A B2B Buyer’s Guide to Worm And Wheel Gear: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for worm and wheel gear

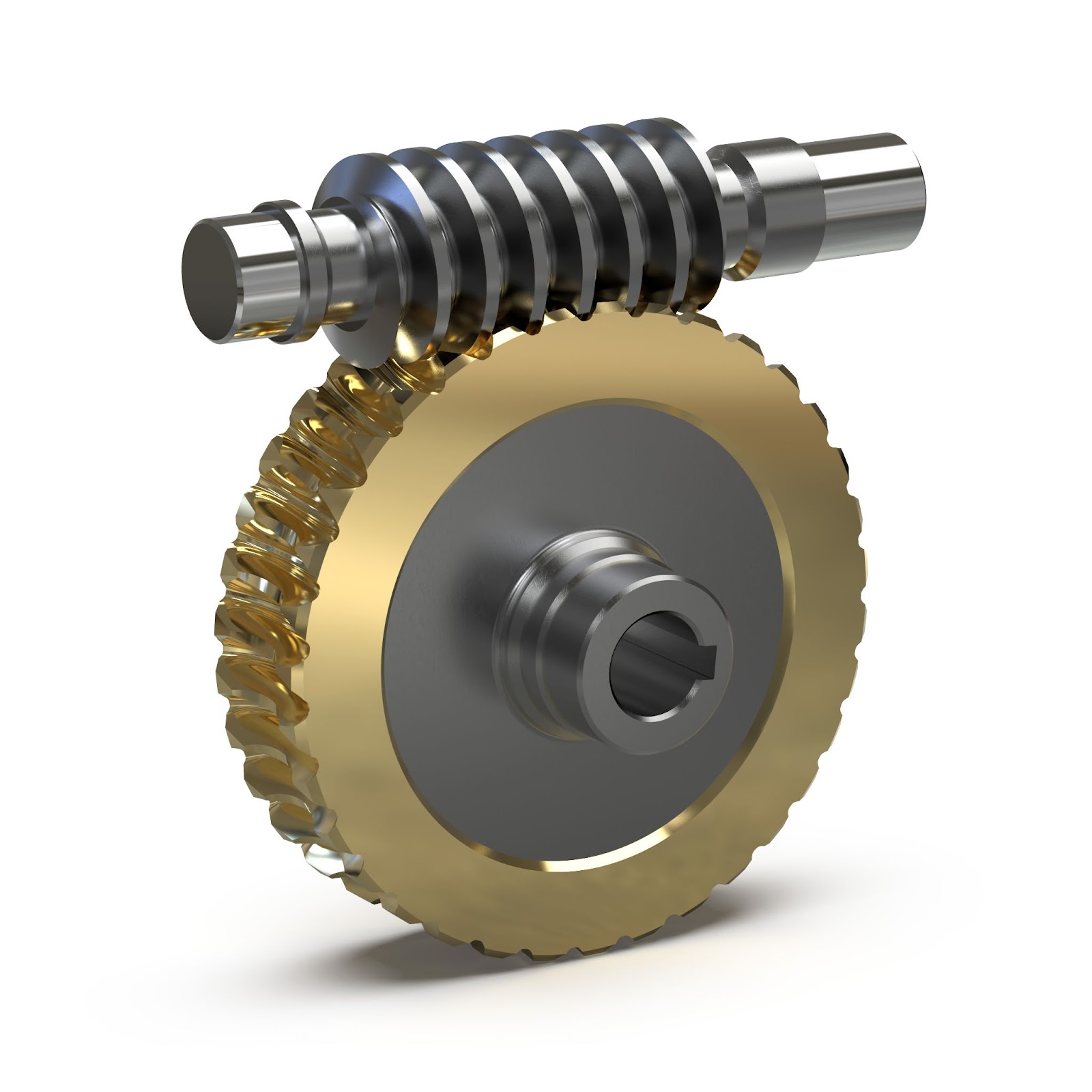

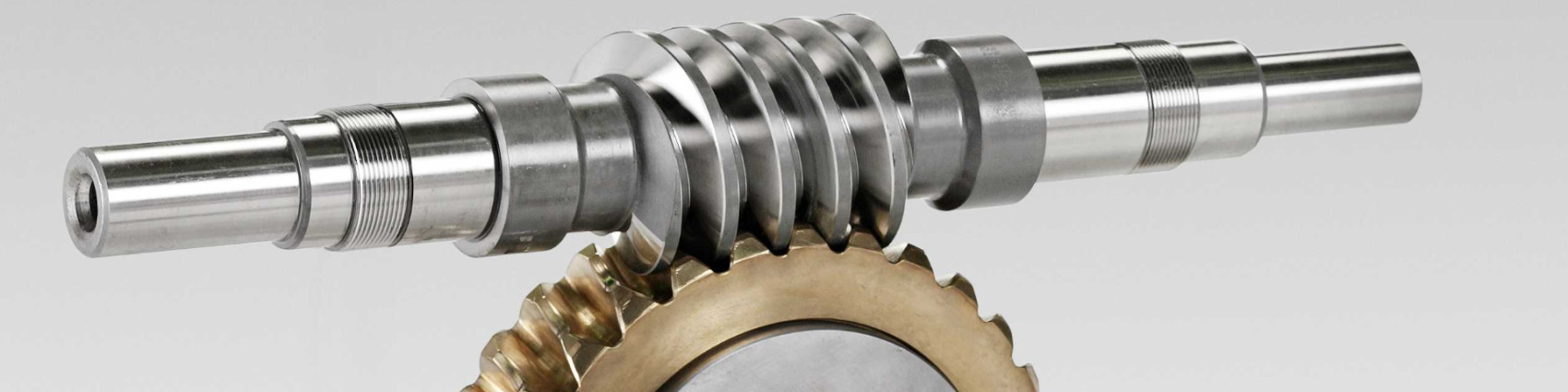

In today’s global marketplace, sourcing high-quality worm and wheel gears can be a complex challenge for B2B buyers, particularly those operating in dynamic regions like Africa, South America, the Middle East, and Europe. These specialized gear systems, essential for applications ranging from speed reducers to automotive power steering, require careful consideration of factors such as material composition, efficiency, and compatibility. This comprehensive guide aims to demystify the intricacies of worm and wheel gears by exploring various types, their applications, supplier vetting processes, and cost considerations.

