A Deep Dive into Bed Caster Wheels Solution

Introduction: Navigating the Global Market for bed caster wheels

The global market for bed caster wheels presents a unique set of challenges for B2B buyers seeking reliable, high-quality products. With diverse applications ranging from hospital beds to residential furniture, sourcing the right bed caster wheels can significantly impact operational efficiency and customer satisfaction. This guide aims to empower international buyers, particularly those in Africa, South America, the Middle East, and Europe, by providing a comprehensive overview of the various types of bed caster wheels available, their specific applications, and key considerations for supplier selection.

Throughout this guide, you will discover detailed insights into different materials, load capacities, and design features that cater to distinct market needs. We will delve into the intricacies of supplier vetting, ensuring you have the knowledge to identify reputable manufacturers and negotiate favorable terms. Additionally, we will explore cost factors and shipping logistics, crucial for buyers in regions such as Brazil and Germany, where local market dynamics can influence pricing strategies.

By equipping you with actionable information, this guide is designed to facilitate informed purchasing decisions, helping you navigate the complexities of the global bed caster wheel market. Whether you are looking to enhance the mobility of hospital equipment or improve the aesthetics and functionality of furniture, understanding these key elements will enable you to source products that meet your specific requirements efficiently.

Understanding bed caster wheels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Locking Casters | Available in various sizes, robust construction | Industrial beds, hospital beds | Pros: High load capacity; Cons: May be pricier |

| Swivel Stem Casters | 360-degree rotation, easy maneuverability | Furniture, carts, and portable beds | Pros: Versatile; Cons: Less stability when stationary |

| Non-Locking Casters | Simple design, lightweight materials | Home use, light-duty applications | Pros: Cost-effective; Cons: No locking mechanism |

| Bariatric Casters | Designed for heavier loads, often with locking features | Hospital beds, specialized care facilities | Pros: Enhanced safety; Cons: Heavier and bulkier |

| Composite Bed Casters | Made from recycled materials, non-marking wheels | Eco-friendly products, high-end furniture | Pros: Sustainable; Cons: May not be as durable as metal |

What Are the Characteristics of Heavy-Duty Locking Casters?

Heavy-duty locking casters are engineered for high weight capacities, often exceeding 150 lbs per wheel. These casters are typically made from durable materials like steel and feature a locking mechanism that secures the bed in place, making them ideal for industrial and hospital environments. B2B buyers should consider the size and load requirements specific to their applications, as well as the quality of the locking mechanism to ensure safety and reliability.

How Do Swivel Stem Casters Enhance Maneuverability?

Swivel stem casters allow for 360-degree movement, enabling easy navigation in tight spaces. They are often used in furniture and portable bed applications where maneuverability is crucial. When purchasing, businesses should assess the wheel diameter and material to ensure compatibility with their existing frames and surfaces. These casters are particularly beneficial in environments requiring frequent repositioning, such as hospitals and event spaces.

What Are the Benefits of Non-Locking Casters?

Non-locking casters are straightforward in design and are typically made from lightweight materials, making them cost-effective for light-duty applications. They are suitable for home use and environments where mobility is prioritized over stability. Buyers should keep in mind that while these casters are economical, they lack a locking feature, which may pose challenges in maintaining bed position during use.

Illustrative image related to bed caster wheels

Why Choose Bariatric Casters for Specialized Needs?

Bariatric casters are specifically designed to support heavier loads, often featuring robust construction and locking capabilities. These are essential in healthcare settings where patient safety and stability are paramount. When selecting bariatric casters, businesses should evaluate the load ratings and ensure they meet regulatory standards for medical equipment, as well as consider the ease of installation and replacement.

What Are the Advantages of Composite Bed Casters?

Composite bed casters are made from environmentally friendly materials, offering a sustainable option for B2B buyers. They often feature non-marking wheels that protect flooring surfaces, making them ideal for high-end furniture applications. When considering composite casters, buyers should assess their strength and durability compared to traditional metal options, especially in high-traffic environments where wear and tear may be a concern.

Key Industrial Applications of bed caster wheels

| Industry/Sector | Specific Application of Bed Caster Wheels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Hospital Beds | Enhances mobility for patient care; improves workflow | Durability, locking mechanisms, ease of maintenance |

| Hospitality | Hotel Furniture | Facilitates room reconfiguration; improves guest comfort | Aesthetic design, load capacity, noise reduction |

| Furniture Manufacturing | Bed Frame Production | Streamlines assembly and shipping processes | Material quality, compatibility with various designs |

| Retail | Display Furniture | Allows for flexible merchandising setups | Weight capacity, ease of movement, design versatility |

| Elderly Care Facilities | Adjustable Beds for Seniors | Provides safety and accessibility for residents | Stability, locking features, ease of use |

How Are Bed Caster Wheels Used in Healthcare Settings?

In healthcare, bed caster wheels are essential for hospital beds, enabling seamless movement of patients and medical equipment. These casters often feature locking mechanisms to ensure stability during patient transfers. International buyers, particularly from regions with diverse healthcare standards like Africa and the Middle East, should prioritize durability and ease of maintenance when sourcing. The ability to withstand high loads while providing smooth mobility is crucial in enhancing patient care and optimizing workflow in medical facilities.

What Role Do Bed Casters Play in the Hospitality Industry?

