A Deep Dive into Buchymix Blender Solution

Introduction: Navigating the Global Market for buchymix blender

In today’s fast-paced global market, sourcing high-quality buchymix blenders can be a daunting challenge for international B2B buyers. With a growing demand for efficient kitchen appliances that align with health-conscious consumer trends, businesses must navigate a complex landscape of product types, performance specifications, and supplier reliability. This comprehensive guide addresses these challenges by exploring the diverse range of buchymix blenders available, including high-performance models, soundproof options, and multifunctional devices designed for various applications.

Within this guide, you’ll find detailed insights into the distinct features of each blender, which are engineered to meet the needs of both commercial kitchens and home users. We will also delve into best practices for vetting suppliers, ensuring that you partner with reputable manufacturers who prioritize quality and customer satisfaction. Furthermore, we will provide cost analysis to help you make informed purchasing decisions that align with your budgetary constraints.

By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—with actionable insights, this guide empowers you to confidently invest in buchymix blenders. Elevate your kitchen capabilities while meeting the rising expectations of your clientele, ensuring that you stay competitive in an evolving marketplace.

Understanding buchymix blender Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ultra Heavy Duty Soundproof Blender | High-performance motor, soundproof design, digital/manual controls | Restaurants, cafes, and juice bars | Pros: Quiet operation, versatile controls. Cons: Higher initial investment. |

| 3 in 1 High Performance Turbocrush Blender | Multiple functions (blending, chopping, grinding), digital presets | Catering services, food trucks, and health bars | Pros: Multi-functionality, user-friendly. Cons: May require more space. |

| Powerful Heavy Duty Ultra Turbocrush Blender | BPA-free materials, robust construction, designed for heavy use | Smoothie shops, health-focused cafes | Pros: Durable, safe materials. Cons: Limited to specific markets. |

| Hands-Free Automatic Feeding Cold Pressed Juicer | Automatic feeding, efficient juicing, heavy-duty motor | Juice bars, health food stores | Pros: Labor-saving, efficient for high volumes. Cons: More complex to maintain. |

| Multifunctional Food Processor with Immersion Blender | Combines food processing and immersion blending capabilities | Catering, meal prep services | Pros: Space-saving, versatile. Cons: May have a steeper learning curve. |

What Are the Key Features of the Ultra Heavy Duty Soundproof Blender?

The Ultra Heavy Duty Soundproof Blender is designed to cater to high-demand environments such as restaurants and cafes where noise reduction is crucial. Its soundproof design allows for quiet operation without compromising performance. B2B buyers should consider the initial investment against the long-term benefits of durability and efficiency, especially in settings where customer experience is paramount.

Illustrative image related to buchymix blender

How Does the 3 in 1 High Performance Turbocrush Blender Stand Out?

This blender excels in versatility, combining blending, chopping, and grinding functions into one unit. The digital presets enable easy operation, making it ideal for catering services and food trucks that require quick and consistent results. B2B buyers should evaluate their space constraints and the frequency of use, as its multifunctionality can greatly enhance workflow efficiency.

What Makes the Powerful Heavy Duty Ultra Turbocrush Blender Ideal for Smoothie Shops?

Built with BPA-free materials, this blender is engineered for heavy usage, making it perfect for smoothie shops and health-focused cafes. Its robust construction ensures longevity, which is a critical factor for B2B buyers looking for reliable kitchen equipment. The investment in this blender can lead to significant returns through enhanced customer satisfaction and repeat business.

Why Consider the Hands-Free Automatic Feeding Cold Pressed Juicer?

This juicer is designed for efficiency, featuring an automatic feeding system that saves labor and time, crucial for high-volume juice bars. With a heavy-duty motor, it can handle a variety of fruits and vegetables, making it an excellent choice for health food stores. Buyers must consider the complexity of maintenance and operation, but the labor savings can justify the investment.

Illustrative image related to buchymix blender

How Does the Multifunctional Food Processor with Immersion Blender Benefit Meal Prep Services?

This unit combines food processing and immersion blending, offering space-saving benefits for catering and meal prep services. Its versatility allows for a range of food preparation tasks, which can streamline operations in busy kitchens. B2B buyers should assess their specific needs, as the multifunctionality may require additional training for staff, but the efficiency gains can be substantial.

Key Industrial Applications of buchymix blender

| Industry/Sector | Specific Application of buchymix blender | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Smoothie and Juice Production | Enhances product offerings with high-quality beverages | Ensure compatibility with local electrical standards |

| Hospitality | Food Preparation for Restaurants and Cafés | Increases efficiency and consistency in food preparation | Consider volume capacity and durability under heavy use |

| Health and Wellness | Nutritional Supplement Manufacturing | Provides a reliable method for creating smoothies and shakes | Assess ease of cleaning and maintenance for hygiene |

| Retail and Distribution | Resale of Blenders for Home Use | Attracts health-conscious consumers looking for quality | Evaluate warranty and customer support options |

| Agriculture | Processing of Organic Ingredients for Value-Added Products | Supports sustainable practices and enhances product value | Focus on energy efficiency and sourcing of raw materials |

How is the Buchymix Blender Used in the Food and Beverage Industry?