By addressing the unique needs and challenges faced by international buyers, this guide equips decision-makers with the knowledge necessary to make informed purchasing choices. Whether you are looking to optimize your machinery performance or ensure reliable operation in harsh environments, understanding the nuances of worm gear systems is crucial. We delve into key aspects such as the advantages and limitations of different materials, the importance of reduction ratios, and the significance of supplier reliability in ensuring product quality.

Ultimately, this resource empowers B2B buyers to navigate the global market with confidence, facilitating effective procurement strategies that align with operational goals and regional demands. With a focus on actionable insights and practical guidance, this guide serves as your roadmap to successfully sourcing worm and wheel gears tailored to your specific business needs.

Understanding worm and wheel gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cylindrical Worm Gear | Features a cylindrical thread; offers compact design | Speed reducers, machine tools | Pros: High speed reduction, compact size. Cons: Lower efficiency (30-60%). |

| Drum-Shaped Worm Gear | Drum-shaped thread; also known as throated worm gear | Elevators, automotive power steering | Pros: Enhanced load capacity. Cons: More complex design may increase costs. |

| Dual-Lead Worm Gear | Two different leads; allows for axial adjustment | Robotics, precision machinery | Pros: Adjustable backlash, improved performance. Cons: Higher manufacturing complexity. |

| Small Module Worm Gear | Smaller module sizes (0.25 to 0.8) for precision tasks | Medical equipment, robotics | Pros: Ideal for tight spaces and high precision. Cons: Limited load capacity. |

| Plastic Worm Gear | Made from engineering plastics; lightweight and corrosion-resistant | Light-duty applications, consumer products | Pros: Low weight, no lubrication needed. Cons: Limited load and temperature tolerance. |

What Are the Characteristics of Cylindrical Worm Gears?

Cylindrical worm gears consist of a screw-shaped worm that meshes with a cylindrical worm wheel. This design allows for a compact configuration that can achieve significant speed reductions, often up to 1/120. They are commonly used in applications requiring efficient torque transmission, such as speed reducers and machine tools. Buyers should consider the efficiency ratings, typically between 30-60%, as well as material choices that affect durability and wear.

How Do Drum-Shaped Worm Gears Differ from Other Types?

Drum-shaped worm gears, or throated worm gears, feature a drum-like thread that enhances load capacity compared to cylindrical types. This design is particularly beneficial in applications such as elevators and automotive power steering, where higher torque is essential. While they provide greater strength, the complexity of the design may lead to higher manufacturing costs, which buyers should factor into their purchasing decisions.

What Advantages Do Dual-Lead Worm Gears Offer?

Dual-lead worm gears feature two different lead angles, allowing for axial adjustment to maintain optimal performance and reduce backlash. This makes them suitable for precision applications such as robotics and high-tech machinery. While they provide enhanced functionality, the increased complexity in manufacturing can lead to higher costs. Buyers must evaluate the trade-off between performance and expense when considering this type.

Why Choose Small Module Worm Gears for Precision Applications?

Small module worm gears, typically ranging from 0.25 to 0.8, are designed for applications requiring high precision in tight spaces, such as medical devices and robotics. Their compact size allows for integration into smaller assemblies, but they may have limitations in load capacity. Buyers should assess the specific requirements of their applications to determine if the benefits of precision outweigh the potential constraints on performance.

What Are the Key Benefits and Limitations of Plastic Worm Gears?

Plastic worm gears are constructed from engineering plastics, making them lightweight and resistant to corrosion. They are ideal for light-duty applications where lubrication is not feasible, such as in consumer products. However, their load capacity and temperature tolerance are limited compared to metal counterparts. Buyers should consider the specific operational environment and load requirements when opting for plastic worm gears, ensuring they align with the intended application.

Key Industrial Applications of worm and wheel gear

| Industry/Sector | Specific Application of worm and wheel gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machining | High precision and reliability in motion control | Material quality, precision standards, and customization options |

| Automotive | Power Steering Systems | Enhanced steering control and safety | Compatibility with existing systems and durability under stress |

| Material Handling | Conveyor Systems | Efficient material movement and space optimization | Load capacity, gear ratio, and environmental resistance |

| Elevators and Lifts | Elevator Mechanisms | Space-saving design and smooth operation | Compliance with safety regulations and maintenance requirements |

| Robotics and Automation | Robotic Arms and Automated Machinery | Precision in positioning and movement control | Size, weight, and power efficiency for specific applications |

How are Worm and Wheel Gears Used in Manufacturing?

In the manufacturing sector, worm and wheel gears are critical for CNC machining applications. They provide high precision and reliability in controlling the movement of machine parts, ensuring accurate cuts and assembly. The self-locking feature of worm gears prevents reverse motion, enhancing safety and operational efficiency. For international buyers, sourcing gears made from high-quality materials and adhering to strict precision standards is essential to maintain the integrity of manufacturing processes, especially in regions with varying industrial regulations.

What Role Do Worm and Wheel Gears Play in Automotive Applications?

Worm and wheel gears are integral to automotive power steering systems, where they facilitate enhanced steering control and safety. By converting rotational motion into linear movement, these gears allow for a smoother driving experience, particularly in heavy vehicles. Buyers in the automotive sector should prioritize sourcing gears that demonstrate compatibility with existing systems and are designed for durability under stress, especially in markets like Saudi Arabia and South America where road conditions can be challenging.

