A B2B Buyer’s Guide to What Is Laboratory Bench: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for what is laboratory bench

In the dynamic landscape of global laboratory operations, understanding what a laboratory bench is and how to source the right one can significantly impact efficiency and safety. For international B2B buyers, particularly those in emerging markets like Africa and South America, as well as established regions in the Middle East and Europe, the challenge lies in identifying laboratory benches that meet diverse operational needs while ensuring compliance with local regulations and standards. This guide is designed to provide a comprehensive overview of laboratory benches, including their types, applications, and configurations tailored to specific laboratory environments, whether they are wet labs requiring utility connections or dry labs focused on expansive surfaces.

Additionally, we will delve into crucial aspects such as supplier vetting, assessing product quality, and understanding cost implications. With an emphasis on actionable insights, this guide empowers buyers to make informed purchasing decisions, ensuring that the laboratory benches they choose not only enhance productivity but also align with their unique operational requirements. By navigating the complexities of the global market for laboratory benches, buyers can optimize their laboratory setups, ultimately leading to improved research outcomes and operational success.

Understanding what is laboratory bench Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wet Lab Bench | Features sinks, reagent racks, and utility connections | Chemistry, biology, and medical labs | Pros: Supports liquid handling; customizable. Cons: Requires regular maintenance. |

| Dry Lab Bench | Flat surface with minimal attachments; often adjustable | Physics and engineering labs | Pros: Easy to clean; versatile. Cons: Limited utility connections. |

| Adjustable Workbench | Height-adjustable for ergonomic use | Various laboratory settings | Pros: Ergonomic benefits; accommodates different users. Cons: More expensive. |

| Portable Workbench | Lightweight and mobile; easy to relocate | Field research, temporary setups | Pros: Flexibility and mobility; quick setup. Cons: Less stability for heavy equipment. |

| Island Bench | Centralized workspace, often with multiple access points | Collaborative labs and open spaces | Pros: Encourages teamwork; maximizes space. Cons: May require more floor area. |

What Are the Key Characteristics of Wet Lab Benches?

Wet lab benches are integral to laboratories that handle liquids and chemicals. They typically come equipped with sinks, reagent racks, and built-in utility connections for gas, water, and electricity. This design allows for efficient liquid handling and waste disposal, making them ideal for chemistry and biology applications. When purchasing, consider the material (often epoxy resin or stainless steel) for durability and resistance to chemical spills. Regular maintenance is essential to ensure safety and hygiene.

How Do Dry Lab Benches Differ from Other Types?

Dry lab benches are characterized by their flat surfaces and minimal attachments, making them suitable for labs that do not require water or chemical handling, such as physics or engineering labs. These benches often feature adjustable heights to enhance user ergonomics. When selecting a dry lab bench, buyers should focus on surface material and stability, as these benches are primarily used for equipment setups. Their simplicity allows for easy cleaning, but they may lack the utility connections found in wet lab benches.

What Advantages Do Adjustable Workbenches Offer?

Adjustable workbenches are designed to accommodate users of varying heights, promoting ergonomic practices in laboratory settings. These benches can be raised or lowered to suit specific tasks, making them particularly valuable in multi-user environments. Buyers should evaluate the adjustment mechanism for ease of use and durability. While they provide significant ergonomic benefits, adjustable workbenches may come at a higher price point compared to standard models.

Why Choose Portable Workbenches for Laboratory Use?

Portable workbenches offer flexibility and mobility, allowing laboratories to adapt to changing needs or temporary setups. They are lightweight and easy to transport, making them ideal for field research or situations requiring quick assembly. However, buyers should assess the stability and weight capacity of these benches, as they may not support heavy equipment as effectively as fixed models. Their convenience is a significant advantage, but potential trade-offs in stability should be considered.

What Are the Benefits of Island Benches in Collaborative Settings?

Island benches provide a central workspace that can be accessed from multiple sides, fostering collaboration among lab users. They are particularly suited for open-plan laboratories where teamwork is essential. When selecting an island bench, consider the space available, as they require more floor area than traditional benches. While they enhance interaction and workflow, the need for additional space may be a limitation for smaller laboratories.

Key Industrial Applications of what is laboratory bench

| Industry/Sector | Specific Application of what is laboratory bench | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Drug formulation and testing | Enhances precision and safety in drug development | Compliance with regulatory standards, durability, and chemical resistance |

| Education | Science labs in schools and universities | Facilitates hands-on learning and research opportunities | Customization for specific disciplines and ergonomic design |

| Environmental Testing | Sample analysis and testing | Supports accurate data collection for environmental studies | Resistant materials for chemical exposure and easy cleaning features |

| Food and Beverage | Quality control and testing | Ensures product safety and compliance with health standards | Sanitary design, easy access to utilities, and storage solutions |

| Research and Development | Prototype testing and experimentation | Drives innovation and accelerates product development | Modular designs for flexibility and adaptability to changing needs |

How are Laboratory Benches Used in the Pharmaceutical Industry?

In the pharmaceutical sector, laboratory benches serve as the primary work surface for drug formulation and testing. These benches are designed to accommodate specialized equipment and provide utility connections for gas, water, and electricity. The precision and safety they offer are crucial for compliance with stringent regulatory standards. Buyers in this industry should prioritize benches made from durable, chemical-resistant materials to ensure longevity and protect against spills.

