A Deep Dive into Belt Driven Blower Solution

Introduction: Navigating the Global Market for belt driven blower

In today’s competitive landscape, sourcing high-quality belt driven blowers presents a significant challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As businesses strive to enhance operational efficiency while managing costs, understanding the intricacies of belt driven blower technology becomes essential. This guide is designed to equip international buyers with the knowledge to navigate the complexities of the global market for belt driven blowers.

Within these pages, we will explore various types of blowers, their applications across different industries, and how to effectively vet suppliers to ensure reliability and quality. Additionally, we will delve into the cost factors associated with these essential tools, providing a comprehensive overview that empowers informed purchasing decisions.

By addressing the unique needs and challenges faced by B2B buyers in diverse markets such as Nigeria and Brazil, this guide serves as a vital resource. It not only simplifies the selection process but also enhances negotiation strategies, ultimately leading to better investment outcomes. Whether you’re looking to optimize HVAC systems, improve manufacturing processes, or enhance air circulation, understanding the nuances of belt driven blowers will be a critical asset in achieving your business goals.

Understanding belt driven blower Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Squirrel Cage Blowers | Compact design, high efficiency, low maintenance | HVAC systems, industrial ventilation | Pros: High airflow, durable. Cons: Limited pressure capabilities. |

| Centrifugal Blowers | Designed for high pressure and airflow, often larger in size | Manufacturing, dust collection, pneumatic conveying | Pros: High efficiency, suitable for heavy-duty applications. Cons: Bulkier and may require more space. |

| Furnace Blowers | Specifically designed for heating systems | Residential and commercial heating systems | Pros: Optimized for heating applications. Cons: May not be versatile for other uses. |

| Inline Duct Blowers | Slim profile, designed for ducted systems | HVAC systems, air distribution | Pros: Space-saving, efficient for ductwork. Cons: Limited airflow compared to larger models. |

| Backward Inclined Blowers | Unique blade design reduces noise and increases efficiency | Industrial applications, clean air systems | Pros: Quieter operation, efficient. Cons: Higher initial cost. |

What Are Squirrel Cage Blowers and Where Are They Used?

Squirrel cage blowers are characterized by their compact design and high efficiency, making them ideal for HVAC systems and industrial ventilation. These blowers feature a cylindrical rotor with blades that create airflow through centrifugal force. Businesses should consider the installation space and maintenance requirements when purchasing, as these blowers are generally low-maintenance but can be less effective in high-pressure scenarios.

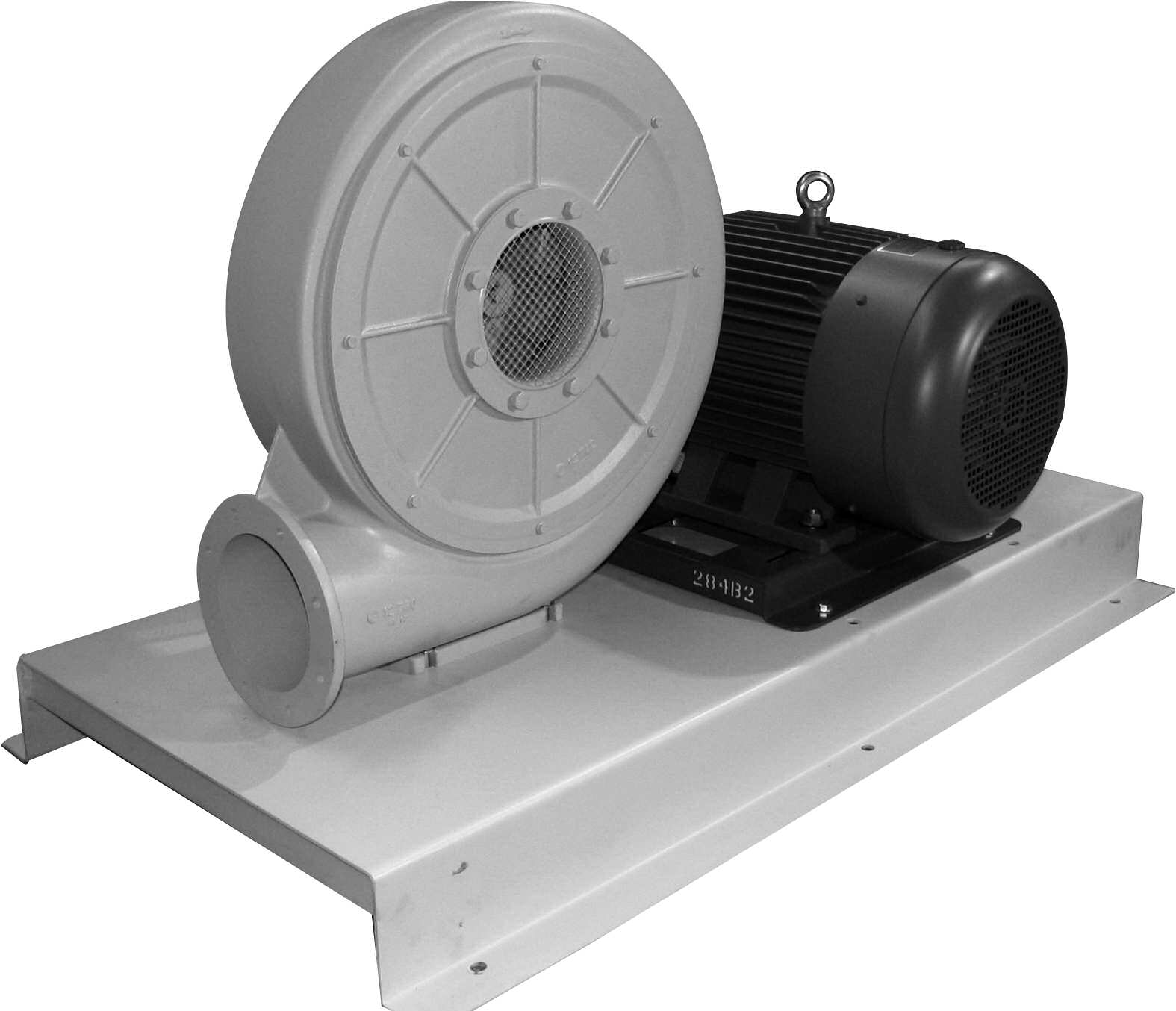

How Do Centrifugal Blowers Stand Out?

