A Deep Dive into Broaching Machine Solution

Introduction: Navigating the Global Market for broaching machine

Navigating the complexities of sourcing broaching machines can pose significant challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With the demand for precision machining processes growing across various industries—such as automotive, aerospace, and medical equipment—understanding the nuances of broaching technology becomes crucial. This guide aims to demystify the global market for broaching machines by providing comprehensive insights into different types of machines, their applications, and key factors to consider when selecting a supplier.

In an increasingly competitive landscape, buyers need to make informed decisions that balance quality, cost, and supplier reliability. This guide offers actionable strategies for vetting suppliers, understanding pricing structures, and recognizing the potential return on investment for broaching machinery. By addressing these critical aspects, we empower B2B buyers to navigate the market confidently, ensuring that they select the right equipment to meet their operational needs. As you explore this guide, you will gain the knowledge necessary to optimize your procurement process and enhance your manufacturing capabilities, ultimately driving efficiency and precision in your production lines.

Understanding broaching machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Linear Broaching | Utilizes a straight line movement for cutting | Automotive, Aerospace, General Manufacturing | Pros: High precision, efficient for internal features. Cons: Limited to linear cuts. |

| Rotary Broaching | Involves simultaneous rotation of the tool and workpiece | Aerospace, Automotive, Custom Tooling | Pros: Creates complex shapes in one pass. Cons: Requires precise setup and tool selection. |

| Vertical Broaching | Vertical orientation for pulling or pushing broaches | Heavy Machinery, Automotive, Aerospace | Pros: Space-efficient, ideal for large components. Cons: May require more floor space. |

| Surface Broaching | Focuses on creating flat surfaces | Manufacturing, Tooling, Automotive Components | Pros: Excellent surface finish, efficient process. Cons: Limited to flat surfaces. |

| Pull Broaching | Broach is pulled through the workpiece | Automotive, Aerospace, Custom Parts Manufacturing | Pros: High accuracy, suitable for high-volume production. Cons: Setup can be complex and time-consuming. |

What Are the Characteristics of Linear Broaching Machines?

Linear broaching machines are characterized by their ability to move the broach in a straight line through the workpiece, making them ideal for cutting internal features such as keyways and splines. This method is highly efficient and allows for precise cuts in a single pass, reducing the need for multiple machining operations. B2B buyers should consider the machine’s compatibility with various materials and the specific shapes they need to produce, as well as the initial investment versus long-term productivity benefits.

How Does Rotary Broaching Differ from Other Types?

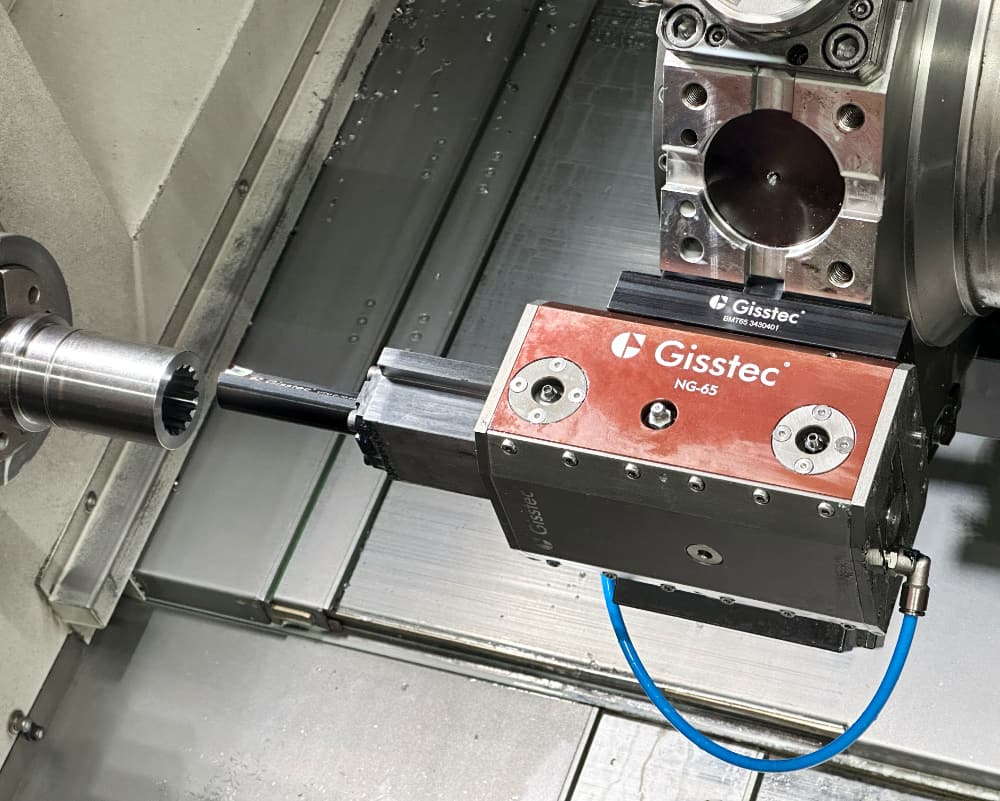

Rotary broaching machines operate by rotating both the broach and the workpiece, enabling the creation of intricate shapes such as hexagons or custom designs. This method is particularly advantageous for producing complex geometries with high precision in a single pass, making it suitable for industries requiring detailed components. Buyers should evaluate the versatility of rotary broaching machines and the types of broaches available, ensuring they can meet their specific production needs effectively.

What Are the Advantages of Vertical Broaching Machines?

