry standards requires investment in quality control processes. Certifications such as ISO can add to the costs but may be essential for compliance and market acceptance.

-

Logistics: Shipping and handling expenses, including freight, insurance, and tariffs, can add significant costs, especially for international shipments. Understanding the Incoterms used in transactions is vital to clarify responsibility for these costs.

-

Margin: Suppliers typically include a margin to cover their risks and profit. This can vary widely based on market conditions and supplier reputation.

How Do Price Influencers Impact Centrifugal Blower Costs?

Several factors influence the pricing of centrifugal blowers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower unit prices due to economies of scale. Suppliers may offer tiered pricing based on volume, making it advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Customized blowers designed to meet specific performance criteria can significantly increase costs. Buyers should assess whether standard models can meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials and additional certifications can justify a higher price point. Buyers should weigh the benefits of investing in premium options against their specific application requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings can influence pricing. Established suppliers with a track record of quality and service may charge a premium but can provide peace of mind.

-

Incoterms: Understanding the terms of sale (e.g., FOB, CIF) is critical. The chosen Incoterms dictate who bears the shipping costs and risks, impacting the overall price.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing Centrifugal Blowers?

To ensure cost-efficient sourcing, buyers should consider the following strategies:

-

Negotiate Effectively: Leverage volume commitments or long-term contracts to negotiate better pricing. Building a relationship with suppliers can also lead to favorable terms and conditions.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the total cost of ownership, which includes maintenance, energy consumption, and operational efficiency over the blower’s lifecycle.

-

Research Market Prices: Stay informed about market trends and competitor pricing. This knowledge can empower buyers during negotiations and help identify fair market prices.

-

Be Aware of Pricing Nuances for International Buyers: Different regions may have distinct pricing structures based on local demand, currency fluctuations, and import tariffs. Buyers from Africa, South America, and the Middle East should account for these factors when comparing quotes.

Disclaimer on Indicative Prices

Prices for centrifugal blowers can vary widely based on the factors mentioned above. It is essential to obtain tailored quotes from multiple suppliers to ensure competitive pricing and align with specific project requirements.

Alternatives Analysis: Comparing centrifugal blower With Other Solutions

Understanding Alternatives to Centrifugal Blowers

When evaluating the best solution for air movement and pressure applications, it’s crucial to consider various technologies available in the market. Centrifugal blowers are widely recognized for their efficiency and reliability, but alternative solutions may offer unique advantages depending on specific requirements. This analysis compares centrifugal blowers against two viable alternatives: Axial Fans and Positive Displacement Blowers. Each technology has distinct characteristics that may influence your purchasing decision.

Comparison Table

| Comparison Aspect | Centrifugal Blower | Axial Fan | Positive Displacement Blower |

|---|---|---|---|

| Performance | High pressure, moderate volume | High volume, low pressure | Constant pressure, variable flow |

| Cost | Moderate upfront cost | Lower upfront cost | Higher initial investment |

| Ease of Implementation | Requires more space, complex installation | Easier to install, compact | Moderate complexity, may require custom setup |

| Maintenance | Moderate, depending on design | Low, fewer moving parts | Moderate, regular checks needed |

| Best Use Case | HVAC, material handling | Ventilation, cooling | Vacuum applications, chemical processing |

In-Depth Analysis of Alternatives

Axial Fans

Axial fans are designed to move large volumes of air at relatively low pressures. They are best suited for applications where space is limited and large airflows are required, such as in ventilation systems or cooling towers. The primary advantage of axial fans lies in their lower upfront costs and simpler installation processes. However, they are less efficient at generating high pressures compared to centrifugal blowers, which may limit their effectiveness in applications requiring substantial pressure differentials.

