A Deep Dive into Air Conditioner Filter Material Solution

Introduction: Navigating the Global Market for air conditioner filter material

In an increasingly interconnected world, navigating the global market for air conditioner filter material presents unique challenges for B2B buyers. Selecting the right air filter media can significantly impact indoor air quality, energy efficiency, and ultimately, customer satisfaction. With diverse options ranging from cost-effective fiberglass to high-efficiency HEPA filters, understanding the nuances of each type is essential for making informed purchasing decisions. This guide aims to equip international buyers, particularly those from Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—with the insights necessary to source the best filter materials for their specific needs.

Throughout this comprehensive resource, we will explore various types of air filter media, their applications, and the factors influencing their performance and longevity. Additionally, we will delve into supplier vetting processes, pricing considerations, and maintenance practices that ensure optimal functionality. By understanding these critical aspects, B2B buyers can confidently navigate the complexities of the air filter market, enhance their procurement strategies, and ultimately improve air quality for their clients. This guide empowers you to make strategic decisions that align with your organizational goals and the evolving demands of the global marketplace.

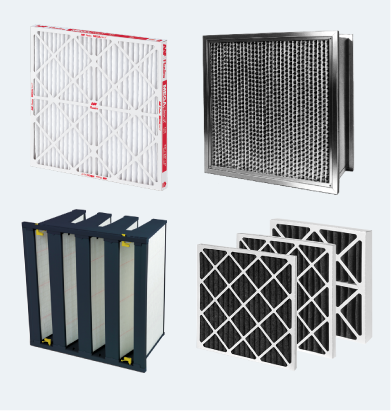

Understanding air conditioner filter material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fiberglass Filters | Cost-effective, single-use, low MERV ratings | Basic residential and commercial settings | Pros: Affordable, easy to replace. Cons: Low efficiency, limited pollutant capture. |

| Pleated Filters | Increased surface area, higher efficiency ratings | Homes, offices, and industrial facilities | Pros: Better air quality, longer lifespan. Cons: Higher initial cost, may require more maintenance. |

| HEPA Filters | High particle capture efficiency, tightly woven fibers | Hospitals, laboratories, and sensitive environments | Pros: Excellent for allergen removal, long-lasting. Cons: More expensive, requires compatible systems. |

| Activated Carbon Filters | Specialized in odor and gas removal | Restaurants, commercial kitchens, and industrial applications | Pros: Effective for VOCs and odors. Cons: Limited particle filtration, may need frequent replacement. |

| Electrostatic Filters | Uses static electricity to trap particles | Industrial settings and HVAC systems | Pros: Reusable, efficient particle capture. Cons: Requires regular cleaning, initial investment. |

What Are the Characteristics of Fiberglass Filters and Their Suitability for B2B Buyers?

Fiberglass filters are the most basic type of air filter, constructed from layers of spun glass fibers. They are designed primarily for capturing larger particles like dust and debris, making them suitable for environments where air quality is not a primary concern, such as basic residential or commercial settings. For B2B buyers, the low cost and ease of replacement are appealing; however, their low efficiency ratings (MERV 1-4) mean they may not be ideal for businesses that require higher air quality standards.

How Do Pleated Filters Enhance Air Quality and What Should Buyers Consider?

Pleated filters are designed with multiple folds, increasing their surface area and allowing them to capture more particles compared to fiberglass filters. With a higher MERV rating, they are suitable for a variety of applications, from homes to offices and industrial facilities. B2B buyers should consider the balance between initial costs and long-term efficiency, as pleated filters typically offer longer lifespans and better air quality, making them a more cost-effective option over time.

Why Are HEPA Filters Essential for Sensitive Environments?

HEPA (High-Efficiency Particulate Air) filters are renowned for their ability to capture 99.97% of particles as small as 0.3 microns. This makes them essential in environments where air quality is critical, such as hospitals, laboratories, and clean rooms. B2B buyers must be aware of the higher initial investment required for HEPA filters, as well as the need for compatible HVAC systems. However, their efficiency in allergen removal and longevity can justify the costs in settings that prioritize health and safety.

Illustrative image related to air conditioner filter material

What Advantages Do Activated Carbon Filters Offer for Specific Applications?

Activated carbon filters excel in removing odors and volatile organic compounds (VOCs), making them ideal for restaurants, commercial kitchens, and industrial applications where air quality can be compromised by strong smells and chemical emissions. While they are effective in their specialized role, B2B buyers should note that activated carbon filters are not designed for particulate filtration, which may necessitate the use of additional filters for comprehensive air quality management. Regular replacement is also essential to maintain their effectiveness.

How Do Electrostatic Filters Function and What Are Their Benefits?

Electrostatic filters utilize static electricity to attract and trap airborne particles, making them an efficient choice for industrial settings and HVAC systems. These filters can be reusable, providing a sustainable option for businesses focused on reducing waste. However, B2B buyers should consider the need for regular cleaning to maintain performance, as well as the initial investment. Their efficiency in capturing a wide range of particle sizes makes them a valuable option for environments that require consistent air quality.

Key Industrial Applications of air conditioner filter material

| Industry/Sector | Specific Application of air conditioner filter material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | HVAC systems in hospitals and clinics | Ensures high indoor air quality, reducing infection rates | Compliance with health regulations, filter efficiency ratings, and longevity |

| Manufacturing | Air filtration in production facilities | Protects machinery from dust, enhancing operational efficiency | Material durability, compatibility with existing systems, and maintenance requirements |

| Food and Beverage | Climate control in food processing plants | Maintains product quality and safety by filtering contaminants | Food-grade certification, filter lifespan, and replacement frequency |

| Automotive | Air conditioning in manufacturing plants | Improves worker comfort and productivity in assembly lines | Customization options, energy efficiency, and cost-effectiveness |

| Hospitality | Air filtration in hotels and resorts | Enhances guest experience by providing clean and fresh air | Aesthetic integration, noise levels, and maintenance ease |

How is Air Conditioner Filter Material Utilized in Healthcare Settings?

In healthcare facilities, air conditioner filter materials are critical for maintaining sterile environments. Filters such as HEPA are employed in HVAC systems to capture airborne pathogens, allergens, and pollutants, which is vital for patient safety and comfort. International buyers from regions with diverse health regulations, like Africa and Europe, must ensure that the filters comply with local health standards and provide high efficiency ratings. Longevity and ease of maintenance are also significant factors, as frequent replacements can disrupt operations and increase costs.

