A Deep Dive into Air Conditioner Motor Parts Solution

Introduction: Navigating the Global Market for air conditioner motor parts

In today’s competitive landscape, sourcing high-quality air conditioner motor parts presents a significant challenge for international B2B buyers. Whether you are a supplier in Nigeria seeking reliable components or a distributor in Brazil aiming to expand your product offerings, understanding the nuances of the global market is crucial. This comprehensive guide delves into the various types of air conditioner motor parts, their applications, and essential factors to consider when making purchasing decisions.

Our exploration covers everything from fan motors and capacitors to contactors and relays, ensuring that you are well-informed about the essential components that keep air conditioning systems operational. Additionally, we will provide insights into supplier vetting processes, helping you identify trustworthy manufacturers and distributors. Cost considerations are also addressed, enabling you to navigate pricing structures effectively while ensuring quality and performance.

By equipping you with actionable insights and expert guidance, this guide empowers B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—to make informed purchasing decisions. With a focus on both technical specifications and market trends, you will be positioned to enhance your procurement strategy and ultimately drive success in your business endeavors.

Understanding air conditioner motor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Condenser Fan Motor | Typically single-phase, closed enclosure, various HP ratings | Used in outdoor AC units and heat pumps | Pros: Efficient cooling, OEM compatibility; Cons: May require specific voltage and amperage specifications. |

| Blower Motor | Varies in speed (single or multi-speed), often reversible | Found in central air systems and furnaces | Pros: Versatile, enhances airflow; Cons: Higher initial costs for advanced models. |

| Draft Inducer Motor | Designed for combustion air supply, often high RPM | Used in gas furnaces and HVAC systems | Pros: Improves efficiency, essential for safety; Cons: Maintenance-intensive due to exposure to heat. |

| Fan Motor | One-speed or multi-speed, varying horsepower and RPM | Applicable in both residential and commercial units | Pros: Wide range of options, easy replacement; Cons: Lower quality motors may have shorter lifespans. |

| Capacitor | Used for starting and running motors, varies in microfarads | Essential in various AC motor applications | Pros: Cost-effective, improves motor performance; Cons: Incorrect ratings can lead to motor failure. |

What are the Key Characteristics of a Condenser Fan Motor?

Condenser fan motors are crucial components in outdoor air conditioning units and heat pumps. They typically feature a closed enclosure, ensuring protection against environmental elements, and are available in various horsepower ratings. When sourcing these motors, B2B buyers should consider compatibility with existing systems, voltage requirements, and the efficiency ratings of the motor. A reliable condenser fan motor can significantly enhance cooling performance and energy efficiency, making it an important investment for HVAC contractors and maintenance teams.

How Does a Blower Motor Enhance Airflow in HVAC Systems?

Blower motors play a vital role in circulating air through central air conditioning systems and furnaces. They can be single-speed or multi-speed, with some models offering reversible operation for enhanced flexibility. Buyers should evaluate the motor’s horsepower, RPM, and compatibility with existing systems when making a purchase. Investing in a quality blower motor can lead to improved airflow, increased energy efficiency, and better overall comfort within a space, making it a strategic component for HVAC professionals.

Why is a Draft Inducer Motor Essential for Safety and Efficiency?

Draft inducer motors are specifically designed to facilitate combustion air supply in gas furnaces and HVAC systems. They typically operate at high RPMs to ensure efficient exhaust removal and proper venting. For B2B buyers, it is essential to understand the safety implications of these motors, as they are critical in preventing dangerous gas buildup. Although they may require more maintenance due to their exposure to heat, investing in a high-quality draft inducer motor can significantly improve system efficiency and safety.

What Should Buyers Consider When Selecting a Fan Motor?

Fan motors are versatile components found in both residential and commercial HVAC units. They come in various configurations, including one-speed and multi-speed options, with different horsepower and RPM ratings. When selecting a fan motor, buyers should assess the specific application requirements, including size, energy efficiency, and compatibility with existing systems. While fan motors are generally easy to replace, opting for higher-quality models can lead to longer lifespans and reduced operational costs.

How Do Capacitors Affect Motor Performance in Air Conditioning Systems?

Capacitors are integral to the operation of air conditioning motors, used to start and run motors efficiently. They come in various microfarad ratings, and selecting the correct capacitor is crucial for optimal motor performance. B2B buyers should consider the specific requirements of their motors, as incorrect ratings can lead to failure or inefficiency. Capacitors are relatively inexpensive, making them a cost-effective solution for enhancing motor performance and longevity in HVAC applications.

Key Industrial Applications of air conditioner motor parts

| Industry/Sector | Specific Application of air conditioner motor parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Replacement of fan motors in HVAC systems for hotels | Ensures guest comfort and satisfaction, reducing complaints. | OEM compatibility, energy efficiency ratings, local regulations. |

| Manufacturing | Use of blower motors in climate control systems | Maintains optimal working conditions, enhancing productivity. | Durability under heavy use, maintenance support, lead times. |

| Retail | Air conditioning motors in commercial cooling units | Protects perishable goods and improves customer experience. | Cost-effectiveness, energy efficiency, availability of parts. |

| Residential | Motors for home HVAC systems and split units | Improves energy efficiency and reduces utility costs for homeowners. | Compatibility with existing systems, warranty options, installation support. |

| Agriculture | Motors for cooling systems in greenhouses | Enhances plant growth and crop yield by maintaining ideal temperatures. | Climate resilience, power consumption, local sourcing options. |

How Are Air Conditioner Motor Parts Used in the Hospitality Industry?