In the food and beverage sector, the Buchymix blender is pivotal for producing high-quality smoothies and juices. Businesses can leverage its powerful motor and advanced blending technology to create consistent products that meet consumer demand for nutritious options. The ability to process a variety of ingredients quickly helps businesses maintain productivity while also offering an appealing range of beverages. For international buyers, ensuring the blender meets local electrical standards is essential for seamless operation.

What Role Does the Buchymix Blender Play in Hospitality?

In the hospitality industry, the Buchymix blender serves as a vital tool for restaurants and cafés, streamlining food preparation processes. It allows chefs to create sauces, soups, and beverages efficiently, enhancing the overall dining experience. The consistency achieved with the Buchymix blender can lead to improved customer satisfaction and repeat business. Buyers should consider the blender’s capacity and durability, especially in high-volume settings, to ensure it can withstand daily use.

How is the Buchymix Blender Beneficial for Health and Wellness Businesses?

Health and wellness companies utilize the Buchymix blender to manufacture nutritional supplements, smoothies, and health-focused beverages. Its high-performance capabilities enable the blending of fibrous fruits and vegetables, ensuring a smooth texture that appeals to health-conscious consumers. This blender simplifies the process of creating nutritious products, which is essential for businesses aiming to cater to the growing health market. Buyers should prioritize models that are easy to clean and maintain to meet strict hygiene standards.

Illustrative image related to buchymix blender

Why is the Buchymix Blender Ideal for Retail and Distribution?

Retailers and distributors can benefit from offering Buchymix blenders as part of their product lineup, targeting health-conscious consumers who are increasingly investing in home kitchen appliances. The quality and performance of the Buchymix blender can attract customers looking for reliable options to enhance their home cooking. When sourcing, it is crucial to evaluate warranty options and customer support services, as these factors significantly influence buyer confidence and satisfaction.

How Can Agricultural Businesses Utilize the Buchymix Blender?

In agriculture, the Buchymix blender can be instrumental in processing organic ingredients for value-added products, such as smoothies and purees. This capability supports sustainable practices by enabling farmers to create products that maximize the value of their harvest. The blender’s energy efficiency is an important consideration for buyers in this sector, as it can contribute to lower operational costs while ensuring high-quality output. Sourcing raw materials that align with sustainable practices can further enhance the appeal of these products.

3 Common User Pain Points for ‘buchymix blender’ & Their Solutions

Scenario 1: Limited Noise Control in Commercial Settings

The Problem: In bustling environments such as restaurants or cafes, noise can be a significant concern. B2B buyers often find that traditional blenders create excessive noise, which disrupts the dining experience and can deter customers. The challenge becomes finding a blender that can handle heavy-duty tasks while minimizing sound output, especially in open kitchen concepts where customers are nearby.

The Solution: Buchymix offers ultra-heavy-duty soundproof blenders designed specifically for commercial use. When sourcing these blenders, buyers should prioritize models that emphasize noise reduction features, such as advanced soundproofing technology. Implementing these blenders not only enhances the customer experience by maintaining a quieter atmosphere but also allows staff to operate efficiently without the need to raise their voices. For optimal performance, ensure the blenders are strategically placed away from the dining area, and consider using them during peak hours to maximize their advantages.

Scenario 2: Inconsistent Blending Results

The Problem: Many businesses face the frustration of inconsistent blending results, which can lead to dissatisfaction among customers, especially in smoothie bars or health food cafes. B2B buyers need a blender that can handle a variety of ingredients—from hard vegetables to soft fruits—while delivering a consistent texture and flavor in every batch. Inconsistent performance can affect product quality and brand reputation.

Illustrative image related to buchymix blender

The Solution: To address this issue, B2B buyers should consider Buchymix’s high-performance Turbocrush blenders, which feature digital presets tailored for different types of ingredients. Buyers should invest time in training staff on how to utilize these presets effectively, ensuring that they select the appropriate settings based on the ingredients being blended. Additionally, regular maintenance checks on the blades and motor can help maintain blending consistency. Encouraging feedback from staff about the blending process can also lead to adjustments in techniques or ingredient preparation, ensuring that every blend meets the desired standards.

Scenario 3: Difficulty in Cleaning and Maintenance

The Problem: Cleaning and maintaining kitchen equipment can be a daunting task for busy restaurants or food service providers, leading to delays and inefficiencies in operations. B2B buyers often encounter blenders that are cumbersome to disassemble and clean, resulting in a build-up of residues that can affect the performance and hygiene of the equipment.

The Solution: Buchymix blenders are designed with ease of cleaning in mind. B2B buyers should focus on models with easy-to-clean features, such as removable parts and dishwasher-safe components. To streamline the cleaning process, establish a routine that includes rinsing the blender immediately after use and utilizing a simple cleaning cycle with soap and water. This not only enhances hygiene but also prolongs the life of the blender. Buyers can also consider incorporating a scheduled maintenance plan that includes deep cleaning sessions and inspections, ensuring that the blenders remain in optimal condition and reducing the likelihood of performance issues down the line.

