A Deep Dive into 55 Gallon Plastic Drum Dimensions Solution

Introduction: Navigating the Global Market for 55 gallon plastic drum dimensions

In the fast-paced world of international trade, sourcing 55 gallon plastic drums can present significant challenges for businesses aiming to streamline their supply chains. Understanding the dimensions, specifications, and applications of these versatile containers is crucial for companies in Africa, South America, the Middle East, and Europe, particularly in regions like Germany and Saudi Arabia. This guide aims to demystify the complexities surrounding 55 gallon plastic drum dimensions, providing B2B buyers with essential insights to make informed purchasing decisions.

Throughout this comprehensive resource, we will explore various types of plastic drums, including closed-head and open-head options, and their specific applications in industries ranging from hazardous material storage to food and beverage packaging. Additionally, we will delve into critical factors such as supplier vetting processes, cost considerations, and compliance with international shipping regulations. By equipping buyers with the knowledge needed to navigate the global market effectively, this guide empowers businesses to enhance their operational efficiency and reduce risks associated with procurement.

Whether you are a purchasing manager, logistics coordinator, or supply chain strategist, understanding the nuances of 55 gallon plastic drum dimensions will enable you to make choices that align with your company’s needs and regulatory requirements. Let’s embark on this journey to ensure that your sourcing strategy is not only effective but also sustainable and compliant with global standards.

Understanding 55 gallon plastic drum dimensions Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Closed-Head Plastic Drum | Sealed top with no openings; typically has a screw cap | Storage and transport of hazardous materials | Pros: Leak-proof, secure; Cons: Limited access for filling/emptying. |

| Open-Head Plastic Drum | Removable lid with a lever-lock closure; often has multiple openings | Waste disposal, chemical containment | Pros: Easy access for filling; Cons: More prone to spills if not sealed properly. |

| Lab Pack Drum | Designed for safe transport of smaller containers; often UN-rated | Hazardous materials handling | Pros: Compact, efficient for small items; Cons: May require additional packing materials. |

| Food-Grade Plastic Drum | Made from food-safe materials; often BPA-free | Food and beverage storage | Pros: Safe for consumables; Cons: Higher cost due to material compliance. |

| UN Rated Plastic Drum | Certified for hazardous materials transport; features specific markings | Shipping hazardous goods internationally | Pros: Regulatory compliance; Cons: May have restrictions on contents. |

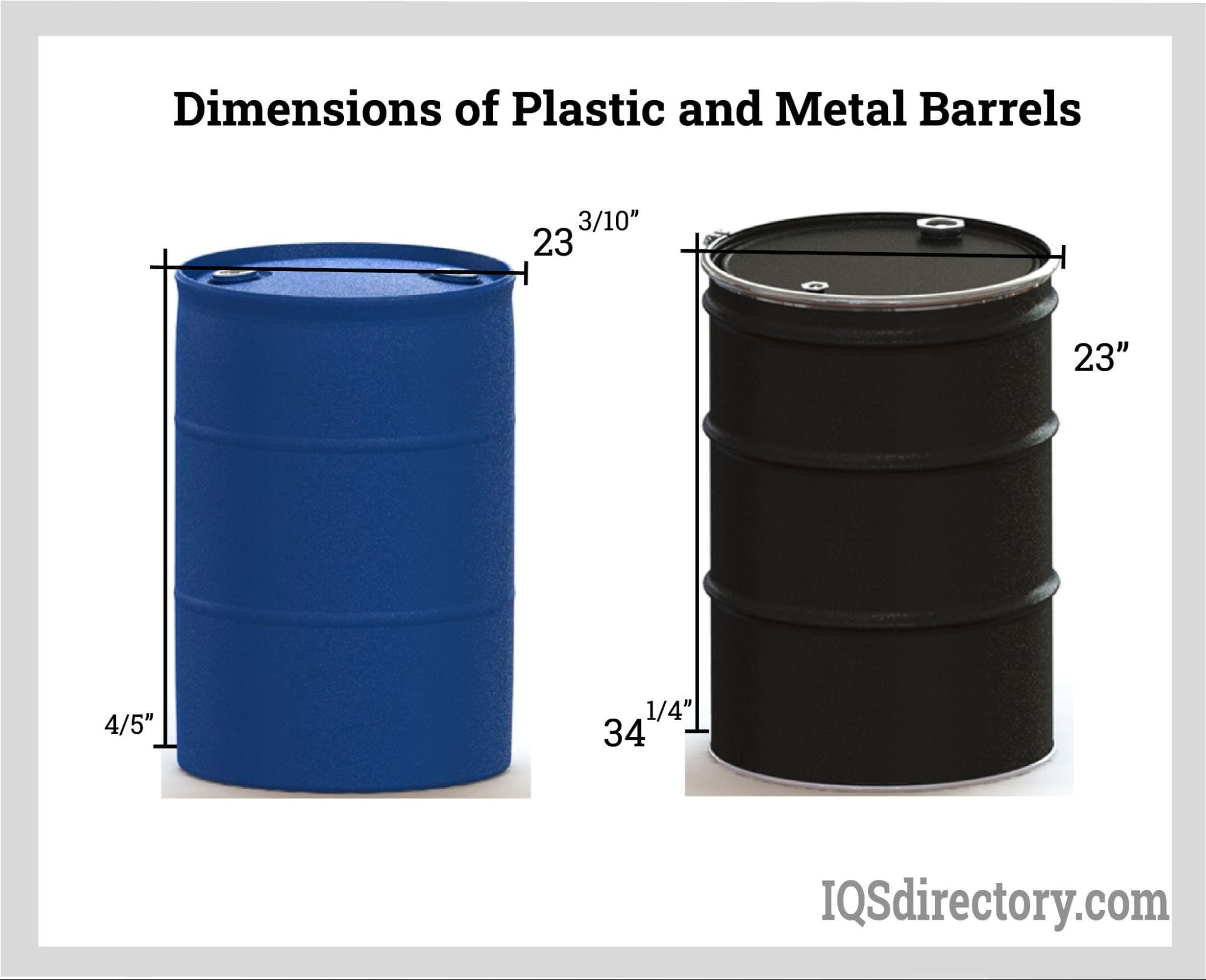

What Are the Key Characteristics of Closed-Head Plastic Drums?

Closed-head plastic drums are designed with a sealed top, typically featuring a screw cap for secure closure. This design minimizes the risk of leaks and contamination, making them ideal for storing and transporting hazardous materials. B2B buyers should consider the drum’s compatibility with their specific substances, as well as its UN rating, which indicates its suitability for hazardous goods. The limited access for filling and emptying can be a drawback for operations requiring frequent content changes.

How Do Open-Head Plastic Drums Differ in Functionality?