In the hospitality sector, air conditioner motor parts, particularly fan motors, are critical for maintaining a comfortable environment in hotels and resorts. These motors ensure that HVAC systems function optimally, providing consistent cooling and heating. By ensuring guest comfort, businesses can enhance customer satisfaction and minimize complaints. When sourcing, buyers should prioritize OEM compatibility and energy efficiency ratings to comply with local regulations, especially in regions like Africa and South America where energy costs can be significant.

What Role Do Air Conditioner Motor Parts Play in Manufacturing?

Manufacturing facilities rely heavily on air conditioning systems to maintain optimal working conditions for employees and machinery. Blower motors are essential components that help regulate temperature and humidity levels, thereby enhancing productivity. When sourcing these parts, businesses should focus on durability, as manufacturing environments can be demanding. Additionally, maintenance support and lead times are crucial considerations, particularly for international buyers from regions like the Middle East and Europe, where quick replacements may be necessary to avoid production downtime.

How Are Air Conditioner Motor Parts Applied in Retail?

In retail environments, air conditioning motors are vital for commercial cooling units that protect perishable goods and enhance customer experience. These systems ensure that products remain at safe temperatures, preventing spoilage and maintaining quality. For retailers, sourcing cost-effective and energy-efficient motors is essential to manage operational costs. Buyers should also consider the availability of replacement parts to ensure minimal disruption, especially in regions like Brazil and Nigeria, where local support may vary.

Why Are Air Conditioner Motor Parts Important for Residential Use?

In residential settings, air conditioner motor parts are crucial for the efficient operation of HVAC systems and split units. These components significantly improve energy efficiency, leading to reduced utility costs for homeowners. When sourcing, buyers should ensure compatibility with existing systems and consider warranty options for peace of mind. Installation support is also a valuable factor, particularly for international buyers who may face challenges in accessing local installation services.

How Do Air Conditioner Motor Parts Benefit Agriculture?

In agriculture, air conditioner motor parts are used in cooling systems within greenhouses, playing a vital role in maintaining ideal growth conditions. By regulating temperatures, these motors help optimize plant growth and increase crop yields. Buyers in this sector should focus on sourcing motors that are climate-resilient and energy-efficient, as power consumption can greatly impact operational costs. Additionally, local sourcing options can be advantageous, particularly in regions where logistics may pose challenges.

3 Common User Pain Points for ‘air conditioner motor parts’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right Air Conditioner Motor Parts

The Problem:

B2B buyers often face challenges when trying to identify the correct air conditioner motor parts for specific models. This issue is exacerbated in regions where the availability of technical documentation may be limited, leading to confusion over part numbers and compatibility. For example, a buyer in Nigeria may need to replace a fan motor but struggles to determine the exact specifications due to variations in model types and manufacturers. This uncertainty can lead to incorrect orders, resulting in wasted time and financial resources.

The Solution:

To overcome this challenge, buyers should invest time in understanding the specifications of the air conditioning systems they are working with. It’s essential to locate and document the information plate or sticker on the current motor, which typically includes critical details like the part number, voltage, and horsepower. Additionally, leveraging online resources, such as manufacturer websites or trusted HVAC parts suppliers, can provide clarity on part compatibility. Collaborating with local HVAC technicians who possess hands-on experience can also be beneficial, as they can offer insights on common issues and part requirements for specific brands. Maintaining a detailed inventory of parts and their specifications can further streamline the ordering process.

Scenario 2: Long Lead Times for Air Conditioner Motor Parts

The Problem:

In international markets, particularly in regions like South America and Africa, long lead times for acquiring air conditioner motor parts can significantly disrupt business operations. Buyers often face delays that can extend from weeks to months due to logistical challenges, including customs regulations and limited local suppliers. For example, a company in Brazil may require a replacement condenser fan motor urgently to ensure continued operation of their cooling systems, but the delayed delivery can lead to service interruptions and lost revenue.

The Solution:

To mitigate lead times, B2B buyers should establish relationships with multiple suppliers, including local distributors, to ensure quick access to essential parts. It’s advisable to create a network of reliable suppliers across different regions, which can provide alternative sourcing options in case of delays. Implementing a just-in-time inventory strategy can also be effective, where businesses keep a limited stock of the most critical parts to bridge the gap during longer lead times. Additionally, buyers should inquire about expedited shipping options and track orders closely to anticipate any potential delays, allowing for proactive planning.

Scenario 3: Increased Operational Costs Due to Inefficient Motor Parts

The Problem:

B2B buyers often encounter increased operational costs stemming from inefficient air conditioner motor parts that lead to higher energy consumption and maintenance expenses. For instance, a company in the Middle East may use older motors that are not energy-efficient, resulting in inflated electricity bills and frequent breakdowns. This inefficiency not only affects the bottom line but can also lead to dissatisfaction among clients who expect reliable cooling solutions.

The Solution:

To address these inefficiencies, buyers should evaluate the energy ratings and performance specifications of air conditioner motor parts before purchasing. Opting for OEM (Original Equipment Manufacturer) parts that are designed for specific models can ensure optimal compatibility and performance. Additionally, investing in energy-efficient motors can significantly reduce operational costs in the long run. Conducting regular maintenance checks and replacing worn-out components promptly can help maintain system efficiency. Buyers should also consider upgrading to modern motor technologies, such as variable speed motors, which provide better energy efficiency and can adapt to changing cooling demands.

Strategic Material Selection Guide for air conditioner motor parts

What Are the Key Materials Used in Air Conditioner Motor Parts?

