A Deep Dive into 6 Inch Upvc Pipe Solution

Introduction: Navigating the Global Market for 6 inch upvc pipe

In an increasingly interconnected world, sourcing high-quality 6 inch UPVC pipes poses a significant challenge for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. The demand for durable, cost-effective, and versatile piping solutions is on the rise as industries expand and infrastructure projects proliferate. This comprehensive guide addresses the complexities involved in navigating the global market for 6 inch UPVC pipes, offering insights into various types, applications, and supplier vetting processes.

Buyers will gain a thorough understanding of the specific requirements for 6 inch UPVC pipes, including their applications in drainage, sewage, and non-pressure systems. The guide delves into essential factors such as material specifications, cost considerations, and regional compliance standards that can impact procurement decisions. Moreover, it emphasizes the importance of assessing supplier reliability and product quality, equipping international buyers with the tools necessary to make informed purchasing choices.

By synthesizing critical information and actionable insights, this guide empowers B2B buyers to navigate the complexities of the global UPVC pipe market confidently. Whether you are a contractor in Saudi Arabia or a project manager in Brazil, the knowledge contained within this resource will enhance your procurement strategy and facilitate successful project outcomes.

Understanding 6 inch upvc pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Schedule 40 UPVC Pipe | Standard wall thickness, suitable for non-pressure systems | Drainage, waste management | Pros: Cost-effective, easy to install. Cons: Limited pressure tolerance. |

| Schedule 80 UPVC Pipe | Thicker walls for higher pressure applications | Industrial plumbing, irrigation | Pros: Higher pressure rating, durable. Cons: More expensive, heavier. |

| Foam-Core UPVC Pipe | Lightweight with a foam core for insulation | HVAC systems, venting | Pros: Reduced weight, thermal insulation. Cons: Lower structural integrity. |

| Dual Rated UPVC Pipe | Suitable for both pressure and non-pressure applications | Water supply, sewage systems | Pros: Versatile, compliant with various standards. Cons: Can be pricier. |

| DWV UPVC Pipe | Specifically designed for drainage, waste, and venting | Residential and commercial drainage | Pros: Excellent flow capacity, corrosion-resistant. Cons: Not suitable for pressurized systems. |

What are the key characteristics of Schedule 40 UPVC Pipe?

Schedule 40 UPVC pipes are commonly used in non-pressure applications, making them ideal for drainage and waste management systems. With a standard wall thickness, they provide a balance between strength and flexibility. B2B buyers should consider their cost-effectiveness and ease of installation, especially in large-scale projects where budget constraints are crucial. However, their limited pressure tolerance means they are not suitable for high-pressure scenarios, which could lead to failures in certain applications.

How does Schedule 80 UPVC Pipe differ from Schedule 40?

Schedule 80 UPVC pipes feature thicker walls, allowing them to handle higher pressure levels compared to Schedule 40. This makes them suitable for industrial plumbing and irrigation systems where durability and resistance to pressure fluctuations are essential. B2B buyers looking for long-term solutions may find the investment worthwhile despite the higher initial cost. However, the increased weight may necessitate additional support during installation, which is a consideration for logistics and handling.

What advantages does Foam-Core UPVC Pipe offer?

Foam-core UPVC pipes are designed to be lightweight, featuring a foam insulation layer that provides thermal benefits. This type of pipe is particularly useful in HVAC systems and venting applications, where reduced weight can facilitate easier handling and installation. B2B buyers should note the advantages in thermal insulation, but they must also weigh these against the lower structural integrity, which may not be suitable for all applications, especially those requiring high mechanical strength.

Why consider Dual Rated UPVC Pipe for your projects?

Dual rated UPVC pipes are versatile, designed to accommodate both pressure and non-pressure applications. This flexibility makes them ideal for water supply systems and sewage management. B2B purchasers should appreciate the compliance with various industry standards, which can simplify regulatory hurdles. However, the cost may be higher compared to single-rated options, so buyers should evaluate their specific needs against the benefits of versatility and compliance.

What makes DWV UPVC Pipe a reliable choice for drainage systems?

DWV UPVC pipes are specifically engineered for drainage, waste, and venting applications. Their design allows for excellent flow capacity and resistance to corrosion, making them a reliable choice for both residential and commercial projects. B2B buyers will find that these pipes can significantly reduce maintenance costs due to their durability. However, they are not suitable for pressurized systems, which is an important factor to consider when planning plumbing solutions.

Key Industrial Applications of 6 inch upvc pipe

| Industry/Sector | Specific Application of 6 inch upvc pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Management | Used in sewage and drainage systems | Corrosion resistance and durability reduce maintenance costs. | Ensure compliance with local regulations and standards. |

| Construction | Utilized in building infrastructure for plumbing systems | Lightweight and easy installation speeds up project timelines. | Verify compatibility with existing plumbing systems. |

| Agriculture | Implemented in irrigation systems for crop production | Efficient water delivery improves crop yield and resource use. | Consider pipe length and fittings for specific agricultural needs. |

| Industrial Manufacturing | Serves in chemical processing and waste management | Chemical resistance minimizes downtime and enhances safety. | Assess chemical compatibility and pressure ratings. |

| Telecommunications | Acts as conduit for cabling and fiber optics | Protects sensitive cables from environmental damage. | Evaluate the pipe’s UV resistance and installation ease. |

How is 6 Inch UPVC Pipe Used in Water Management?

In water management, 6 inch UPVC pipes are primarily employed in sewage and drainage systems. Their inherent corrosion resistance and durability provide a long-lasting solution that reduces the need for frequent maintenance. This is particularly crucial in regions prone to harsh environmental conditions, such as parts of Africa and the Middle East. Buyers should ensure that the pipes comply with local regulations regarding waste management and environmental protection to avoid potential legal issues.