Strategic Material Selection Guide for buchymix blender

What Are the Common Materials Used in Buchymix Blenders?

When selecting materials for Buchymix blenders, several factors come into play, including performance, durability, cost, and compliance with international standards. Here’s an analysis of four common materials used in the manufacturing of these blenders, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to buchymix blender

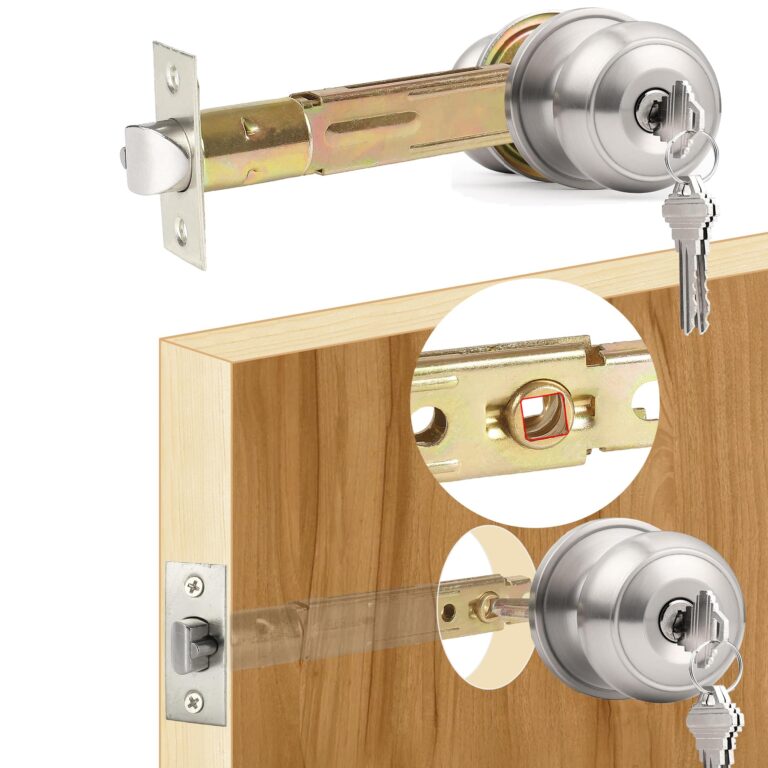

How Does Stainless Steel Perform in Buchymix Blenders?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand high temperatures. It typically has a temperature rating up to 870°C and is suitable for various food processing applications.

Pros & Cons: The durability of stainless steel makes it a popular choice for commercial kitchen appliances. It is easy to clean and maintain, ensuring hygiene in food preparation. However, it can be more expensive than other materials, which may affect the overall cost of the blender. Additionally, the manufacturing complexity can be higher due to the need for precision engineering.

Impact on Application: Stainless steel is compatible with a wide range of food media, making it ideal for blending, juicing, and food processing. Its robust nature means it can handle tough ingredients without warping or degrading.

Illustrative image related to buchymix blender

Considerations for International Buyers: Buyers from regions like Europe and the Middle East often prefer stainless steel due to its compliance with food safety standards such as ASTM and DIN. However, the higher cost may be a consideration for buyers in developing regions like Africa and South America.

What Role Does BPA-Free Plastic Play in Buchymix Blenders?

Key Properties: BPA-free plastic is lightweight, has good impact resistance, and can withstand moderate temperatures (typically up to 100°C). It is also less prone to breaking compared to glass or metal components.

Pros & Cons: The primary advantage of BPA-free plastic is its affordability and light weight, making it easy to handle. However, it may not be as durable as stainless steel and can be prone to scratches and discoloration over time. Additionally, it may have a lower temperature tolerance, which could limit its use in certain applications.

Impact on Application: This material is suitable for blending softer ingredients and is often used in the jug or container of blenders. It is important for applications where weight and ease of use are critical.

Considerations for International Buyers: Compliance with health and safety regulations is crucial, especially in markets like Brazil and Saudi Arabia, where consumer safety is a priority. Buyers should ensure that the plastic used is certified BPA-free to meet local standards.

Illustrative image related to buchymix blender

Why Is Glass Used in Some Buchymix Blenders?

Key Properties: Glass is chemically inert, non-porous, and can withstand high temperatures (up to 200°C). It also offers excellent clarity, allowing users to monitor blending progress easily.

Pros & Cons: The main advantage of glass is its ability to maintain the purity of food flavors and nutrients, making it a preferred choice for health-conscious consumers. However, glass is heavier and more fragile than other materials, increasing the risk of breakage during use or transport.

Impact on Application: Glass is often used in blender jars for smoothies and juices, where visibility and flavor integrity are important. Its inert nature ensures that no harmful chemicals leach into food.

Considerations for International Buyers: Buyers in Europe and North America may prefer glass for its safety and quality attributes. However, in regions with higher transportation risks, such as parts of Africa and South America, the fragility of glass may pose challenges.

Illustrative image related to buchymix blender

How Does Aluminum Benefit Buchymix Blenders?

Key Properties: Aluminum is lightweight, has excellent thermal conductivity, and is resistant to corrosion when anodized. It can withstand moderate temperatures up to 250°C.