When selecting materials for air conditioner motor parts, it is crucial to consider their properties, advantages, and limitations. This decision directly impacts the performance, durability, and cost-effectiveness of the components. Below, we analyze four common materials used in the manufacturing of air conditioner motor parts, focusing on their specific applications and considerations for international B2B buyers.

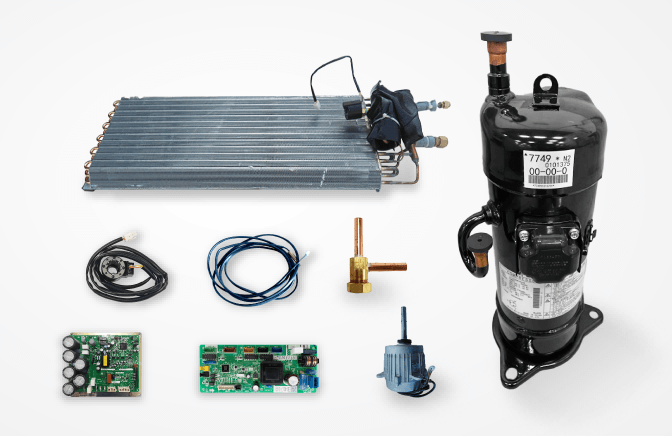

Illustrative image related to air conditioner motor parts

How Does Aluminum Perform in Air Conditioner Motor Parts?

Aluminum is widely used in air conditioner motor parts due to its excellent thermal conductivity and lightweight nature. It typically has a temperature rating of up to 150°C, making it suitable for various applications within HVAC systems. Aluminum is also resistant to corrosion, particularly when anodized, which enhances its longevity in humid environments.

Pros: Aluminum’s lightweight nature reduces the overall weight of motor assemblies, facilitating easier installation and transportation. Its thermal properties help improve energy efficiency by allowing better heat dissipation.

Cons: While aluminum is generally durable, it can be less robust than steel in high-stress applications. Additionally, it may be more expensive than some other materials, impacting overall production costs.

Impact on Application: Aluminum is compatible with various refrigerants and lubricants, ensuring optimal performance in air conditioning systems. However, its lower tensile strength should be considered in high-load scenarios.

International Considerations: Buyers in regions like Africa and South America should ensure compliance with local standards for aluminum alloys, such as ASTM or JIS specifications, to guarantee quality and performance.

Illustrative image related to air conditioner motor parts

What Role Does Steel Play in Air Conditioner Motor Parts?

Steel is another popular choice for air conditioner motor parts, particularly for components that require high strength and durability. With a temperature rating that can exceed 300°C, steel is ideal for high-performance applications. It also offers excellent resistance to mechanical wear.

Pros: Steel’s high tensile strength makes it suitable for heavy-duty applications, ensuring longevity and reliability. It is also cost-effective, making it a preferred choice for manufacturers looking to balance performance with budget.

Cons: Steel is heavier than aluminum, which can complicate installation and increase shipping costs. Additionally, it is prone to corrosion if not properly treated or coated.

Impact on Application: Steel is compatible with a wide range of operational environments, but its weight may necessitate additional support structures in certain designs.

International Considerations: Compliance with international standards like ASTM A36 or DIN 17100 is essential for ensuring the quality of steel components, especially in regions with varying environmental conditions.

Why Is Copper Important for Air Conditioner Motor Parts?

Copper is often utilized in electrical components of air conditioner motors due to its exceptional electrical conductivity and thermal properties. It can handle high temperatures, typically rated up to 200°C, making it suitable for electrical windings and connections.

Pros: Copper’s high conductivity ensures efficient energy transfer, reducing energy losses and improving overall system efficiency. Its natural resistance to corrosion further enhances its suitability for HVAC applications.

Cons: Copper is generally more expensive than aluminum or steel, which can increase the overall cost of motor assemblies. Additionally, it is heavier, which may affect the design and installation of certain components.

Impact on Application: Copper is compatible with most refrigerants and lubricants, making it a reliable choice for electrical connections in air conditioning systems.

International Considerations: Buyers should verify compliance with standards such as ASTM B170 for copper quality, especially in regions where electrical performance is critical.

How Does Plastic Contribute to Air Conditioner Motor Parts?

Plastics, particularly engineering thermoplastics, are increasingly used in air conditioner motor parts for components such as housings and insulators. Plastics can withstand temperatures up to 100°C and offer good chemical resistance.

Pros: The lightweight nature of plastics reduces the overall weight of assemblies, and their versatility allows for complex shapes and designs. Additionally, plastics are generally more cost-effective than metals.

Cons: Plastics may not offer the same level of strength as metals and can be susceptible to degradation under UV exposure or extreme temperatures.

Impact on Application: Plastics are suitable for non-load-bearing components and can provide excellent insulation for electrical parts, ensuring safety and efficiency.

International Considerations: Buyers should ensure that plastics meet relevant standards such as ISO 9001 for quality assurance, particularly in regions where environmental regulations may apply.

Summary Table of Material Properties for Air Conditioner Motor Parts

| Material | Typical Use Case for air conditioner motor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Fan housings, heat sinks | Lightweight and excellent thermal conductivity | Less robust than steel | Medium |

| Steel | Structural components, motor frames | High tensile strength and durability | Prone to corrosion if untreated | Low |

| Copper | Electrical windings, connectors | High electrical conductivity | More expensive and heavier | High |

| Plastic | Insulators, non-load-bearing components | Cost-effective and versatile | Less strength and UV susceptibility | Low |

This strategic material selection guide equips international B2B buyers with essential insights into the materials used in air conditioner motor parts, facilitating informed purchasing decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for air conditioner motor parts

What Are the Key Manufacturing Processes for Air Conditioner Motor Parts?