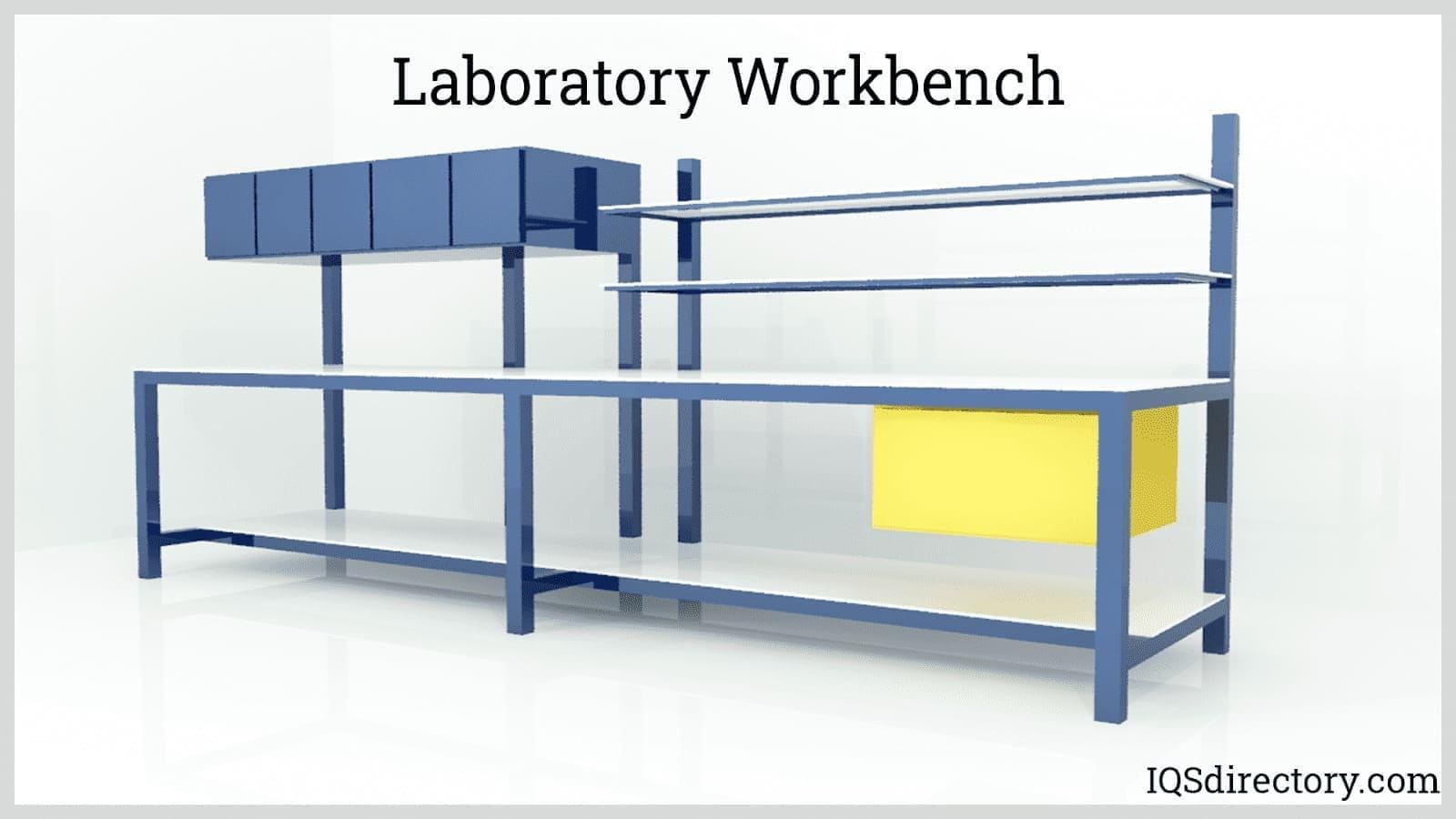

Illustrative image related to what is laboratory bench

What Role Do Laboratory Benches Play in Education?

In educational institutions, laboratory benches are vital for facilitating hands-on learning in science labs. They provide students with a designated workspace to conduct experiments, thereby enhancing their understanding of scientific principles. The design of these benches can be customized to cater to different disciplines, such as chemistry or biology, ensuring that students have the right tools for their studies. Ergonomic considerations are essential to accommodate various user heights and promote a comfortable learning environment.

How are Laboratory Benches Utilized in Environmental Testing?

Laboratory benches in environmental testing labs are essential for sample analysis and testing. They are equipped to handle various materials while offering features like sinks for washing equipment and storage for samples. The accuracy of data collected on these benches is critical for environmental studies, influencing policy and regulatory decisions. Buyers should consider benches that are resistant to chemicals and easy to clean, as these features enhance safety and efficiency in the lab.

What is the Importance of Laboratory Benches in the Food and Beverage Sector?

In the food and beverage industry, laboratory benches are crucial for quality control and testing. They provide a clean and organized space for conducting safety tests on food products, ensuring compliance with health standards. The benches should be designed for easy access to utilities and made from materials that can withstand frequent cleaning. This ensures that the workspace remains sanitary and meets the rigorous standards required in food safety.

How Do Laboratory Benches Support Research and Development?

In research and development environments, laboratory benches are utilized for prototype testing and experimentation. Their modular designs allow for flexibility, enabling teams to adapt the workspace as projects evolve. This adaptability fosters innovation and accelerates product development cycles. Buyers should seek benches that offer robust storage solutions and can be easily reconfigured to meet changing project requirements, ensuring a productive research environment.

3 Common User Pain Points for ‘what is laboratory bench’ & Their Solutions

Scenario 1: Customization for Diverse Laboratory Needs

The Problem: Many B2B buyers face the challenge of selecting a laboratory bench that meets the specific needs of various scientific applications. For instance, a research facility might require benches that accommodate both wet and dry lab environments. However, off-the-shelf solutions often fail to provide the necessary configurations, leading to inefficient workflows and potential safety hazards.

