A Deep Dive into Carbon Rock Board Solution

Introduction: Navigating the Global Market for carbon rock board

In an increasingly competitive global market, sourcing high-quality carbon rock boards presents a significant challenge for B2B buyers looking to enhance their projects with durable and aesthetically pleasing materials. As industries across Africa, South America, the Middle East, and Europe seek innovative solutions for interior design, hospitality, and healthcare applications, understanding the nuances of carbon rock board products becomes essential. This comprehensive guide is designed to equip international buyers with the knowledge needed to navigate the complexities of sourcing carbon rock boards, covering various types, applications, and the critical factors for supplier vetting.

From the cost-effective advantages of carbon rock panels to their lightweight and easy-to-install nature, this guide delves into the myriad benefits that make them a preferred choice over traditional materials like natural marble. Additionally, we will explore the environmental implications and performance characteristics that set carbon rock boards apart in the construction industry. By providing actionable insights on pricing, supplier selection, and design versatility, this guide empowers buyers to make informed purchasing decisions that align with their project needs and budget constraints.

Whether you are operating in Brazil, Saudi Arabia, or other key markets, this resource aims to streamline your sourcing process, ensuring that you can confidently integrate high-quality carbon rock boards into your next project.

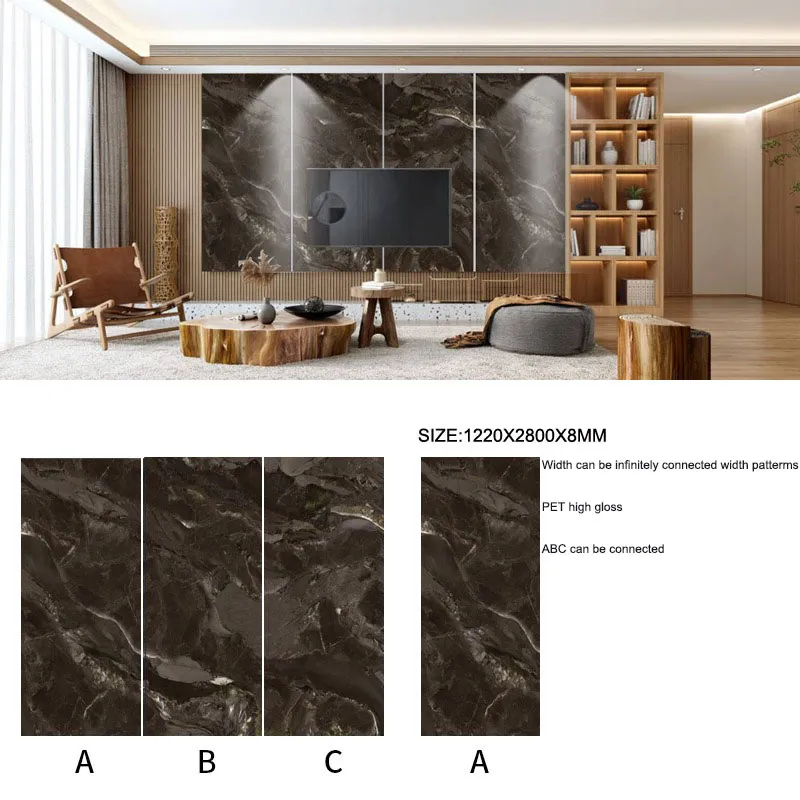

Understanding carbon rock board Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Capstone Carbon Rock | Wide range of designs, customizable patterns | Interior design, retail displays | Pros: Versatile aesthetics, customizable. Cons: May require professional installation. |

| Antibacterial Panels | Infused with antibacterial properties | Healthcare, kitchens, bathrooms | Pros: Enhances hygiene, easy to clean. Cons: Slightly higher cost due to specialized features. |

| Lightweight Panels | Low density, easy to handle and install | DIY projects, commercial renovations | Pros: Cost-effective, fast installation. Cons: May not be suitable for high-impact areas. |

| High-Strength Variants | Enhanced durability and impact resistance | Transportation interiors, high-traffic areas | Pros: Long-lasting performance, moisture-resistant. Cons: Higher initial investment. |

| Decorative Profiles | Elegant designs mimicking natural stone | Hospitality, luxury residential projects | Pros: Luxurious appearance, low maintenance. Cons: Limited design options compared to panels. |

What are the Characteristics of Capstone Carbon Rock Panels?

Capstone Carbon Rock Panels are known for their extensive range of designs and customizable patterns, allowing businesses to create unique interior spaces. Their aesthetic flexibility makes them suitable for various applications, including interior design and retail displays. When considering Capstone panels, B2B buyers should evaluate their design preferences and whether they require professional installation for optimal results.

How Do Antibacterial Panels Enhance Hygiene in Commercial Spaces?

Antibacterial Panels are specifically engineered to provide enhanced hygiene, making them ideal for healthcare facilities, kitchens, and bathrooms. These panels are easy to clean, ensuring that businesses can maintain a sanitary environment. Buyers should assess the cost-benefit ratio when investing in these specialized panels, especially in sectors where cleanliness is paramount.

Why Choose Lightweight Panels for DIY and Commercial Renovations?

