A Deep Dive into 2005 Toyota Camry Transmission U250 Torque Converter Solution

Introduction: Navigating the Global Market for 2005 toyota camry transmission u250 torque converter

Navigating the global market for a 2005 Toyota Camry transmission U250 torque converter presents unique challenges, particularly for B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe. The complexity of sourcing high-quality torque converters at competitive prices can be daunting, especially when considering the myriad of suppliers and potential variations in product specifications. This comprehensive guide aims to demystify the procurement process by detailing the various types of torque converters available, their applications, and critical factors for supplier vetting.

In addition to product specifications, this guide will provide insights into the cost structures associated with the U250 torque converter, including potential core deposits and shipping considerations. Understanding these nuances can significantly enhance purchasing decisions, ensuring that B2B buyers select the most reliable and cost-effective options for their needs.

By equipping international buyers with actionable insights and a structured approach to sourcing, this guide empowers businesses to make informed decisions, ultimately leading to successful transactions and operational efficiency. Whether you’re a distributor seeking to expand your inventory or a repair shop looking for dependable parts, this resource will serve as a valuable tool in navigating the intricate landscape of the automotive parts market.

Understanding 2005 toyota camry transmission u250 torque converter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| TC Remanufacturing TO42-9 | 9″ bolt circle, lock-up feature, designed for U151E and U250E transmissions. | General automotive repair and replacements. | Pros: Cost-effective, reliable remanufactured option. Cons: Core deposit required, limited availability. |

| Pro-King TO55L | 11.150″ overall diameter, low stall speed, advanced friction material, and slotted hub. | High-performance applications and racing. | Pros: Enhanced performance and durability. Cons: Higher price point compared to standard options. |

| TC Remanufacturing TO82 | Compact design, specifically for U250E, with a focus on affordability and reliability. | Budget-conscious repair shops. | Pros: Affordable, easy to source. Cons: May lack advanced features of premium options. |

| Pro-King TO42 | Slight low stall speed, 10.30″ diameter, compatible with various Toyota models. | Versatile applications in Toyota vehicles. | Pros: Good balance of performance and cost. Cons: Standard features may not meet high-performance needs. |

| PNH Performance Torque Converters | Custom-built options with extreme upgrades for maximum performance, multi-disc lock-up. | Racing and high-performance builds. | Pros: Tailored to specific performance requirements. Cons: Lead time for customization, premium pricing. |

The TC Remanufacturing TO42-9 torque converter is designed specifically for the U151E and U250E transmissions, making it a reliable choice for general automotive repairs. Its lock-up feature enhances fuel efficiency during highway driving. B2B buyers seeking a cost-effective solution will find it appealing, although the core deposit and occasional limited availability can be drawbacks.

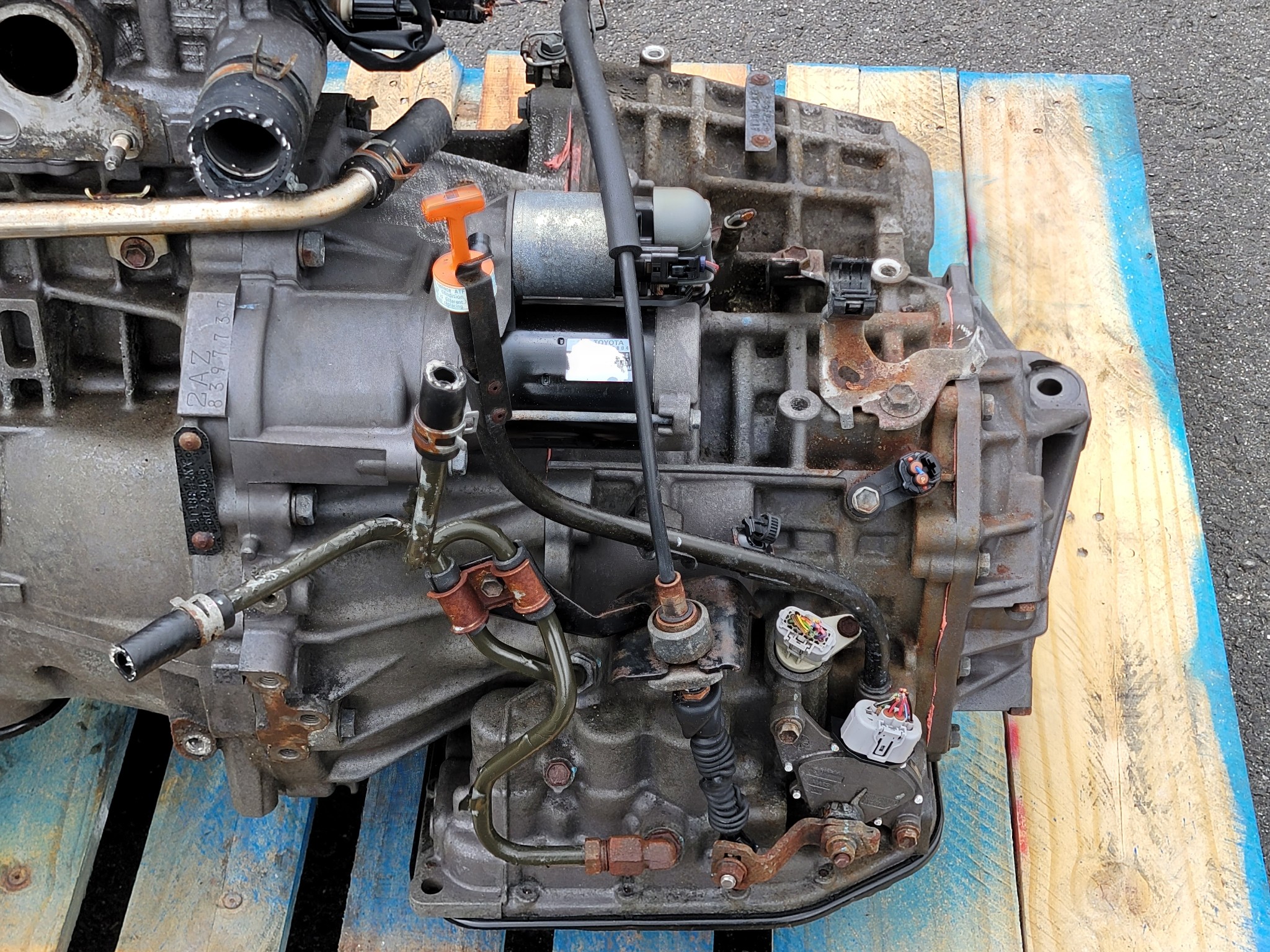

Illustrative image related to 2005 toyota camry transmission u250 torque converter

The Pro-King TO55L is tailored for high-performance applications, boasting an overall diameter of 11.150 inches and a low stall speed. This converter employs advanced friction materials, making it suitable for racing environments. B2B buyers focused on performance enhancements may appreciate its durability and engineering, though the higher price point could deter budget-conscious businesses.

