A Deep Dive into 110-130 Volt At 50Hz Solution

Introduction: Navigating the Global Market for 110-130 volt at 50hz

Navigating the complexities of sourcing equipment that operates on a 110-130 volt at 50Hz frequency can be a daunting task for international B2B buyers. As businesses expand globally, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of voltage compatibility becomes critical. This guide delves into the diverse types of devices that utilize this voltage range, their applications across various industries, and the implications of frequency differences.

From ensuring the compatibility of electrical appliances to identifying reliable suppliers, this comprehensive resource equips you with the knowledge necessary for informed purchasing decisions. You’ll discover key insights into vetting suppliers, evaluating costs, and understanding the logistics of shipping equipment that meets local electrical standards. The guide also highlights potential challenges, such as the need for voltage converters and the importance of considering local infrastructure variations.

By providing actionable strategies and expert recommendations, this guide empowers B2B buyers to make confident choices that enhance operational efficiency and minimize the risk of equipment failure. Whether you’re sourcing for construction projects in Nigeria, energy solutions in Brazil, or technological innovations in the Middle East, you’ll find the necessary tools to navigate the global market effectively. Embrace the opportunity to streamline your purchasing process and ensure your operations run smoothly in any electrical landscape.

Understanding 110-130 volt at 50hz Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Flat blade plug, ungrounded, used primarily in North America | Consumer electronics, appliances | Pros: Widely available; Cons: Lack of grounding can pose safety risks. |

| Type B | Flat blade plug with a grounding pin | Industrial machinery, heavy equipment | Pros: Grounding enhances safety; Cons: Less common in some regions. |

| Type F | Round pins, grounded, used in Europe and Asia | Commercial appliances, power tools | Pros: High safety standard; Cons: Requires adapters for Type A/B plugs. |

| Dual Voltage Systems | Devices that support both 110-130V and 220-240V | Electronics manufacturing, travel goods | Pros: Versatile for global use; Cons: Higher initial cost. |

| Frequency Converters | Devices that convert 50Hz to 60Hz | Specialized equipment, medical devices | Pros: Essential for frequency-sensitive devices; Cons: Can be expensive and complex. |

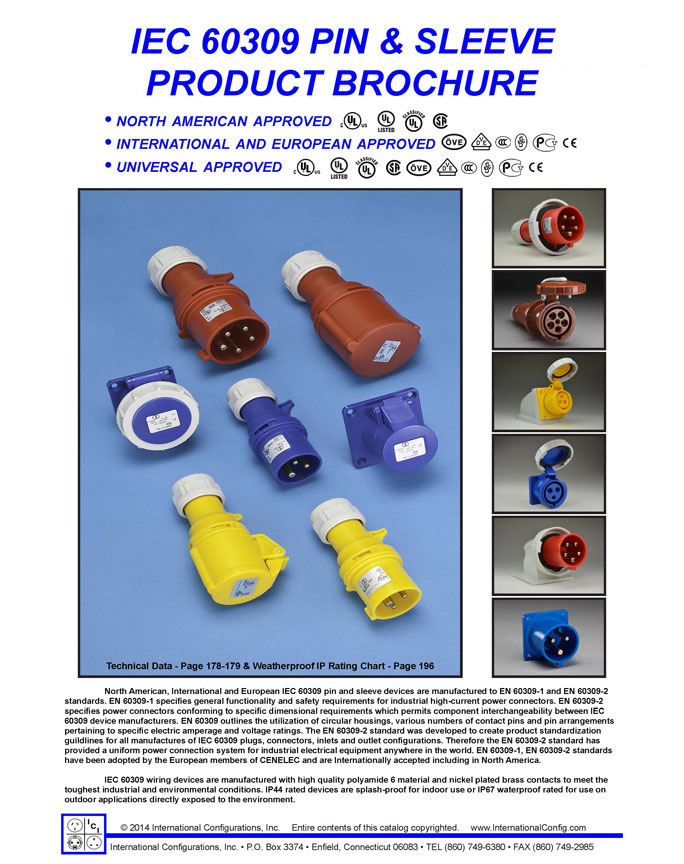

What are the Characteristics of Type A Plugs?

Type A plugs are characterized by their flat blade design, which is ungrounded. Commonly found in North America, they are used for a variety of consumer electronics and appliances. While they are widely available, businesses should consider the safety implications of using ungrounded plugs, especially for high-powered devices. When sourcing Type A equipment, ensure that the devices are compatible with local voltage levels to prevent damage.

How Does Type B Differ from Type A?

Type B plugs feature a similar flat blade design to Type A but include a grounding pin, enhancing safety during operation. These plugs are commonly used in industrial machinery and heavy equipment, making them suitable for B2B applications that require reliable electrical connections. While Type B plugs provide a safer option, they may not be as readily available in regions where Type A is predominant. Buyers should assess their equipment’s compatibility and consider the need for adapters when operating in different markets.

What Makes Type F Plugs a Preferred Choice?

Type F plugs, with their round pins and grounding feature, are prevalent in Europe and parts of Asia. They are designed for commercial appliances and power tools, providing a higher safety standard due to their grounding capabilities. Businesses sourcing equipment for international operations should prioritize Type F compatibility to ensure safety and reliability. However, buyers must be aware that Type F plugs may require adapters for use with Type A or B devices, adding an extra step in the procurement process.