Illustrative image related to what is laboratory bench

The Solution: To address this challenge, buyers should engage with manufacturers who specialize in customizable laboratory furniture. Start by conducting a needs assessment that considers the specific experiments to be conducted, available space, and required utilities (like gas and water). When discussing options with suppliers, ensure they offer modular designs or benches that can be tailored to fit the lab’s unique requirements. For example, consider benches with integrated sinks and reagent racks for wet labs, while also evaluating options for electrical connections and ample storage for dry labs. This approach not only enhances operational efficiency but also ensures compliance with safety standards.

Scenario 2: Ergonomic Design for Enhanced Productivity

The Problem: Ergonomics is often overlooked in laboratory settings, leading to discomfort and decreased productivity for lab personnel. Buyers may find that standard benches do not provide adequate height adjustability or support, resulting in strain during prolonged use. This is particularly problematic in environments where tasks require extended periods of standing or leaning over work surfaces.

The Solution: To combat ergonomic challenges, it is essential to prioritize the selection of adjustable workbenches. When sourcing laboratory benches, look for models that allow for height adjustments to accommodate various users and tasks. Additionally, consider benches with features such as anti-fatigue mats or integrated seating options. Collaborating with ergonomic specialists can also help identify the best configurations for specific tasks. By investing in ergonomic furniture, businesses can enhance employee comfort, reduce the risk of workplace injuries, and ultimately improve overall productivity in the lab.

Scenario 3: Space Optimization in Compact Laboratories

The Problem: For many laboratories, especially in emerging markets, space is at a premium. B2B buyers often struggle to find laboratory benches that maximize functionality without compromising on space. Overcrowded work areas can lead to clutter, inefficient workflows, and increased risk of accidents.

The Solution: To optimize space in compact laboratories, buyers should consider multi-functional laboratory benches. Look for benches that incorporate vertical storage solutions, such as shelving or cabinets, to minimize the footprint while maximizing storage capacity. Additionally, portable workbenches can offer flexible configurations that can be moved as needed, allowing for dynamic use of space. When selecting benches, prioritize designs that include built-in utilities (like electrical outlets) to reduce the need for additional equipment. Collaborating with a laboratory design consultant can provide insights into efficient layouts that not only enhance space utilization but also promote a safer and more organized work environment.

Illustrative image related to what is laboratory bench

Strategic Material Selection Guide for what is laboratory bench

When selecting materials for laboratory benches, it is essential to consider various factors that influence performance, durability, and compliance with international standards. Below, we analyze four common materials used in laboratory bench construction, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Steel Laboratory Benches?

Steel is one of the most widely used materials for laboratory benches due to its strength and durability. Key properties include high tensile strength, resistance to deformation under pressure, and the ability to withstand high temperatures. Steel benches can be coated with various finishes to enhance corrosion resistance, making them suitable for both wet and dry labs.

Pros & Cons: The primary advantage of steel benches is their longevity and robustness, which can withstand heavy equipment and rigorous use. However, they can be susceptible to rust if not properly coated or maintained, especially in humid environments. Additionally, the cost of high-quality stainless steel can be significant, which may impact budget considerations for buyers.

Impact on Application: Steel benches are particularly suitable for laboratories that handle harsh chemicals or require high load-bearing surfaces. Their compatibility with various media makes them versatile across different scientific disciplines.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local standards for material quality and safety, such as ASTM or JIS. In Europe, adherence to DIN standards is crucial, particularly regarding corrosion resistance and structural integrity.

What Are the Benefits of Phenolic Resin Laboratory Benches?

Phenolic resin is a composite material known for its excellent chemical resistance and durability. It can withstand a wide range of temperatures and is non-porous, making it ideal for wet labs where spills are common.

Illustrative image related to what is laboratory bench

Pros & Cons: The main advantage of phenolic resin benches is their resistance to chemicals and moisture, which reduces maintenance needs. However, they can be more expensive than traditional wood or laminate options and may require specialized manufacturing processes.

Impact on Application: These benches are perfect for laboratories that regularly work with corrosive substances, such as chemical or biological labs, where traditional materials might degrade.

Considerations for International Buyers: Ensure that phenolic resin products meet international safety standards and certifications, particularly in regions with stringent regulations, such as Europe. Understanding the local market’s acceptance of composite materials is also essential.

Illustrative image related to what is laboratory bench

How Do Laminate Laboratory Benches Compare?

Laminate laboratory benches are constructed from a core material covered with a decorative and protective layer. They are lightweight and available in various colors and finishes, providing aesthetic flexibility.

Pros & Cons: Laminate benches are cost-effective and easy to clean, making them suitable for many environments. However, they are less durable than steel or phenolic resin and can be prone to chipping or delamination over time, especially in high-use settings.

Impact on Application: These benches are ideal for educational laboratories or environments where aesthetics are important, but they may not be suitable for heavy-duty applications.

Considerations for International Buyers: Buyers should verify that laminate products meet relevant safety and performance standards. In regions like the Middle East, where humidity can be high, moisture resistance is an important factor.

What Are the Characteristics of Wood Laboratory Benches?

Wooden laboratory benches are often used in educational settings or less demanding environments. They provide a warm aesthetic and are generally easy to customize.

Illustrative image related to what is laboratory bench

Pros & Cons: The primary advantage of wooden benches is their natural appearance and ease of modification. However, they can be less durable than other materials and may absorb chemicals or moisture, leading to degradation over time.

Impact on Application: Wooden benches are suitable for dry labs or situations where chemical exposure is minimal. They are less ideal for wet labs due to potential water damage.

Considerations for International Buyers: Ensure that the wood used is sourced sustainably and treated to resist moisture and chemicals. Compliance with local regulations regarding wood treatment and safety is also essential.