How Are Worm and Wheel Gears Beneficial in Material Handling?

In material handling, worm and wheel gears are commonly used in conveyor systems, optimizing the movement of goods across production lines. Their compact design and ability to provide a significant speed reduction make them ideal for fitting into tight spaces while maintaining efficiency. Businesses should consider factors such as load capacity and gear ratio when sourcing these components, as well as their resistance to environmental factors like dust and moisture, which are prevalent in many industrial settings.

Why Are Worm and Wheel Gears Important for Elevators and Lifts?

Worm and wheel gears are essential in elevator mechanisms, offering a space-saving design that is crucial for urban infrastructure. Their ability to provide smooth operation and high reduction ratios ensures that elevators function efficiently and reliably. Buyers in this sector must focus on compliance with safety regulations and the maintenance requirements of these systems, particularly in regions where elevator technology may be subject to strict inspection and certification processes.

How Do Worm and Wheel Gears Enhance Robotics and Automation?

In robotics and automation, worm and wheel gears facilitate precise positioning and movement control in robotic arms and automated machinery. Their unique design allows for compact setups while delivering high torque and low backlash, which are critical in automated processes. International buyers should seek suppliers who offer custom solutions tailored to specific applications, ensuring that the size, weight, and power efficiency meet the demands of advanced robotic systems, particularly in emerging markets across Africa and Asia.

3 Common User Pain Points for ‘worm and wheel gear’ & Their Solutions

Scenario 1: Difficulty in Achieving Desired Speed Reduction Ratios

The Problem: Many B2B buyers, particularly those in industries like manufacturing and robotics, struggle to achieve the required speed reduction ratios with standard gear systems. This challenge often leads to operational inefficiencies, as the wrong gear configuration can result in excessive wear, noise, and even failure of machinery. Buyers may find themselves overwhelmed by the technical specifications needed to select the right worm and wheel gear combination, especially when they require specific performance metrics for their applications.

Illustrative image related to worm and wheel gear

The Solution: To effectively address this challenge, buyers should start by conducting a thorough analysis of their application’s requirements, including desired output speed, torque, and load capacity. Once these parameters are established, they can utilize specialized gear selection tools or software offered by manufacturers, like KHK, which provide detailed insights on gear combinations, including reduction ratios. Buyers should also consider engaging with technical support teams from gear suppliers to ensure they are selecting the most suitable products. This proactive approach not only optimizes performance but also extends the lifecycle of machinery by preventing issues related to incorrect gear selection.

Scenario 2: High Wear Rates and Inefficiencies in Power Transmission

The Problem: A common pain point for B2B buyers is the high wear rates associated with worm and wheel gears, which often leads to increased maintenance costs and downtime. This issue can be particularly pronounced in environments that demand high torque and continuous operation, such as in conveyor systems or automotive applications. Buyers frequently face the dilemma of balancing cost with the need for durability, leading to frustration when the components do not perform as expected.

The Solution: To mitigate wear and improve efficiency, buyers should consider specifying gears made from superior materials and coatings designed for high-load applications. For example, opting for worm gears made from hardened steel or stainless steel can significantly enhance durability compared to standard materials. Additionally, implementing proper lubrication practices is crucial; using synthetic or high-viscosity lubricants can reduce friction and wear. Buyers should also regularly monitor the performance of their gear systems and be open to adjusting the gear combination if excessive wear is detected. This proactive maintenance strategy can lead to more efficient operations and lower long-term costs.

Scenario 3: Challenges with Backlash and Precision Alignment

The Problem: In applications requiring high precision, such as robotics or CNC machinery, backlash can pose significant challenges. This unwanted play between the worm and the worm wheel can lead to inaccuracies in positioning and control, ultimately affecting product quality. B2B buyers often encounter difficulties in achieving the necessary precision due to varying manufacturing tolerances and the natural wear of components over time.

The Solution: To effectively manage backlash, buyers should look for worm gear sets that include adjustable features, such as dual-lead worms, which allow for precise axial movement. This capability enables easy backlash adjustments without altering the gear center distance, making maintenance more efficient. Additionally, buyers should prioritize suppliers that offer high-precision gear manufacturing standards and quality control processes. Regular inspections and maintenance checks, including alignment assessments, can also help identify potential issues before they escalate. Investing in precision-engineered components and maintaining them diligently will ensure that the machinery operates at optimal levels, thereby improving overall output quality and reliability.

Strategic Material Selection Guide for worm and wheel gear

What Are the Key Properties of Common Materials for Worm and Wheel Gears?

When selecting materials for worm and wheel gears, several factors such as mechanical properties, environmental resistance, and manufacturing complexity must be considered. Below, we analyze four common materials used in the production of worm and wheel gears: carbon steel, stainless steel, bronze, and engineering plastics.

How Does Carbon Steel Perform in Worm and Wheel Gear Applications?

Key Properties: Carbon steel, particularly grades like S45C and SCM440, offers high strength and hardness, making it suitable for high-load applications. It has good wear resistance and can withstand moderate temperatures.

Pros & Cons: The primary advantage of carbon steel is its durability and cost-effectiveness. However, it is prone to corrosion if not properly treated, which can limit its use in humid or corrosive environments. Additionally, the manufacturing process can be complex, requiring heat treatment for optimal performance.

Impact on Application: Carbon steel is ideal for general-purpose applications where strength is crucial, such as in machinery and automotive components. However, it may not be suitable for environments exposed to moisture or chemicals without protective coatings.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards (e.g., ASTM, JIS) for carbon steel. The availability of quality carbon steel can vary, making it essential to source from reputable suppliers.

What Advantages Does Stainless Steel Offer for Worm and Wheel Gears?