In the hospitality sector, bed caster wheels are vital for hotel furniture, such as beds and rolling carts. They allow for quick reconfiguration of room layouts, enhancing guest comfort and enabling efficient housekeeping operations. Buyers from Europe and South America should consider aesthetics and noise reduction when sourcing these wheels, as guest experience can be significantly impacted by both. Ensuring that the casters can support the weight of various furniture pieces while maintaining a stylish appearance is key for hospitality brands.

How Are Bed Casters Beneficial in Furniture Manufacturing?

Furniture manufacturers utilize bed caster wheels to streamline the assembly and shipping processes of bed frames. These wheels facilitate easy movement within factories and during transportation, reducing labor costs and improving efficiency. For B2B buyers in regions like Brazil, where manufacturing logistics can be challenging, sourcing high-quality casters that are compatible with various bed designs is essential. Additionally, manufacturers should consider the weight capacity and material quality to ensure product longevity.

In What Ways Are Bed Casters Used in Retail?

In the retail sector, bed caster wheels are employed in display furniture to create flexible merchandising setups. This mobility allows retailers to adapt their displays quickly based on customer needs and sales strategies. B2B buyers from different regions should focus on weight capacity and design versatility when sourcing these casters. The ability to move heavy displays effortlessly can significantly enhance operational efficiency and improve the shopping experience for customers.

Why Are Bed Casters Important in Elderly Care Facilities?

In elderly care facilities, bed caster wheels are critical for adjustable beds, providing safety and accessibility for residents. These wheels often include locking features to prevent accidental movement, ensuring stability for users. Buyers from Africa and the Middle East should prioritize sourcing casters that offer both stability and ease of use, as these factors are vital for the well-being of elderly patients. Ensuring that the casters are designed for high usage and can accommodate the specific needs of elderly residents is crucial for effective care.

3 Common User Pain Points for ‘bed caster wheels’ & Their Solutions

Scenario 1: Navigating Weight Limitations of Bed Caster Wheels

The Problem: B2B buyers often face the challenge of selecting bed caster wheels that can adequately support the weight of various bed types, especially in healthcare or hospitality settings. Many buyers may not be aware that different caster wheels come with varying load ratings, and selecting the wrong one can lead to failures, safety hazards, or additional costs due to replacements. This issue is particularly pertinent when dealing with bariatric beds or high-end mattresses, where the weight can exceed standard limits.

The Solution: To mitigate this issue, buyers should conduct a thorough assessment of the weight requirements for the specific application. Start by calculating the total weight that the caster wheels will need to support, including the bed frame, mattress, and user load. When sourcing bed caster wheels, opt for products with a load rating exceeding your calculated weight by at least 20%. This ensures a safety margin that can account for any variances. Additionally, consider investing in heavy-duty locking casters that provide stability and prevent unintended movement. Suppliers should be asked for detailed specifications and certifications to guarantee that the casters meet the necessary safety standards.

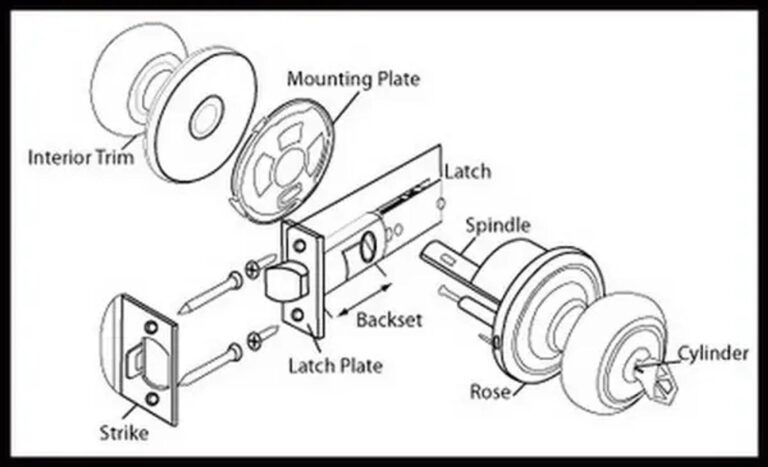

Scenario 2: Compatibility Issues with Existing Bed Frames

The Problem: A common frustration for B2B buyers is the compatibility of bed caster wheels with existing bed frames. Many buyers might find themselves with a set of casters that do not fit their specific frame design, leading to delays in project timelines and increased costs due to returns or exchanges. This is particularly relevant when dealing with custom or older bed models that may not adhere to standard sizing.

The Solution: To avoid compatibility issues, buyers should take detailed measurements of the existing bed frame’s caster socket size and stem dimensions before placing an order. It’s advisable to source casters that offer adjustable features or come with a variety of stem sizes to ensure a proper fit. When purchasing, request samples or specifications sheets that provide detailed dimensions. Additionally, engaging directly with manufacturers can be beneficial as they may offer custom solutions tailored to specific frame designs. Ensuring the right fit from the outset saves time and resources in the long run.

Scenario 3: Managing Noise and Mobility in Sensitive Environments

The Problem: In environments such as hospitals or high-end hotels, noise from moving beds can be disruptive to patients or guests. B2B buyers often struggle to find bed caster wheels that offer smooth mobility without excessive noise, which can detract from the overall experience and satisfaction of the users. This is particularly challenging when the focus is on creating a serene and comfortable atmosphere.

The Solution: To address noise concerns, buyers should prioritize sourcing casters made from softer materials, such as rubber or polyurethane, which tend to operate more quietly than plastic or metal counterparts. Look for casters specifically designed for quiet operation and smooth rolling capabilities. Additionally, consider purchasing casters with ball bearings, as they provide smoother movement and reduce friction, which contributes to noise reduction. It may also be beneficial to test various casters in the actual environment before finalizing purchases. Engaging with suppliers who specialize in noise-reducing technology can also provide insights into the latest innovations in bed caster wheels that meet these specific needs.