Summary Table of Material Selection for Laboratory Benches

| Material | Typical Use Case for what is laboratory bench | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty labs, chemical handling | High durability and load-bearing | Susceptible to rust without coating | High |

| Phenolic Resin | Wet labs, chemical labs | Excellent chemical resistance | Higher manufacturing cost | High |

| Laminate | Educational labs, aesthetic environments | Cost-effective and easy to clean | Less durable, prone to chipping | Medium |

| Wood | Dry labs, low-demand environments | Aesthetic appeal and customization | Less durable, moisture absorption | Medium |

This strategic material selection guide provides a comprehensive overview of the materials commonly used for laboratory benches, helping international B2B buyers make informed decisions tailored to their specific laboratory needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for what is laboratory bench

What Are the Main Stages in the Manufacturing Process of Laboratory Benches?

Manufacturing laboratory benches involves a series of well-defined stages that ensure the final product meets the necessary specifications for quality and functionality. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Laboratory Benches?

The first step in manufacturing laboratory benches is material selection and preparation. Common materials used include stainless steel, laminate, and epoxy resin, each chosen for their durability, resistance to chemicals, and ease of cleaning.

Materials undergo rigorous quality checks upon arrival at the manufacturing facility. They are inspected for defects, and specifications such as thickness, weight, and chemical resistance are verified. This initial quality control step is crucial to ensure that only materials meeting the required standards are used in production.

What Techniques Are Used for Forming Laboratory Benches?

After material preparation, the forming stage begins. Techniques such as cutting, bending, and welding are commonly employed to shape the components of the laboratory bench.

- Cutting: Precision cutting machines are utilized to ensure accurate dimensions and clean edges.

- Bending: For metal components, hydraulic presses may be used to achieve the desired angles and shapes without compromising the material’s integrity.

- Welding: For stainless steel benches, welding is essential for joining different parts together securely. This process requires skilled technicians to ensure strong, clean welds that can withstand the rigors of a laboratory environment.

How is Assembly of Laboratory Benches Conducted?

The assembly stage involves putting together the various components manufactured in previous steps. This can include attaching legs, securing shelves, and installing utility connections such as gas and water lines.

Quality control at this stage focuses on ensuring that all components fit together correctly and function as intended. For instance, ensuring that sinks are properly aligned and sealed to prevent leaks is crucial.

What Finishing Processes Are Applied to Laboratory Benches?

Finishing processes enhance the aesthetic and functional qualities of laboratory benches. This may include powder coating for metal surfaces, which provides a durable and resistant finish, or laminating wooden surfaces to improve chemical resistance.

Final inspections are conducted to check for surface defects, ensuring that the finish meets the required standards. This stage also includes the application of any necessary branding or identification labels.

What Quality Assurance Measures Are Implemented in Laboratory Bench Manufacturing?

Quality assurance (QA) is a critical aspect of laboratory bench production, ensuring that the final products meet international standards and customer expectations.

Which International Standards Should B2B Buyers Consider?

International standards play a significant role in the quality assurance process. ISO 9001 is one of the most recognized standards, focusing on maintaining a quality management system. Compliance with this standard indicates that a manufacturer has established processes to ensure consistent quality in their products.

Illustrative image related to what is laboratory bench

Additionally, industry-specific certifications such as CE marking (for compliance with European health, safety, and environmental standards) or API (American Petroleum Institute) certifications may be relevant, especially for benches used in specialized environments.

What Are the Key Quality Control Checkpoints During Manufacturing?

The quality control process involves several critical checkpoints:

- Incoming Quality Control (IQC): This step verifies the quality of materials before they are used in production. Materials that do not meet specifications are rejected.

- In-Process Quality Control (IPQC): This involves monitoring the manufacturing process at various stages to identify and rectify any issues before final assembly.

- Final Quality Control (FQC): After assembly, the entire bench undergoes a final inspection to ensure it meets all specifications and is free of defects.

What Common Testing Methods Are Used to Ensure Quality?

Various testing methods are employed throughout the manufacturing process to ensure quality. These may include:

- Load Testing: To ensure that the bench can support the intended weight without deforming.

- Chemical Resistance Testing: Conducted on surfaces to confirm they can withstand exposure to various chemicals typically used in laboratories.

- Ergonomic Testing: Ensures that the bench height and design meet ergonomic standards for user comfort and safety.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential for ensuring that the laboratory benches meet their operational needs. Here are some methods to conduct due diligence:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request and review quality assurance documentation, including:

- Audit Reports: These provide insights into the supplier’s compliance with quality standards and highlight any non-conformities.

- Quality Control Records: Documentation of inspections, tests, and any corrective actions taken should be available for review.

Why Is Third-Party Inspection Important for Quality Assurance?

Engaging a third-party inspection service can add an additional layer of assurance. These independent organizations can conduct thorough assessments of the manufacturing processes and finished products, providing an unbiased report on quality compliance.

Illustrative image related to what is laboratory bench

What Are the Quality Control Nuances for International Buyers?

International buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, must consider additional factors:

- Regulatory Compliance: Ensure that the manufacturer complies with local regulations in their country as well as international standards.

- Cultural Differences: Understanding regional standards and practices can aid in better communication and expectation management with suppliers.

- Logistical Considerations: Quality control processes may vary depending on shipping and handling practices, so ensure that the supplier has robust measures in place for international shipping.

By focusing on these elements, B2B buyers can navigate the complexities of sourcing laboratory benches, ensuring they partner with reliable suppliers committed to quality and excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is laboratory bench’

When sourcing a laboratory bench, it is essential to follow a structured approach to ensure you select the best fit for your specific laboratory needs. This guide outlines critical steps to assist international B2B buyers in making informed decisions when procuring laboratory benches.