The manufacturing of air conditioner motor parts involves several critical stages, each designed to ensure that the final product meets stringent performance and reliability standards. Understanding these processes can help B2B buyers evaluate suppliers and their capabilities effectively.

How Are Raw Materials Prepared for Air Conditioner Motor Parts?

The first step in the manufacturing process is material preparation. Typically, manufacturers use high-grade materials such as copper for windings, high-strength steel for frames, and durable plastics for housings. These materials undergo rigorous testing to ensure they meet industry specifications. Suppliers may conduct assessments to verify the material’s chemical composition and physical properties, ensuring they are suitable for high-performance applications. Proper material selection is vital, as it directly impacts the motor’s efficiency and lifespan.

What Techniques Are Employed in Forming Air Conditioner Motor Components?

Forming processes transform raw materials into usable components. Common techniques include:

-

Stamping: Used for creating metal parts such as frames and end bells. This process involves using dies to cut and shape metal sheets into precise forms.

-

Injection Molding: Essential for producing plastic components. This technique involves injecting molten plastic into a mold, allowing for complex shapes and high-volume production.

-

Winding: Electric motor windings are crafted by wrapping insulated copper wire around a core. This step is crucial for creating the electromagnetic fields necessary for motor operation.

-

Machining: Involves cutting and shaping materials to achieve precise dimensions. Components like shafts may undergo processes such as turning and milling to ensure they meet tight tolerances.

These forming techniques ensure that each component is manufactured to the required specifications, which is essential for the overall functionality and efficiency of the air conditioning system.

How Are Air Conditioner Motor Parts Assembled?

The assembly stage combines all individual components into a complete motor. This process typically includes:

-

Sub-Assembly: Components like windings, bearings, and housings are pre-assembled before the final assembly. This helps streamline the manufacturing process and allows for easier troubleshooting.

-

Final Assembly: All sub-assemblies are brought together. Skilled technicians use specialized tools to ensure that each part fits correctly and is securely fastened.

-

Electrical Connections: Wiring is carefully connected to ensure proper functionality. Attention to detail is crucial in this stage to prevent electrical failures.

-

Quality Checks: Before moving to the finishing stage, a series of quality checks are performed to ensure assembly integrity and functionality.

What Finishing Techniques Are Utilized for Air Conditioner Motor Parts?

Finishing processes enhance the durability and aesthetics of air conditioner motor parts. Common techniques include:

Illustrative image related to air conditioner motor parts

-

Coating: Protective coatings, such as powder coating or galvanization, are applied to metal parts to prevent corrosion and wear.

-

Balancing: Rotating components like rotors are balanced to minimize vibrations during operation, which can lead to premature wear or failure.

-

Testing: Final testing involves running the assembled motor under various conditions to ensure it meets performance criteria, such as efficiency and noise levels.

These finishing techniques are essential for ensuring that air conditioner motor parts can withstand demanding operational environments.

What Quality Assurance Standards Are Relevant for Air Conditioner Motor Parts?

Quality assurance (QA) is paramount in the manufacturing of air conditioner motor parts. It ensures that products meet both international standards and specific industry requirements. Understanding these standards can help B2B buyers make informed purchasing decisions.

Which International Standards Should Buyers Be Aware Of?

-

ISO 9001: This is a widely recognized international standard for quality management systems. It ensures that manufacturers maintain consistent quality and continuously improve their processes.

-

CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards. It is essential for ensuring that products can be legally marketed within the European Economic Area.

-

API Standards: The American Petroleum Institute (API) standards are relevant for motors used in HVAC systems that involve petrochemical processes. Compliance with these standards ensures safety and reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to the manufacturing process. They typically include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials and components before production begins. Any materials that do not meet specifications are rejected.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various checks ensure that production is on track and components are being manufactured to specifications.

-

Final Quality Control (FQC): After assembly, motors undergo rigorous testing to validate performance, including efficiency tests and operational noise levels.

These checkpoints help maintain high standards throughout the manufacturing process.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring the reliability of air conditioner motor parts. Here are some actionable steps:

-

Request Audits and Reports: Suppliers should provide documentation of their QA processes, including results from internal audits and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes and quality control measures.

-

Site Visits: If possible, visiting the manufacturing facility can give buyers firsthand insight into the production environment and quality control practices.

-

Certifications: Buyers should verify that suppliers hold relevant certifications (e.g., ISO 9001, CE marking) and ensure these are up to date.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate various quality control nuances. Considerations include:

-

Regulatory Compliance: Understanding local regulations and standards in the buyer’s region is essential to avoid compliance issues upon import.

-

Cultural Differences: Different regions may have varying approaches to quality assurance and customer service. Building strong relationships with suppliers can enhance communication and ensure mutual understanding.

-

Logistics and Supply Chain: Buyers should consider the impact of logistics on quality control, as longer shipping times can lead to issues such as damage or degradation of components.

By taking these factors into account, B2B buyers can enhance their procurement strategies, ensuring they source high-quality air conditioner motor parts that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air conditioner motor parts’

This guide serves as a practical checklist for B2B buyers looking to source air conditioner motor parts effectively. Whether you are operating in Africa, South America, the Middle East, or Europe, following these steps will ensure that you make informed purchasing decisions that meet your technical and budgetary needs.

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, clearly outline the technical specifications required for the air conditioner motor parts. This includes details such as horsepower, voltage, RPM, and phase. Understanding these specifications is vital as it ensures compatibility with existing systems, reducing the risk of costly errors.