Lightweight Panels are designed for ease of handling and installation, making them a popular choice for DIY projects and commercial renovations. Their cost-effectiveness and quick installation process appeal to budget-conscious buyers. However, businesses should consider the suitability of these panels in high-impact areas, as their lightweight nature may not withstand heavy use.

What Makes High-Strength Variants Ideal for High-Traffic Areas?

High-Strength Variants of carbon rock boards are engineered for enhanced durability and impact resistance, making them suitable for transportation interiors and high-traffic areas. Their moisture-resistant properties add to their appeal in environments prone to spills or humidity. Buyers should weigh the higher initial investment against the long-term benefits of reduced maintenance and replacement costs.

How Do Decorative Profiles Contribute to Luxury Projects?

Decorative Profiles offer an elegant appearance that closely mimics natural stone, making them ideal for hospitality and luxury residential projects. These profiles require low maintenance while providing a sophisticated aesthetic. B2B buyers should consider the design limitations compared to panels, ensuring that the chosen profiles align with their overall project vision.

Key Industrial Applications of carbon rock board

| Industry/Sector | Specific Application of Carbon Rock Board | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Interior Design | Wall and ceiling decoration in residential and commercial spaces | Offers a luxurious aesthetic at a lower cost than natural stone | Ensure availability of diverse patterns and colors |

| Hospitality | Decorative surfaces in hotels and restaurants | Enhances ambiance while being easy to maintain and clean | Look for suppliers with bulk shipping options and warranties |

| Retail | Countertops and display fixtures | Creates a high-end look that attracts customers | Assess durability and resistance to wear in high-traffic areas |

| Transportation | Interior finishes for buses, yachts, and trains | Lightweight and durable, improving fuel efficiency and aesthetics | Check for compliance with safety and fire regulations |

| Healthcare | Wall and floor coverings in clinics and hospitals | Provides a hygienic surface that is easy to clean | Verify antibacterial properties and certifications |

How is Carbon Rock Board Used in Interior Design?

In the interior design sector, carbon rock board is utilized extensively for wall and ceiling decoration in both residential and commercial projects. Its ability to mimic the luxurious appearance of natural stone makes it an attractive choice for designers aiming for high-end aesthetics without the associated costs. Buyers in this sector should consider the availability of a variety of patterns and colors to meet diverse design needs. Additionally, ease of installation can significantly reduce labor costs, making it a practical choice for large-scale projects.

What Role Does Carbon Rock Board Play in Hospitality?

In hospitality settings such as hotels and restaurants, carbon rock board serves as a decorative surface that enhances the overall ambiance. Its aesthetic appeal, combined with its easy maintenance, makes it ideal for high-traffic areas where cleanliness is paramount. For international buyers, especially those in regions like the Middle East or Africa, sourcing options that include bulk shipping and product warranties can ensure a seamless supply chain and reduce operational risks.

How is Carbon Rock Board Beneficial for Retail Spaces?

Retail environments benefit from carbon rock board used in countertops and display fixtures, as it creates a sophisticated atmosphere that can draw in customers. The material’s durability ensures that it can withstand the rigors of high foot traffic while maintaining its visual appeal. Buyers should focus on sourcing products that are resistant to wear and easy to clean, as these factors contribute to long-term cost savings and customer satisfaction.

What Advantages Does Carbon Rock Board Offer in Transportation?

In the transportation industry, carbon rock board is applied as an interior finish for buses, yachts, and trains. Its lightweight nature contributes to better fuel efficiency, while its robust durability ensures longevity in challenging environments. Buyers should ensure that their sourcing aligns with safety and fire regulations, particularly in regions with stringent compliance standards, to avoid costly penalties and ensure passenger safety.

How is Carbon Rock Board Used in Healthcare Facilities?

In healthcare settings, carbon rock board is employed for wall and floor coverings, providing hygienic surfaces that are easy to clean and maintain. This is critical in environments where cleanliness is essential for patient safety. Buyers in the healthcare sector should prioritize products with verified antibacterial properties and necessary certifications to ensure compliance with health regulations, particularly in international markets where standards may vary.

3 Common User Pain Points for ‘carbon rock board’ & Their Solutions

Scenario 1: Navigating Supply Chain Challenges for Carbon Rock Board Procurement

The Problem: For B2B buyers, sourcing carbon rock boards can often be a daunting task due to supply chain complexities. Buyers may struggle with inconsistent product availability, long lead times, and unexpected price fluctuations, especially when dealing with international suppliers. This unpredictability can delay projects and lead to budget overruns, creating tension between suppliers and contractors who depend on timely delivery to meet client expectations.

The Solution: To mitigate these supply chain challenges, B2B buyers should consider establishing relationships with multiple suppliers to diversify their sourcing options. It is advisable to conduct thorough market research to identify reliable suppliers with a proven track record of timely deliveries and consistent product quality. Utilizing platforms that aggregate suppliers or offer digital marketplaces can streamline this process. Additionally, engaging in direct communication with suppliers about projected needs and timelines can lead to better forecasting and inventory management. Setting up a contract that includes flexible terms for volume purchases can also help lock in prices and ensure availability during peak demand seasons.