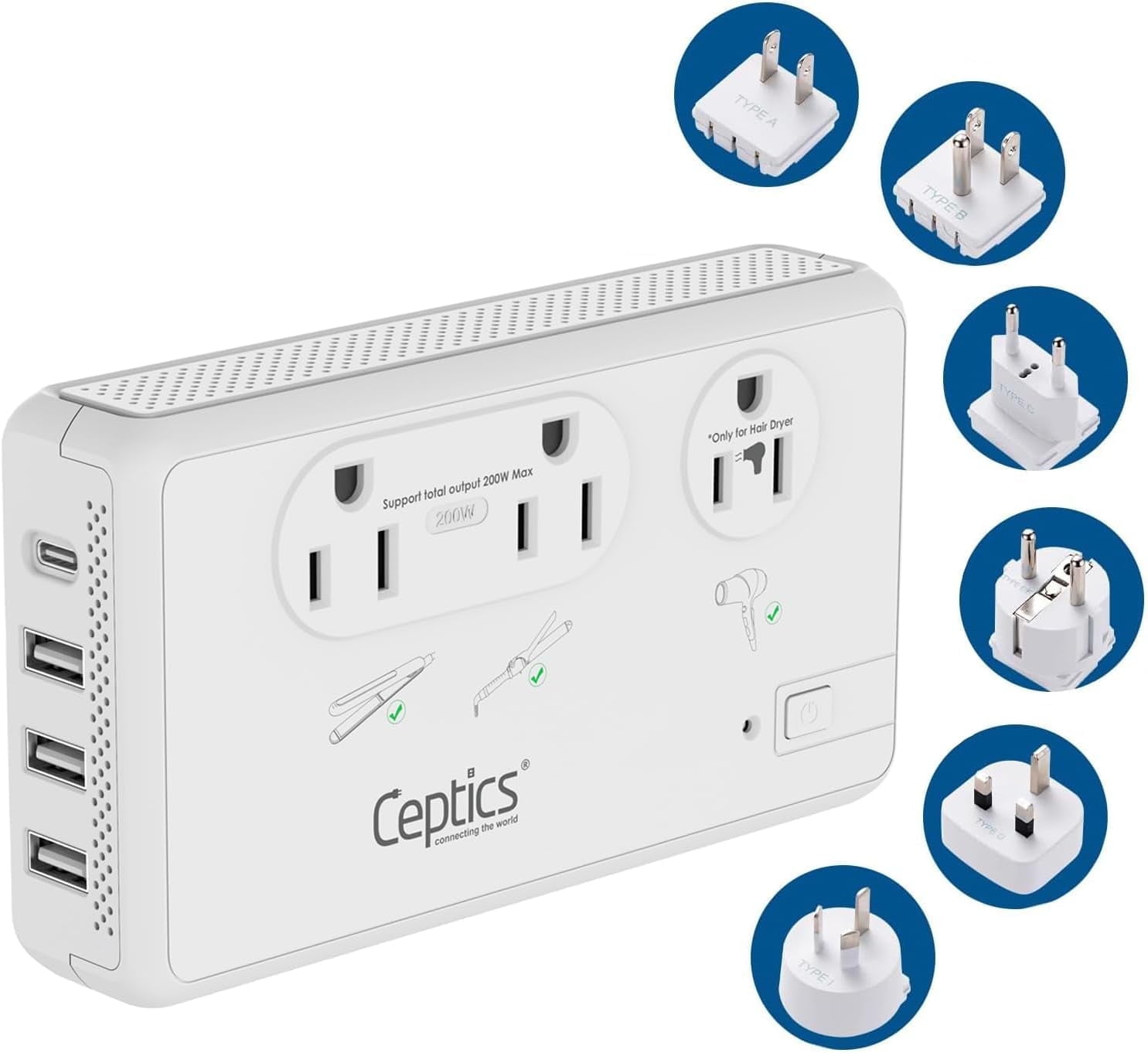

Why Consider Dual Voltage Systems for Global Operations?

Dual voltage systems are designed to operate at both 110-130V and 220-240V, making them ideal for businesses engaged in international trade. These systems are particularly beneficial for electronics manufacturers and companies that frequently travel. While they offer versatility and convenience, dual voltage devices typically come with a higher initial investment. B2B buyers should evaluate their specific needs against the cost implications when considering dual voltage options.

How Do Frequency Converters Fit into the 110-130 Volt Landscape?

Frequency converters are essential for devices that require a specific frequency to operate correctly, especially when transitioning from 50Hz to 60Hz. This is crucial for specialized equipment, including medical devices and certain industrial machinery. While frequency converters can be a costly investment, they ensure the safe operation of sensitive devices in regions with differing electrical standards. Businesses must assess the necessity and compatibility of frequency converters in their operations to avoid potential damage to equipment.

Key Industrial Applications of 110-130 volt at 50hz

| Industry/Sector | Specific Application of 110-130 volt at 50hz | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Operation of assembly line machinery | Consistent power supply enhances productivity and efficiency | Ensure equipment compatibility with local voltage and frequency; consider energy efficiency ratings. |

| Telecommunications | Powering network infrastructure equipment | Reliable power ensures uninterrupted service and connectivity | Look for durable equipment that can withstand local conditions and fluctuations. |

| Medical Equipment | Functioning of diagnostic and monitoring devices | Accurate and reliable patient data enhances care quality | Verify devices meet local safety standards and are compatible with voltage variations. |

| Hospitality | Powering guest room amenities and appliances | Improved guest satisfaction through reliable services | Assess the need for voltage converters for international guests; ensure adaptability of devices. |

| Agriculture | Operation of irrigation systems and equipment | Increased efficiency and yield in crop management | Source equipment that can handle local voltage variations and ensure energy efficiency. |

How is ‘110-130 volt at 50hz’ Utilized in Various Industries?

In the manufacturing sector, machinery and assembly lines often rely on a stable 110-130 volt at 50hz power supply. This voltage range is essential for the operation of equipment like conveyor belts and robotic arms, where any fluctuations can lead to production delays or equipment damage. B2B buyers in this industry should prioritize sourcing machinery that is specifically rated for this voltage and frequency to ensure optimal performance.

Telecommunications companies depend on a consistent power supply to maintain network infrastructure. Equipment such as routers, switches, and servers require reliable 110-130 volt at 50hz power to function effectively. For international buyers, it’s crucial to consider sourcing equipment that is designed to withstand local power conditions, as well as ensuring compatibility with existing systems to avoid service interruptions.

In the medical field, devices such as diagnostic machines and patient monitoring systems need a stable power source to provide accurate readings and reliable operation. Equipment designed for 110-130 volts at 50hz can help healthcare facilities avoid costly downtime and ensure patient safety. Buyers should ensure that all medical devices comply with local regulations and standards, particularly when importing from regions with different power specifications.