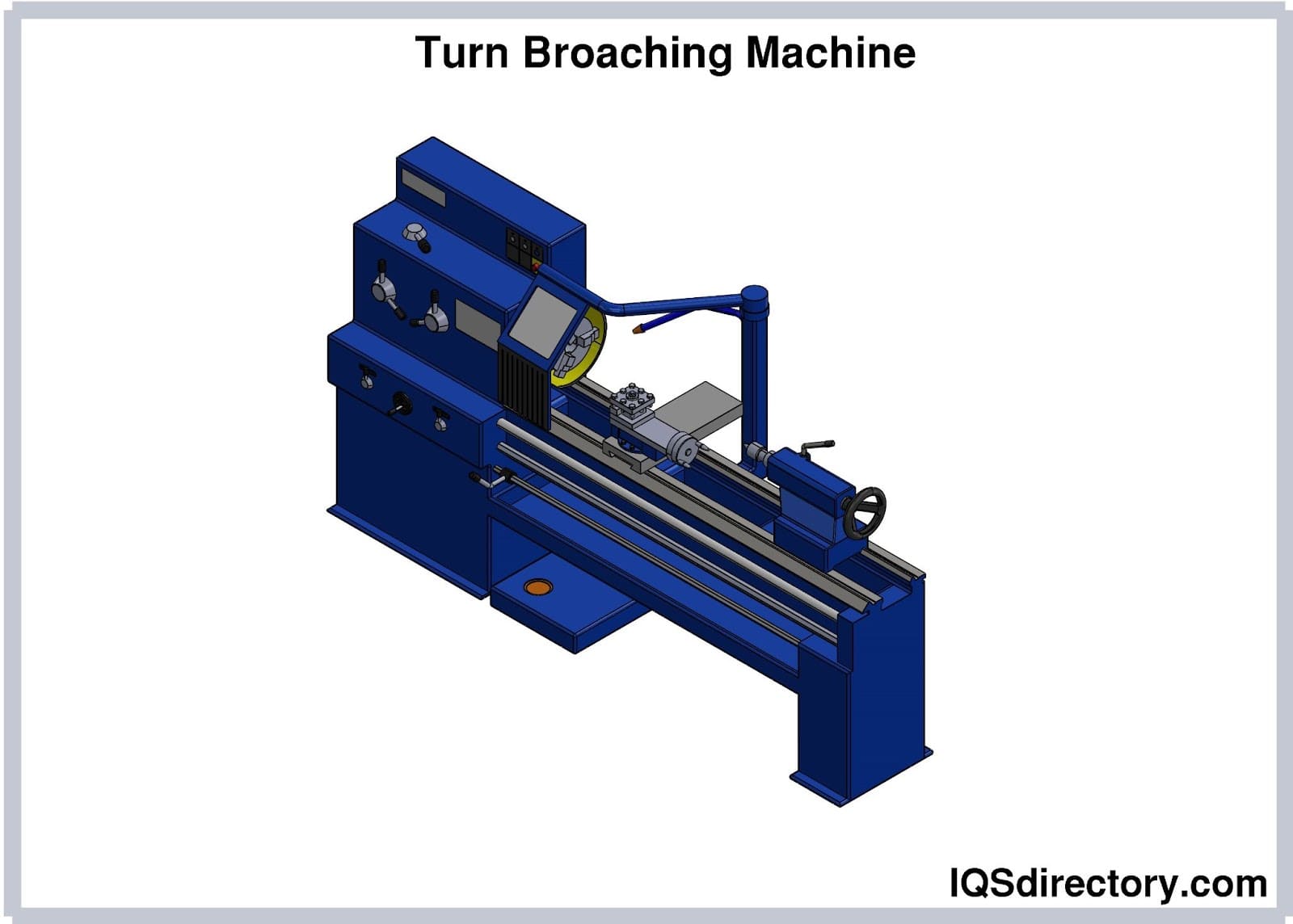

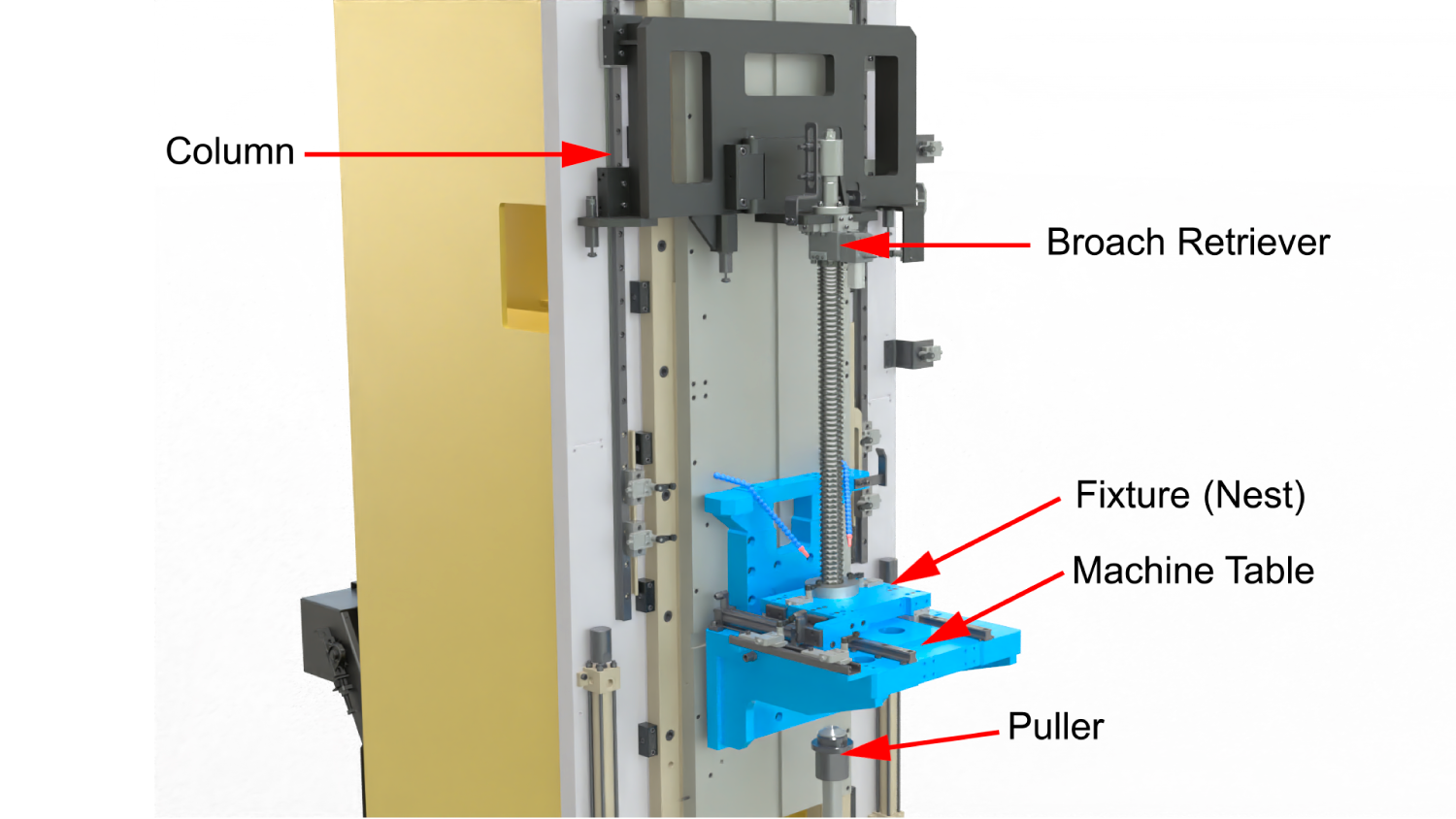

Vertical broaching machines are designed with a vertical orientation that allows for either pull or push broaching operations. This configuration is particularly beneficial for larger components and heavy-duty applications. The vertical setup often saves floor space, making it an attractive option for manufacturers with limited room. When purchasing, B2B buyers should assess the machine’s capacity and the types of materials it can handle to ensure it aligns with their production requirements.

In What Scenarios Is Surface Broaching Most Effective?

Surface broaching is specifically employed for creating flat surfaces on workpieces, offering a superior finish and high precision. This technique is often used in manufacturing applications where surface quality is critical, such as in tooling and automotive components. Buyers should consider the machine’s ability to handle different materials and the expected surface finish quality, as well as the efficiency of the broaching process to minimize production time and costs.

Why Choose Pull Broaching for High-Volume Production?

Pull broaching machines pull the broach through the workpiece, which is typically fixed in place. This method is known for its accuracy and is ideal for high-volume production runs where consistent quality is essential. B2B buyers should evaluate the machine’s setup complexity and the potential for automation to enhance productivity. Additionally, considering the long-term maintenance and tool wear will help in making an informed purchasing decision.

Key Industrial Applications of broaching machine

| Industry/Sector | Specific Application of broaching machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing of gears and spline shafts | High precision and efficiency in complex part production | Need for specialized broaches to match specific designs |

| Aerospace | Production of turbine blades and engine components | Ensures reliability and performance in critical parts | Compliance with strict industry standards and certifications |

| Medical Equipment | Creation of intricate surgical instruments and implants | Vital for patient safety and operational precision | Quality assurance and material compatibility requirements |

| Firearms Manufacturing | Rifling in gun barrels | Enhances accuracy and performance of firearms | Need for specialized broaching tools and maintenance plans |

| General Engineering | Production of custom mechanical parts | Versatility in producing diverse shapes and finishes | Consideration of material types and production volumes |

How is Broaching Used in the Automotive Industry and What Problems Does It Solve?

