A Deep Dive into Burn Cleaner Solution

Introduction: Navigating the Global Market for burn cleaner

In today’s competitive landscape, sourcing effective burn cleaners is crucial for businesses across various sectors, from food service to manufacturing. The challenge lies not only in identifying high-quality products but also in understanding their diverse applications and regulatory compliance requirements. This comprehensive guide on burn cleaners addresses these challenges by providing valuable insights into the different types of burn cleaners available, their specific applications, and essential supplier vetting strategies.

International B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, will find this guide indispensable for making informed purchasing decisions. It covers critical aspects such as cost analysis, market trends, and safety standards that directly impact operational efficiency and product quality. By equipping buyers with detailed knowledge about burn cleaners, this guide empowers them to select the most suitable products for their needs, ensuring not only compliance with local regulations but also enhancing workplace safety and cleanliness.

Navigating the global market for burn cleaners can be complex, but with the right information at hand, businesses can streamline their procurement processes, mitigate risks, and ultimately improve their bottom line. Whether you are looking to enhance your cleaning protocols or comply with industry standards, this guide serves as your roadmap to successful sourcing in the burn cleaner market.

Understanding burn cleaner Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alkaline Oven Cleaners | High pH level, effective against grease and carbon | Commercial kitchens, food processing plants | Pros: Strong cleaning power, fast-acting. Cons: Can be harsh on surfaces, requires protective gear. |

| Non-toxic Bioenzymatic Cleaners | Uses natural enzymes to break down organic materials | Restaurants, catering services, eco-friendly businesses | Pros: Safe for food areas, environmentally friendly. Cons: May require longer contact time for effectiveness. |

| Caustic Cleaners | Contains strong chemicals for heavy-duty cleaning | Industrial kitchens, manufacturing facilities | Pros: Highly effective on tough stains. Cons: Potentially harmful, necessitates careful handling. |

| Solvent-based Cleaners | Fast-drying, effective on various surfaces | Automotive, maintenance sectors | Pros: Quick application and drying time. Cons: Flammable and may require ventilation. |

| Foam Cleaners | Cling to surfaces for targeted cleaning | Food service, hospitality, and catering | Pros: Easy application, minimal splatter. Cons: May require rinsing, can be more expensive. |

What Are Alkaline Oven Cleaners and Where Are They Best Used?

Alkaline oven cleaners feature a high pH level that effectively tackles grease, carbon buildup, and food residues. These cleaners are primarily used in commercial kitchens and food processing plants, where heavy-duty cleaning is essential. When considering alkaline cleaners, buyers should evaluate the surface compatibility and ensure that staff are equipped with appropriate protective gear, as these products can be harsh on certain materials.

How Do Non-toxic Bioenzymatic Cleaners Work for B2B Applications?

Non-toxic bioenzymatic cleaners utilize natural enzymes to break down organic materials, making them ideal for environments where safety and cleanliness are paramount, such as restaurants and catering services. Their eco-friendly composition appeals to businesses aiming for sustainability. Buyers should consider the required contact time for optimal results, as these cleaners may take longer to work compared to traditional chemical options.

What Are the Key Features of Caustic Cleaners in Industrial Settings?

Caustic cleaners are formulated with strong chemicals designed for heavy-duty cleaning tasks, making them suitable for industrial kitchens and manufacturing facilities. Their high effectiveness on tough stains is a significant advantage. However, potential buyers must be cautious about handling and application, as these cleaners can be harmful if not used correctly. Ensuring proper training for staff is crucial.

Why Choose Solvent-based Cleaners for Quick Cleaning Solutions?

Solvent-based cleaners are favored in automotive and maintenance sectors due to their fast-drying properties and effectiveness on various surfaces. They can quickly remove grease and grime, making them a go-to choice for businesses needing rapid cleaning solutions. However, buyers should be aware of the flammability of these products and ensure proper ventilation during use to maintain safety.

What Advantages Do Foam Cleaners Offer in the Food Service Industry?

Foam cleaners are designed to cling to surfaces, allowing for targeted cleaning without excessive splatter, making them particularly useful in food service and hospitality settings. Their ease of application can enhance cleaning efficiency. However, buyers should factor in the potential need for rinsing after application and the cost, as foam cleaners can be pricier than traditional options.

Key Industrial Applications of burn cleaner

| Industry/Sector | Specific Application of burn cleaner | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Cleaning ovens and grills in production areas | Ensures compliance with health standards and enhances food safety | Look for non-toxic, low-fume formulations that are safe for food contact. |

| Hospitality | Maintenance of kitchen equipment in hotels and restaurants | Reduces downtime and extends equipment life through effective cleaning | Consider environmentally friendly options to align with sustainability goals. |

| Manufacturing | Cleaning industrial cooking equipment and machinery | Enhances operational efficiency and prevents equipment failure | Ensure compatibility with various materials and surfaces in industrial settings. |

| Automotive | Cleaning burnt-on residues in automotive repair shops | Improves workshop cleanliness and safety, enhancing worker satisfaction | Evaluate the chemical composition for safety and effectiveness in confined spaces. |

| Construction & Renovation | Removing burnt residues from equipment and tools | Maintains equipment functionality and worker safety on job sites | Source products with high cling and low volatility for better performance in outdoor conditions. |

How is Burn Cleaner Used in Food Processing Facilities?

