A B2B Buyer’s Guide to What Is A Linear Actuator: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for what is a linear actuator

In today’s fast-paced industrial landscape, understanding the intricacies of linear actuators is essential for businesses seeking to enhance operational efficiency and productivity. Sourcing the right linear actuator can be a daunting task, especially for B2B buyers navigating the global market. This comprehensive guide demystifies linear actuators by exploring various types—including electric, hydraulic, and pneumatic—and their diverse applications across multiple industries.

From robotics to industrial automation, understanding how different actuators function and their suitability for specific tasks is crucial for making informed purchasing decisions. This guide also addresses critical factors such as supplier vetting, cost considerations, and maintenance requirements, ensuring that you can confidently select the right solutions for your business needs.

Designed specifically for international B2B buyers from Africa, South America, the Middle East, and Europe—regions characterized by unique market dynamics—this resource provides actionable insights tailored to your operational context. By leveraging this guide, you will gain a deeper understanding of linear actuators, empowering your organization to optimize performance and drive innovation in your projects. Whether you are in Saudi Arabia, Vietnam, or beyond, navigate the complexities of the global market with confidence and clarity.

Understanding what is a linear actuator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Linear Actuator | Uses electric motors for precise control; low maintenance | Robotics, industrial automation, medical devices | Pros: High precision, flexibility, low noise. Cons: Limited in high-force applications. |

| Hydraulic Actuator | Utilizes pressurized fluid for high force; robust design | Construction equipment, aerospace, industrial machinery | Pros: High force output; suitable for heavy-duty tasks. Cons: Noisy and requires more maintenance. |

| Pneumatic Actuator | Operates using compressed air; quick response times | Assembly lines, automation systems, robotics | Pros: Fast and cost-effective; good for repetitive tasks. Cons: Less precise than electric actuators. |

| Mechanical Linear Actuator | Simple design using cams or levers; low force applications | Low-force machinery, basic automation | Pros: Cost-effective and easy to implement. Cons: Limited precision and force capabilities. |

| Piezoelectric Actuator | Employs piezoelectric effect for rapid, precise movement | Nano-positioning, microscopy, optical instruments | Pros: High precision and fast response. Cons: Limited stroke length and higher cost. |