Centrifugal blowers are designed to handle high pressure and airflow, often featuring a larger size to accommodate their robust performance. Commonly utilized in manufacturing and dust collection applications, they excel in pneumatic conveying tasks. Buyers should consider the blower’s size, energy consumption, and application requirements, as these blowers are efficient but may require additional space and resources.

What Makes Furnace Blowers Essential?

Furnace blowers are specifically engineered for heating systems, offering optimized performance for both residential and commercial heating applications. They are designed to move warm air efficiently throughout a space, ensuring consistent temperature control. When selecting a furnace blower, businesses should evaluate compatibility with existing systems and the blower’s energy efficiency, as these factors directly impact operational costs.

Why Choose Inline Duct Blowers for Ducted Systems?

Inline duct blowers feature a slim profile, making them suitable for installation within ductwork. They are particularly effective for air distribution in HVAC systems and are designed to be energy-efficient. B2B buyers should assess the blower’s airflow capacity and noise levels, as these factors can influence overall system performance and comfort levels in a facility.

How Do Backward Inclined Blowers Enhance Efficiency?

Backward inclined blowers are known for their unique blade design that minimizes noise while maximizing efficiency. They are commonly used in industrial applications and clean air systems where noise reduction is a priority. Buyers should consider the initial investment, as these blowers may have a higher upfront cost but offer long-term savings through their energy-efficient operation and reduced maintenance needs.

Key Industrial Applications of belt driven blower

| Industry/Sector | Specific Application of belt driven blower | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC | Air circulation in commercial buildings | Enhances indoor air quality and energy efficiency | Ensure compatibility with existing HVAC systems and local regulations. |

| Manufacturing | Dust and fume extraction in production facilities | Improves workplace safety and compliance with regulations | Select blowers that offer high CFM ratings and durability under continuous use. |

| Automotive Repair | Ventilation in workshops | Maintains a safe and comfortable working environment | Consider noise levels and energy efficiency for long-term operational costs. |

| Agriculture | Ventilation in greenhouses | Optimizes plant growth conditions and reduces pests | Look for models that can operate in humid environments and provide adjustable airflow. |

| Firefighting | Air supply for firefighting equipment | Ensures effective operation of equipment in emergencies | Focus on blowers with high durability and portability for rapid deployment. |

How Is a Belt Driven Blower Used in HVAC Applications?

In HVAC systems, belt driven blowers are integral for air circulation within commercial buildings. They efficiently distribute conditioned air, ensuring optimal indoor air quality and temperature control. These blowers address issues like stagnant air and excessive humidity, which can impact occupant comfort and health. International buyers, especially in regions with varying climates such as Africa and the Middle East, should consider sourcing blowers that comply with local energy standards and can handle diverse environmental conditions.

What Role Does a Belt Driven Blower Play in Manufacturing?

In manufacturing settings, belt driven blowers are essential for dust and fume extraction. They help maintain a clean and safe workspace by removing hazardous particles from the air, thus ensuring compliance with health and safety regulations. This not only protects workers but also minimizes the risk of equipment damage caused by dust accumulation. Buyers in South America and Europe should prioritize blowers with high airflow capacities and robust construction to withstand continuous operation in demanding environments.

How Do Belt Driven Blowers Enhance Automotive Repair Shops?

In automotive repair shops, belt driven blowers are used for ventilation, providing fresh air circulation and preventing the buildup of harmful fumes. This is crucial for maintaining a safe working environment for technicians. Additionally, effective ventilation can enhance the drying process of painted surfaces. B2B buyers in Brazil and Nigeria should consider blowers that operate quietly and are energy-efficient to reduce overall operational costs, especially in high-traffic workshops.

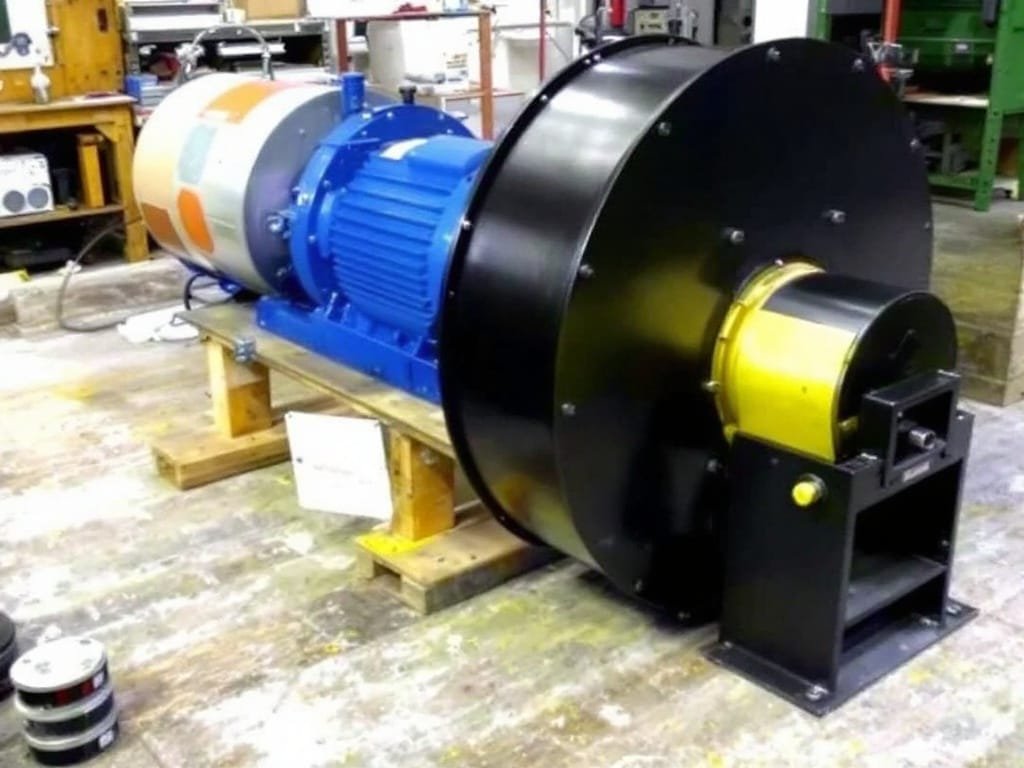

Illustrative image related to belt driven blower

What Benefits Do Belt Driven Blowers Offer in Agriculture?