Key Properties: Stainless steel, particularly grades like SUS303, provides excellent corrosion resistance and durability. It can withstand higher temperatures and is often used in applications requiring hygiene, such as food processing.

Pros & Cons: The key advantage of stainless steel is its resistance to rust and staining, making it suitable for harsh environments. However, it is more expensive than carbon steel and can be more challenging to machine, potentially increasing manufacturing costs.

Impact on Application: Stainless steel gears are ideal for applications in the food and beverage industry, pharmaceuticals, and marine environments. They ensure longevity and reliability in corrosive conditions.

Considerations for International Buyers: Buyers in the Middle East and Europe may prefer stainless steel due to its compliance with health and safety regulations. Understanding the specific grade requirements is crucial for ensuring compatibility with local standards.

How Does Bronze Compare in Terms of Performance for Worm and Wheel Gears?

Key Properties: Bronze, particularly phosphor bronze, is known for its excellent wear resistance and low friction properties. It performs well under high loads and has good corrosion resistance, particularly in marine environments.

Pros & Cons: The primary advantage of bronze is its ability to withstand wear and tear, making it suitable for high-load applications. However, it is generally more expensive than steel options and can be heavier, which may not be ideal for all applications.

Impact on Application: Bronze is commonly used in applications such as marine equipment, automotive components, and heavy machinery, where durability and resistance to wear are critical.

Considerations for International Buyers: In regions like Europe and South America, buyers should be aware of the specific bronze alloys available and their compliance with local standards. The cost and availability can vary significantly, influencing purchasing decisions.

What Role Do Engineering Plastics Play in Worm and Wheel Gear Applications?

Key Properties: Engineering plastics, such as MC nylon, offer lightweight and corrosion-resistant properties. They are capable of operating in a wide temperature range and are often self-lubricating.

Pros & Cons: The main advantage of engineering plastics is their low weight and resistance to corrosion, making them suitable for applications where reducing weight is essential. However, they may not withstand high loads as effectively as metals, limiting their use in heavy-duty applications.

Impact on Application: Engineering plastics are ideal for applications in robotics, medical equipment, and consumer products where weight and corrosion resistance are priorities.

Illustrative image related to worm and wheel gear

Considerations for International Buyers: Buyers in regions like Africa and Vietnam should consider the availability and cost of engineering plastics, as well as their compliance with local manufacturing standards. Understanding the specific application requirements is crucial for selecting the appropriate plastic material.

Summary Table of Material Selection for Worm and Wheel Gears

| Material | Typical Use Case for worm and wheel gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Machinery, automotive components | High strength and cost-effective | Prone to corrosion without treatment | Medium |

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Bronze | Marine equipment, heavy machinery | Excellent wear resistance | More expensive and heavier | High |

| Engineering Plastics | Robotics, medical equipment | Lightweight and corrosion-resistant | Limited load-bearing capacity | Medium |

This strategic material selection guide provides B2B buyers with actionable insights to make informed decisions when sourcing worm and wheel gears, considering performance, cost, and regional compliance factors.

In-depth Look: Manufacturing Processes and Quality Assurance for worm and wheel gear

What Are the Key Manufacturing Processes for Worm and Wheel Gears?

Manufacturing worm and wheel gears is a specialized process that requires precision and adherence to strict quality standards. The main stages of manufacturing include material preparation, forming, assembly, and finishing. Understanding these processes is vital for B2B buyers to ensure they select reliable suppliers who can deliver high-quality products.

How Is Material Prepared for Worm and Wheel Gear Production?

The first step in the manufacturing process is material preparation. The choice of material is crucial, as it influences the performance and durability of the gears. Common materials used include mechanical structural carbon steel, alloy steel, stainless steel, and various non-ferrous materials like bronze and aluminum.

-

Material Selection: Suppliers typically provide a range of materials based on the application requirements. For instance, harder materials are often chosen for worms to reduce wear against the softer worm wheels.

-

Cutting and Shaping: After selecting the appropriate material, it undergoes cutting to achieve the desired dimensions. This may involve methods like machining or laser cutting, depending on the complexity and specifications of the gear.

What Techniques Are Used in Forming Worm and Wheel Gears?

The forming stage is where the actual shape of the worm and wheel is created. This involves several techniques:

-

Hobbing: A common method for producing the teeth of the worm wheel. A hob cuts the gear teeth into the wheel with high precision.

-

Thread Cutting: For the worm, the process involves cutting a screw-like thread into a cylindrical rod. This is crucial as the geometry of the worm’s thread directly affects the gear’s performance.

-

Grinding: After forming, gears may undergo grinding to achieve the required surface finish and dimensional accuracy. This step is especially important for high-precision applications, as it enhances the wear resistance of the gears.

How Are Worm and Wheel Gears Assembled?

The assembly process involves fitting the worm and wheel together to ensure they operate smoothly. This includes:

-

Alignment: Proper alignment is critical to prevent excessive wear and ensure efficient power transmission. Suppliers may use specialized fixtures to maintain precise alignment during assembly.

-

Backlash Adjustment: The assembly must account for backlash, which is the slight movement between the worm and wheel. Some designs allow for axial movement of the worm to adjust this gap, ensuring optimal performance.

-

Lubrication: Appropriate lubrication is applied during assembly to minimize friction and heat generation during operation. The choice of lubricant can vary based on the operating environment and load conditions.

What Are the Finishing Processes for Worm and Wheel Gears?

Finishing processes enhance the gear’s performance and longevity. These processes may include:

-

Heat Treatment: This process involves heating the gears to alter their physical properties, improving hardness and resistance to wear.

-

Coating: Some manufacturers apply coatings to improve corrosion resistance or reduce friction. Common coatings include zinc plating or specialized polymer coatings.

-

Quality Inspection: Before final packaging, gears undergo rigorous inspection to ensure they meet specified tolerances and quality standards.

What Quality Control Standards Should B2B Buyers Look For?

