A Deep Dive into 1.5V C/Lr14 Solution

Introduction: Navigating the Global Market for 1.5v c/lr14

In the dynamic landscape of global commerce, sourcing reliable 1.5V C/LR14 batteries poses unique challenges for international B2B buyers. The proliferation of brands, varying quality standards, and fluctuating prices can make informed purchasing decisions daunting. This guide is designed to demystify the complexities of the 1.5V C/LR14 battery market, offering insights into different battery types, their applications across various industries, and essential criteria for supplier vetting.

We delve into the myriad applications of 1.5V C/LR14 batteries, from household devices to medical equipment, ensuring buyers understand where these batteries can deliver optimal performance. Additionally, we provide a detailed analysis of pricing structures and cost-effective procurement strategies, tailored specifically for businesses operating in regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Nigeria.

By equipping decision-makers with comprehensive knowledge and actionable insights, this guide empowers B2B buyers to navigate the global market with confidence, fostering partnerships that prioritize reliability, sustainability, and value. Whether you are looking to enhance your supply chain efficiency or ensure product quality, our resource offers the strategic framework needed to make sound purchasing decisions in today’s competitive environment.

Understanding 1.5v c/lr14 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alkaline C Battery (LR14) | Long shelf life (up to 10 years), reliable power output | Household electronics, flashlights, and toys | Pros: Cost-effective, widely available. Cons: Limited high-drain performance. |

| Rechargeable NiMH C Battery | Rechargeable, lower environmental impact | Portable electronics, emergency lighting | Pros: Eco-friendly, cost-saving in the long run. Cons: Higher upfront cost, shorter shelf life when not in use. |

| Lithium C Battery | High energy density, excellent performance in extreme temperatures | Professional devices, medical equipment | Pros: Long-lasting, stable in extreme conditions. Cons: More expensive, limited availability. |

| Heavy-Duty C Battery | Designed for low-drain devices, less power than alkaline | Toys, remote controls, and clocks | Pros: Economical for low-drain usage. Cons: Not suitable for high-drain applications. |

| Specialty C Battery | Specific formulations for unique applications | Specialized equipment, high-performance devices | Pros: Tailored for specific needs. Cons: Often higher cost and less availability. |

What are the Characteristics of Alkaline C Batteries (LR14)?

Alkaline C batteries, also known as LR14, are the most common type of 1.5V battery used in various household devices. They offer a long shelf life of up to 10 years and are designed to deliver reliable power for low to moderate-drain devices. B2B buyers often choose alkaline batteries due to their affordability and widespread availability. However, they may not be suitable for high-drain applications, where performance may diminish faster.

Why Choose Rechargeable NiMH C Batteries?

Rechargeable nickel-metal hydride (NiMH) C batteries are an eco-friendly alternative to traditional alkaline batteries. They can be recharged hundreds of times, making them a cost-effective option for businesses that frequently use battery-powered devices. While they have a lower initial voltage compared to alkaline batteries, their long-term savings and reduced environmental impact make them appealing for B2B buyers focused on sustainability. However, they may not hold their charge as long when stored, which is a consideration for buyers.

What Benefits Do Lithium C Batteries Offer?

Lithium C batteries are known for their high energy density and ability to perform well in extreme temperatures. This makes them ideal for professional applications such as medical devices and high-performance electronics. Although they come at a higher price point, their longevity and reliability in demanding conditions can justify the investment for businesses that require dependable power. However, the limited availability and cost can be a barrier for some buyers.

When to Use Heavy-Duty C Batteries?

Heavy-duty C batteries are designed for low-drain applications like toys and remote controls. They are generally more economical than alkaline batteries for devices that do not require high power output. B2B buyers looking to minimize costs for low-drain devices may find heavy-duty batteries to be a practical solution. However, their performance in high-drain situations is subpar, making them unsuitable for devices that demand more power.

What are the Applications of Specialty C Batteries?

Specialty C batteries are formulated for specific applications, such as high-performance devices or equipment that requires unique power characteristics. These batteries often come with tailored features to meet specific operational needs, making them invaluable in specialized industries. While they can be more expensive and less available than standard options, their targeted performance can be crucial for businesses that rely on precise power delivery.

Key Industrial Applications of 1.5v c/lr14

| Industry/Sector | Specific Application of 1.5v c/lr14 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Remote controls for TVs and audio devices | Ensures reliable operation of devices, enhancing user satisfaction | Quality assurance, shelf life, and compatibility with devices |

| Medical Equipment | Portable medical devices (e.g., blood pressure monitors) | Provides consistent power for critical health monitoring | Compliance with medical standards, reliability, and safety certifications |

| Security Systems | Alarm systems and surveillance cameras | Maintains functionality during power outages, ensuring safety | Long shelf life, resistance to temperature variations, and bulk purchasing options |

| Automotive Accessories | Flashlights and portable jump starters | Enhances safety and convenience for users in emergency situations | Durability, performance in extreme conditions, and supplier reputation |

| Industrial Equipment | Battery-operated tools and machinery | Reduces downtime and maintenance costs, improving operational efficiency | Availability of bulk orders, performance specifications, and support services |

How is 1.5v c/lr14 Used in Consumer Electronics?