In the automotive industry, broaching machines are essential for manufacturing components such as gears and spline shafts, which require high precision and complex geometries. The broaching process allows manufacturers to produce these intricate shapes efficiently in a single pass, reducing machining time and costs. For international buyers, especially in regions like Brazil and South Africa, sourcing specialized broaches tailored to specific designs is crucial to meet the unique demands of automotive engineering.

What Are the Aerospace Applications of Broaching Machines?

Broaching machines are widely used in the aerospace sector for producing critical components like turbine blades and engine parts. The precision offered by broaching ensures that these parts meet stringent reliability and performance standards, which are vital in the aerospace industry. Buyers from the Middle East and Europe must consider compliance with industry-specific regulations and certifications when sourcing broaching machinery to ensure safety and performance in their applications.

How Does Broaching Impact Medical Equipment Manufacturing?

In medical equipment manufacturing, broaching machines are utilized to create intricate surgical instruments and implants that demand high precision. The broaching process enables the production of complex internal features necessary for functionality and safety in medical devices. Buyers in this sector should prioritize quality assurance and ensure that the materials used for broaching are compatible with medical standards, particularly in regions with evolving healthcare regulations.

What is the Role of Broaching in Firearms Manufacturing?

Broaching machines play a pivotal role in firearms manufacturing, particularly in the rifling of gun barrels, which is critical for enhancing accuracy and performance. This process allows manufacturers to create precise grooves that improve the bullet’s stability during flight. For B2B buyers in this sector, sourcing specialized broaching tools and establishing maintenance plans for consistent performance are essential considerations to ensure quality and reliability in their products.

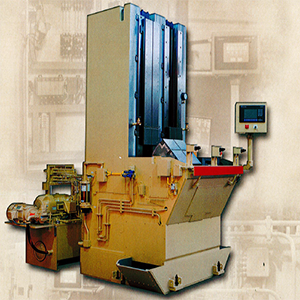

Illustrative image related to broaching machine

How is Broaching Beneficial in General Engineering Applications?

In general engineering, broaching machines are employed for producing custom mechanical parts, offering versatility in creating a variety of shapes and finishes. The efficiency of broaching allows for the rapid production of components, meeting diverse engineering needs. Buyers should consider the types of materials they intend to work with and the anticipated production volumes, as these factors will influence the selection of broaching machinery and tooling for their specific applications.

3 Common User Pain Points for ‘broaching machine’ & Their Solutions

Scenario 1: High Initial Setup Costs Hindering Production

The Problem: Many B2B buyers encounter the challenge of high initial setup costs associated with purchasing and installing broaching machines. This includes not only the capital expenditure for the machines themselves but also expenses related to tooling, fixtures, and skilled labor for setup. For companies, especially in regions like Africa and South America, where budgets may be tighter, these costs can be a significant barrier to adopting broaching technology. The fear of not achieving a quick return on investment can lead to hesitation in making such a substantial financial commitment.

The Solution: To address this pain point, buyers should conduct a thorough cost-benefit analysis before making a purchase. This analysis should include not only the initial setup costs but also the long-term savings from improved efficiency and reduced cycle times. Additionally, consider sourcing remanufactured or used broaching machines, which can substantially lower initial costs while still providing reliable performance. Collaborating with suppliers who offer flexible financing options or leasing agreements can also alleviate the burden of upfront costs. Establishing a phased implementation plan allows companies to spread out expenses and gradually integrate broaching into their production processes, maximizing return on investment over time.

Scenario 2: Tool Wear Affecting Production Quality

The Problem: As with any machining process, tool wear is a common issue that significantly impacts the quality of the machined parts. Over time, the cutting edges of the broach can dull, leading to increased tolerances and potential defects in the finished product. For industries like aerospace and automotive, where precision is critical, even minor deviations can result in costly rework or scrap, ultimately affecting profitability and customer satisfaction.

The Solution: Implementing a rigorous maintenance and monitoring schedule is essential to mitigate tool wear. B2B buyers should invest in high-quality broaching tools with advanced coatings that enhance durability and reduce wear. Regular inspections and timely replacements of worn tools can prevent quality issues before they arise. Moreover, integrating predictive maintenance technologies, such as IoT sensors, can help monitor the condition of broaching tools in real time, allowing for proactive adjustments to the machining process. This approach not only improves the quality of the output but also extends the lifespan of the tools, leading to significant cost savings.

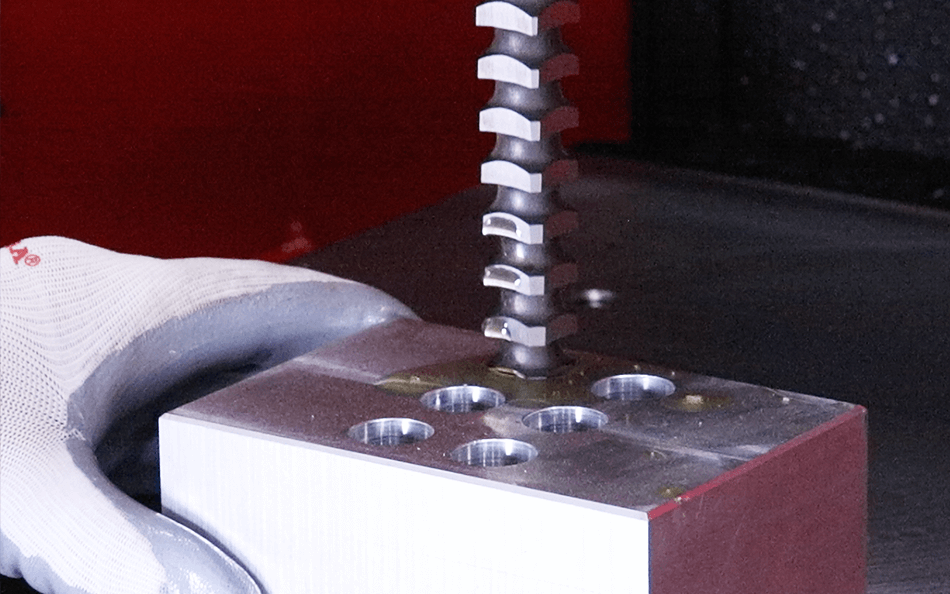

Illustrative image related to broaching machine

Scenario 3: Difficulty in Selecting the Right Broach for Specific Applications

The Problem: Choosing the correct broach for a specific application can be overwhelming for B2B buyers, especially given the wide variety of broach types and sizes available in the market. Inadequate selection can lead to inefficiencies, such as prolonged machining times or the inability to achieve desired tolerances. This challenge is compounded in regions with less access to technical support or expertise, leading to frustration and potential production delays.

The Solution: To simplify the broach selection process, buyers should engage with suppliers that offer comprehensive technical support and consultation services. It is beneficial to request demonstrations or trials to understand how different broaches perform on specific materials and applications. Buyers can also leverage online resources, such as webinars or detailed product guides, to educate themselves about broach types, including internal, external, and rotary broaching, and their respective applications. Establishing a close partnership with suppliers can facilitate ongoing support and knowledge sharing, ensuring that buyers can make informed decisions tailored to their unique production needs.

Strategic Material Selection Guide for broaching machine

What Materials Are Commonly Used in Broaching Machines?

When selecting materials for broaching machines, it’s essential to consider their properties and how they align with specific operational needs. Below, we analyze four common materials used in broaching machines, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

1. Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It typically has excellent wear resistance and can withstand high temperatures, which is crucial during broaching operations.