Quality assurance in the manufacturing of worm and wheel gears is vital for ensuring product reliability. International standards, such as ISO 9001, provide a framework for quality management systems that manufacturers should adhere to. Industry-specific certifications, like CE marking or API standards, may also be relevant depending on the application.

What Are the Key Quality Control Checkpoints in Gear Manufacturing?

Quality control involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials before they enter production to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, various checks are performed to monitor the process and detect any deviations from specifications. This may include dimensional checks and surface finish assessments.

-

Final Quality Control (FQC): Once the gears are completed, they undergo final inspection, which may include functional testing and dimensional verification to confirm they meet quality standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of suppliers is crucial to mitigating risks associated with product failure. Here are effective methods:

-

Supplier Audits: Conducting on-site audits can provide insight into the supplier’s manufacturing processes and quality control measures. This also allows buyers to assess compliance with international standards.

-

Quality Assurance Reports: Requesting detailed reports on quality control practices, including inspection results and testing methodologies, can help buyers evaluate supplier reliability.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of the supplier’s quality management practices and product quality.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face specific challenges in ensuring quality control. These include:

-

Understanding Local Standards: Different regions may have varying quality standards and certifications. Buyers should familiarize themselves with local regulations and standards applicable to their industries.

-

Communication Barriers: Language and cultural differences can complicate supplier interactions. Establishing clear communication protocols and expectations is essential for effective collaboration.

-

Logistics and Supply Chain Risks: The complexity of international logistics can impact product quality. Buyers should evaluate the supplier’s ability to manage logistics efficiently, including transportation and storage conditions that may affect product integrity.

By understanding the manufacturing processes and quality assurance practices for worm and wheel gears, B2B buyers can make informed decisions, ensuring they partner with suppliers who meet their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘worm and wheel gear’

This practical guide serves as a checklist for B2B buyers seeking to procure worm and wheel gears effectively. It outlines key steps to ensure that your sourcing process is efficient, reliable, and tailored to your specific requirements.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your worm and wheel gear. This includes factors such as gear ratio, material specifications, and dimensional tolerances. Understanding your application’s needs will help you select the right type of gear that ensures optimal performance and longevity.

- Gear Ratio: Determine the required speed reduction ratio and the load capacity necessary for your application.

- Material: Choose materials based on the operating environment (e.g., corrosion resistance, temperature tolerance).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Look for manufacturers and distributors with a strong reputation in the gear industry. This step is essential to ensure that you are working with credible and experienced partners who can meet your specifications.

Illustrative image related to worm and wheel gear

- Industry Presence: Check how long the suppliers have been in business and their market reach.

- Product Range: Ensure they offer a variety of worm and wheel gears to accommodate different applications.

Step 3: Evaluate Supplier Certifications

Verify the certifications and quality standards of potential suppliers. Certifications such as ISO 9001 can indicate a commitment to quality management and continuous improvement. This is crucial for ensuring that the products you receive meet international quality standards.

- Quality Control: Ask for details on their quality assurance processes.

- Compliance: Ensure they comply with industry-specific regulations relevant to your region.

Step 4: Request Samples and Technical Documentation

Before making a bulk purchase, request samples and technical documentation. Evaluating samples allows you to assess the quality and compatibility of the worm and wheel gears with your machinery. Technical documentation provides insights into the product specifications and performance characteristics.

- Performance Testing: Look for data on load capacity and efficiency.

- Installation Guidelines: Ensure you have access to installation and maintenance instructions.

Step 5: Analyze Pricing and Payment Terms

Compare pricing structures and payment terms across different suppliers. While cost is important, it should not be the sole determining factor. Consider the total cost of ownership, including shipping and potential tariffs, to assess the best value for your investment.

- Bulk Discounts: Inquire about discounts for larger orders.

- Payment Flexibility: Evaluate payment options and terms to find a supplier that aligns with your financial strategy.

Step 6: Establish Communication and Support

Ensure that the supplier offers robust communication and support. Good communication is vital for addressing any issues that may arise during the procurement process. A responsive supplier can help resolve problems quickly, ensuring minimal disruption to your operations.

- Technical Support: Confirm the availability of technical support for installation and troubleshooting.

- After-Sales Service: Investigate warranty and service options for the products purchased.

Step 7: Finalize the Contract

Once you have selected a supplier, finalize the contract with clear terms and conditions. This step is essential to protect both parties and outline responsibilities, delivery timelines, and quality expectations. A well-drafted contract can prevent misunderstandings and ensure compliance.

- Delivery Schedule: Specify delivery timelines to align with your project needs.

- Quality Assurance Measures: Include clauses regarding quality checks and returns.

By following this checklist, B2B buyers can streamline their sourcing process for worm and wheel gears, ensuring they make informed decisions that align with their operational requirements.

Comprehensive Cost and Pricing Analysis for worm and wheel gear Sourcing

What Are the Key Cost Components in Worm and Wheel Gear Sourcing?

When sourcing worm and wheel gears, understanding the cost structure is essential. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. Common materials for worms include carbon steel, stainless steel, and alloy steels, while worm wheels may be made from bronze, cast iron, or engineering plastics. Prices can vary widely based on the material’s quality and properties, such as wear resistance and corrosion resistance.

-

Labor: The complexity of manufacturing worm gears requires skilled labor. This includes the costs associated with machining, assembly, and finishing processes. Labor costs can fluctuate based on geographical location and local wage standards.

-

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, impacting the final price.

-

Tooling: The initial investment in tooling, including molds and specialized machinery, is a significant upfront cost. However, these costs can be amortized over higher production volumes, making it more economical for larger orders.

-

Quality Control (QC): Ensuring that worm and wheel gears meet industry standards requires rigorous QC processes. This includes testing for durability, precision, and performance, which adds to overall costs.

