A Deep Dive into Capacitive Touch Panel Solution

Introduction: Navigating the Global Market for capacitive touch panel

In the rapidly evolving landscape of technology, sourcing high-quality capacitive touch panels can pose significant challenges for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe increasingly adopt advanced touch solutions for applications ranging from consumer electronics to industrial machinery, understanding the nuances of capacitive touch panel technology becomes essential. This guide offers a comprehensive overview of various types of capacitive touch panels, their applications, and critical factors for supplier vetting, enabling businesses to make informed purchasing decisions.

With a focus on key aspects such as cost analysis, technological specifications, and market trends, this resource empowers buyers to navigate the complexities of sourcing capacitive touch panels. By detailing the advantages of different panel technologies—including projected capacitive, multi-touch capabilities, and customizable options—this guide equips decision-makers with the insights needed to evaluate potential suppliers effectively. Furthermore, it addresses regional considerations and compliance requirements specific to markets like Nigeria and Germany, ensuring that buyers are well-prepared to engage with manufacturers and distributors.

Ultimately, this guide serves as a strategic tool, facilitating smarter investments in capacitive touch panel technology that drive operational efficiency and enhance user experiences across diverse applications.

Understanding capacitive touch panel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Projected Capacitive Touch | Utilizes a grid of electrodes for multi-touch support; high clarity and sensitivity | Consumer electronics, automotive displays | Pros: High resolution, no backlight needed; Cons: More expensive than other types. |

| Surface Capacitive Touch | Senses touch through the surface; typically supports single touch | Kiosks, ATMs, industrial controls | Pros: Durable and cost-effective; Cons: Limited multi-touch capability. |

| Mutual Capacitance Touch | Measures capacitance changes between multiple electrodes; supports multi-touch | Smartphones, tablets, industrial devices | Pros: Excellent for complex gestures; Cons: Can be sensitive to environmental factors. |

| Self-Capacitance Touch | Each electrode acts as an independent sensor; generally supports single touch | Home appliances, smart devices | Pros: Cost-effective for simple applications; Cons: Limited sensitivity and accuracy. |

| In-Cell Touch Technology | Integrates touch sensors directly into the display; thinner profile | Smartphones, tablets, wearables | Pros: Space-saving design, improved aesthetics; Cons: Repairing can be more complicated. |

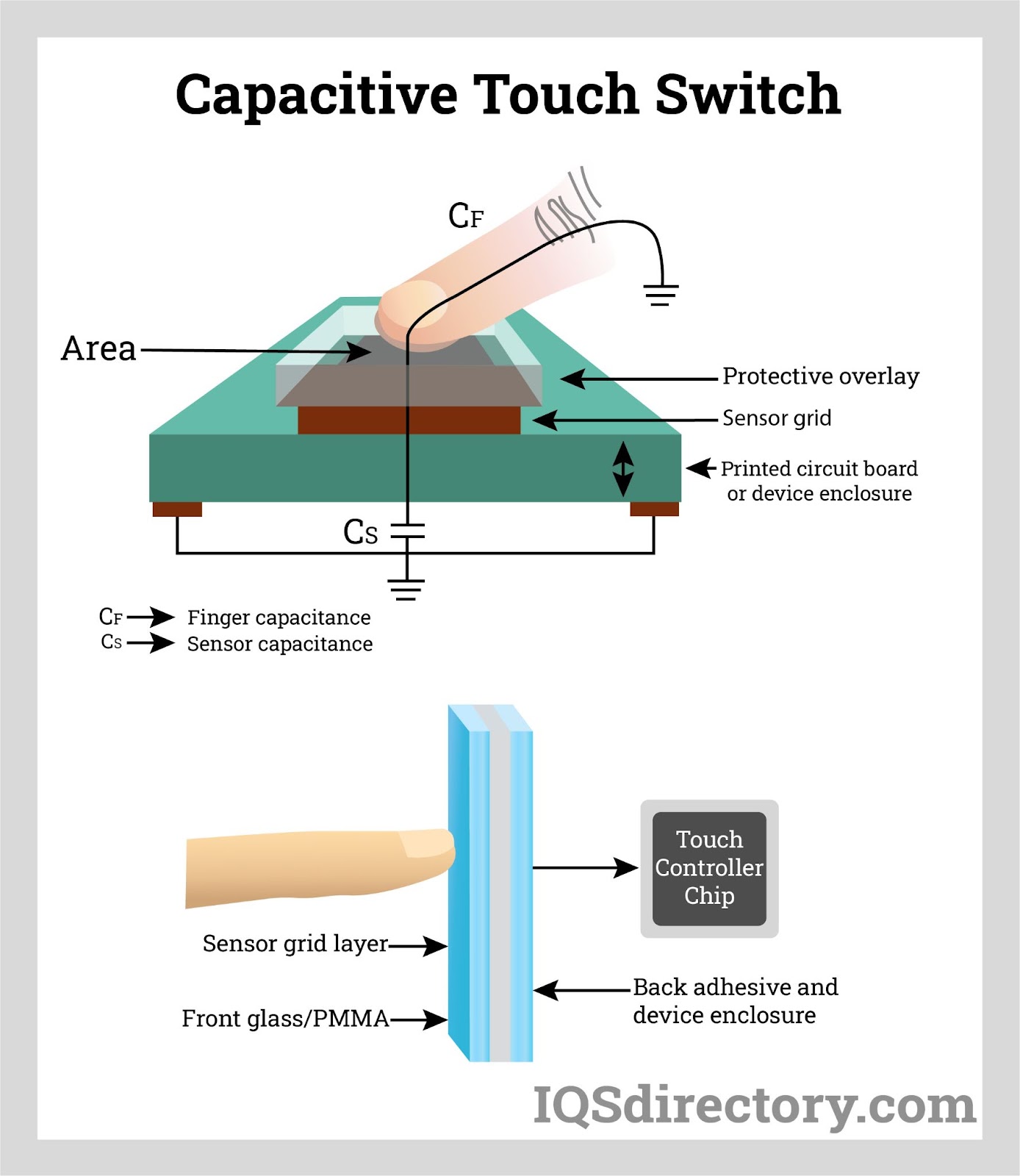

What are the Characteristics of Projected Capacitive Touch Panels?

Projected capacitive touch panels leverage a matrix of tiny electrodes beneath the glass surface, allowing for precise touch detection and multi-touch capabilities. This technology excels in environments where display clarity and responsiveness are critical, making it ideal for consumer electronics and automotive displays. B2B buyers should consider the higher costs associated with projected capacitive panels, but the benefits of durability and performance often justify the investment.

How Does Surface Capacitive Touch Technology Work?

Surface capacitive touch panels detect touch through a conductive layer on the screen’s surface. They are typically more durable and cost-effective, making them suitable for applications such as kiosks and ATMs. However, their limitation lies in supporting only single-touch interactions. Buyers should weigh the cost advantages against the functionality requirements of their applications when choosing this type.

What are the Benefits of Mutual Capacitance Touch Panels?

