A Deep Dive into 6X8 Vinyl Fence Panels Solution

Introduction: Navigating the Global Market for 6×8 vinyl fence panels

In an increasingly competitive landscape, sourcing high-quality 6×8 vinyl fence panels can pose significant challenges for international B2B buyers. The demand for durable, aesthetically pleasing fencing solutions continues to rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. However, navigating this global market requires a keen understanding of the various types of vinyl panels available, their applications, and the associated costs.

This comprehensive guide aims to equip B2B buyers with the insights needed to make informed purchasing decisions. We delve into the different styles and functionalities of 6×8 vinyl fence panels, exploring their versatility for residential, commercial, and industrial applications. Additionally, we provide essential tips on vetting suppliers, ensuring you partner with reliable manufacturers who uphold quality standards and ethical practices.

Furthermore, we analyze pricing structures, helping you identify cost-effective options without compromising on quality. By the end of this guide, international buyers, including those from Nigeria and Vietnam, will be empowered to streamline their procurement processes, minimize risks, and ultimately enhance their project outcomes. Whether you’re looking to fortify property lines or enhance curb appeal, this guide serves as your roadmap to success in the vinyl fencing market.

Understanding 6×8 vinyl fence panels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Privacy Vinyl Fence Panels | Solid, tongue-and-groove design, 6’ height, 8’ width | Residential, commercial, security | Pros: High privacy, low maintenance. Cons: Higher upfront cost. |

| Picket Vinyl Fence Panels | Open design with spaced pickets, customizable colors | Decorative, boundary marking | Pros: Aesthetic appeal, customizable. Cons: Less privacy. |

| Semi-Privacy Vinyl Fence Panels | Combination of solid and spaced pickets | Residential, pool areas | Pros: Offers privacy while allowing airflow. Cons: May not be suitable for high-security needs. |

| Ranch Rail Vinyl Fence Panels | Horizontal rail design, typically 4-rail configuration | Agricultural, property demarcation | Pros: Durable, rustic appearance. Cons: Limited privacy. |

| Decorative Vinyl Fence Panels | Unique designs, such as lattice or ornamental patterns | Landscaping, garden borders | Pros: Enhances visual appeal. Cons: May require more maintenance. |

What Are the Characteristics of Privacy Vinyl Fence Panels?

Privacy vinyl fence panels are designed to provide maximum seclusion, typically featuring a solid, tongue-and-groove construction. These panels stand 6 feet tall and span 8 feet in width, making them ideal for enclosing residential properties or commercial spaces that require security. When considering a B2B purchase, buyers should assess the material’s durability, warranty options, and any specific installation requirements, as these factors can influence long-term satisfaction and maintenance costs.

Illustrative image related to 6×8 vinyl fence panels

How Do Picket Vinyl Fence Panels Differ?

Picket vinyl fence panels feature an open design with spaced vertical pickets, allowing for visibility while still defining boundaries. These panels can be customized in various colors to match the aesthetic of a property. They are commonly used in decorative applications, such as gardens or front yards. For B2B buyers, it’s essential to consider the intended use—if aesthetics and charm are priorities, picket panels are ideal; however, they may not provide the privacy some clients require.

What Are the Benefits of Semi-Privacy Vinyl Fence Panels?

Semi-privacy vinyl fence panels combine solid and spaced pickets to offer a balance between seclusion and airflow. This design is particularly beneficial for residential applications and pool areas, where some visibility is desired without compromising too much on privacy. Buyers should evaluate the panel’s wind resistance and material quality, especially in regions prone to severe weather, to ensure that they meet local building codes and safety standards.

In What Situations Are Ranch Rail Vinyl Fence Panels Appropriate?

Ranch rail vinyl fence panels are characterized by their horizontal rail structure, typically featuring four rails. They are commonly used in agricultural settings or for property demarcation. Their robust design makes them suitable for containing livestock or marking boundaries. B2B buyers in agricultural sectors should consider the panel’s resistance to environmental factors and its ability to withstand the pressures of animal movement, as these aspects are crucial for long-term functionality.

Why Choose Decorative Vinyl Fence Panels?

Decorative vinyl fence panels come in unique designs, including lattice and ornamental patterns, making them a popular choice for enhancing landscaping and garden borders. While they offer aesthetic benefits, buyers should be aware of potential maintenance challenges, as intricate designs may require more upkeep than standard panels. For B2B buyers focused on enhancing property aesthetics, these panels can provide significant visual appeal, but it’s important to balance beauty with functionality and durability.

Illustrative image related to 6×8 vinyl fence panels

Key Industrial Applications of 6×8 vinyl fence panels

| Industry/Sector | Specific Application of 6×8 Vinyl Fence Panels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Residential Development | Privacy fencing for residential properties | Enhances property value and aesthetics, providing privacy and security | Local climate considerations, availability of installation services, and compliance with local regulations |

| Agriculture & Livestock | Enclosures for livestock and crop protection | Durable and maintenance-free option that protects crops and livestock | Resistance to environmental factors, UV stability, and ease of installation |

| Commercial & Retail Spaces | Boundary fencing for shopping centers and office parks | Improves security and delineates property boundaries | Customization options, durability against vandalism, and aesthetic appeal |

| Public Sector & Municipalities | Fencing for parks, schools, and public spaces | Provides safety, privacy, and aesthetic value to community areas | Compliance with safety standards, environmental impact, and local sourcing regulations |

| Industrial & Manufacturing | Security fencing around warehouses and manufacturing facilities | Enhances security and restricts unauthorized access | Strength and durability against wear, availability of bulk purchasing options, and local installation expertise |

How Are 6×8 Vinyl Fence Panels Used in Residential Development?