For budget-conscious repair shops, the TC Remanufacturing TO82 offers a compact design optimized for U250E transmissions. It prioritizes affordability without sacrificing reliability, making it an attractive option for those looking to keep costs low. However, businesses should be aware that it may not include the advanced features found in premium products.

The Pro-King TO42 strikes a balance between performance and cost, with a 10.30-inch diameter and slight low stall speed. Its compatibility with various Toyota models makes it versatile for B2B applications. While it offers good value, it may not meet the demands of high-performance enthusiasts.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Lastly, PNH Performance Torque Converters provide customized options for extreme applications, featuring multi-disc lock-up designs. These converters are ideal for racing and high-performance builds, allowing buyers to tailor specifications to their needs. However, the customization process can lead to longer lead times and higher costs, which may be a consideration for some businesses.

Key Industrial Applications of 2005 toyota camry transmission u250 torque converter

| Industry/Sector | Specific Application of 2005 Toyota Camry Transmission U250 Torque Converter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Replacement for faulty torque converters in Toyota Camry vehicles | Enhances vehicle performance and reliability | Availability of OEM or high-quality remanufactured parts |

| Fleet Management | Maintenance of fleet vehicles including Toyota Camrys | Reduces downtime and maintenance costs | Bulk purchasing options and warranties |

| Auto Parts Distribution | Resale of torque converters to local repair shops and mechanics | Expands product offerings and increases revenue | Sourcing from reputable manufacturers with quality assurance |

| Performance Tuning Shops | Upgrading torque converters for enhanced vehicle performance | Improves acceleration and overall driving experience | Customization options and performance specifications |

| Export Markets | Supply of torque converters to international markets for local vehicle repairs | Meets demand for reliable vehicle components | Compliance with regional regulations and shipping logistics |

The 2005 Toyota Camry transmission U250 torque converter plays a crucial role in various sectors, particularly in automotive repair and maintenance. In automotive repair shops, it serves as a replacement component for malfunctioning torque converters, which are essential for efficient vehicle performance. By ensuring that vehicles operate smoothly, repair shops can enhance customer satisfaction and loyalty, ultimately driving repeat business. Buyers in this sector should prioritize sourcing high-quality OEM or remanufactured parts to maintain vehicle integrity.

In fleet management, the U250 torque converter is vital for maintaining a fleet of Toyota Camry vehicles. Regular maintenance, including torque converter replacements, minimizes vehicle downtime and reduces overall operational costs. Fleet managers should consider bulk purchasing options to ensure consistent supply and negotiate favorable warranties for long-term reliability.

Auto parts distribution is another key application area, where the U250 torque converter can be resold to local mechanics and repair shops. Distributors can expand their product offerings by including these high-demand components, leading to increased revenue streams. When sourcing, distributors should focus on reputable manufacturers known for quality assurance to build trust with their customers.

Performance tuning shops utilize the U250 torque converter to enhance the performance of Toyota Camry vehicles. By upgrading to high-performance converters, these shops can significantly improve acceleration and driving dynamics, appealing to car enthusiasts. Buyers in this sector should seek customization options to meet specific performance requirements.

Lastly, the export market represents a significant opportunity for sourcing and distributing the U250 torque converter. As demand for reliable vehicle components rises in international markets, suppliers must ensure compliance with regional regulations and effectively manage shipping logistics to facilitate smooth transactions. By addressing these considerations, businesses can capitalize on the growing need for automotive parts in various regions, including Africa, South America, the Middle East, and Europe.

3 Common User Pain Points for ‘2005 toyota camry transmission u250 torque converter’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Replacement Parts

The Problem:

B2B buyers often struggle with sourcing reliable replacement torque converters for the 2005 Toyota Camry with the U250 transmission. The market is flooded with options, but many parts are substandard or poorly remanufactured, leading to frequent failures and increased downtime. Buyers may find themselves in a bind when their existing suppliers cannot guarantee quality or availability, especially in regions with limited access to high-quality automotive components.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

The Solution:

To ensure sourcing high-quality torque converters, buyers should establish relationships with reputable manufacturers and suppliers known for their rigorous quality control processes. Conduct thorough due diligence by reviewing supplier certifications, customer testimonials, and product warranty policies. When selecting a torque converter, look for manufacturers who provide detailed specifications and performance features, such as those that include anti-balloon plates and high-performance friction materials. Additionally, consider suppliers that offer remanufactured options with a proven history of reliability, and always inquire about the manufacturing process to understand how they address common failure points.

Scenario 2: Incompatibility Issues with Aftermarket Parts

The Problem:

Many B2B buyers face challenges with aftermarket torque converters that claim to fit the 2005 Toyota Camry’s U250E transmission but do not perform as expected. This can lead to misalignment, poor vehicle performance, and even damage to the transmission system. Such compatibility issues can significantly increase maintenance costs and create frustration for fleet managers who rely on consistent vehicle performance.

The Solution:

To mitigate incompatibility issues, buyers should prioritize OEM (Original Equipment Manufacturer) parts or high-quality aftermarket alternatives specifically designed for the U250E transmission. It’s crucial to cross-reference part numbers and ensure that any aftermarket converter has been tested for compatibility with the 2005 Camry. Utilize suppliers that provide comprehensive installation guides and technical support to ensure correct fitment. Additionally, consider leveraging diagnostic tools to assess compatibility before purchasing, which can save time and prevent costly errors during installation.

Scenario 3: Performance Degradation Over Time

The Problem:

Over time, torque converters can experience performance degradation, leading to issues such as slipping, overheating, and inefficient power transfer. B2B buyers may notice that their fleet’s vehicles are consuming more fuel and exhibiting reduced acceleration, which can be attributed to a failing torque converter. This performance decline not only affects the vehicles’ reliability but also impacts operational costs.