The hospitality industry utilizes 110-130 volt at 50hz power for various guest amenities, including HVAC systems, lighting, and electronic devices in hotel rooms. A reliable power supply enhances guest satisfaction and operational efficiency. B2B buyers in this sector must consider the voltage compatibility of appliances, especially when catering to international visitors who may require adapters or converters.

Agricultural applications, particularly in irrigation systems and automated farming equipment, also benefit from a consistent 110-130 volt at 50hz supply. This power range supports the operation of pumps and sensors that optimize water usage and improve crop yields. Buyers in this industry should look for equipment that can handle voltage fluctuations and is energy-efficient to reduce operational costs.

3 Common User Pain Points for ‘110-130 volt at 50hz’ & Their Solutions

Scenario 1: Navigating Voltage Variability for Equipment Compatibility

The Problem: B2B buyers often face confusion regarding voltage compatibility when sourcing equipment intended for use in regions where the power supply fluctuates between 110-130 volts at 50 Hz. For instance, a company importing machinery from the U.S. may find that while their equipment is rated for 120 volts, the actual voltage available locally can sometimes dip below or spike above this range. This variability can lead to operational inefficiencies or even damage to sensitive equipment, especially if the machinery is not designed to handle such fluctuations.

The Solution: To mitigate this risk, buyers should focus on sourcing equipment with a wider voltage tolerance. When evaluating machinery, specifically look for devices rated for 100-240 volts. This range ensures compatibility with various voltage levels while accommodating slight fluctuations. Additionally, consider investing in voltage stabilizers or surge protectors that can handle the expected voltage range. These devices help maintain a consistent voltage level, thus protecting sensitive equipment and enhancing operational reliability. Suppliers should be transparent about the voltage specifications of their products, allowing buyers to make informed decisions.

Scenario 2: Adapting to Different Plug Types in Diverse Markets

The Problem: International B2B buyers frequently encounter issues with plug compatibility when dealing with 110-130 volt at 50 Hz devices. For instance, a company looking to utilize portable electrical tools in multiple countries may struggle with varying socket types, leading to delays and additional costs associated with acquiring the right adapters. This can hinder productivity and create frustration among teams that need to deploy equipment quickly.

The Solution: To address this, companies should invest in universal power adapters and multi-socket power strips that can accommodate various plug types. Before purchasing equipment, conduct thorough research on the plug types used in the target market—such as types A, B, and F in regions like Curaçao. Always include a few universal adapters in your equipment kits to ensure immediate usability. Furthermore, establishing relationships with local suppliers can provide access to readily available adapters, minimizing downtime and ensuring that your teams can operate seamlessly across different regions.

Scenario 3: Managing Frequency Differences and Device Performance

The Problem: A critical challenge for B2B buyers is dealing with frequency differences, particularly when operating devices designed for 60 Hz in regions with a 50 Hz supply. For example, medical equipment or precision tools that depend on a consistent frequency for accurate operation may experience performance issues or even failure when used on a 50 Hz supply, leading to costly repairs and potential compliance issues.

The Solution: To overcome this issue, buyers should prioritize sourcing equipment explicitly designed for dual-frequency operation (50/60 Hz). This specification allows devices to function correctly in both environments without compromising performance. Additionally, consider implementing frequency converters for devices that cannot accommodate 50 Hz. When making procurement decisions, ensure that suppliers provide detailed specifications regarding frequency compatibility, and consider conducting pilot tests in the target market to verify that devices perform as expected before full-scale deployment. This proactive approach minimizes the risk of disruptions and ensures compliance with local operational standards.

Strategic Material Selection Guide for 110-130 volt at 50hz

What Are the Key Materials for 110-130 Volt at 50Hz Applications?

When selecting materials for electrical applications operating at 110-130 volts and 50 Hz, several factors come into play, including electrical conductivity, thermal stability, and mechanical strength. Below is an analysis of four common materials used in such applications, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Copper: The Standard for Electrical Conductivity

Key Properties: Copper is renowned for its excellent electrical conductivity, with a conductivity rating of approximately 59.6 x 10^6 S/m. It also has good thermal conductivity and is relatively ductile, making it easy to work with.

Pros & Cons: The primary advantage of copper is its superior conductivity, which minimizes energy loss. However, copper is susceptible to corrosion, especially in humid environments, which can lead to reduced performance over time. Additionally, copper can be more expensive compared to alternatives like aluminum.

Impact on Application: Copper is ideal for wiring and components in electrical systems, ensuring efficient power transmission. However, it may not be suitable for environments with high corrosion potential unless adequately protected.

Considerations for International Buyers: Compliance with international standards such as ASTM B3 (for copper wire) is essential. Buyers should also consider local regulations regarding material sourcing and environmental impact.

Aluminum: A Lightweight Alternative

Key Properties: Aluminum offers good electrical conductivity (approximately 37.7 x 10^6 S/m) and is significantly lighter than copper, making it easier to handle and install.

Pros & Cons: The lightweight nature of aluminum makes it a cost-effective choice for large-scale installations. However, it has lower conductivity than copper, requiring larger wire sizes to carry the same current. Aluminum is also more prone to oxidation, which can affect performance.

Impact on Application: Aluminum is often used in overhead power lines and large electrical installations where weight is a critical factor. Its lower conductivity necessitates careful design considerations to avoid overheating.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B800 for aluminum conductors. Additionally, the cost-effectiveness of aluminum may be attractive in developing markets like Nigeria and Brazil.

PVC (Polyvinyl Chloride): Insulation and Housing

Key Properties: PVC is a versatile thermoplastic known for its excellent insulation properties, chemical resistance, and durability.

Pros & Cons: PVC is lightweight, cost-effective, and provides excellent insulation for electrical applications. However, it has a lower temperature tolerance compared to other materials, which may limit its use in high-heat environments.

Impact on Application: PVC is commonly used for insulation on wires and cables, ensuring safety and reducing the risk of electrical faults. Its chemical resistance makes it suitable for various environments.