In residential development, 6×8 vinyl fence panels are primarily used for privacy fencing around homes and gardens. These panels provide a solid barrier that enhances privacy and security for homeowners, which is a significant selling point in many markets. Buyers in regions like Africa and South America may seek panels that withstand extreme weather conditions, while European buyers often prioritize aesthetic appeal and compliance with local regulations. Sourcing considerations include the availability of local suppliers who can provide installation services and meet specific design requirements.

What Is the Role of 6×8 Vinyl Fence Panels in Agriculture & Livestock?

In the agricultural sector, 6×8 vinyl fence panels serve as enclosures for livestock and protection for crops. Their durability and resistance to weathering make them an ideal choice for farmers looking to secure their assets without the ongoing maintenance that wood fencing requires. Buyers from regions with harsh climates, such as the Middle East, should consider panels that offer UV protection and strength against high winds. Additionally, sourcing should focus on local suppliers who can provide panels that meet agricultural standards.

How Are 6×8 Vinyl Fence Panels Beneficial for Commercial & Retail Spaces?

For commercial and retail spaces, 6×8 vinyl fence panels are utilized to establish boundaries for shopping centers, office parks, and other properties. These panels enhance security by creating a physical barrier against unauthorized access, while also improving the overall aesthetic of the property. B2B buyers in Europe may look for customizable options that align with branding, while those in emerging markets might prioritize cost-effectiveness and durability. Key sourcing considerations include the availability of various colors and styles to fit the commercial environment.

Why Are 6×8 Vinyl Fence Panels Important for Public Sector Projects?

In the public sector, 6×8 vinyl fence panels are essential for fencing around parks, schools, and other community areas. They provide safety and privacy while enhancing the visual appeal of public spaces. International buyers, particularly in developing regions, may require panels that can withstand vandalism and environmental wear. When sourcing, it’s crucial to ensure compliance with local safety standards and to consider the environmental impact of materials used in the panels.

Illustrative image related to 6×8 vinyl fence panels

How Do 6×8 Vinyl Fence Panels Enhance Security in Industrial & Manufacturing Settings?

In industrial and manufacturing environments, 6×8 vinyl fence panels are deployed as security fencing around warehouses and facilities. They effectively restrict unauthorized access, which is vital for protecting valuable assets and maintaining operational integrity. Buyers should consider the strength and durability of the panels to withstand potential wear and tear from industrial activities. Additionally, bulk purchasing options and local installation expertise are essential factors to consider when sourcing for these applications.

3 Common User Pain Points for ‘6×8 vinyl fence panels’ & Their Solutions

Scenario 1: Difficulty with Shipping and Logistics of Vinyl Fence Panels

The Problem:

For international B2B buyers, especially in regions like Africa and South America, sourcing 6×8 vinyl fence panels can pose significant logistical challenges. Many suppliers may not offer shipping to these regions, or the cost of shipping can be prohibitively expensive. Additionally, the large size of the panels can complicate transportation and increase the risk of damage during transit. Buyers may find themselves stuck with high shipping costs or delayed deliveries, impacting their project timelines and overall costs.

The Solution:

To mitigate these shipping and logistics issues, B2B buyers should prioritize suppliers who have established international shipping capabilities and a solid reputation for reliability. It is advisable to request quotes from multiple suppliers, emphasizing the need for competitive shipping rates and delivery times. Buyers can also explore local distributors or suppliers who may stock 6×8 vinyl fence panels, thereby reducing transportation costs. Collaborating with a logistics partner experienced in handling oversized shipments can also streamline the process, ensuring that the panels arrive safely and on schedule. Finally, leveraging technology for real-time tracking of shipments can provide peace of mind and improve transparency throughout the delivery process.

Scenario 2: Challenges in Installation and Assembly of Vinyl Fence Panels

The Problem:

Another common pain point for B2B buyers is the complexity of installing 6×8 vinyl fence panels, especially for those who are not familiar with vinyl fencing systems. Many buyers may lack the technical expertise or the necessary tools, leading to improper installation that can compromise the structural integrity of the fence. This can result in costly repairs, increased labor costs, and delays in project completion.

The Solution:

To address installation challenges, buyers should seek suppliers who offer comprehensive installation guides and resources. Many manufacturers provide detailed instructions, videos, and even customer support to assist with the installation process. Buyers should also consider investing in training for their installation teams or hiring experienced contractors familiar with vinyl fencing. Additionally, utilizing modular components, such as pre-assembled panels and easy-to-install post systems, can significantly simplify the installation process. Offering a warranty on installation services can further ensure peace of mind, as it protects against potential future issues.

Scenario 3: Concerns Over Quality and Longevity of Vinyl Fence Panels

The Problem:

Quality assurance is a critical concern for B2B buyers investing in 6×8 vinyl fence panels. Given the initial higher cost compared to traditional wood fences, buyers may worry about the longevity and durability of the product, especially in harsh climates. Issues such as fading, cracking, or warping can lead to dissatisfaction and additional costs for replacements or repairs, affecting the buyer’s bottom line.