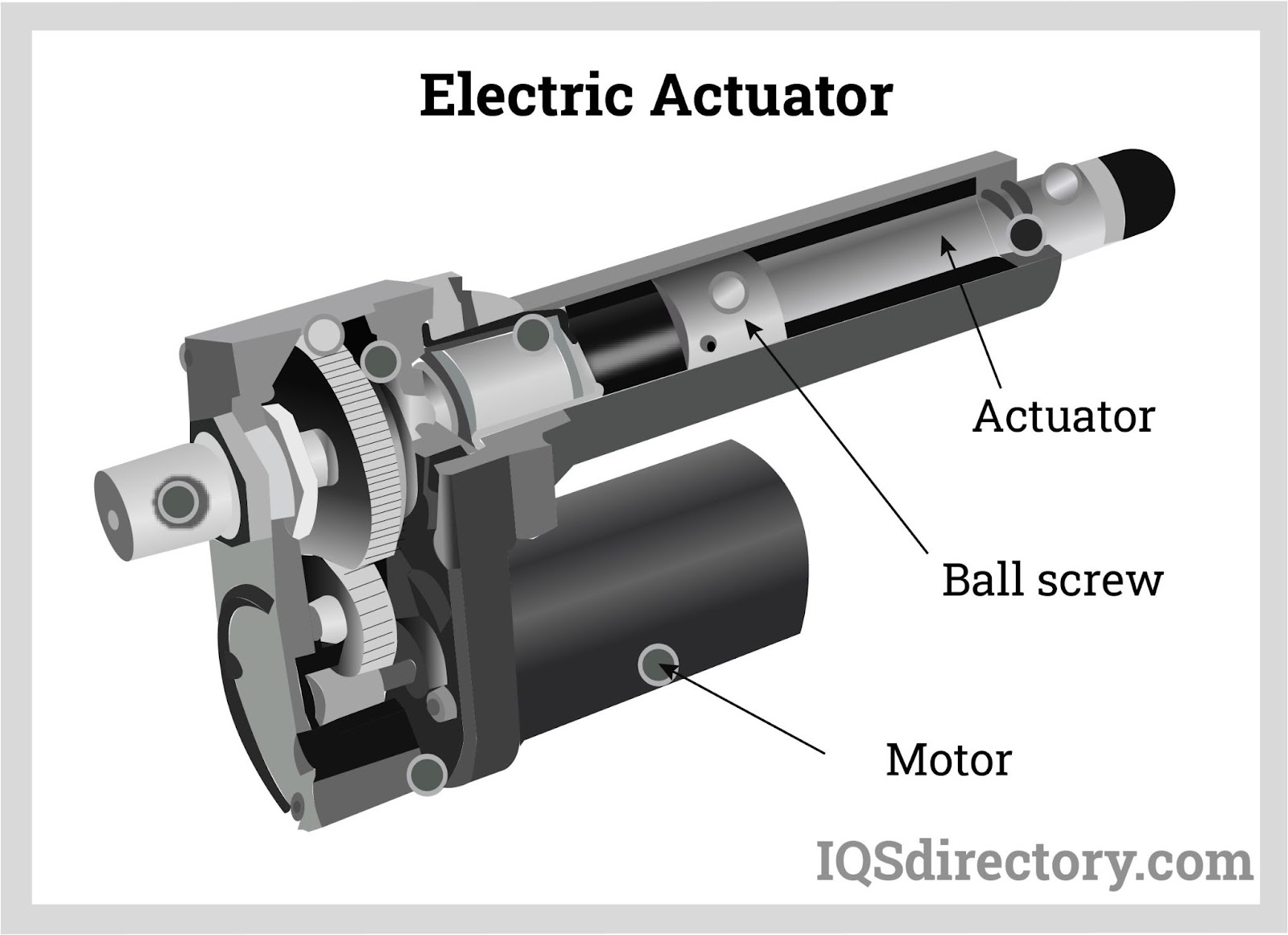

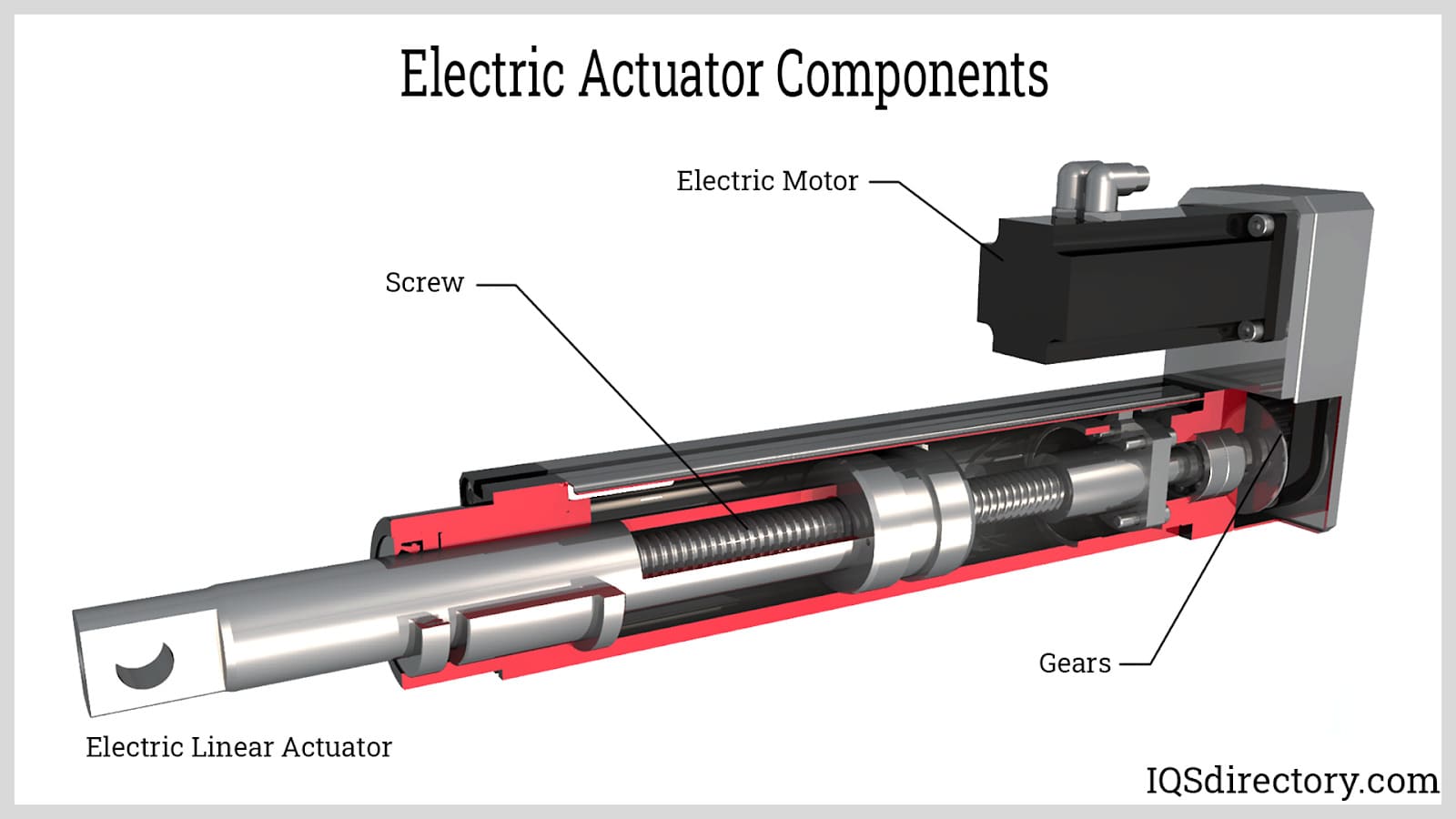

What are Electric Linear Actuators and Their B2B Relevance?

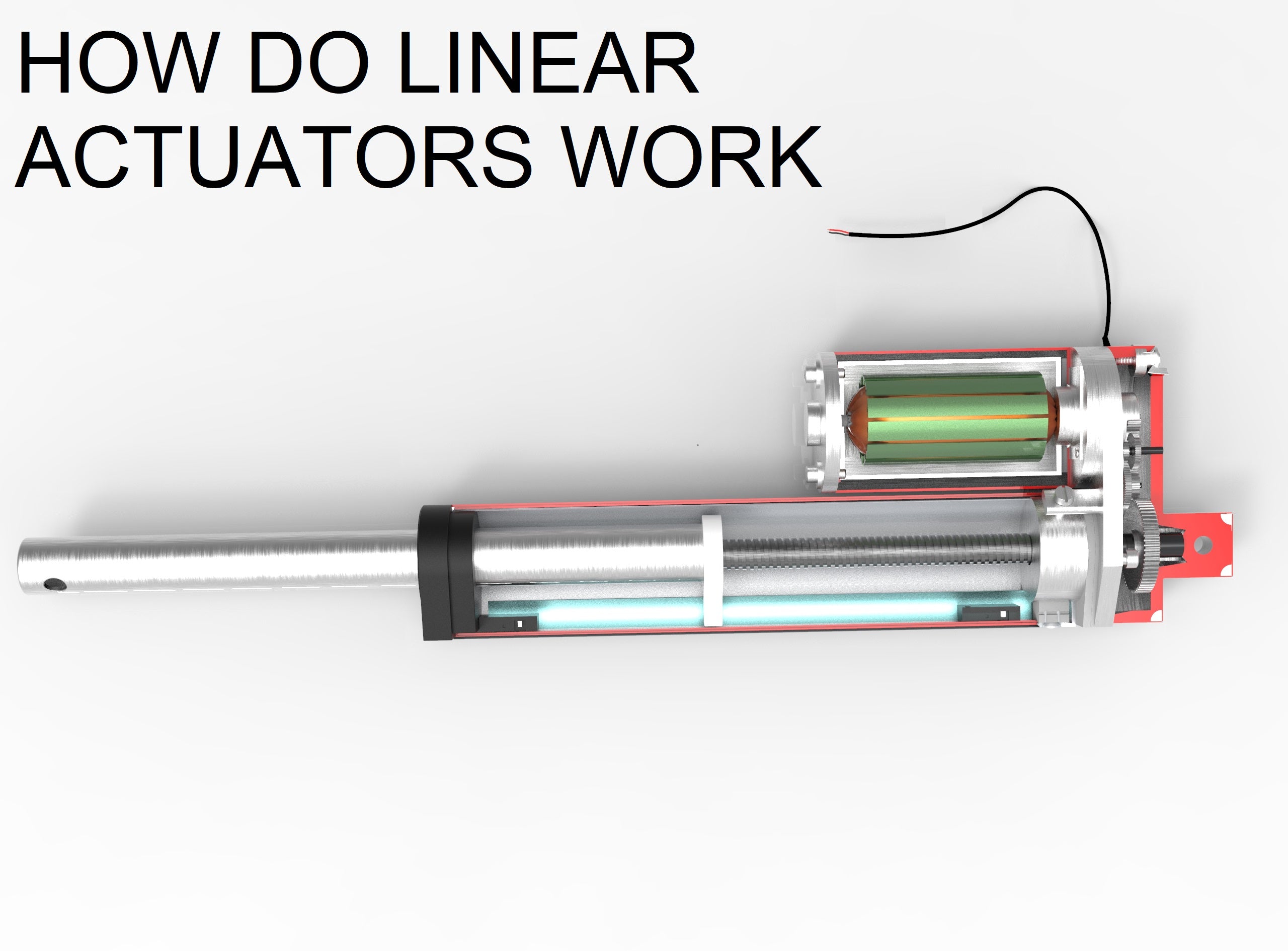

Electric linear actuators convert electrical energy into linear motion through electric motors, offering high precision and control. They are ideal for applications in robotics, industrial automation, and medical devices, where accuracy is paramount. Buyers should consider factors such as the required load capacity, speed, and environmental conditions, as electric actuators excel in low-maintenance environments. However, they may not be suitable for applications demanding high force output.