Strategic Material Selection Guide for bed caster wheels

What Are the Key Materials Used in Bed Caster Wheels?

When selecting bed caster wheels, understanding the materials used is crucial for ensuring performance, durability, and suitability for specific applications. Here, we analyze four common materials: plastic, rubber, metal, and composite materials. Each material has distinct properties, advantages, and disadvantages that can impact decision-making for international B2B buyers.

How Does Plastic Perform in Bed Caster Wheels?

Plastic casters are widely used due to their lightweight nature and cost-effectiveness. They typically offer good resistance to corrosion and are available in various colors and designs, making them suitable for aesthetic applications. However, plastic has limitations in terms of load-bearing capacity and can become brittle under extreme temperatures.

Pros:

– Lightweight and easy to install.

– Cost-effective, making them ideal for high-volume production.

– Corrosion-resistant.

Cons:

– Limited load capacity compared to metal options.

– Susceptible to wear and tear over time, especially in high-traffic environments.

For international buyers, understanding the specific grades of plastic and compliance with local standards is essential, especially in regions like Europe where regulations may be stricter.

What Are the Advantages of Rubber in Bed Caster Wheels?

Rubber casters are favored for their excellent shock absorption and noise reduction properties. They provide a stable grip on various surfaces, making them ideal for hospital beds and furniture that require mobility without damaging floors. However, rubber can degrade over time, particularly when exposed to UV light or extreme temperatures.

Illustrative image related to bed caster wheels

Pros:

– Superior traction and shock absorption.

– Quiet operation, ideal for sensitive environments like hospitals.

Cons:

– Potential for degradation under UV exposure.

– Higher manufacturing complexity, which can increase costs.

International buyers should consider the specific rubber compounds used and their compliance with health and safety standards, particularly in medical applications.

Illustrative image related to bed caster wheels

How Do Metal Casters Compare for Bed Frames?

Metal casters, often made from steel or aluminum, are known for their strength and durability. They can support heavy loads and are less likely to deform compared to plastic or rubber options. However, they may be more expensive and can corrode if not properly treated or coated.

Pros:

– High load-bearing capacity and durability.

– Long lifespan with proper maintenance.

Cons:

– Heavier, which may complicate installation.

– Higher cost and potential for corrosion without protective coatings.

For B2B buyers, especially in regions with high humidity or exposure to corrosive environments, understanding the types of coatings available is critical to ensure longevity.

Illustrative image related to bed caster wheels

What Are the Benefits of Composite Materials in Bed Caster Wheels?

Composite materials, such as reinforced plastics or blends of plastic and rubber, offer a balance between weight, strength, and cost. They can be designed to be both aesthetically pleasing and functional. These materials are often lighter than metal while still providing decent load capacity.

Pros:

– Lightweight with good strength-to-weight ratio.

– Can be designed for specific applications, offering versatility.

Cons:

– May not match the load capacity of pure metal options.

– Manufacturing complexity can lead to higher costs.

International buyers should evaluate the specific composite formulations and their compliance with relevant standards, such as ASTM or DIN, to ensure they meet application requirements.

Summary Table of Material Selection for Bed Caster Wheels

| Material | Typical Use Case for bed caster wheels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Lightweight furniture and beds | Cost-effective and corrosion-resistant | Limited load capacity | Low |

| Rubber | Hospital beds and sensitive furniture | Excellent shock absorption and traction | Degrades under UV exposure | Medium |

| Metal | Heavy-duty applications | High load-bearing capacity and durability | Heavier and susceptible to corrosion | High |

| Composite | Versatile applications | Good strength-to-weight ratio | May not match metal load capacities | Medium |

This guide provides a comprehensive overview of material selection for bed caster wheels, enabling international B2B buyers to make informed decisions based on performance requirements, cost considerations, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bed caster wheels

What Are the Main Stages of Manufacturing Bed Caster Wheels?

The manufacturing of bed caster wheels involves several key stages that ensure the final product meets durability and functionality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing products.

-

Material Preparation: The first step involves selecting high-quality raw materials, typically including plastic, rubber, and various metals like steel or aluminum. These materials are often evaluated for their strength, weight, and resistance to wear and tear. Suppliers may conduct initial tests to ensure that the materials meet industry standards before they proceed.

-

Forming: This stage includes various techniques like injection molding, extrusion, and stamping, depending on the material used. For instance, plastic caster wheels are often produced through injection molding, which allows for intricate designs and shapes. Metal components might be shaped through stamping or forging, providing the necessary strength and durability.

-

Assembly: After forming, the individual parts are assembled. This can include attaching wheels to stems, adding brakes, and integrating any additional features like swivel mechanisms. Automated assembly lines are commonly used to enhance efficiency and ensure precision during this phase.

-

Finishing: The final stage involves applying surface treatments such as painting, plating, or polishing to enhance aesthetics and protect against corrosion. Quality assurance checks are also conducted during this stage to ensure that the finished products meet specifications before they are packaged and shipped.

How Is Quality Assurance Implemented in Bed Caster Wheel Production?

Quality assurance (QA) is critical in ensuring that bed caster wheels are safe and reliable. Various international and industry-specific standards guide QA processes.