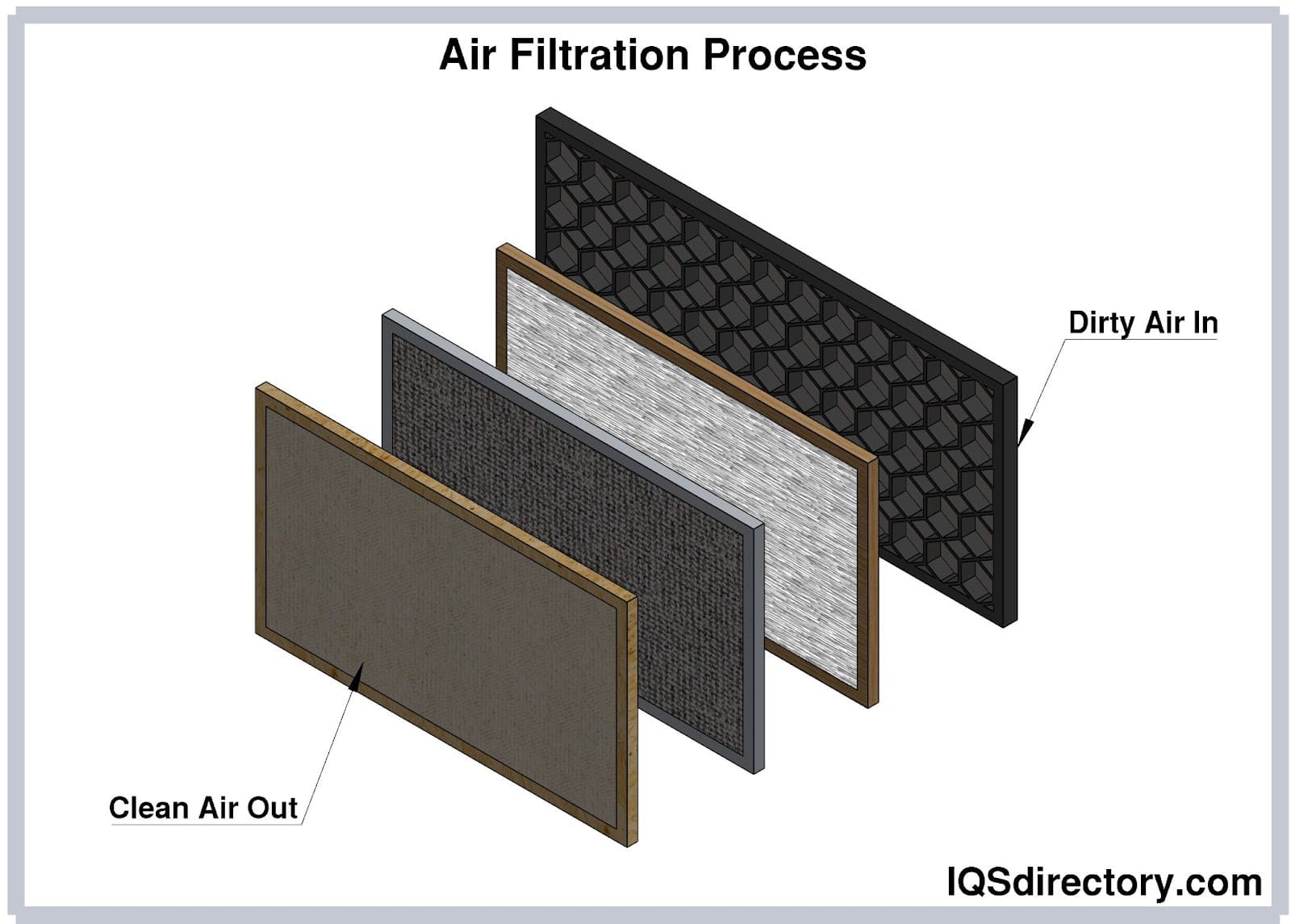

Illustrative image related to air conditioner filter material

What Role Does Air Filter Material Play in Manufacturing Industries?

In manufacturing environments, air conditioner filter materials are essential for protecting machinery from dust and particulate matter. Filters in these settings enhance operational efficiency by ensuring that equipment operates smoothly and reduces downtime caused by maintenance issues. Buyers in South America and the Middle East should focus on sourcing durable materials that can withstand the rigors of industrial environments while also considering compatibility with existing HVAC systems. The total cost of ownership, including maintenance and replacement frequency, is a crucial aspect of the purchasing decision.

How is Air Filter Material Applied in Food and Beverage Production?

In the food and beverage industry, air conditioner filter materials are used to ensure that the air quality in processing plants meets strict safety standards. Activated carbon and HEPA filters help eliminate contaminants that could compromise product quality. For international buyers, especially in regions with stringent food safety regulations like Europe, sourcing filters with food-grade certifications is paramount. Additionally, understanding the lifespan and maintenance needs of these filters can lead to significant cost savings and operational efficiency.

How Do Automotive Manufacturers Utilize Air Conditioner Filter Materials?

Air conditioning systems in automotive manufacturing plants rely on efficient air filter materials to enhance worker comfort and productivity. By filtering out dust and pollutants, these filters contribute to a healthier working environment. Buyers in the automotive sector, particularly in emerging markets like Brazil, should consider customization options to fit specific assembly line conditions. Energy efficiency and cost-effectiveness also play a vital role in the sourcing process, as manufacturers seek to optimize their operational budgets.

Why is Air Filter Material Important in the Hospitality Industry?

In the hospitality sector, air conditioner filter materials are crucial for providing guests with a clean and comfortable environment. Filters help maintain air quality by removing allergens, odors, and pollutants, which is essential for customer satisfaction. When sourcing filters, international buyers should consider aesthetic integration into existing HVAC systems, as well as noise levels during operation, to ensure a pleasant guest experience. Regular maintenance and filter replacement schedules are also important to sustain air quality over time.