In agricultural applications, particularly in greenhouses, belt driven blowers are used to ensure adequate ventilation and airflow. This helps to regulate temperature and humidity, creating optimal conditions for plant growth while deterring pests. Buyers in regions with humid climates should seek blowers that can withstand moisture and provide adjustable airflow to cater to varying crop needs. Ensuring the blower is suitable for agricultural settings can significantly enhance productivity and crop yield.

How Are Belt Driven Blowers Utilized in Firefighting?

Belt driven blowers are vital in firefighting scenarios, providing a reliable air supply for various firefighting equipment. Their high airflow rates ensure efficient operation during emergencies, which is critical for rapid response. International buyers in the Middle East, where firefighting equipment needs to be robust and portable, should focus on sourcing durable blowers that can operate effectively under extreme conditions. The ability to quickly deploy these blowers can be a lifesaver in critical situations.

3 Common User Pain Points for ‘belt driven blower’ & Their Solutions

Scenario 1: Inconsistent Airflow Disrupts Operations

The Problem: A manufacturing facility in Brazil relies on a belt-driven blower to maintain consistent airflow for its production line. However, the blower often experiences fluctuations in performance, leading to inconsistent air delivery. This inconsistency not only hampers productivity but also affects product quality, ultimately resulting in financial losses and dissatisfied customers. The facility manager is frustrated, as the blower’s specifications don’t seem to align with operational needs.

The Solution: To address this issue, the facility should conduct a thorough evaluation of the blower’s specifications, including its airflow capacity (CFM) and pressure capabilities (inches of water column). It’s crucial to ensure that the selected blower is appropriately sized for the application. Engaging with a reputable supplier who understands the nuances of belt-driven blowers can help in sourcing a unit that meets specific operational demands. Additionally, implementing regular maintenance protocols, such as checking belt tension and inspecting bearings, can help prevent performance inconsistencies. By aligning the blower’s capabilities with operational requirements and ensuring proper maintenance, the facility can achieve stable airflow, enhancing productivity and product quality.

Scenario 2: High Operating Costs Due to Inefficiency

The Problem: A woodworking shop in Nigeria is facing escalating energy costs, largely attributed to the inefficiency of their outdated belt-driven blower. The blower consumes excessive electricity, leading to increased operational expenses. The owner is concerned that these rising costs may threaten the business’s profitability, especially in a competitive market where profit margins are slim.

The Solution: The shop owner should consider upgrading to a more energy-efficient belt-driven blower model. Modern blowers are designed with advanced technology that improves energy consumption without sacrificing performance. When sourcing a new blower, the owner should look for models that have high-efficiency ratings and are equipped with variable speed drives, allowing for better control over energy use. Furthermore, conducting an energy audit can help identify specific inefficiencies in the current setup. By investing in an energy-efficient blower and optimizing airflow settings based on actual production needs, the shop can significantly reduce energy costs and improve its bottom line.

Scenario 3: Maintenance Challenges Leading to Downtime

The Problem: A HVAC contractor in South America frequently encounters issues with the maintenance of belt-driven blowers, resulting in unexpected downtime during critical projects. The contractor struggles to keep up with regular maintenance schedules due to a lack of clear guidelines on what maintenance tasks are necessary and how often they should be performed. This unpredictability affects project timelines and client satisfaction.

The Solution: To mitigate maintenance challenges, the contractor should develop a structured maintenance plan that outlines specific tasks, frequencies, and responsibilities. This plan should include regular inspections of belts for wear, lubrication of bearings, and cleaning of blower components to prevent dust buildup. Additionally, the contractor can leverage digital tools or maintenance management software to set reminders for maintenance tasks and track performance metrics. Engaging with a knowledgeable supplier who can provide detailed maintenance guidelines specific to the blower model can also enhance understanding and efficiency. By establishing a comprehensive maintenance strategy, the contractor can reduce downtime, improve reliability, and enhance overall service delivery to clients.

Strategic Material Selection Guide for belt driven blower

What Are the Key Materials Used in Belt Driven Blowers?

When selecting materials for belt driven blowers, it’s crucial to consider their properties, advantages, disadvantages, and application impacts. Here, we analyze four common materials used in the construction of belt driven blowers: aluminum, steel, composite materials, and rubber.

Illustrative image related to belt driven blower

How Does Aluminum Benefit Belt Driven Blowers?

Aluminum is frequently used in the manufacturing of belt driven blowers due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 200°C (392°F) and can withstand moderate pressure levels, making it suitable for various applications.

Pros: Aluminum’s lightweight characteristic facilitates easier installation and maintenance. Its resistance to corrosion extends the lifespan of the blower, making it a cost-effective choice in the long run.

Cons: While aluminum is durable, it may not withstand extreme pressures as well as steel. Additionally, the manufacturing process can be more complex due to the need for specialized tooling.

Impact on Application: Aluminum is compatible with a wide range of media, including air and gases, but may not be ideal for applications involving abrasive materials.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential. Buyers in Africa and South America may prefer aluminum for its lightweight properties, which reduce shipping costs.

What Role Does Steel Play in Belt Driven Blowers?

Steel is another common material used in belt driven blowers, known for its high strength and durability. It can handle higher temperature and pressure ratings, typically up to 300°C (572°F), making it suitable for demanding environments.

Pros: Steel’s robustness ensures long-term reliability and performance, especially in heavy-duty applications. It is also relatively cost-effective compared to other materials.

Cons: Steel is heavier than aluminum, which can complicate installation and increase transportation costs. Additionally, it is more prone to corrosion unless treated or coated.

Impact on Application: Steel is suitable for applications involving high-pressure air or corrosive gases, but it may require additional coatings to prevent rust.

Illustrative image related to belt driven blower

Considerations for International Buyers: Buyers in the Middle East may prioritize steel for its strength in high-temperature environments. Compliance with local standards is critical, especially in industrial applications.

How Do Composite Materials Enhance Performance in Belt Driven Blowers?

Composite materials, often used for impellers and fan blades, offer unique benefits such as high strength-to-weight ratios and excellent corrosion resistance. They can withstand temperatures up to 150°C (302°F) and are designed to handle various pressures.