Mutual capacitance touch panels are designed to detect touch through the interaction of multiple electrodes, allowing for complex gestures and multi-touch capabilities. This makes them particularly effective for smartphones and tablets where user interaction is dynamic. While they offer superior functionality, B2B buyers must be aware of their sensitivity to environmental factors, which can affect performance.

Why Choose Self-Capacitance Touch Panels?

Self-capacitance touch panels operate by having each electrode act independently, typically supporting single touch interactions. They are often used in simpler applications like home appliances and smart devices due to their cost-effectiveness. However, buyers should note that while these panels are budget-friendly, they may not provide the same level of sensitivity and accuracy as other types, which could impact user experience.

What is In-Cell Touch Technology and Its Applications?

In-cell touch technology integrates touch sensors directly within the display panel, resulting in a thinner and more aesthetically pleasing design. This technology is commonly found in smartphones, tablets, and wearables. While it offers significant space-saving advantages, the complexity of repairs can be a drawback. B2B purchasers should consider the long-term maintenance implications alongside the initial benefits when selecting in-cell touch solutions for their products.

Key Industrial Applications of capacitive touch panel

| Industry/Sector | Specific Application of capacitive touch panel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | In-vehicle infotainment systems | Enhanced user experience and safety | Durability, multi-touch capabilities, and responsiveness in various environments |

| Consumer Electronics | Smartphones and tablets | High clarity and responsiveness | Compatibility with existing devices and ease of integration |

| Industrial Automation | Control panels for machinery and robotics | Improved operational efficiency and safety | Customization options for different environments and interfaces |

| Home Appliances | Smart home devices (thermostats, security systems) | User-friendly interfaces and energy savings | Resistance to environmental factors and integration with IoT systems |

| Healthcare | Medical devices (patient monitors, diagnostic tools) | Accurate and quick data input | Compliance with health regulations and ease of cleaning |

How Are Capacitive Touch Panels Used in the Automotive Industry?

In the automotive sector, capacitive touch panels are integral to in-vehicle infotainment systems, allowing drivers and passengers to interact seamlessly with navigation, music, and communication features. These panels solve issues related to user interface complexity and improve safety by enabling hands-free operations. Buyers in this sector must prioritize durability to withstand vibrations and temperature fluctuations, alongside multi-touch capabilities for enhanced functionality.

What Role Do Capacitive Touch Panels Play in Consumer Electronics?

Capacitive touch panels are widely used in smartphones and tablets, providing users with an intuitive and responsive interface. They address the challenge of precision in user interactions, ensuring high clarity and minimal lag. For international buyers, especially in regions like Africa and Europe, sourcing panels that are compatible with various devices and have robust supply chains is crucial to meet consumer demand and maintain competitive advantage.

Illustrative image related to capacitive touch panel

How Are Capacitive Touch Panels Transforming Industrial Automation?

In industrial automation, capacitive touch panels are utilized in control systems for machinery and robotics, enabling operators to manage complex processes with ease. These panels enhance operational efficiency by providing a clear and responsive interface for real-time monitoring and adjustments. Buyers in this space should consider customization options that cater to specific machinery requirements and ensure that panels are resilient in challenging industrial environments.

Why Are Capacitive Touch Panels Essential for Home Appliances?

Capacitive touch panels are increasingly found in smart home devices, such as thermostats and security systems, where user-friendly interfaces are critical. They facilitate intuitive control, allowing users to manage energy consumption effectively. Buyers should focus on sourcing panels that are resistant to environmental factors, such as humidity and temperature variations, to ensure long-term functionality and integration with IoT systems.

How Do Capacitive Touch Panels Enhance Healthcare Applications?

In the healthcare industry, capacitive touch panels are employed in medical devices like patient monitors and diagnostic tools, allowing for quick and accurate data input. These panels address the need for precision in critical situations where time is of the essence. Buyers must ensure that the panels comply with health regulations and are easy to clean, as hygiene is paramount in medical environments.

3 Common User Pain Points for ‘capacitive touch panel’ & Their Solutions

Scenario 1: Difficulty with Multitouch Functionality in Industrial Applications

The Problem: Many B2B buyers in industrial sectors face challenges with the multitouch capabilities of capacitive touch panels. For instance, in a manufacturing plant where operators need to use both hands for equipment control while simultaneously interacting with a touchscreen, a lack of reliable multitouch functionality can lead to operational delays and safety risks. The problem is exacerbated in environments where workers may wear gloves or have wet hands, which can interfere with the touch sensitivity of standard capacitive panels.

The Solution: To address this issue, buyers should prioritize sourcing capacitive touch panels specifically designed for multitouch applications. When selecting a panel, ensure it supports advanced touch technologies that can recognize multiple touch points accurately even under challenging conditions. Consider panels that are engineered for use with gloves or those that support stylus input. It’s also advisable to conduct thorough testing of the panels in real-world conditions prior to purchase, ensuring they perform as expected in the specific environment. Partnering with manufacturers who offer customizable solutions can also provide the necessary adjustments for enhanced functionality tailored to your operational needs.

Scenario 2: Screen Durability Concerns in Harsh Environments

The Problem: Buyers in sectors such as construction, agriculture, or outdoor retail often encounter issues related to the durability of capacitive touch panels. Exposure to dust, moisture, and extreme temperatures can compromise the screen’s integrity and functionality. A cracked or malfunctioning screen not only disrupts operations but can also lead to costly downtime and repairs, as well as safety hazards if users are unable to interact with essential equipment or information.

The Solution: To mitigate durability concerns, it’s crucial to source capacitive touch panels that are built to withstand harsh environmental conditions. Look for panels with protective features such as anti-glare, anti-fingerprint, and anti-scratch coatings, as well as those certified for water and dust resistance (e.g., IP67 or higher). Additionally, consider panels made from robust materials like Gorilla Glass or chemically strengthened glass to enhance impact resistance. Working closely with suppliers who specialize in ruggedized touch technology can provide insights into the best options available for your specific application, ensuring the longevity and reliability of your devices.

Scenario 3: Integration Issues with Legacy Systems

The Problem: Many businesses, particularly in the Middle East and Africa, still rely on legacy systems that may not seamlessly integrate with newer capacitive touch technology. This can lead to significant complications, including compatibility issues and the need for costly modifications to existing hardware and software. Buyers may find that their new touch panels do not communicate effectively with older machinery or software platforms, resulting in operational inefficiencies and increased labor costs.