In the consumer electronics sector, 1.5v c/lr14 batteries are predominantly utilized in remote controls for televisions, audio systems, and gaming devices. These batteries provide a reliable power source that enhances user experience by ensuring devices operate smoothly. For B2B buyers, key considerations include battery quality, compatibility with various devices, and the shelf life, particularly in regions like Africa and South America, where access to reliable power sources can be inconsistent.

Illustrative image related to 1.5v c/lr14

What Role Does 1.5v c/lr14 Play in Medical Equipment?

1.5v c/lr14 batteries are critical in powering portable medical devices such as blood pressure monitors and heart rate monitors. These devices require a steady and dependable power supply to ensure accurate readings and timely patient care. Buyers in the medical field must prioritize sourcing batteries that comply with health regulations and possess certifications for safety and reliability, especially in regions with stringent health standards like Europe and the Middle East.

How Are 1.5v c/lr14 Batteries Essential for Security Systems?

In security systems, 1.5v c/lr14 batteries are essential for powering alarm systems and surveillance cameras. These batteries ensure that security devices remain operational during power outages, which is crucial for maintaining safety and security. B2B buyers should focus on sourcing batteries with a long shelf life and the ability to perform well in various environmental conditions, especially in areas prone to extreme weather.

In What Ways Are 1.5v c/lr14 Batteries Used in Automotive Accessories?

1.5v c/lr14 batteries are commonly found in automotive accessories like flashlights and portable jump starters. These applications are vital for enhancing user safety and convenience during emergencies. When sourcing these batteries, businesses should consider factors such as durability and performance in extreme temperatures, which are especially pertinent in regions like Africa, where conditions can vary significantly.

How Does 1.5v c/lr14 Benefit Industrial Equipment?

In the industrial sector, 1.5v c/lr14 batteries power various battery-operated tools and machinery, helping to reduce downtime and maintenance costs. This efficiency is crucial for businesses aiming to enhance productivity. B2B buyers should look for suppliers that can provide bulk orders and detailed performance specifications, ensuring they receive reliable products that meet their operational needs, particularly in emerging markets in South America and Africa.

3 Common User Pain Points for ‘1.5v c/lr14’ & Their Solutions

Scenario 1: Inconsistent Performance in Critical Equipment

The Problem: B2B buyers often face the challenge of ensuring that devices powered by 1.5V C/LR14 batteries, such as medical equipment or industrial tools, operate reliably. Inconsistent battery performance can lead to device malfunction during critical operations, which is particularly concerning in sectors like healthcare or manufacturing. The stakes are high; a failure could result in operational delays, safety risks, or significant financial loss.

The Solution: To mitigate this risk, buyers should prioritize sourcing batteries from reputable manufacturers known for quality and reliability, such as Duracell or Energizer. It is advisable to conduct a performance comparison of different brands and models, focusing on specifications like shelf life, capacity, and discharge rates. Implementing a systematic battery testing protocol before deployment can also help ensure that only high-performing batteries are used in essential devices. Regularly scheduled inventory checks will assist in managing battery expiration and replacement proactively, ensuring that devices always have reliable power.

Scenario 2: Challenges in Bulk Purchasing and Supply Chain Issues

The Problem: Many businesses in regions like Africa and South America encounter difficulties when it comes to bulk purchasing 1.5V C/LR14 batteries. These challenges often stem from inconsistent supply chains, fluctuating prices, and limited access to trusted suppliers. As a result, businesses may find themselves with inadequate stock when demand spikes, leading to operational disruptions.

The Solution: Establishing relationships with multiple suppliers can provide a buffer against supply chain disruptions. Buyers should evaluate local distributors and international suppliers that offer bulk purchasing options with favorable terms. Consider negotiating long-term contracts to lock in prices and ensure consistent supply. Additionally, utilizing data analytics to forecast demand can help in planning purchases more effectively. Creating an inventory management system that tracks usage rates will also aid in preventing shortages and optimizing stock levels.

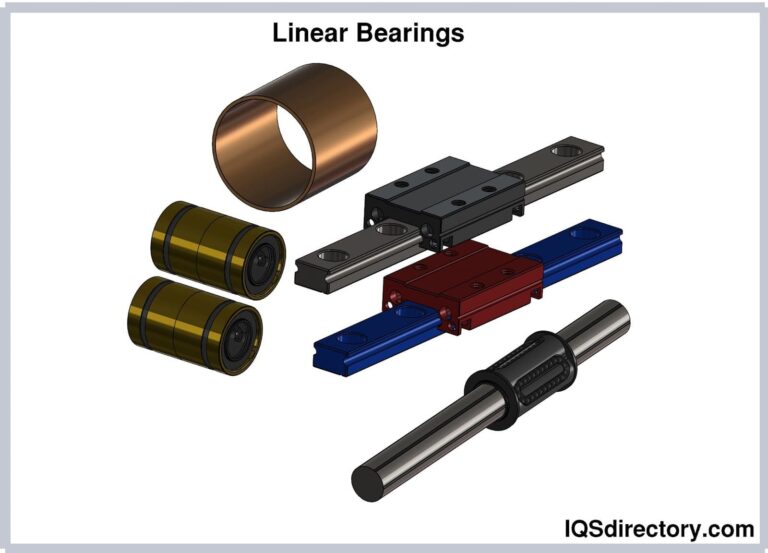

Illustrative image related to 1.5v c/lr14

Scenario 3: Environmental Concerns and Battery Disposal

The Problem: With increasing regulatory scrutiny on environmental sustainability, B2B buyers are often faced with the challenge of responsibly disposing of used 1.5V C/LR14 batteries. Improper disposal can lead to legal repercussions and damage to the company’s reputation, especially in regions where environmental regulations are stringent.