Illustrative image related to what is laboratory bench

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider the type of laboratory (wet or dry) and the specific functions the bench will serve. Look for features such as chemical resistance, weight capacity, and integration of utility connections like gas, water, and electricity.

- Identify Bench Type: Determine if you need a standard lab bench, adjustable workbench, or specialized tables like demo or assistant tables.

- Material Consideration: Choose between materials like stainless steel, wood, or polymer based on durability and compatibility with lab activities.

Step 2: Assess Space and Layout Requirements

Evaluate the physical dimensions of your laboratory space to ensure the bench fits and complements the workflow.

- Measure Available Space: Take precise measurements of the area designated for the bench, considering clearance for movement and additional equipment.

- Consider Workflow: Think about how the bench location will affect the efficiency of lab operations, ensuring that it integrates seamlessly into existing setups.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a thorough evaluation.

- Request Documentation: Ask for company profiles, certifications, and case studies that demonstrate their experience and reliability.

- Check References: Reach out to previous clients in similar industries or regions to gain insights into their experiences with the supplier.

Step 4: Review Customization Options

Laboratory benches often need to be tailored to specific functions.

- Customization Flexibility: Inquire if the supplier can modify bench designs to suit unique laboratory requirements, such as adding storage solutions or specialized utility connections.

- Future Scalability: Consider whether the bench can be easily adapted or expanded as your laboratory needs change over time.

Step 5: Analyze Quality and Durability Standards

Quality assurance is paramount in laboratory environments.

- Material Quality: Ensure that the materials used in the benches meet industry standards for durability and safety, particularly in chemical handling.

- Warranty and Support: Look for suppliers that offer warranties and after-sales support, which can provide peace of mind regarding long-term investments.

Step 6: Compare Pricing and Total Cost of Ownership

While initial costs are important, consider the total cost of ownership, including maintenance and potential replacement.

- Obtain Multiple Quotes: Request quotes from various suppliers to compare pricing structures, ensuring you understand what is included in each offer.

- Evaluate Long-Term Costs: Factor in maintenance, potential upgrades, and the lifespan of the bench when making your decision.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure all terms are clearly defined in a purchase agreement.

- Detail Specifications: Include all agreed-upon specifications, delivery timelines, and payment terms in the contract.

- Clarify Responsibilities: Make sure both parties understand their responsibilities regarding delivery, setup, and any ongoing support needed.

By following these steps, B2B buyers can effectively navigate the sourcing process for laboratory benches, ensuring they select a product that meets their specific needs while also aligning with their budget and operational goals.

Comprehensive Cost and Pricing Analysis for what is laboratory bench Sourcing

Understanding the cost structure and pricing for laboratory benches is crucial for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. This analysis will explore the various components that contribute to the overall cost, identify price influencers, and offer actionable tips for buyers to optimize their procurement strategies.

What Are the Key Cost Components of Laboratory Benches?

The cost of laboratory benches can be broken down into several key components:

-

Materials: The type of materials used significantly affects the cost. Common materials include steel, wood, and chemical-resistant surfaces. High-quality materials that meet safety and durability standards will naturally come at a premium.

-

Labor: Labor costs encompass the wages paid to skilled workers involved in the manufacturing process. This varies by region and can be influenced by local labor laws and market conditions.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: The cost of tools and equipment necessary for production also plays a role. Custom tooling for specialized benches can lead to higher initial costs but may provide better long-term value.

-

Quality Control (QC): Ensuring that laboratory benches meet specific standards and certifications incurs costs. This is especially pertinent for buyers in regulated industries, where compliance is critical.

-

Logistics: Transportation costs, including shipping and handling, can vary significantly based on distance and the chosen shipping method. Incoterms will influence who bears these costs.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on market conditions and competition.

What Influences the Pricing of Laboratory Benches?

Several factors can influence the pricing of laboratory benches:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can often lead to bulk discounts, which significantly reduce the per-unit cost. Buyers should consider negotiating MOQ to optimize pricing.

-

Specifications and Customization: Customized benches designed to meet specific laboratory needs (e.g., wet vs. dry labs) may come at a higher price point due to the additional design and manufacturing efforts.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (ISO, CE, etc.) can affect pricing. Buyers should weigh the benefits of high-quality materials against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but can offer better service and quality assurance.

-

Incoterms: Understanding the implications of Incoterms is vital. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) will determine the cost responsibility and can affect the overall price.

What Are Effective Strategies for Buyers to Optimize Costs?

To navigate the complexities of laboratory bench sourcing, buyers can employ several strategies:

-

Negotiate Effectively: Build relationships with suppliers and engage in negotiations to secure better terms. Leverage factors like order volume and long-term partnerships to enhance bargaining power.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, durability, and potential resale value. A higher initial cost may lead to lower overall expenses if the bench lasts longer and requires less maintenance.

-

Be Aware of Pricing Nuances for International Procurement: Different regions may have varying standards and pricing structures. Buyers should research local market conditions, tariffs, and import regulations that could impact costs.

-

Request Multiple Quotes: Gathering quotes from various suppliers can provide a clearer picture of the market and help identify competitive pricing.

-

Evaluate Supplier Reliability: Choose suppliers with a proven track record of quality and timely delivery. This can mitigate risks associated with delays and defects, ultimately saving costs in the long run.

Conclusion

In summary, understanding the comprehensive cost structure and pricing dynamics of laboratory benches is essential for international B2B buyers. By focusing on key cost components, recognizing pricing influencers, and employing strategic purchasing tactics, buyers can optimize their sourcing processes while ensuring they meet their laboratory requirements efficiently and effectively.