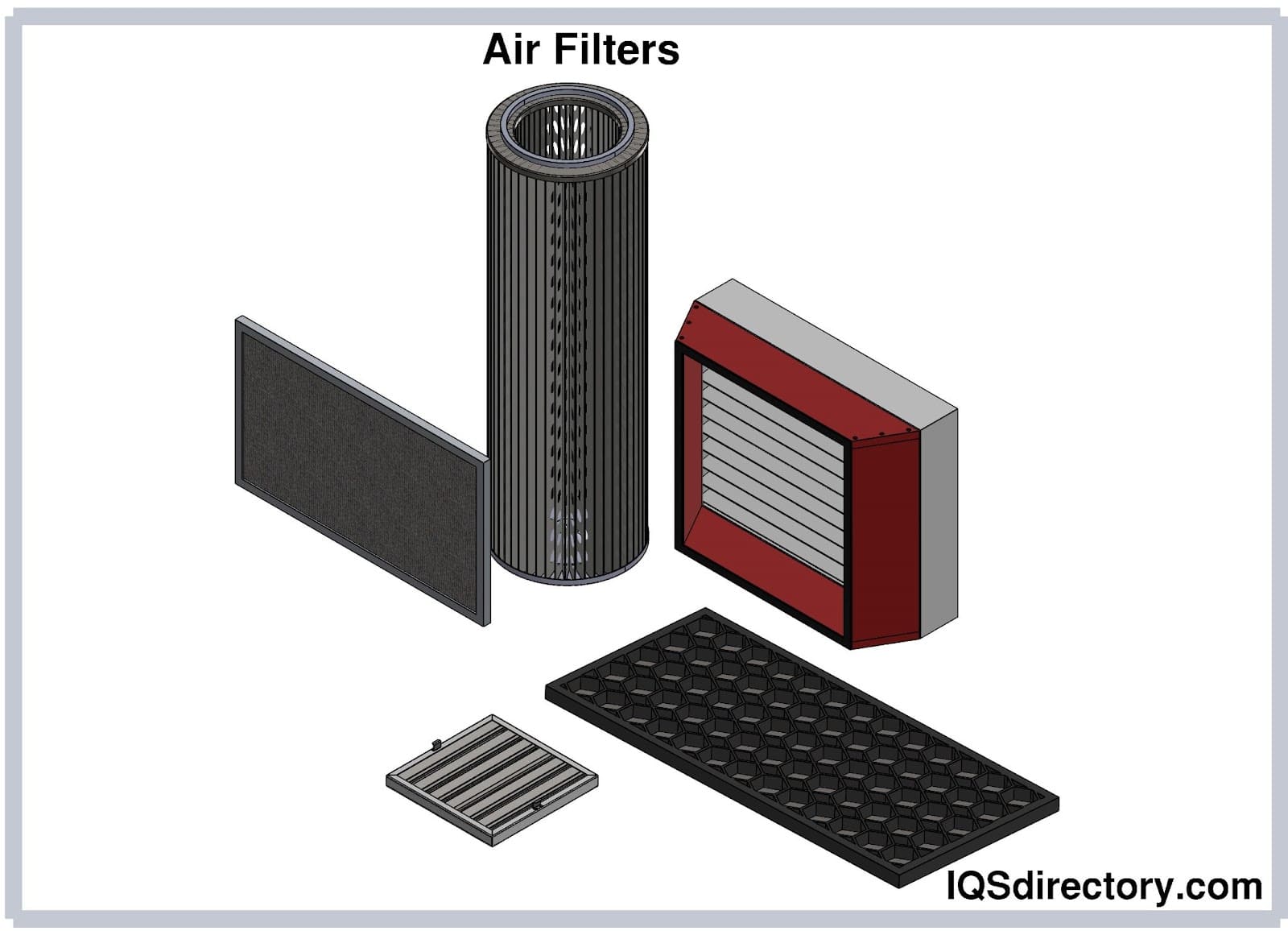

Illustrative image related to air conditioner filter material

3 Common User Pain Points for ‘air conditioner filter material’ & Their Solutions

Scenario 1: Navigating Quality Variability in Air Filter Materials

The Problem: B2B buyers often grapple with inconsistent quality across different suppliers of air conditioner filter materials. This variability can lead to unreliable filtration performance, impacting air quality and potentially damaging HVAC systems. Businesses in regions with high dust levels, such as parts of Africa and South America, are particularly vulnerable. These buyers might find themselves sourcing filters that don’t meet specified MERV ratings or fail to trap harmful particulates, leading to increased maintenance costs and operational disruptions.

The Solution: To ensure consistent quality, buyers should implement a stringent supplier evaluation process that includes comprehensive product testing. Requesting samples from multiple suppliers and conducting side-by-side performance tests can help verify the filtration efficiency and durability of different materials. Additionally, collaborating with manufacturers who provide detailed specifications and certifications, such as ISO compliance, can assure that the filter materials meet industry standards. Establishing long-term partnerships with reliable suppliers who offer consistent quality will reduce the risk of purchasing subpar products.

Scenario 2: Understanding the Lifespan and Maintenance Needs of Filter Materials

The Problem: Many B2B buyers underestimate the importance of filter lifespan and maintenance requirements, leading to premature filter changes and unnecessary expenses. In commercial settings, such as offices or manufacturing facilities, this can result in increased downtime and inefficiencies. Buyers may also struggle to balance cost with performance, often opting for cheaper options that require more frequent replacements, further complicating their operational budgets.

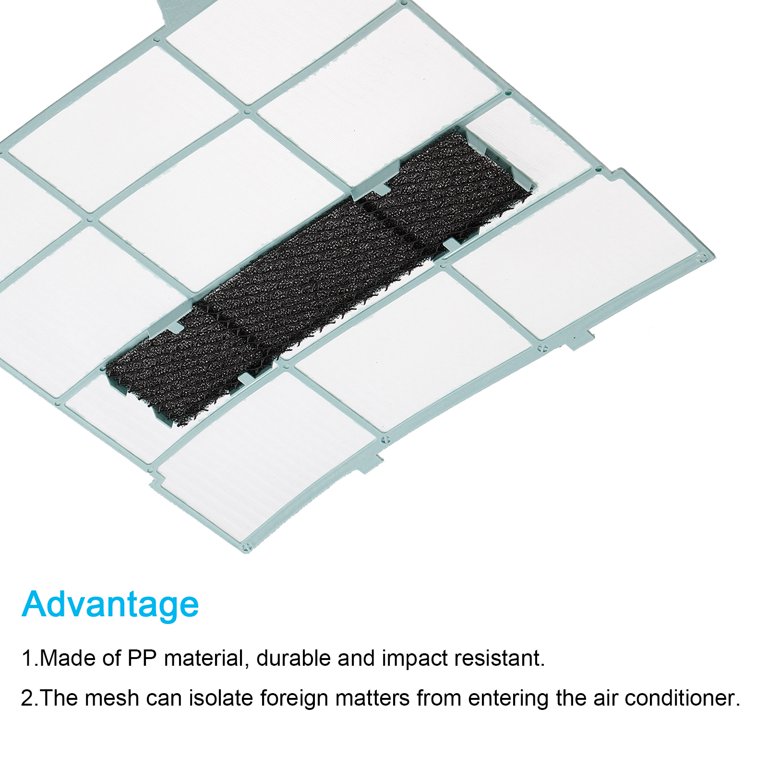

Illustrative image related to air conditioner filter material

The Solution: To mitigate this issue, buyers should conduct a thorough analysis of their specific air quality needs and operational conditions before selecting filter materials. Utilizing data on air quality and filter performance, they can better understand the optimal replacement intervals for different types of filters. For instance, pleated filters may have a longer lifespan than standard fiberglass options, providing better overall value despite a higher upfront cost. Regular maintenance schedules should be established, including routine inspections and replacements based on usage patterns, to ensure that air quality remains at acceptable levels without incurring excessive costs.