In food processing, burn cleaners are essential for maintaining hygiene in ovens and grills. These cleaners effectively dissolve carbonized grease and food residues, ensuring compliance with strict health regulations. For international buyers, especially in regions like Africa and South America, sourcing burn cleaners that are non-toxic and safe for food contact is critical. This not only protects consumer health but also enhances the brand’s reputation in a competitive market.

What Are the Benefits of Burn Cleaners in the Hospitality Industry?

In the hospitality sector, particularly in hotels and restaurants, burn cleaners are employed to maintain kitchen equipment. Regular use of these cleaners minimizes downtime caused by equipment failures, thus enhancing service efficiency. Buyers in Europe and the Middle East should prioritize environmentally friendly formulations that align with sustainability initiatives, ensuring compliance with local regulations while also appealing to eco-conscious customers.

How Do Manufacturing Facilities Utilize Burn Cleaners?

Manufacturers use burn cleaners to maintain industrial cooking equipment and machinery, which is crucial for operational efficiency. These cleaners help prevent equipment failures by removing burnt residues that can hinder performance. For international B2B buyers, especially in emerging markets, it is essential to select products that are compatible with various materials used in industrial settings, ensuring effective cleaning without damaging equipment.

What Role Do Burn Cleaners Play in Automotive Repair Shops?

In automotive repair shops, burn cleaners are vital for removing burnt-on residues from tools and machinery. A clean workspace improves safety and worker satisfaction, which can lead to increased productivity. Buyers in regions like Africa and Vietnam should evaluate the chemical composition of burn cleaners to ensure safety in confined spaces, as well as effectiveness in dealing with tough residues commonly found in automotive environments.

How Are Burn Cleaners Used in Construction and Renovation?

In construction and renovation, burn cleaners are used to remove burnt residues from equipment and tools, maintaining their functionality and safety. This is particularly important on job sites where equipment performance directly impacts project timelines. Buyers should consider sourcing products with high cling and low volatility to ensure effective cleaning even in outdoor conditions, thus enhancing the overall efficiency of construction operations.

3 Common User Pain Points for ‘burn cleaner’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Burn Cleaner for Specific Applications

The Problem: Many B2B buyers face the challenge of choosing the appropriate burn cleaner that meets their specific cleaning needs. For instance, a restaurant manager may need a cleaner that effectively removes carbon buildup from grills without damaging the equipment or leaving harmful residues. This scenario is particularly prevalent in regions with varying regulations regarding cleaning agents, like parts of Africa and South America, where compliance with local health standards is crucial.

The Solution: To effectively source the right burn cleaner, B2B buyers should start by clearly identifying the types of surfaces they need to clean (e.g., grills, ovens, deep fryers) and the nature of the residues (e.g., grease, carbon, food particles). It is advisable to choose products that specify compatibility with the intended surfaces and are safe for food contact if applicable. Additionally, engaging with suppliers who provide technical data sheets can offer insights into the efficacy and safety profiles of the products. For example, a cleaner with a high-cling formula can be more effective as it stays in place longer, allowing for deeper penetration and easier removal of tough residues. Always request samples or trial sizes to evaluate performance before committing to larger orders.

Scenario 2: Concerns Over Toxicity and Environmental Impact of Cleaning Products

The Problem: Buyers are increasingly concerned about the toxicity of cleaning chemicals, especially in industries like food service and hospitality. In regions like Europe and parts of the Middle East, there is a growing demand for eco-friendly cleaning solutions. A restaurant owner may find it difficult to balance the need for effective cleaning with the desire to minimize environmental impact and ensure employee safety.

The Solution: To address these concerns, B2B buyers should prioritize sourcing burn cleaners that are labeled as low-fume or non-toxic. Look for products that have certifications or endorsements from recognized environmental organizations. Suppliers may offer bio-based or enzymatic cleaners that not only clean effectively but also break down naturally in the environment, reducing ecological footprints. When evaluating products, consider their safety data sheets (SDS) for detailed information on chemical compositions and potential hazards. Implementing a trial phase with environmentally friendly cleaners can help assess their performance while demonstrating a commitment to sustainability, which can enhance brand reputation in the marketplace.

Scenario 3: Inefficient Cleaning Processes Leading to Downtime

The Problem: A common pain point for businesses using burn cleaners is the time-consuming nature of the cleaning process, which can lead to operational downtime. For example, a commercial kitchen may require extensive cleaning after peak hours, and ineffective cleaning solutions can prolong the process, affecting service efficiency and ultimately customer satisfaction.

The Solution: To streamline cleaning processes and reduce downtime, buyers should consider investing in high-efficiency burn cleaners that promise quick action and easy wipe-off features. Look for products that have a high concentration level, which can be diluted according to the cleaning task, thus maximizing value. Training staff on the proper application techniques—such as letting the cleaner sit for the recommended time—can also enhance effectiveness. Additionally, implementing a regular maintenance schedule using these cleaners can prevent the buildup of residues, making routine cleanings quicker and easier. Collaborating with suppliers who offer training resources or support can further improve the efficacy of the cleaning regimen, leading to a more efficient operational flow.

Strategic Material Selection Guide for burn cleaner

What Are the Key Materials Used in Burn Cleaners?