The Solution: To address this concern, businesses should implement a comprehensive battery recycling program. This involves educating staff on proper disposal methods and partnering with certified recycling facilities that can handle alkaline batteries. Buyers can also explore suppliers that offer take-back programs, where old batteries can be returned for recycling. By incorporating eco-friendly practices into their operations, companies not only comply with regulations but also enhance their brand image as environmentally responsible organizations. Additionally, promoting sustainability initiatives internally can foster a culture of environmental awareness among employees.

Strategic Material Selection Guide for 1.5v c/lr14

What Are the Key Materials Used in 1.5V C/LR14 Batteries?

When selecting materials for 1.5V C/LR14 batteries, it’s essential to consider the properties and performance of the materials involved. The most common materials used in the construction of these batteries include alkaline manganese dioxide, zinc, and plastic. Each material has its unique characteristics that affect battery performance, durability, and cost.

Alkaline Manganese Dioxide: The Core Component

Alkaline manganese dioxide is the primary chemical used in 1.5V C/LR14 batteries. This material is known for its high energy density and long shelf life, making it suitable for various applications, including household electronics and medical devices.

- Key Properties: Offers a nominal voltage of 1.5V, operates effectively in a temperature range of -18°C to 55°C, and has a typical shelf life of up to 10 years.

- Pros: High energy output, low self-discharge rate, and reliable performance in high-drain devices.

- Cons: More expensive than zinc-carbon batteries and may not perform as well in extreme temperatures.

- Impact on Application: Ideal for devices requiring consistent and long-lasting power, such as flashlights and portable stereos.

- Considerations for International Buyers: Compliance with international standards like IEC 60086 is crucial. Buyers from regions like Africa and South America should also consider local climate conditions that may affect battery performance.

Zinc: A Cost-Effective Alternative

Zinc is often used as a negative electrode material in alkaline batteries, including the 1.5V C/LR14. Its affordability makes it a popular choice for manufacturers looking to reduce costs.

- Key Properties: Provides a lower energy density compared to alkaline manganese dioxide but is highly effective for low-drain applications.

- Pros: Cost-effective, widely available, and environmentally friendly due to its non-toxic nature.

- Cons: Limited shelf life and performance in high-drain applications, which can lead to quicker depletion.

- Impact on Application: Suitable for low-drain devices, such as remote controls and clocks, but not ideal for high-performance electronics.

- Considerations for International Buyers: Buyers should be aware of local regulations regarding battery disposal, especially in regions with strict environmental laws.

Plastic: The Essential Housing Material

Plastic is commonly used in the casing of 1.5V C/LR14 batteries. It provides structural integrity and protects the internal components from environmental factors.

- Key Properties: Lightweight, corrosion-resistant, and can be molded into various shapes and sizes.

- Pros: Cost-effective, durable, and can be produced in bulk with minimal waste.

- Cons: Not biodegradable, which raises environmental concerns, and may not provide adequate protection in extreme conditions.

- Impact on Application: Essential for ensuring the battery maintains its integrity and performance during use.

- Considerations for International Buyers: Buyers should consider sourcing plastics that comply with local environmental regulations, particularly in Europe where there are stringent recycling laws.

Summary Table of Material Selection for 1.5V C/LR14 Batteries

| Material | Typical Use Case for 1.5V C/LR14 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alkaline Manganese Dioxide | Household electronics, medical devices | High energy density and long shelf life | Higher cost than zinc-carbon batteries | High |

| Zinc | Low-drain devices like remote controls | Cost-effective and environmentally friendly | Limited shelf life and performance | Low |

| Plastic | Battery casing and structural integrity | Durable and lightweight | Environmental concerns (non-biodegradable) | Medium |

This guide provides B2B buyers with essential insights into the materials used in 1.5V C/LR14 batteries, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 1.5v c/lr14

What Are the Key Stages in the Manufacturing Process of 1.5V C/LR14 Batteries?

The manufacturing process for 1.5V C/LR14 batteries is a complex procedure that involves several key stages: material preparation, forming, assembly, and finishing.

Illustrative image related to 1.5v c/lr14

Material Preparation

The first stage of manufacturing starts with the careful selection and preparation of raw materials. The primary components of alkaline batteries, including zinc powder, manganese dioxide, potassium hydroxide, and carbon, are sourced from reputable suppliers. Quality assurance begins at this stage, as the purity and consistency of these materials directly impact the battery’s performance and longevity. Suppliers often undergo rigorous vetting to ensure they meet industry standards.

Forming

In the forming stage, the prepared materials are processed to create the battery components. This includes the mixing of the active materials and the production of the anode and cathode. The mixture is pressed into the desired shapes and sizes, which are then dried to remove moisture. Advanced techniques such as automated pressing and precise temperature control ensure uniformity in the battery components, which is crucial for achieving optimal performance.