-

Relevant International Standards: Many manufacturers adhere to ISO 9001, which emphasizes quality management systems and continuous improvement. Compliance with this standard demonstrates a commitment to quality in every aspect of production, from material sourcing to final inspection. Additionally, specific certifications like CE mark (in Europe) and API (American Petroleum Institute) may apply based on the intended use of the caster wheels.

-

Quality Control Checkpoints: Throughout the manufacturing process, multiple checkpoints are established to verify quality:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for defects or non-compliance with specifications.

– In-Process Quality Control (IPQC): During the manufacturing stages, random samples are tested to ensure that production processes are consistently producing items within the required tolerances.

– Final Quality Control (FQC): Before shipping, finished products undergo thorough inspections to verify that they meet all technical and aesthetic standards. -

Common Testing Methods: Various testing methods are employed, including load testing, dynamic testing (to simulate real-world use), and environmental testing (to assess resistance to conditions like humidity and temperature). These tests are crucial for confirming the durability and safety of the caster wheels.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational practices of potential suppliers. This firsthand observation can help identify any discrepancies or areas for improvement.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QA processes and testing results. These reports should ideally include data from IQC, IPQC, and FQC stages, as well as any certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These agencies can conduct inspections at various stages of production and provide certificates that confirm compliance with international standards.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers must navigate various quality control and certification requirements that may differ by region.

-

Understanding Regional Standards: Buyers should familiarize themselves with the specific quality standards and regulations applicable in their regions. For instance, European buyers need to be aware of CE marking requirements, which indicate conformity with health, safety, and environmental protection standards.

-

Language and Documentation Barriers: When dealing with suppliers from different countries, language differences and varying documentation standards can pose challenges. Buyers should ensure that all quality assurance documentation is available in a language they understand and that it complies with their local regulations.

-

Cultural Sensitivity and Relationship Building: Establishing strong relationships with suppliers can enhance communication and collaboration on quality control issues. Being culturally sensitive and aware of local business practices can facilitate smoother interactions and more effective problem-solving.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for bed caster wheels is vital for B2B buyers looking to source reliable products. By being aware of the key stages in production, the importance of quality control, and how to verify supplier practices, buyers can make informed decisions that align with their needs and standards. This knowledge will ultimately contribute to better procurement strategies and improved product performance in their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bed caster wheels’

To streamline your procurement process for bed caster wheels, this checklist provides actionable steps that will guide you in making informed purchasing decisions. By adhering to these steps, you can ensure that the caster wheels meet your operational needs, comply with regional standards, and come from reputable suppliers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical before initiating the sourcing process. Consider the dimensions, load capacity, material, and wheel type (e.g., swivel, locking) that are necessary for your application. This ensures that you target products that will function effectively in your specific environment, whether it be for hospital beds, furniture, or industrial use.

Step 2: Research Market Trends and Standards

Understanding current market trends and standards in your target regions can significantly influence your sourcing strategy. Investigate the common materials, designs, and technologies used in bed caster wheels within Africa, South America, the Middle East, and Europe. Look for compliance with international safety and quality standards, as this may vary from one region to another.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Evaluate suppliers based on their production capabilities, quality assurance processes, and customer service responsiveness to ensure they align with your business needs.

- Check for certifications: Verify that suppliers hold relevant industry certifications, such as ISO 9001, which can indicate a commitment to quality.

- Request product samples: Testing samples before placing a bulk order can help assess the quality and suitability of the caster wheels.

Step 4: Analyze Cost and Value Propositions

While cost is a significant factor, it should not be the sole determinant in your decision-making process. Analyze the total cost of ownership, including shipping, potential duties, and the lifespan of the caster wheels. Consider the value proposition offered by suppliers, including warranties, replacement parts, and after-sales support.

Step 5: Negotiate Terms and Conditions

Once you have shortlisted suppliers, engage in negotiations to clarify pricing, payment terms, delivery schedules, and any bulk order discounts. Ensure that you understand the terms of return or replacement policies in case the products do not meet your expectations upon delivery. Effective negotiation can lead to better pricing and more favorable terms that benefit your bottom line.

Step 6: Establish a Quality Control Process

Before finalizing your order, outline a quality control process that will be implemented upon receipt of the caster wheels. Define the criteria for inspection, including dimensions, load capacity, and functionality. This proactive approach minimizes the risk of defects and ensures that the products adhere to your specifications.

Step 7: Plan for Future Needs

Consider your long-term requirements and potential growth. Establish a relationship with suppliers who can scale with your needs, whether that means providing larger quantities or adapting to new product developments. Having a reliable supplier relationship can facilitate smoother transactions and better support as your business evolves.

Following this checklist will equip you with the necessary insights and actions to effectively source bed caster wheels that meet your operational needs and ensure a successful procurement process.

Comprehensive Cost and Pricing Analysis for bed caster wheels Sourcing

What Are the Key Cost Components for Sourcing Bed Caster Wheels?

When sourcing bed caster wheels, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. Common materials include plastic, rubber, and metal, each varying in price and durability. For instance, heavy-duty metal casters typically have a higher upfront cost but offer greater longevity compared to their plastic counterparts.

-

Labor: Labor costs encompass the wages paid to workers involved in the production process. This varies by region, with labor costs generally lower in developing countries, which can be advantageous for international buyers.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which is crucial for maintaining competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. However, these costs can be amortized over larger production runs, making it essential to consider order volume when evaluating total costs.

-

Quality Control (QC): Investing in QC processes ensures that the casters meet safety and performance standards, which can reduce returns and complaints. However, higher QC standards may lead to increased costs.