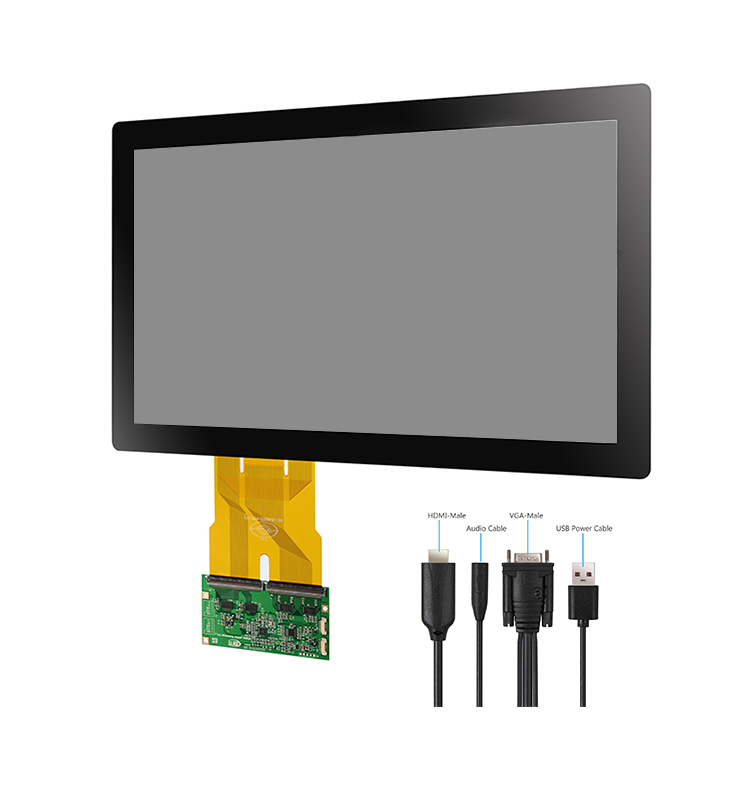

Illustrative image related to capacitive touch panel

The Solution: To tackle integration challenges, it is essential to conduct a comprehensive assessment of existing systems before selecting a capacitive touch panel. Engage with suppliers who understand both the new technologies and the legacy systems in use. When sourcing a touch panel, inquire about compatibility with existing interfaces, such as USB, RS-232, or other protocols. It may be beneficial to choose panels that offer customizable firmware or APIs that facilitate easier integration with older systems. Additionally, consider investing in a phased approach to technology upgrades, which allows for gradual integration and testing without disrupting ongoing operations. By ensuring compatibility and planning for future upgrades, businesses can minimize risks and maximize the return on their investment in new technology.

Strategic Material Selection Guide for capacitive touch panel

What Are the Key Materials Used in Capacitive Touch Panels?

Capacitive touch panels are integral to modern electronic devices, and their performance heavily relies on the materials used in their construction. Understanding the properties, advantages, and limitations of these materials is crucial for B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in capacitive touch panels: Glass, Polyethylene Terephthalate (PET), Polycarbonate (PC), and Indium Tin Oxide (ITO).

How Does Glass Impact the Performance of Capacitive Touch Panels?

Key Properties: Glass is known for its excellent optical clarity and scratch resistance, making it a popular choice for touch panels. It typically has a high temperature rating, can withstand significant pressure, and is resistant to various chemicals.

Pros & Cons: The primary advantage of glass is its durability and premium feel, which enhances user experience. However, glass is heavier and more fragile than other materials, increasing the risk of breakage during handling and installation. Additionally, the manufacturing process can be complex and costly.

Impact on Application: Glass panels are compatible with a wide range of media, including styluses and gloved hands, making them versatile for various applications. They are particularly suitable for high-end consumer electronics.

Considerations for International Buyers: Buyers should ensure compliance with international safety standards, such as ASTM and DIN, especially in regions where safety regulations are stringent, like Germany. Glass panels may also require additional coatings for anti-reflective or anti-glare properties, which can influence cost.

What Role Does PET Play in Capacitive Touch Panel Manufacturing?

Key Properties: PET is a lightweight, flexible material that offers good optical clarity and is resistant to moisture and chemicals. It has a moderate temperature rating and can endure some level of pressure.

Pros & Cons: The flexibility of PET allows for thinner designs, making it ideal for applications where space is a constraint. However, it is less scratch-resistant than glass and may not provide the same premium feel, which could affect market perception.

Impact on Application: PET is suitable for applications where weight and flexibility are more critical than durability, such as in portable devices. Its compatibility with various touch technologies makes it a versatile choice.

Illustrative image related to capacitive touch panel

Considerations for International Buyers: Buyers should be aware of the varying quality of PET materials available globally. Compliance with standards such as JIS can help ensure product reliability, particularly in regions with less stringent regulations.

Why Choose Polycarbonate for Capacitive Touch Panels?

Key Properties: Polycarbonate is known for its high impact resistance and lightweight nature. It has a good temperature rating and can withstand significant pressure without breaking.

Pros & Cons: The primary advantage of polycarbonate is its durability, making it ideal for rugged applications. However, it is more prone to scratching than glass and may require additional coatings to improve its surface hardness.

Impact on Application: Polycarbonate is often used in industrial settings and applications where durability is paramount, such as automotive displays. It can also be used in environments where safety is a concern due to its shatter-resistant properties.

Illustrative image related to capacitive touch panel

Considerations for International Buyers: B2B buyers should ensure that polycarbonate panels meet international safety and quality standards, particularly in the automotive sector, where compliance with rigorous regulations is essential.