Assembly

The assembly stage involves the integration of all battery components into a single unit. Automated machinery is typically used to enhance efficiency and reduce human error. Components such as the anode, cathode, separator, and electrolyte are assembled in a clean environment to prevent contamination. The battery casing is then sealed to protect against external elements. This stage is critical, as any defects can lead to performance issues or safety hazards.

Finishing

The final stage is finishing, where the batteries undergo various treatments to enhance their performance and longevity. This includes labeling, packaging, and additional quality checks. Batteries are often subjected to aging tests to ensure they meet the required shelf life and performance specifications. Quality control measures during this stage focus on the physical and chemical properties of the batteries, ensuring they adhere to international standards.

What Quality Assurance Measures Are Commonly Used in Battery Manufacturing?

Quality assurance (QA) in the manufacturing of 1.5V C/LR14 batteries is paramount to ensure that the final product meets safety and performance standards. Several international and industry-specific standards guide these processes.

International Standards and Certifications

Manufacturers often comply with ISO 9001, which outlines the requirements for a quality management system. This certification ensures that the manufacturing process consistently meets customer and regulatory requirements. Other relevant certifications may include CE marking, which indicates compliance with European health, safety, and environmental protection standards.

Industry-Specific Quality Control Checkpoints

Quality control is segmented into various checkpoints during the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival at the factory. Tests may include visual inspections and laboratory analysis to verify material integrity.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular checks are performed to monitor the process. This may involve measuring the dimensions of components or testing the chemical composition of materials.

-

Final Quality Control (FQC): Before shipping, batteries undergo extensive testing to ensure they meet performance specifications. This can include capacity testing, leakage testing, and safety assessments.

What Testing Methods Are Commonly Used to Ensure Battery Quality?

Testing methods are essential to validate the performance and safety of 1.5V C/LR14 batteries. Commonly used methods include:

-

Capacity Testing: Measures the battery’s ability to hold and deliver charge over a specified period.

-

Leakage Testing: Ensures that the battery casing is sealed correctly and free from leaks, which could compromise performance and safety.

-

Shelf Life Testing: Batteries are subjected to long-term storage conditions to assess how well they maintain their charge over time.

-

Temperature Cycling: Tests the battery’s performance under extreme temperature variations, simulating real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of battery suppliers is crucial.

Audits and Supplier Evaluations

Conducting audits is one of the most effective ways to assess a supplier’s quality assurance practices. Buyers can request to see documentation of certifications, quality control processes, and past audit reports. Regular audits help maintain transparency and ensure adherence to quality standards.

Quality Reports and Testing Documentation

Buyers should request detailed quality reports from suppliers, outlining the results of various tests conducted on the batteries. This documentation should include information on compliance with international standards and any certifications obtained.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These services can conduct on-site inspections and testing, offering buyers peace of mind regarding the reliability of the products they are sourcing.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate several nuances when dealing with quality control in battery manufacturing.

Understanding Regional Standards

Different regions may have specific regulatory requirements that batteries must meet. For instance, batteries sold in Europe must comply with the EU’s Battery Directive, which sets standards for battery disposal and recycling. Buyers should familiarize themselves with these regulations to ensure compliance.

Language and Communication Barriers

Language differences can complicate the verification of quality control measures. Buyers should ensure that documentation is available in a language they understand and that suppliers are capable of communicating effectively about quality issues.

Cultural Considerations

Cultural differences may affect how quality control is perceived and implemented. Understanding the local business culture can help buyers navigate negotiations and establish stronger relationships with suppliers.

Conclusion

The manufacturing processes and quality assurance measures for 1.5V C/LR14 batteries are critical for ensuring reliable performance and safety. By understanding the key stages of production, relevant quality standards, testing methods, and verification processes, B2B buyers can make informed decisions when sourcing batteries from international suppliers. Adhering to these practices not only enhances product quality but also builds trust and long-term partnerships in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1.5v c/lr14’

To assist international B2B buyers in sourcing 1.5V C/LR14 batteries effectively, this guide provides a structured checklist that outlines critical steps in the procurement process. By following these steps, buyers can ensure they select the best suppliers and products to meet their needs.

Step 1: Define Your Technical Specifications

Begin by determining the specific technical requirements for the 1.5V C/LR14 batteries you need. Consider factors such as voltage, chemistry (alkaline, lithium, etc.), and capacity. This clarity helps in selecting a product that aligns with your applications, whether for consumer electronics, medical devices, or industrial use.

- Voltage: Ensure it meets the required 1.5V.

- Chemistry: Choose between alkaline and other types based on discharge rates and shelf life.

Step 2: Research Market Trends and Pricing

Understand current market dynamics to identify competitive pricing and trends in battery technology. This knowledge helps in negotiating better prices and ensuring you’re not overpaying for outdated products.

- Check multiple suppliers for price comparisons.

- Investigate emerging battery technologies that may provide better performance.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Look for company profiles, product certifications, and references from other businesses in similar industries.

Illustrative image related to 1.5v c/lr14

- Request case studies or testimonials to gauge reliability.

- Ensure suppliers adhere to international standards and regulations for battery production.

Step 4: Verify Supplier Certifications

Confirm that suppliers possess relevant certifications to guarantee product quality and safety. This includes certifications like ISO, IEC, and any local compliance standards specific to your region.