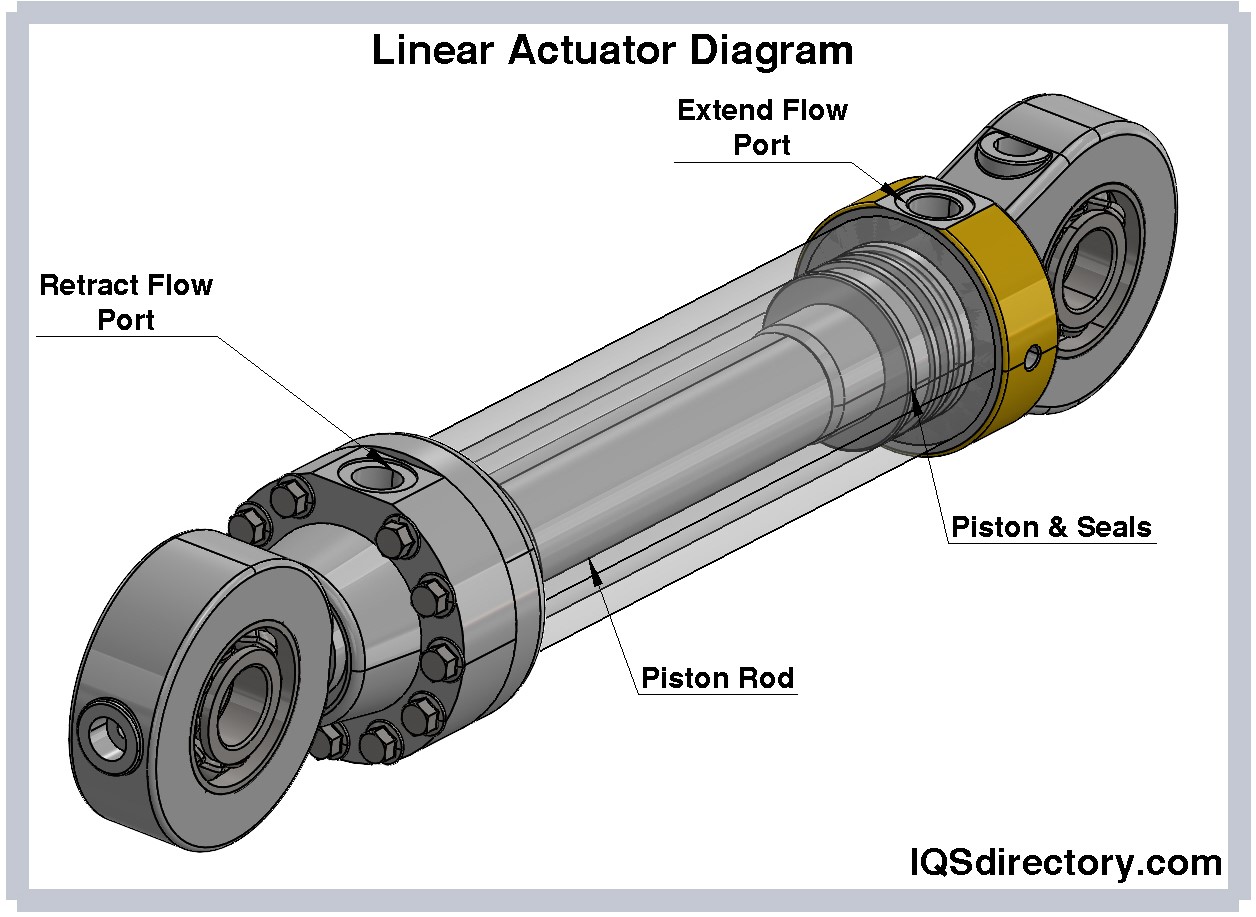

Why Choose Hydraulic Actuators for Heavy-Duty Applications?

Hydraulic actuators generate linear motion using pressurized fluid, making them suitable for heavy-duty applications such as construction equipment and industrial machinery. Their robust design allows them to deliver high force output, essential for tasks requiring significant lifting or pushing capabilities. Buyers should evaluate factors like maintenance requirements and potential noise levels, as hydraulic systems can be noisier and require more upkeep compared to other actuator types.

How Do Pneumatic Actuators Benefit Automation Systems?

Pneumatic actuators utilize compressed air to create linear motion, making them particularly effective for automation systems and assembly lines where speed and responsiveness are crucial. They are generally more cost-effective and simpler to implement, which appeals to B2B buyers looking for efficient solutions. However, their precision may be lower than electric actuators, and they may not be suitable for applications requiring fine control.

What are the Advantages of Mechanical Linear Actuators?

Mechanical linear actuators are straightforward devices that convert rotary motion into linear motion using mechanisms like cams or levers. They are often used in low-force applications where cost-effectiveness is a priority. While they are easy to implement and maintain, B2B buyers should recognize their limitations in terms of precision and force capabilities, making them less suitable for high-demand applications.

When to Consider Piezoelectric Actuators?

Piezoelectric actuators offer exceptional precision and fast response times, making them ideal for specialized applications such as nano-positioning and microscopy. These actuators leverage the piezoelectric effect to achieve small, controlled movements. While they provide significant advantages in precision, buyers must weigh the higher costs and limited stroke lengths against their specific application needs.

Key Industrial Applications of what is a linear actuator

| Industry/Sector | Specific Application of what is a linear actuator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated assembly lines | Increased efficiency and reduced labor costs | Precision, load capacity, and speed requirements |

| Automotive | Adjustable seating systems | Enhanced comfort and user experience | Space constraints, reliability, and customization |

| Medical Devices | Patient lift systems | Improved patient safety and care | Compliance with medical standards and durability |

| Agriculture | Automated irrigation systems | Optimized water usage and crop yields | Environmental resistance and energy efficiency |

| Aerospace | Control surfaces for aircraft | Enhanced performance and safety | Weight considerations and precision engineering |

How are Linear Actuators Used in Manufacturing Automation?

In manufacturing, linear actuators play a crucial role in automated assembly lines, where they facilitate the precise movement of components. They enable tasks such as lifting, pushing, and positioning parts with high accuracy, which significantly increases efficiency and reduces labor costs. For international B2B buyers, especially in regions like Africa and South America, sourcing actuators with robust performance specifications and adaptability to varying load capacities is essential. Additionally, understanding the local manufacturing environment can help in selecting the right actuator type, whether electric or pneumatic, based on energy availability and operational needs.

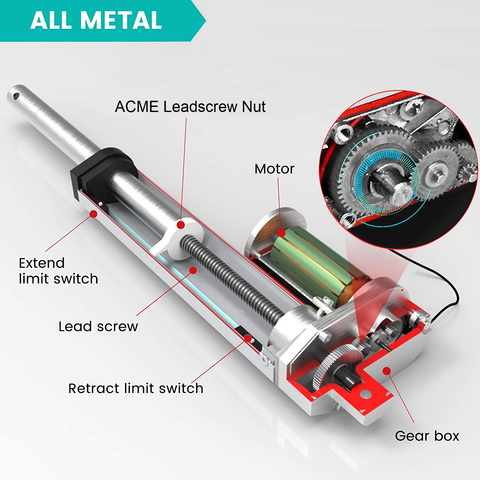

Illustrative image related to what is a linear actuator

What Role Do Linear Actuators Play in the Automotive Sector?