-

Logistics: Transportation and warehousing costs can affect the final price, particularly for international shipments. Factors such as shipping methods, distances, and import tariffs must be considered.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market competition and the supplier’s business strategy.

How Do Price Influencers Affect Worm Gear Costs?

Several factors can influence the pricing of worm and wheel gears:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can often secure better pricing due to economies of scale. Conversely, low-volume orders may incur higher per-unit costs.

-

Specifications and Customization: Custom gears designed to meet specific application requirements can significantly increase costs. The more complex the specifications, the higher the price.

-

Materials and Quality Certifications: Higher-quality materials or specific certifications (e.g., ISO standards) can lead to increased costs. Buyers should assess whether these certifications are essential for their applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for budgeting.

What Tips Can Help Buyers Negotiate Better Prices for Worm Gears?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Leverage Negotiation: Engage in discussions with multiple suppliers to compare offers. Highlighting competitive offers can encourage suppliers to adjust their pricing.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price, but also the long-term costs associated with maintenance, potential downtime, and energy efficiency. A higher upfront cost may result in lower TCO.

-

Understand Pricing Nuances: Be aware of seasonal fluctuations, currency exchange rates, and local market conditions that can impact pricing. Building relationships with suppliers can also provide insights into upcoming price changes.

-

Consider Local Suppliers: Sourcing from local manufacturers may reduce logistics costs and lead times, providing a competitive advantage.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of costs, allowing for better comparison and understanding of pricing structures.

Conclusion

Navigating the cost and pricing landscape for worm and wheel gear sourcing requires a comprehensive understanding of the various components and influencing factors. By strategically evaluating these elements, international B2B buyers can make informed decisions that optimize their procurement processes. Always remember that prices can vary based on numerous factors, and it is advisable to seek multiple quotes for a well-rounded understanding of market rates.

Alternatives Analysis: Comparing worm and wheel gear With Other Solutions

Exploring Alternatives to Worm and Wheel Gears: A Comparative Analysis

When selecting mechanical solutions for power transmission, understanding the available alternatives to worm and wheel gears is essential. This analysis provides insights into two viable alternatives: spur gears and helical gears, allowing B2B buyers to make informed decisions based on their specific operational needs.

| Comparison Aspect | Worm and Wheel Gear | Spur Gear | Helical Gear |

|---|---|---|---|

| Performance | High torque, compact design, 30-60% efficiency | High efficiency, direct power transmission | Smooth operation, high load capacity |

| Cost | Moderate to high, depends on materials used | Generally low, widely available | Higher than spur gears due to complexity |

| Ease of Implementation | Requires precise alignment; self-locking feature | Simple installation; no special tools required | More complex to install due to angled teeth |

| Maintenance | Moderate; requires lubrication and monitoring for wear | Low; minimal maintenance needed | Moderate; regular lubrication needed for optimal performance |

| Best Use Case | Applications needing high torque in limited space (e.g., elevators) | High-speed applications with minimal space (e.g., conveyors) | Applications requiring high load capacity and quiet operation (e.g., automotive) |

In-Depth Look at Alternatives

Spur Gears

Spur gears are the simplest type of gear, featuring straight teeth that are parallel to the gear axis. Their design allows for efficient power transmission and high reliability. They are typically less expensive than worm and wheel gears, making them an attractive option for many manufacturers. However, they are best suited for applications where the shafts are parallel, which limits their versatility compared to worm gears. In applications where space is at a premium, spur gears may not provide the same level of torque reduction as worm gears do.

Helical Gears

Helical gears are characterized by their angled teeth, which allow for smoother engagement and increased load-carrying capacity. They operate more quietly and efficiently than spur gears, making them ideal for applications where noise reduction is crucial, such as in automotive transmissions. However, their design complexity makes them more expensive and may require more maintenance due to the need for regular lubrication. Helical gears excel in high-speed applications, but they do not offer the same compact design advantages as worm and wheel gears.

Conclusion: Choosing the Right Gear Solution for Your Needs

Selecting the appropriate gear solution depends on the specific requirements of your application. Worm and wheel gears provide unique advantages in torque and compactness, making them suitable for applications where space and high torque are critical. Conversely, spur gears offer a cost-effective and straightforward solution for parallel shaft applications, while helical gears excel in high-load and noise-sensitive environments. B2B buyers should carefully evaluate their operational needs, considering factors such as performance requirements, budget constraints, and maintenance capabilities to determine the best gear solution for their applications.

Essential Technical Properties and Trade Terminology for worm and wheel gear

What Are the Key Technical Properties of Worm and Wheel Gears?

Understanding the essential technical properties of worm and wheel gears is vital for B2B buyers involved in manufacturing, machinery, and engineering applications. Below are critical specifications that influence the performance and suitability of these gears.

Illustrative image related to worm and wheel gear

-

Material Grade

– The materials used in worm gears significantly impact their durability and performance. Common materials include mechanical structural carbon steel (like S45C), stainless steel, and various bronzes. For instance, using harder materials for worms compared to worm wheels reduces wear and extends service life. Choosing the right material ensures the gear can withstand operational stresses and environmental conditions, which is crucial for reliability in industrial applications. -

Reduction Ratio

– The reduction ratio defines how much the input speed is decreased when transferred through the gear set. Worm gears can achieve high reduction ratios, sometimes up to 1/120, making them ideal for applications requiring significant speed reduction in a compact space. Understanding the required reduction ratio helps buyers select appropriate gear pairs for specific applications, enhancing system efficiency. -

Efficiency Rating

– Worm gears typically exhibit lower efficiency (about 30-60%) due to sliding contact between the worm and the wheel. This characteristic can lead to heat retention, which may affect performance. Buyers must consider the efficiency rating to ensure their systems can operate effectively and avoid overheating, especially in high-load applications. -

Backlash

– Backlash refers to the amount of play between the gear teeth when the direction of motion changes. In worm gears, this can be adjusted, particularly with dual-lead worms, allowing for fine-tuning of the gear assembly. Understanding backlash is essential for applications requiring precision, such as robotics and CNC machinery, where even small deviations can lead to significant errors. -

Lead Angle

– The lead angle of the worm affects its self-locking properties. A smaller lead angle can prevent reverse motion, making it useful in applications like lifts and conveyors. However, this feature is not entirely reliable, so it’s advisable to combine it with other mechanisms for safety. Buyers should assess lead angles based on application requirements to ensure optimal functionality. -

Module Size

– The module size indicates the tooth size and spacing, affecting load capacity and compatibility with other gears. Smaller modules are suitable for high-tech applications, while larger modules can handle heavier loads. Selecting the right module size is crucial for ensuring that the gear system meets the operational demands without failure.