- Check for environmental compliance, especially if sourcing from regions with strict regulations.

- Look for certifications that ensure the absence of harmful substances in battery production.

Step 5: Request Samples for Testing

Before placing a bulk order, request samples of the 1.5V C/LR14 batteries for testing. This step allows you to evaluate performance, longevity, and compatibility with your devices.

- Assess the battery’s shelf life, discharge rates, and overall quality.

- Conduct tests in real-world applications to ensure they meet your requirements.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate terms that protect your interests. This includes pricing, payment terms, delivery schedules, and return policies.

- Ensure clarity on minimum order quantities and lead times.

- Discuss warranty terms and support for defective products.

Step 7: Establish a Reliable Supply Chain

Finally, ensure that your supply chain is robust and capable of meeting your ongoing needs. This involves setting up agreements that allow for timely reorders and maintaining communication with your supplier for any future changes.

- Consider establishing long-term contracts for better pricing stability.

- Maintain regular check-ins to discuss any product updates or improvements.

By following this structured approach, B2B buyers can effectively navigate the complexities of sourcing 1.5V C/LR14 batteries, ensuring they secure high-quality products that meet their operational needs.

Illustrative image related to 1.5v c/lr14

Comprehensive Cost and Pricing Analysis for 1.5v c/lr14 Sourcing

What Are the Key Cost Components for 1.5V C/LR14 Batteries?

When sourcing 1.5V C/LR14 batteries, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The main materials used in alkaline batteries are zinc, manganese dioxide, and other chemical compounds. The quality and source of these materials significantly affect the overall cost. Suppliers that use high-quality, sustainable materials may charge a premium, but this can lead to better performance and longer shelf life.

-

Labor: Labor costs encompass the workforce needed for production, assembly, and quality control. Regions with lower labor costs may offer competitive pricing, but it’s essential to balance this with quality assurance.

-

Manufacturing Overhead: This includes utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can reduce overhead costs, which can be reflected in the pricing of the batteries.

-

Tooling: The initial investment in molds and production tools can be substantial, especially for custom battery designs. This cost is typically amortized over larger production runs, making it essential for buyers to consider minimum order quantities (MOQs).

-

Quality Control (QC): Robust QC processes ensure product reliability and compliance with international standards. While this adds to the cost, it is a necessary expense to minimize returns and maintain brand reputation.

-

Logistics: Transportation and warehousing costs can vary significantly based on the sourcing country and destination. International shipping, tariffs, and insurance should all be factored into the total cost.

-

Margin: Suppliers will add a profit margin to their costs. Understanding the typical margin in your supplier’s region can aid in negotiation.

How Do Price Influencers Impact 1.5V C/LR14 Battery Costs?

Several factors can influence the pricing of 1.5V C/LR14 batteries:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer significant discounts for bulk purchases, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Batteries designed for specific applications may incur additional costs due to custom specifications. Buyers should weigh the necessity of these features against their budget.

-

Materials and Quality Certifications: Batteries that meet higher quality standards or certifications (e.g., RoHS, CE) may cost more but can provide reassurance regarding safety and performance.

-

Supplier Factors: The supplier’s location, reputation, and reliability can affect pricing. Established brands may command higher prices due to perceived quality and trust.

-

Incoterms: Understanding the delivery terms can significantly influence total costs. Different Incoterms (e.g., FOB, CIF) can shift responsibility and costs between buyers and sellers, impacting overall pricing.

What Tips Can Buyers Utilize for Cost-Efficiency in Sourcing?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, here are actionable tips:

-

Negotiate Effectively: Understand the supplier’s pricing structure and be prepared to negotiate based on volume, payment terms, and delivery schedules. Establishing a long-term relationship can also provide leverage for better pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also factors such as shipping, storage, and disposal costs. Batteries with longer shelf lives may reduce TCO by minimizing waste.

-

Assess Pricing Nuances for International Markets: Be aware of currency fluctuations and local economic conditions that may impact pricing. Understanding regional market dynamics can enhance negotiation strategies.

-

Leverage Local Suppliers: Whenever possible, consider sourcing from local manufacturers to reduce logistics costs and lead times. This can also simplify quality control processes.

-

Stay Informed on Market Trends: Regularly review market trends and competitor pricing to make informed sourcing decisions. This knowledge can provide leverage in negotiations and help avoid overpaying.

Disclaimer on Indicative Prices

Prices for 1.5V C/LR14 batteries can vary widely based on the aforementioned factors. It’s essential for buyers to conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing. Always verify current market conditions and consult with suppliers for the most accurate pricing information.

Alternatives Analysis: Comparing 1.5v c/lr14 With Other Solutions

Exploring Alternatives to the 1.5V C/LR14 Battery

When evaluating battery solutions, it is essential for B2B buyers to consider not just one option but a range of alternatives that can meet specific operational needs. The 1.5V C/LR14 battery is widely used for various devices, but several alternatives may offer distinct advantages depending on the application, cost considerations, and maintenance requirements. Below is a comparative analysis of the 1.5V C/LR14 battery against two viable alternatives: rechargeable NiMH batteries and lithium batteries.