Pros & Cons: The lightweight nature of aluminum makes it easy to handle, and its thermal properties allow for quick heating and cooling. However, it can be less durable than stainless steel and may require additional coatings to prevent scratching and wear.

Impact on Application: Aluminum is often used in the motor housing or base of blenders, where weight savings are beneficial. Its thermal conductivity is advantageous for applications requiring rapid heating.

Considerations for International Buyers: Buyers should be aware of the potential for aluminum to react with acidic foods unless properly coated. Compliance with food safety standards is essential, especially in markets like the Middle East and Europe.

Summary Table of Material Selection for Buchymix Blenders

| Material | Typical Use Case for buchymix blender | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Blender body and blades | Excellent durability and hygiene | Higher cost and manufacturing complexity | High |

| BPA-Free Plastic | Blender jug/container | Lightweight and affordable | Less durable and lower temperature tolerance | Low |

| Glass | Blender jar | Maintains flavor integrity | Heavy and fragile | Medium |

| Aluminum | Motor housing/base | Lightweight and good thermal conductivity | Less durable without coatings | Medium |

This material selection guide equips international B2B buyers with essential insights into the materials used in Buchymix blenders, aiding in informed decision-making that aligns with regional standards and market preferences.

Illustrative image related to buchymix blender

In-depth Look: Manufacturing Processes and Quality Assurance for buchymix blender

What Are the Main Stages of Manufacturing for Buchymix Blenders?

The manufacturing process of Buchymix blenders is designed to ensure high performance, durability, and compliance with international standards. The process can be broken down into several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials such as BPA-free plastics, stainless steel, and other components that meet stringent safety standards. Suppliers are carefully vetted to ensure they provide materials that align with Buchymix’s commitment to health and performance.

-

Forming: In this stage, raw materials are shaped into specific components using advanced techniques such as injection molding for plastic parts and stamping or CNC machining for metal components. These methods ensure precision and consistency, which are critical for the functionality of high-performance blenders.

-

Assembly: The assembly process is carried out in a controlled environment to minimize contamination and ensure quality. Skilled technicians follow detailed assembly protocols to combine various parts, including motors, blades, and electronic controls. Automation is often utilized to enhance efficiency, while human oversight ensures quality control at each step.

-

Finishing: After assembly, blenders undergo a finishing process that includes surface treatments and quality checks. This may involve polishing, coating, and inspection to ensure that each unit not only looks appealing but also functions perfectly. The finishing stage is crucial as it impacts both aesthetics and durability.

How Does Quality Assurance Work at Buchymix?

Quality assurance is a cornerstone of Buchymix’s manufacturing philosophy, focusing on delivering products that meet or exceed customer expectations. Buchymix adheres to several international and industry-specific quality standards.

-

International Standards: Buchymix is committed to ISO 9001 certification, which signifies a robust quality management system. This certification ensures that processes are consistently monitored and improved, leading to enhanced customer satisfaction.

-

Industry-Specific Standards: Compliance with standards such as CE (Conformité Européenne) and API (American Petroleum Institute) ensures that products meet safety, health, and environmental requirements. These certifications are particularly important for international B2B buyers who need assurance of compliance with local regulations.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process to identify and rectify potential issues early. Key QC checkpoints include:

Illustrative image related to buchymix blender

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the facility. The goal is to verify that materials meet specified standards before they enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, various tests are conducted at each stage to ensure that the assembly and forming processes are yielding products that meet quality standards. This includes dimensional checks, functionality tests, and visual inspections.

-

Final Quality Control (FQC): Once the blenders are fully assembled, a comprehensive final inspection is conducted. This may include performance testing under various conditions to ensure reliability and durability. Only products that pass FQC are packaged and shipped.

What Common Testing Methods Are Used for Buchymix Blenders?

To verify the quality and performance of Buchymix blenders, several testing methods are employed:

-

Performance Testing: Blenders are tested for their ability to blend, puree, and crush various ingredients under different conditions. This ensures they meet the performance specifications outlined in their design.

-

Durability Testing: Blenders undergo stress testing to evaluate their durability over time. This includes simulating years of use in a shorter timeframe to ensure that components can withstand rigorous conditions.

-

Safety Testing: Safety tests are conducted to ensure that the blenders operate within safe temperature ranges and do not pose any hazards to users. This includes electrical safety tests to prevent issues such as overheating or short-circuiting.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several methods to ensure reliability:

-

Supplier Audits: Conducting audits of the manufacturing facility can provide firsthand insight into the quality control measures in place. This includes reviewing documentation, observing processes, and assessing compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC processes and results. These reports should include information on defects, returns, and overall performance metrics.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality control measures. This is particularly beneficial for buyers who may not have the resources to conduct their own audits.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various nuances when it comes to quality control. Here are key considerations:

-

Cultural and Regulatory Differences: Different regions may have varying expectations and regulations regarding quality and safety. Understanding these differences is essential for ensuring compliance and satisfaction.

-

Logistics and Supply Chain Challenges: Issues such as shipping delays, customs inspections, and local regulations can impact the quality and timing of deliveries. B2B buyers should have contingency plans in place to address these challenges.