Scenario 2: Ensuring Compliance with Local Building Codes and Regulations

The Problem: When integrating carbon rock boards into construction projects, B2B buyers often encounter challenges related to compliance with local building codes and regulations. These regulations can vary significantly by region and may include requirements for fire resistance, moisture control, and environmental impact. Non-compliance can lead to costly reworks, project delays, and even legal ramifications, jeopardizing the reputation of the buyer’s business in the industry.

The Solution: To ensure compliance, it is crucial for B2B buyers to conduct detailed research on local building codes before specifying carbon rock boards for projects. Consulting with local architects or engineers who are familiar with these regulations can provide valuable insights. Buyers should also request certification documents from manufacturers that demonstrate the product meets relevant standards. Furthermore, attending workshops or training sessions on local building regulations can enhance the buyer’s understanding of compliance requirements. Engaging with a knowledgeable supply partner who can provide guidance on the specific certifications needed for carbon rock boards can also streamline the process and reduce the risk of compliance issues.

Scenario 3: Overcoming Misconceptions about Performance and Durability

The Problem: Many B2B buyers may hold misconceptions regarding the performance and durability of carbon rock boards compared to traditional materials like natural marble. Concerns about the longevity, maintenance, and aesthetic appeal of carbon rock boards can hinder decision-making, especially when stakeholders are accustomed to using established materials. These misconceptions may lead to reluctance in adopting new materials, thereby missing out on potential cost savings and design flexibility.

The Solution: To address these concerns, B2B buyers should invest in educational resources that highlight the advantages of carbon rock boards over traditional materials. Organizing product demonstrations or site visits where potential users can see and touch the material in real-world applications can significantly enhance confidence in its performance. Providing case studies or testimonials from other businesses that successfully transitioned to carbon rock boards can also help build credibility. Buyers should ensure that the specifications clearly outline the product’s resistance to moisture, fire, and wear, as well as its low maintenance requirements. Furthermore, offering a warranty or satisfaction guarantee can reassure stakeholders about the durability and reliability of carbon rock boards, encouraging broader acceptance of this innovative material.

Strategic Material Selection Guide for carbon rock board

What Are the Key Properties of Carbon Rock Board Materials?

When selecting materials for carbon rock boards, it is essential to consider various alternatives that can meet specific performance requirements. Below, we analyze three common materials used in the production of carbon rock boards: natural stone, PVC, and engineered composites. Each material has unique properties, advantages, and limitations that can impact their suitability for various applications.

How Does Natural Stone Compare in Performance and Suitability?

Natural stone, such as marble or granite, is known for its durability and aesthetic appeal. Key properties include high temperature resistance and excellent compressive strength, making it suitable for high-traffic areas. However, natural stone can be heavy and difficult to install, which may increase labor costs. Additionally, it is prone to staining and requires regular maintenance to preserve its appearance.

For international buyers, natural stone must comply with local building codes and standards, such as ASTM in the U.S. or EN standards in Europe. In regions like Africa and South America, sourcing natural stone may involve logistical challenges due to transportation costs and availability.

What Are the Advantages and Disadvantages of PVC?

PVC (polyvinyl chloride) is a widely used material in construction due to its low cost and ease of installation. It is lightweight and resistant to moisture, making it suitable for areas prone to humidity. However, PVC lacks the durability of natural stone and can warp or discolor under extreme conditions. Additionally, it may release harmful substances when exposed to heat.

International buyers should consider compliance with environmental regulations, as PVC is not recyclable and may face scrutiny in markets prioritizing sustainability. In regions like the Middle East, where high temperatures are common, the material’s performance under heat should be carefully evaluated.

How Do Engineered Composites Stand Out?

Engineered composites, which combine natural minerals with synthetic materials, offer a balanced approach between performance and cost. These materials are designed to mimic the appearance of natural stone while providing enhanced durability and resistance to moisture, fire, and chemicals. They are lightweight and easy to install, making them suitable for both residential and commercial applications.

However, the manufacturing complexity of engineered composites can lead to higher costs compared to basic materials like PVC. International buyers should be aware of compliance with local standards, as engineered composites may require certifications such as DIN in Europe or JIS in Japan. In regions like Brazil, where construction standards are stringent, ensuring product compliance is crucial.

Summary Table of Material Comparisons for Carbon Rock Board

| Material | Typical Use Case for carbon rock board | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Stone | High-end residential and commercial spaces | Exceptional durability and aesthetic appeal | Heavy, requires maintenance, and costly installation | High |

| PVC | Budget-friendly applications, temporary installations | Low cost and easy installation | Prone to warping, less durable, environmental concerns | Low |

| Engineered Composites | Versatile applications in residential and commercial projects | Balanced performance with aesthetic appeal | Higher manufacturing complexity and cost | Medium |

In conclusion, selecting the right material for carbon rock boards involves evaluating the specific application requirements, performance properties, and compliance with international standards. By understanding the advantages and limitations of each material, B2B buyers can make informed decisions that align with their project goals and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for carbon rock board

What Are the Key Stages in the Manufacturing Process of Carbon Rock Board?