Illustrative image related to 1.5v c/lr14

| Comparison Aspect | 1.5V C/LR14 | Rechargeable NiMH Batteries | Lithium Batteries |

|---|---|---|---|

| Performance | Consistent power for household devices | High capacity and rechargeability, but lower voltage (1.2V) | Higher energy density and longer shelf life |

| Cost | Relatively low ($2.50 each) | Higher upfront cost ($10-$15 each) but cost-effective over time | Moderate to high ($5-$10 each) |

| Ease of Implementation | Simple, plug-and-play usage | Requires compatible charger | Easy installation, but disposal can be complex |

| Maintenance | Low maintenance; single-use | Requires periodic charging and maintenance | Low maintenance; long life span |

| Best Use Case | Everyday household electronics | Devices requiring frequent use, like cameras | High-drain devices like digital cameras and medical equipment |

Understanding Rechargeable NiMH Batteries

Rechargeable Nickel-Metal Hydride (NiMH) batteries present a compelling alternative to the 1.5V C/LR14. While they typically operate at a lower voltage (1.2V), they can be recharged hundreds of times, making them cost-effective in the long run. NiMH batteries are particularly beneficial for devices that require frequent power, such as digital cameras or gaming controllers. However, they do require a compatible charger and may have a shorter shelf life compared to alkaline batteries, which could lead to performance concerns if not used regularly.

Evaluating Lithium Batteries

Lithium batteries are another strong alternative, known for their high energy density and long shelf life. They can provide a reliable power source for high-drain devices, making them ideal for applications in medical equipment or advanced electronics. While lithium batteries tend to have a higher initial cost, their longevity and performance can offset this expense over time. However, disposal and recycling can pose challenges due to environmental regulations, which may be a consideration for businesses committed to sustainability.

Conclusion: How to Choose the Right Battery Solution

For B2B buyers, selecting the appropriate battery solution involves assessing the specific needs of their applications. The 1.5V C/LR14 battery is an excellent choice for low-maintenance, everyday devices, while rechargeable NiMH batteries may be more suitable for devices that see frequent use. On the other hand, lithium batteries excel in high-drain scenarios but come with a higher upfront investment and disposal complexities. Ultimately, understanding the operational requirements, budget constraints, and environmental considerations will guide businesses in making the most informed decision for their power solutions.

Essential Technical Properties and Trade Terminology for 1.5v c/lr14

What Are the Key Technical Properties of 1.5V C/LR14 Batteries?

-

Nominal Voltage

The nominal voltage of 1.5V indicates the standard voltage output of the battery. This specification is crucial for ensuring compatibility with devices designed to operate at this voltage level, such as flashlights, portable radios, and various household appliances. Buyers must verify that the devices they supply to can utilize this voltage to avoid operational failures. -

Battery Chemistry

Most 1.5V C/LR14 batteries are alkaline, which means they utilize a chemical reaction between zinc and manganese dioxide to generate electricity. Alkaline batteries are favored for their long shelf life and energy density, making them suitable for both high-drain and low-drain devices. Understanding the chemistry helps buyers assess the suitability of batteries for specific applications. -

Shelf Life

The shelf life of a 1.5V C/LR14 battery can range up to 10 years when stored under optimal conditions. This property is vital for B2B buyers who need to manage inventory effectively, ensuring that batteries remain functional when needed, especially in industries where emergency preparedness is crucial. -

Dimensions and Weight

The standard size for a C/LR14 battery is approximately 26.2 mm in diameter and 50 mm in height, with a typical weight around 66 grams. Accurate knowledge of these dimensions is essential for manufacturers and distributors to ensure compatibility with battery holders and devices, optimizing logistics and storage. -

Terminal Type

C/LR14 batteries typically have flat contact terminals. This specification affects how batteries connect with devices, influencing both performance and safety. Understanding terminal types is essential for ensuring that the batteries will fit securely into devices without risk of malfunction. -

Operating Temperature Range

The operational temperature range for 1.5V C/LR14 batteries usually spans from -18°C to 55°C (0°F to 130°F). This factor is critical for applications in diverse environments, such as outdoor equipment or industrial settings. Buyers need to consider the temperature specifications to ensure the batteries will perform reliably under expected conditions.

What Are Common Trade Terms Related to 1.5V C/LR14 Batteries?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce products that are marketed under another company’s brand. In the context of batteries, an OEM might produce 1.5V C/LR14 batteries that are branded and sold by a different company. Understanding OEM relationships can help buyers identify reliable suppliers and manufacturers. -

MOQ (Minimum Order Quantity)

MOQ specifies the least number of units a buyer must purchase in a single order. This term is important for budgeting and inventory management, as it directly affects the cost and feasibility of procurement. Buyers should negotiate MOQs that align with their sales forecasts and storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price estimates on specific products. For B2B buyers, issuing an RFQ for 1.5V C/LR14 batteries allows them to compare prices, terms, and delivery options, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping, risk, and cost responsibilities when sourcing batteries globally. -

BOM (Bill of Materials)

A BOM is a comprehensive list of materials and components required to manufacture a product. In the battery industry, this includes specifications for 1.5V C/LR14 batteries. A well-defined BOM helps streamline production and ensures that all necessary components are available. -

Battery Life Cycle

This term refers to the duration a battery can operate effectively before it needs to be replaced. Understanding the life cycle of 1.5V C/LR14 batteries is essential for B2B buyers to evaluate long-term costs and performance, especially in applications requiring frequent battery replacements.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions regarding their procurement strategies for 1.5V C/LR14 batteries, enhancing their supply chain efficiency and product reliability.