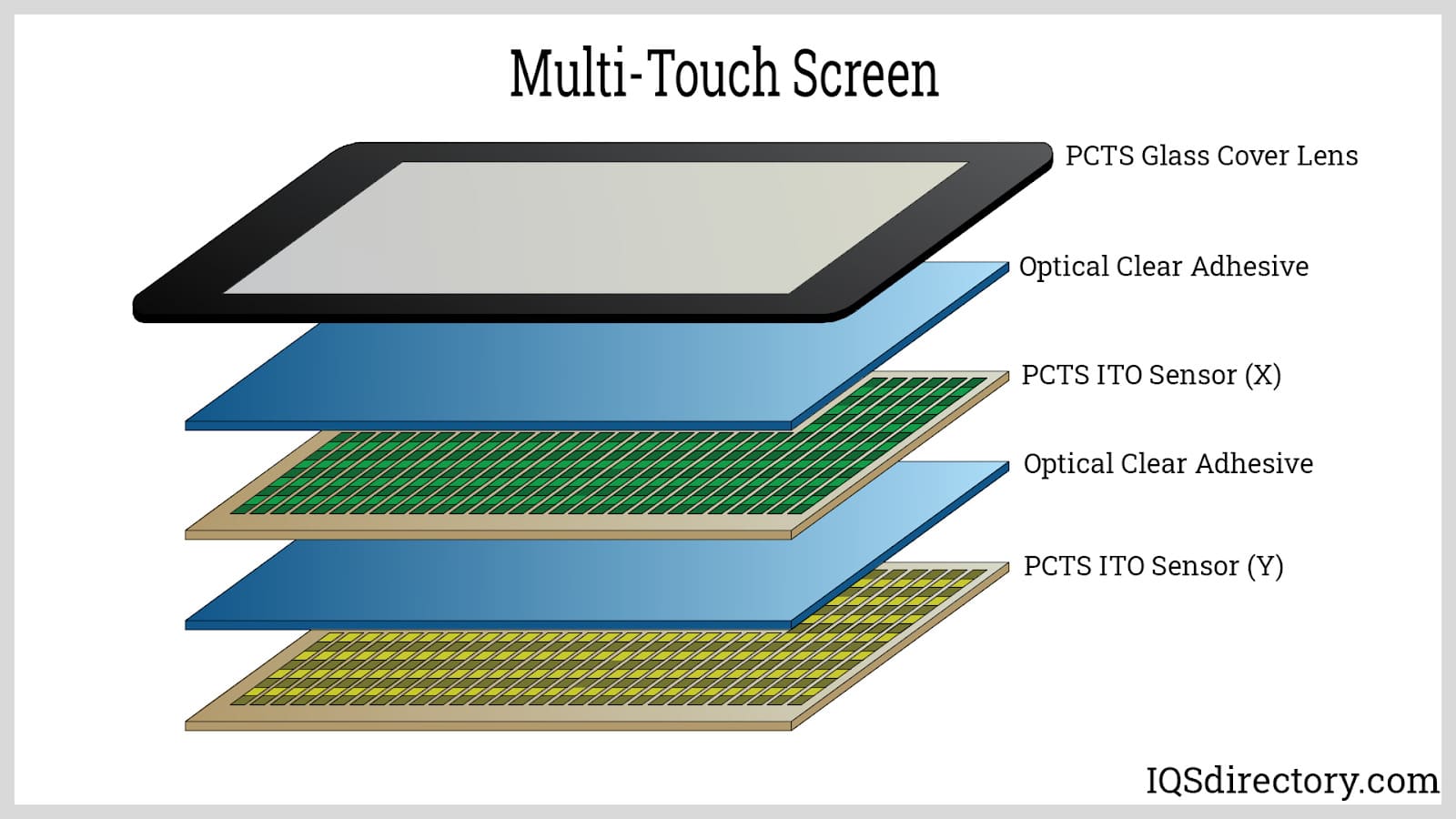

What Is the Importance of ITO in Capacitive Touch Panels?

Key Properties: Indium Tin Oxide (ITO) is a transparent conductive material that allows for touch sensitivity while maintaining optical clarity. It has a high conductivity rating and is compatible with various substrates.

Pros & Cons: ITO provides excellent performance in terms of touch sensitivity and clarity. However, it is brittle and can be expensive, impacting overall production costs.

Impact on Application: ITO is critical for applications requiring high transparency and touch sensitivity, such as smartphones and tablets. Its performance is vital for multitouch capabilities.

Considerations for International Buyers: Buyers should consider the sourcing of ITO, as it is a limited resource. Compliance with environmental regulations regarding the use of indium is also crucial, especially in Europe.

Summary of Material Selection for Capacitive Touch Panels

| Material | Typical Use Case for capacitive touch panel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | High-end consumer electronics | Excellent durability and clarity | Heavy and fragile | High |

| Polyethylene Terephthalate (PET) | Portable devices | Lightweight and flexible | Less scratch-resistant | Medium |

| Polycarbonate | Industrial and automotive displays | High impact resistance | Prone to scratching | Medium |

| Indium Tin Oxide (ITO) | Smartphones and tablets | High transparency and conductivity | Brittle and expensive | High |

By understanding these materials and their respective advantages and limitations, B2B buyers can make informed decisions that align with their product requirements and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for capacitive touch panel

What Are the Main Stages in the Manufacturing Process of Capacitive Touch Panels?

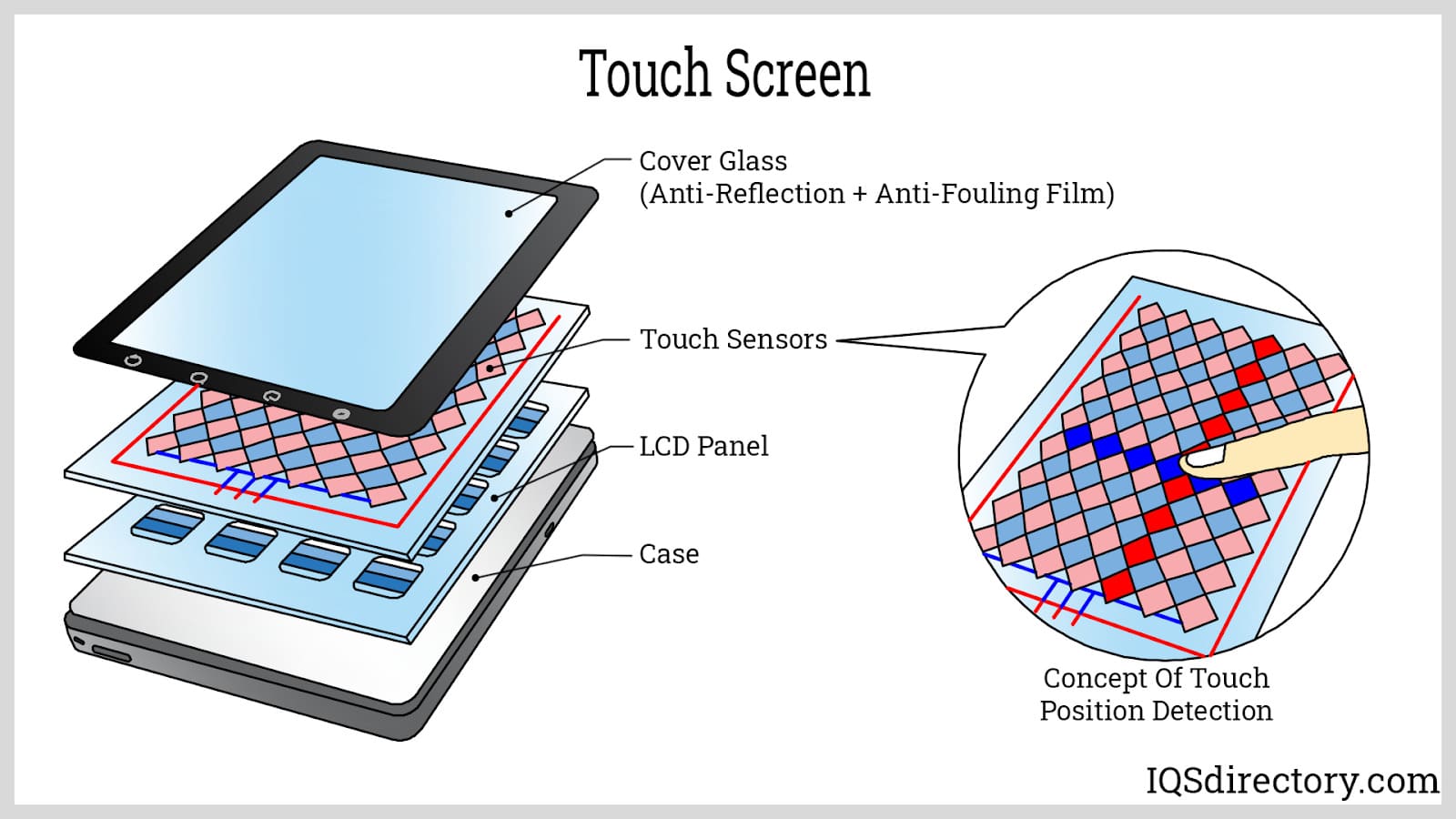

The manufacturing process of capacitive touch panels involves several critical stages, each designed to ensure high-quality output. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing and preparing raw materials, which typically include glass substrates, conductive materials (like Indium Tin Oxide), and adhesives. Quality assurance starts here; suppliers must meet stringent standards to ensure material integrity. For B2B buyers, it’s essential to inquire about the sourcing practices and certifications of these materials to avoid issues down the line.