Open-head plastic drums come equipped with a removable lid, often secured with a lever-lock closure. This design allows easy access for filling and dispensing, making them particularly useful for waste disposal and chemical containment. However, the potential for spills exists if the drum is not properly sealed after use. Buyers should evaluate their operational needs, especially regarding the frequency of access required, and consider the implications of any spills or leaks on their processes.

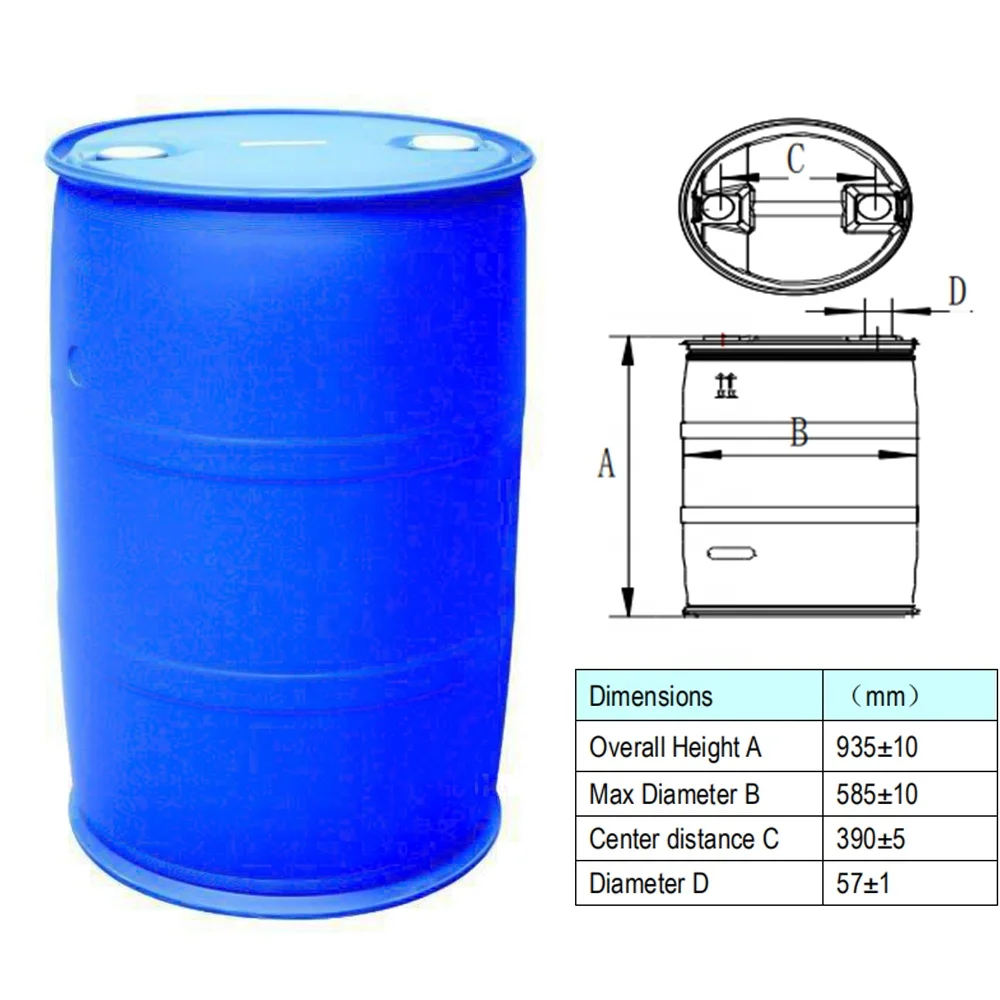

Illustrative image related to 55 gallon plastic drum dimensions

Why Choose Lab Pack Drums for Hazardous Materials?

Lab pack drums are specialized containers designed for the safe transport of smaller hazardous materials. These drums are often UN-rated, ensuring compliance with international shipping regulations. Their compact design allows for efficient packing of smaller containers, reducing the risk of spills during transit. However, buyers should be aware that additional packing materials may be necessary to ensure safety and compliance, which can add to overall costs.

What Makes Food-Grade Plastic Drums Essential for B2B Operations?

Food-grade plastic drums are crafted from materials that meet stringent safety standards for food storage. They are often BPA-free and designed to prevent contamination, making them suitable for the food and beverage industry. While these drums offer high safety levels for consumables, the cost may be higher due to the regulatory compliance required for food-safe materials. B2B buyers should assess their food storage needs and budget to determine the best option.

How Do UN Rated Plastic Drums Ensure Compliance in International Shipping?

UN rated plastic drums are specifically designed for the transport of hazardous materials, featuring certifications that comply with international regulations. These drums are marked with specific UN codes that indicate their suitability for various types of contents. While they provide peace of mind for B2B operations shipping dangerous goods, buyers should be aware of the restrictions that may apply to the contents, ensuring they remain compliant with shipping regulations.

Key Industrial Applications of 55 gallon plastic drum dimensions

| Industry/Sector | Specific Application of 55 gallon plastic drum dimensions | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Storage and transportation of hazardous chemicals | Ensures safety and compliance with regulatory standards | UN certification, material compatibility, and durability ratings |

| Food and Beverage | Bulk storage of food ingredients and beverages | Maintains product integrity and safety during transport | Food-grade certification, BPA-free materials, and easy handling |

| Waste Management | Collection and disposal of hazardous waste | Facilitates safe and compliant waste handling | Leak-proof design, appropriate labeling, and capacity for waste types |

| Agriculture | Transport of fertilizers and pesticides | Protects contents from environmental factors and contamination | UV resistance, chemical compatibility, and ease of stacking |

| Pharmaceuticals | Storage of raw materials and finished products | Ensures product safety and regulatory compliance | Tamper-evident seals, cleanroom compatibility, and traceability |

How Are 55 Gallon Plastic Drums Used in Chemical Manufacturing?

In the chemical manufacturing sector, 55-gallon plastic drums are crucial for the safe storage and transportation of hazardous substances. Their dimensions allow for efficient stacking and handling, while their construction from high-density polyethylene ensures durability and chemical resistance. International buyers need to ensure that the drums are UN-certified, as this guarantees compliance with global safety regulations. Additionally, understanding the compatibility of the drum material with the specific chemicals being stored is essential to prevent reactions that could compromise safety.

What Role Do 55 Gallon Plastic Drums Play in Food and Beverage Storage?

In the food and beverage industry, 55-gallon plastic drums are commonly used for bulk storage of ingredients such as oils, syrups, and powders. Their dimensions facilitate easy transport while maximizing storage space. These drums must be food-grade certified and BPA-free to ensure that the contents remain uncontaminated. Buyers from regions with stringent food safety regulations, like Europe and the Middle East, should prioritize suppliers who provide detailed documentation of compliance to avoid costly recalls or health issues.