Scenario 3: Addressing Environmental Concerns with Filter Material Disposal

The Problem: As environmental regulations tighten across various regions, B2B buyers face increasing pressure to consider the ecological impact of their filter materials. Many traditional filter options are not recyclable, leading to significant waste accumulation and potential compliance issues. This concern is heightened in regions like Europe, where sustainability is a key focus for businesses. Buyers may feel overwhelmed by the need to transition to more sustainable options while still meeting performance requirements.

The Solution: Buyers can explore eco-friendly filter materials, such as washable filters or those made from recycled materials, which offer a more sustainable alternative. When selecting filters, it’s crucial to evaluate the entire lifecycle of the product, including disposal methods. Implementing a recycling program for used filters can also help mitigate waste and demonstrate corporate responsibility. Collaborating with suppliers who prioritize sustainability and provide clear information on the environmental impact of their products can facilitate a smoother transition. Additionally, engaging in training sessions for staff on proper disposal and recycling practices can enhance overall compliance and reduce the environmental footprint of air conditioning operations.

Strategic Material Selection Guide for air conditioner filter material

What Are the Key Properties of Fiberglass Air Filters for Air Conditioners?

Fiberglass air filters are widely used in HVAC systems due to their cost-effectiveness and basic filtration capabilities. These filters are made from spun glass fibers, which are lightweight and allow for good airflow. The typical temperature rating for fiberglass filters is around 100°F (37.8°C), making them suitable for standard residential and commercial applications. However, they are not designed for high-pressure environments, which limits their use in industrial settings.

Pros include their affordability and ease of installation, making them a popular choice for budget-conscious buyers. However, cons include low efficiency in capturing smaller particles, with a MERV rating typically ranging from 1 to 4. This makes them less suitable for environments requiring high air quality, such as hospitals or cleanrooms. International buyers should consider local regulations regarding air quality standards, as fiberglass filters may not meet stringent requirements in regions like Europe.

How Do Pleated Air Filters Enhance Air Conditioner Performance?

Pleated air filters are designed with a larger surface area compared to fiberglass filters, allowing them to trap more contaminants effectively. Made from polyester or cotton paper, these filters typically have a higher temperature tolerance, often exceeding 150°F (65.6°C), which makes them suitable for various climates. Their MERV ratings usually range from 6 to 12, depending on the specific design and material used.

Illustrative image related to air conditioner filter material

The key advantage of pleated filters is their efficiency in capturing both large and small particles, making them ideal for residential and commercial applications where air quality is a concern. However, their disadvantage lies in the higher initial cost and the need for more frequent replacements, particularly in dusty environments. B2B buyers in regions like Africa and South America should ensure that pleated filters comply with local air quality standards, which may vary significantly.

What Are the Benefits of HEPA Filters in Air Conditioning Systems?

HEPA (High-Efficiency Particulate Air) filters are renowned for their superior filtration capabilities, capturing up to 99.97% of particles as small as 0.3 microns. Constructed from tightly woven fiberglass fibers, these filters can handle higher temperatures and pressures, making them suitable for various applications, including hospitals and laboratories. They typically have a temperature rating of around 200°F (93.3°C).

The primary advantage of HEPA filters is their exceptional performance in improving indoor air quality, which is crucial in settings with vulnerable populations. However, their key limitation is the cost, which is significantly higher than other filter types. Additionally, HEPA filters may require specialized housing to fit into existing HVAC systems, complicating installation. International buyers should be aware of certifications like EN 1822 in Europe and the need for compliance with local standards.

How Do Activated Carbon Filters Work in Air Conditioning Applications?

Activated carbon filters are designed to remove odors, gases, and volatile organic compounds (VOCs) from the air, making them an excellent complement to other filter types. These filters utilize a porous carbon medium, which can absorb a wide range of contaminants. Their temperature rating is typically around 150°F (65.6°C), making them suitable for standard air conditioning systems.

The advantage of activated carbon filters is their ability to enhance air quality by removing unpleasant odors and harmful gases, which is particularly beneficial in industrial and commercial settings. However, their disadvantage is that they have a limited lifespan and must be replaced frequently, depending on the level of contaminants in the air. B2B buyers in regions like the Middle East, where air quality can be a significant concern, should consider the specific needs of their applications and the local availability of these filters.

Summary Table of Air Conditioner Filter Materials

| Material | Typical Use Case for air conditioner filter material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fiberglass | Basic residential and light commercial applications | Cost-effective and easy to install | Low efficiency for small particles | Low |

| Pleated | Residential and commercial air quality improvement | Higher efficiency in capturing contaminants | Higher initial cost and frequent replacements | Medium |

| HEPA | Hospitals, labs, and environments needing high air quality | Exceptional filtration performance | High cost and potential installation complexity | High |

| Activated Carbon | Odor and VOC removal in commercial settings | Effective in removing odors and harmful gases | Limited lifespan and frequent replacements required | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for air conditioner filter material

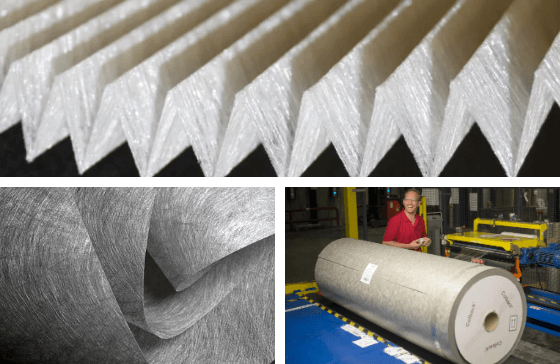

What Are the Main Stages of Manufacturing Air Conditioner Filter Materials?

The manufacturing process of air conditioner filter materials involves several key stages, each crucial for ensuring the final product meets performance and quality standards. The typical stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Air Conditioner Filters?

Material preparation is the initial phase where raw materials are selected based on the desired filter type. Common materials used include fiberglass, pleated paper, synthetic fibers, and activated carbon. Each material is sourced to meet specific filtration needs, such as particle size and air quality requirements.

During this stage, materials undergo processes like shredding, bonding, and layering. For instance, fiberglass is spun into fine fibers, while pleated paper is treated to enhance its filtering capabilities. The selection and preparation of these materials are essential for achieving the required efficiency and durability of the filters.