-

Logistics: Transportation costs are influenced by the distance from the supplier, shipping methods, and associated tariffs. For international buyers, understanding Incoterms can help clarify responsibilities and cost implications.

-

Margin: Finally, the supplier’s profit margin can vary based on their market position, brand strength, and competitive landscape.

How Do Price Influencers Affect Bed Caster Wheel Costs?

Several factors can influence the pricing of bed caster wheels, impacting what a buyer can expect to pay:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk orders. Understanding the MOQ is crucial for maximizing cost efficiency.

-

Specifications and Customization: Customized casters tailored to specific requirements can incur additional charges. Standard products typically offer lower prices due to economies of scale.

-

Material Quality and Certifications: Higher quality materials and certifications (such as ISO) often translate to increased costs but can enhance product reliability and reduce the total cost of ownership.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may command higher prices, but they may also offer better quality assurance.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly influence the overall cost.

What Buyer Tips Can Help Optimize Bed Caster Wheel Sourcing?

For B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, several strategies can help optimize sourcing:

-

Negotiate Effectively: Leverage volume and long-term contracts to negotiate better terms. Suppliers may be willing to lower prices for guaranteed orders.

-

Focus on Cost-Efficiency: Consider the total cost of ownership, including maintenance, replacement, and disposal costs. Investing in higher-quality casters may lead to lower long-term expenses.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, import duties, and regional pricing strategies that may affect overall costs.

-

Evaluate Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and priority in fulfillment, especially during high-demand periods.

-

Conduct Market Research: Stay informed about market trends and pricing benchmarks to ensure you are making competitive purchasing decisions.

Disclaimer

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier pricing strategies, and other external factors. Always conduct thorough due diligence when sourcing bed caster wheels to ensure the best value for your investment.

Alternatives Analysis: Comparing bed caster wheels With Other Solutions

Exploring Alternatives to Bed Caster Wheels

In the realm of bed mobility solutions, bed caster wheels are a popular choice due to their versatility and functionality. However, several alternatives exist that may cater to specific operational needs and preferences of B2B buyers. This section analyzes bed caster wheels against other viable solutions, helping businesses make informed decisions based on performance, cost, and practical application.

| Comparison Aspect | Bed Caster Wheels | Adjustable Bed Frame Legs | Hospital Bed Track Systems |

|---|---|---|---|

| Performance | High mobility and stability | Moderate mobility; fixed height | Excellent mobility, limited to tracks |

| Cost | Moderate ($20 – $80/set) | High ($100 – $300/set) | High initial investment ($500+) |

| Ease of Implementation | Easy to install and replace | Requires more assembly | Complex installation; needs professional setup |

| Maintenance | Low maintenance; occasional checks | Minimal maintenance needed | Regular checks for track integrity |

| Best Use Case | Residential and light commercial use | Premium residential applications | Medical facilities needing constant mobility |

What Are the Pros and Cons of Adjustable Bed Frame Legs?

Adjustable bed frame legs are a sturdy alternative to caster wheels, primarily used in premium bedding setups. They provide a fixed height and can support a considerable amount of weight. While they offer improved stability, their lack of mobility can be a drawback in environments where frequent rearrangement is necessary. Additionally, the installation process is more complex, which could require specialized knowledge or tools. The cost is also higher, making them less appealing for budget-conscious buyers.

How Do Hospital Bed Track Systems Compare?

Hospital bed track systems provide a sophisticated solution for medical environments where patient mobility is essential. They allow beds to move smoothly along designated tracks, ensuring safety and ease of use. However, the initial investment is substantial, and installation often requires professional assistance, which can lead to additional costs. Maintenance is also more involved, as the integrity of the track system must be regularly monitored. These systems are best suited for hospitals and healthcare facilities that prioritize patient care and require frequent bed repositioning.

Conclusion: How Can B2B Buyers Choose the Right Bed Mobility Solution?

When selecting the right bed mobility solution, B2B buyers should assess their specific operational needs and constraints. Bed caster wheels offer a balance of mobility, cost-effectiveness, and ease of installation, making them ideal for various settings. Conversely, adjustable bed frame legs and hospital bed track systems cater to niche markets that may require more stability or specialized movement. By carefully evaluating performance, costs, and maintenance requirements, businesses can align their choice with their operational objectives, ensuring they invest in a solution that enhances efficiency and meets their unique needs.

Essential Technical Properties and Trade Terminology for bed caster wheels

When selecting bed caster wheels for commercial applications, understanding the essential technical properties and industry terminology is crucial. This knowledge enables B2B buyers to make informed decisions, ensuring they select the right products that meet their operational needs.

What Are the Key Technical Properties of Bed Caster Wheels?