When selecting materials for burn cleaners, it is essential to consider their chemical properties, compatibility with various surfaces, and performance under different conditions. Below, we analyze four common materials used in burn cleaners, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Sodium Hydroxide in Burn Cleaners?

Sodium hydroxide, commonly known as lye, is a strong alkaline compound frequently used in industrial cleaning applications. It is effective in breaking down organic matter, grease, and burnt residues.

Key Properties:

– Temperature/Pressure Rating: Stable at high temperatures, typically up to 60°C (140°F) in solution.

– Corrosion Resistance: Highly corrosive; requires careful handling to avoid damage to equipment and surfaces.

Pros & Cons:

– Pros: Highly effective in removing tough stains and residues; low cost and readily available.

– Cons: Requires protective gear during handling; can damage certain surfaces (e.g., aluminum).

Impact on Application:

Sodium hydroxide is compatible with many surfaces but can react adversely with metals, necessitating careful application.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding hazardous materials. For instance, in Europe, adherence to REACH regulations is crucial.

How Does Potassium Hydroxide Compare as a Material for Burn Cleaners?

Potassium hydroxide is another strong base used in burn cleaners, similar to sodium hydroxide but with different solubility properties.

Key Properties:

– Temperature/Pressure Rating: Effective at similar temperatures as sodium hydroxide.

– Corrosion Resistance: Also highly corrosive, requiring similar safety precautions.

Pros & Cons:

– Pros: More soluble in water than sodium hydroxide, making it easier to work with in liquid formulations.

– Cons: Higher cost compared to sodium hydroxide; similar handling risks.

Impact on Application:

Potassium hydroxide is effective for cleaning organic residues and is less likely to leave a residue compared to sodium hydroxide.

Considerations for International Buyers:

Compliance with local safety standards is essential, especially in regions with strict chemical handling regulations.

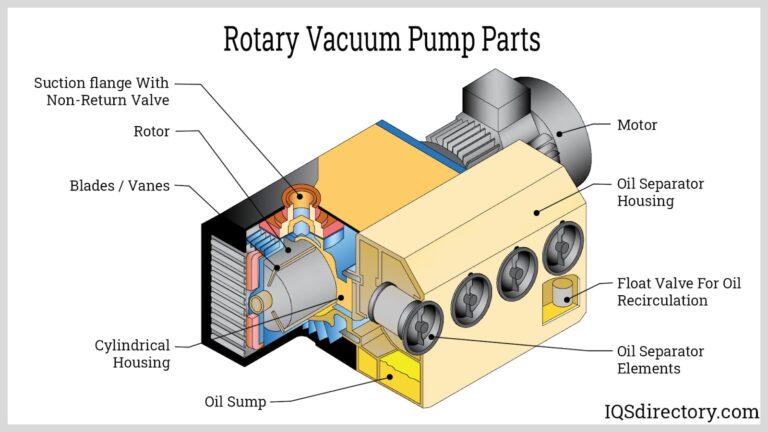

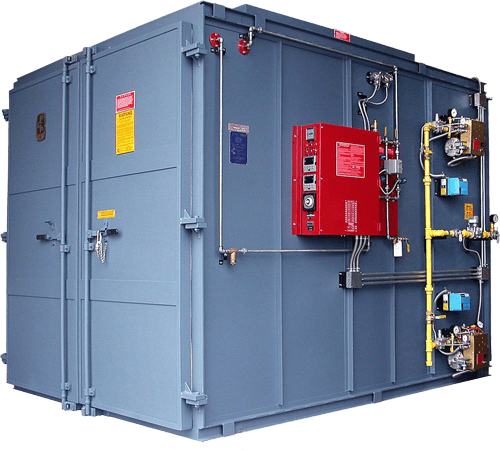

Illustrative image related to burn cleaner

What Role Does Surfactants Play in Burn Cleaner Formulations?

Surfactants are compounds that lower the surface tension between liquids and solids, enhancing the cleaning efficacy of burn cleaners.

Key Properties:

– Temperature/Pressure Rating: Varies widely; some are stable at high temperatures.

– Corrosion Resistance: Generally non-corrosive but can vary based on formulation.

Pros & Cons:

– Pros: Enhances the cleaning power of formulations; versatile and can be tailored for specific applications.

– Cons: May require careful formulation to avoid foaming issues; potential environmental concerns with certain types.

Illustrative image related to burn cleaner

Impact on Application:

Surfactants improve the penetration of cleaning agents into burnt residues, making them more effective.

Considerations for International Buyers:

Buyers should look for eco-friendly surfactants to meet sustainability goals, especially in regions like Europe where environmental regulations are stringent.

How Do Solvents Factor into Burn Cleaner Effectiveness?

Solvents are often included in burn cleaners to dissolve organic materials and facilitate easier cleaning.

Key Properties:

– Temperature/Pressure Rating: Varies; some solvents can be volatile at higher temperatures.

– Corrosion Resistance: Depends on the solvent; some can be corrosive to certain materials.

Pros & Cons:

– Pros: Effective at breaking down stubborn residues; quick-evaporating solvents can leave surfaces dry.

– Cons: Potential health hazards; flammable and may require special handling and storage.

Impact on Application:

Solvents can be particularly effective in industrial settings where heavy grease and burnt residues are common.