Pros: Composites are lightweight, reducing the overall weight of the blower, which can enhance performance and efficiency. They also provide safety advantages, as they are designed to disintegrate upon impact.

Cons: The manufacturing process for composites can be more complex and costly. Additionally, they may not be suitable for all applications, particularly those involving extreme temperatures.

Impact on Application: Composites are ideal for applications requiring high airflow and low maintenance, such as HVAC systems.

Considerations for International Buyers: Buyers in Europe may favor composites for their safety features. Understanding local regulations regarding composite materials is essential for compliance.

What Is the Importance of Rubber in Belt Driven Blowers?

Rubber is primarily used for belts and seals in belt driven blowers. It can withstand moderate temperatures and pressures, making it suitable for various applications.

Pros: Rubber offers excellent flexibility and durability, allowing for smooth operation and reduced vibration in blowers. It is also cost-effective and easy to manufacture.

Illustrative image related to belt driven blower

Cons: Rubber has a lower temperature resistance compared to metals and composites, typically around 100°C (212°F). It may degrade over time, especially when exposed to UV light or harsh chemicals.

Impact on Application: Rubber is ideal for applications where vibration dampening is essential, but it may not be suitable for high-temperature or high-pressure environments.

Considerations for International Buyers: Buyers in regions with extreme weather conditions, such as Africa, should consider the longevity of rubber materials in their specific environments.

Summary Table of Material Selection for Belt Driven Blowers

| Material | Typical Use Case for belt driven blower | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight blowers for HVAC systems | Corrosion resistance | Limited pressure handling | Medium |

| Steel | Heavy-duty industrial applications | High strength and durability | Heavier and prone to corrosion | Low |

| Composite | Impellers and fan blades | Lightweight and safe | Higher manufacturing complexity | High |

| Rubber | Belts and seals | Flexibility and cost-effectiveness | Lower temperature resistance | Low |

This guide provides a comprehensive overview of material options for belt driven blowers, helping international B2B buyers make informed decisions based on performance requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for belt driven blower

What Are the Main Stages of the Manufacturing Process for Belt Driven Blowers?

The manufacturing process for belt driven blowers involves several critical stages, each designed to ensure the highest quality and efficiency. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Belt Driven Blowers?

Material preparation is the first step in manufacturing belt driven blowers. High-quality raw materials, typically metals like aluminum or steel, are sourced based on the specific requirements of the blower design. These materials undergo rigorous inspections to ensure they meet predefined specifications. For instance, steel components may be assessed for tensile strength and corrosion resistance. Additionally, rubber belts are selected for their durability and resistance to high temperatures, which are essential for maintaining performance under operational stress.

What Forming Techniques Are Used in the Production of Belt Driven Blowers?

The next stage is forming, where the prepared materials are shaped into usable components. Techniques such as stamping, machining, and welding are commonly employed.

- Stamping is used to create fan blades and housing components, allowing for precision and uniformity.

- Machining is utilized to achieve specific dimensions and tolerances on critical parts, such as motor mounts and drive shafts.

- Welding is applied to join various metal components, ensuring structural integrity and durability. Advanced welding techniques, such as TIG and MIG welding, are often used to enhance the quality of joints.

This stage is crucial, as the accuracy in forming will directly impact the blower’s performance.

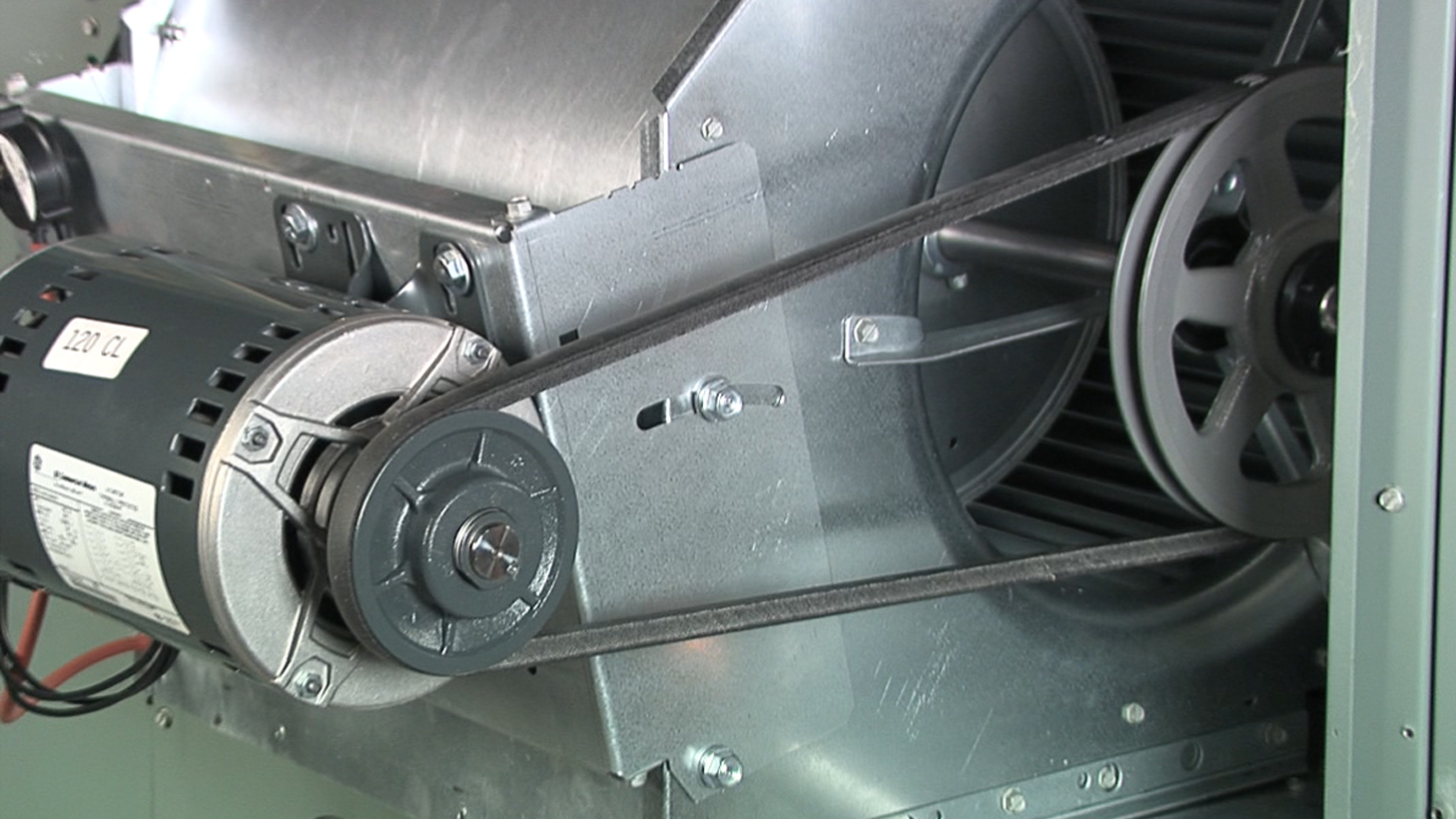

How Is the Assembly Process Conducted for Belt Driven Blowers?