Illustrative image related to 1.5v c/lr14

Navigating Market Dynamics and Sourcing Trends in the 1.5v c/lr14 Sector

What Are the Key Trends Shaping the 1.5V C/LR14 Battery Market?

The global market for 1.5V C/LR14 batteries is being driven by several key factors, including the increasing demand for portable electronic devices, the growth of the renewable energy sector, and a shift towards more efficient battery technologies. As consumers and industries alike prioritize sustainability, there is a rising interest in rechargeable battery options, which are more environmentally friendly and economically viable in the long term.

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. In emerging markets, the proliferation of consumer electronics is leading to a higher demand for reliable power sources. Conversely, in developed markets, the focus is on sourcing high-quality batteries that offer longevity and performance, particularly for high-drain devices.

Emerging technologies such as smart batteries with integrated monitoring systems and innovations in battery chemistry are also influencing sourcing trends. These advancements not only enhance battery performance but also allow for better energy management in devices, appealing to environmentally conscious businesses. Moreover, partnerships with local suppliers can facilitate faster delivery times and reduced logistical costs, which is essential for maintaining competitive pricing in these regions.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the 1.5V C/LR14 Sector?

Sustainability and ethical sourcing are paramount considerations for B2B buyers in the 1.5V C/LR14 battery market. The environmental impact of battery production, particularly concerning the mining of raw materials, necessitates a focus on responsible sourcing practices. Buyers should prioritize suppliers that adhere to recognized environmental standards and certifications, such as ISO 14001, which demonstrates a commitment to minimizing ecological footprints.

Additionally, the increasing availability of ‘green’ materials and technologies—such as batteries that utilize recycled components or are free from harmful substances like mercury—offers a pathway for businesses to align with sustainability goals. Engaging with suppliers who prioritize ethical labor practices and transparent supply chains not only mitigates risks associated with reputational damage but also appeals to a growing consumer base that values corporate responsibility.

Implementing a comprehensive sustainability strategy can also lead to cost savings over time, as energy-efficient products often result in lower operational costs. B2B buyers should seek partnerships with manufacturers who invest in research and development aimed at creating more efficient, sustainable battery solutions, ensuring they stay ahead in a competitive landscape.

Illustrative image related to 1.5v c/lr14

What Is the Historical Context of 1.5V C/LR14 Battery Development?

The 1.5V C/LR14 battery has evolved significantly since its introduction in the mid-20th century. Initially designed for household devices, these batteries have undergone numerous improvements in chemistry and manufacturing processes, leading to enhanced performance and reliability. The transition from zinc-carbon to alkaline technologies marked a significant milestone, providing longer shelf lives and better energy density.

In recent years, the focus has shifted towards developing batteries that not only meet consumer demands but also adhere to stricter environmental regulations. Innovations in battery recycling and the reduction of hazardous materials have become critical, reflecting a broader trend towards sustainability in the battery manufacturing sector. Understanding this evolution is essential for B2B buyers, as it highlights the importance of sourcing from manufacturers who are committed to ongoing innovation and environmental stewardship.

In conclusion, navigating the 1.5V C/LR14 battery market requires a keen awareness of emerging trends, a commitment to sustainability, and an understanding of the historical context that shapes current practices. By aligning sourcing strategies with these insights, international B2B buyers can make informed decisions that enhance their competitive edge and contribute positively to the environment.

Frequently Asked Questions (FAQs) for B2B Buyers of 1.5v c/lr14

-

How do I choose the right supplier for 1.5V C/LR14 batteries?

Selecting the right supplier for 1.5V C/LR14 batteries involves evaluating several key factors. Start by checking the supplier’s certifications and compliance with international quality standards, such as ISO 9001. Look for suppliers with a proven track record and positive reviews from other B2B buyers in your region. Additionally, consider their manufacturing capabilities and whether they can meet your specific demands, such as custom packaging or branding. Request samples to assess product quality before making a larger commitment. -

What is the typical minimum order quantity (MOQ) for 1.5V C/LR14 batteries?

Minimum order quantities for 1.5V C/LR14 batteries can vary significantly between suppliers, typically ranging from 100 to 1,000 units per order. Some manufacturers may offer lower MOQs for first-time buyers or bulk purchases. It’s advisable to clarify the MOQ during initial discussions and assess how it aligns with your inventory needs. Always factor in the potential for future orders, as establishing a solid relationship with your supplier can lead to more favorable terms over time. -

What payment terms are commonly accepted by suppliers of 1.5V C/LR14 batteries?

Payment terms can differ widely among suppliers, but common practices include payment in advance, net 30, or net 60 days upon receipt of goods. Some suppliers may also offer letters of credit or escrow services for larger transactions to provide security for both parties. Before finalizing an agreement, ensure you understand the payment terms and negotiate any conditions that could impact your cash flow. Always request a pro forma invoice that outlines all costs clearly. -

What quality assurance measures should I expect from battery suppliers?