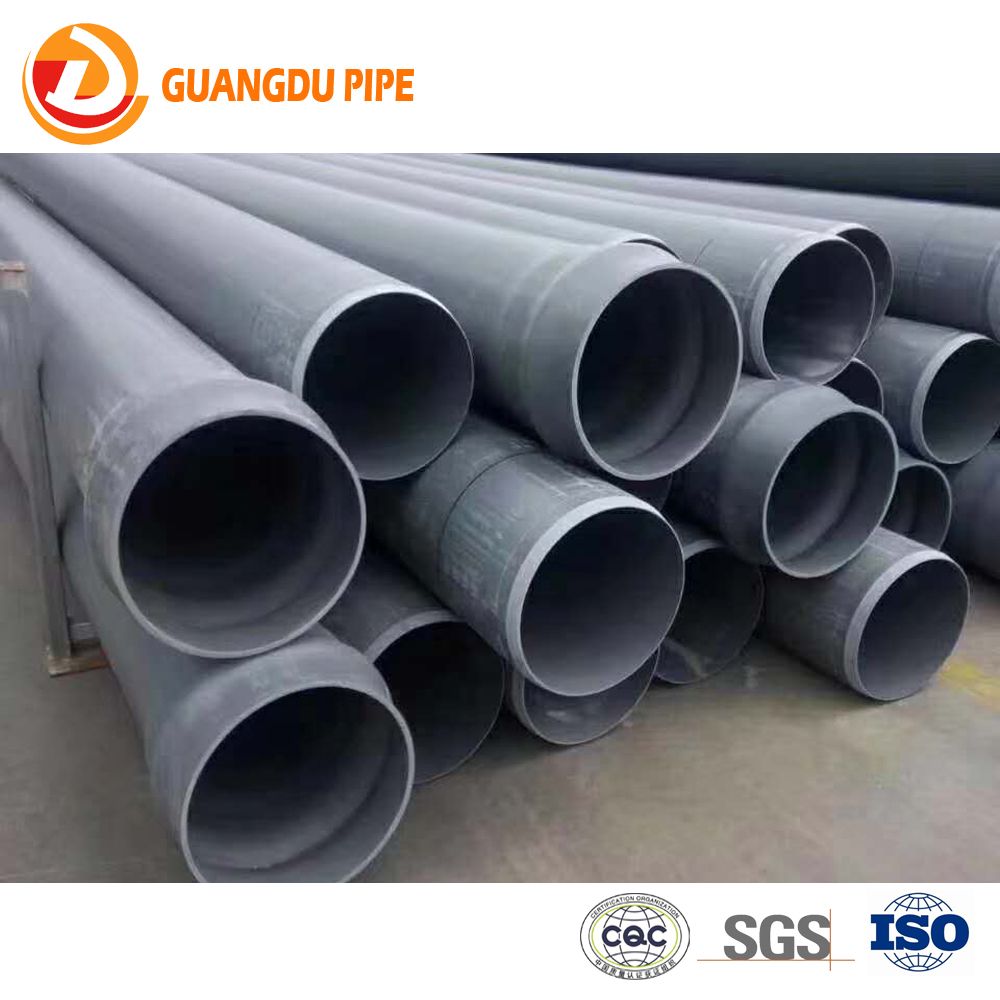

Illustrative image related to 6 inch upvc pipe

What Role Does 6 Inch UPVC Pipe Play in Construction?

In the construction sector, 6 inch UPVC pipes are critical for plumbing systems, facilitating the efficient transport of water and waste. Their lightweight nature makes installation straightforward, thereby accelerating project timelines. For B2B buyers in Europe and South America, it’s essential to verify that the pipes are compatible with existing plumbing systems to ensure seamless integration and functionality.

How Does 6 Inch UPVC Pipe Benefit Agriculture?

Agriculture benefits significantly from 6 inch UPVC pipes, which are utilized in irrigation systems to ensure efficient water delivery to crops. This efficiency not only conserves water but also enhances crop yields, making it a vital resource for farmers in arid regions. International buyers should consider specific agricultural needs, such as pipe length and required fittings, to optimize their irrigation setups.

Why is 6 Inch UPVC Pipe Important in Industrial Manufacturing?

In industrial manufacturing, 6 inch UPVC pipes are used in chemical processing and waste management applications. Their chemical resistance helps minimize downtime and enhances workplace safety by preventing leaks and spills. B2B buyers must assess the compatibility of UPVC pipes with the specific chemicals they will transport, as well as their pressure ratings, to ensure safe and effective operation.

How is 6 Inch UPVC Pipe Utilized in Telecommunications?

In telecommunications, 6 inch UPVC pipes serve as conduits for protecting sensitive cabling and fiber optics from environmental damage. This application is crucial in maintaining the integrity of communication infrastructure, especially in regions with extreme weather conditions. Buyers should evaluate the pipe’s UV resistance and ease of installation to ensure optimal performance and longevity in the field.

3 Common User Pain Points for ‘6 inch upvc pipe’ & Their Solutions

Scenario 1: Complications with Sizing and Specifications

The Problem: B2B buyers often face challenges when determining the appropriate size and specifications for 6-inch UPVC pipes to fit their specific applications. Miscalculating the required pipe dimensions can lead to installation delays, project overruns, and increased costs. Additionally, different regions may have varying standards and regulations, which can complicate sourcing the right product. For instance, a contractor in Saudi Arabia may require different pressure ratings compared to a buyer in Brazil, leading to potential mismatches in pipe performance.