-

Communication Barriers: Clear communication is vital for ensuring quality standards are understood and maintained. Establishing strong relationships with suppliers can help mitigate misunderstandings and foster collaboration.

In conclusion, the manufacturing processes and quality assurance practices at Buchymix are designed to ensure high-quality, reliable blenders that meet international standards. By understanding these processes and implementing verification strategies, B2B buyers can make informed decisions when sourcing Buchymix products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘buchymix blender’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure Buchymix blenders. With a growing demand for high-performance kitchen appliances across diverse markets, it is essential to follow a structured approach to ensure you make informed purchasing decisions. This checklist will help you evaluate specifications, supplier reliability, and post-purchase support to facilitate a successful sourcing process.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical requirements for the Buchymix blender you intend to purchase. This includes understanding the power capacity, blending technology (such as soundproofing features), and any special functionalities like digital controls or presets.

– Key Considerations: Assess whether the blenders need to handle specific volumes or types of ingredients based on your target market’s preferences.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers who offer Buchymix blenders. Utilize various resources such as online marketplaces, industry forums, and trade shows to compile a list of reputable suppliers.

– What to Look For: Prioritize suppliers with a solid track record, positive customer reviews, and a clear commitment to quality. Ensure they have experience in your specific market region.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Verification Process: Look for certifications that demonstrate compliance with international quality standards, especially if you are sourcing from different continents like Africa or South America.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the Buchymix blenders. Testing the products firsthand will provide insights into their performance, durability, and ease of use.

– Testing Criteria: Evaluate the blenders on noise levels, blending efficiency, and user-friendliness. This step is vital to ensure the product meets your quality expectations before bulk purchasing.

Step 5: Negotiate Pricing and Terms

Engage in discussions with your chosen suppliers to negotiate pricing, payment terms, and delivery schedules. It’s essential to establish clear terms that protect your business interests while ensuring you get competitive pricing.

– Negotiation Tips: Be transparent about your purchasing volume and potential for future orders, as this can help leverage better pricing agreements.

Step 6: Confirm Warranty and Support Services

Before finalizing your order, confirm the warranty terms and after-sales support provided by the supplier. A robust warranty and reliable customer service can save you from future headaches and financial losses.

– Support Evaluation: Check if the supplier offers 24/7 customer support and an easy return process, especially important for international transactions.

Step 7: Place Your Order and Plan for Logistics

Once all terms are agreed upon, place your order and prepare for logistics. Coordinate shipping, customs clearance, and delivery timelines to ensure a smooth procurement process.

– Logistics Considerations: Understand the shipping costs and potential tariffs that may apply when importing the blenders into your region.

Illustrative image related to buchymix blender

By following this step-by-step checklist, you can navigate the complexities of sourcing Buchymix blenders effectively, ensuring that you select a reliable supplier and acquire high-quality products tailored to your business needs.

Comprehensive Cost and Pricing Analysis for buchymix blender Sourcing

What Are the Key Cost Components for Buchymix Blenders?

Understanding the cost structure of Buchymix blenders is essential for international B2B buyers to make informed purchasing decisions. The primary cost components include:

-

Materials: Buchymix utilizes high-quality materials for their blenders, including durable plastics and stainless steel components. The choice of materials significantly affects both the cost and the durability of the product.

-

Labor: Labor costs encompass the wages of the skilled workforce involved in the manufacturing process. In regions with higher labor costs, such as Europe, the overall price may be elevated.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and maintenance of manufacturing facilities. Efficient manufacturing processes can help minimize overhead costs, contributing to competitive pricing.

-

Tooling: The initial investment in tooling and molds for production can be substantial. These costs are amortized over the production run, influencing the per-unit price.

-

Quality Control (QC): Rigorous QC measures ensure that each blender meets the required standards. This involves additional costs, but it enhances the reliability and longevity of the products.

-

Logistics: Shipping costs can vary widely based on the destination and volume of orders. Efficient logistics planning is crucial for minimizing these costs, especially when exporting to distant markets like Africa or South America.

-

Margin: The profit margin added by Buchymix will vary based on market conditions, competition, and brand positioning. Understanding the margin can help buyers gauge the overall value proposition.

How Do Pricing Influencers Affect Buchymix Blender Costs?

Several factors influence the pricing of Buchymix blenders, especially for international buyers:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Buyers should negotiate minimum order quantities (MOQs) to leverage better pricing.

-

Specifications/Customization: Customizing blenders to meet specific market demands can increase costs. Buyers should balance customization needs against the potential price impact.

-

Materials and Quality/Certifications: Premium materials and certifications (e.g., BPA-free, energy-efficient) can raise the price. Buyers should assess whether these features align with their target market’s expectations.

-

Supplier Factors: The reliability and reputation of the supplier can also impact pricing. Engaging with well-established suppliers like Buchymix may warrant higher costs but can ensure better service and product quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. Choosing the right Incoterms can affect the total landed cost of the product.

What Are the Best Buyer Tips for Negotiating Buchymix Blender Prices?