In the automotive industry, linear actuators are integral to adjustable seating systems, allowing for smooth and precise adjustments for driver and passenger comfort. This technology enhances user experience and contributes to ergonomic design. Buyers in the Middle East and Europe should consider sourcing actuators that can withstand the automotive environment’s demands, including temperature fluctuations and heavy usage. Reliability and customization options are also critical factors, as automotive manufacturers often require specific actuator configurations to fit their design specifications.

Why are Linear Actuators Important in Medical Devices?

Linear actuators are vital in medical devices, such as patient lift systems, where they ensure safe and efficient patient handling. These actuators provide smooth motion, which is crucial for maintaining patient safety and comfort during transfers. For international B2B buyers from regions like Europe and the Middle East, compliance with medical standards is paramount. Therefore, sourcing actuators that are not only durable but also meet stringent health regulations is essential. Additionally, understanding the specific load capacities and operational speeds required for various medical applications can guide effective procurement.

How Do Linear Actuators Enhance Agricultural Efficiency?

In agriculture, linear actuators are increasingly used in automated irrigation systems, allowing for precise control over water distribution. This technology optimizes water usage and enhances crop yields, making it a valuable investment for farmers. B2B buyers in regions such as Africa, where water scarcity is a pressing issue, should prioritize sourcing actuators that offer energy efficiency and environmental resistance. Understanding the specific requirements for irrigation systems, including the actuator’s ability to operate under varying weather conditions, is essential for successful implementation.

What is the Significance of Linear Actuators in Aerospace Applications?

In the aerospace sector, linear actuators are critical for controlling surfaces on aircraft, such as flaps and landing gear. These components must operate with high precision to ensure safety and performance during flight. For international B2B buyers, particularly in Europe and the Middle East, weight considerations and the need for precision engineering are key factors in sourcing linear actuators. Additionally, the ability to withstand extreme conditions and maintain reliability over time is essential for aerospace applications, making the selection of high-quality actuators a priority for manufacturers in this industry.

3 Common User Pain Points for ‘what is a linear actuator’ & Their Solutions

Scenario 1: Understanding the Right Type of Linear Actuator for Your Application

The Problem: Many B2B buyers struggle with selecting the appropriate type of linear actuator for their specific application. With multiple options such as electric, hydraulic, and pneumatic actuators available, understanding the nuances of each type can be overwhelming. Buyers may find themselves unsure about factors such as force requirements, speed, precision, and the operational environment. This confusion can lead to miscalculations in purchasing decisions, resulting in increased costs, inefficiencies, or even equipment failures.

The Solution: To effectively navigate this challenge, B2B buyers should conduct a comprehensive needs assessment before making a purchase. Start by defining the specific requirements of your application, including load capacity, speed, and precision. Consider environmental factors such as temperature, humidity, and exposure to contaminants, as these will influence the actuator’s performance and longevity. Once your requirements are clear, consult with reputable suppliers who can provide technical expertise and guide you through the selection process. It’s beneficial to ask for detailed specifications, including torque ratings and operational cycles, to ensure the actuator meets your needs. Utilizing simulation software or prototypes can also help visualize how the actuator will perform in your specific application, allowing for more informed decisions.

Scenario 2: Managing Maintenance and Longevity of Linear Actuators

The Problem: Buyers often overlook the importance of maintenance when it comes to the longevity of linear actuators. Many B2B companies may experience unexpected downtime due to actuator failures, often stemming from inadequate maintenance practices. This can lead to costly repairs and production delays, negatively impacting operational efficiency and profitability.

The Solution: Establishing a proactive maintenance program is essential to ensure the reliability and performance of linear actuators. Begin by creating a maintenance schedule that includes regular inspections, lubrication, and performance testing. Document each actuator’s operational history to identify any patterns of wear or failure. Depending on the type of actuator used, specific maintenance tasks may vary. For instance, electric actuators may require checks on electrical connections and motor performance, while hydraulic actuators may need fluid level checks and seal inspections. Training your maintenance team on these procedures is crucial. Additionally, consider implementing predictive maintenance strategies using sensors to monitor actuator performance in real-time. This approach can help identify potential issues before they lead to failure, ensuring continuous operation and minimizing unexpected downtimes.

Scenario 3: Integration Challenges with Existing Systems

The Problem: Integrating new linear actuators with existing machinery or automation systems can pose significant challenges for B2B buyers. Compatibility issues may arise from differing control systems, communication protocols, or mechanical interfaces, leading to frustrating delays and additional costs during installation.

The Solution: To mitigate integration challenges, buyers should prioritize compatibility during the selection process. Begin by thoroughly reviewing the specifications of your existing systems, including control mechanisms, power supply requirements, and physical dimensions. Engage with suppliers who can provide actuators designed for easy integration with common automation platforms. Look for actuators that support standard communication protocols like Modbus or CAN bus, which can facilitate seamless connectivity. Additionally, consider consulting with system integrators or automation specialists who can offer insights into best practices for integration. Developing a clear integration plan that outlines each step and potential troubleshooting scenarios can also help streamline the installation process, reducing downtime and ensuring a smooth transition to the new linear actuator system.

Strategic Material Selection Guide for what is a linear actuator

What Are the Key Materials Used in Linear Actuators?

When selecting materials for linear actuators, it’s crucial to consider their properties, advantages, and limitations. The choice of material directly impacts performance, durability, and suitability for specific applications. Below, we analyze four common materials used in linear actuators: aluminum, stainless steel, plastic composites, and bronze.

How Does Aluminum Perform in Linear Actuators?

Aluminum is a popular choice for linear actuators due to its lightweight nature and excellent strength-to-weight ratio. It typically has a temperature rating of up to 150°C and offers good corrosion resistance when anodized.

Pros: Aluminum is relatively inexpensive and easy to machine, making it suitable for various manufacturing processes. Its lightweight characteristic helps in applications where weight reduction is critical, such as in automotive and aerospace sectors.

Cons: While aluminum is durable, it is not as strong as steel and may not be suitable for heavy-duty applications. It can also be prone to wear in high-friction environments unless properly treated.

Impact on Application: Aluminum is compatible with a wide range of media, but its lower strength may limit its use in applications requiring high load capacities.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM and ISO for aluminum alloys. In regions like the Middle East and Africa, availability and local manufacturing capabilities may affect procurement.

What Are the Benefits of Stainless Steel in Linear Actuators?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it ideal for harsh environments. It can withstand temperatures up to 300°C and is often used in applications exposed to moisture or chemicals.

Pros: Stainless steel provides excellent durability and longevity, making it suitable for heavy-duty applications in industries like food processing, pharmaceuticals, and marine environments.

Cons: The primary drawback is its cost, as stainless steel is generally more expensive than aluminum. Additionally, its weight can be a disadvantage in applications where weight is a critical factor.

Impact on Application: Stainless steel’s corrosion resistance allows it to perform well with aggressive media, making it suitable for applications in wet or corrosive environments.

Considerations for International Buyers: Buyers must consider compliance with standards such as ASTM A276 or DIN 17440. In regions like Europe, adherence to environmental regulations regarding material sourcing and processing is essential.

How Do Plastic Composites Compare for Linear Actuators?

Plastic composites are increasingly used in linear actuators due to their lightweight and corrosion-resistant properties. They can operate effectively in a temperature range of -40°C to 80°C, depending on the specific composite used.