The Solution: To overcome these sizing and specification challenges, buyers should engage in thorough planning and consultation before purchasing. Begin by clearly defining the application and expected pressure requirements. Utilize industry-standard sizing charts to determine the right dimensions for your project. Additionally, consult with suppliers who can provide detailed technical specifications and compliance documents. It is crucial to verify that the UPVC pipes meet the necessary local regulations and standards, such as ASTM or ISO certifications, depending on your region. Building a strong relationship with suppliers can also help ensure you receive tailored advice and assistance regarding the specifications needed for your unique project.

Scenario 2: Concerns Over Durability and Chemical Resistance

The Problem: Another common issue faced by B2B buyers is the durability and chemical resistance of 6-inch UPVC pipes, particularly when used in harsh environments. Buyers need assurance that the pipes will withstand various chemicals, temperatures, and external conditions without degrading over time. For example, industries such as agriculture and chemical processing may require pipes that can endure corrosive substances, which, if not addressed, could lead to costly failures and safety hazards.

The Solution: To address concerns about durability and chemical resistance, buyers should conduct a thorough assessment of the environment where the pipes will be installed. It’s essential to select UPVC pipes that are specifically designed for chemical resistance, checking the manufacturer’s data sheets for compatibility with the chemicals involved. When sourcing these pipes, opt for trusted manufacturers known for their quality control and testing standards. Additionally, consider investing in protective coatings or linings if the pipes will be exposed to particularly aggressive chemicals. By prioritizing these factors during the procurement process, buyers can significantly reduce the risk of pipe failure and ensure long-term reliability.

Scenario 3: Installation and Maintenance Challenges

The Problem: Many B2B buyers encounter installation and maintenance challenges when working with 6-inch UPVC pipes, particularly if their team lacks the necessary expertise or tools. Improper installation can lead to leaks, misalignments, and even system failures, resulting in significant downtime and repair costs. For buyers in regions where skilled labor is scarce, the risk of installation errors can be particularly high.

The Solution: To mitigate installation and maintenance challenges, buyers should invest in training and resources for their teams. Collaborating with experienced contractors or suppliers who can provide installation guidance can be invaluable. Additionally, consider using pre-fabricated sections or modular systems that simplify the installation process and reduce the likelihood of errors. It’s also beneficial to establish a regular maintenance schedule to monitor the condition of the pipes and address any potential issues before they escalate. Providing your team with the right tools and knowledge can lead to more efficient installations and a longer lifespan for the piping system, ultimately saving costs in the long run.

Strategic Material Selection Guide for 6 inch upvc pipe

What Are the Key Properties of Common Materials for 6 Inch UPVC Pipe?

When selecting materials for 6-inch UPVC pipes, it is essential to consider various options that align with the specific needs of international B2B buyers. The most common materials include UPVC, PVC, CPVC, and HDPE. Each material has unique properties that affect performance, cost, and application suitability.

How Does UPVC Compare in Terms of Performance and Suitability?

UPVC (Unplasticized Polyvinyl Chloride) is a widely used material for pipes due to its excellent chemical resistance and durability. It can handle temperatures up to 60°C (140°F) and is suitable for non-pressure applications, making it ideal for drainage and sewage systems. The material is also resistant to corrosion, which is crucial for applications in humid or chemically aggressive environments.

Pros: UPVC is lightweight, easy to install, and cost-effective compared to other materials. Its smooth interior surface reduces friction, enhancing flow efficiency.

Cons: While UPVC is durable, it can become brittle over time when exposed to UV light. Additionally, it is not suitable for high-pressure applications.

Impact on Application: UPVC is compatible with a wide range of media, including wastewater and chemicals, making it a versatile choice for various installations.

Considerations for International Buyers: Compliance with local standards such as ASTM and DIN is critical. In regions like Africa and the Middle East, buyers should ensure that UPVC pipes meet local regulations for sewage and drainage systems.

What Advantages Does PVC Offer for 6 Inch Pipe Applications?

PVC (Polyvinyl Chloride) is another common material for pipes, particularly in pressure applications. It can withstand temperatures up to 60°C (140°F) and is often used in potable water systems.

Pros: PVC is highly durable, resistant to corrosion, and has a long lifespan. It is also relatively inexpensive and widely available.

Cons: PVC can be more challenging to work with than UPVC due to its flexibility, which may require additional fittings and support.

Impact on Application: PVC is suitable for transporting both potable and non-potable water, making it a versatile option for various applications.

Considerations for International Buyers: Buyers should check for compliance with international standards such as ISO and local regulations, especially in regions like South America where water quality standards may vary.

How Does CPVC Enhance Performance in High-Temperature Applications?

CPVC (Chlorinated Polyvinyl Chloride) is designed for higher temperature applications, with a temperature rating of up to 93°C (200°F). This makes it suitable for hot water systems and industrial applications.

Pros: CPVC is highly resistant to heat and corrosion, making it ideal for hot water transport. It is also easy to install and can be joined using solvent cement.

Cons: CPVC is generally more expensive than UPVC and PVC. Its increased rigidity can also make it more challenging to handle during installation.

Impact on Application: CPVC’s high-temperature resistance allows it to be used in applications involving hot water and aggressive chemicals.

Considerations for International Buyers: Ensure that CPVC pipes meet local standards and regulations, particularly in industrial settings in regions like the Middle East, where high-temperature applications are common.

What Role Does HDPE Play in 6 Inch Pipe Systems?

HDPE (High-Density Polyethylene) is known for its strength and flexibility, making it suitable for various applications, including water supply and drainage.