Positive Displacement Blowers

Positive displacement blowers operate by trapping a fixed volume of air and forcing it into a discharge pipe, providing consistent pressure regardless of the flow rate. This makes them ideal for applications requiring precise air delivery, such as in chemical processing and pneumatic conveying. While they offer reliable performance, the initial investment is typically higher than that of centrifugal blowers. Additionally, they require regular maintenance to ensure operational efficiency, which could lead to increased lifecycle costs. However, their ability to deliver constant pressure makes them a preferred choice for specific industrial applications.

Illustrative image related to centrifugal blower

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the most suitable air movement technology, B2B buyers should carefully assess their specific requirements, including performance, cost constraints, ease of installation, maintenance capabilities, and the nature of the application. Centrifugal blowers excel in high-pressure applications and material handling, making them a solid choice for industries like HVAC and dust collection. Conversely, if your needs lean towards high airflow with lower pressure, or if budget constraints are a priority, axial fans may be the more economical option. On the other hand, for applications demanding consistent pressure delivery, positive displacement blowers could be the best fit despite their higher costs. By aligning your operational needs with the characteristics of each solution, you can make an informed purchasing decision that optimally meets your business objectives.

Essential Technical Properties and Trade Terminology for centrifugal blower

What Are the Key Technical Properties of Centrifugal Blowers?

Understanding the technical properties of centrifugal blowers is crucial for B2B buyers to make informed purchasing decisions. Here are some essential specifications:

-

Airflow Rate (CFM)

The airflow rate, measured in cubic feet per minute (CFM), indicates the volume of air that a centrifugal blower can move. This specification is vital for determining whether a blower meets the requirements of specific applications, such as ventilation or material handling. A higher CFM is generally preferred for large-scale operations, ensuring efficient air distribution and preventing stagnation. -

Static Pressure (SP)

Static pressure, measured in inches of water gauge (in wg), represents the resistance the blower must overcome to move air through a system. Understanding SP is essential for selecting a blower that can maintain optimal performance under various operating conditions. Buyers should consider their system’s requirements to ensure the blower can deliver the necessary pressure without excessive energy consumption. -

Temperature Tolerance

The temperature tolerance indicates the maximum operating temperature the blower can withstand. This is particularly important in applications where hot air or gases are involved, such as in industrial processes or HVAC systems. Choosing a blower with the appropriate temperature tolerance ensures longevity and reliability in harsh environments. -

Material Construction

The material used in the construction of the blower affects its durability and suitability for specific applications. Common materials include steel, stainless steel, and aluminum. For instance, stainless steel is ideal for corrosive environments, while aluminum is lightweight and cost-effective. Understanding material properties helps buyers select a blower that aligns with their operational needs and budget. -

Drive Type

Centrifugal blowers can be either direct drive or belt-driven. Direct drive systems offer higher efficiency and lower maintenance, while belt-driven systems provide flexibility in speed adjustments. Buyers should assess their operational requirements to determine which drive type best fits their application.

What Are Common Trade Terms in the Centrifugal Blower Industry?

Familiarity with industry jargon helps B2B buyers navigate procurement processes effectively. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are then sold under another company’s brand name. In the context of centrifugal blowers, partnering with an OEM can ensure quality and reliability in the products supplied, as they often provide specialized designs tailored to specific applications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers, particularly when planning inventory and budget, as it can affect cash flow and storage capabilities. -

RFQ (Request for Quote)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. This is an essential step in procurement, allowing buyers to compare options and negotiate better deals. -

Incoterms

Incoterms, or International Commercial Terms, are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and risks in the procurement process. -

VFD (Variable Frequency Drive)

A VFD is a device used to control the speed and torque of an electric motor by varying the frequency and voltage of the power supplied. In centrifugal blowers, VFDs can enhance efficiency and allow for better control of airflow, making them a valuable feature in energy-conscious operations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right centrifugal blower for their specific applications and operational needs.

Navigating Market Dynamics and Sourcing Trends in the centrifugal blower Sector

What Are the Key Trends Shaping the Centrifugal Blower Market?