Alternatives Analysis: Comparing what is laboratory bench With Other Solutions

In the realm of laboratory operations, the choice of workspace is critical to efficiency and functionality. While laboratory benches are often seen as the cornerstone of lab environments, various alternative solutions can also serve specific needs. Understanding these alternatives is essential for B2B buyers, particularly those looking to optimize their laboratory settings in diverse regions such as Africa, South America, the Middle East, and Europe.

| Comparison Aspect | What Is Laboratory Bench | Mobile Workstations | Modular Lab Furniture |

|---|---|---|---|

| Performance | High stability for various experiments; customizable for specific tasks | Portable; versatile for different lab activities | Flexible layout; can be reconfigured as needed |

| Cost | Moderate to high depending on materials and customization | Generally lower initial investment | Higher upfront cost but cost-effective in long-term adaptability |

| Ease of Implementation | Requires planning for installation and utility connections | Quick setup; usually pre-assembled | Installation may require professional services |

| Maintenance | Moderate; regular cleaning and occasional repairs needed | Low; portable units are easy to clean and maintain | Moderate; depends on materials used |

| Best Use Case | Ideal for fixed lab environments needing specific configurations | Best for labs requiring mobility and flexibility | Suitable for labs anticipating growth or changes in function |

What Are the Advantages and Disadvantages of Mobile Workstations?

Mobile workstations present a flexible alternative to traditional laboratory benches. They are designed for easy transport, allowing lab personnel to rearrange their workspace as needed. This adaptability is particularly beneficial in dynamic environments where experiments may require different setups throughout the day. However, while they offer convenience, mobile workstations may lack the stability and durability of fixed benches, potentially affecting performance during rigorous experiments.

Illustrative image related to what is laboratory bench

How Do Modular Lab Furniture Systems Compare?

Modular lab furniture systems provide a unique solution for laboratories that anticipate changes in their operations. These systems consist of interchangeable components that can be reconfigured to adapt to new workflows or technologies. The initial investment is typically higher, but the long-term cost-effectiveness and adaptability can justify the expense. On the downside, the installation process may require professional assistance, which can add to overall costs and time delays.

Conclusion: How Should B2B Buyers Choose the Right Laboratory Solution?

When selecting the right laboratory workspace solution, B2B buyers must consider their specific operational needs, budget constraints, and future growth plans. Laboratory benches remain a robust option for stable environments requiring specific configurations, while mobile workstations offer unmatched flexibility for dynamic tasks. Modular lab furniture stands out for its adaptability, making it ideal for labs expecting changes. By evaluating performance, cost, ease of implementation, and maintenance, buyers can make informed decisions that align with their strategic objectives, ensuring that their laboratory remains efficient and functional in the long run.

Essential Technical Properties and Trade Terminology for what is laboratory bench

What Are the Key Technical Properties of Laboratory Benches?

When considering laboratory benches for your organization, understanding their essential technical properties is vital. Here are some critical specifications that can influence your purchasing decision:

Illustrative image related to what is laboratory bench

1. Material Grade

Laboratory benches are typically constructed from materials like stainless steel, epoxy resin, or high-density polyethylene (HDPE). Stainless steel offers durability and resistance to corrosion, making it ideal for wet labs, while epoxy resin provides a non-porous surface that is resistant to chemicals. Choosing the right material is crucial for longevity and suitability for specific laboratory applications.

2. Load Capacity

Load capacity refers to the maximum weight a laboratory bench can safely support. This specification is vital, especially for research environments where heavy equipment or multiple instruments may be used. Understanding load capacity helps ensure that the bench can accommodate the intended workload without compromising safety or performance.

3. Dimensions and Ergonomics

The dimensions of a laboratory bench, including height, width, and depth, are essential for creating an ergonomic workspace. An adjustable height feature can enhance user comfort and productivity, catering to various tasks and personnel. Proper ergonomics can reduce the risk of strain or injury, which is particularly important in demanding laboratory settings.

4. Chemical Resistance

Laboratory benches, especially in wet labs, must have surfaces that can withstand exposure to various chemicals without degrading. Understanding the chemical resistance properties helps in selecting the right bench for specific experiments, ensuring that the surface remains intact and functional over time.

Illustrative image related to what is laboratory bench

5. Configuration and Customization Options

Laboratory benches can be configured in various ways—such as L-shaped, U-shaped, or island configurations—to optimize space and workflow. Customization options may include built-in storage, sinks, or utility connections. Knowing the available configurations allows buyers to tailor their laboratory setup to specific operational needs.

What Trade Terms Should B2B Buyers Understand When Purchasing Laboratory Benches?

Navigating the procurement process for laboratory benches involves familiarizing yourself with key industry jargon. Here are some common terms that can enhance your purchasing experience:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers ensure they are sourcing high-quality components that meet industry standards, especially for customized laboratory benches.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers, as it affects budget considerations and inventory planning. Suppliers may have different MOQs based on the type of laboratory bench being purchased.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for a specific product or service. Utilizing an RFQ helps buyers compare options and negotiate better deals, ensuring that they receive competitive pricing for laboratory benches.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers, as they determine shipping responsibilities, risk, and cost allocation, which can significantly impact the overall procurement strategy.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is critical for project planning and inventory management, especially in laboratory environments where timely access to equipment can be vital for research and experimentation.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when purchasing laboratory benches, ensuring that their investments align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the what is laboratory bench Sector

What Are the Current Market Dynamics and Key Trends for Laboratory Benches?

The laboratory bench market is experiencing significant growth driven by the expanding sectors of healthcare, education, and research across the globe. Particularly in regions like Africa, South America, the Middle East, and Europe, there is an increasing demand for customized lab environments that cater to specific scientific needs. As international B2B buyers seek more adaptable and multifunctional solutions, the trend towards modular and adjustable laboratory benches is gaining traction. These benches allow for flexibility in laboratory design, enabling users to modify configurations based on evolving research requirements.