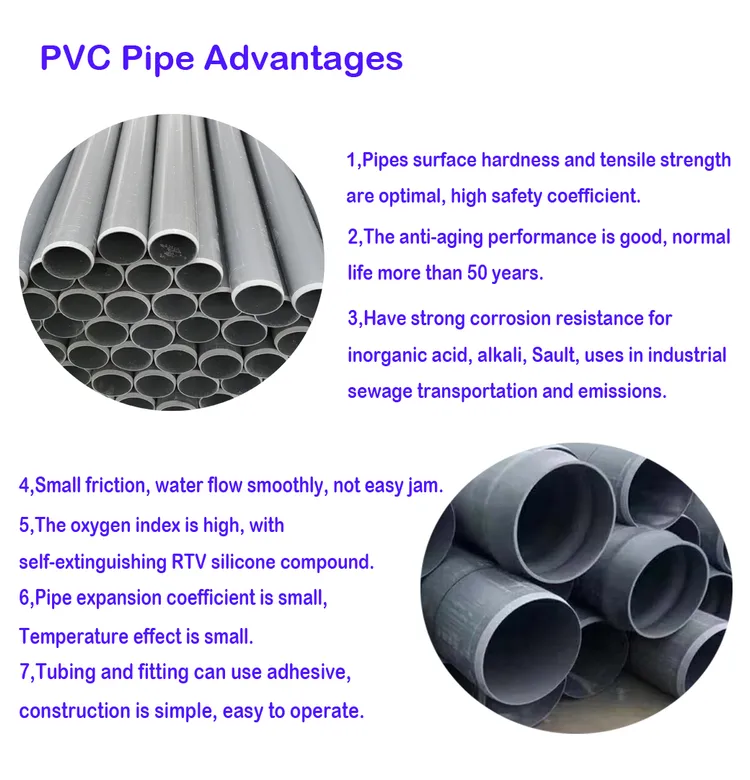

Illustrative image related to 6 inch upvc pipe

Pros: HDPE is highly resistant to impact, corrosion, and UV radiation. It is also flexible, which allows for easier installation in challenging environments.

Cons: The cost of HDPE can be higher than that of PVC and UPVC. Additionally, its flexibility may require additional support to prevent sagging.

Impact on Application: HDPE is ideal for transporting water and chemicals, particularly in underground installations where flexibility is advantageous.

Considerations for International Buyers: Compliance with local standards such as ASTM and ISO is essential, especially in regions like Africa where infrastructure projects may require specific material certifications.

Summary of Material Selection for 6 Inch UPVC Pipe

| Material | Typical Use Case for 6 inch upvc pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| UPVC | Drainage and sewage systems | Excellent chemical resistance | Becomes brittle with UV exposure | Low |

| PVC | Potable and non-potable water systems | Highly durable and cost-effective | More challenging to install | Medium |

| CPVC | Hot water transport | High-temperature resistance | More expensive and rigid | High |

| HDPE | Water supply and drainage | Impact and UV resistance | Higher cost and requires support | Medium |

This guide provides a comprehensive overview of the strategic material selection process for 6-inch UPVC pipes, tailored to the needs of international B2B buyers. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their specific applications and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 6 inch upvc pipe

What Are the Key Stages in the Manufacturing Process of 6 Inch UPVC Pipe?

The manufacturing process of 6 inch UPVC (Unplasticized Polyvinyl Chloride) pipes involves several critical stages that ensure the final product meets industry standards and customer requirements. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation

The first stage begins with the selection and preparation of raw materials. UPVC is created from a combination of PVC resin, stabilizers, lubricants, and other additives. The resin is typically sourced from reputable suppliers to ensure quality. The raw materials are then mixed in a precise formulation, which is crucial for achieving the desired properties in the final product.

After mixing, the materials are typically granulated into pellets for easier handling during the next stages of production. This preparation stage is essential as it lays the foundation for the pipe’s performance characteristics, such as strength, flexibility, and resistance to UV rays and chemicals.

How Is 6 Inch UPVC Pipe Formed?

Once the materials are prepared, the next step is the forming process. This is generally achieved through one of several techniques:

-

Extrusion: This is the most common method for producing UPVC pipes. The granulated material is heated until it melts and is then forced through a die to create a continuous pipe shape. The diameter and wall thickness are controlled by the die and the extrusion speed.

-

Molding: In some cases, especially for fittings, molding techniques may be used. The molten UPVC is injected into molds that shape the pipe or fitting as it cools and solidifies.

-

Calendering: This method may be used for producing flat sheets of UPVC that can be further processed into various products, though it is less common for pipe manufacturing.

The extrusion process is typically followed by a cooling phase, where the formed pipe is cooled and solidified. This cooling is essential for maintaining the dimensional stability of the pipe.

What Are the Finishing Processes for UPVC Pipes?

Once formed, the pipes undergo several finishing processes to ensure they meet the required specifications. These processes include cutting the pipes to specific lengths, surface finishing to remove any imperfections, and applying protective coatings if necessary.

Labeling and marking are also essential at this stage, as pipes must carry relevant information such as size, manufacturer details, and compliance marks. Proper labeling helps in inventory management and compliance with international standards.

What Quality Assurance Measures Are Essential for 6 Inch UPVC Pipe?

Quality assurance (QA) is a critical aspect of manufacturing UPVC pipes, ensuring that they meet regulatory and customer standards. This is particularly important for international B2B buyers who must comply with various regulations across different regions.

Which International Standards Are Relevant for UPVC Pipe Quality?

Compliance with international standards is crucial for ensuring the safety and performance of UPVC pipes. Key standards include:

-

ISO 9001: This standard outlines the criteria for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

-

CE Marking: In Europe, products must comply with the relevant directives to achieve CE marking, indicating conformity with health, safety, and environmental protection standards.

-

API Standards: For certain applications, especially in oil and gas, compliance with American Petroleum Institute (API) standards is necessary.