Illustrative image related to air conditioner filter material

What Techniques Are Used in Forming Air Conditioner Filters?

Once the materials are prepared, they move to the forming stage, where they are shaped into the desired filter structure. This can involve techniques such as:

- Pleating: For pleated filters, layers of material are folded into pleats, which increase the surface area for trapping particles while maintaining airflow efficiency.

- Binding: In the case of fiberglass filters, adhesive bonding may be employed to hold the fibers together and create a robust structure.

- Molding: Activated carbon filters might be molded to incorporate specific designs that maximize their absorption capabilities.

These forming techniques directly influence the filter’s performance, airflow resistance, and overall effectiveness in capturing pollutants.

How Are Air Conditioner Filters Assembled?

The assembly stage integrates various components of the filter into a complete unit. This involves assembling the frame, media, and any additional features like support grids or sealing materials.

Quality control is paramount during assembly to ensure that all parts fit together correctly and that the final product meets specifications. Automated assembly lines are often used to enhance consistency and reduce human error, but manual inspection remains crucial for quality assurance.

Illustrative image related to air conditioner filter material

What Finishing Processes Are Involved in Air Conditioner Filter Manufacturing?

Finishing processes are the final steps in the manufacturing of air conditioner filters, where the products undergo final inspections, cleaning, and packaging. This stage may include:

- Trimming: Excess material is trimmed to achieve precise dimensions.

- Labeling: Filters are labeled with specifications, including MERV ratings and usage instructions, to inform buyers about their performance capabilities.

- Packaging: Proper packaging protects the filters during transportation and storage, ensuring they remain clean and undamaged.

This attention to detail in the finishing stage enhances the product’s appeal and reliability in the market.

What Are the Quality Control Measures for Air Conditioner Filter Materials?

Quality control (QC) is a critical aspect of the manufacturing process, ensuring that air conditioner filters meet international standards and customer expectations. Various QC checkpoints are employed throughout production, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

What International Standards Apply to Air Conditioner Filter Manufacturing?

Manufacturers of air conditioner filters often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO standards demonstrates a commitment to consistent quality and customer satisfaction.

In addition to ISO certifications, industry-specific standards like CE marking in Europe and API standards in the oil and gas sector may apply, depending on the filter’s intended use. These certifications assure buyers that the products have undergone rigorous testing and meet safety and performance criteria.

How Are Quality Control Checkpoints Implemented?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure compliance with specifications:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival. Suppliers must provide documentation and certificates of compliance to verify material quality.

- In-Process Quality Control (IPQC): Throughout production, operators conduct inspections to monitor adherence to processes and specifications. This includes checking dimensions, filter media integrity, and assembly accuracy.

- Final Quality Control (FQC): Before packaging, finished products undergo comprehensive testing, including airflow resistance, filtration efficiency, and durability tests. Any filters that do not meet standards are either reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are actionable steps buyers can take:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed audit reports and certifications from potential suppliers. These documents should outline the supplier’s compliance with international standards and highlight any third-party inspections conducted.

Regular audits can reveal a supplier’s commitment to maintaining quality standards. Buyers can also consider visiting manufacturing facilities to conduct their own inspections, which allows for a firsthand assessment of quality control practices.

How Do Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection agencies can provide an impartial assessment of a supplier’s quality control processes. These agencies can conduct periodic audits and testing to ensure compliance with international standards and specifications.

Illustrative image related to air conditioner filter material

Third-party inspections can be particularly beneficial for international buyers, as they offer an additional layer of assurance regarding product quality and supplier reliability.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances when it comes to quality control in air conditioner filter manufacturing. Understanding regional compliance requirements and certifications is crucial, as different markets may have varying standards.

For instance, filters intended for the European market must comply with CE marking regulations, while those sold in the U.S. may need to meet specific EPA guidelines. Buyers should familiarize themselves with these requirements to ensure compliance and avoid costly penalties or product recalls.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear communication channels and documentation practices can help mitigate misunderstandings and ensure that both parties are aligned on quality standards.

In summary, a comprehensive understanding of manufacturing processes and quality assurance in air conditioner filter materials is vital for international B2B buyers. By focusing on supplier quality control, compliance with international standards, and effective communication, buyers can make informed decisions that enhance their procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air conditioner filter material’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure air conditioner filter material. With various types of filter media available, it’s essential to follow a systematic approach to ensure the selection of high-quality materials that meet specific air quality needs and operational requirements.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the air filter materials you need. This includes factors such as filter efficiency ratings (MERV ratings), dimensions, and specific air quality standards. Defining these specifications helps streamline the sourcing process and ensures that the filters will meet the operational demands of your HVAC systems.

Step 2: Research Material Types and Their Applications

Familiarize yourself with the different types of air filter materials available, such as fiberglass, pleated paper, HEPA, and activated carbon. Each material has unique properties suited for different applications:

– Fiberglass: Cost-effective and suitable for basic filtration.

– HEPA: Ideal for environments requiring high air quality, such as hospitals.

Understanding the strengths and weaknesses of each type will help you make informed decisions based on your specific needs.

Illustrative image related to air conditioner filter material

Step 3: Evaluate Potential Suppliers

Before making any commitments, it’s crucial to thoroughly vet potential suppliers. Request company profiles, certifications, and case studies that demonstrate their capability in delivering quality materials. Look for:

– Industry experience: Suppliers with a proven track record in air filtration.

– Client references: Testimonials from businesses in similar sectors can provide insights into reliability and service quality.

Step 4: Request Samples for Testing

Once you’ve shortlisted potential suppliers, request samples of their filter materials for testing. This step allows you to evaluate the performance of the materials in real-world conditions. Pay attention to:

– Filter efficiency: Conduct tests to ensure the materials meet your defined specifications.

– Durability and lifespan: Assess how well the materials hold up under typical operating conditions.

Step 5: Verify Supplier Certifications

Ensure that the suppliers hold relevant certifications that reflect their compliance with industry standards. Certifications such as ISO 9001 for quality management and ASHRAE standards for air filtration are essential indicators of a supplier’s credibility. This verification process reduces the risk of sourcing subpar materials.

Step 6: Negotiate Pricing and Terms

Engage in negotiations with your selected suppliers to establish favorable pricing and terms. Consider factors such as bulk purchase discounts, payment terms, and delivery schedules. A well-negotiated agreement can lead to significant cost savings and improved supply chain efficiency.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to regularly monitor the performance of the air filter materials once procured. This includes setting up a schedule for inspections and replacements based on the expected lifespan of the filters. Maintaining high air quality standards is crucial for operational efficiency and customer satisfaction.