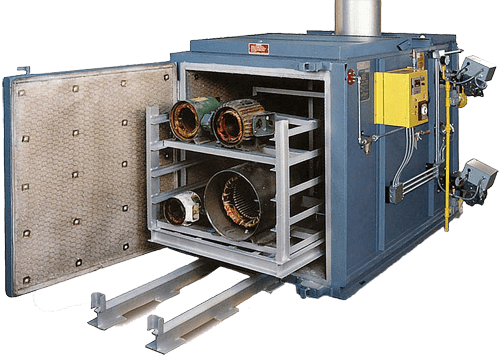

Illustrative image related to burn cleaner

Considerations for International Buyers:

Compliance with VOC regulations is critical, especially in regions like the Middle East and Europe where environmental standards are high.

Summary Table of Material Selection for Burn Cleaners

| Material | Typical Use Case for Burn Cleaner | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Sodium Hydroxide | Heavy-duty cleaning of ovens and grills | Highly effective on tough residues | Corrosive; can damage some surfaces | Low |

| Potassium Hydroxide | Cleaning organic residues | More soluble; easier to work with | Higher cost; similar handling risks | Medium |

| Surfactants | General-purpose cleaning | Enhances cleaning power | Potential environmental concerns | Medium |

| Solvents | Dissolving organic materials | Effective on stubborn residues | Health hazards; flammable | Medium to High |

This strategic material selection guide provides insights into the various materials used in burn cleaners, aiding international B2B buyers in making informed decisions based on performance, compliance, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for burn cleaner

What Are the Key Stages in the Manufacturing Process of Burn Cleaners?

The manufacturing process of burn cleaners involves several critical stages, each designed to ensure the final product meets industry standards for effectiveness and safety. The main stages include material preparation, formulation, filling, and finishing.

-

Material Preparation: The initial step involves sourcing high-quality raw materials, which may include surfactants, solvents, and stabilizers. These materials are often pre-tested for purity and concentration to ensure they meet the required specifications. Suppliers should provide Material Safety Data Sheets (MSDS) for all chemicals, outlining their properties and potential hazards.

-

Formulation: This stage involves mixing the raw materials according to a precise formula. Advanced mixing techniques, such as high-shear mixing or batch processing, are employed to ensure homogeneity. The formulation is critical as it determines the product’s cleaning efficacy, safety, and environmental impact. Manufacturers often utilize computer-controlled systems to maintain consistency.

-

Filling: Once the formulation is complete, the product is transferred to filling machines that accurately dispense the burn cleaner into containers. This stage requires careful monitoring to prevent contamination. Automated systems can help ensure that each container is filled to the correct volume and that the packaging is sealed properly to maintain product integrity.

-

Finishing: The final stage includes labeling, packaging, and preparing the product for shipment. Quality checks are conducted to ensure that labels are accurate and comply with local regulations, including language requirements and safety warnings. Packaging must also be designed to withstand transportation and storage conditions, minimizing the risk of leakage or damage.

How Does Quality Assurance (QA) Ensure Product Integrity in Burn Cleaner Manufacturing?

Quality assurance is a fundamental aspect of manufacturing burn cleaners, ensuring that the products are safe, effective, and compliant with industry standards. Several international and industry-specific standards guide this process.

-

International Standards: Compliance with ISO 9001 is essential for any manufacturing operation, including burn cleaners. This standard focuses on quality management systems (QMS) and requires manufacturers to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Adhering to ISO 9001 enhances product reliability and customer satisfaction.

-

Industry-Specific Certifications: For burn cleaners, certifications like CE marking (for products sold in Europe) and compliance with the American Petroleum Institute (API) standards for chemical products are crucial. These certifications ensure that the products are tested for safety and performance in specific applications, such as food processing environments.

-

Quality Control Checkpoints: Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are tested upon arrival to ensure they meet the specified standards before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during production helps identify any deviations from quality standards immediately.

– Final Quality Control (FQC): Once the product is complete, it undergoes rigorous testing to verify that it meets all specifications and regulatory requirements. -

Common Testing Methods: Manufacturers utilize various testing methods, including chemical analysis, viscosity testing, and performance testing against competitors. These tests help confirm the product’s effectiveness in removing burnt-on residues and its safety for use in various environments.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

As an international B2B buyer, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial for ensuring product reliability. Here are several strategies to consider:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control systems, and compliance with relevant standards. Audits can be performed internally or by third-party organizations specializing in supply chain assessments.

-

Requesting Quality Reports: Suppliers should be able to provide detailed reports on their quality control processes, including results from IQC, IPQC, and FQC tests. These documents should outline any issues encountered during production and how they were resolved.

-

Third-Party Inspections: Engaging third-party inspection services can help validate the quality of products before shipment. These services can perform random sampling, testing, and verification of compliance with international standards.

-

Certifications and Compliance Documents: Buyers should request copies of relevant certifications and compliance documents from suppliers. This includes ISO certifications, CE markings, and any other industry-specific compliance documents. Ensuring that these certifications are current and valid is essential for maintaining product safety and efficacy.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges when sourcing burn cleaners, particularly concerning quality control. Understanding these nuances can help mitigate risks associated with international procurement.

-

Regulatory Compliance: Different regions have varying regulations regarding chemical products. For example, the European Union has stringent REACH regulations that govern the use of chemicals. B2B buyers must ensure that their suppliers are compliant with local regulations to avoid legal issues and ensure product safety.