-

Material Grade

The material of caster wheels significantly impacts durability and performance. Common materials include plastic, rubber, and metal. For instance, high-grade rubber is preferred for its noise-dampening properties and load-bearing capacity, while metal offers superior strength for heavy-duty applications. Choosing the right material is essential for longevity and functionality, especially in environments such as hospitals or hotels. -

Load Rating

This specification indicates the maximum weight a caster can safely support. Load ratings typically range from 125 lbs for lighter applications to over 1,000 lbs for industrial uses. Understanding load ratings is vital for ensuring safety and preventing damage to both the caster and the furniture or equipment it supports. Businesses must evaluate their specific needs to avoid premature wear or failure. -

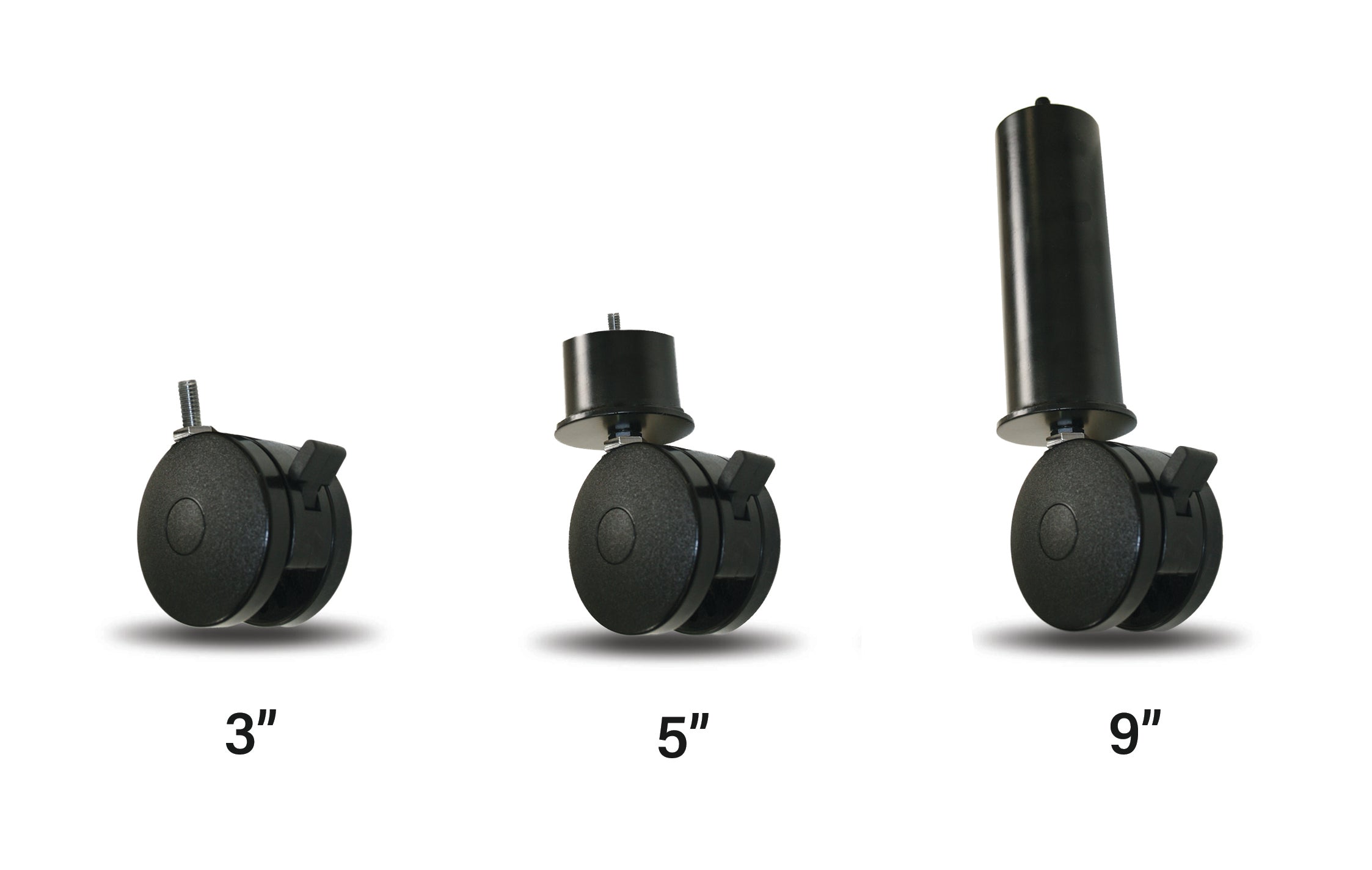

Wheel Diameter

The diameter of the wheel affects maneuverability and stability. Smaller wheels (around 2 inches) are better for tight spaces, while larger wheels (up to 9 inches) enhance mobility over uneven surfaces. This property is especially important in settings where beds need to be moved frequently, such as in healthcare facilities. -

Swivel vs. Rigid

Casters can be swivel (allowing for easy directional changes) or rigid (fixed in one direction). Swivel casters are advantageous for navigating tight corners, while rigid casters provide stability in a straight line. Understanding the application context helps in selecting the right type to optimize movement and control. -

Brake Mechanism

Many bed caster wheels come with locking mechanisms that prevent unwanted movement. Brakes can be foot-operated or hand-activated, and their presence is crucial for safety, particularly in medical and hospitality environments where stability is paramount. Evaluating the type of brake needed is essential for ensuring user safety and convenience.

What Are Common Trade Terms Used in the Bed Caster Wheel Industry?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are used in another company’s end product. In the context of bed caster wheels, an OEM might supply casters that are integrated into bed frames manufactured by another company. Understanding OEM relationships helps buyers assess quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. This is crucial for B2B buyers as it affects inventory management and costs. Knowing the MOQ helps businesses plan their purchases effectively to avoid overstocking or running out of essential components. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It is particularly useful in B2B transactions where multiple suppliers may offer similar products. A well-structured RFQ can help buyers compare pricing, delivery times, and terms effectively. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers navigate logistics and reduce potential disputes during the procurement process. -

Lead Time

This term refers to the time taken from placing an order to delivery. Understanding lead times is critical for inventory planning and ensuring that operations continue smoothly without delays. B2B buyers should always inquire about lead times when negotiating with suppliers.