Pros: These materials are often less expensive than metals and offer excellent resistance to chemicals and moisture. They are also easier to mold into complex shapes, allowing for innovative designs.

Cons: Plastic composites generally have lower strength and stiffness compared to metals, which may limit their use in high-load applications. They can also be sensitive to UV exposure, leading to degradation over time.

Impact on Application: Plastic composites are suitable for applications where weight and corrosion resistance are critical, such as in consumer electronics and automotive interiors.

Considerations for International Buyers: Buyers should verify compliance with standards like ASTM D638 for tensile properties. In regions with high humidity, ensuring the material’s performance in such environments is crucial.

What Role Does Bronze Play in Linear Actuators?

Bronze is often used for components that require good wear resistance and low friction. It typically performs well in temperatures up to 300°C and offers excellent corrosion resistance, especially in marine environments.

Pros: Bronze has superior wear resistance, making it ideal for applications involving sliding or rotating parts. It also provides good machinability and can be easily cast into complex shapes.

Cons: The cost of bronze can be higher than aluminum and some plastics, and it may not be suitable for all environments due to its susceptibility to galvanic corrosion when in contact with dissimilar metals.

Impact on Application: Bronze is particularly effective in applications involving high friction, such as bearings and bushings, where its low friction properties are advantageous.

Considerations for International Buyers: Compliance with ASTM B584 or similar standards is essential. Buyers in regions like South America should consider local sourcing options to mitigate import costs.

Summary Table of Material Selection for Linear Actuators

| Material | Typical Use Case for what is a linear actuator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive and aerospace applications | Lightweight and cost-effective | Lower strength than steel | Low |

| Stainless Steel | Food processing and marine environments | Excellent corrosion resistance | Higher cost and weight | High |

| Plastic Composites | Consumer electronics and automotive interiors | Corrosion resistance and moldability | Lower strength and UV sensitivity | Medium |

| Bronze | Bearings and bushings in high-friction applications | Superior wear resistance | Higher cost and galvanic corrosion risk | Medium |

This guide serves as a strategic overview for international B2B buyers in selecting materials for linear actuators, ensuring informed decisions that align with specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a linear actuator

What Are the Key Manufacturing Processes for Linear Actuators?

Understanding the manufacturing processes of linear actuators is crucial for B2B buyers, particularly those sourcing from international markets. The production of these devices involves several key stages, each requiring precise techniques and quality controls to ensure the final product meets industry standards.

What Are the Main Stages of Manufacturing Linear Actuators?

-

Material Preparation

The manufacturing process begins with the selection of high-quality materials, typically aluminum, steel, or plastic, depending on the actuator’s design and intended application. Materials are sourced from certified suppliers to ensure compliance with international quality standards. During this stage, materials are inspected for defects and prepared through cutting, machining, and surface treatment processes to meet the specifications required for further processing. -

Forming

Forming processes include machining, extrusion, and injection molding. For example, electric linear actuators often utilize precision machining for components such as screws and housings. Techniques such as CNC (Computer Numerical Control) machining provide high accuracy and consistency in producing parts. For hydraulic actuators, forming may involve more robust processes like forging, ensuring they can withstand high pressures and loads. -

Assembly

The assembly stage is critical as it combines various components such as motors, gears, and sensors. This process can be manual or automated, depending on the scale of production. Automated assembly lines enhance efficiency and reduce human error, while manual assembly allows for greater attention to detail in quality assurance. Each actuator may undergo a series of tests during assembly to verify component functionality before moving to the next stage. -

Finishing

The finishing process involves surface treatments such as anodizing, painting, or coating to enhance durability and resistance to corrosion. This is especially important for linear actuators used in harsh environments, such as construction or marine applications. Finishing not only improves the actuator’s aesthetic appeal but also contributes to its longevity and performance.

What Quality Control Measures Are Essential in Linear Actuator Manufacturing?

Quality control (QC) is paramount in the manufacturing of linear actuators, ensuring that each product meets both customer expectations and regulatory requirements. Adopting international standards helps maintain consistency and reliability.

Which International Standards Are Relevant for Linear Actuator Quality Assurance?

-

ISO 9001

ISO 9001 is a widely recognized standard for quality management systems (QMS). Manufacturers of linear actuators often implement ISO 9001 to ensure their processes are efficient and that products consistently meet customer and regulatory requirements. This standard emphasizes continuous improvement and customer satisfaction. -

CE Marking

For products sold in the European market, CE marking indicates compliance with EU safety, health, and environmental protection standards. Linear actuators must meet specific directives to obtain CE certification, providing assurance to B2B buyers regarding product safety and performance. -

API Certification

For linear actuators used in oil and gas applications, the American Petroleum Institute (API) certification may be required. This certification ensures that products meet industry-specific standards for quality, safety, and reliability.

What Are the QC Checkpoints in Linear Actuator Manufacturing?

Implementing rigorous QC checkpoints is essential to maintaining the integrity of the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC)

This initial stage involves inspecting raw materials and components upon receipt. Suppliers must provide documentation that verifies the quality and specifications of their materials, which are then assessed against predetermined criteria. -

In-Process Quality Control (IPQC)

During manufacturing, IPQC monitors various stages of production. This includes measuring dimensions, verifying assembly correctness, and ensuring that all processes adhere to established protocols. Statistical process control (SPC) tools may be utilized to identify trends or deviations in production quality. -

Final Quality Control (FQC)

The FQC stage involves comprehensive testing of the final product. Linear actuators may undergo functional testing, load testing, and performance assessments to ensure they meet all specifications and standards. This stage is critical for identifying any defects before products are shipped to customers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier QC practices is vital to ensuring product reliability.

-

Supplier Audits

Conducting supplier audits is an effective way to assess a manufacturer’s QC processes. This can involve on-site visits to evaluate manufacturing practices, QC checkpoints, and adherence to international standards. -

Quality Reports

Requesting quality assurance reports from suppliers can provide insights into their manufacturing processes and QC outcomes. These reports often include details on testing methods, compliance with standards, and historical performance data. -

Third-Party Inspections

Engaging third-party inspection services can help verify that products meet specified standards before shipment. These inspections can cover materials, workmanship, and compliance with relevant certifications, providing additional assurance for B2B buyers.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating the complexities of quality assurance and certification can be particularly challenging for international buyers. Differences in regulations and standards across regions necessitate a thorough understanding of local requirements. Buyers should consider the following:

Illustrative image related to what is a linear actuator

-

Local Regulations

Familiarize yourself with the specific regulations and standards in the target market. For example, products entering the EU must comply with CE marking, while those sold in the Middle East may have different requirements. -

Cultural Considerations

Be aware of cultural differences that may affect manufacturing practices and quality perceptions. Building strong relationships with suppliers can facilitate better communication and understanding of quality expectations. -

Documentation and Traceability

Ensure that suppliers maintain comprehensive documentation for all QC processes. This includes records of inspections, testing results, and certifications, which are crucial for compliance and traceability in international markets.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing linear actuators, ensuring they select reliable suppliers that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a linear actuator’

Introduction

In the world of industrial automation and machinery, linear actuators play a vital role in converting rotational motion into linear movement. This step-by-step sourcing checklist is designed to guide B2B buyers through the process of procuring linear actuators, ensuring that they choose the right products for their specific needs and applications.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of your application is the first step in sourcing a linear actuator. Consider factors such as load capacity, stroke length, speed, and precision.