By following this checklist, B2B buyers can navigate the complexities of sourcing air conditioner filter materials effectively, ensuring that they select the best options for their specific needs.

Comprehensive Cost and Pricing Analysis for air conditioner filter material Sourcing

What Are the Key Cost Components in Sourcing Air Conditioner Filter Material?

When sourcing air conditioner filter material, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

Illustrative image related to air conditioner filter material

-

Materials: The choice of filter media—such as fiberglass, pleated paper, HEPA, or activated carbon—significantly influences costs. Premium materials like HEPA are more expensive due to their superior filtration capabilities and certifications.

-

Labor: Labor costs vary by region and can impact overall pricing. In countries with higher labor costs, such as Germany, buyers may face increased prices compared to regions with lower labor expenses.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, ultimately benefiting the buyer.

-

Tooling: For custom filter designs, tooling costs can be substantial. Investment in specialized molds or machines may be necessary, particularly for unique specifications.

-

Quality Control (QC): Ensuring product quality often incurs additional costs. Rigorous QC procedures guarantee that filters meet required standards, especially for markets that demand certifications.

-

Logistics: Shipping and handling costs can be significant, particularly for international transactions. Factors such as shipping distance, mode of transport, and import duties can affect the total logistics expense.

-

Margin: Suppliers typically apply a margin to cover their costs and ensure profitability. Understanding the market dynamics can help buyers gauge whether margins are reasonable.

How Do Pricing Influencers Affect Air Conditioner Filter Material Costs?

Several factors influence the pricing of air conditioner filter materials, and being aware of these can lead to more informed purchasing decisions:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts. Buyers should negotiate MOQs to optimize costs and ensure they are not overcommitting to inventory.

-

Specifications and Customization: Custom filters tailored to specific needs tend to cost more. Buyers should evaluate whether standard options meet their requirements to avoid unnecessary expenses.

-

Materials Quality and Certifications: Filters with higher efficiency ratings or certifications (like HEPA) command higher prices. Buyers should assess whether the added cost aligns with their air quality needs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their experience and quality assurances, while newer entrants may offer competitive pricing.

-

Incoterms: The terms of shipping and delivery can significantly influence costs. Understanding Incoterms is crucial for determining who bears responsibilities and costs during shipping.

What Tips Should Buyers Consider for Negotiating Costs Effectively?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following tips to negotiate better pricing:

-

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, evaluate the TCO, which includes maintenance, replacement frequency, and energy efficiency. This perspective can justify investing in higher-quality filters.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices across different suppliers. This knowledge can strengthen negotiating positions and help identify competitive offers.

-

Build Long-Term Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms over time. Consider long-term contracts for consistent supply at negotiated rates.

-

Be Open to Alternatives: Explore different filter types and materials that may offer cost benefits without compromising quality. Flexibility can yield significant savings.

-

Understand Local Market Dynamics: Familiarize yourself with regional market trends, tariffs, and regulations that may affect pricing. This knowledge can help anticipate cost fluctuations.

Disclaimer on Indicative Prices

Prices for air conditioner filter materials can vary significantly based on the factors discussed above. Buyers should approach sourcing with a clear understanding of their specific needs and market conditions to negotiate effectively. Always request detailed quotes and consider all cost components to ensure a comprehensive evaluation.

Alternatives Analysis: Comparing air conditioner filter material With Other Solutions

Understanding the Importance of Alternatives in Air Filtration Solutions

When evaluating air conditioner filter materials, it is essential for B2B buyers to consider alternative solutions that can provide similar air quality benefits. Different technologies and methods can offer unique advantages depending on specific application needs, environmental conditions, and budget constraints. Below, we compare traditional air conditioner filter materials with two viable alternatives: UV air purification systems and electrostatic air filters.

| Comparison Aspect | Air Conditioner Filter Material | UV Air Purification Systems | Electrostatic Air Filters |

|---|---|---|---|

| Performance | Effective at trapping particulate matter; varies by type (e.g., HEPA, pleated). | Destroys microorganisms and allergens effectively; does not capture particles. | High efficiency in trapping both large and small particles; reusable options available. |

| Cost | Generally low to moderate; varies based on material and efficiency rating. | Higher initial investment; ongoing electricity costs for operation. | Moderate; reusable filters can lower long-term expenses. |

| Ease of Implementation | Simple to replace; standard sizes available for most HVAC systems. | Requires installation and electrical setup; may need professional service. | Easy to install; can be used in conjunction with existing filters. |

| Maintenance | Regular replacement needed (every 1-3 months); simple upkeep. | Requires bulb replacement and regular cleaning; maintenance can be complex. | Minimal maintenance; washable options available. |

| Best Use Case | Suitable for residential and commercial settings needing basic to advanced filtration. | Ideal for environments requiring sterilization (e.g., hospitals, laboratories). | Effective in settings with high dust or allergen levels; can be used in homes and businesses. |

What Are the Pros and Cons of UV Air Purification Systems?

UV air purification systems utilize ultraviolet light to eliminate microorganisms, including bacteria and viruses, from the air. One of the primary advantages of this technology is its ability to provide a higher level of air sterilization, making it ideal for hospitals and environments where air quality is critical. However, the initial investment can be significant, and ongoing energy costs must be considered. Additionally, UV systems do not capture particulate matter; therefore, they are often used alongside traditional filters for optimal performance.

How Do Electrostatic Air Filters Compare to Traditional Filters?

Electrostatic air filters leverage static electricity to attract and capture airborne particles. These filters often boast higher efficiency than standard fiberglass options and are available in both disposable and washable formats. Their reusable nature can lead to cost savings over time, making them an appealing option for environmentally conscious buyers. However, they may require more maintenance to ensure optimal performance and can be less effective against larger particles compared to some mechanical filters.

How Can B2B Buyers Choose the Right Air Filtration Solution?

When selecting the right air filtration solution, B2B buyers should assess their specific needs regarding air quality, environmental conditions, and budget constraints. For standard filtration needs, traditional air conditioner filter materials remain a reliable choice. However, if the environment demands higher sterilization levels or if there are concerns about allergens, exploring alternatives such as UV systems or electrostatic filters may prove beneficial. Ultimately, the decision should factor in both initial costs and long-term maintenance to ensure that the chosen solution aligns with operational goals and enhances overall air quality.

Essential Technical Properties and Trade Terminology for air conditioner filter material

What Are the Key Technical Properties of Air Conditioner Filter Material?