Following forming, the assembly process begins. This stage involves integrating all components, including the blower housing, motor, belts, and impellers. Skilled technicians typically perform this assembly under stringent guidelines to maintain quality and safety standards.

Illustrative image related to belt driven blower

During assembly, each component is inspected for fit and functionality. Proper alignment of the motor and blower housing is essential to minimize vibration and ensure efficient operation. Additionally, the installation of belts must be precise to prevent slippage or premature wear.

What Finishing Techniques Are Applied to Ensure Quality in Belt Driven Blowers?

The final manufacturing stage is finishing, which includes surface treatment and painting. Components may undergo processes such as powder coating or anodizing to enhance corrosion resistance and aesthetic appeal. This not only improves the lifespan of the blower but also contributes to its overall performance.

What Quality Assurance Standards Are Relevant for Belt Driven Blowers?

Quality assurance is a critical aspect of the manufacturing process for belt driven blowers. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain a consistent quality management system. This certification indicates that the manufacturer has implemented effective processes for continuous improvement and customer satisfaction.

Which Industry-Specific Standards Should B2B Buyers Be Aware Of?

In addition to ISO standards, specific industry certifications may apply, such as CE marking in Europe, which signifies compliance with health, safety, and environmental protection standards. The American Petroleum Institute (API) certification is also relevant for blowers used in the oil and gas industry, ensuring that products meet rigorous safety and performance criteria.

Illustrative image related to belt driven blower

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process with specific checkpoints to ensure compliance with standards.

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials before they enter the production line. It ensures that all materials meet predefined quality standards.

-

In-Process Quality Control (IPQC): During manufacturing, various inspections are conducted at each stage, including checks on dimensional accuracy and assembly integrity. This ongoing monitoring helps catch defects early in the process.

-

Final Quality Control (FQC): Once assembly is complete, the final product undergoes comprehensive testing. This may include performance tests to verify airflow, noise levels, and energy efficiency.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should actively verify the QC processes of potential suppliers to ensure they meet their expectations. Here are some effective strategies:

-

Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into the quality management systems in place. Buyers should review the supplier’s adherence to international standards and specific industry certifications.

-

Request Quality Reports: Suppliers should be able to provide documentation, such as inspection reports and quality certifications. These documents serve as evidence of compliance with quality standards.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspectors can provide an unbiased assessment of the manufacturing processes and the final product quality. This is especially important for international transactions where language and cultural barriers may exist.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and compliance requirements is essential. Buyers should be aware that different countries may have varying safety and quality regulations that could impact the importation and use of belt driven blowers.

It is advisable for buyers to:

-

Research Local Standards: Familiarize themselves with local certifications and regulations that may apply to the blower products they are considering.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can facilitate better communication regarding quality expectations and compliance.

-

Stay Updated on Global Standards: Global standards can change, and it is crucial for buyers to remain informed about any modifications that could affect their supply chain.

In conclusion, the manufacturing processes and quality assurance protocols for belt driven blowers are complex and multi-faceted. By understanding these processes, B2B buyers can make informed decisions, ensuring they procure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt driven blower’

Introduction

Sourcing a belt-driven blower involves careful consideration of various factors to ensure that you select the right product for your business needs. This guide provides a step-by-step checklist that will help B2B buyers streamline their procurement process, ensuring they make informed decisions that align with their operational requirements and budget constraints.

1. Define Your Technical Specifications

Start by outlining the specific requirements for your belt-driven blower. Consider factors such as airflow capacity (CFM), pressure ratings, and the type of application (HVAC, manufacturing, etc.). Clearly defined specifications will help you narrow down your options and ensure compatibility with existing systems.

2. Research Different Types of Belt-Driven Blowers

Familiarize yourself with the various types of belt-driven blowers available in the market, such as squirrel cage fans, centrifugal fans, and furnace blowers. Each type has distinct characteristics suited for different applications, so understanding these can guide you towards the most effective choice for your needs.

Illustrative image related to belt driven blower

3. Evaluate Potential Suppliers

Before making a purchase, it’s essential to thoroughly vet potential suppliers. Request company profiles, product catalogs, and references from other buyers in similar industries or regions. Look for suppliers with a proven track record in quality and customer service, as this can significantly impact your satisfaction with the purchase.

4. Check for Compliance and Certifications

Ensure that the blowers and suppliers comply with relevant industry standards and certifications. Certifications such as ISO, CE, or UL can indicate a commitment to quality and safety. This step is crucial to avoid future complications, particularly in regulated industries.

5. Analyze Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing structures. Look beyond just the initial purchase price; consider factors such as shipping costs, warranties, and potential discounts for bulk purchases. Understanding payment terms is also important, especially for international transactions, as favorable terms can enhance cash flow.

6. Request Samples or Demonstrations

Whenever possible, request samples or demonstrations of the blowers before finalizing your order. This allows you to assess performance, noise levels, and overall build quality firsthand. Testing the product in a real-world scenario can help confirm that it meets your operational expectations.

Illustrative image related to belt driven blower

7. Review After-Sales Support and Maintenance Options

Inquire about after-sales support, including warranty policies and maintenance services. A good supplier should offer comprehensive support to address any issues that arise post-purchase. Understanding maintenance requirements and available services can help you plan for long-term operational efficiency.

By following this checklist, B2B buyers can navigate the complexities of sourcing belt-driven blowers with greater confidence and clarity, ensuring that they secure the best solutions for their business needs.