– Load Capacity: Ensure the actuator can handle the weight it will be moving.

– Stroke Length: Determine how far the actuator needs to move to complete its task.

– Speed and Precision: Assess how quickly and accurately the actuator must operate.

Step 2: Identify the Type of Linear Actuator Required

Different applications may require different types of linear actuators, such as electric, hydraulic, pneumatic, or mechanical.

– Electric Actuators: Ideal for precision and control in various environments.

– Hydraulic Actuators: Best suited for heavy-duty tasks requiring high force.

– Pneumatic Actuators: Useful for quick movements in automation applications.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, case studies, and references from buyers in similar industries or regions.

– Company Profiles: Look for information about their experience and reputation in the market.

– Case Studies: Review real-life applications of their products to assess performance.

Step 4: Check for Compliance and Certifications

Ensure that the suppliers adhere to relevant industry standards and certifications, which can indicate product quality and reliability.

– ISO Certifications: Look for ISO 9001 or other relevant certifications that demonstrate quality management.

– Safety Standards: Verify compliance with local and international safety standards to mitigate risks.

Step 5: Request Samples and Technical Support

Before finalizing your purchase, request samples to test in your application. Additionally, inquire about the technical support provided by the supplier.

– Samples: Testing samples allows you to evaluate the actuator’s performance in real-world conditions.

– Technical Support: Ensure that the supplier offers robust support for installation, maintenance, and troubleshooting.

Step 6: Consider Total Cost of Ownership (TCO)

When evaluating pricing, consider the total cost of ownership rather than just the initial purchase price. This includes maintenance, energy consumption, and potential downtime.

– Maintenance Costs: Factor in any regular maintenance or servicing that may be required.

– Energy Efficiency: Assess how the actuator’s energy consumption will impact operating costs over time.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, review and finalize the purchase agreement carefully. Ensure that all terms, including warranties, delivery timelines, and payment options, are clearly outlined.

– Warranties: Look for warranties that provide assurance of product quality and performance.

– Delivery Timelines: Confirm expected delivery dates to align with your project schedules.

By following this checklist, B2B buyers can confidently procure linear actuators that meet their operational needs, ensuring efficient and reliable performance in their applications.

Comprehensive Cost and Pricing Analysis for what is a linear actuator Sourcing

What Are the Key Cost Components in Linear Actuator Sourcing?

When sourcing linear actuators, understanding the various cost components is essential for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Illustrative image related to what is a linear actuator

-

Materials: The choice of materials significantly influences the cost of linear actuators. For instance, electric actuators may require high-grade metals and plastics to ensure durability and efficiency, while hydraulic actuators often need robust components to handle high pressure. Premium materials can increase costs but may enhance performance and longevity.

-

Labor: Labor costs vary widely depending on the region and the complexity of the actuator being produced. Skilled labor for assembly and testing can add to expenses. In regions with higher labor costs, such as parts of Europe, buyers might find it beneficial to explore sourcing from countries with lower labor costs, such as Vietnam or South Africa.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can reduce overhead costs, impacting the final price of the actuator.

-

Tooling: Tooling costs are particularly relevant when custom designs are requested. Specific molds or machining tools may need to be created, which can significantly increase initial costs. Buyers should inquire about the potential need for specialized tooling when requesting customizations.

-

Quality Control (QC): Investing in rigorous quality control processes is crucial, especially for applications requiring high precision. While QC can increase costs, it ultimately ensures reliability and performance, reducing the risk of failures and warranty claims.

-

Logistics: The logistics of transporting linear actuators can add considerable expense, especially for international shipments. Factors such as distance, shipping method, and customs duties play a role. Understanding Incoterms is vital for accurately estimating these costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on factors such as brand reputation, market demand, and competition. It’s important for buyers to compare quotes from multiple suppliers to ensure they are getting a fair price.

What Influences the Pricing of Linear Actuators?

Several factors can influence the pricing of linear actuators, making it essential for buyers to consider these when evaluating quotes.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower unit prices due to economies of scale. Buyers should negotiate MOQ terms to maximize cost efficiency.

-

Specifications and Customization: Custom specifications, such as unique sizes or performance characteristics, can drive up costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials not only affects performance but also the cost. High-performance materials may incur higher costs but can lead to lower total cost of ownership (TCO) due to reduced maintenance and longer lifespan.

-

Quality and Certifications: Actuators that meet specific industry standards or possess certifications (e.g., ISO, CE) may carry higher prices. However, these certifications can enhance reliability and compliance, making them worth the investment.

-

Supplier Factors: Supplier reputation and location can influence pricing. Established suppliers may charge more due to their experience and reliability, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms is critical for cost estimation. Incoterms dictate who bears the costs and risks at various stages of the shipping process, impacting the final landed cost of the product.

How Can Buyers Negotiate Better Pricing for Linear Actuators?

Buyers can adopt several strategies to negotiate better pricing on linear actuators:

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Suppliers may offer discounts or favorable conditions to long-term clients.

-

Request Quotes from Multiple Suppliers: Obtaining quotes from several suppliers allows buyers to compare prices and negotiate more effectively. This competition can drive down costs.

-

Focus on Total Cost of Ownership (TCO): Buyers should consider not just the initial purchase price but the TCO, which includes maintenance, operational efficiency, and lifespan. This approach helps justify higher upfront costs if they lead to long-term savings.

-

Be Prepared to Walk Away: Sometimes, the best negotiation tactic is to be willing to explore alternative suppliers. This mindset can empower buyers to secure better deals.

-

Understand Pricing Nuances: International buyers should be aware of local market conditions, currency fluctuations, and regional supply chain dynamics that can affect pricing.

By considering these factors and employing effective negotiation strategies, buyers can make informed decisions that balance cost with quality, ensuring they select the best linear actuators for their needs.

Alternatives Analysis: Comparing what is a linear actuator With Other Solutions

In the realm of industrial automation and control systems, linear actuators stand out as pivotal devices that convert rotational motion into linear movement. However, various alternatives exist that can fulfill similar operational needs. Understanding these alternatives can help international B2B buyers make informed decisions tailored to their specific applications and operational environments.

Comparison Table

| Comparison Aspect | What Is A Linear Actuator | Hydraulic Actuator | Pneumatic Actuator |

|---|---|---|---|

| Performance | High precision, suitable for various loads | High force output, ideal for heavy-duty applications | Quick response, suitable for rapid motion |

| Cost | Moderate, varies by type | Higher due to complexity and fluid requirements | Generally lower, especially for basic models |

| Ease of Implementation | Requires electrical setup | Complex setup with hydraulic lines | Easier to implement with compressed air systems |

| Maintenance | Low maintenance, but requires electrical checks | Higher maintenance due to fluid management | Moderate maintenance, dependent on air supply |

| Best Use Case | Robotics, medical devices, automation | Construction equipment, industrial machinery | Assembly lines, packaging, and automation tasks |

Detailed Breakdown of Alternatives

Hydraulic Actuator

Hydraulic actuators utilize pressurized fluids to generate linear motion, delivering significant force suitable for heavy-duty applications. Their primary advantage lies in their ability to handle substantial loads, making them ideal for industries such as construction and manufacturing. However, they come with a higher initial cost due to the complexity of hydraulic systems, including pumps and fluid reservoirs. Maintenance can be more demanding as it involves monitoring fluid levels and potential leaks, which can lead to downtime if not managed properly.