Pros & Cons:

The primary advantage of steel is its robustness, which leads to longevity and reduced maintenance costs. However, it can be susceptible to corrosion if not properly treated or coated, which may necessitate additional protective measures. The manufacturing complexity can vary depending on the specific steel grade used.

Impact on Application:

Steel is compatible with a wide range of media, including oils and coolants used in broaching processes. Its strength allows for effective broaching of tough materials.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure compliance with local standards, such as ASTM or ISO, particularly regarding the steel grade. In Europe, adherence to DIN standards is crucial.

2. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, making it ideal for applications where weight reduction is essential. It also has excellent thermal conductivity, which can help in dissipating heat during machining.

Illustrative image related to broaching machine

Pros & Cons:

The main advantage of aluminum is its lightweight nature, which can lead to reduced energy consumption during operation. However, it is less durable than steel and may not withstand high-pressure applications as effectively. Manufacturing complexity can be lower due to easier machinability.

Impact on Application:

Aluminum is suitable for broaching softer materials and is often used in industries that prioritize weight, such as aerospace.

Considerations for International Buyers:

Buyers should be aware of the specific aluminum grades that comply with international standards, as well as the potential for variations in availability based on regional supply chains.

3. Cast Iron

Key Properties:

Cast iron is known for its excellent wear resistance and vibration-damping properties. It can handle high temperatures and is often used in environments where thermal stability is required.

Illustrative image related to broaching machine

Pros & Cons:

The durability of cast iron makes it an excellent choice for heavy machinery, but it is brittle and can crack under extreme stress. The manufacturing process can be complex, leading to higher initial costs.

Impact on Application:

Cast iron is particularly suitable for broaching operations that require stability and precision, especially in automotive and heavy machinery applications.

Considerations for International Buyers:

Compliance with international standards for cast iron, such as ASTM A48, is essential. Buyers should also consider the availability of specific grades in their region.

4. Composite Materials

Key Properties:

Composite materials combine different substances to enhance properties like strength, weight, and corrosion resistance. They can be engineered for specific applications, providing versatility.

Illustrative image related to broaching machine

Pros & Cons:

The primary advantage of composites is their tailored properties, allowing for high performance in specialized applications. However, they can be more expensive and complex to manufacture, which may deter some buyers.

Impact on Application:

Composites are ideal for specialized broaching applications, particularly in industries requiring lightweight and high-strength components, such as aerospace and automotive.

Considerations for International Buyers:

Buyers should ensure that the composites meet relevant international standards and are compatible with the specific broaching processes they intend to use.

Illustrative image related to broaching machine

Summary Table of Material Selection for Broaching Machines

| Material | Typical Use Case for broaching machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty machining | High durability and wear resistance | Susceptible to corrosion | Medium |

| Aluminum | Aerospace components | Lightweight and good corrosion resistance | Less durable under high pressure | Medium |

| Cast Iron | Automotive and heavy machinery | Excellent wear resistance | Brittle and can crack | High |

| Composite Materials | Specialized aerospace components | Tailored properties for specific needs | Higher cost and manufacturing complexity | High |

This guide provides a comprehensive overview of material selection for broaching machines, assisting international B2B buyers in making informed decisions based on performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for broaching machine

What Are the Key Stages in the Manufacturing Process of Broaching Machines?

The manufacturing process for broaching machines involves several critical stages that ensure the final product meets the stringent requirements of various industries. Understanding these stages can help B2B buyers make informed decisions when sourcing machinery.

1. Material Preparation: What Materials Are Commonly Used?

The first step in manufacturing a broaching machine is material preparation. High-quality steel is typically used for the machine’s structure due to its strength and durability. Other materials, such as aluminum and specialized alloys, may also be employed for specific components to reduce weight while maintaining structural integrity. Material selection is crucial as it affects the machine’s performance and longevity. Buyers should inquire about the source and grade of materials used in the manufacturing process to ensure they meet industry standards.

2. What Techniques Are Employed in the Forming Stage?

The forming stage involves various machining techniques to shape the components of the broaching machine. This may include processes like CNC machining, laser cutting, and stamping. CNC (Computer Numerical Control) machining is particularly prevalent due to its precision and ability to create complex geometries. During this stage, components like the machine frame, guideways, and drive systems are formed to exact specifications, ensuring that they can withstand operational stresses during broaching.

3. How Is Assembly Conducted for Broaching Machines?

Once the individual components are prepared, the assembly stage begins. This involves fitting together the machined parts, including the motor, broach holder, and hydraulic systems, in a systematic manner. The assembly process requires skilled technicians who can ensure that all parts align correctly and function seamlessly. Buyers should look for suppliers who emphasize careful assembly practices, as this directly impacts the machine’s performance and reliability.

4. What Finishing Techniques Are Utilized?

The finishing stage is essential for improving the performance and aesthetics of the broaching machine. This may involve processes such as surface grinding, polishing, and applying protective coatings. Surface finishing enhances wear resistance and reduces friction, which is vital for the longevity of the machine. Additionally, proper finishing contributes to the overall precision of the broaching operation. Buyers should inquire about the finishing processes used by suppliers to ensure they align with their operational needs.

What Quality Assurance Measures Are Essential for Broaching Machines?

Quality assurance is a critical aspect of the manufacturing process, particularly for broaching machines that demand high precision and reliability.

1. Which International Standards Should B2B Buyers Be Aware Of?

International quality standards such as ISO 9001 are crucial for manufacturers of broaching machines. ISO 9001 outlines the requirements for a quality management system, ensuring that suppliers maintain consistent quality in their products. Additionally, industry-specific standards like CE marking and API certifications may apply, depending on the machine’s intended application. B2B buyers should verify that their suppliers comply with these standards, as this can significantly impact the machine’s safety and performance.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials upon arrival to ensure they meet the required specifications before production begins.

- IPQC monitors the manufacturing process, checking components at various stages to identify any deviations from quality standards early on.

- FQC is conducted after assembly and finishing to ensure the final product meets all specifications and performance criteria.

Buyers should request information about the QC processes from their suppliers to understand how quality is maintained throughout production.

3. What Testing Methods Are Commonly Used?

Various testing methods are employed to verify the quality of broaching machines. These may include dimensional inspections, functional testing, and performance evaluations under operational conditions. Dimensional inspections ensure that all components adhere to specified tolerances, while functional testing evaluates the machine’s ability to perform broaching operations effectively. Buyers should consider suppliers that provide detailed testing reports as part of their quality assurance documentation.

Illustrative image related to broaching machine

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for making informed purchasing decisions.

1. What Role Do Audits Play in Supplier Verification?

Conducting audits is one of the most effective ways for buyers to assess a supplier’s quality control processes. Audits can be performed by the buyers themselves or through third-party organizations. This involves a comprehensive review of the supplier’s manufacturing practices, QC measures, and adherence to international standards. Buyers should prioritize suppliers that welcome audits and are transparent about their quality management systems.

2. How Important Are Reports and Certifications?

Requesting quality control reports and certifications from suppliers is crucial for verifying their compliance with industry standards. These documents should detail the testing methods used, results obtained, and any certifications achieved. Buyers should ensure that these reports are current and relevant to the specific broaching machines being sourced.

3. What Are the QC Considerations for International Transactions?

When engaging in international transactions, B2B buyers must be aware of the nuances in quality certification requirements across different regions. For instance, while ISO 9001 is globally recognized, specific certifications like CE marking may be mandatory for machines sold within the European Union. Buyers should educate themselves on the regulatory landscape of their target markets to ensure compliance and avoid potential legal issues.