Comprehensive Cost and Pricing Analysis for belt driven blower Sourcing

What Are the Key Cost Components for Belt Driven Blowers?

Understanding the cost structure of belt driven blowers is crucial for international B2B buyers. The primary cost components include:

-

Materials: The raw materials for belt driven blowers typically involve metals, rubber for belts, and various bearings. The quality and source of these materials can significantly affect the overall cost.

-

Labor: Labor costs can vary depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, equipment depreciation, and factory rent. Efficient manufacturing processes can reduce overhead, benefiting the final price.

-

Tooling: Initial tooling costs can be substantial, especially for custom blowers. These costs are often spread across production runs, making larger orders more cost-effective.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability, which can raise costs but is essential for maintaining standards, especially for industries that require certifications.

-

Logistics: Transportation costs, including shipping and handling, can vary widely based on distance, shipping method, and Incoterms. Buyers should consider these factors to understand the total landed cost.

-

Margin: The supplier’s profit margin will influence the final price. Understanding market dynamics can help buyers negotiate better terms.

How Do Price Influencers Impact Belt Driven Blower Costs?

Several factors can influence the pricing of belt driven blowers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize pricing.

-

Specifications and Customization: Custom designs or specific requirements can lead to increased costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Material Quality and Certifications: High-quality materials and certifications (e.g., ISO standards) can increase initial costs but may reduce maintenance and replacement expenses over time.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more but often provide better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and responsibilities, impacting overall pricing.

What Tips Can Help Buyers Negotiate Better Prices?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can employ several strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. A well-prepared negotiation can yield significant savings.

-

Focus on Total Cost of Ownership (TCO): Assess not just the purchase price but also long-term costs, including maintenance, energy consumption, and potential downtime. This broader view can justify higher upfront costs for more reliable products.

-

Understand Pricing Nuances for International Sourcing: Currency fluctuations and import duties can affect overall costs. Buyers should factor these elements into their budgeting and pricing strategies.

-

Conduct Market Research: Understanding market trends and competitor pricing can empower buyers during negotiations. Utilize resources like industry reports and price comparison tools to stay informed.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Regular communication fosters trust and can result in preferential treatment.

In conclusion, a thorough understanding of the cost structure, price influencers, and negotiation tactics is essential for international B2B buyers looking to source belt driven blowers effectively. While indicative prices can provide a starting point, strategic procurement practices can significantly enhance cost efficiency and product quality.

Alternatives Analysis: Comparing belt driven blower With Other Solutions

In the pursuit of optimal air movement solutions, businesses often explore various technologies to meet their specific operational needs. Belt driven blowers are a popular choice due to their reliability and performance, but it’s essential to consider alternative solutions that may offer distinct advantages. This section compares belt driven blowers with two viable alternatives: direct drive blowers and axial fans. Each option has unique characteristics that can influence a buyer’s decision based on their particular requirements.

| Comparison Aspect | Belt Driven Blower | Direct Drive Blower | Axial Fan |

|---|---|---|---|

| Performance | High efficiency, versatile for different applications | Very high efficiency, suitable for high-speed operations | Good airflow at low resistance, effective for ventilation |

| Cost | Moderate initial investment, potential long-term savings | Higher upfront cost, lower operating costs | Lower initial cost, varying performance based on application |

| Ease of Implementation | Requires more space for installation and alignment | Easier installation, compact design | Simple installation, often portable |

| Maintenance | Moderate maintenance needs, belts require periodic checks | Minimal maintenance, fewer moving parts | Low maintenance, but blades may require cleaning |

| Best Use Case | HVAC systems, industrial applications, air circulation | High-speed applications, manufacturing | General ventilation, cooling, and exhaust systems |

What Are the Advantages and Disadvantages of Direct Drive Blowers?

Direct drive blowers utilize a motor that directly powers the fan, eliminating the need for belts. This design enhances efficiency and minimizes energy loss. They are particularly advantageous in high-speed applications where consistent airflow is critical, such as in manufacturing settings. However, the initial investment can be higher than that of belt driven blowers, and the need for precise motor control can complicate installation. Additionally, while they require less maintenance than belt driven systems, any motor issues can be more expensive to repair.

How Do Axial Fans Compare in Terms of Functionality?

Axial fans are designed to move air parallel to the fan’s axis and are well-known for their effective ventilation capabilities. They offer a lower initial cost compared to both belt driven and direct drive blowers, making them an attractive option for businesses on a budget. However, their performance can be less effective in high-resistance applications, and they may not provide the same efficiency in air movement as belt driven blowers in certain scenarios. Maintenance is generally straightforward, but over time, the blades may accumulate dust and debris, requiring periodic cleaning to maintain optimal performance.

How to Choose the Right Air Movement Solution for Your Business Needs

When selecting an air movement solution, B2B buyers should assess their specific operational requirements, including performance needs, budget constraints, and maintenance capabilities. Belt driven blowers are ideal for applications demanding versatility and reliability, especially in HVAC systems. In contrast, direct drive blowers may be more suitable for high-speed tasks, while axial fans excel in general ventilation applications. By carefully considering these factors, businesses can make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for belt driven blower

What Are the Key Technical Properties of Belt Driven Blowers?

When evaluating belt driven blowers, several critical specifications are essential for making informed purchasing decisions. Understanding these properties can significantly impact operational efficiency, maintenance, and overall cost-effectiveness.

1. Material Grade

The material grade of a belt driven blower typically refers to the quality of metals and composites used in its construction. Common materials include galvanized steel, aluminum, and high-grade plastics. The choice of material affects durability, resistance to corrosion, and performance under various environmental conditions. For B2B buyers, selecting blowers made from high-quality materials can lead to reduced maintenance costs and longer equipment lifespan.

Illustrative image related to belt driven blower

2. Airflow Capacity (CFM)

Airflow capacity, measured in cubic feet per minute (CFM), indicates how much air a blower can move. This specification is crucial for applications requiring specific airflow rates, such as HVAC systems or industrial processes. Understanding CFM helps buyers select blowers that meet the demands of their operations, ensuring efficiency and effectiveness in air movement.

3. Static Pressure Rating

Static pressure rating, expressed in inches of water gauge (in WG), measures the blower’s ability to overcome resistance in the system, such as ductwork or filters. A higher static pressure rating is essential for applications with significant airflow resistance. For B2B buyers, this specification is vital in ensuring that the chosen blower can perform effectively in their specific installation environment.