The centrifugal blower market is experiencing significant transformation driven by various global factors. Increased industrialization across Africa, South America, and the Middle East is leading to a surge in demand for efficient air-moving solutions. B2B buyers are particularly focused on products that optimize performance while minimizing energy consumption. Technological advancements, such as the integration of IoT for real-time monitoring and predictive maintenance, are emerging trends. These innovations allow companies to enhance operational efficiency and reduce downtime, which is crucial for competitive advantage.

In Europe, particularly in Germany, regulatory frameworks are increasingly emphasizing energy efficiency and emissions reduction. This shift is prompting manufacturers to invest in high-performance centrifugal blowers that comply with stringent environmental standards. Additionally, the rise of smart manufacturing practices is influencing procurement strategies, with companies favoring suppliers who can demonstrate a commitment to innovation and sustainability. As such, B2B buyers are advised to consider not only the technical specifications but also the technological capabilities of suppliers.

How Is Sustainability Influencing Sourcing Decisions in the Centrifugal Blower Sector?

Sustainability is becoming a pivotal consideration in the centrifugal blower market. The environmental impact of industrial operations has prompted businesses to prioritize ethical sourcing and the adoption of ‘green’ certifications. Buyers are increasingly seeking centrifugal blowers that utilize eco-friendly materials and energy-efficient designs. Products that achieve certifications, such as Energy Star or ISO 14001, are more appealing as they signify a commitment to reducing carbon footprints.

Moreover, the importance of ethical supply chains cannot be overstated. Companies are now scrutinizing their suppliers to ensure compliance with environmental regulations and social responsibility standards. This shift is not merely a trend but a fundamental change in how businesses operate. By choosing suppliers who prioritize sustainability, B2B buyers can enhance their brand reputation and align with the growing consumer demand for environmentally responsible products. Additionally, investing in sustainable technology can result in long-term cost savings through reduced energy consumption and maintenance.

What Is the Historical Context of Centrifugal Blowers Relevant to Today’s Market?

The evolution of centrifugal blowers dates back to the early industrial revolution when the need for efficient air movement in manufacturing processes became apparent. Initially, these devices were rudimentary, primarily serving basic ventilation needs. Over the decades, advancements in materials science and engineering led to the development of high-performance centrifugal blowers capable of handling various applications, from HVAC systems to complex industrial processes.

Today, the centrifugal blower market is characterized by a diverse range of products designed to meet specific operational requirements. Innovations such as backward-inclined fan designs and advanced motor technologies have enhanced efficiency and reliability. This historical context is essential for B2B buyers as it underscores the ongoing commitment to innovation within the sector, which continues to shape purchasing decisions and sourcing strategies. Understanding this evolution helps buyers appreciate the technological capabilities of current products and the potential for future advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of centrifugal blower

-

How do I solve performance issues with my centrifugal blower?

Performance issues can arise due to various factors such as improper sizing, blockage in the airflow, or wear and tear of components. First, ensure that the blower is correctly sized for your application; an oversized blower may lead to inefficiencies. Regular maintenance, including cleaning filters and checking for obstructions in the ductwork, can also help. If the problem persists, consult your supplier for a detailed inspection or consider upgrading to a more efficient model that better suits your operational needs. -

What is the best centrifugal blower for high-pressure applications?

For high-pressure applications, centrifugal blowers designed specifically for high static pressure are ideal. Models such as the backward inclined or radial tip fans are known for their efficiency in handling high pressure while maintaining airflow. When selecting a blower, consider the maximum CFM (cubic feet per minute) and static pressure ratings, ensuring they meet your system’s requirements. Consulting with manufacturers can help identify the best model tailored to your specific operational demands. -

What factors should I consider when sourcing centrifugal blowers internationally?

When sourcing centrifugal blowers internationally, consider factors like the supplier’s reputation, compliance with local regulations, and the availability of after-sales support. Assessing the quality of materials used and the manufacturing process is crucial to ensure durability. Additionally, investigate lead times, shipping logistics, and potential tariffs or duties that may affect overall costs. Engaging with suppliers who have a proven track record in your region can also help mitigate risks. -

How can I verify the reliability of a centrifugal blower supplier?