Technological advancements are also shaping the market dynamics, with an uptick in digital integrations such as built-in connectivity for power, gas, and water. This trend is particularly relevant for wet labs, where specialized features like integrated sinks and reagent storage are essential. Furthermore, the rise of remote work and digital collaboration tools is influencing the design of laboratory spaces, prompting manufacturers to create benches that facilitate both individual and group work environments.

Emerging markets are increasingly adopting laboratory benches that prioritize ergonomics and user comfort, acknowledging that a well-designed workspace can enhance productivity and safety. B2B buyers are encouraged to consider suppliers that offer customizable options tailored to their specific laboratory needs, ensuring they remain competitive in a rapidly evolving global landscape.

How Is Sustainability and Ethical Sourcing Impacting Laboratory Bench Procurement?

As environmental consciousness grows, sustainability has become a paramount concern in the procurement of laboratory benches. Buyers are increasingly prioritizing suppliers who adhere to ethical sourcing practices and utilize environmentally friendly materials. The production of laboratory benches often involves materials such as steel, wood, and various composites; therefore, opting for suppliers who provide ‘green’ certifications ensures that the materials used are sourced responsibly and sustainably.

Incorporating sustainable practices not only reduces the environmental impact but also enhances the reputation of organizations among stakeholders. B2B buyers are advised to seek out manufacturers that utilize recycled materials, low-VOC (volatile organic compound) finishes, and energy-efficient production processes. Additionally, the longevity and durability of laboratory benches should be considered, as investing in high-quality products can reduce waste and the need for frequent replacements.

The trend towards sustainability is also influencing the design of laboratory spaces. Buyers are encouraged to consider products that promote efficient energy use, such as benches with built-in energy-saving features. By aligning procurement strategies with sustainability goals, businesses can contribute to a healthier planet while also meeting the growing demand for responsible corporate practices.

What Is the Brief Evolution of Laboratory Benches in a B2B Context?

Laboratory benches have evolved significantly from their humble origins as simple work surfaces to complex, multifunctional furniture tailored to specific scientific needs. Initially, lab benches were primarily constructed from wood or metal, serving basic purposes. However, as scientific research advanced, the demand for specialized features such as integrated utilities, adjustable heights, and ergonomic designs became apparent.

The late 20th century saw the introduction of modular designs, allowing laboratories to optimize their space and adapt to various functions. This evolution was fueled by the rapid advancement of technology in scientific research, prompting manufacturers to innovate and integrate features that cater to diverse laboratory environments, including wet and dry labs.

Today, the market for laboratory benches reflects a blend of functionality and sustainability, with an emphasis on customization and ergonomic design. As international B2B buyers navigate this dynamic landscape, understanding the historical context of laboratory benches can provide valuable insights into current trends and future developments in laboratory design and procurement.

Frequently Asked Questions (FAQs) for B2B Buyers of what is laboratory bench

-

How do I choose the right laboratory bench for my specific needs?

Choosing the right laboratory bench requires understanding your laboratory’s specific functions and requirements. Assess whether you need a wet lab bench with built-in sinks and utility connections or a dry lab bench that offers a larger surface area for equipment. Consider the size of your space, the type of experiments conducted, and any necessary ergonomic features. Collaborating with a supplier who offers customization can ensure that the bench meets your operational needs effectively. -

What are the key features to look for in a laboratory bench?

When evaluating laboratory benches, consider features such as durability, material type, and ease of cleaning. Look for benches with built-in utilities like gas, water, and electrical connections, especially for wet labs. Storage options underneath the bench are essential for keeping equipment organized. Additionally, ensure that the bench design promotes ergonomics, allowing for comfortable use during extended periods. -

What customization options are available for laboratory benches?

Customization options for laboratory benches can include variations in size, material, and features tailored to specific laboratory needs. For instance, you can select between stainless steel, laminate, or epoxy resin surfaces, depending on chemical resistance requirements. Suppliers often offer configurations that include additional storage, integrated sinks, or specific utility connections. Collaborating with manufacturers who specialize in lab furniture will help ensure that your bench aligns with operational workflows. -

What are the minimum order quantities (MOQ) for laboratory benches?

Minimum order quantities for laboratory benches can vary significantly between suppliers. Some manufacturers may have a low MOQ for standard models, while custom benches may require larger orders to justify production costs. It’s advisable to inquire with multiple suppliers to compare MOQs and negotiate terms that align with your procurement strategy. This is especially important for international buyers to optimize shipping costs and logistics. -

How do I vet suppliers for laboratory benches?

When vetting suppliers for laboratory benches, consider their experience, reputation, and certifications. Look for suppliers who have a proven track record in the laboratory furniture industry, ideally with positive testimonials from previous clients. Request samples of materials and finishes to assess quality. Additionally, verify their compliance with international standards for safety and performance, especially if you are importing to regions with strict regulations. -

What payment terms should I expect when sourcing laboratory benches internationally?

Payment terms for international purchases of laboratory benches typically range from upfront payments to net 30 or net 60 days post-delivery. Some suppliers may offer letters of credit or escrow services for higher-value transactions to secure the buyer’s investment. It’s important to clarify these terms before finalizing an order and to understand any additional costs related to currency exchange or international shipping. -

What quality assurance measures should be in place for laboratory benches?

Quality assurance measures for laboratory benches should include rigorous testing for durability, stability, and resistance to chemicals, especially for wet lab benches. Suppliers should provide certificates of compliance with relevant industry standards and conduct inspections throughout the manufacturing process. Request documentation related to the materials used and any warranties offered, ensuring that the products meet your laboratory’s operational demands and safety requirements. -

What logistics considerations are important when importing laboratory benches?