Reputable battery suppliers typically implement rigorous quality assurance (QA) measures, including multiple stages of testing during production and before shipment. Look for suppliers that provide certifications or reports indicating compliance with international safety standards, such as IEC or ANSI. It’s also beneficial to inquire about their return policy for defective products and whether they offer warranties. Establishing clear QA expectations from the outset will help ensure product reliability and performance. -

How can I effectively manage logistics for importing 1.5V C/LR14 batteries?

Managing logistics for importing 1.5V C/LR14 batteries involves careful planning and coordination. Collaborate closely with your supplier to understand shipping options, estimated delivery times, and customs requirements for your region. Consider partnering with a freight forwarder experienced in battery imports to navigate regulations and ensure compliance with local laws. Additionally, factor in lead times and potential delays in your supply chain planning to maintain consistent inventory levels. -

Are there customization options available for 1.5V C/LR14 batteries?

Many suppliers offer customization options for 1.5V C/LR14 batteries, including private labeling, custom packaging, and specific branding requirements. When discussing customization, be clear about your needs and the quantities required, as some modifications may have minimum order restrictions. Additionally, inquire about the design process and timelines to ensure that your branding aligns with your marketing strategy. This can help differentiate your products in a competitive market. -

What are the common applications for 1.5V C/LR14 batteries in various industries?

1.5V C/LR14 batteries are widely used across multiple industries, powering devices such as flashlights, portable radios, and medical equipment. They are also utilized in consumer electronics, alarm systems, and toys. Understanding the specific applications relevant to your target market can help you tailor your offerings and marketing strategies effectively. Engage with industry stakeholders to identify emerging trends and opportunities for product expansion. -

What are the environmental considerations for sourcing 1.5V C/LR14 batteries?

Sourcing 1.5V C/LR14 batteries requires awareness of environmental regulations and sustainability practices. Ensure that your suppliers adhere to proper disposal and recycling practices, as batteries can be hazardous if not managed correctly. Look for manufacturers that have implemented eco-friendly production processes or offer recyclable options. Engaging with suppliers who prioritize sustainability can enhance your brand reputation and align with the growing consumer demand for environmentally responsible products.

Top 3 1.5V C/Lr14 Manufacturers & Suppliers List

1. Duracell – Coppertop MN1400 1.5V C Size Alkaline Battery

Domain: batteriesplus.com

Registered: 1997 (28 years)

Introduction: {“Item Number”:”DURMN1400B4″,”Brand”:”Duracell Coppertop”,”Terminal Type”:”Consumer Top”,”Voltage”:”1.5V”,”Product Sub Category”:”Consumer”,”Product Category”:”Primary Common”,”Chemistry”:”Alkaline”,”Weight”:”0.65 lbs”,”Pack Size”:”4 Pack”,”Description”:”Duracell Coppertop MN1400 1.5V C size alkaline batteries engineered for household devices. Trusted for reliability and long-lasting power. Duralo…

2. Energizer – Energizer 1.5V C LR14 MAX Alkaline Batteries

Domain: helptechco.com

Registered: 2012 (13 years)

Introduction: {“Product Name”: “Energizer 1.5V C LR14 MAX Alkaline Batteries (2 Pack)”, “Availability”: “in stock”, “Brand”: “Energizer”, “Product Number”: “E93BP2”, “Category”: “Power Solution Battery Batteries”, “Description”: “Dependable, powerful performance. Mercury-free. Long-life alkaline.”, “Shelf Life”: “10 years at 21°C”, “Chemical System”: “Zinc-Manganese Dioxide (Zn/MnO2)”, “Nominal Voltage”: “1.5 v…

3. Panasonic – 1.5V C LR14 Pro Power Alkaline Battery

Domain: f4p-products.com

Registered: 2006 (19 years)

Introduction: {‘brand’: ‘Panasonic’, ‘product_name’: ‘1.5V C LR14 Pro Power Alkaline Battery (Pack of 2)’, ‘description’: ‘Developed to provide reliable and dependable power, any place any time. Ideal for high and medium drain appliances.’, ‘quantity’: ‘Pack of 2’, ‘stock_number’: ‘0218-9245’, ‘catalogue_number’: ‘LR14/2BP’, ‘battery_iec_code’: ‘LR14’, ‘battery_size’: ‘C’, ‘battery_type’: ‘Alkaline’, ‘diameter’…

Strategic Sourcing Conclusion and Outlook for 1.5v c/lr14

In today’s competitive marketplace, strategic sourcing of 1.5V C/LR14 batteries is essential for ensuring reliability and cost-effectiveness. By partnering with reputable suppliers, buyers can access high-quality products from trusted brands like Duracell, Energizer, and Panasonic, which have proven track records in performance and longevity. The ability to source batteries with extended shelf life, such as those featuring PowerSeal™ technology, not only enhances operational efficiency but also reduces the frequency of replenishment, ultimately driving down costs.

As businesses expand into emerging markets across Africa, South America, the Middle East, and Europe, understanding regional demand and supplier capabilities becomes crucial. Buyers must leverage strategic sourcing to mitigate risks associated with supply chain disruptions and to capitalize on local market opportunities.

Looking ahead, international B2B buyers are encouraged to adopt a proactive approach in their sourcing strategies. By fostering strong relationships with suppliers and continuously evaluating market trends, businesses can ensure they remain competitive while meeting the growing demand for reliable power solutions. Embrace the future of sourcing by prioritizing quality, sustainability, and strategic partnerships in your procurement processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.