Considerations for International Buyers: Compliance with international standards such as IEC 60227 (for PVC insulated cables) is crucial. Buyers should also consider the environmental impact of PVC, especially in regions with stringent regulations.

Steel: Structural Support and Durability

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for structural applications in electrical installations.

Pros & Cons: Steel provides excellent mechanical support for electrical components but is not a conductor of electricity. It is also prone to corrosion unless treated, which can lead to increased maintenance costs.

Impact on Application: Steel is often used in the construction of electrical enclosures and support structures. Its strength ensures stability, but protective coatings are necessary to prevent rust and degradation.

Considerations for International Buyers: Compliance with standards such as ASTM A36 for structural steel is essential. Buyers should also evaluate local availability and costs, as steel prices can vary significantly across regions.

Summary Table of Material Selection for 110-130 Volt at 50Hz

| Material | Typical Use Case for 110-130 volt at 50hz | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and electrical components | Superior conductivity | Susceptible to corrosion | High |

| Aluminum | Overhead power lines and large installations | Lightweight and cost-effective | Lower conductivity | Medium |

| PVC | Insulation for wires and cables | Excellent insulation | Lower temperature tolerance | Low |

| Steel | Structural support for enclosures | High tensile strength | Prone to corrosion | Medium |

This strategic material selection guide provides insights into the properties and applications of materials commonly used in 110-130 volt at 50Hz systems, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 110-130 volt at 50hz

What Are the Main Stages of Manufacturing 110-130 Volt at 50Hz Electrical Equipment?

The manufacturing processes for equipment designed to operate at 110-130 volts and 50 Hz typically follow a structured approach that includes several key stages: material preparation, forming, assembly, and finishing.

Material Preparation: Sourcing Quality Components

The first step in the manufacturing process involves sourcing high-quality raw materials. This includes metals for conductors, plastics for housings, and other electronic components. Suppliers should be vetted to ensure they meet relevant international standards, such as ISO 9001, which ensures quality management systems are in place. Additionally, materials must be compliant with safety and environmental regulations, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals).

Forming: Techniques Used in Electrical Component Manufacturing

Once materials are sourced, the next stage is forming. This process can include various methods such as stamping, molding, and machining. For electrical components, precision is critical; thus, CNC (Computer Numerical Control) machining is often employed to ensure accuracy in dimensions. Moreover, forming techniques must accommodate the specific voltage and frequency requirements, ensuring that components can handle the electrical load without overheating or failing.

Assembly: Ensuring Proper Connectivity and Functionality

The assembly stage involves integrating various components into a final product. This may include soldering, crimping, and using screws or fasteners to secure parts. Automated assembly lines are increasingly common, as they enhance efficiency and reduce human error. Quality checks during assembly are vital; for instance, continuity tests can ensure that electrical connections are secure and functioning as intended.

Finishing: Final Touches and Quality Checks

The finishing stage includes processes such as painting, coating, and labeling the products. These not only enhance aesthetic appeal but also provide necessary protective features against environmental factors. Final quality checks, including visual inspections and functional tests, are performed to ensure that the product meets the required specifications before it is packaged for shipment.

What Are the Key Quality Control Standards for Electrical Equipment?

Quality assurance in manufacturing processes for electrical equipment operating at 110-130 volts and 50 Hz is paramount, particularly for B2B buyers in diverse markets. Several international and industry-specific standards guide these quality control measures.

What Are Relevant International Standards?

International standards such as ISO 9001 set the framework for a quality management system. This standard emphasizes the importance of continuous improvement and customer satisfaction. Additionally, CE marking is crucial for products sold within the European Economic Area (EEA), indicating compliance with health, safety, and environmental protection standards.

What Industry-Specific Certifications Should Buyers Consider?

Depending on the specific application, industry-specific certifications may be necessary. For example, the API (American Petroleum Institute) certification is vital for products used in the oil and gas sector. Similarly, UL (Underwriters Laboratories) certification may be required for safety testing, particularly for electrical devices. B2B buyers should ensure that their suppliers possess these certifications to mitigate risks associated with safety and compliance.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control checkpoints are essential throughout the manufacturing process to ensure that products meet established standards.

What Are the Common Quality Control Checkpoints?

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of materials received from suppliers. Any materials that do not meet the specified standards are rejected.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are performed to monitor processes and ensure that they adhere to quality standards. This may include checks on dimensions, functionality, and assembly integrity.

-

Final Quality Control (FQC): Before products are shipped, final inspections and tests are conducted to verify that each unit meets quality specifications. This may involve functional testing under simulated operating conditions.

What Common Testing Methods Are Used to Ensure Product Safety?

B2B buyers should be aware of the common testing methods employed to validate the safety and functionality of electrical equipment.

-

Electrical Testing: This includes voltage testing to ensure that devices can handle their rated voltage without failure. Insulation resistance testing is also performed to prevent short circuits.

-

Thermal Testing: Devices are subjected to temperature variations to ensure they can operate efficiently without overheating.

-

Durability Testing: Mechanical stress tests are conducted to ensure that the product can withstand typical usage conditions over its intended lifespan.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. This can include:

What Auditing Practices Should Buyers Implement?

-

Supplier Audits: Conducting regular audits of suppliers helps ensure that their manufacturing processes align with international standards. This can include reviewing quality management systems, production methods, and compliance with relevant certifications.

-

Requesting Quality Reports: Buyers should request documentation of quality control measures, including inspection reports, test results, and compliance certifications. This transparency helps build trust and ensures that suppliers adhere to quality standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an additional layer of assurance. These agencies can conduct independent audits and testing to verify that products meet specified quality standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is critical.

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying standards and regulations that can impact product quality. For instance, CE certification is essential for products sold in the European market, while UL certification holds significant weight in North America. Buyers must ensure that their suppliers are compliant with the specific standards applicable in their target market to avoid costly compliance issues.

What Role Does Communication Play in Ensuring Quality?