The Solution:

To ensure the purchase of high-quality vinyl fence panels, buyers should conduct thorough research on potential suppliers, focusing on their materials and manufacturing processes. Requesting samples or visiting manufacturing facilities can provide insights into product quality. Additionally, buyers should look for panels that come with warranties, which indicate the manufacturer’s confidence in their product’s durability. It’s also beneficial to select panels that are engineered for UV resistance and designed to withstand local climate conditions. Engaging with other businesses in the industry for reviews and testimonials can also help in making informed decisions about the longevity and performance of the vinyl fence panels.

Strategic Material Selection Guide for 6×8 vinyl fence panels

What Are the Key Materials Used in 6×8 Vinyl Fence Panels?

When selecting materials for 6×8 vinyl fence panels, several options stand out based on performance, durability, and cost. Understanding these materials is crucial for international B2B buyers, particularly those operating in diverse climates and regulatory environments across Africa, South America, the Middle East, and Europe.

How Do Different Vinyl Materials Affect Performance and Durability?

-

PVC (Polyvinyl Chloride)

– Key Properties: PVC is a synthetic plastic polymer known for its strength and durability. It exhibits excellent weather resistance, maintaining structural integrity in various temperatures and conditions. PVC can withstand pressures up to 200 psi, making it suitable for fencing applications.

– Pros & Cons: PVC is highly durable and resistant to corrosion, making it a long-lasting choice. However, it can be more expensive than traditional wood fencing. The manufacturing process is relatively straightforward, but the initial investment may deter some buyers.

– Impact on Application: PVC is compatible with various environmental conditions, including high humidity and UV exposure, which is essential for regions with intense sunlight.

– Considerations for International Buyers: Buyers should ensure that the PVC used complies with local standards such as ASTM D1784 for PVC materials. In regions like Nigeria and Vietnam, it’s also essential to consider the availability of local suppliers to reduce shipping costs. -

Vinyl Composite

– Key Properties: Vinyl composite materials combine PVC with other materials, such as wood fibers, to enhance strength and aesthetics. These composites can offer improved impact resistance and lower thermal expansion.

– Pros & Cons: The key advantage of vinyl composites is their ability to mimic the appearance of wood while providing the durability of vinyl. However, they can be more complex to manufacture and may require specific conditions during installation.

– Impact on Application: These materials are suitable for areas where aesthetics are a priority, as they can be designed to look like traditional wood fencing without the maintenance issues.

– Considerations for International Buyers: Compliance with local building codes is critical, especially in regions with strict regulations. Buyers should also assess the availability of composite materials in their region to avoid delays in project timelines. -

Reinforced Vinyl

– Key Properties: Reinforced vinyl panels incorporate materials such as aluminum or steel inserts to enhance structural support, particularly in high-wind areas. This reinforcement can significantly increase the pressure rating, making it suitable for challenging environments.

– Pros & Cons: The primary advantage is the added durability and resistance to bending or breaking under stress. However, the complexity of manufacturing and the higher costs can be limiting factors for some buyers.

– Impact on Application: Ideal for regions prone to severe weather, reinforced vinyl panels ensure longevity and reliability, making them a smart investment for long-term projects.

– Considerations for International Buyers: Buyers should consider the specific weather conditions in their regions and ensure that the materials meet local standards for wind resistance and structural integrity. -

UV-Stabilized Vinyl

– Key Properties: This type of vinyl is treated with UV inhibitors to prevent fading and degradation from sunlight exposure. It maintains its color and structural integrity over time, making it suitable for outdoor applications.

– Pros & Cons: The main advantage is its longevity and minimal maintenance requirements. However, the cost may be higher than non-treated options.

– Impact on Application: Particularly beneficial in sunny regions, UV-stabilized vinyl panels will retain their appearance and performance longer than untreated materials.

– Considerations for International Buyers: Buyers should verify that the UV stabilization meets international standards, ensuring compliance with regulations in their respective countries.

Summary of Material Selection for 6×8 Vinyl Fence Panels

| Material | Typical Use Case for 6×8 Vinyl Fence Panels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General fencing in residential and commercial applications | Excellent durability and weather resistance | Higher initial cost compared to wood | Medium |

| Vinyl Composite | Aesthetic-focused projects needing wood-like appearance | Mimics wood without maintenance issues | Complex manufacturing process | High |

| Reinforced Vinyl | High-wind areas requiring additional support | Enhanced durability and structural integrity | Higher cost and complexity | High |

| UV-Stabilized Vinyl | Regions with intense sunlight exposure | Long-lasting color and minimal maintenance | Higher cost than non-treated options | Medium |

This strategic material selection guide provides valuable insights for B2B buyers considering 6×8 vinyl fence panels, ensuring informed decisions that align with their specific project requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 6×8 vinyl fence panels

In the competitive landscape of vinyl fencing, understanding the manufacturing processes and quality assurance (QA) protocols for 6×8 vinyl fence panels is critical for B2B buyers. This comprehensive guide outlines the stages of manufacturing, key techniques employed, and international quality standards that ensure product reliability and compliance.

What Are the Key Stages in the Manufacturing Process of 6×8 Vinyl Fence Panels?

The production of 6×8 vinyl fence panels involves several crucial stages:

-

Material Preparation: The primary material used in vinyl fencing is polyvinyl chloride (PVC). This phase includes sourcing high-quality resin, stabilizers, and additives. The resin is typically mixed with stabilizers and UV inhibitors to enhance durability and resistance to environmental factors. The mixture is then compounded to achieve the desired consistency and properties.

-

Forming: The compounded material is fed into an extruder, where it is heated and shaped into profiles. In the case of 6×8 panels, the extrusion process typically forms tongue-and-groove designs that interlock for enhanced stability. This process ensures that each panel meets the dimensional specifications required for assembly.