When selecting air conditioner filter material, several technical properties are critical for ensuring optimal performance and longevity. Understanding these properties helps B2B buyers make informed purchasing decisions that align with their specific operational needs.

Illustrative image related to air conditioner filter material

1. Material Grade

Material grade refers to the quality and type of fibers used in the filter media, such as fiberglass, polyester, or activated carbon. Higher-grade materials typically offer better filtration efficiency and longer service life. For B2B buyers, investing in higher-grade filters can reduce maintenance costs and improve air quality, making it a vital consideration in procurement.

2. Filtration Efficiency

Filtration efficiency is often measured using the MERV (Minimum Efficiency Reporting Value) rating, which ranges from 1 to 20. A higher MERV rating indicates better particle capture capabilities, including the ability to trap smaller contaminants. For businesses, selecting filters with appropriate MERV ratings is crucial for maintaining air quality, especially in environments where allergens and pollutants are a concern.

3. Airflow Resistance

Airflow resistance is the measure of how easily air can pass through the filter material. Low airflow resistance is essential to prevent strain on HVAC systems, which can lead to increased energy costs and equipment wear. B2B buyers should consider this property to ensure that selected filters enhance system efficiency while providing adequate filtration.

4. Lifespan and Replacement Cycle

The lifespan of filter media indicates how long it can function effectively before requiring replacement. Filters with longer lifespans, such as HEPA or pleated filters, often provide better value by reducing the frequency of replacements. Understanding the expected lifespan helps businesses plan maintenance schedules and budget accordingly.

5. Chemical Compatibility

This property refers to the filter material’s ability to withstand exposure to various chemicals and pollutants without degrading. For industrial applications where air quality may be compromised by chemical vapors, selecting filters with high chemical resistance is essential. This ensures safety and compliance with health regulations.

Illustrative image related to air conditioner filter material

What Are Common Trade Terms in the Air Conditioner Filter Industry?

Navigating the air conditioner filter market requires familiarity with specific jargon and trade terminology that can impact purchasing decisions. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand name. In the filter industry, understanding OEM relationships can help buyers ensure they are sourcing quality materials that meet specific industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management, as it affects the overall procurement strategy and cost-effectiveness.

Illustrative image related to air conditioner filter material

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. This process helps buyers compare offers and negotiate better deals. Familiarity with RFQs is crucial for efficient sourcing in a competitive market.

4. Incoterms (International Commercial Terms)

Incoterms are standardized shipping and delivery terms that define the responsibilities of buyers and sellers. Understanding Incoterms is vital for international B2B transactions, as they clarify shipping costs, risk transfer, and delivery obligations, minimizing potential disputes.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. For air conditioner filter materials, shorter lead times can be crucial for maintaining inventory levels and meeting customer demands. Buyers should evaluate lead times when planning purchases to ensure timely availability.

Illustrative image related to air conditioner filter material

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions that enhance their air quality management efforts and align with their operational goals.

Navigating Market Dynamics and Sourcing Trends in the air conditioner filter material Sector

What Are the Current Market Dynamics and Key Trends in the Air Conditioner Filter Material Sector?

The air conditioner filter material market is witnessing significant growth driven by increasing awareness of indoor air quality and the demand for energy-efficient HVAC systems. Global drivers include urbanization, rising disposable incomes, and a growing focus on health and wellness, particularly in emerging markets across Africa, South America, and the Middle East. In Europe, particularly in Germany, stringent regulations regarding air quality standards are compelling manufacturers to innovate and enhance filter materials.

Current B2B sourcing trends indicate a shift towards advanced filter technologies, including HEPA and electrostatic filters, which cater to specific needs such as allergy reduction and odor control. Buyers are increasingly seeking multifunctional filters that not only trap particulate matter but also neutralize volatile organic compounds (VOCs) and other harmful gases. Additionally, digital technologies are emerging as crucial tools for optimizing supply chain management and inventory control, enabling buyers to track filter performance and lifecycle effectively.

Emerging markets are adopting innovative filtration solutions at a rapid pace. In regions like Brazil and South Africa, local manufacturers are beginning to incorporate sustainable practices into their operations, providing a competitive edge in the global marketplace. As buyers become more informed, they are looking for suppliers who can offer comprehensive solutions, including customized filter designs tailored to specific operational environments.

How Does Sustainability and Ethical Sourcing Impact the Air Conditioner Filter Material Sector?

Sustainability and ethical sourcing are becoming paramount in the air conditioner filter material sector. The environmental impact of manufacturing processes, including waste generation and energy consumption, is under scrutiny. Buyers are increasingly prioritizing suppliers who adhere to sustainable practices and demonstrate a commitment to reducing their carbon footprint.

Ethical supply chains are critical for maintaining brand reputation and customer loyalty. Many international buyers are now demanding transparency in sourcing materials, leading to a rise in certifications such as ISO 14001 for environmental management and various green certifications for materials used in air filters. These certifications not only assure buyers of a product’s environmental integrity but also enhance marketability.

Furthermore, the use of sustainable materials, such as recycled fibers and biodegradable polymers, is gaining traction. Companies that invest in the development of eco-friendly filter media can differentiate themselves in the market, appealing to environmentally conscious consumers and businesses alike. As regulations around environmental sustainability tighten globally, the air conditioner filter material sector is poised to evolve, aligning product offerings with the values of a more eco-aware market.

What Is the Brief Evolution of Air Conditioner Filter Materials?

The evolution of air conditioner filter materials has been marked by significant technological advancements. Initially, filters were primarily made from basic materials like fiberglass, offering minimal filtration efficiency. However, as awareness of air quality issues increased, the industry saw a shift towards more sophisticated materials such as HEPA and activated carbon, which can effectively capture smaller particles and neutralize odors.

In recent years, the introduction of electrostatic filters has further revolutionized the sector, utilizing static electricity to enhance particle capture rates. This evolution reflects a broader trend towards higher efficiency and performance in air filtration. The demand for sustainable materials has also influenced product development, with manufacturers exploring eco-friendly options to meet the expectations of modern consumers.

As the market continues to grow, the focus will likely remain on innovation, efficiency, and sustainability, paving the way for new materials and technologies that meet the evolving needs of B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of air conditioner filter material

-

How do I select the right air conditioner filter material for my needs?

Selecting the appropriate air conditioner filter material depends on several factors, including the specific pollutants you aim to capture, the environment in which the filter will be used, and your budget. For high-efficiency needs, consider HEPA filters, which capture microscopic particles. If cost is a concern, fiberglass filters may suffice for basic dust control. Assess your air quality requirements and the type of HVAC system in place to ensure compatibility and optimal performance. -

What is the best air filter material for high humidity environments?