Effective communication with suppliers is vital to ensure that quality expectations are clearly understood and met. Regular updates on production status, potential issues, and quality metrics can help buyers stay informed and address any concerns proactively.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for 110-130 volt at 50 Hz electrical equipment is essential for B2B buyers. By focusing on quality at every stage—from material sourcing to final testing—buyers can ensure they are procuring reliable products that meet international standards. Implementing robust quality control measures and verifying supplier practices will further enhance buyer confidence, ultimately leading to successful business partnerships in diverse global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘110-130 volt at 50hz’

Introduction

Navigating the procurement of electrical products designed for 110-130 volts at 50 Hz can be complex, particularly for B2B buyers operating across different regions. This guide provides a practical checklist to ensure you make informed decisions while sourcing these products, considering factors like compatibility, supplier reliability, and compliance with local regulations.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is crucial before initiating the sourcing process. Determine the specific voltage and frequency range needed for your applications, as well as any additional specifications such as power capacity or environmental considerations. This clarity will help you communicate effectively with suppliers and ensure compatibility with your operational environment.

Step 2: Research Local Regulations and Standards

Familiarize yourself with the local electrical standards and regulations in the regions where you plan to operate, especially in markets like Africa, South America, and the Middle East. Compliance with local codes is not only a legal requirement but also impacts the safety and performance of your equipment. Look for certifications such as CE, UL, or IEC that indicate adherence to international safety standards.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to conduct thorough due diligence. Request company profiles, certifications, and references from other businesses in your industry. Evaluate their experience with 110-130 volt systems and assess their production capacity to meet your demands. This step helps mitigate risks associated with unreliable suppliers.

Step 4: Assess Product Compatibility

Ensure that the products you are considering are compatible with the voltage and frequency specifications of your target markets. Many devices are rated for a range of voltages, but not all can handle the frequency difference. Check the labels on devices and consult with manufacturers to confirm that they will operate correctly in your specified conditions.

Step 5: Request Samples for Testing

Before placing a large order, request samples of the products for testing. This allows you to evaluate their performance and compatibility firsthand. Pay attention to how they handle voltage fluctuations and frequency variations, which are common in certain regions. Testing can prevent costly mistakes and ensure that the products meet your operational needs.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate terms and conditions that protect your interests. This includes payment terms, delivery schedules, warranty provisions, and after-sales support. Clear agreements can prevent misunderstandings and ensure you receive the level of service you expect throughout the procurement process.

Step 7: Plan for Logistics and Importation

Consider the logistics involved in importing electrical equipment to your target market. Factor in shipping times, customs regulations, and potential tariffs. Collaborate with a logistics partner familiar with international shipping and local regulations to streamline the process and minimize delays.

By following this checklist, B2B buyers can enhance their sourcing strategies for 110-130 volt at 50 Hz electrical products, ensuring they meet both technical and regulatory requirements while maintaining operational efficiency.

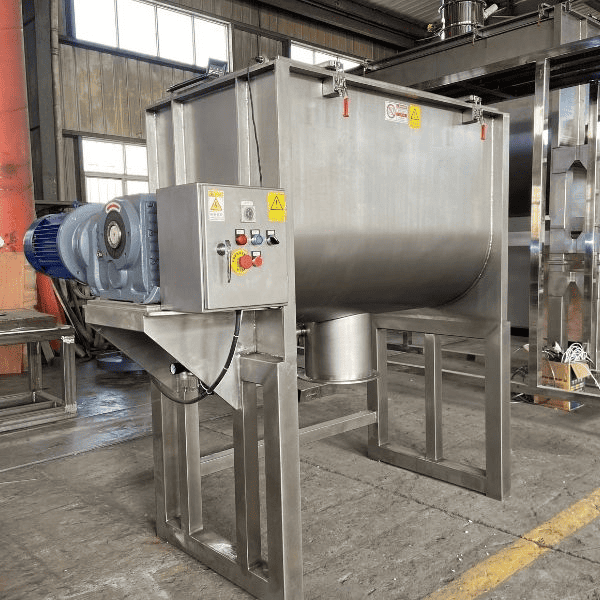

Illustrative image related to 110-130 volt at 50hz

Comprehensive Cost and Pricing Analysis for 110-130 volt at 50hz Sourcing

What Are the Key Cost Components for 110-130 Volt at 50Hz Sourcing?

When sourcing equipment operating at 110-130 volts and 50 Hz, several cost components must be taken into account. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The choice of materials significantly affects cost. For example, high-grade copper for wiring or durable plastics for enclosures can increase upfront expenses but reduce long-term failure rates and maintenance costs.

-

Labor: Labor costs vary widely depending on the country of manufacture. Regions with lower labor costs, such as parts of Asia or Eastern Europe, may offer more competitive pricing, but this can come at the expense of quality control.

-

Manufacturing Overhead: This includes utilities, rent, and administrative costs associated with the production facility. Efficient manufacturing processes can help lower these costs, impacting the final pricing of products.

-

Tooling: Initial tooling costs can be significant, especially for custom or specialized equipment. These costs need to be amortized over the production run, influencing unit pricing.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability but adds to the overall cost. Buyers should assess the QC standards of potential suppliers to gauge the impact on pricing.

-

Logistics: Shipping and handling costs can vary greatly, especially for international buyers. Factors such as distance, freight rates, and import duties play a crucial role in the total cost structure.

-

Margin: Supplier margins typically range from 10% to 40%, depending on the product and market conditions. Understanding a supplier’s pricing strategy can aid in negotiations.

How Do Price Influencers Impact 110-130 Volt at 50Hz Products?

Various factors influence the pricing of products operating at 110-130 volts and 50 Hz, which are particularly relevant for international B2B buyers.

-

Volume/MOQ: Minimum order quantities (MOQs) and bulk purchases often lead to significant discounts. Suppliers are generally more flexible in pricing for larger orders, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Customized products that cater to specific requirements typically command higher prices. Buyers should determine if standard solutions can meet their needs to avoid unnecessary expenses.