B2B buyers should verify that their suppliers are certified to these standards, as this indicates a commitment to quality and compliance.

What Are the Key Quality Control Checkpoints in UPVC Pipe Production?

Quality control (QC) is typically segmented into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During production, various parameters such as temperature, pressure, and dimensional accuracy are monitored to ensure consistency.

-

Final Quality Control (FQC): Finished pipes undergo rigorous testing to verify their properties, such as tensile strength, impact resistance, and dimensional accuracy. Common testing methods include hydrostatic testing, where pipes are subjected to high-pressure water to check for leaks and structural integrity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for B2B buyers, especially when sourcing from international markets. Here are actionable steps buyers can take:

-

Conduct Audits: Regularly scheduled audits can help ensure that suppliers adhere to their quality management systems and industry standards.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance certificates.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing processes and product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control and certification is essential. Different regions may have specific requirements or certifications that must be met. For instance:

-

Africa: Buyers should be aware of local regulations and standards that may differ significantly from international norms. Engaging with local representatives can help navigate these complexities.

-

South America: Import regulations can be stringent, and it may be necessary to provide documentation proving compliance with local standards.

-

Middle East: In regions like Saudi Arabia, local certifications such as the Saudi Standards, Metrology and Quality Organization (SASO) may be required.

-

Europe: Understanding the CE marking process and ensuring compliance with European directives is critical for market entry.

By being proactive and diligent in verifying supplier quality control practices, B2B buyers can minimize risks and ensure that they receive high-quality 6 inch UPVC pipes that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘6 inch upvc pipe’

In the dynamic landscape of B2B procurement, sourcing the right materials like 6-inch UPVC pipe requires a systematic approach. This guide offers a step-by-step checklist to help international buyers streamline their sourcing process, ensuring they make informed decisions that align with their project requirements.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the 6-inch UPVC pipe you need. This includes understanding the pipe’s intended application, pressure ratings, and any relevant industry standards. A precise specification helps in comparing products from different suppliers and ensures compliance with regional regulations.

- Considerations:

- Schedule type (e.g., Schedule 40 or Schedule 80)

- Material characteristics (e.g., corrosion resistance, flexibility)

- Dimensions and weight requirements

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is critical to ensure product quality and reliability. Research potential vendors through online platforms, trade shows, and industry contacts. A solid supplier network can provide insights into the best practices and standards in your region.

- Key Actions:

- Check supplier reviews and ratings.

- Verify their experience in supplying UPVC pipes.

- Look for suppliers with a robust distribution network.

Step 3: Evaluate Supplier Certifications

Ensure that your suppliers possess the necessary certifications that validate their product quality and compliance with international standards. Certifications like ISO 9001 can indicate a commitment to quality management.

- What to Look For:

- Compliance with local regulations and standards (e.g., ASTM, EN)

- Certifications related to environmental impact (e.g., eco-labels)

- Evidence of quality control processes

Step 4: Request Samples

Before finalizing your order, request samples of the 6-inch UPVC pipe. This allows you to assess the quality and suitability of the product for your specific needs. Testing samples can save costs and avoid complications during installation.

- Sample Considerations:

- Check the physical dimensions and weight.

- Assess the quality of joints and fittings.

- Conduct pressure tests if applicable.

Step 5: Negotiate Pricing and Terms

Once you are satisfied with the samples, engage in price negotiations. Understanding market rates and having clear discussions about payment terms, delivery schedules, and bulk purchase discounts can significantly impact your overall procurement costs.

- Negotiation Tips:

- Compare quotes from multiple suppliers.

- Discuss volume discounts for larger orders.

- Ensure transparency in pricing to avoid hidden costs.

Step 6: Finalize Logistics and Delivery

Plan the logistics of transporting the 6-inch UPVC pipes from the supplier to your site. Consider shipping methods, delivery timelines, and any customs regulations that may apply, especially when sourcing internationally.

- Logistics Checklist:

- Confirm shipping options and costs.

- Understand customs duties and import regulations.

- Ensure timely delivery aligns with your project timelines.

Step 7: Establish a Quality Control Process

After the pipes arrive, implement a quality control process to inspect the materials before installation. This step is crucial to identify any defects or discrepancies early, ensuring that the pipes meet your specifications.

- Quality Control Actions:

- Conduct visual inspections for damage.

- Verify dimensions against specifications.

- Document any issues for future reference.

By following these steps, B2B buyers can navigate the complexities of sourcing 6-inch UPVC pipes effectively, ensuring that they procure high-quality materials that meet their project needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for 6 inch upvc pipe Sourcing

Understanding the cost structure and pricing for 6-inch UPVC pipes is crucial for international B2B buyers seeking to optimize procurement strategies. This analysis will break down the key components influencing costs and prices, as well as offer practical tips for effective negotiation and sourcing.

What Are the Key Cost Components for 6-Inch UPVC Pipe Production?

The cost structure of 6-inch UPVC pipes encompasses several critical components:

-

Materials: The primary material for UPVC pipes is unplasticized polyvinyl chloride, which is relatively cost-effective but subject to market fluctuations. Prices can vary based on the quality and source of the resin, impacting the overall cost.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as some areas in Africa and South America, manufacturers can offer more competitive pricing. Conversely, regions with higher wages may see increased costs reflected in product prices.

-

Manufacturing Overhead: This includes costs associated with production facilities, utilities, and other operational expenses. Efficient manufacturing processes can lower these overhead costs, thereby reducing the final price of the pipes.

-

Tooling: The initial investment in molds and machinery can be substantial. Custom tooling for specific pipe dimensions or features can increase costs, making it essential to consider this when evaluating suppliers.