4. Belt Type and Size

The type and size of the belt used in a belt driven blower are critical for ensuring optimal performance and longevity. Common belt types include V-belts and flat belts, each designed for specific applications. Additionally, the size of the belt affects the blower’s efficiency and power transfer. Buyers should consider these factors to prevent frequent replacements and ensure smooth operation.

5. Motor Power Rating

The motor power rating, typically measured in horsepower (HP) or kilowatts (kW), indicates the energy consumption and performance capability of the blower. Selecting the appropriate motor power ensures that the blower operates efficiently without overloading or wasting energy. For international buyers, understanding local electrical standards and compatibility is essential.

6. Noise Level

Noise level, measured in decibels (dB), is an important consideration, especially in environments where sound levels are regulated. Lower noise levels improve workplace comfort and compliance with local regulations. B2B buyers should prioritize blowers with acceptable noise levels for their specific applications to enhance user experience.

What Are Common Trade Terms Associated with Belt Driven Blowers?

Navigating the purchasing process for belt driven blowers involves understanding specific trade terminology. Familiarity with these terms can streamline communications with suppliers and enhance procurement efficiency.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of belt driven blowers, purchasing OEM parts ensures compatibility and reliability, which can be crucial for maintaining equipment performance.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, as it can affect inventory management and cost efficiency. Buyers must assess their needs against the supplier’s MOQ to avoid overstocking or understocking.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and other relevant details for specific products. This term is significant for B2B transactions, as it allows buyers to compare offers from multiple suppliers and make informed purchasing decisions.

Illustrative image related to belt driven blower

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international shipping. They clarify who bears the risk and costs at various stages of transport. Understanding these terms helps B2B buyers manage logistics effectively and mitigate risks associated with global trade.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. For businesses, understanding lead time is essential for planning operations and inventory levels. Buyers should consider lead times when making procurement decisions to ensure timely availability of equipment.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement processes, ensuring they select the right belt driven blowers that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the belt driven blower Sector

Market Overview & Key Trends in the Belt Driven Blower Sector

The global belt-driven blower market is witnessing significant growth, driven by increasing demand in various industries such as HVAC, manufacturing, and automotive. As businesses seek to enhance operational efficiency, the versatility of belt-driven blowers—known for their durability and ability to handle high volumes of air—positions them as a preferred choice. Moreover, technological advancements, including the integration of IoT for predictive maintenance, are emerging trends that provide international buyers with enhanced data for operational decisions.

In regions such as Africa and South America, where industrialization is rapidly expanding, the demand for reliable air-moving solutions is surging. For instance, countries like Nigeria and Brazil are investing in infrastructure and manufacturing capabilities, fostering a robust market for belt-driven blowers. Additionally, the Middle East is focusing on sustainable energy solutions, which is influencing sourcing strategies for energy-efficient blowers.

Buyers are increasingly prioritizing suppliers who offer not only competitive pricing but also customizable solutions that meet specific operational needs. As the market evolves, the ability to source products with advanced features—such as improved efficiency and lower maintenance requirements—will be critical for B2B buyers looking to stay competitive.

How Does Sustainability Impact Sourcing Decisions for Belt Driven Blowers?

Sustainability is becoming a cornerstone of procurement strategies in the belt-driven blower sector. The environmental impact of manufacturing processes and the lifecycle of products are under scrutiny, making it essential for buyers to consider the sustainability credentials of their suppliers. Companies are increasingly seeking partners who prioritize ethical sourcing and utilize eco-friendly materials in their products.

Green certifications, such as ISO 14001, are gaining traction as buyers look for assurance that their suppliers adhere to environmental management standards. Moreover, sourcing materials that are recyclable or made from sustainable resources can significantly reduce the ecological footprint of belt-driven blowers.

In addition, manufacturers are innovating to create products with lower energy consumption and longer lifespans, further contributing to sustainability goals. For international buyers, especially in regions facing stringent environmental regulations, aligning with suppliers who focus on sustainability not only enhances brand reputation but also ensures compliance with local regulations.

What is the Historical Context of Belt Driven Blowers in the B2B Market?

The belt-driven blower has evolved significantly since its inception in the early 20th century. Initially designed for simple air movement tasks, advancements in engineering and materials have transformed these devices into sophisticated systems capable of handling complex industrial applications.

In the mid-20th century, the introduction of more durable materials and advanced motor technologies allowed for improved performance and reliability, making belt-driven blowers a staple in various industries. The focus has shifted from mere functionality to efficiency and sustainability, with modern designs incorporating features that minimize energy consumption while maximizing airflow.

This evolution reflects broader trends in industrial automation and efficiency, underscoring the importance of selecting the right blower for specific applications. For B2B buyers today, understanding this historical context can inform decisions on product selection and supplier partnerships, ensuring alignment with current market demands and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of belt driven blower

-

How do I choose the right belt driven blower for my application?

Selecting the appropriate belt driven blower involves evaluating several factors including airflow requirements (measured in CFM), the specific application (HVAC, industrial, or woodworking), and the blower’s design type (squirrel cage, centrifugal, etc.). Consider the operating environment and any space constraints as well. Additionally, assess the noise levels and energy efficiency ratings to ensure they meet your operational standards. Consulting with manufacturers or suppliers can provide tailored recommendations based on your specific needs. -

What are the advantages of using a belt driven blower over other types?

Belt driven blowers offer several advantages, including reduced motor wear due to the belt’s ability to absorb vibrations. They provide excellent torque and can operate at various speeds, allowing for greater flexibility in airflow management. These blowers are often more cost-effective for large-scale applications, as they can be powered by different motor types and are easier to maintain compared to direct-drive options. Their adaptability makes them suitable for diverse industrial applications. -

What customization options are available for belt driven blowers?

Many manufacturers offer customization options for belt driven blowers, allowing buyers to specify dimensions, airflow rates, and motor types that suit their operational needs. Custom features may include specialized impeller designs for enhanced performance, specific material choices for durability, and tailored mounting configurations. Discussing your requirements with suppliers can lead to bespoke solutions that improve efficiency and fit seamlessly into your existing systems. -

What is the typical minimum order quantity (MOQ) for belt driven blowers?