How Are 55 Gallon Plastic Drums Utilized in Waste Management?

Waste management companies utilize 55-gallon plastic drums for the collection and disposal of hazardous waste materials. The drums’ leak-proof design is critical for preventing environmental contamination, while their dimensions allow for efficient use of space in waste collection vehicles. Buyers must consider the labeling requirements for hazardous waste and ensure that the drums meet local and international regulations for waste handling. Additionally, the drums should be compatible with the types of waste being collected to ensure safe transport and disposal.

What Advantages Do 55 Gallon Plastic Drums Offer in Agriculture?

In agriculture, these drums are often used for transporting fertilizers and pesticides. Their robust construction protects the contents from moisture and UV rays, preserving the effectiveness of the chemicals. The size of the drums is ideal for bulk applications, reducing the number of containers needed for transport. Buyers should focus on sourcing drums that are chemically compatible with the substances they intend to store, as well as those that can withstand varying environmental conditions during transport across diverse regions.

Illustrative image related to 55 gallon plastic drum dimensions

How Are 55 Gallon Plastic Drums Important for Pharmaceuticals?

In the pharmaceutical industry, 55-gallon plastic drums serve as storage solutions for raw materials and finished products. The dimensions of these drums facilitate efficient storage in cleanroom environments, where space is often at a premium. Buyers must ensure that the drums feature tamper-evident seals and are compliant with regulatory requirements for pharmaceutical packaging. Traceability is also vital, so sourcing from reputable suppliers who provide clear documentation is crucial for maintaining compliance and quality assurance in this highly regulated sector.

3 Common User Pain Points for ’55 gallon plastic drum dimensions’ & Their Solutions

Scenario 1: Inaccurate Dimensions Leading to Supply Chain Delays

The Problem:

B2B buyers often encounter significant challenges when the dimensions of 55-gallon plastic drums do not align with their storage or shipping needs. For instance, a buyer sourcing drums for hazardous materials may discover that the dimensions provided by different suppliers vary. This discrepancy can lead to unexpected supply chain delays, as the drums may not fit properly in existing storage systems or transport vehicles. Such delays can disrupt operations and lead to financial losses, particularly when time-sensitive materials are involved.

The Solution:

To mitigate this issue, buyers should establish a clear and consistent set of specifications before making a purchase. This includes verifying the exact external and internal dimensions of the drums, as well as understanding the dimensional tolerances provided by manufacturers. When requesting quotes, ask suppliers for detailed specification sheets that include measurements in both metric and imperial units. Additionally, consider using standardized drum dimensions where possible, as this simplifies compatibility across different suppliers. Implementing a robust vendor management system can also aid in tracking and comparing drum dimensions across multiple suppliers, ensuring that you select the best fit for your operational requirements.

Illustrative image related to 55 gallon plastic drum dimensions

Scenario 2: Compliance with International Shipping Regulations

The Problem:

For international B2B buyers, ensuring compliance with shipping regulations is critical. Many buyers may not be fully aware of how the dimensions of 55-gallon plastic drums affect compliance with international regulations, such as the UN’s Dangerous Goods Regulations. A buyer may purchase drums that do not meet the required specifications, resulting in penalties or delays at customs. This situation is particularly prevalent in regions like Africa and the Middle East, where regulations can vary significantly and may not be well understood.

The Solution:

To navigate these complexities, buyers should engage with suppliers who are knowledgeable about international shipping regulations. Before placing an order, it is essential to confirm that the drums are UN-rated and compliant with the specific regulations pertinent to the cargo being transported. This includes verifying that the dimensions of the drums meet the required standards for hazardous materials. Buyers should also stay updated on international regulations by consulting resources from organizations like the International Air Transport Association (IATA) or the International Maritime Organization (IMO). Collaborating with logistics partners who specialize in hazardous materials can provide additional assurance that the right drums are used for compliance.

Scenario 3: Inconsistent Quality Across Suppliers

The Problem:

B2B buyers often face the challenge of inconsistent quality in 55-gallon plastic drums from various suppliers, which can be attributed to differing manufacturing standards. A buyer may receive drums that are dimensionally accurate but lack the required durability or chemical resistance. This inconsistency can lead to leaks or spills, particularly when transporting hazardous substances, creating safety hazards and potential liability issues.

The Solution:

To ensure quality consistency, buyers should establish a rigorous supplier evaluation process that includes assessing manufacturing practices and quality control measures. Request samples from potential suppliers and conduct thorough inspections to ensure that the drums meet specified dimensions and quality standards. Certifications, such as ISO 9001, can serve as indicators of a supplier’s commitment to quality management. Additionally, maintaining a close relationship with suppliers can facilitate open communication about quality expectations and allow for rapid resolution of any issues that arise. Implementing a return policy for non-compliant products can also protect your business from financial losses due to subpar drum quality.

Strategic Material Selection Guide for 55 gallon plastic drum dimensions

What are the Common Materials Used for 55 Gallon Plastic Drums?

In the B2B landscape, selecting the appropriate material for 55-gallon plastic drums is critical for ensuring product performance and compliance with international standards. Here, we analyze four common materials used in the manufacturing of these drums: High-Density Polyethylene (HDPE), Polypropylene (PP), Polyvinyl Chloride (PVC), and Linear Low-Density Polyethylene (LLDPE).

Illustrative image related to 55 gallon plastic drum dimensions

How Does High-Density Polyethylene (HDPE) Perform?

HDPE is the most widely used material for 55-gallon plastic drums. It boasts excellent chemical resistance, making it suitable for storing a variety of substances, including hazardous materials. HDPE drums typically have a temperature rating of -40°F to 120°F (-40°C to 49°C), which allows them to perform well in diverse environments.

Pros: HDPE is durable, lightweight, and resistant to impact and UV radiation. It is also cost-effective, making it an ideal choice for bulk purchases.

Cons: While HDPE offers good resistance to many chemicals, it is not suitable for storing certain solvents and aromatic hydrocarbons. Additionally, it has a lower temperature tolerance compared to other materials.

Impact on Application: HDPE drums are suitable for a wide range of applications, including food storage, chemicals, and waste disposal. However, buyers must ensure compatibility with the specific media being stored.

International Considerations: Compliance with international standards such as ASTM and UN regulations is crucial. Buyers in regions like Africa and South America should also consider local regulations regarding hazardous materials.

What About Polypropylene (PP)?

Polypropylene is another popular material for 55-gallon drums, particularly for applications requiring higher temperature resistance. PP can withstand temperatures up to 200°F (93°C), making it suitable for hot-fill processes.