The Solution:

To address performance degradation, regular maintenance and timely replacement of the torque converter are essential. Buyers should implement a proactive maintenance schedule that includes periodic inspections of the transmission fluid quality and levels, as well as monitoring for any unusual sounds or changes in vehicle behavior. When it comes time for replacement, choose torque converters that are built with advanced materials and engineering to withstand higher stress and provide enhanced performance. Look for options that feature upgraded components such as furnace-brazed turbines and high-performance clutches, as these can greatly improve longevity and performance. Establishing a partnership with a supplier that offers performance-enhanced options can ensure that your fleet remains efficient and reliable over time.

Strategic Material Selection Guide for 2005 toyota camry transmission u250 torque converter

What are the Key Materials Used in the 2005 Toyota Camry U250 Torque Converter?

When selecting materials for the 2005 Toyota Camry U250 torque converter, several factors must be considered, including performance characteristics, cost-effectiveness, and compliance with international standards. Here, we analyze four common materials: steel, aluminum, composite materials, and high-performance alloys.

How Does Steel Perform as a Material for Torque Converters?

Steel is a widely used material in torque converter manufacturing due to its strength and durability. It can withstand high temperatures and pressures, making it suitable for the demanding conditions of automotive applications. Steel’s corrosion resistance can be enhanced through coatings, which is crucial for longevity in various environments.

Pros: Steel offers excellent durability and high tensile strength, ensuring long service life even under high-stress conditions. It is relatively cost-effective, making it a popular choice for mass production.

Cons: The manufacturing complexity can increase due to the need for machining and heat treatment processes. Additionally, steel’s weight may contribute to increased vehicle weight, potentially impacting fuel efficiency.

Impact on Application: Steel components are compatible with a wide range of fluids and can handle the thermal and mechanical stresses associated with torque converter operations.

Considerations for International Buyers: Steel components must comply with ASTM standards for quality assurance. Buyers from regions like Europe and South America may prefer steel due to its availability and established supply chains.

What Role Does Aluminum Play in Torque Converter Construction?

Aluminum is another common material used in torque converters, particularly for components that benefit from reduced weight. Its lightweight nature can enhance fuel efficiency, making it an attractive option for automotive manufacturers.

Pros: Aluminum is lightweight, which can lead to improved vehicle performance and fuel economy. It also has good corrosion resistance, particularly when anodized or treated.

Cons: While aluminum is easier to machine than steel, it may not provide the same level of strength under extreme conditions. Additionally, it can be more expensive than steel, which may affect overall production costs.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Impact on Application: Aluminum is compatible with most automotive fluids but may require specific treatments to enhance its durability in high-stress environments.

Considerations for International Buyers: Compliance with standards such as DIN and JIS is essential for aluminum components. Buyers from regions like Africa and the Middle East may need to consider local availability and costs associated with aluminum.

How Do Composite Materials Enhance Torque Converter Performance?

Composite materials are increasingly being used in torque converters due to their potential for high strength-to-weight ratios and resistance to corrosion. These materials can be engineered to meet specific performance requirements.

Pros: Composites can be tailored for specific applications, providing excellent performance characteristics. They are lightweight and can reduce overall vehicle weight, positively impacting fuel efficiency.

Cons: The cost of composite materials is generally higher than traditional metals, and the manufacturing processes can be complex. Additionally, composites may not be as widely accepted in all markets.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Impact on Application: Composites can offer superior resistance to various automotive fluids, making them suitable for modern torque converters.

Considerations for International Buyers: Buyers should be aware of the varying acceptance of composite materials in different regions. Standards compliance may differ, requiring thorough research into local regulations.

What Advantages Do High-Performance Alloys Offer for Torque Converters?

High-performance alloys, such as those containing nickel or titanium, are designed for extreme conditions. These materials can withstand high temperatures and pressures, making them ideal for high-performance applications.

Pros: High-performance alloys provide exceptional strength and thermal stability, ensuring reliability in demanding environments. They are often used in racing applications due to their superior performance.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Cons: The cost of high-performance alloys can be significantly higher than traditional materials, which may not be feasible for all manufacturers. Additionally, the complexity of manufacturing these components can lead to longer lead times.

Impact on Application: These alloys are compatible with a range of fluids and can withstand extreme conditions, making them suitable for high-performance applications.

Considerations for International Buyers: Compliance with international standards for high-performance materials is crucial. Buyers in Europe and South America may prioritize these materials for their advanced applications.

Summary Table of Material Selection for 2005 Toyota Camry U250 Torque Converter

| Material | Typical Use Case for 2005 Toyota Camry Transmission U250 Torque Converter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Main structural components | Excellent durability and strength | Heavier weight | Medium |

| Aluminum | Housing and lightweight components | Lightweight, improves fuel efficiency | Less strength under extreme conditions | Medium |

| Composite Materials | Specialty applications requiring high strength-to-weight ratios | Tailored performance characteristics | Higher cost and manufacturing complexity | High |

| High-Performance Alloys | Racing applications and extreme environments | Exceptional strength and thermal stability | Very high cost and longer lead times | High |

This analysis provides a comprehensive overview of material options for the 2005 Toyota Camry U250 torque converter, aiding B2B buyers in making informed decisions tailored to their specific needs and regional considerations.