-

Materials: The quality of materials directly influences cost. For example, products made from premium components may have a higher upfront cost but can lead to lower Total Cost of Ownership (TCO) through durability and efficiency.

-

Quality and Certifications: Certifications such as ISO or CE mark can increase the price due to the compliance costs involved. However, they also provide assurance of quality and reliability, which is crucial in many industries.

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may charge a premium for their products due to proven performance and support services.

-

Incoterms: Understanding Incoterms is critical for international transactions. They define the responsibilities of buyers and sellers, impacting shipping costs, insurance, and risk during transit.

What Are the Best Buyer Tips for Sourcing 110-130 Volt at 50Hz Equipment?

For B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency.

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for bulk orders. Leverage competitive quotes from multiple suppliers to negotiate better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. Evaluate potential long-term savings from energy efficiency and lower maintenance costs.

-

Pricing Nuances: Be aware of currency fluctuations and international tariffs that can impact pricing. Establishing long-term relationships with suppliers may also yield better pricing over time.

-

Market Research: Stay informed about market trends and pricing benchmarks in different regions. This knowledge can empower buyers during negotiations and sourcing decisions.

-

Quality Assurance: Always prioritize quality over cost. Cheaper products may lead to higher long-term expenses due to failures or inefficiencies, undermining initial savings.

By understanding these components and tips, international B2B buyers can navigate the complexities of sourcing 110-130 volt at 50 Hz equipment more effectively, ensuring they achieve optimal pricing and quality.

Alternatives Analysis: Comparing 110-130 volt at 50hz With Other Solutions

Introduction to Alternatives in Voltage Standards

When evaluating electrical systems, particularly in a global B2B context, understanding the nuances of voltage standards is crucial. The 110-130 volt at 50Hz standard presents one viable option, but various alternatives exist that may better suit specific operational needs. This analysis explores alternatives, focusing on their performance, cost, ease of implementation, and maintenance to help buyers make informed decisions.

Illustrative image related to 110-130 volt at 50hz

Comparison Table

| Comparison Aspect | 110-130 Volt At 50Hz | 220-240 Volt At 50Hz | 120 Volt At 60Hz |

|---|---|---|---|

| Performance | Moderate | High | Moderate |

| Cost | Lower initial setup | Higher infrastructure costs | Moderate |

| Ease of Implementation | Easy in compatible regions | More complex in certain areas | Easy for US-based systems |

| Maintenance | Low | Moderate | Low |

| Best Use Case | General use in certain regions | Industrial applications | Residential use in the US |

Detailed Breakdown of Alternatives

220-240 Volt At 50Hz

The 220-240 volt at 50Hz standard is widely used in Europe, Africa, and parts of Asia. Its primary advantage is its ability to deliver more power with less current, which can enhance efficiency in industrial settings. However, the initial infrastructure costs can be substantial, particularly for companies transitioning from a 110-130 volt system. Maintenance is moderate due to the requirement for specialized equipment and training for technicians. This standard is best suited for businesses that require high power output, such as manufacturing plants, but may pose challenges for smaller enterprises or those operating in regions with different voltage standards.

120 Volt At 60Hz

The 120 volt at 60Hz standard is predominantly used in North America and some parts of Latin America. This system is known for its compatibility with a wide range of consumer electronics and appliances, making it a practical choice for residential applications. While the performance is moderate, it can lead to increased power loss over long distances due to higher current draw. The ease of implementation is a strong point for businesses based in the US, as it aligns with existing infrastructure. However, companies expanding internationally may face challenges when interfacing with 50Hz systems, which could necessitate additional investment in converters or new equipment.

Conclusion: How to Choose the Right Voltage Solution

Selecting the appropriate voltage solution requires a thorough understanding of operational needs, regional compatibility, and future growth plans. For businesses operating primarily in regions that utilize 110-130 volts at 50Hz, this standard offers a balanced approach with lower initial setup costs and minimal maintenance. However, companies planning to expand into markets with different voltage standards should consider the implications of transitioning to 220-240 volts or 120 volts at 60Hz. Analyzing the performance, cost, and maintenance needs of each option will empower B2B buyers to make informed decisions that align with their strategic objectives.

Illustrative image related to 110-130 volt at 50hz

Essential Technical Properties and Trade Terminology for 110-130 volt at 50hz

What Are the Key Technical Properties for 110-130 Volt at 50Hz Systems?

When dealing with electrical systems operating at 110-130 volts and a frequency of 50Hz, several critical specifications are essential to understand for effective B2B transactions.

1. Voltage Rating

Voltage rating specifies the maximum voltage an electrical device can handle safely. For equipment designed for 110-130V, this range is crucial as it directly impacts compatibility with local power supplies. B2B buyers must ensure that their devices match the voltage requirements of the regions they operate in to prevent equipment damage and ensure safety.

2. Frequency Tolerance

Frequency tolerance refers to the acceptable deviation from the standard frequency of 50Hz. Many devices are designed to operate within a specific frequency range, and exceeding this can lead to operational failures. Understanding frequency tolerance is vital for buyers, especially when sourcing equipment from regions with different electrical standards, as it affects performance and longevity.

3. Current Rating (Amperage)

Current rating, measured in amperes (A), indicates the maximum current a device can safely carry. This specification is important for ensuring that electrical wiring and components can handle the load without overheating or failing. B2B buyers should consider the current requirements of their devices to ensure compliance with local electrical codes and safe operation.

4. Power Factor

Power factor is a measure of how effectively electrical power is being converted into useful work output. It is particularly relevant for businesses using motors and other inductive loads. A low power factor can indicate inefficiencies and higher energy costs, making it a critical consideration for B2B buyers focused on operational efficiency.

5. Insulation Resistance

Insulation resistance measures how well the insulation of a device prevents electrical leakage. High insulation resistance is crucial for safety and equipment longevity. B2B buyers should prioritize equipment with excellent insulation properties to minimize the risk of electrical shocks and equipment failures.

6. Operating Temperature Range

The operating temperature range specifies the conditions under which a device can function optimally. Devices rated for certain temperatures are essential for environments that experience extreme conditions. Understanding this specification helps buyers select the right equipment for their specific operational environments.