The manufacturing of carbon rock boards involves several critical stages that ensure the final product meets high-quality standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The foundation of carbon rock board manufacturing begins with the careful selection and preparation of raw materials. Approximately 70% of the composition is natural calcite (calcium carbonate), while the remaining 30% consists of engineered additives. These materials are sourced from reputable suppliers, ensuring they meet safety and environmental standards. The calcite is processed to achieve the desired particle size, which is crucial for the subsequent forming process.

Forming

Once the materials are prepared, the next step is forming the carbon rock board. This involves mixing the calcite and additives in precise proportions, followed by a high-tech molding process. Advanced machinery is employed to ensure consistent thickness and density across all panels. This stage is essential for achieving the natural stone-like appearance and durability characteristics that make carbon rock boards an attractive alternative to natural marble.

Assembly

After forming, the boards are subjected to a meticulous assembly process. This may involve cutting the panels to specific dimensions, adding backing materials for enhanced stability, and ensuring that the panels can accommodate various installation methods. The assembly stage is also where additional features, such as antibacterial properties, can be integrated into the product.

Finishing

The final stage of manufacturing is finishing, where the carbon rock boards undergo surface treatments to enhance their aesthetic appeal and durability. This includes applying protective coatings that improve resistance to moisture, chemicals, and scratches. The finishing process also allows for the application of various colors and patterns, catering to diverse design preferences in the market.

How Is Quality Assurance Implemented in Carbon Rock Board Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that carbon rock boards meet both international standards and customer expectations. Various quality control (QC) methodologies and checkpoints are established throughout the production process.

International Standards for Quality Assurance

Manufacturers of carbon rock boards often adhere to internationally recognized standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards ensures that the manufacturing process is consistent, efficient, and capable of producing high-quality products. Additionally, industry-specific certifications like CE marking indicate conformity with European health, safety, and environmental protection standards.

Quality Control Checkpoints

Quality control checkpoints are strategically placed throughout the manufacturing process to monitor product quality at different stages:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Materials are tested for compliance with specifications, ensuring that only high-quality components are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC is implemented to monitor the production process in real-time. This includes regular checks on machinery calibration, material mixing ratios, and panel dimensions to ensure adherence to design specifications.

-

Final Quality Control (FQC): Once the carbon rock boards are finished, FQC involves comprehensive testing of the final products. This may include visual inspections, physical tests for durability, moisture resistance, and chemical exposure. Any panels failing to meet quality standards are rejected and reprocessed.

What Common Testing Methods Are Used for Carbon Rock Boards?

Several testing methods are commonly employed to ensure the durability and safety of carbon rock boards. These methods help verify compliance with international standards and industry regulations.

-

Mechanical Testing: This includes tests for impact resistance, tensile strength, and flexural strength. These tests assess how well the panels can withstand physical stress and impacts, crucial for applications in high-traffic areas.

-

Chemical Resistance Testing: Panels are subjected to various cleaning agents and chemicals to evaluate their resistance to discoloration and degradation. This testing is particularly important for applications in kitchens and bathrooms, where exposure to cleaning products is frequent.

-

Moisture Absorption Testing: The ability of carbon rock boards to resist moisture is tested to ensure they do not warp or degrade in humid environments. This is vital for applications in regions with high humidity levels.

-

Fire Resistance Testing: Fire safety is a major concern in construction materials. Testing for flammability and smoke emissions is conducted to ensure compliance with safety regulations.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensuring product reliability.

-

Supplier Audits: Conducting on-site audits of the manufacturing facility allows buyers to assess the quality control measures in place. This includes evaluating the manufacturing processes, equipment, and adherence to safety and environmental standards.

-

Reviewing Quality Control Reports: Suppliers should provide detailed quality control reports that outline testing results, certifications, and any corrective actions taken for non-conforming products. Buyers should request these documents to understand the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality. These inspections can be particularly beneficial for buyers unfamiliar with local manufacturing practices.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is crucial for B2B buyers operating in different regions. Variations in standards and regulations can impact the purchasing decision.

-

Regional Standards: Buyers must be aware of the specific quality standards and certifications required in their region. For instance, European buyers may prioritize CE marking, while those in the Middle East might look for compliance with local building codes.

-

Cultural Considerations: Different regions may have varying approaches to quality assurance. Buyers should familiarize themselves with local practices and expectations to ensure effective communication and collaboration with suppliers.

-

Long-term Relationships: Establishing long-term relationships with suppliers can enhance trust and improve communication regarding quality control. Engaging in regular discussions about quality expectations and product performance can lead to better outcomes for both parties.

In conclusion, understanding the manufacturing processes and quality assurance measures associated with carbon rock boards equips B2B buyers with the necessary insights to make informed purchasing decisions. By focusing on supplier quality control and adhering to international standards, buyers can secure reliable products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carbon rock board’

Introduction

This practical sourcing guide aims to equip B2B buyers with a structured approach to procuring Carbon Rock Panels. By following this checklist, buyers can ensure they make informed decisions that align with their project requirements and budget while collaborating with reliable suppliers.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to have a clear understanding of your technical requirements for Carbon Rock Panels. Consider factors such as size, thickness, color, pattern, and performance characteristics like moisture resistance and fire safety. Establishing these specifications early on will streamline communication with suppliers and ensure you receive products that meet your exact needs.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify suppliers who specialize in Carbon Rock Panels. Look for companies with a strong reputation in the market and a proven track record of delivering quality products. Utilize online resources, trade shows, and industry publications to compile a list of potential suppliers, focusing on those with positive customer reviews and case studies relevant to your sector.