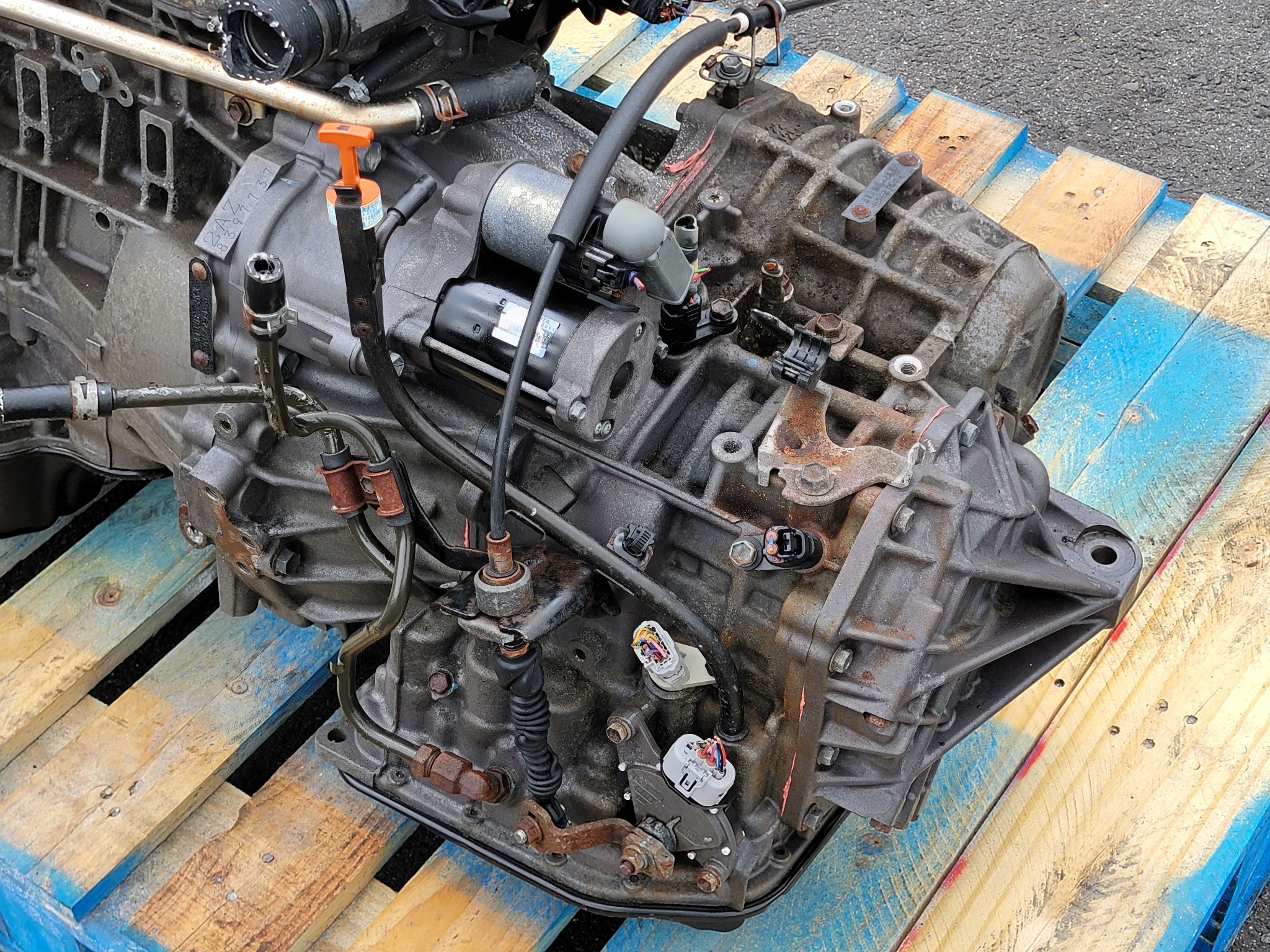

In-depth Look: Manufacturing Processes and Quality Assurance for 2005 toyota camry transmission u250 torque converter

What Are the Main Stages in the Manufacturing Process of the 2005 Toyota Camry U250 Torque Converter?

The manufacturing of the 2005 Toyota Camry U250 torque converter involves several critical stages, each designed to ensure the final product meets stringent performance and durability standards.

1. Material Preparation

The process begins with sourcing high-quality materials. Common materials used include high-strength steel for the housing and turbine, as well as friction materials for clutch components. Suppliers must adhere to international standards for material quality, such as ASTM or SAE, ensuring that only the best materials are selected for production.

2. Forming

Once the materials are prepared, they undergo forming processes. This typically includes stamping, machining, and welding. For instance, the housing is often stamped into shape, while the turbine and impeller may be machined for precision. Advanced techniques like CNC machining are employed to achieve tight tolerances, crucial for the torque converter’s performance.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

3. Assembly

The assembly stage integrates all components, including the turbine, impeller, and clutch elements. This phase often involves the use of automated assembly lines to enhance efficiency and consistency. Each unit is carefully assembled to ensure proper fit and function, which is critical for the torque converter’s operation.

4. Finishing

Finally, the torque converters undergo finishing processes, including surface treatment and balancing. Surface treatments may involve coating to enhance corrosion resistance, while balancing ensures that the converter operates smoothly at high speeds. This stage is essential for minimizing vibrations and enhancing the overall performance of the vehicle.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance is a vital part of the manufacturing process for the U250 torque converter, ensuring that each unit meets the required specifications and standards.

Relevant International Standards

Manufacturers often comply with international quality management standards such as ISO 9001. This certification ensures that the manufacturing process consistently produces products that meet customer and regulatory requirements. Additionally, manufacturers may adhere to industry-specific standards such as CE marking for products sold in Europe and API certifications for automotive components.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Key Quality Checkpoints

Quality control checkpoints are implemented throughout the manufacturing process to maintain high standards:

-

Incoming Quality Control (IQC): Materials are inspected upon arrival to verify their quality before production begins. This step prevents defective materials from entering the manufacturing process.

-

In-Process Quality Control (IPQC): During manufacturing, various checkpoints monitor the process to ensure that each stage meets quality standards. This includes checks on dimensions and assembly accuracy.

-

Final Quality Control (FQC): Once the torque converter is fully assembled, it undergoes a thorough inspection and testing phase. This typically includes performance tests to verify functionality, as well as visual inspections for any defects.

What Testing Methods Are Commonly Used for Torque Converters?

Testing methods for torque converters are critical to ensuring performance and reliability. Several testing techniques are commonly employed:

-

Hydraulic Testing: This test evaluates the converter’s ability to handle hydraulic pressure and fluid flow, ensuring that it operates as designed under various conditions.

-

Balance Testing: A precision balance test is conducted to ensure that the torque converter runs smoothly without excessive vibration, which could lead to premature failure.

-

Torque Testing: The converter’s ability to transmit torque under load is assessed, confirming that it meets the required performance specifications.

-

Durability Testing: Some manufacturers conduct extended durability tests to simulate real-world conditions, ensuring that the torque converter can withstand prolonged use.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Conducting Audits

Buyers should consider conducting regular audits of their suppliers. This can involve visiting manufacturing facilities to assess quality control measures firsthand. Audits should focus on the supplier’s adherence to ISO standards and their internal quality management systems.

Reviewing Quality Reports

Requesting quality reports and documentation from suppliers can provide insights into their manufacturing processes and quality assurance measures. These reports should detail inspection results, testing outcomes, and any corrective actions taken in response to quality issues.