What Are Common Trade Terms Relevant to 110-130 Volt at 50Hz?

Understanding industry jargon is crucial for navigating B2B transactions effectively. Here are key terms that relate to electrical equipment operating at 110-130 volts and 50Hz.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electrical equipment, sourcing from an OEM ensures that components meet specific voltage and frequency specifications, maintaining compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it affects inventory management and cost efficiency. Suppliers often set MOQs based on production costs and logistics.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. When sourcing electrical equipment, issuing an RFQ can help buyers compare offers and negotiate better deals, ensuring they secure the right products at competitive prices.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms is vital for B2B transactions involving electrical equipment, as they clarify who is responsible for shipping, insurance, and tariffs, which can significantly affect overall costs.

5. CE Marking

CE marking indicates that a product meets European safety, health, and environmental protection requirements. For B2B buyers sourcing electrical devices, ensuring that products are CE marked is crucial for compliance with regulations and for market acceptance in Europe.

6. UL Certification

UL certification signifies that a product has been tested for safety and meets specific standards set by Underwriters Laboratories. B2B buyers should look for UL certification to ensure the electrical equipment they purchase is safe and reliable, which is especially important in industries with strict safety regulations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing equipment operating at 110-130 volts and 50Hz, ensuring compatibility, safety, and efficiency in their operations.

Navigating Market Dynamics and Sourcing Trends in the 110-130 volt at 50hz Sector

What Are the Key Market Drivers in the 110-130 Volt at 50Hz Sector?

The 110-130 volt at 50Hz sector is shaped by a variety of global drivers that influence demand and sourcing strategies. The increasing reliance on electronic devices in emerging markets such as Nigeria and Brazil is a significant factor. These countries are experiencing rapid urbanization and economic growth, leading to a surge in demand for reliable power solutions. Additionally, the expansion of renewable energy sources in regions like South America and the Middle East is creating new opportunities for businesses to integrate sustainable technologies into their operations.

Another critical trend is the rise of smart technologies and IoT devices, which often require specific voltage and frequency specifications. As international B2B buyers look to source equipment that meets these requirements, there is a growing need for suppliers to provide products that can function effectively within the 110-130 volt range. Furthermore, the market is witnessing an increased focus on energy efficiency, prompting manufacturers to innovate and deliver products that not only comply with these voltage standards but also minimize energy consumption.

How Are Sustainability and Ethical Sourcing Impacting the 110-130 Volt at 50Hz Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the 110-130 volt at 50Hz sector. The environmental impact of electrical products is under scrutiny as businesses and consumers alike prioritize green practices. Suppliers that adopt eco-friendly manufacturing processes and materials can gain a competitive edge in the market. Certifications such as Energy Star and RoHS (Restriction of Hazardous Substances) are becoming essential for manufacturers aiming to appeal to environmentally-conscious B2B buyers.

Illustrative image related to 110-130 volt at 50hz

Moreover, the importance of ethical supply chains cannot be overstated. International buyers are increasingly concerned about the origins of their products and the practices employed in their production. This has led to a demand for transparency and accountability from suppliers. Companies that can demonstrate ethical sourcing practices, such as fair labor conditions and responsible sourcing of materials, are likely to foster stronger relationships with B2B partners. As a result, integrating sustainability and ethical considerations into sourcing strategies is not just a trend but a necessity for businesses looking to thrive in this evolving landscape.

What Is the Brief Evolution of the 110-130 Volt at 50Hz Sector?

The evolution of the 110-130 volt at 50Hz sector can be traced back to the early days of electrical engineering when standardization efforts began in the late 19th century. The adoption of these voltage levels was influenced by various factors, including regional power generation capabilities and the need for compatibility with existing electrical systems. Initially, the focus was primarily on ensuring safety and functionality, but as the technology advanced, the emphasis shifted towards efficiency and sustainability.

In recent decades, the emergence of digital technologies and renewable energy sources has further transformed the landscape. The integration of smart grids and energy-efficient appliances has led to a reevaluation of traditional voltage standards, prompting manufacturers to innovate continuously. As the global demand for reliable and sustainable electrical solutions grows, the 110-130 volt at 50Hz sector is positioned for ongoing evolution, driven by technological advancements and changing market needs.

Conclusion

For international B2B buyers, understanding the dynamics of the 110-130 volt at 50Hz sector is crucial for making informed sourcing decisions. By keeping an eye on market trends, prioritizing sustainability and ethical sourcing, and recognizing the historical context of this sector, businesses can better navigate the complexities of global supply chains and position themselves for success in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of 110-130 volt at 50hz

-

How do I ensure compatibility of my devices with 110-130 volt at 50 Hz?

To ensure compatibility, check the voltage and frequency specifications on your devices. Many modern electronics, such as chargers and laptops, are designed to operate within a voltage range of 100-240V and can handle both 50Hz and 60Hz frequencies. If your device is not compatible, you may need a voltage converter or transformer. Additionally, using a power plug adapter is essential, as plug types may vary by region. Always consult the manufacturer’s guidelines for specific voltage and frequency requirements. -

What are the common plug types used for 110-130 volt at 50 Hz?

Common plug types for 110-130 volt systems at 50 Hz include Type A, Type B, and Type F. Type A and B are prevalent in the United States, while Type F is more common in parts of Europe and Asia. When sourcing products, ensure that your suppliers can provide the correct plug type or offer adapters to fit your needs. It’s advisable to check local regulations and standards to ensure compliance and compatibility with local electrical systems. -

What are the key considerations for sourcing electrical equipment operating at 110-130 volts?

When sourcing electrical equipment, consider the voltage tolerance, frequency compatibility, and the device’s certification standards. Ensure that suppliers provide documentation verifying that their products meet international safety and quality standards, such as CE or UL certifications. Additionally, evaluate the supplier’s reputation and track record, as well as their ability to provide after-sales support and warranty services. -

How can I verify the reliability of a supplier for 110-130 volt products?