-

Assembly: Once extruded, panels undergo assembly where they are fitted with rails and reinforced with aluminum inserts if required. This step is critical to ensure the structural integrity of the panels, especially in regions prone to high winds or extreme weather conditions.

-

Finishing: The final stage involves surface treatments and quality checks. Panels may be coated with a UV-resistant finish to prevent color fading and enhance aesthetic appeal. Any necessary trimming or adjustments are made to ensure panels fit precisely with the associated posts and gates.

Which Quality Assurance Standards Are Relevant for Vinyl Fence Manufacturing?

Quality assurance in the vinyl fence industry is governed by various international and industry-specific standards. For B2B buyers, understanding these standards is vital for verifying product quality and compliance.

-

ISO 9001 Certification: This international standard outlines the criteria for a quality management system (QMS). Manufacturers with ISO 9001 certification demonstrate their commitment to consistent quality and customer satisfaction. B2B buyers can request documentation of a supplier’s ISO certification as part of their due diligence.

-

CE Marking: For companies operating in the European market, CE marking is essential. It signifies that the product meets EU safety, health, and environmental protection standards. Buyers in Europe should verify that their suppliers can provide CE certification for their vinyl fence panels.

-

API Standards: While primarily associated with the oil and gas industry, API standards can also apply to materials used in construction, ensuring they are safe and reliable. Buyers should inquire about any applicable API certifications if their projects require stringent material specifications.

What Are the Common Quality Control Checkpoints in Vinyl Fence Production?

Quality control checkpoints are integrated into various stages of the manufacturing process to ensure that panels meet specified standards. Here are the key checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers must provide certifications for the PVC resin and additives used in production. Any substandard materials should be rejected to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During the extrusion and assembly phases, continuous monitoring is essential. Operators typically check for dimensional accuracy, surface quality, and the structural integrity of panels. This proactive approach helps identify issues early in the manufacturing process, minimizing waste and rework.

-

Final Quality Control (FQC): Before shipment, panels undergo a comprehensive final inspection. This includes checking for visual defects, dimensional conformity, and performance testing. Common tests may include flexibility assessments, UV resistance checks, and impact tests to ensure the product meets or exceeds industry standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are actionable steps buyers can take:

Illustrative image related to 6×8 vinyl fence panels

-

Conduct Supplier Audits: Regular audits of suppliers’ facilities can provide insights into their manufacturing processes and quality control practices. Buyers should consider scheduling on-site visits or utilizing third-party audit services to assess compliance with relevant standards.

-

Request Quality Reports: Suppliers should be able to provide documentation on their quality control processes, including IQC, IPQC, and FQC records. These reports should outline testing methods and results, giving buyers confidence in the reliability of the products.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can further validate product quality. These independent firms can perform pre-shipment inspections, ensuring that the panels meet the specified requirements before leaving the manufacturing facility.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of specific nuances in quality control that may vary by region. Here are a few considerations:

-

Compliance with Local Regulations: Different countries may have varying regulations regarding construction materials. Buyers should familiarize themselves with local building codes and standards to ensure that the products they source comply.

-

Cultural and Language Barriers: Communication is key when dealing with international suppliers. Buyers should ensure that quality specifications are clearly defined and understood by all parties involved. It may be beneficial to have bilingual representatives or use translation services to mitigate misunderstandings.

-

Long-Term Partnerships: Establishing long-term relationships with reliable suppliers can enhance quality assurance. Regular communication, feedback, and collaboration can lead to continuous improvements in product quality and innovation.

In summary, understanding the manufacturing processes and quality assurance protocols for 6×8 vinyl fence panels is essential for B2B buyers seeking reliable products. By leveraging international standards, conducting thorough supplier evaluations, and maintaining clear communication, businesses can ensure they are sourcing high-quality vinyl fencing solutions that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘6×8 vinyl fence panels’

Introduction

This guide serves as a comprehensive checklist for international B2B buyers seeking to procure 6×8 vinyl fence panels. Understanding the nuances of sourcing these products can help you make informed decisions, ensuring both quality and value for your investment. By following these steps, you can streamline your purchasing process and mitigate potential risks.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the vinyl fence panels you require. Consider factors such as height, width, material quality, and design. Knowing exactly what you need will help you communicate effectively with suppliers and avoid misunderstandings that could lead to costly mistakes.

- Material Composition: Ensure the panels are made from high-quality PVC to withstand various environmental conditions.

- Design Features: Decide if you want additional features like UV protection or color options to maintain aesthetics.

Step 2: Research and Identify Potential Suppliers

Take the time to identify and research suppliers who specialize in vinyl fencing. Look for companies with a solid reputation in the market and a history of serving international clients.

- Supplier Reviews: Check online platforms for customer feedback and ratings.

- Industry Associations: Membership in relevant industry associations can indicate reliability and adherence to standards.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that suppliers hold necessary certifications. This step is crucial for ensuring the quality and safety of the products you are purchasing.

- ISO Certification: Check if the supplier is ISO-certified, which indicates adherence to international quality management standards.

- Product Certifications: Look for certifications that validate the durability and safety of vinyl fencing products.

Step 4: Request Samples for Quality Assessment

Always request samples of the vinyl fence panels before finalizing your order. This allows you to assess the quality and craftsmanship firsthand.

- Visual Inspection: Examine the panels for defects or inconsistencies in color and finish.