Utilizing Third-Party Inspections

Engaging third-party inspection services can further enhance confidence in a supplier’s quality assurance processes. These services provide impartial evaluations of manufacturing practices, ensuring that products meet the required standards before shipment.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of specific quality control nuances that can affect procurement decisions.

Understanding Regional Standards

Different regions may have varying quality standards and certifications. For example, products sold in Europe must comply with CE marking requirements, while North American markets may emphasize compliance with SAE standards. B2B buyers should ensure that suppliers are well-versed in these regulations to avoid compliance issues.

Cultural Considerations in Quality Control

Cultural differences can also influence quality control practices. Buyers should engage with suppliers to understand their quality control philosophies and practices, ensuring alignment with the buyer’s expectations.

Establishing Clear Communication

Effective communication is vital for maintaining quality standards. Buyers should establish clear lines of communication with suppliers to address quality concerns promptly and ensure that any issues are resolved efficiently.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Conclusion

The manufacturing processes and quality assurance for the 2005 Toyota Camry U250 torque converter are crucial for delivering a reliable and high-performing product. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier practices, B2B buyers can make informed decisions that enhance their procurement strategies. This knowledge is particularly valuable for buyers operating in diverse international markets, where adherence to quality standards can significantly impact business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2005 toyota camry transmission u250 torque converter’

Introduction

This sourcing guide provides a structured approach for B2B buyers looking to procure the 2005 Toyota Camry U250 torque converter. It is essential to understand the technical specifications, supplier capabilities, and logistical considerations to ensure a successful procurement process. This checklist will help you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications required for the U250 torque converter. This includes understanding the diameter, spline count, and lock-up features, as these factors will determine compatibility with the transmission system.

– Key Specifications: The U250 torque converter typically features a diameter of 10.3 inches and 26 input splines. Knowing these details helps prevent compatibility issues and ensures optimal performance.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Step 2: Conduct Market Research

Understanding market trends and pricing for the U250 torque converter is crucial. Investigate various suppliers and manufacturers to gauge average costs and product availability.

– Price Comparison: Prices for remanufactured units can range from $197 to $287, depending on the supplier and specific features. This knowledge allows you to identify fair market value and negotiate better deals.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request company profiles, references, and case studies from buyers in similar industries or regions to assess their reliability and product quality.

– Supplier Credentials: Look for suppliers with certifications and a proven track record in manufacturing torque converters. This ensures that you are working with reputable companies that adhere to industry standards.

Step 4: Verify Product Quality and Warranty

Ensure that the torque converters you are considering are built to high-quality standards. Inquire about the manufacturing processes, materials used, and warranty terms offered by the suppliers.

– Quality Assurance: Suppliers should provide information about their quality control measures and the materials used in production. A solid warranty not only protects your investment but also reflects the supplier’s confidence in their product.

Step 5: Assess Logistics and Delivery Options

Evaluate the logistics involved in transporting the torque converter from the supplier to your location. Understanding shipping costs, delivery times, and core return policies will help you plan effectively.

– Shipping Considerations: Some suppliers may offer free shipping or expedited delivery options. Be sure to clarify these details upfront to avoid unexpected costs and delays.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. This step is vital for maximizing value and ensuring that both parties are aligned.

– Contractual Clarity: Ensure that all agreed-upon terms are documented clearly in a contract. This protects both parties and sets clear expectations for the transaction.

Step 7: Place Your Order and Monitor Progress

After finalizing the agreement, place your order and keep track of its status throughout the delivery process. Regular communication with your supplier will help address any potential issues promptly.

– Follow-Up: Stay in touch with the supplier to confirm shipping dates and to resolve any discrepancies. Proactive communication can prevent misunderstandings and ensure a smooth procurement process.

By following these steps, B2B buyers can effectively source the 2005 Toyota Camry U250 torque converter, ensuring they acquire the right product at the right price while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for 2005 toyota camry transmission u250 torque converter Sourcing

What Are the Key Cost Components in Sourcing a 2005 Toyota Camry U250 Torque Converter?

When evaluating the cost structure for the 2005 Toyota Camry U250 torque converter, several key components come into play. Understanding these can help B2B buyers make informed decisions.

-

Materials: The primary materials involved include high-grade steel, friction materials, and specialized components like the slotted hub and pilot. The quality of materials directly influences durability and performance, which in turn impacts pricing.

-

Labor: Labor costs can vary significantly based on geographic location and the expertise required. For instance, labor in countries with higher wages may lead to increased production costs, whereas manufacturers in regions with lower labor costs may offer more competitive pricing.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and operational costs associated with the production facility. Efficient manufacturing processes can reduce overhead, allowing for more competitive pricing.

-

Tooling: Custom tooling for specific torque converter designs can be a substantial upfront cost. However, if a supplier has existing tooling for the U250 model, this can help reduce initial costs, benefiting buyers.

-

Quality Control (QC): Rigorous QC processes are essential to ensure that each torque converter meets industry standards. High-quality components may come at a premium, but they often result in lower failure rates and increased longevity, leading to cost savings over time.

-

Logistics: Shipping costs, including packaging, freight, and customs duties, can add significantly to the total cost. Buyers should consider the logistics efficiency of their suppliers, as local sourcing can help mitigate these expenses.

-

Margin: Finally, the supplier’s desired profit margin will influence pricing. Understanding the typical margins within the industry can help buyers gauge if a quoted price is reasonable.

How Do Price Influencers Affect the Cost of U250 Torque Converters?

Several factors can influence the pricing of U250 torque converters, which buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases can often lead to discounts. Suppliers are typically more willing to negotiate prices for larger orders, making it beneficial for businesses with higher demand.

-

Specifications and Customization: Customized torque converters designed for specific performance requirements can incur additional costs. Buyers should balance their need for specialized features with budget constraints.

-

Quality and Certifications: Products that meet international quality standards or come with certifications may command higher prices. However, these typically offer better reliability and performance, which can justify the cost.

-

Supplier Factors: The reputation and reliability of suppliers play a critical role in pricing. Established suppliers may charge a premium due to their track record, while newer suppliers may offer lower prices to attract business.

-

Incoterms: The terms of delivery can significantly impact overall costs. Buyers should be aware of shipping responsibilities, insurance, and customs duties associated with Incoterms to accurately calculate total expenditures.

What Tips Can Help B2B Buyers Optimize Costs for U250 Torque Converters?