Conclusion: Making Informed Decisions on Broaching Machine Procurement

Understanding the manufacturing processes and quality assurance measures for broaching machines is vital for B2B buyers. By focusing on the key stages of manufacturing, quality standards, and verification methods, buyers can ensure they select reliable suppliers that meet their operational needs. This knowledge not only aids in procurement decisions but also fosters long-term partnerships based on quality and trust.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘broaching machine’

Introduction

When sourcing a broaching machine, it’s essential to follow a structured approach to ensure that your investment aligns with your operational needs and quality standards. This checklist will guide you through the critical steps to make an informed decision, maximizing the efficiency and effectiveness of your procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting a broaching machine that meets your production requirements. Consider factors such as the types of materials you will be machining, the dimensions of the workpieces, and the specific shapes or features needed (e.g., internal keyways, splines). This clarity will help you identify machines that can handle your production volume and complexity.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to create a list of reputable suppliers. Look for manufacturers that specialize in broaching machines and have a strong presence in your target markets, such as Africa, South America, the Middle East, and Europe. Utilize industry directories, trade shows, and online platforms to gather information about potential suppliers.

Step 3: Evaluate Supplier Experience and Expertise

Before committing to a supplier, assess their experience in the industry. Check their portfolio for successful projects and customer testimonials, focusing on their expertise in manufacturing broaching machines tailored to your specific needs. A supplier with a proven track record can provide valuable insights and support throughout the purchasing process.

Step 4: Verify Supplier Certifications and Compliance

It’s essential to ensure that your chosen supplier complies with international quality standards and certifications. Verify certifications such as ISO 9001 or relevant safety standards, which indicate a commitment to quality and reliability. Compliance with these standards minimizes the risk of machine failures and ensures better performance in your operations.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that outline the costs involved, including machine price, shipping, installation, and maintenance services. Compare these quotes not only on price but also on value-added services like training and after-sales support, which can significantly impact your overall investment.

Illustrative image related to broaching machine

Step 6: Assess Warranty and Support Services

A robust warranty and support service are critical factors in your decision-making process. Understand the warranty terms, including coverage duration and conditions, as well as the availability of technical support and spare parts. Strong after-sales support can enhance machine uptime and reduce operational disruptions.

Step 7: Conduct a Final Supplier Visit or Virtual Meeting

If possible, arrange a visit to the supplier’s facility or conduct a virtual meeting to assess their operations and capabilities. This visit can provide insights into their manufacturing processes, quality control measures, and overall professionalism. Engaging directly with the supplier can also clarify any remaining questions and build a rapport for future collaboration.

By following these steps, you can ensure a well-informed procurement process for your broaching machine, ultimately leading to improved production efficiency and quality in your operations.

Comprehensive Cost and Pricing Analysis for broaching machine Sourcing

What Are the Key Cost Components in Broaching Machine Sourcing?

When sourcing broaching machines, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The quality of raw materials significantly affects the cost of broaching machines. High-grade steel or specialized alloys used in the manufacturing process can increase costs but also enhance durability and performance.

-

Labor: Labor costs involve both skilled and unskilled workers engaged in the manufacturing, assembly, and quality control processes. Skilled labor is often required for precision machining, leading to higher wage expenses.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, equipment maintenance, and administrative expenses. These indirect costs are often allocated to each unit produced, impacting the final pricing.

-

Tooling: Tooling costs encompass the expenses related to the broaches and fixtures necessary for the broaching process. Specialized tooling can be a significant investment, especially for custom projects.

-

Quality Control (QC): Ensuring that broaching machines meet required specifications involves rigorous quality control measures. QC processes can add to the overall cost but are crucial for maintaining product reliability and performance.

-

Logistics: Shipping and transportation costs are vital, particularly for international buyers. Factors like distance, shipping method, and customs duties can significantly influence overall costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the margin can help buyers gauge the competitiveness of a supplier’s pricing.

How Do Price Influencers Affect Broaching Machine Costs?

Several factors can influence the pricing of broaching machines:

-

Volume/MOQ (Minimum Order Quantity): Ordering larger quantities can often lead to significant discounts. Buyers should evaluate their production needs to optimize order sizes for cost efficiency.

-

Specifications and Customization: Custom-built machines tailored to specific requirements will typically incur higher costs. Buyers must balance the need for customization against budget constraints.

-

Materials: The choice of materials can dramatically affect pricing. High-performance materials that enhance longevity and performance often come at a premium.

-

Quality and Certifications: Machines that meet international standards or have specific certifications may cost more but can provide assurance of reliability and performance, particularly important for industries like aerospace and automotive.

-

Supplier Factors: The reputation, location, and financial stability of the supplier can influence pricing. Suppliers with robust support services or warranties may charge higher prices but offer better long-term value.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) affect pricing and risk allocation. Understanding these terms can help buyers evaluate total costs more accurately.

What Are the Best Buyer Tips for Cost-Efficient Broaching Machine Sourcing?

B2B buyers can leverage several strategies to enhance cost-efficiency in sourcing broaching machines:

Illustrative image related to broaching machine

-

Negotiation: Always negotiate pricing and payment terms. Suppliers may be willing to offer discounts for early payments or bulk orders.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with a broaching machine, including maintenance, energy consumption, and replacement parts, rather than just the initial purchase price.

-

Research Supplier Backgrounds: Investigate potential suppliers’ histories, customer reviews, and case studies. A reliable supplier may justify a higher price through better service, warranty options, and support.

-

Consider Regional Variations: Pricing can vary significantly across regions. Understanding market conditions in Africa, South America, the Middle East, and Europe can help buyers identify the most cost-effective sourcing options.

-

Stay Informed on Pricing Trends: Market fluctuations in raw materials and labor costs can affect broaching machine pricing. Keeping abreast of these trends can help buyers make timely purchasing decisions.

Disclaimer on Indicative Prices

While indicative prices for broaching machines can be found (e.g., a 10-ton hydraulic vertical broaching machine priced at approximately $19,635), actual costs may vary based on the factors discussed above. Buyers should always request quotes tailored to their specific needs to ensure accurate budgeting and cost planning.

Alternatives Analysis: Comparing broaching machine With Other Solutions

Introduction: Understanding Alternatives to Broaching Machines

In the world of precision machining, selecting the right technology is crucial for achieving optimal performance and cost efficiency. While broaching machines are widely recognized for their high precision and efficiency in producing complex shapes, several alternative solutions can also meet similar manufacturing needs. This analysis explores viable alternatives to broaching machines, including their unique advantages and potential drawbacks, enabling B2B buyers to make informed decisions.

Comparison Table

| Comparison Aspect | Broaching Machine | CNC Machining | Electrical Discharge Machining (EDM) |

|---|---|---|---|

| Performance | High precision, single-pass efficiency | Versatile, multi-operation capability | Excellent for intricate shapes and hard materials |

| Cost | Moderate initial investment, lower long-term costs | Higher initial setup costs, variable operating costs | High initial costs, tooling and maintenance expenses |

| Ease of Implementation | Requires skilled setup and operation | Requires programming knowledge and setup | Complex setup, requires trained personnel |

| Maintenance | Regular tool wear management needed | Routine maintenance required | Tool wear management is critical, but less frequent |

| Best Use Case | Internal features, keyways, splines | General machining, versatile materials | Intricate shapes in hard metals, thin sections |

Detailed Breakdown of Alternatives

CNC Machining

CNC (Computer Numerical Control) machining is a highly versatile manufacturing process that uses computerized controls to operate machine tools. Its primary advantage lies in its flexibility; CNC machines can perform various operations such as milling, turning, and drilling, making them suitable for a broad range of applications. However, the initial setup and programming can be more complex and time-consuming compared to broaching machines. While CNC machining offers excellent performance for many tasks, it may not match the single-pass efficiency of broaching for specific internal features.