Logistics considerations for importing laboratory benches include shipping methods, customs regulations, and delivery timelines. Collaborate with suppliers who can assist with freight forwarding and customs clearance to streamline the process. Assess the shipping costs based on the size and weight of the benches, and consider insurance options to protect against damages during transit. Understanding local import regulations will help avoid delays and ensure compliance upon arrival.

Top 9 What Is Laboratory Bench Manufacturers & Suppliers List

1. IQS Directory – Lab Benches

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Lab benches are customized tables designed to support various lab tasks and experiments, focusing on durability and functionality. They are classified into wet and dry types, with wet lab benches featuring sinks and storage for liquid processing, while dry lab benches offer extensive work surfaces and electrical hookups. Lab benches can be categorized by function (physical, chemical, biological), …

2. Coda – Laboratory Instrument Tables

Domain: coda.io

Registered: 2012 (13 years)

Introduction: Laboratory instrument tables, also known as island benches, are essential for various laboratory settings including hospitals, schools, and research institutions. They come in different configurations such as central, side, and corner benches, and are made from materials like all-steel, PP, steel-wood, and stainless steel. Key benefits include: providing surfaces for experiments, integrated utilit…

3. SACCLS – Laboratory Benches

Domain: saccls.org.au

Introduction: There are various types of laboratory benches, each with specific features and benefits. Common types include: 1. Traditional Laboratory Bench: Sturdy, heavy, equipped with a working surface, storage area, and comfortable seating. 2. Workstation Bench: Smaller, designed for single-person use, limited storage, versatile for various equipment. 3. Lab Tables: Compact, used for small-scale experiments…

4. Lab Tech Supply Co – Epoxy and Phenolic Resins

Domain: labtechsupplyco.com

Registered: 2014 (11 years)

Introduction: 1. Epoxy Resin: Durable, aesthetic, resistant to chemicals, UV light, shock, and antimicrobial. Requires maintenance to avoid scratches and stains. 2. Phenolic Resin: Lower price, less durable, suitable for lighter lab activities, resistant to chemicals, bacteria, and fungus. 3. Stainless Steel: Highly durable, resistant to impacts, heat, moisture, and chemicals. Easy to maintain but highly induct…

5. Genie Scientific – Lab Benches

Domain: geniescientific.com

Registered: 2001 (24 years)

Introduction: Lab benches are classified into three subsections: Purpose, Function, and Structure. Purpose includes specialized designs like cleanroom benches, sink lab benches (with plumbing), and island lab benches (larger for more staff). Function includes dry lab benches (for non-reactive activities) and wet lab benches (for handling chemicals and biological samples). Structure includes suspended (immovable…

6. Fisher Scientific – Laboratory Benches and Tables

Domain: fishersci.com

Registered: 1995 (30 years)

Introduction: Laboratory benches and tables designed for safe laboratory tasks and handling of reagents and samples. Features include corrosion-resistant and vibration-resistant finishes, with options for mobile units. Available colors: Almond, Amber Stain, Auburn Stain, Black, Gray, Gray Maple, Green, Harvest Stain, Honey Stain, Light Gray, Maple, Mocha Stain, Natural Maple, Natural Stain, Oak, Oak Black, Silv…

7. Loc Scientific – Laboratory Benches Overview

Domain: locscientific.com

Registered: 1998 (27 years)

Introduction: 8 Types Of Laboratory Benches: Features And Uses – Selecting the right types of laboratory benches is key to ensuring efficiency, safety, and productivity in any research environment. Features include durability and ease of maintenance. 1. Epoxy Resin Benches: Robust, chemically resistant, non-porous, hygienic, easy to clean. 2. Phenolic Resin Benches: Excellent chemical resistance, lighter weight…

8. Workbench Manufacturers – Laboratory Workbenches

Domain: workbenchmanufacturers.com

Registered: 2012 (13 years)

Introduction: Laboratory workbenches, also known as lab benches, provide space for conducting tests, storing lab equipment, and creating workstations. Key features include: stability, durability, adaptability, heavy-duty locking casters for mobility and secure positioning, and various materials such as High-Density Polyethylene (HDPE), wood, metal (stainless steel or powder-coated), and specialty surfaces (phen…

9. IQ Laboratory – Key Features of Work Benches

Domain: iq-laboratory.com

Registered: 2020 (5 years)

Introduction: Key features of laboratory work benches include: Proper Layout Planning for optimized workflow, Regular Maintenance for cleanliness and longevity, Durable and Chemical-Resistant Work Surfaces made from materials like epoxy resin, phenolic resin, or stainless steel, Various Sizes and Configurations with standard depths of 30″ and widths from 36″ to 96″, Adjustable Height options (manual pin height …

Strategic Sourcing Conclusion and Outlook for what is laboratory bench

In summary, laboratory benches are indispensable components of any laboratory environment, serving as the foundation for experiments and research activities. Their versatility allows for customization, whether in wet or dry labs, ensuring they meet specific needs for storage, utility connections, and ergonomic design. For B2B buyers, understanding the intricacies of laboratory benches is vital for making informed purchasing decisions that enhance operational efficiency and safety.

Strategic sourcing of laboratory benches not only involves selecting high-quality materials but also requires a keen understanding of local regulations and industry standards, particularly for international markets in Africa, South America, the Middle East, and Europe. Collaborating with trusted suppliers can lead to better pricing, improved product quality, and enhanced service support, ultimately contributing to a more productive laboratory environment.

As you look to invest in laboratory infrastructure, consider the long-term benefits of strategic sourcing. Engage with suppliers who prioritize innovation and customization to ensure your laboratory is equipped to meet future challenges. Together, let’s build a safer, more efficient, and highly functional workspace that supports your scientific endeavors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.