Step 3: Evaluate Supplier Certifications and Compliance

It’s vital to verify that your potential suppliers meet industry standards and regulations. Check for certifications such as ISO, CE, or other relevant quality and safety certifications. This not only assures you of the product’s quality but also minimizes risks associated with compliance in your region, especially in markets like Europe and the Middle East where regulations can be stringent.

Step 4: Request Samples for Assessment

Before making a bulk purchase, request samples of the Carbon Rock Panels from shortlisted suppliers. This step allows you to assess the aesthetics, texture, and overall quality firsthand. Pay attention to the panel’s weight, ease of handling, and installation requirements, as these factors can significantly impact your project timeline and costs.

Step 5: Review Pricing and Payment Terms

Once you’ve narrowed down your options, review pricing structures and payment terms offered by each supplier. Ensure you understand the total cost, including shipping and taxes, to avoid any surprises later. Additionally, negotiate payment terms that align with your cash flow, such as deposits or staggered payments, to facilitate smoother transactions.

Step 6: Assess Logistics and Delivery Capabilities

Evaluate the logistics capabilities of your chosen suppliers, including their ability to meet delivery timelines and handle international shipping, especially if sourcing from regions like Europe to Africa or South America. Ensure they have a reliable transportation network and can provide tracking information for shipments. This is crucial for maintaining project schedules and avoiding delays.

Step 7: Establish Communication Channels and Support

Effective communication is key to a successful procurement process. Confirm the availability of dedicated support from your suppliers, including project managers or customer service representatives. Establishing clear communication channels can help address any issues that arise during the procurement process and ensure a smooth collaboration.

By following these steps, B2B buyers can navigate the sourcing of Carbon Rock Panels with confidence, ensuring they select the right products and suppliers for their projects.

Comprehensive Cost and Pricing Analysis for carbon rock board Sourcing

What Are the Key Cost Components for Sourcing Carbon Rock Boards?

When evaluating the sourcing of carbon rock boards, it’s crucial to dissect the cost structure involved. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The core composition of carbon rock boards consists of approximately 70% natural calcite and 30% engineered additives. Prices can fluctuate based on raw material availability and quality. Buyers should consider sourcing from regions where calcite is abundant to potentially reduce material costs.

-

Labor: Labor costs encompass wages for skilled workers involved in manufacturing, installation, and quality assurance. Depending on the country of sourcing, labor costs can vary significantly. For instance, sourcing from regions with lower labor costs may yield a more competitive price.

-

Manufacturing Overhead: This includes expenses related to the factory operation, such as utilities and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, impacting the overall pricing of the final product.

-

Tooling: The setup of manufacturing tools and molds can be a substantial upfront cost. Buyers interested in customized designs may face higher tooling costs, which should be factored into the overall pricing strategy.

-

Quality Control: Ensuring product quality through rigorous testing and quality assurance processes can add to costs. However, investing in quality control is crucial, especially for high-traffic applications like hospitality and healthcare, where durability and hygiene are paramount.

-

Logistics: The transportation of carbon rock boards from the manufacturer to the end user includes shipping, insurance, and potential tariffs. Buyers should be aware of the Incoterms that apply to their purchases, as they dictate who bears the cost of shipping and risks during transit.

-

Margin: Manufacturers typically apply a profit margin to cover their operational costs and generate profit. Understanding the typical margins in the industry can help buyers gauge whether they are receiving competitive pricing.

How Do Price Influencers Affect Carbon Rock Board Costs?

Several factors can influence the pricing of carbon rock boards, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchasing often leads to significant discounts. Buyers should negotiate minimum order quantities (MOQs) to achieve cost-efficiency.

-

Specifications/Customization: Custom designs or specific patterns can drive up costs. Buyers should balance their design needs with budget considerations, opting for standard designs where possible to reduce expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., eco-friendly standards) may increase costs but also enhance product value. Buyers should assess the long-term benefits of investing in higher-quality options.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may command higher prices due to proven quality and service, while newer suppliers may offer lower prices to penetrate the market.

-

Incoterms: Understanding the terms of delivery (e.g., FOB, CIF) is essential for calculating total costs. Buyers should clarify responsibilities to avoid unexpected expenses.

What Are the Best Negotiation and Cost-Efficiency Strategies for Buyers?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes and ensure cost-efficiency:

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the initial purchase price. This includes installation, maintenance, and potential replacement costs. High-quality carbon rock boards may have a higher upfront cost but lower TCO over time.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Repeat business often encourages suppliers to offer favorable conditions.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This can also serve as a negotiation point if the quality does not meet expectations.

-

Market Research: Stay informed about market trends and competitor pricing to strengthen negotiation positions. Understanding the market landscape can provide leverage in discussions.