- Durability Tests: Consider conducting basic durability tests to ensure the panels meet your standards.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers and compare their pricing structures. Look beyond the initial cost; consider the total cost of ownership, including shipping, taxes, and potential tariffs.

- Transparent Pricing: Ensure that the quotes include all potential costs to avoid surprises.

- Payment Terms: Assess payment options and terms, including deposits and credit terms, which can significantly affect your cash flow.

Step 6: Understand Shipping and Delivery Logistics

Logistics play a critical role in international sourcing. Confirm the shipping methods and delivery timelines with your supplier.

- Shipping Options: Choose between air freight for speed or sea freight for cost-effectiveness.

- Customs Regulations: Be aware of customs requirements in your country to prevent delays.

Step 7: Establish Clear Communication Channels

Maintain open lines of communication with your supplier throughout the procurement process. Effective communication can resolve issues swiftly and ensure that both parties are aligned.

- Regular Updates: Schedule regular check-ins to discuss order status and any potential concerns.

- Multilingual Support: If dealing with suppliers in different regions, ensure they can communicate effectively in a language you understand.

By following this checklist, you will be well-equipped to navigate the complexities of sourcing 6×8 vinyl fence panels, ultimately leading to a successful procurement experience.

Comprehensive Cost and Pricing Analysis for 6×8 vinyl fence panels Sourcing

What Are the Key Cost Components for 6×8 Vinyl Fence Panels?

Understanding the cost structure of 6×8 vinyl fence panels is essential for B2B buyers aiming to make informed purchasing decisions. The primary cost components include:

Illustrative image related to 6×8 vinyl fence panels

-

Materials: The main ingredient in vinyl fencing is PVC resin, which is combined with stabilizers, lubricants, and fillers. The quality of these materials affects the durability and appearance of the panels. For instance, higher-grade resins may cost more but offer better UV resistance and longevity.

-

Labor: Manufacturing labor costs can vary widely based on geographic location. In regions with lower labor costs, such as some parts of Africa and South America, buyers may find more competitive pricing.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and facility costs. Efficient production processes can help minimize these overheads, reflecting in the final price.

-

Tooling: Custom designs or specifications may require specialized tooling, which can add to the initial costs. Standardized panels typically incur lower tooling expenses.

-

Quality Control (QC): Ensuring the panels meet safety and quality standards requires investment in QC processes. This is especially important for international buyers who need to comply with local regulations.

-

Logistics: Shipping costs can significantly influence total expenses. Factors such as distance, shipping method, and local import duties should be considered.

-

Margin: Suppliers will add a profit margin, which can vary based on competition and market conditions.

How Do Price Influencers Affect the Cost of Vinyl Fence Panels?

Several factors can influence the pricing of 6×8 vinyl fence panels:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often result in lower unit prices due to economies of scale. Buyers should negotiate for better rates when ordering larger quantities.

-

Specifications and Customization: Customized designs or specific color requirements can lead to higher prices. Buyers should assess whether the customization is necessary or if standard options suffice.

-

Material Quality and Certifications: Panels that meet specific certifications (e.g., UV resistance, fire rating) may command higher prices. Buyers should evaluate the importance of these certifications in their local context.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They dictate who is responsible for shipping costs, insurance, and risk during transit, which can affect overall pricing.

What Tips Can Help Buyers Optimize Costs for Vinyl Fence Panels?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Pricing: Always engage in negotiations with suppliers. Discussing volume discounts and payment terms can lead to significant savings.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in installation costs, maintenance, and potential repairs over the lifespan of the fence. Vinyl fences typically require less maintenance compared to wood, which can lead to long-term savings.

-

Research Local Suppliers: Local sourcing can minimize shipping costs and import duties. Additionally, working with local suppliers often ensures better understanding and compliance with regional regulations.

-

Stay Informed on Market Trends: Prices for materials can fluctuate based on market conditions. Being aware of these trends can help in timing purchases to secure the best deals.

-

Request Samples: Before committing to a large order, request samples to evaluate quality. This can prevent costly mistakes in selecting the right product.

Disclaimer on Indicative Prices

The prices of 6×8 vinyl fence panels can vary significantly based on the factors discussed. The figures from various suppliers indicate a range of costs, but these are subject to change based on market dynamics, local economic conditions, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing 6×8 vinyl fence panels With Other Solutions

Exploring Alternatives to 6×8 Vinyl Fence Panels for B2B Buyers

When considering fencing solutions, B2B buyers often seek options that align with their specific needs, budget constraints, and project requirements. While 6×8 vinyl fence panels offer numerous advantages, it is essential to examine alternative fencing solutions to ensure a well-informed purchasing decision. Below, we compare 6×8 vinyl fence panels with two viable alternatives: wood fencing and chain-link fencing.

Comparison Table

| Comparison Aspect | 6X8 Vinyl Fence Panels | Wood Fencing | Chain-Link Fencing |

|---|---|---|---|

| Performance | Durable, weather-resistant, UV stable | Aesthetic appeal, but prone to decay | Low visibility, less privacy |

| Cost | Higher initial cost (20-30% more than wood) | Generally lower upfront cost | Most affordable fencing option |

| Ease of Implementation | Moderate; requires specific tools | Moderate; can be DIY or professional | Easy; quick installation |

| Maintenance | Low; only requires occasional cleaning | High; regular staining/painting needed | Very low; minimal upkeep required |

| Best Use Case | Privacy, residential, commercial properties | Aesthetic appeal in residential areas | Security and boundary definition |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Wood Fencing Compared to Vinyl?