-

Quality Control (QC): Ensuring that pipes meet industry standards (such as ASTM or ISO certifications) incurs additional costs. Robust QC processes can enhance product reliability but may also raise the purchase price.

-

Logistics: Transportation costs play a significant role, especially for international buyers. Factors such as distance, shipping method, and customs duties can affect the final cost significantly.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the competitive landscape and the perceived value of the product.

How Do Price Influencers Impact 6-Inch UPVC Pipe Pricing?

Several factors influence the pricing of 6-inch UPVC pipes:

-

Volume/MOQ: Larger orders often lead to bulk discounts. Buyers should negotiate minimum order quantities (MOQs) to achieve better pricing.

-

Specifications and Customization: Customized pipes or those with specific technical requirements may incur higher costs. Buyers should clarify specifications upfront to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and industry certifications can justify higher prices. International buyers should ensure that products meet local regulations and standards.

-

Supplier Factors: Supplier reputation, reliability, and service can influence pricing. Established suppliers may charge a premium, but they often offer better quality assurance.

-

Incoterms: Understanding Incoterms is vital for international shipping. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total landed cost.

What Are Effective Buyer Tips for Sourcing 6-Inch UPVC Pipes?

-

Negotiation: Engage in open dialogue with suppliers to negotiate favorable terms. Understand their cost structure to leverage your position effectively.

-

Cost-Efficiency: Look beyond the initial purchase price. Consider the Total Cost of Ownership (TCO), which includes installation, maintenance, and lifespan of the pipes.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and local tariffs that can affect pricing. Establishing contracts in stable currencies can mitigate risks.

-

Market Research: Conduct thorough research to understand the market landscape. Comparing multiple suppliers can provide insight into competitive pricing and help identify the best value.

-

Long-Term Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Loyalty may incentivize suppliers to offer better terms over time.

Conclusion

In summary, the cost and pricing analysis for 6-inch UPVC pipes involves a multifaceted approach that considers various cost components and price influencers. By leveraging negotiation tactics and understanding the nuances of international procurement, B2B buyers can optimize their sourcing strategies for better financial outcomes. Always consult multiple suppliers and consider long-term implications to ensure the best value for your investment.

Alternatives Analysis: Comparing 6 inch upvc pipe With Other Solutions

Exploring Alternatives to 6 Inch UPVC Pipe: A Comprehensive Comparison

In the realm of plumbing and drainage solutions, the choice of pipe material is crucial for ensuring efficiency, durability, and cost-effectiveness. While the 6 inch UPVC pipe is a popular choice for various applications, it is beneficial for B2B buyers to explore alternative solutions that may better meet their specific needs. This analysis compares the 6 inch UPVC pipe with two viable alternatives: HDPE (High-Density Polyethylene) pipe and steel pipe.

Comparison Table

| Comparison Aspect | 6 Inch UPVC Pipe | HDPE Pipe | Steel Pipe |

|---|---|---|---|

| Performance | Good chemical resistance; low friction loss | High flexibility; excellent impact resistance | High strength; suitable for high-pressure applications |

| Cost | Moderate initial cost; low lifecycle cost | Competitive pricing; slightly higher than UPVC | Higher upfront cost; significant maintenance costs |

| Ease of Implementation | Easy to install; requires solvent cement | Simple fusion joining; lighter than steel | Requires welding or threading; heavier |

| Maintenance | Low maintenance; resistant to corrosion | Low maintenance; UV resistant | High maintenance; prone to corrosion without coating |

| Best Use Case | Drainage and sewage systems; non-pressure applications | Water supply, irrigation, and gas pipelines | Industrial applications requiring high pressure and durability |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of HDPE Pipe Compared to 6 Inch UPVC Pipe?

HDPE pipe is renowned for its flexibility and high impact resistance, making it an excellent choice for applications where ground movement or shifting might occur. It is less prone to cracking than UPVC under stress. Moreover, HDPE pipes are often used in water supply and gas distribution due to their ability to handle pressure and maintain integrity over time. However, the installation process can be slightly more complex as it requires fusion joining techniques. While HDPE pipes are competitively priced, their initial cost can be marginally higher than that of UPVC pipes.

How Does Steel Pipe Compare to 6 Inch UPVC Pipe in Terms of Performance?

Steel pipes are known for their exceptional strength and durability, making them suitable for high-pressure applications. They can handle extreme temperatures and are often used in industrial settings. However, they are significantly heavier, which complicates transportation and installation. Additionally, steel pipes are prone to corrosion if not properly treated or coated, leading to higher maintenance costs over their lifecycle. While the upfront cost of steel pipes is higher than that of UPVC, their longevity in specific applications can justify the investment.

Conclusion: Which Pipe Solution Should B2B Buyers Choose?

When selecting the right pipe solution, B2B buyers must consider their specific application requirements, budget constraints, and long-term maintenance expectations. The 6 inch UPVC pipe offers a balanced combination of performance, ease of installation, and cost-effectiveness for non-pressure applications like drainage. In contrast, HDPE pipes provide flexibility and impact resistance, making them ideal for water and gas distribution networks. Steel pipes, while robust and suitable for high-pressure systems, involve greater maintenance and installation complexities. By carefully evaluating these alternatives, buyers can make informed decisions that align with their project needs and operational goals.

Essential Technical Properties and Trade Terminology for 6 inch upvc pipe

What Are the Key Technical Properties of 6 Inch UPVC Pipe?

When considering the procurement of 6-inch UPVC pipe, it is essential to understand its critical technical properties, which influence its performance, suitability for various applications, and overall cost-effectiveness.