-

Timing Purchases: Consider seasonal trends or promotional periods that might affect pricing. Manufacturers may offer discounts during off-peak times to boost sales.

Conclusion

In summary, understanding the comprehensive cost structure, price influencers, and effective negotiation strategies is vital for B2B buyers looking to source carbon rock boards. By carefully evaluating these factors, buyers can make informed decisions that align with their project needs and budget constraints. It is advisable to consult multiple suppliers to ensure competitive pricing and quality assurance before finalizing any contracts.

Alternatives Analysis: Comparing carbon rock board With Other Solutions

In today’s competitive B2B landscape, businesses must carefully evaluate various materials and technologies to meet their design and construction needs. Carbon rock board, known for its aesthetic appeal and durability, presents a strong case for companies looking to enhance their spaces. However, it’s essential to compare it with other viable alternatives to make informed purchasing decisions.

Comparison Table

| Comparison Aspect | Carbon Rock Board | PVC Marble Sheet | Natural Stone (e.g., Marble) |

|---|---|---|---|

| Performance | Highly durable, moisture and impact resistant | Moderate durability, prone to warping | Excellent durability, but heavy and expensive |

| Cost | Cost-effective, competitive pricing | Generally lower cost | High initial investment |

| Ease of Implementation | Fast installation, lightweight | Easy to install but less durable | Requires skilled labor and heavy machinery |

| Maintenance | Low maintenance, easy to clean | Moderate maintenance, prone to staining | High maintenance, requires sealing |

| Best Use Case | Interior design, hospitality, healthcare | Budget-friendly projects, temporary setups | Luxury applications, high-end design |

Detailed Breakdown of Alternatives

PVC Marble Sheet

PVC marble sheets are a popular alternative primarily due to their lower cost and ease of installation. They are lightweight and can mimic the appearance of marble, making them a choice for budget-conscious projects. However, they tend to be less durable than carbon rock boards, with a higher susceptibility to warping and discoloration over time. Additionally, PVC sheets are made from plastic, raising environmental concerns and potential health risks associated with off-gassing when exposed to heat. Thus, while PVC marble sheets can be suitable for temporary or low-traffic applications, they may not be the best long-term investment.

Natural Stone (e.g., Marble)

Natural stone, such as marble, is synonymous with luxury and high-end design. Its natural beauty and durability make it a favorite in upscale projects. However, the cost of natural stone is significantly higher than both carbon rock board and PVC marble sheets. Installation can be labor-intensive and requires specialized skills, which can further inflate project costs. Moreover, natural stone surfaces require regular maintenance, including sealing to prevent staining and damage. While ideal for luxurious applications, the practicality of natural stone can be limited by its weight and cost.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between carbon rock board and its alternatives, B2B buyers should consider several factors, including performance requirements, budget constraints, and the intended application. Carbon rock board stands out for its combination of aesthetic appeal, durability, and ease of maintenance, making it a versatile choice for various industries, from hospitality to healthcare. In contrast, PVC marble sheets may serve well for budget-sensitive projects, while natural stone is best suited for luxury applications where cost is less of a concern. Ultimately, the decision should align with the specific needs and goals of the project, ensuring that the chosen material delivers both value and functionality.

Essential Technical Properties and Trade Terminology for carbon rock board

What Are the Key Technical Properties of Carbon Rock Board?

Understanding the technical properties of carbon rock board is crucial for B2B buyers looking to make informed purchasing decisions. Here are some essential specifications to consider:

1. Material Composition

Carbon rock board is primarily composed of approximately 70% calcite (calcium carbonate) and 30% engineered additives. This composition not only provides the aesthetic appeal of natural stone but also enhances durability and functionality. For B2B buyers, knowing the material composition is essential for assessing the product’s performance, maintenance needs, and suitability for specific applications.

2. Fire Resistance

Carbon rock board exhibits high resistance to fire, making it suitable for various environments, including commercial spaces where safety is paramount. This property is particularly important for industries such as hospitality and healthcare, where compliance with fire safety regulations is mandatory. Buyers should prioritize materials with proven fire resistance to reduce potential liabilities.

3. Moisture and Chemical Resistance

The moisture resistance of carbon rock board is a significant advantage, especially in areas prone to humidity like kitchens and bathrooms. Additionally, its resistance to chemicals ensures longevity in high-traffic environments. This property is vital for B2B buyers in sectors like healthcare and hospitality, where hygiene and maintenance play a critical role in the decision-making process.

4. Installation Efficiency

Carbon rock boards are designed for quick and straightforward installation, with the ability to cover large areas efficiently. This feature translates to reduced labor costs and project timelines, making it an attractive option for contractors and builders. Understanding installation efficiency can help businesses optimize their renovation schedules and budgets.

5. Environmental Impact

The eco-friendly nature of carbon rock board is an essential consideration for modern buyers. Being recyclable and free from harmful substances, it aligns with sustainability goals. Companies prioritizing sustainable materials can leverage this property to enhance their brand image and appeal to environmentally conscious consumers.

What Are Common Trade Terms Associated with Carbon Rock Board?