-

Cultural and Language Barriers: Communication can be a challenge when dealing with suppliers from different countries. It is crucial to establish clear communication channels and ensure that all specifications and requirements are understood by both parties.

-

Supply Chain Transparency: Buyers should seek suppliers who provide transparency in their supply chain processes. This includes information on sourcing raw materials, manufacturing practices, and quality control measures. A transparent supply chain can enhance trust and reliability.

-

Risk Management: Implementing a robust risk management strategy is essential for international procurement. This includes identifying potential risks, such as supply chain disruptions or compliance issues, and establishing contingency plans to address these challenges.

By understanding the manufacturing processes and quality assurance practices for burn cleaners, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality and safety expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘burn cleaner’

When sourcing burn cleaner products for your business, it’s essential to approach the process methodically. This guide offers a structured checklist to help you make informed decisions, ensuring you select the most effective and compliant solutions for your needs.

Step 1: Identify Your Cleaning Requirements

Understanding the specific applications for burn cleaner is the first step. Consider the types of surfaces you will be cleaning, such as ovens, grills, or industrial equipment. Different formulations may be required based on the level of grease or carbon buildup and the material of the surface.

- Surface Compatibility: Ensure the cleaner is safe for the materials being cleaned to avoid damage.

- Cleaning Frequency: Determine how often the cleaner will be used, which can influence the type of product you choose (e.g., concentrated vs. ready-to-use).

Step 2: Research Regulatory Compliance

Ensure that any burn cleaner you consider complies with relevant local and international regulations, especially if you’re operating in regions with strict environmental laws. This is particularly important in markets like Europe and North America, where chemical safety is closely monitored.

- Material Safety Data Sheets (MSDS): Request these documents from suppliers to review the safety and handling instructions.

- Certifications: Look for products certified for use in food-related industries if applicable, such as those accepted in federally inspected meat and poultry plants.

Step 3: Evaluate Supplier Reputation

Before committing, vet potential suppliers thoroughly to ensure reliability and quality. A reputable supplier can significantly impact your operational efficiency and product satisfaction.

- Client Testimonials: Seek out reviews or case studies from businesses similar to yours.

- Industry Experience: Consider suppliers with a proven track record in your specific industry.

Step 4: Compare Product Formulations

Different burn cleaners may use various chemical formulations, which can affect cleaning efficacy and safety. Evaluate these formulations based on your cleaning needs and safety standards.

- Low-Fume Options: Consider low-fume products for better workplace safety and comfort.

- Cling Properties: Look for cleaners that adhere to surfaces, allowing for longer contact time and more effective cleaning.

Step 5: Request Samples for Testing

Before making a bulk purchase, always request samples to test the effectiveness of the burn cleaner in your specific application. This step is crucial to ensure that the product meets your performance expectations.

Illustrative image related to burn cleaner

- Testing Conditions: Use the product under real-world conditions similar to those it will face in your operations.

- Ease of Use: Assess how easy it is to apply and rinse off the cleaner, as this can affect labor costs and cleaning times.

Step 6: Negotiate Pricing and Terms

Once you have selected potential products and suppliers, engage in negotiations to secure the best pricing and delivery terms. This can lead to significant cost savings, especially for bulk purchases.

- Volume Discounts: Inquire about discounts for larger orders or long-term contracts.

- Shipping Costs: Clarify shipping terms, especially if you are importing from international suppliers, as this can impact overall costs.

Step 7: Establish a Reliable Supply Chain

Finally, ensure that your supply chain is stable and reliable. This involves setting up agreements with your chosen supplier for consistent delivery and support.

- Lead Times: Understand the expected lead times for orders and stock levels to avoid interruptions in your cleaning operations.

- Support Services: Confirm that the supplier offers customer support for any product-related inquiries or issues.

By following this checklist, B2B buyers can make informed decisions when sourcing burn cleaners, ensuring they select products that meet their operational needs while adhering to safety and regulatory standards.

Comprehensive Cost and Pricing Analysis for burn cleaner Sourcing

What Are the Key Cost Components in Sourcing Burn Cleaners?

When sourcing burn cleaners, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include:

-

Materials: The choice of active ingredients directly impacts cost. High-quality, eco-friendly chemicals may command a premium, while standard formulations can be more economical.

-

Labor: Labor costs encompass wages for production staff, quality assurance personnel, and maintenance of machinery. In regions with lower labor costs, such as parts of Africa and South America, buyers might find more competitive pricing.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses. Efficient production facilities can reduce overhead costs, which can be beneficial for B2B buyers.

-

Tooling: This refers to the investment in machinery and equipment necessary for production. Custom tooling for specialized formulations can add to initial costs but may lower unit costs in high-volume production.

-

Quality Control (QC): Ensuring compliance with safety and quality standards often requires investment in testing and certification processes, which can impact overall pricing.

-

Logistics: Shipping costs can vary significantly based on distance, mode of transport, and Incoterms used. Buyers should factor in these logistics expenses to get a true picture of costs.

-

Margin: Suppliers will include a margin for profit, which can vary based on market demand and competition.

How Do Price Influencers Affect Burn Cleaner Sourcing?

Several factors influence the pricing of burn cleaners, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases typically lower the price per unit. Buyers should negotiate MOQs to align with their demand forecasts.