To verify a supplier’s reliability, conduct thorough research, including checking customer reviews, ratings, and testimonials. Request references and case studies of previous clients. Additionally, assess their manufacturing processes and quality control measures. It’s beneficial to visit their facilities, if possible, and review their certifications and compliance with international standards. Engaging with trade associations or industry groups can also provide insights into a supplier’s reputation. -

What are the typical minimum order quantities (MOQ) for 110-130 volt equipment?

Minimum order quantities can vary significantly by supplier and product type. Generally, MOQs for electrical equipment may range from a few units to several hundred, depending on the manufacturer’s production capabilities and market demand. It’s advisable to discuss your specific needs with suppliers to negotiate favorable terms, especially if you are a small or medium-sized enterprise. Some suppliers may offer flexibility on MOQs for first-time buyers or bulk orders. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely based on the supplier’s policies, the order size, and the buyer’s negotiation leverage. Common terms include upfront payment, a deposit with the balance upon delivery, or net terms such as 30, 60, or 90 days. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms before finalizing contracts to avoid misunderstandings. -

How do I manage logistics when importing 110-130 volt equipment?

Effective logistics management involves understanding shipping options, customs regulations, and delivery timelines. Work with a reliable freight forwarder who specializes in international shipping to navigate these complexities. Ensure that all documentation, including invoices, packing lists, and certificates of origin, is in order to avoid customs delays. Additionally, factor in potential tariffs or import duties that may apply to your shipments, and plan accordingly to optimize costs. -

What quality assurance measures should I implement for imported electrical devices?

Implementing robust quality assurance measures involves establishing clear criteria for product specifications and testing protocols. Before placing orders, request samples to evaluate quality firsthand. Consider third-party inspections during manufacturing and before shipment to ensure compliance with your standards. Additionally, maintain open communication with suppliers to address any issues that may arise and establish a process for handling defective products or returns efficiently.

Top 7 110-130 Volt At 50Hz Manufacturers & Suppliers List

1. Power Plugs & Sockets – Curaçao Travel Guide

Domain: power-plugs-sockets.com

Registered: 2013 (12 years)

Introduction: On Curaçao, power plugs and sockets (outlets) of type A, type B, and type F are used. The standard voltage is 127 / 220 V at a frequency of 50 Hz. Travelers from the United States need a power plug travel adapter for sockets type A and F. Sockets type B can fit US plugs but may not always be available locally. A voltage converter may also be needed due to varying local voltage levels. Devices oper…

2. ScubaBoard – Electricity Guide for Curacao

Domain: scubaboard.com

Registered: 1999 (26 years)

Introduction: Electricity in Curacao operates at 110-130 Volts and 50 Hz. Travelers may need plug adapters, specifically German/Dutch style, to charge devices. Most US devices (60 Hz) will function properly, but those with internal time mechanisms may not keep accurate time. It’s advisable to check with the hotel for specific outlet types, as some places may have both 110V and 220V options. A power strip or ext…

3. Reddit – Electrical Voltage Differences

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The US supplies electricity at 110V and 60Hz, differing from many countries that use 220V and 50Hz. This difference is attributed to historical factors and the preferences of engineers during the establishment of electrical grids.

4. Facebook – Power Outlet Standards

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Power Outlet Standards, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Curaçao Todo – Electrical Guide

Domain: curacaotodo.com

Registered: 2015 (10 years)

Introduction: Curaçao uses 110-130 volt electricity at a frequency of 50Hz. The electrical outlets are Type A and Type B, which feature flat blades similar to those used in North America. Most modern electronic devices are dual voltage, allowing them to operate on both 110-130V and 220-240V. For high-wattage devices like hair dryers, travel-friendly versions designed for dual voltage use are recommended. Power …

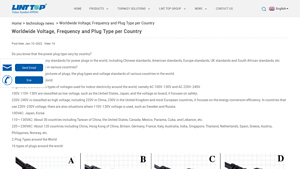

6. Lint Top – Voltage & Frequency Solutions

Domain: linttop.com

Registered: 2010 (15 years)

Introduction: Worldwide Voltage, Frequency and Plug Type per Country, Manufacturer and Supplier: Lint Top offers a variety of products including Rod Casting, Wire Drawing, Rotating Machines, Braiding Machines, Armouring Machines, Extrusion/Pelletizing Lines, Plating/Enamelling Machines, Packaging Machines, LAN Cable Equipment, Optical Fiber Cable Equipment, Auxiliary Equipment, Laser Printers, Pay-off & Take-up…

7. Insignia™ – All-in-One Travel Adapter and Converter

Domain: bestbuy.com

Registered: 1994 (31 years)

Introduction: Insignia™ – All-in-One Travel Adapter and Converter with 2 USB Ports – Black. User rating: 3.4 out of 5 stars based on 893 reviews. Compatible with Curaçao standard current outlets providing 110-130 Volt at 50Hz. Standard plug type: two-pin ‘Type A’ power plug (used in the US). Some devices may operate at both 110V and 220V; check in advance. Some hotels and apartments may have 220V outlets requir…

Strategic Sourcing Conclusion and Outlook for 110-130 volt at 50hz

In the ever-evolving landscape of international business, understanding the nuances of electrical standards, such as the 110-130 volts at 50 Hz, is crucial for effective strategic sourcing. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, this knowledge not only aids in ensuring compatibility with electronic devices but also streamlines procurement processes. Companies must prioritize sourcing reliable voltage converters and plug adapters to mitigate risks associated with voltage fluctuations and frequency differences, which can adversely affect equipment performance.

The strategic sourcing of electrical components should also consider local regulations and standards, as these can vary significantly across regions. By fostering relationships with trusted suppliers who understand these complexities, businesses can secure high-quality products while minimizing operational disruptions.

Looking ahead, as global markets continue to integrate, the demand for standardized electrical solutions will rise. Now is the time for international buyers to invest in partnerships that enhance their sourcing strategies. By aligning with suppliers adept in navigating the intricacies of voltage and frequency requirements, businesses can position themselves for growth and operational efficiency in diverse markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.