Pros: Polypropylene is highly resistant to chemical corrosion and has a lower density than HDPE, making it lighter. It also offers excellent impact resistance.

Cons: The higher manufacturing complexity of PP can lead to increased costs. Additionally, it may not be as UV resistant as HDPE, requiring additional protective measures for outdoor storage.

Impact on Application: PP drums are ideal for storing aggressive chemicals and are often used in the pharmaceutical and food industries. However, they may not be suitable for all applications due to their cost.

International Considerations: Buyers must ensure that PP drums meet local and international safety standards, particularly in Europe and the Middle East, where regulations can be stringent.

Is Polyvinyl Chloride (PVC) a Viable Option?

PVC is less common for 55-gallon drums but is still used in specific applications. It offers good chemical resistance and is often employed in environments where moisture is a concern.

Pros: PVC is highly resistant to a range of chemicals and is relatively inexpensive. It also provides good mechanical strength.

Cons: PVC has a lower temperature tolerance compared to HDPE and PP, typically around 140°F (60°C). It is also less durable in outdoor conditions due to UV degradation.

Illustrative image related to 55 gallon plastic drum dimensions

Impact on Application: PVC drums are suitable for storing aqueous solutions and some chemicals but are not ideal for long-term outdoor use.

International Considerations: Compliance with environmental regulations is essential, especially in regions where PVC usage is scrutinized due to its environmental impact.

What About Linear Low-Density Polyethylene (LLDPE)?

LLDPE is known for its flexibility and toughness, making it suitable for applications requiring impact resistance. It is often used for drums designed for transportation.

Pros: LLDPE offers excellent puncture resistance and is more flexible than HDPE, which can be advantageous in certain applications.

Cons: It has a lower chemical resistance compared to HDPE and PP, which may limit its use for specific hazardous materials.

Impact on Application: LLDPE drums are ideal for transporting liquids but may not be suitable for long-term storage of aggressive chemicals.

International Considerations: Buyers should ensure that LLDPE drums comply with international shipping regulations, especially when transporting hazardous materials.

Summary Table of Material Selection for 55 Gallon Plastic Drums

| Material | Typical Use Case for 55 Gallon Plastic Drum Dimensions | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | General storage for chemicals and food | Excellent chemical resistance | Not suitable for certain solvents | Low |

| Polypropylene (PP) | Hot-fill processes and aggressive chemicals | High temperature tolerance | Higher cost and complexity | Medium |

| Polyvinyl Chloride (PVC) | Storage of aqueous solutions | Cost-effective and strong | Lower temperature tolerance | Low |

| Linear Low-Density Polyethylene (LLDPE) | Transportation of liquids | Excellent puncture resistance | Limited chemical resistance | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the various materials used for 55-gallon plastic drums, enabling informed decision-making tailored to specific applications and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 55 gallon plastic drum dimensions

What Are the Key Stages in the Manufacturing Process of 55 Gallon Plastic Drums?

The manufacturing of 55-gallon plastic drums typically involves several distinct stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary material used for manufacturing these drums is high-density polyethylene (HDPE) due to its durability, chemical resistance, and lightweight properties. Initially, raw HDPE pellets are sourced and inspected for quality. They are then dried to remove moisture, ensuring optimal processing conditions.

-

Forming: The forming process often utilizes blow molding or injection molding techniques. In blow molding, heated HDPE is extruded into a mold and then inflated to take the shape of the drum. Injection molding involves injecting molten HDPE into a mold to create drum components. Both methods are designed to ensure uniform thickness and structural integrity, which are crucial for maintaining the drum’s capacity and strength.

-

Assembly: Once formed, the drum parts—such as the body, lid, and closure mechanisms—are assembled. This stage may include the integration of additional features, like lever-lock closures or screw caps, which enhance safety and usability.

-

Finishing: The final stage includes surface treatment, labeling, and quality inspection. Drums may undergo additional processes, such as UV stabilization to prolong their lifespan when exposed to sunlight. Labels indicating contents, handling instructions, and safety information are affixed to comply with international standards.

How Is Quality Assurance Implemented in the Manufacturing of 55 Gallon Plastic Drums?

Quality assurance (QA) is paramount in ensuring that 55-gallon plastic drums meet both customer expectations and regulatory requirements. International standards such as ISO 9001 are essential benchmarks in the QA process.

-

International Standards: ISO 9001 provides a framework for a quality management system (QMS) that emphasizes continuous improvement and customer satisfaction. Adhering to this standard means that manufacturers must maintain comprehensive documentation of processes, conduct regular audits, and implement corrective actions as necessary.

-

Industry-Specific Certifications: Depending on the intended use of the drums, other certifications may apply. For example, UN/DOT ratings are crucial for drums intended to transport hazardous materials. Compliance with these certifications ensures that the drums can safely contain and transport various substances.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Monitors the manufacturing process at various stages to detect deviations in real-time.

– Final Quality Control (FQC): Conducts thorough inspections of the finished products, including dimensional checks and stress testing.

What Common Testing Methods Are Used to Ensure Drum Quality?

Testing methods for 55-gallon plastic drums can vary based on the end-use but typically include:

- Dimensional Inspection: Ensures that the drums conform to specified dimensions, including height, diameter, and wall thickness.

- Drop Testing: Assesses the drum’s ability to withstand impacts by dropping it from predetermined heights.

- Pressure Testing: Validates the drum’s integrity under pressure, ensuring that it can safely contain liquids without leakage.

- Chemical Resistance Testing: Determines how well the material holds up against various chemicals, which is crucial for drums intended for hazardous materials.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to mitigate risks associated with procurement.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities directly. During these audits, buyers can review quality control processes, equipment, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QA practices. These reports should include testing results, inspection logs, and corrective actions taken for any non-conformance issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality practices. These inspections can occur at various stages, including before shipment and upon receipt of goods.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances when ensuring quality control in their procurement processes:

-

Regulatory Compliance: Different regions have specific regulations regarding the transportation of hazardous materials. Buyers should ensure that their suppliers are compliant with local and international regulations, such as those set forth by the UN for hazardous materials.

-

Cultural and Language Barriers: Communication can pose challenges. Buyers should establish clear communication channels and consider using bilingual representatives to facilitate discussions regarding quality expectations.

-

Time Zone Differences: Coordinating audits or inspections may require careful scheduling due to time zone differences. Buyers should plan well in advance to ensure that all parties are available for critical assessments.

Conclusion

Understanding the manufacturing processes and quality assurance measures for 55-gallon plastic drums is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control checkpoints and testing methods, businesses can ensure they procure high-quality products that meet their specific needs. Engaging in thorough supplier verification processes and understanding the nuances of international trade can further enhance the procurement experience, providing confidence in the quality and reliability of the drums sourced.