- Identify OEM Requirements: If you are replacing parts, ensure they meet Original Equipment Manufacturer (OEM) standards to maintain system efficiency.

- Consider Application Needs: Different applications may require specific features like speed control or enclosure types.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers that specialize in air conditioner motor parts. Look for companies with a solid reputation in the industry, especially those that serve your geographic region.

- Check Online Reviews: Utilize platforms like Google and industry-specific forums to gauge customer satisfaction.

- Evaluate Experience: Suppliers with years of experience in the HVAC sector often have better insights into product quality and reliability.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify the certifications and compliance of potential suppliers. This ensures that the parts you source adhere to international safety and quality standards.

- Look for ISO Certifications: An ISO certification indicates that the supplier follows stringent quality management practices.

- Check for Local Compliance: Ensure that the supplier meets local regulations specific to your region, which can vary significantly.

Step 4: Request Detailed Quotations

Once you have narrowed down your list of suppliers, request detailed quotations. This should include pricing, lead times, and shipping options.

- Compare Total Costs: Don’t just focus on unit prices; consider shipping, duties, and any additional fees.

- Negotiate Terms: Engage in discussions about payment terms and bulk order discounts, which can lead to significant savings.

Step 5: Assess After-Sales Support

Evaluate the after-sales support offered by suppliers. This is critical in ensuring that you receive assistance if any issues arise post-purchase.

Illustrative image related to air conditioner motor parts

- Inquire About Warranty Policies: A comprehensive warranty can indicate the supplier’s confidence in their product quality.

- Check Technical Support Availability: Ensure that the supplier provides technical assistance and troubleshooting support, especially if you are sourcing complex components.

Step 6: Test Samples if Possible

Before finalizing a bulk order, request samples of the air conditioner motor parts to test compatibility and performance. This step is essential to mitigate risks associated with sourcing.

- Conduct Performance Tests: Check for operational efficiency, noise levels, and durability under expected conditions.

- Validate Fit and Compatibility: Ensure that the parts fit seamlessly into your existing systems to avoid installation issues.

Step 7: Establish Long-Term Relationships

Consider establishing long-term relationships with your suppliers. This can lead to better pricing, priority service, and enhanced support over time.

- Communicate Regularly: Keep an open line of communication to foster trust and collaboration.

- Provide Feedback: Share your experiences and suggestions, which can help suppliers improve their offerings and service.

By following this comprehensive checklist, B2B buyers can navigate the sourcing process for air conditioner motor parts more effectively, ensuring they secure high-quality components that meet their specific needs.

Illustrative image related to air conditioner motor parts

Comprehensive Cost and Pricing Analysis for air conditioner motor parts Sourcing

Air conditioner motor parts play a crucial role in the overall efficiency and functionality of HVAC systems. Understanding the cost structure and pricing dynamics is essential for international B2B buyers, particularly those in emerging markets like Africa, South America, the Middle East, and Europe. This analysis will provide insights into the various cost components, price influencers, and actionable tips for buyers.

What Are the Key Cost Components in Air Conditioner Motor Parts?

The cost structure of air conditioner motor parts comprises several critical components:

-

Materials: The choice of materials significantly affects costs. High-quality metals, insulation materials, and electronic components are essential for durability and performance. The ongoing volatility in raw material prices can lead to fluctuations in overall costs.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. Skilled labor is necessary for manufacturing high-quality motor parts, impacting the overall production cost.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help reduce these overheads, impacting the final pricing.

-

Tooling: Specialized tools and machinery for production can be costly. The initial investment in tooling can be a significant part of the cost structure, particularly for custom parts.

-

Quality Control (QC): Rigorous quality checks are necessary to ensure reliability and compliance with international standards. The cost of QC processes can vary, affecting the pricing strategy.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. Factors such as distance, shipping mode, and customs duties can significantly influence overall costs.

-

Margin: Suppliers typically add a profit margin to cover operational expenses and risks. This margin can vary depending on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Affect Air Conditioner Motor Parts Pricing?

Several factors can influence the pricing of air conditioner motor parts:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts due to economies of scale. Buyers should negotiate MOQs that balance their needs with supplier capabilities.

-

Specifications and Customization: Customized parts with specific features or certifications generally come at a higher price. Understanding the balance between necessary specifications and cost is crucial for buyers.

-

Material Quality and Certifications: Parts that meet international quality standards (e.g., ISO certifications) may command higher prices. Buyers should assess whether the added cost aligns with their performance requirements.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more, but they often provide greater assurance of reliability.

-

Incoterms: Understanding shipping terms is critical for cost planning. Incoterms dictate the responsibilities of buyers and sellers in shipping, affecting overall landed costs.

What Are Some Tips for Negotiating Air Conditioner Motor Parts Prices?

For international B2B buyers, particularly in diverse markets like Brazil and Nigeria, negotiating effectively can lead to significant cost savings:

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and energy costs associated with the motor parts. A higher initial investment may lead to lower long-term costs.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Trust can facilitate negotiations and lead to favorable conditions for future orders.

-

Be Informed: Understanding market trends, competitor pricing, and supplier capabilities will empower buyers during negotiations. Conduct market research to gather insights on pricing benchmarks.

-

Consider Local Suppliers: In some cases, local suppliers may offer competitive pricing due to lower shipping costs and tariffs. Evaluating local options could provide cost advantages.

-

Be Flexible: Be open to alternative solutions, such as accepting slightly lower specifications or considering bulk purchases to optimize costs.