To verify the reliability of a supplier, examine their credentials, including certifications and industry experience. Request references or case studies from previous clients to gauge their performance and service quality. Additionally, look for suppliers with a robust warranty and after-sales service. Visiting their manufacturing facility or attending trade shows can provide deeper insights into their operations and product quality. -

What customization options are available for centrifugal blowers?

Many manufacturers offer customization options for centrifugal blowers to meet specific application needs. These may include variations in materials (such as stainless steel for corrosive environments), motor specifications, housing configurations, and sound-dampening features. Discussing your specific requirements with potential suppliers will enable them to recommend suitable modifications that can enhance performance and longevity in your operational context. -

What is the typical minimum order quantity (MOQ) for centrifugal blowers?

The minimum order quantity (MOQ) for centrifugal blowers can vary significantly by supplier and product type. Generally, larger manufacturers may have a higher MOQ due to production efficiencies, while smaller suppliers might accommodate lower quantities. It’s essential to communicate your needs upfront, as some suppliers may offer flexibility or tiered pricing based on order size. Understanding MOQs can help you plan your procurement strategy effectively. -

What payment terms should I expect when purchasing centrifugal blowers internationally?

Payment terms can vary widely among suppliers, but common options include advance payment, letters of credit, or payment upon delivery. It’s advisable to negotiate terms that suit your cash flow and risk tolerance. Consider using secure payment methods that offer buyer protection. Additionally, discuss currency exchange rates and any potential fees that may arise during international transactions to avoid unexpected costs. -

How do I ensure quality assurance for my centrifugal blower purchase?

Quality assurance can be ensured by selecting suppliers who adhere to international quality standards, such as ISO certifications. Request documentation such as test reports and certifications to verify product compliance. Additionally, consider conducting pre-shipment inspections to evaluate product quality before dispatch. Establishing clear communication regarding your quality expectations and specifications will also help mitigate risks associated with subpar products.

Top 9 Centrifugal Blower Manufacturers & Suppliers List

1. McMaster – Centrifugal Blowers

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Centrifugal Blowers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. New York Blower Company – High Pressure & Industrial Fans

Domain: nyb.com

Registered: 1996 (29 years)

Introduction: High Pressure & Industrial Centrifugal Fans & Air Blowers from New York Blower Company. Key product categories include: Inline Fans, Duct Fans, Tubeaxial, Vaneaxial, Centrifugal Fans (Backward Inclined, Forward Curved, Radial, Radial Tip), Pressure Blowers, Custom Fans, Centrifugal Ventilators, Axial Ventilators, Upblast Roof Ventilators, Hooded Roof Ventilators, Plenums and DWDIs, Fan Arrays, Fib…

3. Cincinnati Fan – Centrifugal Fans

Domain: cincinnatifan.com

Registered: 1998 (27 years)

Introduction: Centrifugal Fans: Model HDAF (Airfoil Fan) – up to 48,551 CFM, up to 21 in. wg; Model HDBC (Backward Curved Fan) – up to 270,000 CFM, up to 34 in. wg; Model HDBI (Backward Inclined Fan) – up to 150,000 CFM, up to 25 in. wg; Model CPAF (Airfoil Plug Fan) – up to 42,000 CFM, up to 18 in. wg; Model CPF (Backward Inclined Plug Fan) – up to 100,000 CFM, up to 25 in. wg; Model LM & LMF (Volume Fan) – up…

4. Republic MFG – Centrifugal Blowers

Domain: republic-mfg.com

Registered: 2015 (10 years)

Introduction: Centrifugal Blowers (RB & RBX Series) are belt-driven, generating flow up to 4,100 cfm and pressure greater than 160 in H2O. RB-Series has proven performance across various applications, while RBX-Series offers 80% peak efficiencies, consumes less power, and requires fewer replacements. Features include lifetime greased ceramic hybrid bearings, plated steel or aluminum alloy wetted components, mul…