What Are Common Trade Terms Used in Worm and Wheel Gear Transactions?

Navigating the B2B landscape requires familiarity with specific trade terminology. Here are some essential terms related to worm and wheel gears.

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for compatible gear systems or replacements, ensuring they procure components that meet their specifications. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest number of units a supplier is willing to sell. This term is essential for buyers to understand production economics and inventory management. Knowing the MOQ can help companies avoid overstocking or incurring higher costs per unit. -

RFQ (Request for Quotation)

– An RFQ is a standard business process wherein a buyer requests price quotes from suppliers for specific products or services. This is particularly important in the gear industry, where custom specifications can vary widely. A well-prepared RFQ can streamline the procurement process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

– These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is critical for international buyers to avoid misunderstandings regarding shipping costs, insurance, and delivery responsibilities. -

Lead Time

– Lead time is the amount of time from placing an order to receiving the goods. Understanding lead times helps businesses plan their operations and manage inventory effectively, particularly in industries where downtime can be costly. -

Tolerances

– Tolerance refers to the allowable deviation in dimensions and specifications for gear components. Understanding tolerances is vital for ensuring that components fit together correctly and operate smoothly, especially in precision applications.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing worm and wheel gears, ultimately leading to enhanced operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the worm and wheel gear Sector

What Are the Current Trends and Dynamics in the Global Worm and Wheel Gear Market?

The worm and wheel gear market is witnessing significant evolution driven by technological advancements and shifting industrial needs. Globally, the demand for compact gear systems that can provide high-speed reductions in limited spaces is growing, particularly in sectors such as robotics, automotive, and material handling. Emerging economies in Africa and South America are increasingly adopting automation technologies, driving the need for efficient motion control solutions. In the Middle East, infrastructure projects and energy sectors are pushing the demand for reliable and durable gear systems.

One of the prominent trends is the integration of digital technologies in the sourcing process. B2B buyers are leveraging online platforms for gear selection, allowing them to compare specifications and prices efficiently. The rise of Industry 4.0 has also led to the adoption of smart manufacturing practices, encouraging the use of customizable gear solutions that meet specific operational requirements. Moreover, sustainability is becoming a critical factor, as buyers are increasingly concerned about the environmental impacts of their sourcing choices. This includes a focus on suppliers that offer ‘green’ materials and sustainable manufacturing processes.

Illustrative image related to worm and wheel gear

How Are Sustainability and Ethical Sourcing Impacting the Worm and Wheel Gear Sector?

Sustainability is becoming a cornerstone of procurement strategies within the worm and wheel gear sector. The environmental impact of manufacturing processes, particularly those involving metal and plastic components, has prompted international buyers to seek suppliers committed to reducing their carbon footprint. This includes the use of recycled materials and energy-efficient production methods.

Ethical sourcing practices are also gaining traction, with companies prioritizing suppliers that adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and other green certifications are becoming essential for suppliers aiming to appeal to conscientious B2B buyers. These certifications not only demonstrate a commitment to sustainability but also enhance brand reputation and customer loyalty.

Moreover, the development of alternative materials, such as engineering plastics and composites, is creating opportunities for more sustainable gear solutions. These materials can reduce weight and energy consumption while maintaining performance standards, aligning with the growing emphasis on eco-friendly products in global markets.

What Is the Historical Context of Worm and Wheel Gears in B2B Applications?

The use of worm and wheel gears dates back to ancient times, with early references attributed to Archimedes around 250 BC. Initially, these gears were employed in simple machines for lifting and turning mechanisms. Over centuries, their design and application evolved, leading to the sophisticated variants used today in various industrial applications.

The advent of the Industrial Revolution in the 18th century marked a significant turning point, as the demand for efficient power transmission systems surged. Worm gears became integral to machinery in sectors such as textiles, mining, and transportation, known for their ability to provide high torque with minimal space requirements. In contemporary applications, these gears are ubiquitous in robotics, automotive power steering, and even consumer electronics, highlighting their versatility and enduring significance in the B2B landscape.

Understanding this historical context allows buyers to appreciate the technological advancements that have shaped the worm and wheel gear market, enabling informed sourcing decisions that align with current industry needs and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of worm and wheel gear

-

How do I solve issues with worm gear overheating?

Overheating in worm gears is often due to excessive friction between the worm and the wheel, typically caused by inadequate lubrication or misalignment. To mitigate this, ensure that the correct lubricant is used and that the gear assembly is properly aligned. Additionally, consider using materials with better thermal conductivity or increasing the size of the worm gear to distribute heat more effectively. Regular maintenance and inspections can also help identify potential problems before they escalate. -

What is the best worm gear ratio for high torque applications?

For high torque applications, a worm gear with a higher reduction ratio is generally preferred. Ratios of 30:1 to 120:1 are common in applications requiring significant torque, such as lifts or heavy machinery. The choice of ratio depends on the specific requirements of your application, including load conditions and speed preferences. It’s essential to balance the desired torque with efficiency, as higher ratios can lead to increased heat generation and reduced efficiency. -

What should I consider when vetting suppliers for worm and wheel gears?