Disclaimer on Indicative Prices

Prices for air conditioner motor parts can vary widely based on the factors discussed above. The figures mentioned in various sources are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing air conditioner motor parts With Other Solutions

Understanding Alternative Solutions to Air Conditioner Motor Parts

In the HVAC industry, air conditioner motor parts are critical for maintaining efficient cooling systems. However, as technology evolves, buyers should also consider alternative solutions that may offer similar or enhanced performance. This analysis compares traditional air conditioner motor parts with two alternative technologies: variable speed compressors and smart HVAC control systems.

Comparison Table

| Comparison Aspect | Air Conditioner Motor Parts | Variable Speed Compressors | Smart HVAC Control Systems |

|---|---|---|---|

| Performance | Reliable and effective for specific models | Offers variable cooling based on demand | Enhances overall system efficiency and comfort |

| Cost | Moderate, typically $100-$400 per part | Higher initial investment, $1,000-$3,000 | Varies; typically $200-$1,500 for controls |

| Ease of Implementation | Requires technical knowledge for installation | Complex installation requiring professional help | Generally user-friendly, can be self-installed |

| Maintenance | Regular checks needed for longevity | Minimal maintenance but may require professional service | Low maintenance with software updates |

| Best Use Case | Ideal for specific replacement needs | Best for energy efficiency and fluctuating demand | Excellent for modernizing older systems for efficiency |

Detailed Breakdown of Alternatives

Variable Speed Compressors

Variable speed compressors represent a significant advancement in HVAC technology. Unlike traditional fixed-speed compressors, they adjust their output based on the cooling demand, leading to improved energy efficiency and comfort. While the initial investment is higher, the long-term savings on energy bills can offset this cost. However, installation is complex and typically requires a certified technician, which can add to the overall expense. This option is best suited for environments with variable cooling needs, such as commercial spaces or larger homes.

Smart HVAC Control Systems

Smart HVAC control systems utilize technology to optimize heating and cooling performance. These systems allow users to manage their HVAC units remotely via smartphones or computers, enabling real-time adjustments and monitoring. They can lead to significant energy savings and improved comfort levels. Although the upfront cost can be substantial, the ease of installation and low maintenance requirements make them appealing. This solution is ideal for businesses looking to modernize their HVAC systems without significant structural changes.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between air conditioner motor parts and alternative solutions, B2B buyers should consider several factors, including performance requirements, budget constraints, and the specific needs of their facilities. Traditional motor parts are reliable for direct replacements and maintenance, while variable speed compressors and smart control systems offer advanced efficiency and convenience. Ultimately, the best choice depends on the buyer’s operational goals, existing infrastructure, and willingness to invest in newer technologies that promise greater efficiency and control. By carefully evaluating these options, businesses can make informed decisions that enhance their HVAC systems’ reliability and performance.

Essential Technical Properties and Trade Terminology for air conditioner motor parts

What Are the Key Technical Properties of Air Conditioner Motor Parts?

When sourcing air conditioner motor parts, understanding the technical specifications is vital for ensuring compatibility and performance. Here are several critical specifications to consider:

-

Horsepower (HP)

Horsepower indicates the motor’s power output. Common ratings for air conditioner motors range from 1/10 HP to 1/4 HP. Selecting a motor with the appropriate horsepower is essential for efficient operation and to meet the cooling requirements of the system. Underpowered motors can lead to overheating and system failure, while overpowered units may consume excessive energy. -

Voltage Rating

The voltage rating, typically expressed in volts (e.g., 208-230V), specifies the electrical supply needed for the motor. It’s crucial for buyers to ensure that the voltage rating matches their electrical systems to avoid operational issues. Mismatched voltage can lead to motor burnout or insufficient performance. -

Full-Load Amperage (FLA)

FLA is the maximum current the motor will draw under full load conditions, measured in amps. This specification is critical for determining the electrical infrastructure needed to support the motor. Understanding FLA helps in selecting the right circuit breakers and wiring, ensuring safety and compliance with electrical standards. -

RPM (Revolutions Per Minute)

RPM indicates the rotational speed of the motor, affecting airflow and cooling efficiency. Common RPM ratings for air conditioner motors are 825, 1075, or 1100. The right RPM is essential for maintaining optimal performance; too high or too low can negatively impact system efficiency and lifespan. -

Enclosure Type

The enclosure type, such as open or closed, defines how the motor is protected from environmental factors. Closed enclosures are preferable in harsh conditions as they offer better protection against dust and moisture, which can extend the motor’s operational life. -

Frame Size

The frame size, often denoted by a number (like 48 or 42Y), indicates the dimensions and mounting configurations of the motor. This specification is vital for ensuring that the motor fits properly within the existing air conditioning unit, preventing installation issues.

Which Trade Terms Should B2B Buyers Understand in the Air Conditioner Motor Parts Industry?

Navigating the procurement process requires familiarity with industry-specific terminology. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the same manufacturer that produced the original equipment. These parts are often preferred for their compatibility and reliability. B2B buyers should prioritize OEM parts to maintain warranty coverage and ensure optimal performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it affects inventory management and cost efficiency. Suppliers may offer better pricing for larger orders, but businesses must balance this with their actual needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific parts. It is essential for comparing costs and terms from different vendors. A well-crafted RFQ can lead to better pricing and improved supplier relationships. -

Incoterms

Incoterms are international trade terms that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is crucial for B2B transactions, as they clarify who bears the risk and costs during transportation. Familiarity with Incoterms can help buyers negotiate better shipping arrangements. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Knowing the lead time is essential for planning and inventory management. Buyers should discuss lead times with suppliers to ensure that parts arrive when needed to avoid downtime. -

Warranty Period

The warranty period is the time frame during which the manufacturer guarantees the part against defects. Understanding warranty conditions can provide peace of mind and protect against unforeseen costs. Buyers should always inquire about warranty terms to make informed purchasing decisions.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure the right air conditioner motor parts for their needs.