Practical Sourcing Guide: A Step-by-Step Checklist for ’55 gallon plastic drum dimensions’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure 55-gallon plastic drums. Understanding the specific dimensions and features of these drums is crucial to ensure compatibility with your storage and transportation needs. This guide will help you navigate the procurement process effectively, enabling you to make informed decisions that align with your business objectives.

1. Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the drum’s dimensions, material (usually high-density polyethylene), closure type (e.g., screw cap or lever-lock), and intended use (such as for hazardous materials or food-grade storage).

- Consider weight limits: Ensure the drum can accommodate the weight of the materials you plan to store or transport.

- Check for compatibility: Different materials may react with certain substances, so choose a drum that is chemically resistant to the contents.

2. Research Market Standards and Regulations

Familiarize yourself with international standards and regulations governing the use of plastic drums. Compliance with UN/DOT certifications is critical for transporting hazardous materials, and understanding these standards will help you avoid costly compliance issues.

- Identify relevant certifications: Look for UN ratings, which indicate the drum’s suitability for specific types of materials.

- Stay updated on regional regulations: Different regions may have varying requirements for packaging and shipping hazardous materials.

3. Evaluate Potential Suppliers

Before committing, it is essential to thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions to assess their reliability and quality.

- Review supplier capabilities: Confirm that the supplier can meet your specific drum dimensions and production timelines.

- Consider supplier location: Proximity to your operations can influence shipping costs and lead times.

4. Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the 55-gallon plastic drums. Testing the samples will help you assess their quality, durability, and suitability for your specific application.

- Conduct physical inspections: Check for any defects, such as cracks or improper seals, that could affect performance.

- Test compatibility: If possible, conduct compatibility tests with the intended contents to ensure there are no adverse reactions.

5. Negotiate Pricing and Terms

After selecting your preferred supplier, engage in negotiations to secure favorable pricing and terms. Consider aspects like bulk discounts, payment terms, and delivery schedules.

- Evaluate total cost of ownership: Look beyond the initial purchase price to include shipping, taxes, and any potential tariffs, especially for international transactions.

- Establish clear terms: Ensure that all agreements regarding return policies and warranty terms are documented to prevent future disputes.

6. Finalize Your Order and Logistics

Once terms are agreed upon, finalize your order and coordinate logistics for delivery. Confirm the order details, including the quantity, specifications, and delivery timeline.

- Plan for storage: Ensure your facility can accommodate the drums upon arrival, especially if they will be stored for an extended period.

- Monitor delivery: Keep in contact with the supplier to track the shipment and address any potential delays proactively.

7. Review Post-Purchase Performance

After receiving your drums, evaluate their performance based on your initial requirements. Gathering feedback from your team on the drums’ usability and durability can inform future purchasing decisions.

- Document any issues: Keep records of any problems encountered to discuss with your supplier for future improvements.

- Assess overall satisfaction: Regularly review supplier performance to ensure they continue to meet your evolving needs.

By following these steps, you will be well-equipped to source the right 55-gallon plastic drums that align with your operational needs while ensuring compliance and quality.

Comprehensive Cost and Pricing Analysis for 55 gallon plastic drum dimensions Sourcing

What Are the Key Cost Components in Sourcing 55 Gallon Plastic Drums?

When sourcing 55-gallon plastic drums, understanding the cost structure is essential for international buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of material significantly influences the cost. High-density polyethylene (HDPE) is a common choice due to its durability and resistance to chemicals. Prices can fluctuate based on market conditions for resin. Buyers should consider food-grade certifications if the drums are intended for food storage.

-

Labor and Manufacturing Overhead: Labor costs vary significantly by region. Countries with lower labor costs may offer more competitive pricing. However, manufacturing overhead, which includes utilities, facility costs, and indirect labor, can also impact overall pricing. Efficient production processes can help mitigate these costs.

-

Tooling and Quality Control: Tooling costs depend on the complexity of the drum design and the production volume. Higher volumes can spread these costs across more units, reducing per-unit pricing. Quality control measures are critical, particularly for drums used to transport hazardous materials. Certifications such as UN ratings add to the cost but are essential for compliance.

-

Logistics: Shipping costs can vary based on the destination. For international buyers, factors such as freight forwarding, customs duties, and local transport should be factored into the total cost. It’s advisable to work with suppliers familiar with international shipping to streamline logistics.

-

Margin: Supplier margins can vary widely based on market demand, brand reputation, and the level of service provided. Buyers should evaluate multiple quotes to ensure they are receiving competitive pricing.

What Influences Pricing for 55 Gallon Plastic Drums?

Several factors can influence the pricing of 55-gallon plastic drums:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can significantly reduce the unit price. Suppliers often provide discounts for larger orders, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Custom features, such as specific colors, closures, or dimensions, can affect pricing. Standard products are typically cheaper, so buyers should evaluate whether customization is necessary for their application.

-

Quality and Certifications: Higher-quality drums with certifications (like UN ratings) may come at a premium. However, investing in certified products can save costs in the long run by reducing the risk of leaks or regulatory issues.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can impact pricing. Suppliers with a strong track record in quality and service may charge more but offer better reliability.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the overall cost.

What Are Effective Buyer Tips for Cost-Efficiency?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, can implement various strategies to ensure cost-efficiency when sourcing 55-gallon plastic drums:

-

Negotiation: Always be prepared to negotiate prices and terms. Suppliers may be willing to provide discounts or flexible payment terms, especially for larger orders.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership rather than just the purchase price. This includes shipping, handling, and potential disposal costs. A higher upfront cost may lead to lower long-term expenses if the product is more durable.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and their impact on pricing. Consider locking in prices or using forward contracts to manage exchange rate risks.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and access to new products. Frequent communication can help in understanding market trends and pricing strategies.

-

Market Research: Stay informed about market trends and pricing fluctuations. Understanding supply and demand dynamics can provide leverage during negotiations.

Disclaimer on Indicative Prices

Prices for 55-gallon plastic drums can vary significantly based on the factors outlined above. The prices mentioned in this analysis are indicative and should be verified with suppliers for accurate quotes tailored to specific needs and circumstances.

Alternatives Analysis: Comparing 55 gallon plastic drum dimensions With Other Solutions

Exploring Alternatives to 55 Gallon Plastic Drums

In the realm of industrial storage and transportation, the 55-gallon plastic drum has established itself as a reliable option. However, various alternatives exist that may better suit specific applications or requirements. This analysis explores how these alternatives compare across several critical aspects, enabling B2B buyers to make informed decisions tailored to their unique needs.