-

Forming: During this phase, the prepared materials are shaped and structured. The glass is cut to specific dimensions, and the conductive layer is applied using techniques such as sputtering or chemical vapor deposition. The goal is to create a uniform and precise capacitive layer that can effectively detect touch inputs. Buyers should look for manufacturers that utilize advanced technologies like projected capacitive touch technology, which enhances responsiveness and accuracy.

-

Assembly: This stage involves integrating the touch-sensitive layer with other components, such as the LCD display. The assembly is often done in a clean room environment to prevent contamination. B2B buyers should ensure that manufacturers follow strict protocols during this phase, as any dust or debris can lead to malfunctioning panels.

-

Finishing: The final stage includes testing the assembled panels and applying any additional coatings, such as anti-glare or anti-fingerprint finishes. This is also when quality control checks are critical, ensuring that each panel meets the required specifications before leaving the factory.

What Quality Assurance Measures Are Important for Capacitive Touch Panels?

Quality assurance (QA) in the manufacturing of capacitive touch panels is multi-faceted, with various international and industry-specific standards guiding the process. Understanding these measures is crucial for B2B buyers to ensure they are partnering with reliable suppliers.

-

International Standards: The ISO 9001 standard is a cornerstone of quality management systems across industries, including electronics. Compliance with this standard indicates that a manufacturer has implemented effective processes to enhance customer satisfaction and maintain consistent quality. Additionally, certifications like ISO/IATF 16949 are essential for manufacturers supplying automotive touch panels.

-

Industry-Specific Certifications: Depending on the application, other certifications may be required. For instance, CE marking is necessary for products sold in Europe, indicating compliance with health, safety, and environmental protection standards. Buyers should inquire about these certifications to ensure the products meet necessary regulatory requirements.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integral to the manufacturing process, with specific checkpoints established to catch defects early and ensure the final product meets quality standards.

-

Incoming Quality Control (IQC): This initial QC step focuses on inspecting raw materials and components before they are used in production. It’s essential for B2B buyers to understand how suppliers perform IQC and what criteria they use to accept or reject materials.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks are conducted to monitor production efficiency and product quality. This might include measurements of capacitance and touch sensitivity. Regular reporting from suppliers regarding their IPQC findings can help buyers gain insights into the manufacturing process.

-

Final Quality Control (FQC): The last checkpoint occurs before shipping, where finished products are thoroughly tested for functionality, durability, and compliance with specifications. Common testing methods include touch sensitivity tests, environmental stress tests, and visual inspections. Buyers should request detailed FQC reports to understand the reliability of the products they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is vital to ensure product reliability.

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their quality control processes. These audits can be performed by the buyer’s internal team or through third-party inspection services. Audits should evaluate compliance with international standards and the effectiveness of QC checkpoints.

-

Quality Reports: Requesting documentation related to IQC, IPQC, and FQC can help buyers assess a supplier’s commitment to quality. These reports should detail testing methods, results, and any corrective actions taken in response to identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality assurance practices. These inspectors can evaluate the manufacturing process, material quality, and final products, offering detailed reports that can inform purchasing decisions.

What Quality Control Nuances Should International Buyers Be Aware Of?

International B2B buyers must navigate various nuances related to quality control when sourcing capacitive touch panels from manufacturers in different regions.

-

Regional Standards: Each market may have different regulatory requirements that affect product quality and safety. For instance, products sold in the European market must comply with CE regulations, while products in the U.S. may need to meet FCC standards. Buyers should be well-versed in these regulations to ensure compliance.

-

Cultural Differences: Cultural attitudes towards quality can vary significantly between regions. Buyers should be prepared to engage in discussions about quality expectations and the importance of adherence to standards in the local context.

-

Communication: Clear communication regarding quality expectations is essential. B2B buyers should establish open lines of communication with suppliers to discuss quality control processes, expectations, and any potential challenges that may arise during manufacturing.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing capacitive touch panels, ensuring they select reliable suppliers that meet their quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘capacitive touch panel’

In the dynamic landscape of technology, sourcing a capacitive touch panel requires careful consideration and strategic planning. This guide provides B2B buyers with a practical checklist to ensure they make informed decisions that align with their business needs.

Step 1: Define Your Technical Specifications

Begin by outlining the technical requirements for the capacitive touch panel. Consider factors such as size, resolution, multi-touch capabilities, and environmental conditions (e.g., outdoor usage). Clearly defining these specifications helps streamline the procurement process and ensures that the selected panel meets your operational needs.

Step 2: Research Market Trends and Innovations

Stay updated on the latest advancements in capacitive touch technology. Understanding market trends, such as projected capacitive touchscreens and their applications, can provide insights into which features are becoming standard and which innovations may offer a competitive edge. This knowledge will inform your purchasing decisions and help you identify suppliers who are at the forefront of technology.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, product catalogs, and case studies relevant to your industry. Look for suppliers with a proven track record in manufacturing capacitive touch panels and check their references to ensure reliability and quality.

- Key considerations:

- Supplier certifications (e.g., ISO9001, IATF16949) that ensure quality management.

- Their experience in your specific application area, whether automotive, consumer electronics, or industrial.

Step 4: Request Samples for Testing

Once you have narrowed down your supplier options, request samples of the capacitive touch panels. Testing these samples in real-world scenarios will allow you to evaluate their performance, durability, and user experience. Pay attention to factors like responsiveness, clarity, and ease of use, which are critical for end-user satisfaction.

Step 5: Verify Compliance with Industry Standards

Ensure that the capacitive touch panels comply with relevant industry standards and regulations. This is particularly important if your applications involve sensitive data or are subject to stringent safety requirements. Compliance not only ensures product quality but also protects your business from potential liabilities.

Illustrative image related to capacitive touch panel

Step 6: Consider Customization Options

Discuss customization possibilities with your shortlisted suppliers. Many manufacturers offer tailored solutions that can meet specific project requirements, such as unique form factors or specialized coatings (e.g., anti-glare or anti-fingerprint). Customization can enhance the functionality and aesthetics of the touch panel, making it better suited to your applications.

Step 7: Negotiate Terms and Establish Clear Communication

Once you have selected a supplier, negotiate terms that are favorable for both parties. Ensure clarity on pricing, lead times, payment terms, and after-sales support. Establishing open lines of communication with your supplier will facilitate smoother transactions and foster a strong partnership.