The MOQ for belt driven blowers can vary significantly depending on the manufacturer and the complexity of the product. Generally, it ranges from a few units to several dozen. Suppliers may set MOQs to ensure production efficiency and cost-effectiveness. For small businesses or startups, it’s advisable to inquire about flexibility in order sizes or explore options for purchasing stock units to meet immediate needs. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among international suppliers, but common practices include upfront payments, letters of credit, or Net 30/Net 60 terms. It’s crucial to establish clear agreements regarding payment methods and timelines before finalizing any order. Additionally, consider using escrow services for larger transactions to protect your investment until the goods are received and verified. -

How can I vet suppliers for belt driven blowers?

To ensure you are partnering with a reliable supplier, conduct thorough research by checking their industry reputation, customer reviews, and certifications. Request references from previous clients and assess their production capabilities and quality control processes. It may also be beneficial to visit their facility, if possible, or engage third-party inspection services to evaluate their operations. Establishing communication and building relationships can further enhance trust. -

What are the key quality assurance practices for belt driven blowers?

Quality assurance for belt driven blowers typically includes rigorous testing for airflow efficiency, noise levels, and durability under various operating conditions. Suppliers should implement ISO or similar standards in their manufacturing processes. Requesting documentation of quality checks and certifications can provide insight into the reliability of the products. Additionally, inquire about warranty terms to safeguard your investment against defects or performance issues. -

What logistics considerations should I be aware of when importing belt driven blowers?

Importing belt driven blowers involves several logistics considerations, including shipping methods, customs regulations, and potential tariffs. Ensure that you understand the import duties applicable to your region and factor these costs into your budget. Working with a logistics partner experienced in international trade can help navigate the complexities of shipping schedules, documentation, and compliance requirements. Additionally, consider lead times for production and shipping to align with your operational timelines.

Top 7 Belt Driven Blower Manufacturers & Suppliers List

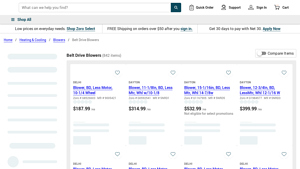

1. Zoro – Belt Drive Blowers

Domain: zoro.com

Registered: 1995 (30 years)

Introduction: Belt Drive Blowers are air-moving devices that use a belt drive system to power the blower fan. They are used in various applications including heating and cooling, air circulation, and more. Types include belt drive squirrel cage fans, belt driven centrifugal fans, and belt driven furnace blowers. Made with metal components, rubber belts, and bearings, these blowers are designed to withstand high…

2. Airdistributor – Portable Ventilation Drum Blowers

Domain: airdistributor.net

Registered: 2008 (17 years)

Introduction: Direct and Belt Driven Portable Ventilation Drum Blowers. Industrial Grade Products available. Airflow capacity ranges from 2,501 to 25,000 CFM. Available colors: Black. Fan sizes range from 14″ to 48″ in diameter. Voltage type: 110V – 120V. Motor enclosure type: Totally Enclosed. Single Phase power. Options for Belt Drive or Direct Drive. Mounting options: Wall, Roof, or Floor. Key products inclu…

3. Canarm – Belt Drive Equipment Blowers

Domain: canarm.com

Registered: 1997 (28 years)

Introduction: Belt Drive Equipment Blowers (OEM) include various series such as 400 Series FC Exhauster, 800 Series DWDI Blowers with Frame, 900 Series DWDI Framed Heavy Duty Blowers, 900-BI Backward Inclined Blower, DPL Series Flat Blade Plenum Fans, DPL-AF Series Air Foil Blade Plenum Fans, and G Series Double Inlet Belt Drive Blowers. Canarm’s HVAC Division designs and manufactures a complete line of quality…

4. Tempest – Belt-Drive Gas Power Blower

Domain: tempest.us.com

Introduction: Tempest Belt-Drive Gas Power Blower features an exclusive belt-drive design that reduces engine wear, improves CFM performance, and provides greater stability. It includes AirFlex composition impellers for maximum air volume, velocity, and pressure, and composite blades designed to disintegrate upon impact for safety. The welded steel roll cage frame enhances strength and eliminates maintenance on…

5. Grainger – HVAC AC Motors

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – HVAC AC Motors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Sterling – V-Belt Drive Blowers

Domain: sterlingblower.com

Registered: 1996 (29 years)

Introduction: V-Belt Drive Blowers offer adjustable air usage through different sheave arrangements. Features include all-welded heavy gauge construction, hand-finished interior to prevent material build-up, easily replaceable blower housing, impeller, and motor. Designed for abrasive materials with ST line options. Available sizes: 3″ to 16″. Adjustable to 16 discharge positions. Construction options: mild ste…

7. Century – Belt Drive Furnace Blower Motors

Domain: electricmotorwarehouse.com

Registered: 1999 (26 years)

Introduction: Belt Drive Furnace Blower Motors from brands like Century, Nidec, and Marathon. Available in various configurations including TEFC (Totally Enclosed Fan Cooled), ODP (Open Drip Proof), and multiple mounting options. Suitable for HVAC applications, including furnace and ventilation systems. Common replacements for various OEM brands such as Armstrong, Amana, Carrier, Goodman, Lennox, Rheem, and Tra…

Strategic Sourcing Conclusion and Outlook for belt driven blower

How Can Strategic Sourcing Enhance Your Procurement of Belt Driven Blowers?

In today’s competitive landscape, strategic sourcing is essential for international B2B buyers looking to optimize their procurement of belt driven blowers. By focusing on key factors such as supplier reliability, product quality, and cost-efficiency, organizations can make informed decisions that lead to substantial long-term savings. Additionally, understanding the diverse applications of belt driven blowers across industries—from HVAC to manufacturing—allows businesses to tailor their purchases to specific operational needs.

The growing demand for energy-efficient and durable blowers highlights the importance of partnering with manufacturers who prioritize innovation and quality. Buyers should seek out suppliers that offer comprehensive support, including maintenance and after-sales service, to ensure their systems remain operational and efficient over time.

Illustrative image related to belt driven blower

As markets evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, staying ahead of trends in technology and sustainability will be paramount. Engaging in strategic sourcing not only mitigates risks but also positions businesses to capitalize on emerging opportunities. Now is the time to refine your procurement strategy and collaborate with trusted suppliers to secure the best belt driven blowers for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.