Comparison Table

| Comparison Aspect | 55 Gallon Plastic Drum Dimensions | IBC Tote (Intermediate Bulk Container) | 30 Gallon Plastic Drum Dimensions |

|---|---|---|---|

| Performance | Excellent for liquids, solids, and powders. Versatile and durable. | High capacity (up to 330 gallons), ideal for bulk liquids. | Suitable for smaller quantities, easy to handle. |

| Cost | Moderate cost (approx. $95 – $125). | Higher initial investment (typically $200 – $400). | Lower cost (approx. $50 – $80). |

| Ease of Implementation | Easy to transport and store; requires minimal setup. | Requires forklifts for movement; more complex storage needs. | Simple to use; can be manually handled. |

| Maintenance | Low maintenance; can be reused multiple times. | Requires regular cleaning; may need replacement after certain uses. | Low maintenance; reusable but limited to smaller volumes. |

| Best Use Case | Ideal for hazardous materials, spill containment, and transport. | Best for large volume liquids and bulk chemicals. | Perfect for smaller quantities or lighter materials. |

In-Depth Analysis of Alternatives

Intermediate Bulk Container (IBC Tote)

IBC totes are large, rectangular containers designed for bulk storage and transport. They often hold up to 330 gallons, making them suitable for businesses dealing with high-volume liquid shipments. The primary advantage of IBC totes is their efficiency in transporting large quantities, which can reduce the overall cost per gallon. However, they require specialized equipment for handling, such as forklifts, which can be a drawback for smaller operations. Additionally, their higher initial cost may not be justified for companies that do not frequently require large-volume storage.

30 Gallon Plastic Drum

For operations that do not need the capacity of a 55-gallon drum, the 30-gallon plastic drum presents a more economical option. These drums are easier to handle and transport, making them ideal for businesses with lighter materials or smaller batch sizes. They are generally less expensive and require minimal maintenance. However, their reduced capacity means that they may necessitate more frequent refills and handling, which could increase labor costs over time.

Making the Right Choice for Your Business Needs

When selecting the appropriate storage and transportation solution, B2B buyers should consider several factors, including the volume of material being handled, budget constraints, and the specific requirements of the materials being stored. The 55-gallon plastic drum remains a versatile and reliable option for many applications, particularly for hazardous materials. However, for operations focused on bulk liquid transport, IBC totes may offer better efficiency. Conversely, businesses that handle smaller quantities may find the 30-gallon plastic drum to be the most practical and cost-effective choice. Ultimately, understanding the specific needs and operational context will guide buyers in making the most informed decision.

Essential Technical Properties and Trade Terminology for 55 gallon plastic drum dimensions

What Are the Key Technical Properties of 55 Gallon Plastic Drums?

When sourcing 55-gallon plastic drums, understanding the technical specifications is critical for ensuring the right fit for your operational needs. Here are several essential properties to consider:

-

Material Grade:

Most 55-gallon plastic drums are made from high-density polyethylene (HDPE), which offers excellent durability, resistance to chemicals, and UV stability. The material grade affects the drum’s ability to withstand various environments, making it essential for international shipping of hazardous materials. -

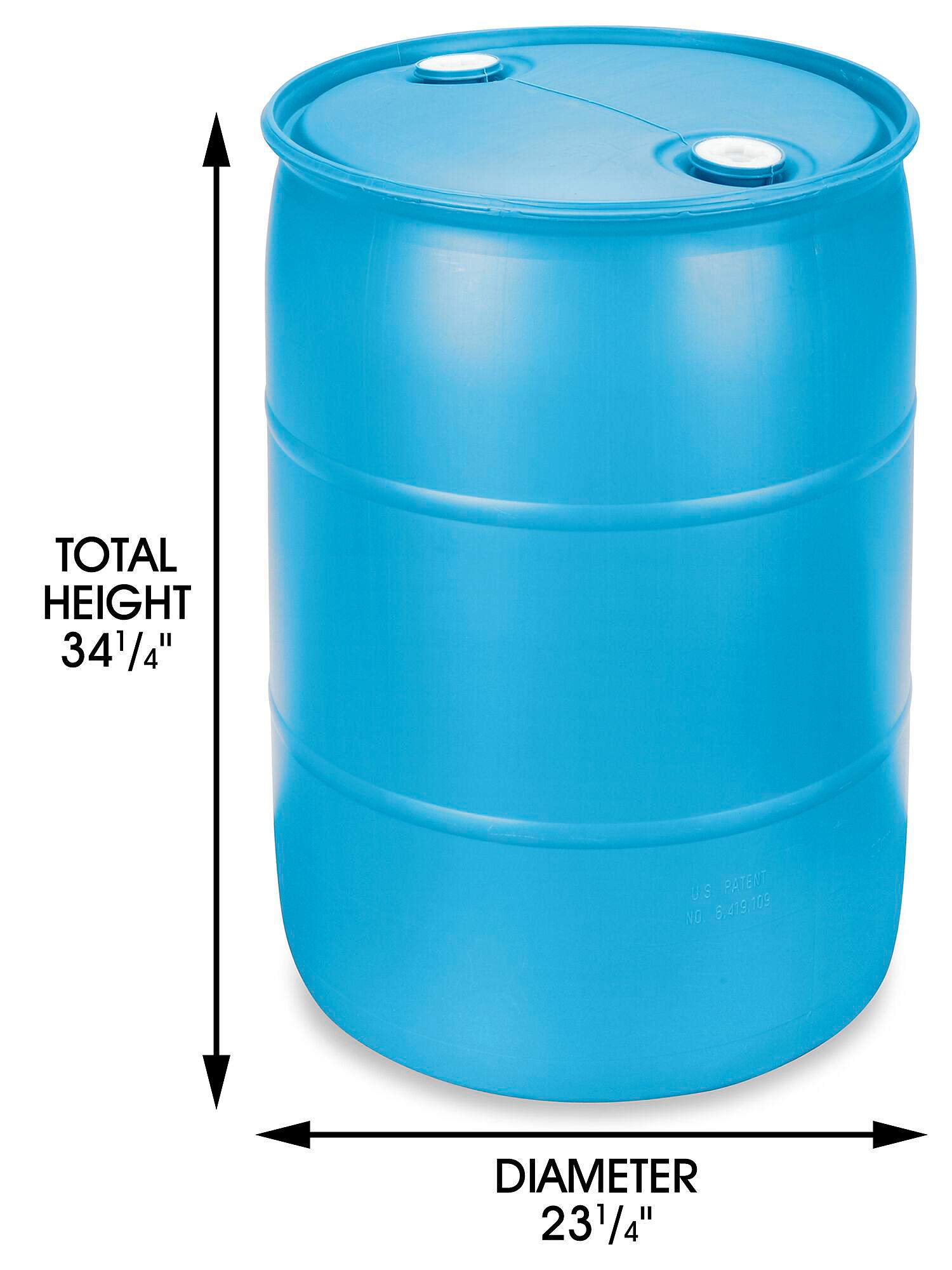

Dimensions:

Standard exterior dimensions for 55-gallon drums typically include a height of around 35 to 36 inches and a diameter of approximately 23 inches. Variations may occur depending on the manufacturer. Proper dimensioning is crucial for storage and transport logistics, ensuring compatibility with pallets and containers. -

Weight Capacity:

The net weight of an empty drum usually ranges from 20 to 25 pounds, while the maximum capacity can reach up to 220 pounds. Understanding weight limits is vital for compliance with shipping regulations and for determining how many drums can be safely transported together. -

UN/DOT Rating:

Many 55-gallon drums are UN-rated, indicating they meet specific safety standards for transporting hazardous materials. This rating is essential for B2B buyers in industries such as chemicals and pharmaceuticals, as it ensures compliance with international shipping regulations. -

Closure Type:

Drums may feature different closure types, such as screw caps or lever-locks. The choice of closure affects the ease of access and security of the contents, which is particularly important for hazardous or sensitive materials. -

Color and Markings:

Color-coding often signifies the type of contents stored (e.g., blue for hazardous materials). Additionally, proper labeling is crucial for compliance with international regulations, ensuring safe handling and identification during transport.

What Are Common Trade Terms Related to 55 Gallon Plastic Drums?

Familiarizing yourself with industry jargon will facilitate smoother transactions and negotiations. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer):

This term refers to companies that manufacture products that are sold under another company’s brand. In the context of plastic drums, knowing the OEM can help buyers ensure quality and consistency in their purchases. -

MOQ (Minimum Order Quantity):

This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for international buyers to manage inventory effectively and avoid overcommitting resources. -

RFQ (Request for Quotation):

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For B2B buyers, submitting an RFQ helps in comparing multiple offers to secure the best deal. -

Incoterms (International Commercial Terms):

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can prevent misunderstandings and legal disputes. -

Lead Time:

This refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for planning inventory and ensuring timely delivery of materials. -

Pallet Quantity:

This indicates how many drums fit on a standard pallet. Knowing the pallet quantity aids in calculating shipping costs and optimizing storage space, which is particularly important for bulk orders.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that their procurement of 55-gallon plastic drums aligns with their operational needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the 55 gallon plastic drum dimensions Sector

What Are the Key Market Trends Influencing 55 Gallon Plastic Drum Dimensions?

The global market for 55-gallon plastic drums is witnessing significant growth, driven by rising demand across various industries, including chemicals, pharmaceuticals, food and beverage, and hazardous waste management. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe explore sourcing options, understanding the dimensions and capacities of these drums becomes crucial. Notably, the standard dimensions typically hover around 23 inches in diameter and 35 inches in height, though variations exist depending on the manufacturer and the specific use case.

Emerging trends in the market include an increased focus on customization, where manufacturers are offering tailored solutions to meet specific customer needs. Additionally, advancements in materials technology, particularly the use of high-density polyethylene (HDPE), have enhanced the durability and chemical resistance of these drums. This trend is particularly relevant for buyers in regions with stringent regulations regarding hazardous materials. Furthermore, the integration of digital platforms for sourcing and procurement is transforming how buyers engage with suppliers, allowing for more efficient comparison and purchasing decisions.

How Is Sustainability Shaping Sourcing Trends for 55 Gallon Plastic Drums?

Sustainability has become a cornerstone of sourcing strategies for B2B buyers globally. The environmental impact of plastic waste is a significant concern, prompting companies to seek suppliers who prioritize ethical sourcing and sustainable practices. Many manufacturers are now offering 55-gallon plastic drums made from recycled materials or those that comply with ‘green’ certifications, which can significantly reduce the carbon footprint associated with their production.

Moreover, buyers are increasingly interested in suppliers who demonstrate a commitment to responsible manufacturing processes. This includes transparency in their supply chains and adherence to environmental regulations. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for buyers looking to align their procurement practices with sustainability goals. This trend is particularly pertinent for international buyers from Europe and the Middle East, where environmental regulations and consumer expectations are increasingly stringent.

How Have 55 Gallon Plastic Drums Evolved Over Time?

The evolution of 55-gallon plastic drums can be traced back to the need for efficient and safe storage solutions for various materials. Initially, these drums were predominantly made from metal, but the shift to plastic began in the late 20th century due to the material’s lightweight nature, resistance to corrosion, and cost-effectiveness. The introduction of high-density polyethylene (HDPE) revolutionized the industry, allowing for greater flexibility in design and application.

As industries have grown and diversified, so too have the applications for 55-gallon plastic drums. They are now widely used not only for transporting liquids but also for storing hazardous materials, food products, and even waste. This evolution has been accompanied by advancements in manufacturing processes, ensuring that these drums meet international safety and quality standards, making them indispensable for B2B buyers across various sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of 55 gallon plastic drum dimensions

-

How do I determine the right dimensions for a 55-gallon plastic drum?

To select the appropriate dimensions for a 55-gallon plastic drum, consider the specific application and the materials you intend to store. Most standard plastic drums have an approximate height of 35 to 36 inches and a diameter of 22 to 23 inches. However, variations exist among manufacturers, so reviewing product specifications is essential. Additionally, ensure the drum’s dimensions comply with local regulations if you’re transporting hazardous materials. For bulk orders, consult your supplier for customized dimensions that may better suit your needs. -

What is the typical weight of a 55-gallon plastic drum?

The weight of a 55-gallon plastic drum can vary based on its construction material and design. Generally, an empty high-density polyethylene (HDPE) drum weighs between 20 to 25 pounds (9 to 11 kg). If you’re considering the drum’s weight for shipping, also account for the packed weight, which can be significantly higher depending on the contents. Always confirm the weight details with the supplier to ensure it aligns with your logistics and shipping calculations. -

Are there different types of 55-gallon plastic drums available?

Yes, there are various types of 55-gallon plastic drums, including closed-head, open-head, and lever-lock models. Closed-head drums are ideal for liquids, featuring a sealed top with bungs for filling and dispensing. Open-head drums allow for easier access, making them suitable for solid materials or when frequent access is required. Selecting the right type depends on your specific storage and handling needs, as well as the nature of the materials being stored. -

What customization options are available for 55-gallon plastic drums?

Many manufacturers offer customization options for 55-gallon plastic drums, including color, labeling, and closure types. Custom colors can help with inventory management and branding, while specific labels can ensure compliance with local regulations regarding hazardous materials. Additionally, some suppliers may provide custom fittings or accessories for enhanced functionality. Discuss your requirements with potential suppliers to explore available customization options that meet your operational needs. -

What are the minimum order quantities (MOQs) for 55-gallon plastic drums?