By following this checklist, B2B buyers can navigate the complexities of sourcing capacitive touch panels with confidence, ensuring they select products that enhance their technological offerings and meet their specific business needs.

Comprehensive Cost and Pricing Analysis for capacitive touch panel Sourcing

What Are the Key Cost Components for Capacitive Touch Panels?

When sourcing capacitive touch panels, understanding the cost structure is crucial for international buyers. The main cost components include:

-

Materials: The primary materials for capacitive touch panels include glass substrates, conductive coatings, and touch sensor components. The choice of materials significantly affects the overall cost, with higher-quality materials typically resulting in better performance and durability.

-

Labor: Labor costs vary by region and manufacturing practices. In regions with lower labor costs, such as parts of Asia, manufacturing expenses can be minimized. However, skilled labor is essential for quality assurance and maintaining production standards.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient production processes can help reduce overhead, which is critical for keeping prices competitive.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. This includes the investment in molds and dies necessary for the production of specific panel sizes and shapes.

-

Quality Control (QC): Ensuring that capacitive touch panels meet international quality standards incurs additional costs. Rigorous testing and certification processes are vital, especially for applications in critical industries such as automotive and medical devices.

-

Logistics: Shipping and handling costs can vary significantly based on the destination and chosen Incoterms. International shipping may involve customs duties and taxes, impacting the total landed cost of the panels.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can fluctuate based on market demand and competition.

How Do Pricing Influencers Affect Capacitive Touch Panel Costs?

Several factors influence the pricing of capacitive touch panels:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Many suppliers offer tiered pricing based on Minimum Order Quantities (MOQs), incentivizing bulk purchases.

-

Specifications and Customization: Custom features, such as size, sensitivity, and durability, can drive up costs. Buyers should be clear about their requirements to avoid unnecessary expenses.

-

Materials: The quality and type of materials chosen can significantly influence the final price. For instance, panels using Gorilla Glass may be more expensive than those made from standard glass.

-

Quality and Certifications: Products that comply with international quality standards (e.g., ISO certifications) typically command higher prices due to the additional costs associated with maintaining these certifications.

-

Supplier Factors: The reputation and reliability of the supplier play a role in pricing. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects the total cost of acquisition. Understanding these terms can help buyers manage risks and logistics more effectively.

What Buyer Tips Can Help Optimize Costs?

To navigate the complexities of sourcing capacitive touch panels, consider the following tips:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage your purchasing power to negotiate better terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as durability, warranty, and maintenance costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and shipping costs when sourcing from different regions. This awareness can help in budgeting and financial planning.

-

Supplier Diversity: Consider sourcing from multiple suppliers to mitigate risks and gain competitive pricing. This approach can also enhance supply chain resilience.

-

Quality Assurance: Invest in quality checks to avoid costly returns or failures in the field, which can significantly impact overall project costs.

Disclaimer on Indicative Prices

Pricing for capacitive touch panels can vary widely based on the factors discussed. It is essential for buyers to seek quotes directly from suppliers and consider their specific needs and circumstances when evaluating costs.

Alternatives Analysis: Comparing capacitive touch panel With Other Solutions

Exploring Alternatives to Capacitive Touch Panels

In the quest for effective touch interface solutions, capacitive touch panels stand out for their responsiveness and clarity. However, businesses often seek alternatives that may better meet their specific needs, be it in terms of cost, performance, or application context. This analysis compares capacitive touch panels with two viable alternatives: resistive touch panels and infrared touch screens.

| Comparison Aspect | Capacitive Touch Panel | Resistive Touch Panel | Infrared Touch Screen |

|---|---|---|---|

| Performance | High sensitivity, supports multitouch | Moderate sensitivity, single touch | High sensitivity, supports multitouch |

| Cost | Generally higher due to technology | Lower initial cost | Higher due to complex setup |

| Ease of Implementation | Requires specialized components | Simple integration | Requires more complex installation |

| Maintenance | Low maintenance, durable | Moderate maintenance, prone to wear | Low maintenance, durable |

| Best Use Case | Smartphones, tablets, high-end applications | Industrial, medical devices | Kiosks, large displays |

What Are the Advantages and Disadvantages of Resistive Touch Panels?

Resistive touch panels operate by sensing pressure applied to the screen. This technology is often more cost-effective than capacitive options, making it attractive for industries with tight budgets. They perform well in industrial settings, where users may wear gloves or use styluses. However, resistive panels typically have lower clarity and sensitivity, which can hinder user experience in applications requiring fast, accurate inputs. Their susceptibility to wear and tear also necessitates more frequent maintenance.

Why Choose Infrared Touch Screens Over Capacitive Touch Panels?

Infrared touch screens utilize an array of infrared light beams to detect touch, allowing for high sensitivity and multitouch capabilities. They are particularly well-suited for large displays and kiosk applications where durability is key. Infrared systems are not affected by environmental factors like temperature or moisture, making them ideal for outdoor settings. However, their higher costs and more complex installation process can deter some buyers, especially in markets where budget constraints are significant.

Illustrative image related to capacitive touch panel

How Can B2B Buyers Make Informed Decisions on Touch Panel Solutions?

When selecting a touch panel solution, B2B buyers should assess their specific requirements against the strengths and weaknesses of each technology. Capacitive touch panels offer superior clarity and responsiveness for consumer electronics and high-end applications, but may not be the best choice for environments where cost or durability is a primary concern. Resistive panels can provide a budget-friendly alternative in industrial applications, while infrared screens are excellent for interactive kiosks and outdoor use.

Ultimately, understanding the unique operational needs, environmental conditions, and budget constraints will guide buyers toward the most suitable touch panel technology for their applications.

Essential Technical Properties and Trade Terminology for capacitive touch panel

What Are the Key Technical Properties of Capacitive Touch Panels?

When evaluating capacitive touch panels, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that significantly impact performance and application suitability:

1. Material Composition

Capacitive touch panels are typically made of glass or plastic, with options for chemically strengthened materials like Gorilla Glass. The choice of material affects durability, scratch resistance, and overall tactile experience. For B2B buyers, selecting the right material is vital for ensuring the panel meets the operational demands of various environments, such as industrial or outdoor settings.

2. Touch Sensitivity

This property refers to how responsive the touch panel is to input. Capacitive touch panels can vary in sensitivity, accommodating different touch methods, including bare fingers, gloves, or styluses. For businesses, understanding touch sensitivity is essential to ensure user satisfaction and functionality, particularly in applications requiring precision, such as medical devices or automotive controls.

Illustrative image related to capacitive touch panel

3. Multi-Touch Capability

Multi-touch technology allows multiple points of contact on the screen simultaneously, enabling complex gestures and interactions. This is particularly important in applications like interactive kiosks and gaming devices. For B2B buyers, ensuring that the touch panel supports the necessary multi-touch features can enhance user engagement and operational efficiency.