Electrical Discharge Machining (EDM)

EDM is a specialized machining process that uses electrical discharges to remove material from a workpiece. This method excels in creating intricate shapes and is particularly effective on hard metals and materials that are challenging to machine through traditional methods. The main advantage of EDM is its ability to produce complex geometries without applying significant mechanical force, which is beneficial for delicate or thin-walled components. However, the initial costs and maintenance of EDM equipment can be high, making it a less economical choice for high-volume production compared to broaching.

Illustrative image related to broaching machine

Conclusion: Making the Right Choice for Your Manufacturing Needs

When selecting between broaching machines and their alternatives, B2B buyers should carefully evaluate their specific production requirements, budget constraints, and the complexity of the components involved. Broaching machines are ideal for high-precision internal machining tasks and can offer lower long-term costs for volume production. In contrast, CNC machining provides versatility for a wider range of applications, while EDM is suited for intricate designs in hard materials. By considering these factors, buyers can determine the most suitable solution that aligns with their operational goals and enhances their manufacturing capabilities.

Essential Technical Properties and Trade Terminology for broaching machine

What Are the Essential Technical Properties of Broaching Machines?

When considering the procurement of broaching machines, international B2B buyers should pay close attention to several critical specifications that directly impact operational efficiency and output quality. Here are key properties to consider:

-

Material Grade: The construction material of the broaching machine affects its durability and performance. High-grade steel or cast iron is commonly used to ensure strength and stability under heavy loads. Selecting a machine made from premium materials can reduce maintenance costs and extend the machine’s lifespan, which is crucial for high-volume production environments.

-

Tolerance Levels: Tolerance defines the permissible limit of variation in a physical dimension. In broaching, tighter tolerances lead to higher precision in the final product, which is essential for industries such as aerospace and automotive, where components must fit together perfectly. Understanding tolerance levels will help buyers assess whether a machine can meet their specific manufacturing requirements.

-

Stroke Length: The stroke length of a broaching machine indicates the maximum distance the broach can travel during a cutting operation. A longer stroke length allows for the processing of larger workpieces or multiple parts in one cycle, enhancing productivity. Buyers should evaluate their typical workpiece sizes to select a machine that fits their production needs.

-

Broach Type Compatibility: Different broaching machines are designed to accommodate various types of broaches—linear, rotary, pull, or push broaches. Understanding the compatibility of the machine with the desired broach type is critical for ensuring operational efficiency and achieving the desired machining outcomes.

-

Hydraulic Pressure Capacity: For hydraulic broaching machines, the pressure capacity is a vital specification. Higher hydraulic pressure can lead to more efficient cutting and reduced cycle times. Buyers should consider the type of materials they will be broaching and choose a machine that can deliver adequate pressure for their specific applications.

What Are Common Trade Terms in Broaching Machine Procurement?

Familiarity with industry terminology can significantly enhance communication and negotiations for B2B buyers. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that are then sold under another company’s brand. In the context of broaching machines, understanding OEM relationships can help buyers identify quality equipment and support options available from manufacturers.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, especially for buyers looking to source machines or replacement parts in bulk.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For broaching machines, submitting an RFQ can help buyers compare costs and features from various manufacturers, facilitating informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is essential for managing shipping costs and risks when importing broaching machines.

-

Lead Time: Lead time refers to the amount of time it takes from placing an order to receiving the goods. For broaching machines, understanding lead times helps buyers plan their production schedules and manage workflow effectively.

By grasping these essential properties and trade terminologies, B2B buyers can navigate the procurement of broaching machines more effectively, ensuring they select the right equipment to meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the broaching machine Sector

What Are the Current Market Dynamics and Key Trends Affecting the Broaching Machine Sector?

The global market for broaching machines is currently experiencing significant growth driven by the increasing demand for precision machining in various industries, including automotive, aerospace, and medical equipment manufacturing. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe engage in sourcing, they must stay attuned to emerging trends such as the rise of automation and digital technologies. The integration of CNC (Computer Numerical Control) systems into broaching machines is enhancing operational efficiency and precision, allowing manufacturers to reduce lead times and improve product quality.

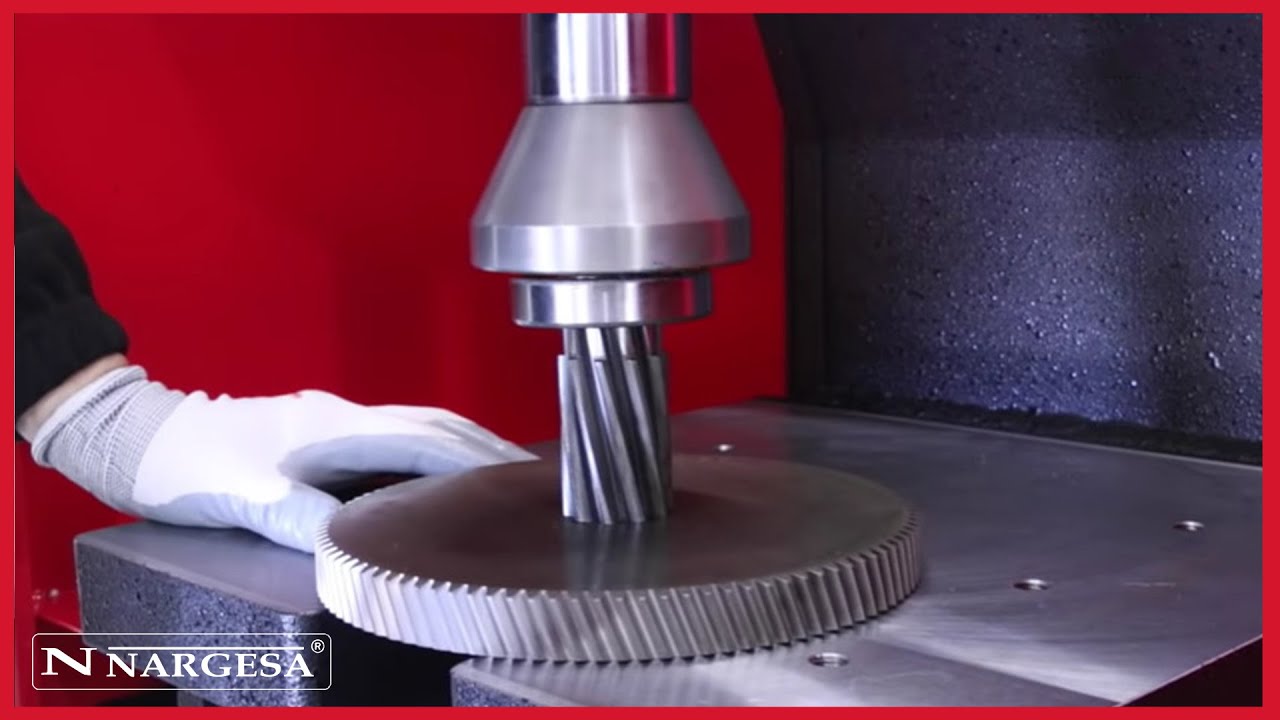

Illustrative image related to broaching machine

Furthermore, sustainability is becoming a critical consideration in sourcing decisions. Buyers are increasingly seeking suppliers that prioritize environmentally friendly practices, including waste reduction and energy-efficient operations. The shift towards Industry 4.0 is also influencing market dynamics, with the adoption of smart manufacturing technologies enabling real-time monitoring and predictive maintenance of broaching machines. This not only optimizes performance but also minimizes downtime, which is essential for maintaining competitive advantage.