5. Surplus Center – Key Products

Domain: surpluscenter.com

Registered: 1996 (29 years)

Introduction: Key product details for AC Centrifugal Blowers include: 1. 115 CFM 230 Volt AC FH133 Reverse Curve Impeller Blower – Item Number: 16-1475, Price: $9.99, Stock: 33. 2. 115 Volt AC Jakel 119278-00 PP-355 Draft Inducer Blower – Item Number: 16-1562, Price: $89.95, Stock: 42. 3. 1175 CFM 230 Volt AC FH320 Reverse Curve Impeller Blower – Item Number: 16-1480, Price: $24.99, Stock: 91. 4. 120 CFM 230 Vo…

6. IQS Directory – Centrifugal Blowers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Centrifugal blowers are mechanisms designed to propel air using centrifugal force from a spinning impeller. Key components include the impeller, housing, and drive mechanism. Blade configurations are categorized as forward curved, backward curved, and radial, affecting performance characteristics like pressure, velocity, and efficiency. Forward curved blowers generate high static pressure and airf…

7. Northern Blower – Custom Centrifugal Fans & Blowers

Domain: northernblower.com

Registered: 1996 (29 years)

Introduction: Custom Centrifugal Fans & Blowers designed for challenging industrial processes. Key series and specifications include:

– Series 4000: Backward Curved Industrial, SISW, Performance 5,000 to 250,000 ACFM to 48″ WG SP.

– Design 5010: Airfoil, SISW & DIDW, Wheel Diameter 13-1/2″ to 80-3/4″, Performance 1,000 to 250,000 ACFM to 21″ WG SP.

– Design 5020: Backward Inclined Blower, SISW & DIDW, Wheel Di…

8. Chart Industries – Centrifugal Blowers

Domain: chartindustries.com

Registered: 2001 (24 years)

Introduction: Centrifugal Blowers from Chart Industries include a range of turbo blowers and compressors designed for various industries such as power, mining, and water. Key features include:

1. **Modular Approach**: Flexible solutions based on a wide performance envelope.

2. **High Efficiency**: Leading engineering technology ensures optimal efficiency for each product type.

3. **Quality Manufacturing**: Pro…

9. Sonic Air Systems – Industrial Centrifugal Blowers

Domain: sonicairsystems.com

Registered: 1997 (28 years)

Introduction: Sonic Air Systems offers a comprehensive line of industrial centrifugal blowers designed for various applications. Key specifications include: 1. **Horsepower Range**: 3 to 50 horsepower. 2. **Airflow Capacities**: 100 to 3,500 CFM. 3. **Vacuum Ratings**: Up to 8″ Hg. 4. **Design Features**: – Sealed, grease-packed bearings. – PTFE shaft seals for reliability. – Compact, belt-driven design. – Corr…

Strategic Sourcing Conclusion and Outlook for centrifugal blower

In the evolving landscape of industrial applications, strategic sourcing of centrifugal blowers is paramount for optimizing operational efficiency and cost management. As global markets expand, particularly in Africa, South America, the Middle East, and Europe, understanding the diverse offerings—from high-pressure centrifugal fans to specialized material handling systems—can significantly enhance procurement decisions.

B2B buyers should prioritize partnerships with manufacturers that offer robust, customizable solutions tailored to specific industry needs, ensuring reliability and longevity. The shift towards energy-efficient designs, such as those utilizing ceramic hybrid bearings and environmentally friendly materials, not only reduces operational costs but also aligns with sustainability goals.

Looking ahead, the demand for centrifugal blowers is set to grow as industries increasingly recognize the advantages of efficient air movement solutions over traditional systems. By leveraging strategic sourcing, international buyers can position themselves advantageously in a competitive marketplace. Engage with leading suppliers today to explore innovative solutions that will propel your operations into the future, ensuring both efficiency and sustainability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.