4. Optical Clarity and Coating

The optical clarity of a capacitive touch panel affects the visibility of the display under various lighting conditions. Anti-reflective (AR) and anti-glare (AG) coatings can improve visibility and reduce fingerprints. This is particularly significant for devices used in bright environments, like outdoor displays. Buyers should prioritize panels with the appropriate coatings to enhance user experience.

5. Durability Ratings

Durability is often specified through ratings like IP (Ingress Protection) or MIL-STD (Military Standard). These ratings indicate resistance to dust, water, and mechanical shocks. For companies operating in harsh conditions, such as construction or marine environments, selecting a panel with suitable durability ratings is crucial for long-term performance.

6. Interface Compatibility

Capacitive touch panels can feature various interface types, such as MIPI or I2C, which determine how they connect to other devices. Understanding interface compatibility is essential for seamless integration into existing systems. B2B buyers must assess their device’s interface requirements to ensure proper functionality.

What Are Common Trade Terms Related to Capacitive Touch Panels?

Navigating the purchasing landscape for capacitive touch panels involves familiarizing oneself with industry jargon. Here are some key terms that every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of touch panels, buyers often source from OEMs to ensure product quality and compatibility. Understanding OEM relationships can help buyers secure reliable suppliers.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell in a single order. This term is crucial for B2B buyers, as it impacts inventory management and cash flow. Knowing the MOQ allows companies to plan their purchases more effectively.

Illustrative image related to capacitive touch panel

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products. For capacitive touch panels, submitting an RFQ can help buyers compare prices and options across different vendors, ensuring they get the best value.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. They determine who pays for shipping, insurance, and tariffs. For international buyers, understanding Incoterms is essential for managing logistical costs and responsibilities effectively.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the touch panel industry, lead times can vary based on customization and production schedules. Buyers should factor lead time into their project timelines to avoid delays.

6. Customization Options

Customization options refer to the ability to modify standard touch panel specifications to meet specific needs, such as size, shape, or functionality. Understanding available customization can help businesses tailor products to their unique applications, enhancing performance and user experience.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing capacitive touch panels, ensuring they select products that align with their operational needs and market requirements.

Navigating Market Dynamics and Sourcing Trends in the capacitive touch panel Sector

What Are the Current Market Dynamics and Key Trends in the Capacitive Touch Panel Sector?

The global capacitive touch panel market is witnessing robust growth, driven by the increasing demand for advanced user interfaces across a multitude of sectors, including consumer electronics, automotive, and industrial applications. Key trends include the shift towards projected capacitive touch technology, which offers superior sensitivity and multi-touch capabilities. This technology allows for thinner displays, making it an attractive option for manufacturers looking to enhance product aesthetics and functionality. Additionally, the rise of smart devices and IoT applications is propelling the demand for capacitive touch panels, particularly in regions like Africa, South America, the Middle East, and Europe.

International B2B buyers should note the growing preference for customized solutions tailored to specific applications, such as automotive interfaces and industrial controls. With manufacturers increasingly offering varied touch panel sizes and functionalities, sourcing strategies must adapt to accommodate these diverse offerings. Companies are also focusing on integrating touch panels with other technologies, such as OLED displays, to provide a more comprehensive solution. The competitive landscape is further influenced by regional manufacturers emerging from markets like China, which are providing high-quality products at lower prices, thus intensifying competition.

How Can Sustainability and Ethical Sourcing Impact Capacitive Touch Panel Procurement?

Sustainability is becoming a critical consideration in the capacitive touch panel sector, particularly as global awareness around environmental issues grows. B2B buyers should be aware of the environmental impacts associated with the production and disposal of electronic components, including capacitive touch panels. Sourcing from manufacturers that prioritize sustainable practices can mitigate these impacts.

Ethical supply chains are increasingly important, with businesses seeking partners who comply with international labor standards and environmental regulations. Certifications such as ISO14001 for environmental management and adherence to the REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations can serve as indicators of a supplier’s commitment to ethical practices. Furthermore, the adoption of ‘green’ materials, such as recyclable substrates and low-impact manufacturing processes, can enhance a company’s sustainability profile. By aligning procurement strategies with sustainable practices, B2B buyers can not only reduce their environmental footprint but also appeal to eco-conscious consumers.

What Is the Brief Evolution and History of Capacitive Touch Panels?

The evolution of capacitive touch panels began in the 1970s with the introduction of the first resistive touch screens. Capacitive technology emerged as a superior alternative, leveraging the electrical properties of the human body to detect touch, thereby providing greater precision and multi-touch capabilities. The 2000s saw rapid advancements in capacitive touch technology, particularly with the introduction of smartphones, which popularized its use in consumer electronics.

By the 2010s, projected capacitive touch screens became the industry standard, enabling thinner displays and enhancing user interaction. The automotive sector also began to adopt capacitive technology, leading to innovations in in-vehicle interfaces. Today, capacitive touch panels are integral to various applications, from consumer gadgets to industrial machinery, reflecting their versatility and adaptability to evolving market demands. As technology continues to advance, the capacitive touch panel sector is poised for further growth and innovation, making it a key area for international B2B buyers to monitor.

Frequently Asked Questions (FAQs) for B2B Buyers of capacitive touch panel

-

How do I solve issues with capacitive touch panel responsiveness?

To address responsiveness issues with capacitive touch panels, ensure that the device is clean and free from any obstructions such as dust or moisture, which can interfere with touch sensitivity. If the panel is integrated into a device, check for software updates that might enhance performance. Additionally, consider the environmental conditions; extreme temperatures or humidity can affect performance. If problems persist, consult with your supplier about potential hardware adjustments or upgrades to a more advanced touch technology. -

What is the best capacitive touch panel for outdoor use?

For outdoor applications, look for capacitive touch panels with high brightness levels and anti-reflective coatings to ensure visibility in direct sunlight. Projected capacitive touchscreens are ideal as they offer greater durability and can function effectively even when the user is wearing gloves. Additionally, panels designed to withstand environmental stressors, such as water resistance and temperature extremes, are essential for outdoor settings. Suppliers may offer customization options to meet specific outdoor requirements. -

What customization options are available for capacitive touch panels?

Customization options for capacitive touch panels include various touch technologies (e.g., single touch, multi-touch), sizes, and aspect ratios. You can also choose different materials for cover lenses, such as Gorilla Glass or PMMA, and select coatings for anti-glare or anti-fingerprint properties. Additionally, many manufacturers offer tailored bonding methods and touch controller integration based on your project’s needs. Be sure to discuss your specifications with potential suppliers to ensure they can meet your requirements. -

What is the minimum order quantity (MOQ) for capacitive touch panels?

The minimum order quantity (MOQ) for capacitive touch panels can vary significantly between suppliers. Some may allow small orders of as few as 10-50 units, while others may have MOQs in the hundreds or thousands, especially for customized panels. When sourcing, inquire about the MOQ upfront and consider negotiating terms based on your project needs and potential for future orders. Understanding the MOQ helps you better manage your inventory and budget. -

How do I vet suppliers for capacitive touch panels?