B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing torque converters:

-

Negotiate Effectively: Always approach negotiations with a clear understanding of market prices and competitor offerings. Leverage volume purchases and long-term partnerships to secure better deals.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with maintenance, warranty, and potential failures. A higher upfront investment in quality may lead to reduced TCO.

-

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, it’s crucial to account for currency fluctuations, import taxes, and regional demand variations, which can affect overall pricing.

-

Evaluate Supplier Diversity: Don’t limit your options to a single supplier. Exploring multiple suppliers can provide insights into competitive pricing and innovative solutions that may better meet your needs.

Disclaimer on Indicative Prices

The prices referenced in the sourcing analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough market research and obtain multiple quotes to ensure optimal pricing.

Alternatives Analysis: Comparing 2005 toyota camry transmission u250 torque converter With Other Solutions

Introduction to Alternative Torque Converter Solutions

When considering the replacement or upgrade of the 2005 Toyota Camry U250 torque converter, it’s crucial to evaluate viable alternatives that can meet or exceed performance expectations. Various options are available in the market, each designed with unique specifications and functionalities. By comparing these alternatives, B2B buyers can make informed decisions tailored to their specific operational needs, whether for vehicle maintenance, fleet management, or automotive repair services.

Comparison Table

| Comparison Aspect | 2005 Toyota Camry Transmission U250 Torque Converter | TC Remanufacturing Torque Converter | Precision of New Hampton (PNH) Torque Converter |

|---|---|---|---|

| Performance | Standard OEM specifications; reliable for daily use | Comparable performance; remanufactured quality | High-performance upgrades available; tailored solutions |

| Cost | $197.99 – $287.99 (plus core deposit) | $199.99 – $287.99 (plus core deposit) | Higher initial investment for performance options |

| Ease of Implementation | Direct fit; minimal adjustments needed | Easy installation; similar specifications | May require more expertise for high-performance setups |

| Maintenance | Standard maintenance required; OEM reliability | Similar maintenance as OEM | Regular checks recommended; performance components may require specialized care |

| Best Use Case | Ideal for standard driving conditions and general use | Suitable for similar applications; budget-friendly | Best for performance applications; racing or heavy-duty use |

Detailed Breakdown of Alternatives

TC Remanufacturing Torque Converter

This alternative presents a cost-effective solution for those seeking a reliable replacement for the U250 torque converter. With comparable performance to the original OEM part, it is remanufactured to meet stringent quality standards. The installation process is straightforward, requiring minimal adjustments, making it a practical choice for automotive shops. However, it may not offer the same level of performance enhancements as other options, making it less ideal for high-demand applications.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Precision of New Hampton (PNH) Torque Converter

For businesses focused on high performance, the PNH torque converter stands out as a premium alternative. This product is designed for extreme applications and includes features like high-performance friction materials and professional computer balancing. While the initial investment is higher, the benefits include enhanced durability and performance, making it suitable for racing or heavy-duty usage. However, the complexity of installation and maintenance may require specialized knowledge, potentially increasing operational costs for businesses lacking technical expertise.

Conclusion: Choosing the Right Torque Converter for Your Needs

In selecting the appropriate torque converter, B2B buyers should consider their specific use cases, budget constraints, and performance requirements. For standard applications, the original U250 torque converter or a remanufactured option like TC Remanufacturing provides reliable functionality at a reasonable price. In contrast, businesses aiming for high-performance applications should invest in the Precision of New Hampton converter, accepting the trade-off of higher costs and potential installation complexities for superior performance. Ultimately, understanding the operational needs and expected outcomes will guide buyers to the best torque converter solution for their fleet or repair services.

Essential Technical Properties and Trade Terminology for 2005 toyota camry transmission u250 torque converter

What Are the Key Technical Properties of the 2005 Toyota Camry U250 Torque Converter?

Understanding the technical specifications of the U250 torque converter is crucial for B2B buyers, particularly those in the automotive parts industry. Here are some essential properties:

-

Overall Diameter (OAD)

The overall diameter of the U250 torque converter is 10.3 inches. This measurement is critical because it affects the converter’s efficiency and compatibility with the vehicle’s transmission system. A precise diameter ensures optimal performance and minimizes issues like overheating. -

Pilot Diameter and Length

The pilot diameter is 0.826 inches, with a pilot length of 1.2 inches. These dimensions are vital for ensuring a proper fit within the transmission. Misalignment can lead to significant operational failures, making it essential for suppliers to maintain these specifications accurately. -

Input Splines

The U250 torque converter features 26 input splines. This specification is crucial for the torque converter’s engagement with the engine. Accurate spline count guarantees a secure connection, enhancing torque transfer and overall vehicle performance. -

Thread Specifications

The torque converter has a 9mm x 1.25 thread. Understanding thread specifications is important for installation and maintenance. Incorrect threading can lead to installation failures and increased wear on components, affecting longevity and reliability. -

Lock-Up Feature

The U250 includes a lock-up mechanism, which significantly enhances fuel efficiency by reducing slippage during high-speed driving. This feature is increasingly sought after in modern automotive applications, making it a key selling point for B2B transactions. -

Mounting Type

The mounting type for the U250 torque converter is a 6-pad configuration. This detail is important for compatibility with various transmission systems, and it ensures stability and reliability under various driving conditions.

What Trade Terminology Should B2B Buyers Know When Purchasing Torque Converters?

Familiarity with industry jargon can streamline communication and transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. For buyers, choosing OEM parts often means higher quality and compatibility, which can reduce warranty issues and maintenance costs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for inventory management and cost calculations. Buyers should evaluate their demand to determine if a supplier’s MOQ aligns with their purchasing strategy. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specific products. This term is crucial in B2B transactions, as it formalizes the process of obtaining pricing information, allowing for better budget planning and negotiation. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, ensuring smoother logistics and compliance with international trade regulations. -

Core Deposit

A core deposit is a fee charged when purchasing a remanufactured part, which is refundable upon returning the old part. This practice encourages recycling and helps manage the supply of remanufactured components, which can be beneficial for cost-conscious buyers. -

Technical Support

Technical support refers to assistance provided by manufacturers or suppliers regarding product installation, maintenance, and troubleshooting. For B2B buyers, knowing how to access technical support can facilitate smoother operations and reduce downtime.

Understanding these properties and terms can significantly enhance the purchasing process for B2B buyers, ensuring informed decisions and successful transactions in the automotive parts market.

Navigating Market Dynamics and Sourcing Trends in the 2005 toyota camry transmission u250 torque converter Sector

What Are the Key Market Dynamics and Trends Influencing the 2005 Toyota Camry Transmission U250 Torque Converter Sector?