Minimum order quantities for 55-gallon plastic drums can vary significantly by supplier. Some manufacturers may offer MOQs as low as 10 drums, while others may require larger bulk orders to ensure cost-effectiveness. When sourcing drums internationally, consider the potential for higher shipping costs with smaller orders. It’s advisable to negotiate MOQs with suppliers, especially if you anticipate regular purchases, to optimize your procurement strategy. -

How do I ensure quality assurance when sourcing 55-gallon plastic drums?

To ensure quality assurance when sourcing 55-gallon plastic drums, request certifications and compliance documentation from your suppliers. Look for drums that meet international standards such as UN certification for hazardous materials. Additionally, consider conducting quality checks or requesting samples before placing larger orders. Establishing a clear communication line with suppliers regarding quality expectations can also help mitigate risks associated with substandard products. -

What payment terms should I expect when ordering 55-gallon plastic drums internationally?

Payment terms for international orders of 55-gallon plastic drums typically vary by supplier and may include options like net 30, net 60, or even payment upon delivery. Some suppliers might require a deposit upfront, especially for large orders, while others may offer credit terms based on your purchasing history. It’s essential to discuss and agree upon payment terms before finalizing your order to avoid misunderstandings and ensure a smooth transaction. -

What logistics considerations should I keep in mind when importing 55-gallon plastic drums?

When importing 55-gallon plastic drums, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Evaluate whether you will use air freight for expedited delivery or ocean freight for cost savings on larger orders. Additionally, ensure that your supplier provides all necessary documentation for customs clearance, including bills of lading and certificates of compliance. Planning for storage upon arrival is also crucial, as you’ll need adequate space to accommodate your order.

Top 6 55 Gallon Plastic Drum Dimensions Manufacturers & Suppliers List

1. Eagle – High-Density Polyethylene Drum

Domain: eagle.justrite.com

Registered: 1997 (28 years)

Introduction: {“Model No”:”1656B”,”Color”:”Blue”,”Brand”:”Eagle”,”Material”:”High-Density Polyethylene (HDPE)”,”Net Weight (lbs)”:”23.5″,”Net Weight (kgs)”:”10.66″,”UN/DOT Rating”:”1H2/X100/S, 1H2/Y100/S”,”Exterior Dimensions (inches)”:”21D x 36.375H”,”Interior Dimensions (Top)”:”20.06″ (31cm)”,”Interior Dimensions (Bottom)”:”22.13″ (56.2cm)”,”Interior Dimensions (Height)”:”35.8″ (91cm)”,”Gallon Capacity”:”55″,…

2. Plastic Pallets and Bins – 55 Gallon Tight-Head Drum

Domain: plasticpalletsandbins.com

Registered: 2015 (10 years)

Introduction: {“Product Name”: “55 Gallon Tight-Head Drum”, “Pack Size”: “1 Pack of 4 Drums”, “Price”: “$232.00”, “Material”: “High density polyethylene”, “Capacity”: “55 Gallons”, “Dimensions”: {“Height”: “36.8 inches”, “Diameter”: “22.8 inches”}, “Weight”: “19 lbs”, “Features”: [“Greater impact strength at low temperatures”, “Complies with FDA regulations for food and drugs”, “UN certified”, “High upper ring …

3. Fluid Bag – 55 Gallon Drum Specifications

Domain: fluid-bag.com

Registered: 1998 (27 years)

Introduction: 55 gallon drum dimensions: 24 inches (61 cm) in diameter, 34 inches (86 cm) in height; capacity: approximately 208.2 liters; empty weight: 38 to 42 pounds (17 to 19 kg); full weight with water: 460 to 500 pounds (209 to 227 kg); full weight with oil: around 440 pounds (200 kg); can hold 350 to 400 pounds (159 to 181 kg) of corn; used in various applications including industrial settings and backya…

4. Air Sea Containers – 55 Gallon HDPE Poly Drum

Domain: airseacontainers.com

Registered: 1997 (28 years)

Introduction: {“item_number”:”1H1-55-AB”,”description”:”55 Gallon Closed-Head UN Rated HDPE Poly Drum with Screw Cap and Rubber Ring (2\” Bung) and 3/4\” Vent in top.”,”dimensions”:”Approx. 23\” x 35\”, “weight”:”21 lbs.”,”color”:”Blue”,”material”:”High Density Polyethylene (HDPE)”,”food_grade”:”Yes”,”BPA_free”:”Yes”,”UN_certification”:”UN1H1/Y1.9/100″,”minimum_quantity”:”8″,”shipping_info”:”Ships within 24 – 4…

5. The Cary Company – 55 Gallon White Tight Head Plastic Drum

Domain: thecarycompany.com

Registered: 1999 (26 years)

Introduction: 55 Gallon White Tight Head Plastic Drum, UN Rated, 2″ NPT & 2″ Buttress Fittings

6. Uline – Plastic Drum with Lid – 55 Gallon

Domain: uline.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Plastic Drum with Lid – 55 Gallon, Open Top, Black”, “Model Number”: “S-9945BL”, “Capacity”: “55 Gallon (208 L)”, “Weight”: “25 lbs (11 Kg)”, “Material”: “High Density Polyethylene (HDPE)”, “Lid Type”: “Quick-lock lid”, “Temperature Range”: “0° – 120° F”, “UN Rating”: “1H2/Y250/S”, “Dimensions”: {“Outside with Lid”: “36 x 22 3/4 in (H x Diam)”, “Height without Lid”: “35 5/8 in”, …

Strategic Sourcing Conclusion and Outlook for 55 gallon plastic drum dimensions

How Can International Buyers Benefit from Understanding 55 Gallon Plastic Drum Dimensions?

In the realm of industrial packaging, 55-gallon plastic drums serve as a vital resource for a diverse range of applications, from hazardous material transport to food storage. Understanding the dimensions and specifications of these drums is crucial for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key takeaways include the importance of selecting the right drum type—closed-head versus open-head—and ensuring compliance with international shipping standards, such as UN ratings.

Strategic sourcing of 55-gallon plastic drums not only enhances operational efficiency but also helps mitigate risks associated with product contamination and regulatory compliance. By leveraging reliable suppliers who offer high-quality products tailored to specific needs, businesses can optimize their supply chains and reduce total cost of ownership.

Looking ahead, the demand for versatile and sustainable packaging solutions will continue to grow. International buyers are encouraged to engage with suppliers who prioritize innovation and sustainability in their product offerings. As you navigate your sourcing strategy, consider the long-term benefits of investing in quality 55-gallon plastic drums that meet your operational requirements and contribute to your business’s success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to 55 gallon plastic drum dimensions

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.