-

Material Grade

The most common material for 6-inch UPVC pipe is unplasticized polyvinyl chloride (UPVC). This material is known for its durability, chemical resistance, and low thermal conductivity. The grade of UPVC affects its ability to withstand varying temperatures and pressures, making it vital to select the correct grade to match the intended application, whether for drainage, sewage, or water supply. -

Wall Thickness

Wall thickness is a crucial specification that directly impacts the pipe’s strength and durability. For 6-inch UPVC pipes, the typical thickness ranges from 5.0 mm to 7.1 mm, depending on the schedule type (e.g., Schedule 40 or Schedule 80). A thicker wall can support higher pressure applications but may also increase costs. Understanding the required wall thickness is essential for ensuring compliance with industry standards and project requirements. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions. For UPVC pipes, maintaining strict tolerances is crucial for ensuring proper fittings and connections. A common tolerance for a 6-inch pipe is ±0.2 mm. Understanding these tolerances helps buyers ensure compatibility with fittings and reduces the risk of leaks or failures in the system. -

Temperature Rating

The temperature rating indicates the maximum temperature at which the pipe can operate without losing structural integrity. For most 6-inch UPVC pipes, this rating is generally around 60°C (140°F). This specification is particularly important for applications involving hot water or industrial processes, where exceeding this temperature could lead to deformation or failure of the pipe. -

Pressure Rating

Pressure rating is another critical property that defines the maximum pressure the pipe can withstand without bursting. For instance, a Schedule 40 6-inch UPVC pipe is typically rated for 280 PSI. Understanding the pressure rating helps in selecting the appropriate pipe for specific applications, ensuring safety and reliability in operation.

Which Trade Terminology Should B2B Buyers Know for 6 Inch UPVC Pipe?

Familiarity with industry jargon is essential for effective communication and negotiation in the procurement process. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of UPVC pipes, understanding OEM specifications can help buyers identify quality standards and sourcing options. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for 6-inch UPVC pipes can help buyers plan their purchasing strategy and manage inventory effectively, especially in large projects. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products. When looking to procure 6-inch UPVC pipes, issuing an RFQ can facilitate competitive pricing and ensure suppliers provide the necessary technical specifications. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is crucial for understanding shipping costs and risks associated with importing UPVC pipes from different regions. -

Schedule Type

Schedule types (such as Schedule 40 or Schedule 80) specify the thickness and pressure ratings of pipes. This classification is vital for buyers to ensure they are selecting the appropriate pipe for their application based on strength and pressure requirements.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring 6-inch UPVC pipes, ensuring quality, compliance, and cost-efficiency in their projects.

Navigating Market Dynamics and Sourcing Trends in the 6 inch upvc pipe Sector

What are the Current Market Dynamics and Key Trends in the 6 Inch UPVC Pipe Sector?

The global market for 6-inch UPVC pipes is driven by several factors, including increasing urbanization, infrastructural development, and the need for efficient drainage systems. Regions such as Africa, South America, the Middle East, and Europe are witnessing rapid urban growth, which necessitates the expansion of water supply and sewage systems. In particular, countries like Saudi Arabia and Brazil are investing heavily in infrastructure projects, creating a robust demand for durable and cost-effective piping solutions.

Emerging B2B technology trends are reshaping sourcing strategies in this sector. The rise of digital platforms facilitates easier procurement processes, allowing buyers to compare products, prices, and suppliers effectively. Additionally, advancements in manufacturing technologies are leading to more efficient production processes, reducing lead times and costs. With the integration of IoT, companies are exploring smart piping solutions that monitor flow rates and detect leaks, adding value to traditional UPVC pipe offerings.

Moreover, buyers are increasingly focusing on sourcing from suppliers that demonstrate reliability and quality assurance. The importance of supplier certifications and compliance with international standards cannot be overstated, as they ensure product quality and safety in various applications, from construction to agricultural uses.

How Does Sustainability and Ethical Sourcing Impact the 6 Inch UPVC Pipe Market?

Sustainability is becoming a crucial consideration for B2B buyers in the 6-inch UPVC pipe market. The environmental impact of plastic manufacturing, including carbon emissions and waste generation, has led to a heightened focus on eco-friendly practices. Ethical sourcing involves selecting suppliers who prioritize sustainable manufacturing processes and responsible sourcing of raw materials.

Buyers are increasingly seeking UPVC pipes that are certified by recognized environmental standards, such as ISO 14001 or those that meet ‘green’ building certifications. These certifications not only demonstrate a commitment to sustainability but also often align with governmental regulations, especially in regions like Europe where environmental legislation is stringent.

The push for sustainable materials extends to the incorporation of recycled content in UPVC pipes, reducing reliance on virgin materials and minimizing ecological footprints. By prioritizing suppliers who adhere to ethical sourcing practices, international buyers can enhance their brand reputation and contribute positively to global sustainability efforts.

What is the Historical Context of the 6 Inch UPVC Pipe Industry?

The evolution of UPVC pipes dates back to the early 20th century when they were introduced as a lightweight alternative to traditional metal pipes. Initially used in plumbing and drainage applications, the versatility of UPVC soon found applications in various sectors, including construction, agriculture, and sewage management.

Over the decades, technological advancements have improved the manufacturing processes, enhancing the durability and performance of UPVC pipes. The introduction of standardized sizes, such as the 6-inch dimension, has further facilitated widespread adoption across different markets. Today, UPVC pipes are recognized for their corrosion resistance, low maintenance requirements, and cost-effectiveness, making them a preferred choice for international B2B buyers looking for reliable piping solutions.