Navigating Market Dynamics and Sourcing Trends in the air conditioner motor parts Sector

What Are the Current Market Dynamics and Key Trends in Air Conditioner Motor Parts?

The air conditioner motor parts market is experiencing significant growth, driven by rising temperatures globally and an increasing demand for energy-efficient cooling solutions. Key trends include the adoption of advanced technologies such as IoT-enabled motors and smart HVAC systems, which enhance operational efficiency and enable predictive maintenance. B2B buyers from regions like Africa, South America, the Middle East, and Europe (notably Brazil and Nigeria) are increasingly looking for suppliers who can provide not only quality parts but also innovative solutions that reduce energy consumption and improve overall system performance.

Emerging sourcing trends reveal a shift toward online procurement platforms, allowing buyers to access a broader range of products and competitive pricing. As the market becomes more competitive, international B2B buyers are prioritizing suppliers who offer quick delivery times and robust customer support. The rise of e-commerce in parts procurement also emphasizes the need for transparency in pricing and product availability. In addition, the growing trend of customization in motor parts to fit specific applications is gaining traction, allowing buyers to tailor solutions that best meet their operational needs.

How Can Sustainability and Ethical Sourcing Impact the Air Conditioner Motor Parts Supply Chain?

Sustainability is becoming a central focus for B2B buyers in the air conditioner motor parts sector, as environmental concerns increasingly influence purchasing decisions. The environmental impact of manufacturing processes and the lifecycle of parts are critical factors in selecting suppliers. Buyers are now seeking manufacturers who adhere to sustainable practices, including reduced carbon emissions and waste management. Furthermore, the use of eco-friendly materials and processes is becoming a prerequisite for many international buyers.

Illustrative image related to air conditioner motor parts

Ethical sourcing is equally important, as companies are scrutinizing their supply chains to ensure compliance with labor and environmental standards. Certifications such as ISO 14001 for environmental management and Fair Trade for labor practices are highly regarded. Buyers from Africa, South America, the Middle East, and Europe are increasingly insisting on transparency in the supply chain, which helps mitigate risks associated with unethical practices and enhances brand reputation. By prioritizing suppliers who demonstrate a commitment to sustainability and ethical sourcing, B2B buyers can contribute to a greener future while fulfilling their operational requirements.

What Is the Historical Evolution of the Air Conditioner Motor Parts Market?

The air conditioner motor parts market has evolved significantly over the decades. Initially, air conditioning systems were basic and primarily mechanical, relying on simple motor designs. As technology advanced, the introduction of electronic controls and variable-speed motors revolutionized the industry, allowing for better efficiency and performance.

The shift towards energy efficiency gained momentum in the late 20th century, driven by rising energy costs and environmental regulations. Manufacturers began focusing on creating more sophisticated motor designs that not only improved energy efficiency but also reduced noise levels and enhanced durability. Today, the market is witnessing a rapid transformation with the integration of smart technologies, setting the stage for a future where air conditioning systems are not just functional but also intelligent and responsive to user needs.

This evolution underscores the importance of staying informed about technological advancements and market shifts, enabling B2B buyers to make strategic sourcing decisions that align with contemporary trends and future demands.

Frequently Asked Questions (FAQs) for B2B Buyers of air conditioner motor parts

-

How do I solve an air conditioner motor that keeps tripping the circuit breaker?

To resolve this issue, first check the motor for any visible signs of damage or obstruction that may be causing it to draw excessive current. Inspect the wiring for frayed or shorted connections. If the motor has a capacitor, ensure it’s functioning properly, as a faulty capacitor can lead to increased load on the motor. Lastly, consider consulting a qualified technician for a thorough diagnosis, as continuous tripping may indicate a deeper electrical issue that requires professional intervention. -

What is the best motor type for high-efficiency air conditioning systems?

For high-efficiency air conditioning systems, inverter-driven motors or EC (Electronically Commutated) motors are highly recommended. These motors adjust their speed based on cooling demands, leading to significant energy savings and quieter operation. They provide better temperature control and are more durable, which is essential for maintaining optimal performance over time. Ensure compatibility with your system’s specifications before purchasing. -

What factors should I consider when selecting a supplier for air conditioner motor parts?

When selecting a supplier, evaluate their reputation, reliability, and experience in the industry. Check for certifications that indicate quality standards, such as ISO 9001. It’s also essential to assess their capacity to meet your order volumes and timelines. Additionally, inquire about their sourcing practices, warranty policies, and customer support services. A reliable supplier should also offer a transparent return policy and be willing to provide references from other clients. -

What are the minimum order quantities (MOQ) for air conditioner motor parts?

Minimum order quantities can vary significantly depending on the supplier and the specific parts you need. Generally, MOQs can range from a few units for standard parts to several dozen for specialized components. It’s advisable to discuss your requirements directly with potential suppliers to negotiate MOQs that align with your business needs, especially if you are looking for bulk purchases or customized parts. -

How can I ensure the quality of air conditioner motor parts before purchasing?

To ensure quality, request detailed specifications and certifications from the supplier. Conduct due diligence by checking reviews and feedback from previous customers. If possible, obtain samples to evaluate the quality firsthand. Additionally, consider asking about the supplier’s quality assurance processes, including testing protocols for their products. This proactive approach can help mitigate risks associated with subpar components. -

What payment terms are typically offered by suppliers of air conditioner motor parts?