By grasping these technical properties and trade terms, international B2B buyers can make strategic decisions that enhance their procurement processes and ensure the reliability of their bed caster wheels.

Navigating Market Dynamics and Sourcing Trends in the bed caster wheels Sector

What Are the Key Trends Driving the Bed Caster Wheels Market?

The global bed caster wheels market is experiencing dynamic shifts influenced by several factors. One of the primary drivers is the increasing demand for mobility solutions in healthcare, particularly in hospital and home care settings. As the elderly population grows, the need for adjustable and easy-to-move beds is paramount. This trend is particularly pronounced in regions such as Europe and North America, where healthcare systems are adapting to an aging demographic.

Moreover, the rise of e-commerce is reshaping how B2B buyers source products, with more companies opting for online purchasing platforms that provide extensive product listings and competitive pricing. International buyers from Africa and South America are increasingly leveraging digital channels to procure bed caster wheels, facilitating access to global suppliers and innovative products.

Emerging technologies, such as automated inventory management and advanced analytics, are also enhancing sourcing efficiencies. These tools allow businesses to predict demand accurately, manage stock levels effectively, and reduce lead times. Furthermore, the integration of IoT in manufacturing processes is leading to smarter, more durable caster wheels that can withstand heavy loads while maintaining ease of movement.

How Is Sustainability Shaping the Bed Caster Wheels Sector?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the bed caster wheels market. Environmental concerns surrounding the production and disposal of materials necessitate a shift towards eco-friendly options. Manufacturers are increasingly adopting sustainable practices by utilizing recycled materials in their products, which not only reduces waste but also minimizes the carbon footprint associated with production.

Buyers are now prioritizing suppliers who can demonstrate compliance with sustainability standards and certifications. These include ISO 14001 for environmental management and certifications for using renewable materials. Additionally, the demand for non-marking, recyclable caster wheels is on the rise, catering to both aesthetic preferences and environmental consciousness.

Ethical supply chains are also gaining traction, as buyers seek to ensure that their suppliers adhere to labor rights and fair trade practices. This emphasis on ethical sourcing not only enhances brand reputation but also aligns with the growing consumer demand for corporate responsibility, particularly in markets such as Europe and North America.

What Is the Historical Context of Bed Caster Wheels?

The evolution of bed caster wheels traces back to the industrial revolution, where the need for mobility in furniture became apparent. Initially made from wood and metal, these casters were primarily functional, designed to facilitate movement. Over the decades, advancements in materials science led to the introduction of plastic and rubber, offering improved durability and noise reduction.

In recent years, the focus has shifted towards design and functionality, with manufacturers innovating to create wheels that are not only practical but also aesthetically pleasing. This evolution reflects the broader trends within the furniture and healthcare industries, where mobility and design are increasingly intertwined. Today, bed caster wheels are essential components that enhance the usability of beds in various settings, from hospitals to residential homes, demonstrating their significant role in modern furniture design.

Conclusion

The bed caster wheels sector is rapidly evolving, driven by market demands for mobility, sustainability, and advanced sourcing technologies. For international B2B buyers, particularly from emerging markets, understanding these dynamics is crucial for making informed purchasing decisions. By aligning with sustainable practices and leveraging digital procurement channels, businesses can enhance their operational efficiency and meet the changing expectations of their customers.

Frequently Asked Questions (FAQs) for B2B Buyers of bed caster wheels

-

How do I solve issues with bed caster wheels not rolling smoothly?

To address problems with bed caster wheels that are not rolling smoothly, first inspect the wheels for debris or damage. Cleaning the wheels can often resolve minor blockages. If the wheels are still not functioning properly, check the mounting system to ensure they are securely attached. Consider replacing the wheels if they are worn out or if you need a higher load capacity. Selecting the right type of wheel—such as rubber for quiet operation or hard plastic for durability—can also enhance performance. -

What is the best type of caster wheel for hospital beds?

For hospital beds, the best type of caster wheels are typically heavy-duty, locking casters made from durable materials like rubber or polyurethane. These wheels provide stability, ease of movement, and can withstand the weight of medical equipment and patients. Locking mechanisms are crucial for safety, preventing the bed from moving unintentionally. When sourcing, ensure the load rating meets or exceeds the requirements of the specific hospital bed model. -

How can I verify the quality of bed caster wheels from suppliers?

To verify the quality of bed caster wheels, request samples and conduct performance tests under typical usage conditions. Check for certifications that indicate compliance with industry standards, such as ISO or ANSI. Additionally, ask for references from other clients and investigate the supplier’s reputation in the market. Quality assurance processes, including regular inspections and testing, should be part of the supplier’s operations to ensure consistent product quality. -

What customization options are available for bed caster wheels?

Customization options for bed caster wheels can include variations in size, material, color, and load capacity. Suppliers may also offer specific design features such as locking mechanisms or specific stem types to fit various bed frames. When discussing customization, provide your specifications and any unique requirements to the supplier to ensure they can meet your needs. It’s essential to confirm lead times for custom orders, as they may differ from standard products. -

What are the typical minimum order quantities (MOQs) for bed caster wheels?

Minimum order quantities (MOQs) for bed caster wheels can vary significantly depending on the supplier and the type of wheel. Generally, MOQs range from 100 to 1,000 units. Some suppliers may offer lower MOQs for standard products, while custom designs may require higher quantities. When negotiating with suppliers, clarify your needs and inquire about flexibility in MOQs, especially if you are testing a new product line. -

What payment terms should I expect when sourcing bed caster wheels internationally?