Wood fencing is often favored for its natural aesthetic, which can enhance the appearance of residential properties. It typically has a lower initial cost compared to vinyl fencing, making it an attractive option for budget-conscious buyers. However, wood is susceptible to rot, insect damage, and weathering, which can lead to increased maintenance costs over time. Regular staining or painting is necessary to preserve its appearance and structural integrity. Therefore, while wood may be a viable option for certain applications, its long-term performance and upkeep can detract from its initial cost advantage.

How Does Chain-Link Fencing Compare to Vinyl in Terms of Functionality?

Chain-link fencing is the most economical fencing option available, making it ideal for large areas or commercial properties needing a cost-effective boundary solution. It is relatively easy to install, requiring minimal tools and time. However, chain-link fences offer limited privacy and aesthetic appeal, often leading to a less visually pleasing environment. They are primarily used for security purposes, such as enclosing properties or keeping pets contained. While chain-link fencing excels in functionality and cost-efficiency, it may not meet the privacy and aesthetic standards that many buyers seek in residential applications.

Conclusion: Which Fencing Solution Should B2B Buyers Choose?

When selecting a fencing solution, B2B buyers should carefully evaluate their specific needs, including performance, cost, ease of installation, maintenance, and the intended use case. While 6×8 vinyl fence panels provide long-lasting durability and low maintenance, wood and chain-link fences present alternative options with distinct benefits and drawbacks. Buyers should consider the environment in which the fencing will be installed, the desired level of privacy, and budget constraints to determine the best solution for their project. By weighing these factors, businesses can make informed decisions that align with their operational requirements and aesthetic preferences.

Essential Technical Properties and Trade Terminology for 6×8 vinyl fence panels

What Are the Key Technical Properties of 6×8 Vinyl Fence Panels?

1. Material Composition

6×8 vinyl fence panels are primarily made from polyvinyl chloride (PVC), which is a durable and weather-resistant synthetic material. This composition ensures longevity and low maintenance compared to traditional wood fencing. B2B buyers should prioritize panels with high-quality PVC to minimize the risk of warping, cracking, or fading over time, particularly in harsh climates.

Illustrative image related to 6×8 vinyl fence panels

2. Panel Dimensions and Thickness

Typically, these panels measure 6 feet in height and 8 feet in width. The thickness of the panels can vary, commonly ranging between 1.5 inches to 2 inches. A thicker panel provides greater strength and stability, making it crucial for buyers to assess panel thickness to ensure the product meets the specific environmental demands of their installation sites.

3. UV Resistance

Vinyl fence panels should include UV inhibitors to prevent discoloration and degradation from sunlight exposure. This property is vital for maintaining the aesthetic appeal and structural integrity of the fence over time. B2B purchasers need to verify the presence of these additives, as they directly impact the longevity and durability of the fencing solution.

4. Impact Resistance

Impact resistance refers to the panel’s ability to withstand physical forces, such as strong winds or accidental collisions. Panels with aluminum reinforcements in the bottom rail exhibit enhanced durability against such impacts. For buyers, understanding this property is essential, especially in regions prone to severe weather conditions.

5. Warranty and Lifespan

A robust warranty, often a limited lifetime guarantee, indicates the manufacturer’s confidence in their product’s durability. This warranty typically covers defects in materials and workmanship. Buyers should evaluate the terms of the warranty to ensure that they are protected against potential failures, which can translate to significant cost savings in the long run.

What Are Common Trade Terminology and Their Importance in Vinyl Fencing?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of vinyl fencing, understanding OEM relationships can help B2B buyers identify trusted suppliers and ensure quality products that meet specific needs.

Illustrative image related to 6×8 vinyl fence panels

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. For international buyers, knowing the MOQ is crucial to managing inventory costs and ensuring that the order aligns with market demand. Lower MOQs can provide flexibility for small businesses or new markets.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing information for specific products. Utilizing RFQs is essential for comparing prices, lead times, and payment terms, enabling buyers to make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to navigate shipping, insurance, and delivery logistics effectively.

Illustrative image related to 6×8 vinyl fence panels

5. Tolerance Levels

In manufacturing, tolerance levels indicate the acceptable range of variation in dimensions or properties of a product. For vinyl fence panels, knowing the tolerance levels ensures that panels will fit correctly during installation, which is crucial for maintaining the structural integrity and aesthetics of the fence.

6. Lead Time

Lead time refers to the time between placing an order and receiving it. This metric is essential for B2B buyers as it impacts project timelines. Understanding lead times helps buyers plan installations and manage customer expectations effectively.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when sourcing 6×8 vinyl fence panels, ensuring they select products that meet their quality and performance standards.

Illustrative image related to 6×8 vinyl fence panels

Navigating Market Dynamics and Sourcing Trends in the 6×8 vinyl fence panels Sector

What Are the Key Trends Driving the 6×8 Vinyl Fence Panels Market?

The global market for 6×8 vinyl fence panels is experiencing significant growth, driven by several key factors. Increasing urbanization, particularly in developing regions such as Africa and South America, is leading to a heightened demand for durable and low-maintenance fencing solutions. As more businesses and residential developers seek to enhance security and aesthetics, vinyl fencing is gaining traction due to its longevity and minimal upkeep requirements.