Payment terms can vary widely among suppliers. Common arrangements include upfront payments, net 30 or 60 days, and letter of credit options for larger orders. It’s crucial to clarify payment terms before finalizing your order to avoid any misunderstandings. Some suppliers may also offer discounts for early payments or bulk purchases. Always ensure that the terms are documented in your contract to protect your interests. -

What logistics considerations should I keep in mind when sourcing internationally?

When sourcing internationally, consider shipping costs, delivery timelines, and customs regulations that may impact your order. It’s important to work with suppliers who have experience with international shipping and can provide accurate lead times. Factor in potential delays due to customs clearance, and ensure that your supplier can provide the necessary documentation for smooth transit. Additionally, evaluate the shipping methods available to find the most cost-effective and reliable options. -

Can I customize air conditioner motor parts to meet specific requirements?

Yes, many suppliers offer customization options for air conditioner motor parts to meet your specific needs. This may include modifications to size, voltage, or functionality. When discussing customization, provide detailed specifications and any relevant performance criteria. Be aware that custom parts may have longer lead times and potentially higher costs, so it’s essential to confirm these factors with your supplier prior to placing an order.

Top 7 Air Conditioner Motor Parts Manufacturers & Suppliers List

1. Home Depot – Air Conditioner Motor Parts

Domain: appliancerepair.homedepot.com

Registered: 1992 (33 years)

Introduction: This company, Home Depot – Air Conditioner Motor Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Indoor Comfort Supply – Air Conditioning Parts

Domain: indoorcomfortsupply.com

Registered: 2007 (18 years)

Introduction: Air Conditioning Parts – Indoor Comfort Supply offers a wide variety of air conditioning replacement parts including: A/C Blower Wheels, A/C Capacitors, A/C Coil Cleaners, A/C Condensate Pumps, A/C Contactors, A/C Control Boards, A/C Controls, A/C Electrical Parts and Fittings, A/C Fan Blades, A/C Filters, A/C Motors (including A/C and Furnace Blower Motor, A/C Condenser Fan Motor), A/C Relays, A/…

3. Gatewaysupply – X-13 Motor Module

Domain: woe.gatewaysupply.net

Registered: 2000 (25 years)

Introduction: This company, Gatewaysupply – X-13 Motor Module, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Bryant – Key AC Parts

Domain: bryant.com

Registered: 1996 (29 years)

Introduction: Key AC Parts: 1. Compressor: Circulates refrigerant and compresses it into a high-pressure gas. 2. Condenser: Dissipates heat from the refrigerant, allowing it to cool and transform into a liquid state. 3. Evaporator Coil: Absorbs heat from indoor air and transfers it to the refrigerant. 4. Fan Motor: Blows air over the evaporator coil and condenser to cool the refrigerant and expel heat. 5. Therm…

5. Ferguson – HVAC Repair Parts & Equipment

Domain: ferguson.com

Registered: 1999 (26 years)

Introduction: HVAC Repair Parts & Maintenance, HVAC Equipment, HVAC Installation Supplies, Ductless Mini-Splits, Bathroom Exhaust Fans, Grilles, Registers & Diffusers, Thermostats, Flexible Air Duct, Equipment Pads, Indoor Air Quality, Capacitors, Motors, HVAC Compressors, Maintenance & Chemicals, Electrical Relays, Contactors, Pipe Fittings, Pipe & Tubing, Fasteners, A2L Tools & Parts, A2L Refrigerants, Trade …

6. Reddit – Condenser Fan Motor Replacement Cost

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: $945 for replacing a condenser fan motor; DIY approach considered due to busy schedule; typical retail price for a single speed 208-230v fan motor is less than $225; motor run capacitor costs around $15; some HVAC professionals suggest a reasonable total cost should be around $450.

7. HVAC Parts Shop – Essential Repair Components

Domain: hvacpartsshop.com

Registered: 2006 (19 years)

Introduction: HVAC Repair Parts & Accessories including Furnace Parts, Air Conditioning Parts, HVAC Controls, Indoor Air Quality products. Key categories include: Blower Motors, Flame Sensors, Condenser Coils, Electronic Air Filters, Capacitors, and Fan Motors. Offers fast shipping with same-day delivery and quality OEM parts from brands like Lennox, Goodman, Armstrong, Trane, and York. Provides expert resource…

Strategic Sourcing Conclusion and Outlook for air conditioner motor parts

In the evolving landscape of air conditioner motor parts, strategic sourcing emerges as a crucial factor for international B2B buyers. Understanding market dynamics, including regional demands and supply chain efficiencies, can significantly enhance procurement strategies. By prioritizing quality OEM components and leveraging partnerships with reliable suppliers, companies can ensure operational reliability and minimize downtime. Furthermore, tapping into localized sourcing opportunities can reduce logistical costs and improve service responsiveness, particularly in regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to air conditioner motor parts

As competition intensifies, the need for cost-effective solutions without compromising quality becomes paramount. Buyers should focus on establishing long-term relationships with manufacturers and distributors who can provide not only competitive pricing but also technical support and product innovation.

Looking ahead, the air conditioning industry is poised for growth, driven by rising temperatures and an increasing emphasis on energy efficiency. B2B buyers are encouraged to stay informed about emerging technologies and market trends to make strategic sourcing decisions that position their businesses for success. Engage with trusted partners and explore new sourcing avenues to secure your competitive edge in this vital market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.