International buyers, particularly from Africa, South America, the Middle East, and Europe, can optimize their purchasing strategy by considering the following tips:

-

Negotiation: Always enter negotiations with a clear understanding of your budget and desired specifications. Be prepared to discuss volume discounts and payment terms to secure favorable conditions.

-

Cost-Efficiency: Analyze the total cost of ownership, which includes purchase price, shipping, and maintenance costs over the product’s lifecycle. This approach helps in assessing the long-term value rather than focusing solely on the initial price.

-

Pricing Nuances: Be aware of the pricing dynamics in your region. Factors such as currency fluctuations, import tariffs, and local demand can influence the final price. Staying informed can help buyers make timely purchasing decisions.

-

Evaluate Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Trust and communication can facilitate smoother transactions and enhance negotiation outcomes.

Conclusion

The cost and pricing structure of Buchymix blenders is multifaceted, influenced by various internal and external factors. By understanding these components and employing strategic negotiation tactics, international B2B buyers can optimize their sourcing decisions to achieve maximum value. It is essential to consider the total cost of ownership and stay informed about market trends to make the best purchasing choices.

Alternatives Analysis: Comparing buchymix blender With Other Solutions

Introduction to Alternatives for Buchymix Blender

In today’s competitive market, understanding the range of available kitchen appliances is crucial for international B2B buyers. The Buchymix Blender is renowned for its performance and features, but other solutions also exist that may meet diverse operational needs. This analysis will explore viable alternatives, enabling businesses to make informed purchasing decisions.

Comparison Table

| Comparison Aspect | Buchymix Blender | Vitamix Blender | Ninja Blender |

|---|---|---|---|

| Performance | High torque, ultra-durable design | Professional-grade blending power | Versatile performance with multiple settings |

| Cost | $145 – $430 depending on model | $350 – $800+ | $100 – $300 |

| Ease of Implementation | User-friendly digital controls | Requires some training for optimal use | Intuitive controls, easy to use |

| Maintenance | Low maintenance, easy to clean | Requires regular maintenance | Moderate maintenance, dishwasher safe parts |

| Best Use Case | Commercial kitchens, heavy-duty use | Smoothies, soups, professional use | Home use, casual blending tasks |

Detailed Breakdown of Alternatives

Vitamix Blender

Vitamix is a benchmark in the blending industry, known for its professional-grade performance. Its powerful motor allows for smooth blending of tough ingredients, making it ideal for soups, smoothies, and even frozen desserts. However, the cost can be significantly higher, making it less accessible for small businesses or startups. Additionally, while it offers a range of features, the learning curve may deter users who require quick and efficient operation. Overall, Vitamix is best suited for businesses looking for high-performance equipment and willing to invest in premium pricing.

Ninja Blender

Ninja blenders are popular for their affordability and versatility, making them suitable for home kitchens and small businesses. They come equipped with multiple blending modes, allowing users to create smoothies, salsas, and even dough. The price point makes Ninja blenders attractive to budget-conscious buyers. However, while they perform well for everyday tasks, they may not match the durability and power of Buchymix or Vitamix in high-demand commercial settings. Ninja blenders are best for businesses that prioritize cost-effectiveness over heavy-duty capabilities.

Conclusion: How to Choose the Right Blender for Your Needs

When selecting a blender for your business, consider the specific operational requirements and budget constraints. The Buchymix Blender stands out for its durability and performance, making it ideal for commercial applications. In contrast, Vitamix offers premium quality for those who can afford it, while Ninja provides a cost-effective solution for lighter use. Assessing these factors will help B2B buyers determine the best fit for their unique needs, ensuring they invest wisely in kitchen technology that enhances productivity and efficiency.

Essential Technical Properties and Trade Terminology for buchymix blender

What Are the Key Technical Properties of the Buchymix Blender?

When considering the Buchymix blender for commercial use, it’s essential to understand its critical technical properties, which directly impact performance, reliability, and user satisfaction.

Illustrative image related to buchymix blender

1. Motor Power (Wattage)

The motor power of a blender, typically measured in watts, determines its ability to blend various ingredients effectively. Buchymix blenders range from 1,500 to 2,500 watts, allowing them to handle tough ingredients like frozen fruits and ice. For B2B buyers, selecting a blender with adequate wattage ensures operational efficiency in high-demand settings, like restaurants or juice bars, minimizing downtime caused by motor strain.

2. Material Grade (BPA-Free Plastics and Stainless Steel)

The materials used in the construction of the blender, such as BPA-free plastics and stainless steel, are crucial for safety and durability. BPA-free components ensure that no harmful chemicals leach into food, which is especially important for health-conscious consumers. Stainless steel parts enhance longevity and resistance to corrosion, making them ideal for commercial environments. B2B buyers should prioritize blenders made from high-quality materials to ensure compliance with health regulations and customer satisfaction.

3. Capacity (Liter Volume)

The capacity of a blender, typically indicated in liters, defines how much product can be blended at once. Buchymix offers models with capacities ranging from 1.5 to 3 liters. For businesses, larger capacities allow for batch processing, increasing productivity and reducing the need for multiple blending cycles. Understanding capacity is vital for aligning equipment with production needs.