The market for the 2005 Toyota Camry transmission U250 torque converter is characterized by several global drivers and trends that international B2B buyers should be aware of. One of the foremost trends is the increasing demand for high-quality remanufactured components, particularly in regions such as Africa, South America, and the Middle East, where cost-effectiveness is crucial. As OEM parts can be expensive, buyers are gravitating towards reputable remanufacturers who offer warranties and quality assurances. The shift towards e-commerce platforms for sourcing automotive parts is also noteworthy, allowing buyers from different geographical regions to access a wider range of suppliers and products, thereby fostering competition and driving prices down.

Emerging technologies, such as AI and machine learning, are enhancing supply chain efficiencies, allowing manufacturers to predict demand more accurately and optimize inventory management. Additionally, the rise of digital marketplaces enables buyers to compare products and suppliers easily, streamlining the procurement process. Sustainability considerations are increasingly influencing buying decisions, with more companies looking for suppliers who adhere to eco-friendly practices. Overall, the market is becoming more interconnected, with international buyers needing to stay informed about global sourcing trends to make competitive purchasing decisions.

How Is Sustainability and Ethical Sourcing Impacting the 2005 Toyota Camry Torque Converter Market?

Sustainability and ethical sourcing have become critical considerations in the automotive parts sector, including the 2005 Toyota Camry transmission U250 torque converter market. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to favor suppliers who implement eco-friendly practices, such as using recycled materials and minimizing waste. Certifications such as ISO 14001 for environmental management systems are becoming benchmarks for assessing suppliers’ commitment to sustainability.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Furthermore, ethical supply chains are essential to maintaining brand integrity and consumer trust. B2B buyers are increasingly conducting due diligence to ensure that their suppliers comply with labor laws and ethical standards. This emphasis on ethical sourcing not only benefits the environment but also enhances corporate social responsibility (CSR) profiles, which can be a significant differentiator in competitive markets.

As businesses strive to align with global sustainability goals, such as reducing carbon footprints, they are also seeking torque converters that incorporate ‘green’ technologies. This includes components designed for better fuel efficiency and reduced emissions, aligning with the automotive industry’s broader shift towards electrification and sustainability.

What Is the Historical Context of the 2005 Toyota Camry U250 Torque Converter?

The 2005 Toyota Camry U250 torque converter is part of a long lineage of automotive advancements in transmission technology. Introduced during a period of increasing consumer demand for reliable, fuel-efficient vehicles, the U250 transmission was designed to enhance driving performance while optimizing fuel consumption. Over the years, manufacturers have focused on refining the torque converter’s design, incorporating features such as lock-up clutches and improved materials to withstand higher performance demands.

The transition from traditional automatic transmissions to more advanced systems reflects a broader industry trend towards innovation. The U250E transmission, specifically, has gained recognition for its durability and efficiency, making it a popular choice among automotive repair professionals and B2B buyers alike. As the automotive landscape continues to evolve, the importance of sourcing high-quality components like the U250 torque converter remains vital for maintaining vehicle performance and reliability.

Illustrative image related to 2005 toyota camry transmission u250 torque converter

Frequently Asked Questions (FAQs) for B2B Buyers of 2005 toyota camry transmission u250 torque converter

-

How do I choose the right torque converter for a 2005 Toyota Camry with a U250 transmission?

When selecting a torque converter for the 2005 Toyota Camry with a U250 transmission, consider factors such as the converter’s specifications (diameter, spline count, and lock-up features), compatibility with your vehicle’s engine type, and intended usage (standard vs. performance). It’s essential to verify the part numbers and consult with suppliers about their offerings. Additionally, check for warranties and customer support to ensure that you’re purchasing from a reliable source. -

What is the best torque converter for performance upgrades on a 2005 Toyota Camry?

For performance upgrades, look for torque converters that feature enhanced designs, such as high-stall converters or those with reinforced components. Brands like PNH offer high-performance options that can handle increased horsepower and provide better torque transfer. Be sure to assess the specifications, such as the number of clutches and overall diameter, to match your performance goals. Consulting with a performance specialist can also provide insights tailored to your specific needs. -

What should I know about the pricing of torque converters for international purchases?

Pricing for torque converters can vary significantly based on factors such as manufacturer, shipping costs, and local tariffs. For international buyers, it’s crucial to consider the total landed cost, including shipping, customs duties, and any applicable taxes. Additionally, inquire about bulk purchase discounts or promotional offers that may be available. Always compare prices from multiple suppliers to ensure competitive rates. -

How can I vet suppliers of torque converters for the 2005 Toyota Camry?

To vet suppliers, start by checking their reputation through online reviews and industry references. Look for suppliers who provide detailed product specifications and have a transparent return policy. It’s also beneficial to request samples or visit the supplier’s facility if possible. Engaging in direct communication about their manufacturing processes and quality control measures can provide further assurance of their reliability and product quality. -

What are the minimum order quantities (MOQ) for torque converters, and how can it impact my purchasing decision?

Minimum order quantities for torque converters can vary by supplier, typically ranging from one unit for smaller suppliers to larger quantities for manufacturers. Understanding the MOQ is vital as it can impact your cash flow and inventory management. If you require a smaller quantity, consider suppliers who cater to small businesses or those that offer flexibility in ordering. Additionally, purchasing in bulk may provide cost savings per unit. -

What payment terms are typically offered by torque converter suppliers?

Payment terms can differ widely among suppliers, with options ranging from upfront payments to net 30 or net 60 terms. For international transactions, be aware of payment methods such as wire transfers, letters of credit, or escrow services, which can provide additional security. Negotiate favorable terms that align with your cash flow and operational needs. Always confirm the supplier’s payment policy before finalizing the transaction. -

How do I ensure quality assurance for torque converters sourced internationally?

To ensure quality assurance, request certifications and quality control documents from the supplier. Many manufacturers follow international standards such as ISO 9001, which indicates a commitment to quality management. Additionally, consider conducting third-party inspections or audits of the manufacturing facility. Establishing a clear communication channel for addressing any quality issues post-purchase is also essential. -

What logistics considerations should I keep in mind when importing torque converters?

When importing torque converters, consider factors such as shipping methods, transit times, and customs clearance processes. Choose a logistics partner experienced in handling automotive parts to navigate regulations and ensure timely delivery. Additionally, factor in storage solutions for inventory management upon arrival. Understanding the local import regulations in your country can also help avoid delays or additional costs.