Familiarity with industry jargon can streamline communication and transactions for B2B buyers. Here are several essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are marketed under another company’s brand. In the context of carbon rock board, understanding OEM relationships can help buyers navigate sourcing and branding options effectively.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. For carbon rock board, knowing the MOQ is crucial for budgeting and inventory management. It helps businesses plan their purchasing strategies and avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Buyers should utilize RFQs to gather competitive quotes for carbon rock board, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are standard trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for international B2B transactions, as they clarify costs and responsibilities, helping to avoid disputes.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. For B2B buyers of carbon rock board, being aware of lead times can influence project timelines and planning. It’s essential to factor in lead time when scheduling installations or renovations.

6. Product Certification

Product certification indicates that the material meets specific industry standards for quality and safety. Buyers should seek products with relevant certifications to ensure compliance with local regulations and standards, enhancing their credibility in the market.

By understanding these key properties and trade terms, B2B buyers can make informed decisions regarding carbon rock board, ensuring they select the right products for their projects and business needs.

Navigating Market Dynamics and Sourcing Trends in the carbon rock board Sector

What Are the Key Trends and Market Dynamics in the Carbon Rock Board Sector?

The carbon rock board sector is experiencing significant growth, driven by increasing demand for cost-effective and environmentally friendly alternatives to traditional materials like natural marble. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly drawn to carbon rock panels due to their lightweight nature, ease of installation, and aesthetic appeal. The global market is witnessing a shift towards innovative sourcing solutions, including digital procurement platforms that enhance supply chain efficiency and transparency.

Emerging technologies, such as advanced manufacturing processes and eco-friendly materials, are reshaping the landscape. Buyers are prioritizing suppliers who can deliver high-quality products with quick turnaround times. Moreover, the rise of e-commerce in B2B sectors is facilitating easier access to carbon rock panels, enabling buyers to compare products and prices from various suppliers worldwide. This trend is particularly beneficial for buyers in developing regions, where local sourcing options may be limited.

Furthermore, the hospitality, retail, and healthcare industries are rapidly adopting carbon rock boards due to their durability and design versatility. As businesses strive for unique aesthetics in their spaces, the demand for customizable panels that mimic natural stone patterns is surging. This trend indicates a robust market potential for suppliers who can offer tailored solutions to meet diverse client needs.

How Does Sustainability Impact Sourcing in the Carbon Rock Board Sector?

Sustainability is a pivotal consideration for B2B buyers in the carbon rock board sector. As environmental awareness grows, companies are increasingly focusing on the ecological impact of their sourcing decisions. Carbon rock panels, made primarily from natural minerals and engineered additives, present a more sustainable option compared to traditional materials that often involve extensive quarrying and resource depletion.

Ethical sourcing is becoming non-negotiable for many businesses. Buyers are actively seeking suppliers who adhere to green certifications and demonstrate a commitment to sustainable practices. This includes sourcing raw materials responsibly, minimizing waste during production, and ensuring recyclability at the end of the product’s life cycle. Suppliers that can provide transparency regarding their supply chains and environmental impact are likely to gain a competitive edge.

Incorporating sustainable materials not only enhances a brand’s reputation but also aligns with the increasing regulatory pressures and consumer demand for eco-friendly products. Companies that prioritize sustainability in their sourcing strategies can effectively differentiate themselves in a crowded market, appealing to environmentally conscious clients across various sectors.

What Is the Historical Context of Carbon Rock Boards in B2B Markets?

The carbon rock board industry has evolved significantly over the past few decades. Initially emerging as a niche product, it has transitioned into a mainstream solution for interior design and construction. The introduction of advanced manufacturing technologies has allowed for the mass production of carbon rock panels, making them more accessible and affordable for international B2B buyers.

Historically, the market was dominated by natural stone products, which were often cost-prohibitive and required extensive maintenance. The innovation of carbon rock panels has provided a viable alternative that combines aesthetic appeal with practical advantages, such as lower weight and enhanced durability. As industries continue to embrace sustainable practices, the carbon rock board sector is poised for further growth, driven by advancements in technology and increasing consumer preferences for eco-friendly materials.

Frequently Asked Questions (FAQs) for B2B Buyers of carbon rock board

-

How do I ensure the quality of carbon rock panels before purchasing?

To ensure the quality of carbon rock panels, consider requesting samples from potential suppliers. Verify their certifications, including compliance with international standards for material safety and durability. Conduct a thorough supplier vetting process, examining their manufacturing practices, quality control measures, and customer reviews. Additionally, ask for references from other B2B buyers who have previously sourced from them to gain insights into their reliability and product quality. -

What are the primary applications of carbon rock panels in various industries?

Carbon rock panels are versatile and can be used in multiple industries. In interior design, they serve as decorative wall and ceiling materials. The hospitality sector utilizes them for creating inviting atmospheres in hotels and restaurants. They are also suitable for retail environments, providing a luxurious look for displays and countertops. Furthermore, their lightweight and durable nature makes them ideal for transportation applications, including buses and trains, as well as in healthcare settings for hygienic surfaces. -

What customization options are available for carbon rock panels?