-

Specifications and Customization: Customized formulations may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Products that meet specific certifications (like eco-friendly or health safety standards) may be priced higher. Buyers should weigh the benefits of these certifications against their costs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers might offer higher-quality products but at a premium.

-

Incoterms: Understanding Incoterms is crucial for calculating total landed costs. Different terms can affect who bears the costs and risks during transportation.

What Tips Can Buyers Use to Negotiate Better Pricing?

B2B buyers can adopt several strategies to negotiate effectively and ensure cost-efficiency:

-

Conduct Market Research: Understand market rates and competitor pricing to leverage during negotiations. Familiarity with average prices helps in recognizing fair offers.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, disposal, and potential downtime costs related to the burn cleaner to make informed decisions.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and terms. Suppliers may offer discounts or favorable terms to loyal customers.

-

Leverage Bulk Purchasing: If feasible, collaborate with other businesses to increase order volumes, thereby lowering per-unit costs.

-

Stay Informed on Market Trends: Awareness of trends in the chemical industry can provide insights into pricing fluctuations and help in timing purchases strategically.

What Are the Pricing Nuances for International Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can significantly affect costs. Locking in prices or using forward contracts may mitigate risks.

-

Regulatory Differences: Compliance with local regulations can impact pricing. Ensure suppliers are familiar with necessary certifications and standards for your region.

-

Logistical Challenges: Understand the logistics landscape in your region. Local infrastructure can affect shipping times and costs, influencing overall pricing strategies.

-

Cultural Considerations: Negotiation styles can vary by culture. Understanding local business practices can facilitate smoother discussions and agreements.

Disclaimer on Pricing

Prices for burn cleaners can fluctuate based on market conditions, supplier capabilities, and other factors. This analysis provides indicative pricing guidance; actual costs may vary. Always conduct due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing burn cleaner With Other Solutions

When evaluating solutions for cleaning ovens and grills, it’s essential to consider various alternatives to traditional burn cleaners. The right choice depends on several factors, including cleaning efficiency, cost, ease of use, and the specific requirements of your business. Below, we analyze the effectiveness of burn cleaners compared to two viable alternatives: enzymatic cleaners and steam cleaning methods.

| Comparison Aspect | Burn Cleaner | Enzymatic Cleaner | Steam Cleaning Method |

|---|---|---|---|

| Performance | High; effectively removes tough, burnt-on residues. | Moderate; works best on organic stains and grease. | High; sanitizes and removes grime with heat. |

| Cost | Moderate; generally affordable per use. | Variable; can be higher depending on formulation. | Higher initial investment for equipment; lower ongoing costs. |

| Ease of Implementation | Simple spray-and-wipe application. | Requires application time and may need scrubbing. | Requires training on equipment use but is straightforward. |

| Maintenance | Low; regular use keeps surfaces clean. | Moderate; requires proper storage and handling. | Moderate to high; equipment needs regular maintenance. |

| Best Use Case | Ideal for heavy-duty cleaning in commercial kitchens. | Suitable for eco-conscious operations and light cleaning. | Excellent for sanitization in food preparation areas. |

What Are the Pros and Cons of Enzymatic Cleaners as an Alternative?

Enzymatic cleaners leverage biological enzymes to break down organic materials, making them effective for grease and food residues. They are eco-friendly and safe for most surfaces, appealing to businesses focused on sustainability. However, their performance may lag behind traditional burn cleaners for heavy-duty tasks, often requiring longer application times and additional scrubbing. While they can be cost-effective for regular maintenance cleaning, the price can escalate with specialized formulations.

Illustrative image related to burn cleaner

How Does Steam Cleaning Compare as a Cleaning Method?

Steam cleaning utilizes high-temperature steam to sanitize surfaces and remove dirt and grime. This method is highly effective for deep cleaning and disinfecting, making it ideal for environments where hygiene is paramount, such as food service establishments. While the initial cost of steam cleaning equipment can be significant, it reduces the need for chemical cleaners, leading to lower long-term costs. The primary downside is the learning curve associated with using the equipment and the time required for thorough cleaning.

Conclusion: How Can B2B Buyers Choose the Right Cleaning Solution?

Selecting the appropriate cleaning solution for ovens and grills hinges on your operational needs, budget, and sustainability goals. Burn cleaners excel in tackling tough, burnt-on residues quickly, making them suitable for high-volume kitchens. Enzymatic cleaners offer a green alternative for lighter cleaning tasks but may require more effort and time. Steam cleaning presents a powerful method for deep sanitization but comes with a higher upfront cost and maintenance requirements. Ultimately, B2B buyers should assess their specific cleaning challenges, environmental commitments, and available resources to determine the most suitable solution for their operations.

Essential Technical Properties and Trade Terminology for burn cleaner

What Are the Key Technical Properties of Burn Cleaners?

When evaluating burn cleaners, it is crucial for B2B buyers to understand specific technical properties that can impact performance, safety, and compliance. Here are some critical specifications to consider:

1. Chemical Composition

The chemical composition of burn cleaners is essential for determining their effectiveness in removing stubborn residues like grease, carbon, and food particles. Most formulations include alkaline agents, surfactants, and solvents. Understanding the chemical makeup helps buyers select products that are effective for specific applications, such as ovens or grills, while ensuring compatibility with the surfaces being cleaned.