Top 3 2005 Toyota Camry Transmission U250 Torque Converter Manufacturers & Suppliers List

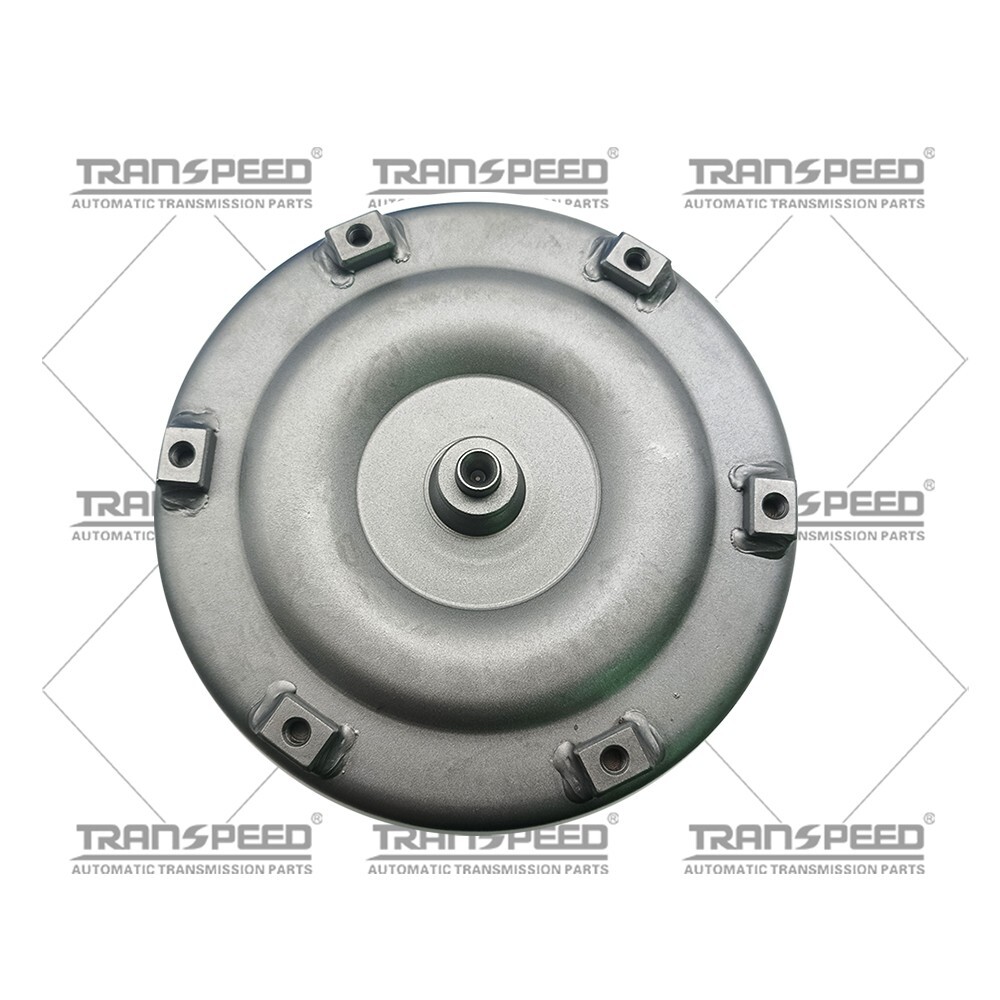

1. Toyota – 2.4L Camry Transmission U250E

Domain: gopnh.com

Registered: 2003 (22 years)

Introduction: {“Manufacturer”:”Toyota”,”Model/Engine”:”2.4L cyl. Camry”,”Transmission”:”U250E”,”Diameter”:”10.300″,”Pilot”:”0.826 stpd. 1.2″,”Input Splines”:”26″,”Ring Gear Teeth”:”Lock Up: YES”,”Hub Type”:”slotted hub”,”OAH”:”4.326″,”Bolt Circle”:”9.000″,”Mounting Type”:”6 pads”,”Thread”:”9mm x 1.25 thread”,”Codes”:”40A980, 43A980″,”Comments”:”Anti-Balloon Plate, Billeted Steel Cover, Billeted Turbine Hub, Ext…

2. TRANSPEED – U250E Torque Converter

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: {“product_name”:”TRANSPEED U250E U250 Auto Transmission Repair Torque Converter”,”compatible_vehicle”:”TOYOTA CAMRY”,”price”:”US$236.80″,”purchase_link”:”https://www.ebay.com”,”related_interests”:[“Transmission Repair”,”Torque Converter”,”Automatic Transmission”,”Toyota Camry”,”Toyota Repair”]}

3. Toyota – Automatic Transmission Torque Converter

Domain: toyotaparts.lakelandtoyota.com

Registered: 1996 (29 years)

Introduction: {“part_number”:”32000-33110″,”make”:”Toyota”,”model”:”Camry”,”years”:”2005-2006″,”part_type”:”Automatic Transmission Torque Converter”,”MSRP”:”$1,468.81″,”discount”:”$444.48 (30.3% off)”,”sale_price”:”$1,024.33″,”condition”:”New”,”manufacturer_warranty”:”Minimum of 12 Months”,”description”:”Japan Built Part”,”warning”:”California Proposition 65 WARNING: Cancer and reproductive harm – www.P65Warnin…

Strategic Sourcing Conclusion and Outlook for 2005 toyota camry transmission u250 torque converter

In conclusion, effective strategic sourcing of the 2005 Toyota Camry U250 torque converter presents a unique opportunity for international B2B buyers. The insights gathered highlight the importance of understanding specifications, supplier reliability, and market trends. With the U250E’s compatibility across various models and its remanufactured options, buyers can enhance their inventory management and meet diverse customer demands more efficiently.

As the global automotive parts market continues to evolve, staying informed about the latest advancements in torque converter technology and supplier capabilities will be crucial. Emphasizing quality and performance can significantly impact customer satisfaction and loyalty, especially in competitive regions like Africa, South America, the Middle East, and Europe.

International buyers are encouraged to engage with reputable suppliers who prioritize quality assurance and offer comprehensive support. By leveraging strategic sourcing practices, companies can secure high-quality products that meet their operational needs while optimizing costs. Moving forward, let’s work together to build resilient supply chains that not only meet today’s demands but also anticipate tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.