In summary, the 6-inch UPVC pipe sector is characterized by dynamic market trends driven by urbanization and technological advancements, alongside a growing emphasis on sustainability and ethical sourcing practices, reflecting the evolving needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of 6 inch upvc pipe

-

1. How do I ensure the quality of 6 inch UPVC pipes from suppliers?

To ensure quality when sourcing 6 inch UPVC pipes, it’s essential to conduct thorough supplier vetting. Request certifications that comply with international standards such as ISO or ASTM. Additionally, consider ordering samples for testing prior to placing large orders. Engaging in factory visits, if feasible, can also provide insights into production practices and quality control measures. Utilize third-party inspection services to verify the quality of the pipes before shipment, ensuring they meet your specifications and regulatory requirements. -

2. What is the best application for 6 inch UPVC pipes in industrial settings?

6 inch UPVC pipes are ideal for various applications in industrial settings, including drainage systems, sewage disposal, and non-potable water supply. Their resistance to corrosion and chemical damage makes them suitable for transporting wastewater and industrial effluents. Additionally, these pipes can be used in irrigation systems and agricultural drainage, offering long-lasting durability. When selecting UPVC pipes, consider the specific environmental conditions and the fluid’s temperature to ensure optimal performance. -

3. What customization options are available for 6 inch UPVC pipes?

Many suppliers offer customization options for 6 inch UPVC pipes, including variations in length, thickness, and color. You can also request specific fittings, such as elbows or tees, tailored to your project needs. Custom branding or markings can be applied to enhance product identification. Discuss your requirements with the supplier to explore available options and ensure that the customized products meet your project specifications and compliance standards. -

4. What are the minimum order quantities (MOQs) for 6 inch UPVC pipes?

Minimum order quantities for 6 inch UPVC pipes can vary significantly based on the supplier and the production capabilities. Typically, MOQs may range from a few hundred to several thousand units. When negotiating, consider your project timelines and budget constraints. Some suppliers may be flexible with MOQs for recurring orders or long-term partnerships, so it’s beneficial to communicate your needs clearly and explore potential bulk discounts. -

5. What payment terms should I expect when sourcing 6 inch UPVC pipes internationally?

Payment terms for international orders of 6 inch UPVC pipes can vary widely. Common terms include advance payment, letters of credit, or payment upon delivery. Some suppliers may offer net terms (e.g., 30, 60, or 90 days) for established customers. It’s crucial to clarify payment methods and terms before placing an order to avoid any misunderstandings. Additionally, ensure that the payment terms align with your cash flow management and procurement strategies. -

6. How can I manage logistics for importing 6 inch UPVC pipes?

Managing logistics for importing 6 inch UPVC pipes involves coordinating with freight forwarders, understanding customs regulations, and ensuring compliance with import duties. Work closely with your supplier to determine the best shipping method, whether by air or sea, based on cost and delivery timelines. Ensure all documentation is prepared, including invoices, packing lists, and certificates of origin. Establishing a reliable logistics partner can streamline the process and mitigate potential delays. -

7. What should I consider regarding transportation and shipping costs for 6 inch UPVC pipes?

When sourcing 6 inch UPVC pipes, transportation and shipping costs can significantly impact your overall budget. Factors to consider include the weight and volume of the pipes, the shipping method (air, sea, or land), and the distance from the supplier to your location. It’s advisable to obtain multiple quotes from different logistics providers to compare costs. Additionally, inquire about any hidden fees, such as handling charges or customs duties, to ensure accurate budgeting. -

8. How do I handle disputes with suppliers of 6 inch UPVC pipes?

Handling disputes with suppliers requires clear communication and documentation. Start by addressing the issue directly with the supplier, providing evidence such as contracts, emails, or photos to support your claims. If resolution is not achieved, consider mediation or arbitration as alternative dispute resolution methods. It’s essential to understand the legal framework governing your agreement and, if necessary, consult with legal experts to navigate the situation effectively. Establishing a good relationship with suppliers can also prevent disputes from escalating.

Top 2 6 Inch Upvc Pipe Manufacturers & Suppliers List

1. UZStore – UPVC PIPE NST 6

Domain: uzstore.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “UPVC PIPE NST 6″”, “length”: “6 Meter”, “price”: “9.975 OMR”, “availability”: “Not Available For Sale”, “shipping_time”: “2-3 Business Days”, “return_policy”: “30-day money-back guarantee”}

2. Reddit – Vertical 6 Inch PVC Tube

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Vertical 6 inch PVC tube; 6 inch diameter; top is about 8 inches above ground; uncapped; about 3 feet below ground is a horizontal piece of plastic; thickness of the plastic is about 1/8 to 1/4 inch; hollow beneath; has 4 tabs around the perimeter for potential threading/unthreading.

Strategic Sourcing Conclusion and Outlook for 6 inch upvc pipe

In the competitive landscape of global supply chains, the strategic sourcing of 6-inch UPVC pipes emerges as a pivotal element for businesses aiming to optimize their plumbing and construction projects. Key considerations for B2B buyers include the importance of selecting reliable suppliers who offer high-quality products that meet international standards, ensuring durability and compliance with local regulations. The ability to source these pipes effectively can lead to significant cost savings and enhanced operational efficiency, particularly in regions like Africa, South America, the Middle East, and Europe.

As the demand for sustainable and efficient plumbing solutions continues to rise, international buyers should prioritize partnerships with manufacturers that utilize innovative materials and production techniques. This not only guarantees superior performance but also aligns with the growing emphasis on eco-friendly construction practices.

Looking ahead, businesses are encouraged to stay proactive in exploring new supplier relationships and leveraging digital platforms to streamline their procurement processes. By doing so, they can position themselves advantageously in an evolving market, ready to meet the challenges and opportunities of tomorrow’s infrastructure demands. Engage with trusted suppliers today to secure a competitive edge in your projects involving 6-inch UPVC pipes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to 6 inch upvc pipe