2. pH Level

The pH level indicates the acidity or alkalinity of the cleaner. Burn cleaners typically have a pH range of 12.5 to 13.5, classifying them as alkaline. This is important because alkaline cleaners are more effective at breaking down organic material, making them ideal for heavy-duty cleaning tasks. B2B buyers should consider pH levels to ensure the product will not damage surfaces or require additional neutralization steps.

3. Concentration

Concentration refers to the strength of the cleaner, often expressed as a ready-to-use or concentrated formula. High-concentration cleaners are cost-effective as they require dilution before use, leading to lower shipping costs and reduced storage space. Buyers should evaluate concentration levels to balance efficacy and cost-effectiveness for their operations.

4. Application Temperature

Burn cleaners may be effective at both hot and cold temperatures. Understanding the application temperature range is vital for industries that operate in high-heat environments, such as restaurants or industrial kitchens. This property affects cleaning efficiency and safety, ensuring that the cleaner can adhere to surfaces properly for optimal performance.

5. Environmental Compliance

Regulatory compliance is increasingly important for B2B buyers. Many burn cleaners must meet specific environmental and safety standards, such as those set by the Environmental Protection Agency (EPA) or local regulations. Buyers should verify that the products are compliant with relevant regulations to avoid legal issues and ensure safe usage in their operations.

What Trade Terminology Should B2B Buyers Know When Purchasing Burn Cleaners?

Familiarity with industry-specific terminology can help B2B buyers navigate the procurement process more effectively. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are marketed by another company. In the context of burn cleaners, OEMs may provide proprietary formulations or branding. Understanding OEM relationships can help buyers identify quality and reliability in their cleaning supplies.

Illustrative image related to burn cleaner

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Knowing the MOQ is essential for buyers to manage inventory effectively and negotiate better purchasing terms, especially for bulk orders.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. B2B buyers can use RFQs to compare pricing, delivery options, and terms from different manufacturers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized shipping terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms can help buyers clarify shipping costs, risk, and delivery obligations, ensuring smoother logistics and compliance.

5. SDS (Safety Data Sheet)

An SDS provides detailed information about the properties of a chemical product, including hazards, handling, and safety precautions. Buyers must review SDS to ensure safe usage and compliance with workplace safety regulations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing burn cleaners, ensuring they select products that meet their operational needs and regulatory requirements.

Illustrative image related to burn cleaner

Navigating Market Dynamics and Sourcing Trends in the burn cleaner Sector

What Are the Current Market Dynamics and Key Trends in the Burn Cleaner Sector?

The burn cleaner market is experiencing significant growth driven by several global factors. As industrialization accelerates in regions such as Africa and South America, the demand for efficient cleaning solutions in kitchens, manufacturing units, and food processing plants is surging. A notable trend is the increasing adoption of low-fume and biodegradable cleaners that prioritize user safety and environmental health. In Europe and the Middle East, stricter regulations regarding chemical use in food-related industries are pushing manufacturers to innovate and produce compliant products, creating opportunities for B2B buyers to source safer, more effective cleaning solutions.

Emerging technologies are also reshaping the sourcing landscape. The integration of e-commerce platforms is enabling international buyers to access a wider variety of products, including specialized burn cleaners that meet specific industry needs. Furthermore, advancements in product formulation, such as high-cling formulas that enhance cleaning efficiency, are gaining traction among commercial buyers. This efficiency not only reduces labor costs but also minimizes waste, aligning with the growing emphasis on sustainability in procurement processes.

Additionally, the rise of digital supply chain management tools is facilitating better inventory control and order tracking for B2B buyers. This technological enhancement allows companies to respond swiftly to market demands and streamline operations, ensuring they remain competitive in a dynamic marketplace.

How Is Sustainability and Ethical Sourcing Impacting the Burn Cleaner Sector?

Sustainability has become a critical consideration for B2B buyers in the burn cleaner sector. The environmental impact of traditional cleaning agents, often laden with harmful chemicals, has prompted a shift towards eco-friendly alternatives. Many suppliers are now focusing on formulations that are biodegradable and free from volatile organic compounds (VOCs), which not only reduce environmental harm but also improve indoor air quality for users.

Ethical sourcing is equally important. Buyers are increasingly scrutinizing their supply chains to ensure that materials are sourced responsibly, minimizing negative social impacts. Certifications such as Green Seal or EcoLogo provide assurance that products meet stringent environmental and health standards. This trend is particularly relevant for international buyers from regions with varying regulations, as they seek to align with global sustainability goals.

Moreover, the demand for transparency in supply chains is driving manufacturers to disclose ingredient sourcing and production practices. This transparency not only fosters trust but also enables B2B buyers to make informed decisions that align with their corporate social responsibility (CSR) objectives. As a result, companies that prioritize sustainability and ethical practices are likely to gain a competitive edge in the increasingly conscientious marketplace.

What Is the Brief Evolution of the Burn Cleaner Sector?

The burn cleaner sector has evolved significantly over the decades, transitioning from harsh, chemical-laden solutions to more sophisticated and eco-friendly products. Initially, the market was dominated by traditional cleaners that posed health risks and environmental concerns. However, as awareness of these issues grew, manufacturers began to innovate.