Pneumatic Actuator

Pneumatic actuators operate using compressed air to produce linear motion. They are known for their quick response times, making them particularly effective in applications that require rapid and repetitive movements, such as in assembly lines and packaging operations. The cost of pneumatic actuators is generally lower than that of hydraulic systems, making them an attractive option for businesses with budget constraints. However, they are limited by their reliance on a consistent air supply and may not provide the same level of precision as electric or hydraulic actuators, which can be a drawback in applications requiring exact positioning.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate actuation solution, B2B buyers must consider multiple factors including the specific application, required force, precision, budget, and maintenance capabilities. While linear actuators offer versatility and precision for a range of applications, hydraulic and pneumatic actuators can be more suitable for heavy-duty tasks or rapid operations, respectively. Evaluating the pros and cons of each option against operational requirements will enable buyers to make informed decisions that enhance efficiency and productivity in their operations.

Essential Technical Properties and Trade Terminology for what is a linear actuator

What Are the Key Technical Properties of Linear Actuators?

When sourcing linear actuators for industrial applications, understanding critical specifications is essential for making informed purchasing decisions. Here are some key properties to consider:

1. Load Capacity

Load capacity refers to the maximum weight or force that a linear actuator can move. This specification is crucial for B2B buyers as it directly impacts the actuator’s suitability for specific applications. Choosing an actuator with insufficient load capacity can lead to equipment failure, increased downtime, and costly repairs.

2. Stroke Length

The stroke length is the distance the actuator can move linearly. It is vital for applications requiring precise positioning. Buyers must evaluate the stroke length based on their operational needs; a mismatch can result in inefficiencies or the need for additional equipment, impacting overall project costs.

3. Speed

Speed is defined as the rate at which the actuator can extend or retract. It is typically measured in millimeters per second (mm/s) or inches per second (in/s). High-speed actuators are essential in automation and robotics, where rapid movements enhance productivity. Understanding speed requirements helps buyers select the right actuator for their workflow.

4. Power Supply

The power supply type—AC or DC—affects the actuator’s compatibility with existing systems. Electric linear actuators are versatile and can operate on various power supplies, but understanding the specific requirements is critical to ensure seamless integration. Buyers should consider their operational environment and existing infrastructure when selecting a power supply type.

5. Control Mechanism

Control mechanisms vary widely among linear actuators, ranging from simple manual switches to sophisticated programmable logic controllers (PLCs). The complexity of the control mechanism can influence installation time and operational efficiency. Buyers must assess their technical capabilities and automation needs to choose an actuator with the appropriate control options.

Illustrative image related to what is a linear actuator

6. Material Grade

The material grade of a linear actuator affects its durability and performance in different environments. Common materials include aluminum, stainless steel, and plastic composites. Selecting the right material is crucial for applications exposed to harsh conditions, as it can impact maintenance costs and the actuator’s overall lifespan.

What Are Common Trade Terms Related to Linear Actuators?

Understanding industry-specific terminology can facilitate smoother transactions and better communication between buyers and suppliers. Here are several important terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of linear actuators, sourcing from OEMs can ensure high-quality components that meet specific industry standards, which is vital for reliability in applications.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers looking to manage inventory costs effectively. Understanding MOQ helps in planning purchases and assessing supplier relationships.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. This process is crucial in the procurement of linear actuators, enabling buyers to compare costs and make informed decisions based on budget and specifications.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping. Familiarity with these terms is essential for B2B buyers to understand shipping costs, risk management, and delivery timelines when purchasing linear actuators from global suppliers.

5. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of a linear actuator. This specification is critical for applications requiring precision. Buyers need to be aware of tolerance levels to ensure compatibility with other components in their systems.

6. Application Environment

This term describes the specific conditions under which a linear actuator will operate, such as temperature, humidity, and exposure to chemicals. Understanding the application environment helps buyers select actuators that are suited for their operational needs, minimizing potential failures.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when selecting linear actuators for their applications, leading to improved operational efficiency and reduced costs.

Navigating Market Dynamics and Sourcing Trends in the what is a linear actuator Sector

What Are the Current Market Dynamics Influencing the Linear Actuator Sector?

The linear actuator market is experiencing a transformative phase driven by technological advancements and increasing automation demands across industries. Globally, the rise of smart manufacturing and Industry 4.0 is prompting businesses to integrate more sophisticated motion control solutions. In regions like Africa, South America, the Middle East, and Europe, buyers are particularly focused on the capabilities of electric linear actuators due to their precision and efficiency. The growing trend towards automation in manufacturing, automotive, and healthcare sectors is leading to increased demand for various types of actuators, including electric, hydraulic, and pneumatic options.

Emerging technologies such as IoT and AI are also influencing the linear actuator market. These technologies enable enhanced monitoring and control of actuator systems, allowing for real-time adjustments and predictive maintenance, which can significantly reduce operational costs. B2B buyers are increasingly looking for suppliers who can provide not only robust products but also integrated solutions that include software for improved operational efficiency.

Additionally, the expansion of e-commerce and digital procurement platforms is reshaping sourcing strategies. Buyers now have access to a broader range of suppliers and products, making it easier to compare specifications, pricing, and delivery options. This shift is particularly beneficial for international buyers in emerging markets, where access to high-quality linear actuators can directly impact productivity and competitiveness.

How Is Sustainability and Ethical Sourcing Impacting the Linear Actuator Market?

As global attention shifts towards sustainability, the linear actuator sector is not immune to these pressures. Buyers are increasingly concerned about the environmental impact of their sourcing decisions, prompting manufacturers to adopt more sustainable practices. This includes the use of recyclable materials, energy-efficient designs, and processes that minimize waste and emissions.

Ethical sourcing is becoming a significant consideration for B2B buyers. Companies are now expected to demonstrate transparency in their supply chains and adhere to ethical labor practices. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming key differentiators in the market, offering buyers assurance of a supplier’s commitment to sustainability.

Moreover, as industries pivot towards greener technologies, the demand for linear actuators that incorporate energy-efficient designs is rising. Electric linear actuators, in particular, are favored for their low energy consumption and minimal maintenance needs. B2B buyers are encouraged to partner with manufacturers that prioritize sustainability in their product lines, as this can enhance their brand reputation and align with corporate social responsibility goals.

What Is the Historical Context of Linear Actuators in B2B Applications?

The evolution of linear actuators dates back to the early 20th century, when mechanical systems dominated the landscape. Initially, linear motion was primarily achieved through manual or mechanical means, which posed limitations in terms of speed and precision. The introduction of electric motors in the mid-20th century marked a significant turning point, allowing for more sophisticated control of linear motion.

As industries grew more complex, so too did the need for reliable and efficient motion control systems. The development of hydraulic and pneumatic actuators expanded the applications for linear motion, particularly in heavy-duty environments such as construction and manufacturing. In recent years, the advent of smart technologies and automation has further transformed the sector, enabling the integration of actuators into advanced systems that enhance productivity and precision.