4. Speed Settings and Control Mechanisms

Buchymix blenders feature multiple speed settings and control options, including digital controls with presets. This versatility allows users to adjust blending speeds for different recipes, ensuring optimal texture and consistency. For B2B buyers, having a range of speed settings can enhance menu offerings and improve operational flexibility, catering to diverse customer preferences.

Illustrative image related to buchymix blender

5. Noise Level (Decibel Rating)

Noise levels, often measured in decibels (dB), are an important consideration, particularly in environments like cafes or open kitchens. Buchymix’s soundproof blenders are designed to operate quietly, which can significantly enhance the customer experience. Choosing a low-noise model can be a competitive advantage in customer-centric markets.

What Are Common Trade Terms Related to Buchymix Blender Procurement?

Understanding industry jargon is essential for navigating B2B transactions effectively. Here are some key terms to be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Buchymix, knowing whether the blender is sourced from an OEM can help buyers ensure they are receiving high-quality, reliable products that meet industry standards.

2. MOQ (Minimum Order Quantity)

The MOQ is the smallest number of units a supplier is willing to sell. For B2B buyers, understanding the MOQ is crucial for budget planning and inventory management. Buchymix might have specific MOQs for bulk orders, which can affect purchasing decisions.

Illustrative image related to buchymix blender

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products. When purchasing Buchymix blenders, submitting an RFQ can help buyers compare prices and terms from different suppliers, ensuring they get the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping goods. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for B2B transactions to avoid misunderstandings regarding shipping costs and responsibilities.

5. Warranty and Service Agreement

A warranty is a guarantee that a product will perform as expected for a certain period. Understanding the warranty terms and any associated service agreements for Buchymix blenders can provide peace of mind and protect your investment, especially in commercial settings where reliability is paramount.

Illustrative image related to buchymix blender

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring Buchymix blenders, ensuring they meet their operational needs while maintaining quality and compliance.

Navigating Market Dynamics and Sourcing Trends in the buchymix blender Sector

What Are the Key Market Dynamics and Trends Influencing the Buchymix Blender Sector?

The global kitchen appliance market, particularly for high-performance blenders, is experiencing significant growth driven by a rising consumer focus on health and wellness. With increasing urbanization and a growing middle class in regions like Africa, South America, the Middle East, and Europe, there is heightened demand for efficient, multifunctional kitchen appliances that promote healthy eating habits. This trend is further accelerated by the adoption of technology in cooking, such as digital controls and preset functions that simplify meal preparation.

For international B2B buyers, particularly from countries like Saudi Arabia and Brazil, understanding local consumer preferences is essential. There is a notable shift towards products that emphasize quality and durability, with buyers seeking blenders that can handle diverse culinary tasks—from smoothie preparation to food processing. Furthermore, the integration of advanced features like soundproofing and easy-clean designs are becoming key differentiators. Buyers are also increasingly looking for brands that offer strong after-sales support and warranty services, which are critical for maintaining operational efficiency in commercial settings.

Emerging sourcing trends include a move towards e-commerce platforms, enabling buyers to access a wider range of products and suppliers beyond their local markets. The emphasis on fast and reliable shipping options, alongside competitive pricing, is critical for B2B transactions, particularly in regions where logistics can pose challenges.

How Does Sustainability and Ethical Sourcing Impact the Buchymix Blender Market?

As sustainability becomes a pressing global concern, the demand for environmentally friendly kitchen appliances is on the rise. B2B buyers are increasingly prioritizing products that minimize environmental impact throughout their lifecycle, from manufacturing to disposal. In the buchymix blender sector, this translates to sourcing materials that are both durable and recyclable, such as BPA-free plastics and stainless steel components.

Ethical sourcing practices are also gaining traction, with buyers looking for suppliers who adhere to fair labor practices and have transparent supply chains. Certifications such as ISO 14001 (Environmental Management) and certifications for sustainable materials can enhance a brand’s credibility and appeal to environmentally conscious consumers. For international buyers, aligning with suppliers that prioritize sustainability not only meets growing consumer expectations but can also be a differentiator in competitive markets.

Incorporating ‘green’ certifications into product offerings can significantly enhance marketability, as it signals a commitment to environmental responsibility. This is particularly relevant for buyers in regions like Europe, where regulatory frameworks increasingly favor sustainable products.

What Is the Evolution of the Buchymix Blender Sector and Its Implications for B2B Buyers?

The evolution of the buchymix blender sector has been marked by significant technological advancements and changing consumer preferences. Originally focused on basic blending functions, modern blenders now incorporate sophisticated features such as digital controls, noise reduction technology, and multifunctionality, allowing them to serve as food processors, juicers, and more.

This transition reflects a broader trend in the kitchen appliance market towards multifunctionality and user convenience. B2B buyers must recognize that investing in high-performance blenders not only meets current consumer demands but also positions their businesses to adapt to future trends. The ability to offer a range of functionalities can attract a diverse customer base, enhancing competitive advantage in various markets. As the sector continues to innovate, staying informed about the latest advancements will be crucial for B2B buyers aiming to capitalize on emerging opportunities in the kitchen appliance landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of buchymix blender

-

How do I ensure the quality of Buchymix blenders before purchase?