In high humidity environments, filters made from synthetic fibers or activated carbon are often the best choices. Synthetic filters resist moisture and prevent mold and mildew growth, while activated carbon filters can absorb odors and volatile organic compounds (VOCs). It’s crucial to regularly monitor and replace these filters, as humidity can reduce their effectiveness over time. Additionally, ensure that your HVAC system is compatible with the chosen material to maintain airflow efficiency. -

What factors should I consider when vetting suppliers of air conditioner filter materials?

When vetting suppliers, consider their reputation, product quality, and compliance with international standards. Look for certifications such as ISO or local regulatory compliance relevant to your region. Request samples to assess material quality and performance. Additionally, inquire about their manufacturing processes, lead times, and customer service responsiveness. A reliable supplier should also be able to provide references from previous clients in your industry. -

What are the minimum order quantities (MOQs) for air conditioner filter materials?

Minimum order quantities (MOQs) can vary significantly based on the supplier and the type of filter material. Many suppliers set MOQs to optimize production costs, which can range from a few hundred to several thousand units. It’s advisable to discuss your specific needs with potential suppliers, as some may offer flexibility, especially for first-time buyers or long-term contracts. Understanding MOQs can help you plan your inventory and cash flow more effectively. -

How can I ensure the quality of air conditioner filter materials?

To ensure quality, request certifications and quality assurance documents from suppliers. Conduct regular inspections of incoming materials and consider third-party testing for performance metrics, such as MERV ratings or particle capture efficiency. Establish a quality control process that includes periodic reviews of filter performance in real-world conditions. Regular communication with suppliers about quality expectations is also essential for maintaining high standards. -

What payment terms should I negotiate when sourcing air conditioner filter materials?

Payment terms can vary widely, so it’s important to negotiate terms that align with your cash flow and business model. Common arrangements include upfront deposits, net 30, 60, or 90 days, and discounts for early payments. Consider using letters of credit for larger orders to mitigate risks. Ensure that all payment terms are clearly documented in the contract to avoid disputes later in the transaction process. -

What logistics considerations should I keep in mind when importing air conditioner filter materials?

When importing, consider shipping methods, lead times, and customs regulations specific to your country. Work with logistics providers experienced in handling air filter materials to ensure proper packaging and compliance with international shipping standards. Additionally, factor in duties and taxes that may apply upon importation. Keeping open lines of communication with your supplier and logistics partner can help prevent delays and additional costs. -

Are there customization options available for air conditioner filter materials?

Many suppliers offer customization options for air conditioner filter materials, allowing you to tailor dimensions, filtration efficiencies, and even branding. Discuss your specific requirements with potential suppliers to determine their capabilities. Custom filters can be advantageous for unique applications or specific HVAC systems. However, be mindful that customized orders may have longer lead times and higher MOQs, so plan accordingly.

Top 5 Air Conditioner Filter Material Manufacturers & Suppliers List

1. Custom Filters Direct – Air Filters

Domain: customfiltersdirect.com

Registered: 2018 (7 years)

Introduction: Air filters are essential components of HVAC systems, designed to filter air by removing dust, pollen, mold spores, pet dander, and other particles. The effectiveness of air filters is largely determined by the materials used in their construction. Common types of air filter materials include: 1. Pleated Air Filters: Made of synthetic materials like cotton or polyester, these filters have increase…

2. Colback Solutions – Nonwoven HVAC Filter Media

Domain: colbacksolutions.com

Registered: 2019 (6 years)

Introduction: HVAC filter material: Colback Nonwoven filter media for pleated HVAC filters. Key features include: flame retardant, easy bonding, improved dust holding capacity, easy to handle, easy to pleat, and improved filtration efficiency. Designed for quick production of stiff, efficient pleats (1cm to 10cm) for high-performing v-shaped HVAC panel filters. Ideal for bonding with melt-blown layers for fine …

3. ACFilters4Less – Allergy-Friendly Air Filters

Domain: acfilters4less.com

Registered: 2009 (16 years)

Introduction: Best AC Filters and Furnace Filters for People with Allergies. Custom made, free shipping. Made in USA. Available types: Custom Size Filters, Fiberglass Air Filters, Polyester Air Filters, Pleated Air Filters, Return Grille Air Vent Filters, Orange & White Media Pads, Metal (Aluminium) Air Filter Frames. Sizes: Custom Size Filters, 1″ Air Filters, 2″ Air Filters, 4″ Air Filters, 3″ – 5″ Air Filter…

4. Environet – 90′ Roll 1 Thick Polyester Filter Media

Domain: airfilterhub.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “90′ Roll 1″ Thick Polyester Filter Media Blue/White – Environet – HVAC Furnace”, “regular_price”: “$167.34”, “available_sizes”: [“16\”x90′”, “17-1/8″ x 90′ x 1”, “18.5” x 90′”, “20\”x90′”, “24\”x90′”, “25\”x90′”], “length”: “90′”, “thickness”: “1” (nominal), “color”: [“blue”, “white”], “made_in”: “USA”, “additional_info”: “May be compressed for shipping. Thickness can range from …

5. Servi-Tek – Types of Air Conditioner Filters

Domain: servi-tek.net

Registered: 2005 (20 years)

Introduction: Types of Air Conditioner Filters: 1. Pleated Filters: Made of polyester or cotton, these filters have increased surface area for capturing airborne contaminants. 2. Electronic Air Cleaners (EACs): Use electricity to attract and capture particles, requiring regular cleaning. 3. Ionic Air Cleaners: Emit negative ions to clump airborne particles, but may cause issues for those with respiratory proble…

Strategic Sourcing Conclusion and Outlook for air conditioner filter material

What Key Insights Should International Buyers Consider for Air Conditioner Filter Materials?

In conclusion, strategic sourcing of air conditioner filter materials is critical for ensuring superior indoor air quality and operational efficiency. Buyers must consider various filter types—such as HEPA, pleated, and activated carbon—tailoring their selections to specific air quality needs and regional environmental challenges. Understanding the lifecycle and maintenance requirements of each filter type can significantly impact long-term costs and performance.

Investing in high-quality filter materials not only enhances air purity but also contributes to energy efficiency, reducing operational costs for businesses. As industries across Africa, South America, the Middle East, and Europe increasingly prioritize sustainability, the demand for advanced filtration solutions is set to rise.

Now is the time for international B2B buyers to engage with reputable suppliers who can provide reliable, innovative filter materials. By fostering partnerships that emphasize quality and sustainability, you can position your organization at the forefront of the market, ensuring a healthier environment for your stakeholders while driving profitability. Embrace the future of air filtration today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to air conditioner filter material

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.