Technological advancements are reshaping the sourcing landscape. B2B buyers are increasingly leveraging online platforms and digital marketplaces to streamline procurement processes. This shift not only enhances visibility but also allows for better price comparisons, enabling buyers to make informed decisions. Furthermore, the integration of augmented reality tools in the purchasing process is helping buyers visualize products in their intended settings, thereby improving customer satisfaction.

Emerging trends also highlight a move towards customization, where buyers are seeking tailored fencing solutions that meet specific design requirements. This trend is particularly relevant for international buyers who may have unique regional preferences. Additionally, manufacturers are exploring innovative materials and designs, such as tongue-and-groove panels, to enhance product offerings. Overall, these market dynamics present ample opportunities for B2B buyers to capitalize on the growing demand for vinyl fencing solutions.

How Is Sustainability and Ethical Sourcing Influencing the 6×8 Vinyl Fence Panels Market?

Sustainability has become a critical focus for B2B buyers in the 6×8 vinyl fence panels sector. The environmental impact of manufacturing processes and materials is under scrutiny, prompting buyers to seek products that minimize ecological footprints. Vinyl fencing, often made from recycled materials, offers a sustainable alternative to traditional wood fencing, which requires deforestation and other environmentally harmful practices.

Ethical sourcing is equally important, with buyers increasingly prioritizing suppliers who adhere to responsible labor practices and environmental standards. Certifications such as the Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) can enhance a supplier’s credibility and appeal to conscientious buyers. Furthermore, manufacturers are investing in eco-friendly production processes that reduce waste and energy consumption, aligning their operations with sustainable business practices.

Illustrative image related to 6×8 vinyl fence panels

B2B buyers are advised to conduct due diligence when sourcing vinyl fence panels, ensuring that suppliers provide transparency regarding their sourcing methods and environmental impact. This not only helps in building a positive brand image but also meets the growing consumer demand for sustainable products. As a result, integrating sustainability and ethical considerations into procurement strategies is becoming essential for businesses aiming to thrive in the competitive fencing market.

What Is the Historical Context of Vinyl Fence Panels and Their Evolution?

The evolution of vinyl fence panels can be traced back to the late 20th century when PVC (polyvinyl chloride) began to gain popularity as a fencing material. Initially, wood was the dominant choice for fencing, but the shortcomings of wood—such as susceptibility to rot, warping, and insect damage—prompted a search for more durable alternatives. The introduction of vinyl as a fencing option provided a solution that not only addressed these issues but also offered enhanced aesthetics and lower maintenance.

Over the years, advancements in manufacturing technology have led to significant improvements in the quality and design of vinyl fence panels. Today, features such as UV resistance, color retention, and customizable designs are standard, making vinyl an attractive choice for both residential and commercial applications. The continuous innovation within the industry reflects a growing understanding of customer needs and preferences, positioning vinyl fence panels as a staple in modern fencing solutions. This historical context is crucial for B2B buyers, as it underscores the reliability and evolution of vinyl fencing as a long-term investment.

Illustrative image related to 6×8 vinyl fence panels

Frequently Asked Questions (FAQs) for B2B Buyers of 6×8 vinyl fence panels

-

How do I ensure the quality of 6×8 vinyl fence panels before purchasing?

To ensure quality, request samples from potential suppliers to assess material durability and finish. Verify if the panels meet international quality standards and certifications, such as ASTM or ISO. It’s also beneficial to read reviews or testimonials from other B2B clients who have previously sourced from the supplier. Conducting factory visits or virtual inspections can provide further assurance of their manufacturing processes and quality control measures. -

What are the main benefits of using vinyl fence panels over traditional materials?

Vinyl fence panels offer significant advantages, including low maintenance, resistance to rot, and long-term durability. Unlike wood, vinyl does not require painting, staining, or sealing, which saves on upkeep costs. Additionally, vinyl is resistant to fading from UV exposure and can withstand harsh weather conditions, making it ideal for various climates. These features contribute to a longer lifespan and lower total cost of ownership compared to traditional materials. -

What is the typical minimum order quantity (MOQ) for 6×8 vinyl fence panels?

The MOQ can vary significantly between suppliers, typically ranging from 50 to 200 panels. It is essential to communicate your project size and needs with potential suppliers to negotiate favorable terms. Some suppliers may offer flexibility on MOQ based on your long-term partnership potential or the volume of other products you may require. Always confirm pricing and shipping costs associated with different order sizes. -

What payment terms should I expect when sourcing vinyl fence panels internationally?

Payment terms can vary widely depending on the supplier and your location. Common terms include a 30% deposit upfront with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or escrow services to enhance security. It’s advisable to negotiate terms that align with your cash flow and project timelines while ensuring that the payment method is secure and reliable. -

Can I customize the color or size of the vinyl fence panels?

Many suppliers offer customization options for both color and size. Common colors include white, beige, and tan, but some manufacturers may provide a wider palette or the ability to match specific colors. Size customization is also possible, but it may impact the MOQ and lead time. Discuss your specific requirements with suppliers to understand their capabilities and any additional costs involved. -

What logistics considerations should I be aware of when importing vinyl fence panels?

When importing, consider shipping methods, lead times, and customs regulations in your destination country. Ensure that the supplier can provide all necessary shipping documentation, including invoices, packing lists, and certificates of origin. Depending on your location, you may need to arrange for freight forwarding services to handle logistics efficiently. It’s also wise to factor in potential tariffs or duties that may apply upon importation. -

How do I assess the reliability of a supplier for vinyl fence panels?