To ensure the quality of Buchymix blenders, request product samples to evaluate performance and durability. Review certifications and compliance with international quality standards, such as ISO or CE. Additionally, consider customer testimonials and reviews from other B2B buyers to gauge satisfaction levels. Establish communication with the supplier to inquire about their quality assurance processes and warranty policies. This due diligence will help you make an informed decision. -

What are the best Buchymix blenders for commercial use?

For commercial applications, the Ultra Heavy Duty Soundproof Blender and the 3 in 1 High Performance Turbocrush Blender are ideal choices. These models are designed for high-volume use, featuring robust motors and advanced blending technology. They can handle tough ingredients and deliver consistent results, essential for restaurants and cafes. Always assess your specific needs, such as capacity and functionality, to determine the best fit for your business. -

What customization options are available for Buchymix blenders?

Buchymix offers customization options, including branding with your logo, color variations, and specific features tailored to your business needs. When placing a bulk order, discuss your requirements with the sales team to explore available modifications. Customization can enhance your brand visibility and ensure that the product aligns with your market’s preferences, making it a valuable investment for your business. -

What are the minimum order quantities (MOQ) for Buchymix blenders?

The minimum order quantity (MOQ) for Buchymix blenders typically varies based on the model and your geographical location. For bulk orders, it is advisable to contact Buchymix directly or your designated distributor to confirm the MOQ. Understanding these requirements will help you plan your procurement strategy effectively and ensure you meet the supplier’s conditions for bulk pricing. -

What payment terms can I expect when purchasing Buchymix blenders?

Payment terms for Buchymix blenders may include options such as advance payment, letter of credit, or payment upon delivery, depending on the agreement with the supplier. It’s important to negotiate terms that suit your cash flow and business operations. Always clarify the payment methods accepted and any associated fees to avoid misunderstandings during the transaction process. -

How does Buchymix handle logistics and shipping for international orders?

Buchymix provides various shipping options for international orders, including air freight and sea freight, depending on your urgency and budget. They typically offer tracking services to monitor your shipment. Discuss logistics with your supplier to understand delivery timelines, customs clearance procedures, and any potential tariffs or duties that may apply to your region. Effective logistics management ensures timely delivery and minimizes disruptions to your operations. -

What kind of warranty and after-sales support does Buchymix provide?

Buchymix offers a warranty period for their blenders, covering defects in materials and workmanship. The duration may vary by model, so it’s essential to review the warranty terms before purchase. After-sales support typically includes customer service for troubleshooting, spare parts availability, and maintenance advice. Establishing a good relationship with the supplier will enhance your experience and ensure that any issues are resolved efficiently. -

How can I vet suppliers when sourcing Buchymix blenders?

When sourcing Buchymix blenders, conduct thorough research on potential suppliers. Look for verified reviews and testimonials from previous B2B buyers. Verify their business credentials, including registration and compliance with local regulations. Consider requesting references and visiting their facilities if possible. Engaging with suppliers who have established reputations in the industry can significantly reduce risks and enhance your purchasing experience.

Top 1 Buchymix Blender Manufacturers & Suppliers List

1. BuchyMix – Ultra Heavy Duty Soundproof Blender

Domain: buchymix.com

Registered: 2020 (5 years)

Introduction: [{‘name’: ‘Ultra Heavy Duty Soundproof Blender With Digital control’, ‘price’: ‘$430.00’, ‘original_price’: ‘$650.00’, ‘reviews’: ’56 reviews’}, {‘name’: ‘Ultra Heavy Duty Soundproof Blender With Manual Control’, ‘price’: ‘$299.00’, ‘original_price’: ‘$550.00’, ‘reviews’: ’10 reviews’}, {‘name’: ‘Powerful Heavy Duty Ultra Turbocrush Blender (CANADA ONLY)’, ‘price’: ‘$245.00’, ‘original_price’: ‘$2…

Strategic Sourcing Conclusion and Outlook for buchymix blender

As international B2B buyers increasingly seek high-performance kitchen appliances, the Buchymix blender stands out as a prime investment for businesses focused on quality and efficiency. By leveraging strategic sourcing, organizations can secure superior products that not only enhance operational efficiency but also contribute to healthier consumer lifestyles. Buchymix’s commitment to utilizing top-grade materials and offering innovative designs ensures that these blenders meet diverse culinary needs across various markets, including Africa, South America, the Middle East, and Europe.

The ongoing trend towards health-conscious eating presents a significant opportunity for businesses to incorporate Buchymix products into their offerings. By prioritizing strategic sourcing of these blenders, companies can differentiate themselves in competitive markets, attract health-focused consumers, and bolster their brand reputation.

Looking ahead, we encourage B2B buyers to explore the extensive range of Buchymix blenders available. Embracing these cutting-edge appliances not only aligns with global health trends but also positions your business for sustained growth and success. Take the next step in enhancing your product portfolio and connect with Buchymix today to seize these opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to buchymix blender