Payment terms for international sourcing can vary widely, but common practices include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Letter of Credit (LC) is also a secure method used in international trade. Discuss payment options with suppliers early in negotiations to align expectations. Be aware of additional costs such as shipping, taxes, and tariffs, which can affect the total cost of procurement. -

How can I ensure timely logistics and delivery of bed caster wheels?

To ensure timely logistics and delivery, work closely with your supplier to establish clear shipping schedules. Use reliable logistics partners with experience in international shipping, and consider options for expedited shipping if necessary. Track shipments regularly and maintain open communication with the supplier to address any potential delays. Including buffer times in your planning can also help mitigate risks associated with unforeseen logistics challenges. -

What should I consider when selecting a supplier for bed caster wheels?

When selecting a supplier for bed caster wheels, consider factors such as product quality, reliability, pricing, and customer service. Research the supplier’s experience in the industry and look for reviews or testimonials from previous clients. Evaluate their production capabilities and willingness to accommodate customization requests. Additionally, ensure they have robust quality assurance processes in place to maintain product standards, which is crucial for long-term partnerships.

Top 6 Bed Caster Wheels Manufacturers & Suppliers List

1. Caster Connection – Hospital Bed Casters

Domain: casterconnection.com

Registered: 1999 (26 years)

Introduction: Hospital Bed Casters include various types such as Kingpin Swivel, Kingpinless Swivel, Maintenance-Free Swivel, Spring-Loaded Swivel, Rigid, and Spring-Loaded Rigid. Available wheel diameters are 3″, 4″, 5″, 6″, 8″. Features include ergonomic performance, noise reduction, durability, and floor protection. Wheel materials include Polyurethane and Neoprene. Wheel width is 1″.

2. Jacob Holtz – Universal Bedframe Casters

Domain: jacobholtz.com

Registered: 1996 (29 years)

Introduction: Bed Casters – Universal Bedframe Casters & Metal Bed Casters. Last US manufacturer of metal bed casters. Universal Bedframe Caster: Green, stronger than metal, fashionable look, non-marking wheels, fits all existing and new frames. Made from recycled materials, 100% recyclable. Composite materials are 20% stronger than traditional rug runners. Certified to 150 lbs. per caster. Weighs 84 grams, red…

3. Delta – Hospital Bed Caster Wheels

Domain: hmemedicalshop.com

Registered: 2011 (14 years)

Introduction: Hospital Bed Casters and Wheels Replacement Parts

1. Delta Hospital Bed Caster Wheel Locking Replacement (Drive Medical 15044CL) – Price: $26.95, Rating: 100% (2 Reviews)

2. Delta & Competitor Hospital Bed Wheel Casters Set of 4 (Drive Medical 15044CSET) – Price: $69.95

3. Wheel, Caster with Lock for Hospital Beds (Probasics 90458) – Price: $39.95

4. Delta Hospital Bed Non-Locking Wheel Caster Re…

4. Caster Wheels – Set of 2

Domain: hotelsalesandsurplus.com

Registered: 2002 (23 years)

Introduction: {“name”: “Caster Wheels (2)”, “price”: “$6.95”, “description”: “In the unlikely event you need to replace the castor wheels, we offer them in sets of two. Each is engineered for strength with the roller centered perfectly beneath the leg and larger 1.5\” reinforced wheels. Different from competitors, these wheels are larger and are not offset at an angle, thus increasing the overall strength of th…

5. Surplus Center – Soft Rubber Tread Casters

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Best caster wheels depend on use, weight restriction, surface condition (smooth poured concrete/gravel), durometer rating (lower is softer), radius, bearing type, and budget. Recommendations include surpluscenter.com for soft rubber tread casters with at least double the weight rating needed. Castercity.com offers a decent selection and pricing. For serious use, Magestic Casters can provide tailor…

6. King’s Brand – Heavy Duty Caster Wheels

Domain: target.com

Registered: 1997 (28 years)

Introduction: King’s Brand Heavy Duty Caster Wheels for Bed Frame, Set of 4 (2 Locking & 2 None Locking), 5 out of 5 stars with 18 reviews, Free & easy returns within 30 days for a full refund, Sold & shipped by 2K Furniture Designs, Eligible for registries and wish lists.

Strategic Sourcing Conclusion and Outlook for bed caster wheels

In the evolving landscape of bed caster wheels, strategic sourcing emerges as a crucial component for international B2B buyers. By focusing on quality, durability, and design, businesses can ensure they are investing in products that not only meet operational needs but also enhance the user experience. Key considerations include understanding load capacities, material specifications, and the adaptability of casters to various bed frames.

Moreover, sourcing from reliable manufacturers can lead to long-term partnerships, ensuring consistent supply and potential cost efficiencies. As markets expand in Africa, South America, the Middle East, and Europe, the demand for innovative and functional caster solutions will continue to rise.

Illustrative image related to bed caster wheels

To stay ahead in this competitive environment, buyers are encouraged to engage with suppliers who prioritize sustainability and advanced engineering in their product offerings. By doing so, companies can align their procurement strategies with broader market trends and consumer expectations.

Now is the time for international buyers to leverage these insights and explore strategic sourcing opportunities that not only fulfill immediate needs but also position their organizations for future growth. Embrace the potential of bed caster wheels and elevate your business operations today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to bed caster wheels

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.