To vet suppliers effectively, consider their industry reputation, production capabilities, and quality certifications (like ISO 9001). Request references from previous clients and evaluate their experience in delivering similar projects. Check if they have a clear quality assurance process in place and inquire about their lead times and logistics capabilities. Conducting a factory visit, if feasible, can also provide valuable insights into their operations and commitment to quality. -

What are the typical payment terms for capacitive touch panel orders?

Payment terms for capacitive touch panel orders vary by supplier but often include options such as a deposit upfront (commonly 30-50%) with the balance due before shipment. Some suppliers may offer letter of credit or payment upon delivery for larger orders. It’s essential to clarify payment terms before placing an order to avoid any misunderstandings. Additionally, consider negotiating terms that align with your cash flow and project timelines. -

How can I ensure quality assurance for my capacitive touch panels?

To ensure quality assurance, request detailed specifications and samples before finalizing your order. Most reputable suppliers should provide testing reports and compliance with industry standards. Discuss their quality control processes, including inspections at various production stages, to ensure the panels meet your expectations. Additionally, consider establishing a clear return policy and warranty terms in case the panels do not meet the agreed-upon standards. -

What logistics considerations should I keep in mind when sourcing capacitive touch panels?

When sourcing capacitive touch panels, consider shipping costs, lead times, and customs regulations that may affect delivery. Ensure that your supplier has reliable logistics partners for timely transportation and inquire about their experience with international shipping, especially to your region. It’s also wise to discuss packaging methods to prevent damage during transit. Having a clear logistics plan will help ensure that your panels arrive safely and on schedule, minimizing potential delays in your project.

Top 9 Capacitive Touch Panel Manufacturers & Suppliers List

1. Tyco – Tyco Touch 10.4 PCAP Touch Screen

Domain: tycotouch.com

Registered: 2008 (17 years)

Introduction: Projected Capacitive Touch Panels (PCAP) are designed for integration into various displays, providing an interactive touch experience similar to smartphones and tablets. The collection includes 25 products with various sizes and prices. Key products include:

– Tyco Touch 10.4″ PCAP Touch screen, Sale price: $115.00

– Tyco Touch 12″ PCAP Touch screen, Sale price: $125.00

– Tyco Touch 15″ PCAP T…

2. TechTarget – Capacitive Touchscreen Solutions

Domain: techtarget.com

Registered: 1999 (26 years)

Introduction: A capacitive touchscreen is a control display that uses the conductive touch of a human finger or a specialized input device for input and control. It requires a finger, special capacitive pen, or glove for operation, as it is coated with a material that can store electrical charges. The change in capacitance signals the location of the touch. Capacitive touchscreens provide higher levels of clari…

3. Orient Display – Capacitive Touch Panels

Domain: orientdisplay.com

Registered: 1999 (26 years)

Introduction: Capacitive Touch Panels from Orient Display include various sizes ranging from 2.4″ to 15.6″ with options for one finger touch, two finger touch, gesture support, and multi-touch capabilities. The company specializes in manufacturing capacitive touch panels and modules, offering both standard and custom solutions. Custom features include different touch materials, coatings (AR, AG, AF, AS, AB), an…

4. DIY Capacitive Touch Panel – ESPHome Project

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: DIY capacitive touch panel based on ESPHome for controlling lights and other devices; uses MPR121 for touch sensitivity with 12 inputs; alternative to ESP32’s built-in touch pads; project shared on GitHub.

5. BuyDisplay – Capacitive Touch Displays

Domain: buydisplay.com

Registered: 2012 (13 years)

Introduction: Capacitive Touch Display options include various sizes and specifications: 0.96″ to 10.1″ diagonal sizes, display formats ranging from 128×64 to 720×1280 pixels, and interfaces such as UART, RS232, RS485, HDMI, USB, DSI, LVDS, RGB, MIPI, I2C, and SPI. The product range includes TFT LCD, OLED, and e-Paper displays, with touch panel options available for many models.

6. JAE – Automotive Capacitive Touch Panels

Domain: jae.com

Registered: 1996 (29 years)

Introduction: JAE’s automotive capacitive touch panels began mass production in 2012, featuring a structure that bonds a sensor unit (glass type, film type) with an overlay cover. They are designed for stable operation in harsh environments (high temperature and humidity) suitable for automotive, medical, and industrial equipment. Key features include: high sensing technology (input with gloves, malfunction pre…

7. Xenarc Technologies – Rugged Touchscreen Solutions

Domain: xenarc.com

Registered: 2001 (24 years)

Introduction: Xenarc Technologies offers rugged small touchscreen solutions with capacitive touch technology. Key features include:

– Screen sizes: 7″, 8″, 9″, 10″, 12″, 15″, 18″, 24″

– Mean Time Between Failure (MTBF): > 55,000 hours (6.2 years) of continuous operation

– Warranty: 3 years

– High reliability and sensitivity, supporting multi-touch technology

– Durable and resistant to water, dust, and dirt…

8. ViewSonic – Touch Panel Technologies

Domain: viewsonic.com

Registered: 1995 (30 years)

Introduction: 4 Touch Panel Types: 1. Resistive Touch: Cost-effective, detects pressure, compatible with various inputs (fingertips, styluses, gloves), single-touch functionality, limited durability, commonly used in POS systems. 2. Infrared Touch: Uses an invisible grid of infrared beams, supports multi-touch, durable, works with any input, poor performance in direct sunlight, used in interactive displays and …

9. Hantronix – Projected Capacitive Touch Controller PCAP7200

Domain: hantronix.com

Registered: 1996 (29 years)

Introduction: Capacitive Touch Panel: Curved or flat glass substrates coated with a transparent metal oxide. Voltage applied creates a uniform electric field; a finger draws current, determining touch location. Projected Capacitive Touch Controller – PCAP7200: Designed for small scale touch panel applications in portable devices. Features up to 22 channels for touch screen connection, three communication pins (…

Strategic Sourcing Conclusion and Outlook for capacitive touch panel

As the global market for capacitive touch panels continues to expand, strategic sourcing remains pivotal for B2B buyers aiming to leverage the latest technological advancements. The advantages of capacitive touch technology, such as superior clarity, responsiveness, and multi-touch capabilities, make it increasingly attractive across various sectors, including automotive, consumer electronics, and industrial applications.

International buyers, particularly from emerging markets in Africa and South America, as well as established regions like Europe and the Middle East, should prioritize suppliers who not only offer high-quality products but also demonstrate robust quality management systems, such as ISO certifications. Collaborating with manufacturers like Orient Display, which leads the industry in custom solutions and comprehensive support, can significantly enhance operational efficiency and product innovation.

Looking ahead, the demand for versatile, high-performance capacitive touch panels is set to grow. By establishing strong partnerships and focusing on strategic sourcing, businesses can position themselves at the forefront of this technology evolution. Engage with reliable suppliers today to ensure your organization remains competitive and ready to meet future market demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.