In the late 20th century, the introduction of enzymatic and biodegradable cleaners marked a pivotal shift in the industry. These formulations not only proved effective at removing tough residues but also aligned with the growing demand for safer alternatives. Today, the focus is on creating specialized products that cater to specific applications, such as commercial kitchens and industrial facilities, while also adhering to stringent environmental regulations. This evolution reflects a broader trend towards sustainability and efficiency in the cleaning industry, positioning the burn cleaner market as a vital component of modern cleaning solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of burn cleaner

-

How do I solve the problem of selecting the right burn cleaner for my business?

Choosing the right burn cleaner involves understanding your specific cleaning needs and the surfaces you’ll be treating. Consider factors such as the type of residue (e.g., grease, carbon) and the surfaces (ovens, grills, etc.) to determine compatibility. It’s also crucial to evaluate the product’s safety profile, including any certifications for food safety if applicable. Request samples from potential suppliers to assess performance before committing to a larger order. -

What is the best burn cleaner for commercial kitchens?

The ideal burn cleaner for commercial kitchens should be highly effective in removing tough residues while being safe for use in food preparation areas. Look for products that are low-fume, biodegradable, and approved for use in federally inspected meat and poultry plants. A concentrated formula can offer cost savings and efficiency, allowing for use on various surfaces such as grills, ovens, and fryers without causing damage. -

What are the typical minimum order quantities (MOQ) for burn cleaners?

Minimum order quantities for burn cleaners can vary significantly by supplier and region. Generally, MOQs can range from a few cases to several pallets, depending on the product type and manufacturer. Discuss your specific needs with suppliers to negotiate favorable terms, especially if you’re testing a new product or entering a new market. Some suppliers may offer flexibility for first-time buyers or bulk orders. -

How can I vet suppliers of burn cleaners for quality and reliability?

To vet suppliers effectively, conduct thorough research on their reputation, certifications, and track record. Request references from other businesses in your industry to gauge customer satisfaction. Evaluate their compliance with international safety and quality standards, such as ISO certifications. Additionally, consider visiting their production facilities if feasible, or ask for product samples to assess quality firsthand. -

What payment terms are common for international purchases of burn cleaners?

Payment terms for international purchases can vary based on the supplier’s policies and the buyer’s relationship with them. Common terms include advance payment, letters of credit, or net 30/60/90 days. It’s advisable to clarify terms upfront to avoid any misunderstandings. Consider using payment methods that offer buyer protection, especially for first-time transactions, to mitigate risks associated with international trade. -

What logistics considerations should I keep in mind when sourcing burn cleaners?

When sourcing burn cleaners internationally, consider shipping methods, customs regulations, and lead times. Evaluate whether the supplier can handle logistics or if you need a third-party logistics provider. Be aware of any hazardous material regulations, especially if the product contains strong chemicals. Ensure clear communication with your supplier regarding delivery schedules and potential delays due to customs or local regulations. -

How important is it to customize burn cleaner formulations for specific markets?

Customizing burn cleaner formulations can be crucial for meeting local regulations and consumer preferences. Different regions may have varying safety standards, environmental regulations, and cultural preferences regarding scents and packaging. Collaborate with suppliers to develop tailored products that address these factors, enhancing marketability and compliance while potentially increasing your competitive advantage. -

What quality assurance practices should I expect from suppliers of burn cleaners?

Reputable suppliers of burn cleaners should have robust quality assurance practices in place. This includes regular testing of products for effectiveness and safety, adherence to safety standards, and providing material safety data sheets (MSDS) for transparency. Ask about their quality control processes, including batch testing and customer feedback mechanisms, to ensure you receive consistent and reliable products.

Top 3 Burn Cleaner Manufacturers & Suppliers List

1. Lawson Products – Burn-Out Oven and Grill Cleaner

Domain: lawsonproducts.com

Registered: 1997 (28 years)

Introduction: Burn-Out Oven and Grill Cleaner, 32 fl. oz.

2. Schiller Heating – Clean Burn Burner Cleaning

Domain: schillerheating.com

Registered: 2018 (7 years)

Introduction: Clean Burn Burner Cleaning is designed to maintain the efficiency and performance of Clean Burn waste oil furnaces and boilers. Regular cleaning helps prevent soot buildup and ensures optimal operation. The product is essential for extending the lifespan of the heating system and improving energy efficiency.

3. Hearth – Clean Burn Solutions

Domain: hearth.com

Registered: 1995 (30 years)

Introduction: This company, Hearth – Clean Burn Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for burn cleaner

In the realm of burn cleaners, strategic sourcing plays a pivotal role in enhancing operational efficiency and ensuring product quality. International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers that offer high-performance, eco-friendly solutions. Key takeaways from our guide highlight the importance of selecting burn cleaners that not only effectively remove residues but also comply with local safety regulations and environmental standards.

Illustrative image related to burn cleaner

Investing in quality burn cleaners, such as those with low-fume and high-cling formulas, can significantly reduce cleaning time while enhancing workplace safety. Furthermore, understanding the unique needs of your market can foster stronger supplier relationships and ensure a steady supply of reliable products.

Looking ahead, the demand for sustainable and efficient cleaning solutions will only grow. As you explore sourcing options, consider partnering with manufacturers who are committed to innovation and sustainability. This proactive approach will not only support your operational goals but also position your business favorably in a competitive landscape. Engage with suppliers today to secure the best burn cleaning solutions for your organization.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to burn cleaner

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.