Another key trend is the diversification of broaching machine types to cater to specialized applications. For instance, the development of vertical and horizontal broaching machines is addressing varying production needs, thereby expanding market opportunities for buyers looking for tailored solutions. These trends collectively shape the landscape for international B2B buyers, emphasizing the need for strategic sourcing that aligns with technological advancements and sustainability goals.

How Are Sustainability and Ethical Sourcing Impacting the Broaching Machine Sector?

Sustainability and ethical sourcing are increasingly pivotal in the decision-making processes of B2B buyers in the broaching machine sector. The environmental impact of manufacturing practices is under scrutiny, prompting companies to adopt greener operations. This includes the use of energy-efficient machines and minimizing waste through recycling and proper disposal of materials. Buyers are now more inclined to partner with manufacturers who can demonstrate a commitment to reducing their carbon footprint and enhancing resource efficiency.

Additionally, the importance of ethical supply chains cannot be overstated. Buyers are advocating for transparency and accountability in sourcing practices, seeking suppliers who adhere to fair labor standards and ethical procurement methods. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming prerequisites for suppliers aiming to compete in the global market.

The trend towards using sustainable materials in the production of broaching machines is also noteworthy. Manufacturers are exploring biodegradable lubricants and cutting fluids that reduce environmental impact without compromising performance. As these practices gain traction, they not only contribute to a positive brand image but also enhance the overall sustainability profile of the buyers’ operations.

What Is the Brief Evolution and History of Broaching Machines Relevant to B2B Buyers?

The evolution of broaching machines dates back to the early 19th century, when the broaching process was first utilized in the United States for producing intricate shapes in metal. Initially, broaching was a manual process, but as industrialization progressed, the introduction of hydraulic and mechanical systems transformed the efficiency and precision of broaching operations. The development of specialized broaching machines allowed for various forms of broaching, including linear, rotary, and surface broaching, catering to diverse industrial needs.

The adoption of CNC technology in the late 20th century marked a significant milestone in the evolution of broaching machines. This innovation enhanced automation, allowing for greater precision and repeatability in manufacturing processes. Today, the continuous advancements in materials and technologies, alongside a growing emphasis on sustainability, are shaping the future landscape of the broaching machine sector. Understanding this evolution is vital for B2B buyers as they navigate sourcing strategies that align with both historical insights and modern manufacturing demands.

Frequently Asked Questions (FAQs) for B2B Buyers of broaching machine

-

How do I choose the right broaching machine for my manufacturing needs?

Choosing the right broaching machine involves assessing your specific manufacturing requirements, including the type of material you will be working with, the complexity of the shapes needed, and your production volume. Evaluate the machine’s capacity, such as stroke length and tonnage, to ensure it can accommodate your workpieces. Additionally, consider whether you need a vertical or horizontal machine, as well as any automation features that could enhance efficiency. Consulting with suppliers and reviewing case studies from similar industries can also provide insights into the best options available. -

What are the benefits of investing in a new versus used broaching machine?

Investing in a new broaching machine typically offers the latest technology, improved efficiency, and warranty coverage, which can lead to lower operational costs in the long term. Conversely, used machines can provide significant cost savings, especially for startups or smaller manufacturers. However, it is crucial to assess the condition, maintenance history, and any potential upgrades of a used machine. Ultimately, your choice should align with your budget, production needs, and long-term growth strategy. -

What customization options are available for broaching machines?

Many manufacturers offer customization options for broaching machines to suit specific production needs. Customizations may include modifications to the broaching head, tooling, software for CNC machines, and additional fixtures. Discussing your requirements with the supplier can lead to tailored solutions that enhance the machine’s performance. Be prepared to provide detailed specifications regarding the types of workpieces and features you need, which will aid the supplier in developing a suitable solution. -

What are the typical minimum order quantities (MOQs) for broaching machines?

Minimum order quantities for broaching machines can vary significantly based on the manufacturer and the complexity of the machine. For standard models, MOQs may be lower, while customized or specialized machines may require larger orders. When sourcing internationally, inquire about MOQs upfront to avoid unexpected costs. Additionally, consider whether suppliers offer financing options or leasing arrangements, which can provide flexibility in managing cash flow. -

How can I verify the credibility of a broaching machine supplier?

To verify a broaching machine supplier’s credibility, start by researching their industry reputation through online reviews, case studies, and client testimonials. Check for certifications and compliance with international standards, such as ISO certifications, which indicate quality management practices. Engaging in direct communication with the supplier can also provide insights into their customer service and technical support capabilities. Requesting references from existing clients can further help in assessing their reliability and service quality. -

What payment terms should I expect when purchasing a broaching machine?

Payment terms for broaching machines can vary by supplier and may include options such as upfront payment, installment plans, or financing. Common practices involve a deposit upon order confirmation, with the balance due upon delivery or installation. When negotiating payment terms, consider factors like your budget, the supplier’s credibility, and any associated risks. It’s advisable to have a clear written agreement that outlines all payment details, including timelines and penalties for late payments. -

What quality assurance measures should I look for in broaching machines?

Quality assurance measures are crucial when purchasing broaching machines. Look for suppliers who adhere to industry standards and conduct rigorous testing on their machines before delivery. Inquire about their quality control processes, including inspection protocols and any certifications they possess. Additionally, consider suppliers who offer warranties or guarantees on their machines, as this indicates confidence in their product quality and provides you with recourse in case of defects or issues. -

How do I manage logistics when importing a broaching machine internationally?

Managing logistics for importing a broaching machine involves coordinating with suppliers, freight forwarders, and customs agents. Start by understanding the shipping options available, including air freight for faster delivery or sea freight for cost savings. Ensure you have all necessary documentation, such as invoices and customs declarations, to facilitate smooth customs clearance. It’s also wise to factor in lead times, import duties, and local regulations in your planning to avoid delays and additional costs upon arrival.

Top 9 Broaching Machine Manufacturers & Suppliers List

1. Broaching Machine – New & Used Broaching Solutions

Domain: broachingmachine.com

Registered: 1996 (29 years)

Introduction: Best New, Used, and Remanufactured Broaching Machines. New Broaching Machines: Numerous standard lines and special machines for unique applications. Used Broaching Machines: Over 350 used machines and broach sharpeners available as remanufactured turnkey systems. Broach Tools: Design and build broaches, sharpening, reconditioning, and repair service. Turbine Disc Machines, Broach Pullers & Retriev…