When vetting suppliers, prioritize their manufacturing capabilities, quality certifications (like ISO), and experience in producing worm gears. Request samples or prototypes to evaluate the gear quality and performance. Inquire about their production processes, material sourcing, and whether they offer customization options. Additionally, check their customer reviews and references, especially from businesses in your industry, to gauge reliability and service quality. -

Can I customize worm gears to fit specific application requirements?

Yes, many manufacturers offer customization options for worm gears, including modifications in size, material, and gear ratios. When requesting custom gears, provide detailed specifications, including load requirements, environmental conditions, and any dimensional constraints. Customization may lead to longer lead times and higher costs, so be clear about your needs to ensure the supplier can meet them effectively. -

What are the typical minimum order quantities (MOQs) for worm gears?

Minimum order quantities for worm gears can vary significantly based on the manufacturer and the complexity of the gear design. Generally, MOQs can range from 50 to several hundred units. For custom gears, MOQs may be higher due to setup costs. It’s advisable to discuss your needs with the supplier to find a mutually beneficial arrangement, especially if you require smaller quantities for prototyping or testing. -

What payment terms should I expect when sourcing worm gears internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, partial deposits, and net payment terms (e.g., Net 30 or Net 60). For international transactions, using secure payment methods like letters of credit or escrow services can provide additional security. Always clarify payment terms before finalizing the order to avoid misunderstandings and ensure a smooth transaction process. -

How do I ensure quality assurance (QA) in my worm gear purchases?

To ensure quality assurance, request a detailed quality control plan from your supplier, which should outline their inspection processes and standards. Consider asking for third-party certifications or testing results for the worm gears. Regular audits and inspections during the manufacturing process can also help maintain quality. Establish clear communication regarding your quality expectations and any specific tests you want the products to undergo before shipment. -

What logistics considerations should I keep in mind when importing worm gears?

When importing worm gears, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner experienced in handling industrial components to ensure timely delivery. Understand the lead times involved in production and shipping, as well as any potential delays at customs. Additionally, ensure that the packaging is robust to prevent damage during transit, and verify that your supplier provides all necessary documentation for customs clearance.

Top 5 Worm And Wheel Gear Manufacturers & Suppliers List

1. KHK Gears – Worm Gear Overview

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Worm Gears Product Overview: A worm gear is a staggered shaft gear that transmits motion between non-intersecting and non-parallel shafts, providing a large speed reduction in a compact design. Types of Worm Gears: 1. Cylindrical Worm Gear: Consists of a cylindrical worm and a worm wheel. 2. Drum-Shaped Worm Gear: Also known as throated worm gear, consists of a drum-shaped worm and a worm wheel. R…

2. RS Online – Worm and Pinion Gears

Domain: twen.rs-online.com

Introduction: Worm and pinion gears, also known as worm wheel gears, are used in various industrial and domestic applications requiring high torque and large reduction ratios. The worm gear resembles a threaded shaft that drives the gear, achieving a gear ratio of 50:1 with a 50-tooth gear. They are utilized in devices such as conveyor systems, tuning instruments, lifts, elevators, gates, and high-performance v…

3. Reddit – Gear Setup Inquiry

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The setup involves a DC motor turning a shaft with a worm gear connected to a small worm gear (green) and a larger gear (blue). The torque on the large gear is around 0.4Nm. The user inquires if all gears can be made of nylon and if a module 1 is sufficient. They also ask about the self-locking nature of worms and worm gears, and whether typical worms and worm gears are self-locking or require spe…

4. WMBerg – Worm Gear Drives

Domain: wmberg.com

Registered: 1996 (29 years)

Introduction: Worm gear drives are shaft gear assemblies that transmit power between non-intersecting drive and driven shafts, typically at 90° angles. They consist of a worm (driving shaft) and a worm gear (driven shaft) with angled teeth for optimal performance. Worm gears can be left or right-hand threaded. They reduce speed and increase torque, making them suitable for applications requiring significant tor…

5. Boston Gear – Worm Gears

Domain: bostongear.com

Introduction: Worm Gears from Boston Gear include various series such as the 700 Series (Standard, Posivent, QC, Modified, CFA, Washdown) and stainless steel options (Gen2 SS700 Series). They are part of the Open Gearing product line, which also features custom and modified gears. Key applications span multiple industries including Aerospace, Amusement Rides, Elevators, Agriculture, Food and Beverage, Marine, M…

Strategic Sourcing Conclusion and Outlook for worm and wheel gear

What Are the Key Takeaways for B2B Buyers in the Worm and Wheel Gear Market?

Strategic sourcing of worm and wheel gears is essential for international buyers seeking reliable, efficient, and high-performance solutions. The unique design of worm gears allows for significant speed reduction in compact applications, making them ideal for various industries, including manufacturing, automotive, and robotics. Understanding the materials used, such as high-strength steels and specialized alloys, can aid in selecting the right gear for your specific needs, ensuring longevity and efficiency.

How Can Buyers Enhance Their Procurement Strategies?

Engaging with multiple suppliers can provide competitive pricing and ensure access to the latest technological advancements in gear design. Additionally, prioritizing suppliers who offer customization options can lead to tailored solutions that meet unique operational requirements. Collaborating with manufacturers that emphasize quality control and testing can further enhance the reliability of sourced products.

What Does the Future Hold for Worm and Wheel Gear Sourcing?

As global markets evolve, the demand for innovative and efficient gear solutions will continue to rise. Buyers from Africa, South America, the Middle East, and Europe should stay informed about market trends and emerging technologies. By adopting a proactive approach to sourcing, businesses can position themselves for growth and success in an increasingly competitive landscape. Explore partnerships with reputable manufacturers today to secure a competitive edge in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to worm and wheel gear

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.