To assess supplier reliability, review their business history, certifications, and industry reputation. Request references from other international clients and inquire about their experiences. An established supplier should be transparent about their production processes and provide clear communication. Utilizing platforms like Alibaba or TradeKey can also help you find verified suppliers with good ratings and feedback from previous buyers. -

What warranty options are available for 6×8 vinyl fence panels?

Most reputable suppliers offer warranties that cover defects in material and workmanship, often lasting from 10 years to a lifetime, depending on the manufacturer. Review the warranty terms carefully, as some may include provisions for fading, warping, or other performance issues. It’s essential to clarify the warranty coverage details with your supplier, including the process for claims, to ensure you’re protected in case of product failure.

Top 7 6X8 Vinyl Fence Panels Manufacturers & Suppliers List

1. Norfolk – 6′ H x 8′ W Privacy Fence Panel White

Domain: fencingdirect.com

Registered: 2007 (18 years)

Introduction: {“name”: “6′ H x 8′ W Norfolk Privacy Fence Panel White”, “sku”: “BV73014727”, “price”: {“original”: “$217.26”, “discounted”: “$152.08”, “savings”: “30%”}, “dimensions”: {“height”: “6′”, “width”: “8′”}, “color”: “White”, “features”: {“rails”: “1 3/4″ x 5 1/2″”, “pickets”: “6” tongue and groove”, “support”: “aluminum insert for bottom rail”}, “shipping_info”: {“shipping_time”: “2-3 Weeks”, “shippin…

2. Fence Outlet – 6X8 T&G Privacy PVC Panel Tan

Domain: fenceoutlet.com

Registered: 2002 (23 years)

Introduction: {“name”: “6X8 T&G PRIVACY PVC PANEL TAN”, “sku”: “T&G6X8UNAS-TAN”, “category”: “Vinyl Sections”, “description”: “6X8 T&G PRIVACY PVC PANEL TAN”, “price”: “Call for price”, “dimensions”: “6×8”, “material”: “PVC”, “color”: “Tan”}

3. Freedom Product – Emblem Vinyl Fencing

Domain: freedomproduct.com

Registered: 2013 (12 years)

Introduction: Emblem Vinyl Fencing | Size: 6′ x 8′ | Color: Driftwood | Features: Full privacy panel, decorative top and bottom rails, GrippLok™ technology to eliminate sag, rackable up to 8-in in height across 8-ft of sloped terrain, 7/8-in x 6-in tongue-and-groove boards, pool code approved panel meets ICC requirements, heavy-duty low maintenance vinyl construction, transferable limited lifetime warranty, Sol…

4. Reddit – Vinyl Fence Installation Costs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 6ft and 8ft width vinyl fence options; installation cost: $7,500 for 8ft, $12,900 for 6ft; 72% cost increase for 6ft panels; considerations for wind load and area-specific recommendations.

5. Weatherables – 6′ Pembroke™ Vinyl Privacy Fence

Domain: weatherables.com

Registered: 2008 (17 years)

Introduction: Product Name: 6′ Pembroke™ Vinyl Privacy Fence

Height: 6 feet

Picket Style: 7/8″ x 11.3″ Tongue & Groove

Thickness: .055″

Color: White

Features:

– Interlocking tongue-and-groove pickets

– Dual-ribbed reinforcement

– Metal-reinforced bottom rail for strength and stability

– Made from high-grade, fade-resistant vinyl

– No chipping, peeling, or rotting

– No painting or staining required

– DIY-friend…

6. Ringsend – White Vinyl Privacy Fence

Domain: ringsend.com

Registered: 1996 (29 years)

Introduction: White Vinyl Privacy Fence, Dimensions: 6 ft. x 8 ft.

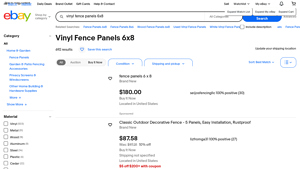

7. Vinyl Fence Panels – Various Styles and Colors

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Vinyl Fence Panels 6×8 available in various colors including White, Brown, Gray, and Beige. Styles include Framed and Lattice with flat, dog-ear, and pointed shapes. Item weights range from 10-20 lb to more than 50 lb. Available in packs of 1, 2, or 3. Items may include fence posts and rails. Fixing types include glue and nail. Prices range from under $120 to over $220. Condition is primarily new,…

Strategic Sourcing Conclusion and Outlook for 6×8 vinyl fence panels

In the dynamic landscape of fencing solutions, strategic sourcing for 6×8 vinyl fence panels emerges as a critical factor for international B2B buyers. The unique advantages of vinyl fencing, including durability, low maintenance, and aesthetic appeal, make it an attractive option for various markets, particularly in Africa, South America, the Middle East, and Europe. Understanding the diverse product specifications, such as panel heights, colors, and installation requirements, can empower buyers to make informed decisions that align with their specific needs.

Moreover, leveraging local suppliers and manufacturers can enhance supply chain efficiency, reduce shipping costs, and improve delivery timelines. By establishing strong relationships with reliable vendors, businesses can ensure consistent product quality and availability, mitigating risks associated with fluctuating market demands.

Looking ahead, the trend towards sustainability and eco-friendly materials will likely shape the future of vinyl fencing. Buyers are encouraged to prioritize suppliers who adopt sustainable practices and offer environmentally friendly products. By doing so, they not only meet consumer expectations but also position their businesses as responsible leaders in the industry. Engage proactively with suppliers today to secure a competitive edge in the evolving market of vinyl fencing solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to 6×8 vinyl fence panels

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.