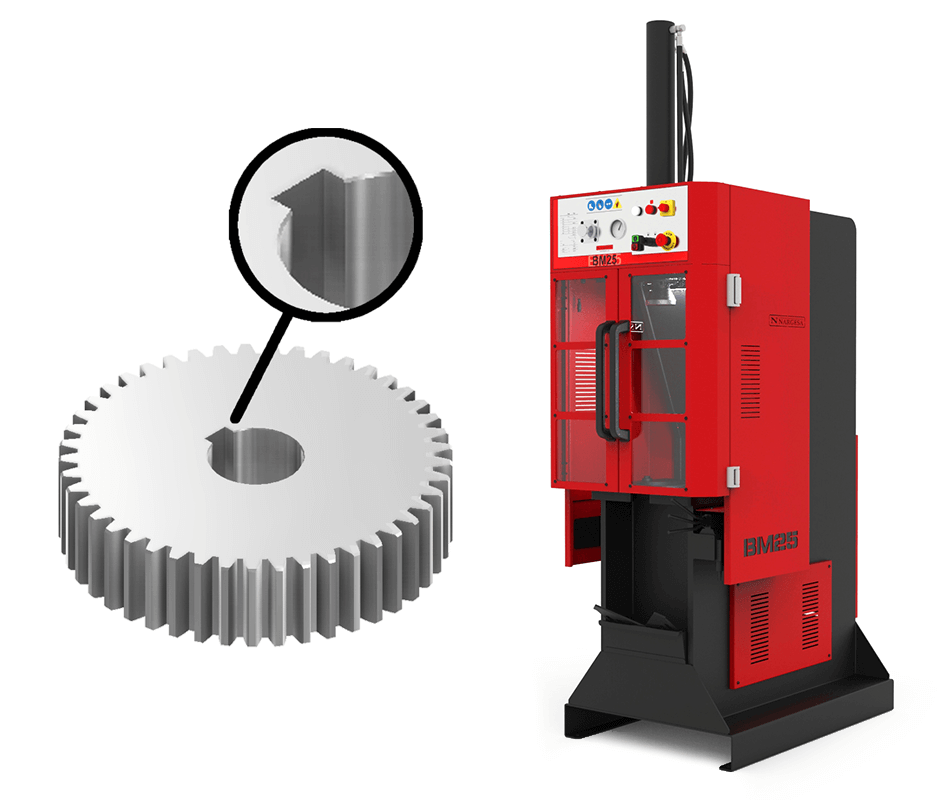

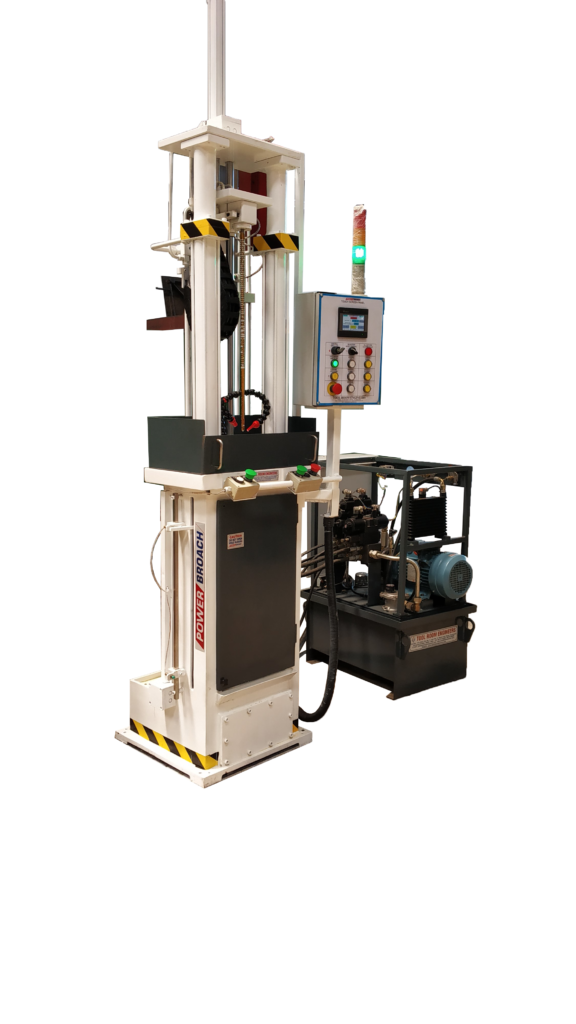

2. Nargesa USA – 10 Ton Hydraulic Vertical Broaching Machine

Domain: nargesausa.com

Registered: 2017 (8 years)

Introduction: This company, Nargesa USA – 10 Ton Hydraulic Vertical Broaching Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Quantum Machinery Group – BM25 Hydraulic Vertical Broaching Machine

Domain: quantummachinerygroup.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “BM25 Hydraulic Vertical Broaching Machine”, “price”: “$19,635.00”, “motor_power”: “2.2Kw / 3 Hp”, “tension”: “3-phased 230/400 V”, “hydraulic_power”: “10 Tons”, “max_broaching_capacity”: “25mm”, “working_speed”: “24mm/s”, “return_speed”: “54mm/s”, “pump_flow”: “7.5 Liters”, “shank_displacement”: “600mm”, “gooseneck”: “300mm”, “max_piece_diameter”: “600mm”, “bench_dimensions”: “42…

4. TFG USA – Broaching Solutions

Domain: tfgusa.com

Registered: 2008 (17 years)

Introduction: Broaching is a machining process that uses a multi-toothed cutting tool called a broach to remove material and create intricate shapes and precise internal features in various workpieces. Key components include the broach, workpiece, broaching machine, fixture, and cutting fluid. The process involves setup and fixturing, broach selection, broaching operation, and inspection. Types of broaching inc…

5. Colonial Tool – CNC Broaching Machines

Domain: colonialtool.com

Registered: 1996 (29 years)

Introduction: CNC Broaching Machine Manufacturer with over 85 years of experience in automotive parts and other industries. High precision CNC broaching machines designed to maximize productivity, minimize downtime, and ensure quality. Features include indexable heads, quick-change broaches and cutters, advanced engineering for high tolerances, and precision-built tooling. Offers a broad range of broaching mach…

6. IQS Directory – Broaching Process

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Broaching is a machining process that uses a hardened tool with serrated edges to remove material from a workpiece. It involves a multi-toothed tool that can move while the workpiece remains stationary or vice versa. Broaching can be internal (e.g., keyways, concentricity) or external (e.g., slab, slot, contour). Broaching machines can be horizontal or vertical, with horizontal machines ideal for …

7. Nachia America – Precision Broaching & Roll Forming Solutions

Domain: nachiamerica.com

Registered: 2003 (22 years)

Introduction: Broaching Machines, Precision Roll Forming Machines, Machining Cell, Power Finishers, Skiving Machining Center for Gears

8. Ty Miles – High Speed Broaching Machines

Domain: tymiles.com

Registered: 1996 (29 years)

Introduction: Ty Miles offers high speed broaching machines with over 60 years of experience and more than a thousand systems in operation. They provide a full line of broaching machines including light duty, heavy duty, special machines, and table-up machines. Their services include production broaching for internal and surface applications, broach sharpening and reconditioning, and retrofitting existing broac…

9. AXISCO – Broaching Machines

Domain: twaxisco.com

Registered: 2007 (18 years)

Introduction: AXISCO offers a range of broaching machines including: 1. CNC Helical Broaching Machine 2. CNC Hard Broaching Machine 3. Servo Drive Table Up Broaching Machine 4. Hydraulic Internal Spline Broaching Machine 5. Hydraulic Surface Broaching Machine 6. Broach Tools & Broach Grinders. The CHU-Series features servo table-up broaching machines with advanced technology and a smart interface. The CHI-Serie…

Strategic Sourcing Conclusion and Outlook for broaching machine

In the evolving landscape of precision machining, broaching machines stand out as a critical asset for industries requiring high accuracy and efficiency. Strategic sourcing of these machines not only facilitates access to innovative designs and advanced technologies but also enhances operational productivity and cost-effectiveness. By leveraging the versatility of broaching, manufacturers can streamline production processes, reduce cycle times, and achieve superior surface finishes, making it an invaluable choice for sectors ranging from automotive to aerospace.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe consider their sourcing strategies, it is essential to focus on suppliers that prioritize quality, innovation, and after-sales support. Investing in reliable broaching solutions can significantly impact your competitive edge in the global marketplace.

Looking ahead, the integration of automation and advanced materials will further shape the future of broaching technology. Buyers should remain proactive in exploring partnerships that embrace these trends, ensuring they are well-positioned to adapt and thrive in an increasingly dynamic industry. Engage with trusted suppliers today to secure the broaching machines that will drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.