Many manufacturers offer customization options for carbon rock panels, including different colors, patterns, and textures. Buyers can often specify their design preferences to match their branding or aesthetic requirements. Inquire about the possibility of creating unique designs through the supplier’s online design platform, which allows you to visualize and adjust your selections before finalizing the order. Customization may require a minimum order quantity (MOQ), so confirm these details with the supplier. -

What is the minimum order quantity (MOQ) for carbon rock panels?

The minimum order quantity (MOQ) for carbon rock panels can vary by supplier and is often influenced by production capabilities and material availability. Typically, MOQs range from a few hundred to several thousand square meters. When contacting suppliers, be clear about your project needs and ask about their flexibility regarding smaller orders, especially if you are testing the product for the first time or are a new buyer. -

What payment terms should I expect when sourcing carbon rock panels internationally?

Payment terms for international purchases of carbon rock panels may include options such as upfront payment, partial payment upon order confirmation, and the balance due prior to shipment. Common payment methods include bank transfers, letters of credit, or payment platforms like PayPal. Be sure to negotiate terms that suit your cash flow and financial practices, and confirm any applicable fees related to currency conversion or international transactions. -

How can I verify the supplier’s credibility in the carbon rock panel market?

To verify a supplier’s credibility, conduct thorough research, including checking their business registration, certifications, and industry reputation. Utilize platforms like Alibaba or Global Sources to read reviews and ratings from other buyers. Additionally, engage in direct communication with the supplier to assess their responsiveness and willingness to provide information. Asking for references and visiting their production facilities, if feasible, can also help establish trust. -

What logistics considerations should I keep in mind when importing carbon rock panels?

When importing carbon rock panels, consider logistics factors such as shipping methods, lead times, and customs regulations. Evaluate whether air freight or sea freight is more suitable for your needs based on urgency and budget. Ensure the supplier provides comprehensive shipping documentation to facilitate customs clearance. Also, be aware of potential tariffs or duties associated with importing materials into your country, particularly in regions like Africa, South America, and the Middle East. -

What are the key advantages of choosing carbon rock panels over traditional materials?

Carbon rock panels offer numerous advantages over traditional materials such as natural stone or PVC. They are lightweight, making them easier to handle and install, thus reducing labor costs. Their durability ensures resistance to moisture, fire, and chemicals, making them suitable for high-traffic or sensitive environments. Additionally, carbon rock panels are eco-friendly, as they are made from over 70% natural minerals and are recyclable, appealing to businesses looking to enhance their sustainability practices.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Carbon Rock Board Manufacturers & Suppliers List

1. Facebook – Carbon Rock Board for Kitchen Countertops

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: carbon rock board for kitchen countertops

2. Etsy – Carbon Rock Boards

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Carbon Rock Boards, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Accio – Carbon Rock Board for Bathroom

Domain: accio.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “Carbon Rock Board for Bathroom”, “Key Features”: [“Waterproof”, “Fireproof”, “Anti-slip surface”, “Mold resistant”, “Easy to install”, “High density”, “Thermal insulation”, “Soundproof”, “Scratch resistant”, “UV resistant”], “Unit Price Range”: “$0.98 – $1419”, “Minimum Order Quantity”: “< 5”, “Supplier Rating”: “4.5+”, “Customizable Attributes”: [“Width”, “Length”, “Surface Trea…

4. Stone Forensics – Carbon Rock Panels

Domain: stoneforensics.com

Registered: 2008 (17 years)

Introduction: Carbon rock panels are composite materials designed to emulate the natural elegance of stone. Key components include: 1. Polymer Resins – provide structural integrity and a durable, weather-resistant surface. 2. Carbon Fiber – offers exceptional strength-to-weight ratio, enhancing durability and resistance to external stresses. 3. Natural Stone Chips or Powder – integrated to replicate the aesthet…

5. Pinterest – Carbon Rock Board

Domain: ru.pinterest.com

Registered: 2009 (16 years)

Introduction: Carbon rock board in 2025 | Living room with fireplace, House rental, House design

6. Carbon Rock – Bamboo Board Face

Domain: fr.pinterest.com

Registered: 2009 (16 years)

Introduction: Carbon Rock Board Face | Bamboo board, Carbon, Crystals

Strategic Sourcing Conclusion and Outlook for carbon rock board

In conclusion, the strategic sourcing of carbon rock panels offers a multitude of benefits that can significantly enhance the value proposition for international B2B buyers. With their remarkable durability, aesthetic appeal, and eco-friendly composition, carbon rock panels represent a cost-effective alternative to traditional materials like natural marble. Their versatility across various industries—from hospitality to healthcare—ensures that these panels can meet diverse design and functional requirements, making them an ideal choice for projects in emerging markets across Africa, South America, the Middle East, and Europe.

As businesses seek innovative solutions to enhance their offerings, strategic sourcing of carbon rock panels not only reduces costs but also provides opportunities to elevate customer satisfaction through superior product quality and aesthetics. By leveraging advanced manufacturing techniques and sustainable materials, buyers can position themselves as leaders in their respective markets.

Now is the time for international buyers to explore the potential of carbon rock panels to transform their projects. Engaging with reliable suppliers and taking advantage of the unique properties of these panels can drive growth and innovation in your business. Embrace this opportunity to redefine your design approach and meet the evolving needs of your customers.