Today, linear actuators are integral to numerous applications, from industrial automation and robotics to healthcare devices and automotive systems. The ongoing innovation in actuator technology continues to drive the market, offering new solutions that meet the evolving needs of B2B buyers across various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a linear actuator

-

How do I choose the right linear actuator for my application?

Choosing the right linear actuator involves assessing key factors such as the required load capacity, speed, precision, and operational environment. For instance, electric actuators are ideal for applications needing precision and quiet operation, while hydraulic actuators are better suited for heavy-duty tasks. Additionally, consider the actuator’s control system compatibility with your existing machinery and whether you need customization for specific project requirements. Consulting with suppliers can help clarify options based on your unique needs. -

What are the key differences between electric, hydraulic, and pneumatic linear actuators?

Electric linear actuators utilize electric motors for precise control and are known for their low maintenance and quiet operation. Hydraulic actuators generate high force using pressurized fluid, making them suitable for heavy-duty applications but often require more maintenance. Pneumatic actuators, powered by compressed air, offer rapid motion and are cost-effective, but may not provide the same force as hydraulic options. The choice depends on your specific application requirements and operational conditions. -

What is the typical lead time for ordering linear actuators from international suppliers?

Lead times can vary significantly based on the supplier, the complexity of the actuator, and the quantity ordered. Generally, for standard products, lead times range from a few weeks to several months. Custom designs may require additional time for engineering and production. It is essential to discuss timelines upfront with suppliers to ensure that your project schedule aligns with their production capabilities. -

What are the minimum order quantities (MOQs) for linear actuators?

Minimum order quantities (MOQs) for linear actuators can vary widely among suppliers and are often influenced by factors such as actuator type, customization level, and supplier policies. Some manufacturers may have no minimums for standard products, while others might require orders of several units for custom solutions. It’s advisable to inquire about MOQs during the initial discussions to plan your procurement strategy effectively. -

How can I ensure the quality of linear actuators I purchase internationally?

To ensure the quality of linear actuators, vet suppliers through certifications like ISO 9001, which indicates a commitment to quality management systems. Request product samples or visit manufacturing sites if feasible. It’s also beneficial to read reviews or seek references from other buyers. Additionally, consider establishing a quality assurance agreement that outlines specific testing and inspection processes before shipment. -

What payment terms should I expect when sourcing linear actuators from international suppliers?

Payment terms can vary depending on the supplier and the nature of the transaction. Common arrangements include upfront deposits (often 30-50%) with the balance due before shipment. Some suppliers may offer credit terms based on your business relationship or order volume. Always clarify payment options and conditions in advance, including currency considerations and transaction fees, to avoid misunderstandings. -

How do I handle logistics and shipping when ordering linear actuators internationally?

When ordering linear actuators internationally, coordinate with your supplier to determine the best shipping methods based on cost, speed, and reliability. You may need to consider freight forwarders or logistics companies experienced in handling industrial equipment. Additionally, be aware of customs regulations and duties in your country to ensure compliance and avoid delays. Establish a clear plan for tracking shipments and managing delivery timelines. -

What customization options are available for linear actuators?

Customization options for linear actuators can include modifications to dimensions, load capacities, speed ratings, and control systems. Some manufacturers offer tailored solutions for specific applications, such as unique mounting configurations or integration with existing systems. When discussing your needs with suppliers, provide detailed specifications and application requirements to ensure they can meet your customization requests effectively.

Top 7 What Is A Linear Actuator Manufacturers & Suppliers List

1. IQS Directory – Linear Actuators

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Linear actuators transform rotary motion into straight-line movement, enabling lifting, lowering, sliding, or tilting of equipment or materials. They provide efficient, clean, and maintenance-free motion control solutions. Electric linear actuators use DC or AC motors with gear assemblies and lead screw systems, with motor sizes ranging from 12V DC to 48V DC. Key considerations include static and …

2. LINAK – Linear Actuators

Domain: linak-us.com

Registered: 1997 (28 years)

Introduction: Linear actuators are mechanical devices that convert rotational motion into linear motion, consisting of a motor, lead screw, and nut assembly. They are used in various applications such as robotics, industrial automation, automotive systems, medical devices, and aerospace technology. Types include: 1. Electric Linear Actuator – uses electric motors, known for precision and flexibility. 2. Hydraul…

3. Reddit – Linear Actuator Overview

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: A linear actuator is a device that moves in one direction, typically a rod-type device, allowing for controlled motion along a single axis. They come in various types, including pneumatic and electric actuators, and are used in a wide range of applications. Key factors that differentiate linear actuators include movement length, available force, precision, and type of voltage input. Examples of th…

4. FIRGELLI – Electric Linear Actuators

Domain: firgelliauto.com

Registered: 2004 (21 years)

Introduction: Linear actuators create straight-line motion using electric, hydraulic, pneumatic, or mechanical energy. They are used in applications such as home automation, robotics, and industrial machinery. FIRGELLI offers a range of electric linear actuators known for their clean, precise, and reliable motion control. Key features include:

– Power Supply: Electric models operate on 12V or 24V DC; hydraulic…

5. Progressive Automations – Linear Actuators

Domain: progressiveautomations.com

Registered: 2008 (17 years)

Introduction: Actuators are components that enable machines to achieve physical movements by converting energy into mechanical force. Types of linear actuators include Electric Linear Actuators, Micro Actuators, Mini Actuators, Standard Actuators, Industrial Actuators, and Tubular and Track Actuators. Key applications span various industries such as Automotive, Agriculture, Medical, and Industrial Automation. P…

6. SMC – Linear Actuators

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: This company, SMC – Linear Actuators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Rollon – Linear Actuators

Domain: rollon.com

Registered: 1996 (29 years)

Introduction: A linear actuator is a self-supporting structural system that transforms circular motion into linear motion, generated by a motor. It is used for movements such as pushing, pulling, raising, lowering, or inclining a load. Common applications include industrial automation, servos, pick-and-place systems, assembly, packaging, and palletization. The main types of motion transmission are belt, rack an…

Strategic Sourcing Conclusion and Outlook for what is a linear actuator

Why Is Strategic Sourcing Essential for Linear Actuator Procurement?

As international B2B buyers navigate the complexities of sourcing linear actuators, understanding the diverse types—electric, hydraulic, pneumatic, and mechanical—is crucial. Each actuator type offers unique advantages tailored to specific applications, from industrial automation to medical devices. Strategic sourcing empowers buyers to evaluate suppliers effectively, ensuring they select products that align with their operational needs, budget constraints, and quality standards.

Moreover, the global market for linear actuators is evolving, with increasing demand for precision and efficiency across various industries. Buyers from regions such as Africa, South America, the Middle East, and Europe must remain vigilant to emerging technologies and supplier innovations that could enhance their operational capabilities. By leveraging strategic sourcing, companies can secure high-quality components that drive productivity and innovation.

Looking ahead, the landscape for linear actuators will continue to evolve, emphasizing sustainability and smart technology integration. B2B buyers are encouraged to embrace this shift by exploring partnerships with forward-thinking suppliers who prioritize innovation and efficiency. By doing so, they position themselves to capitalize on future opportunities in an increasingly competitive market. Engage with suppliers today to future-proof your operations and harness the full potential of linear actuator technology.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to what is a linear actuator